New Aspects of the Pulse Combustion Process

Abstract

1. Introduction

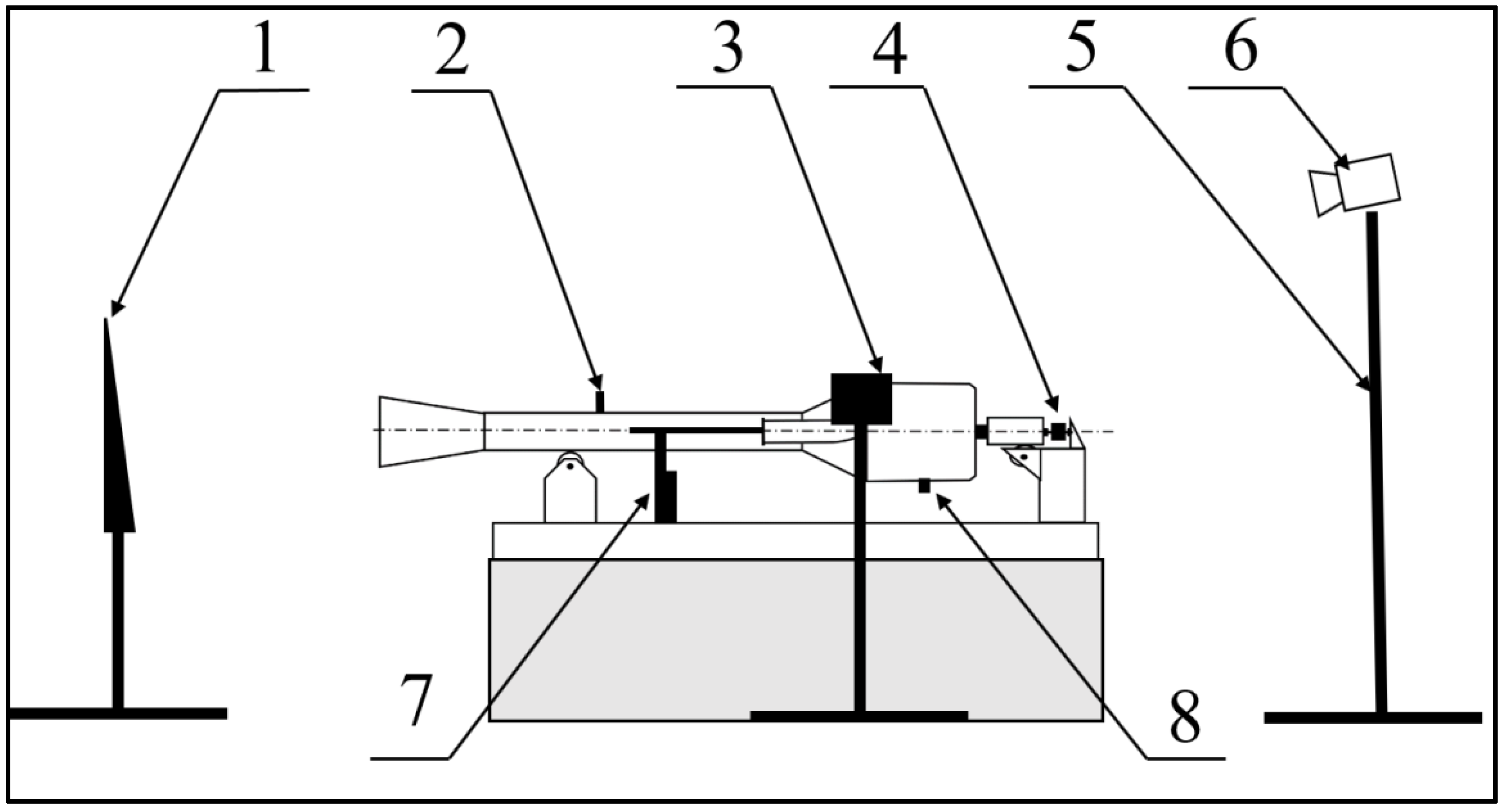

2. Research Stand and Measurement System

- Instantaneous pressure in the combustion chamber using the Kistler piezoelectric sensor 601a cooperating with the 5015 conditioning system with a declared accuracy of 1%;

- Average exhaust gas temperature with a sheathed thermocouple sensor, type K, manufactured by “Czaki thermoproduct”, cooperating with the TED-37 conditioning system of the same manufacturer. The whole system has a declared accuracy of 0.2%;

- Thrust using a miniature CL 21msrs strain gauge force transducer with the use of a CL 101 analogue dedicated amplifier with a declared accuracy of 0.5%;

- Fuel flow using a rotameter with a reading error of 0.15 g/s maximum;

- Exhaust gas composition using an exhaust gas analyser with a measurement error not exceeding 5% of the measured value.

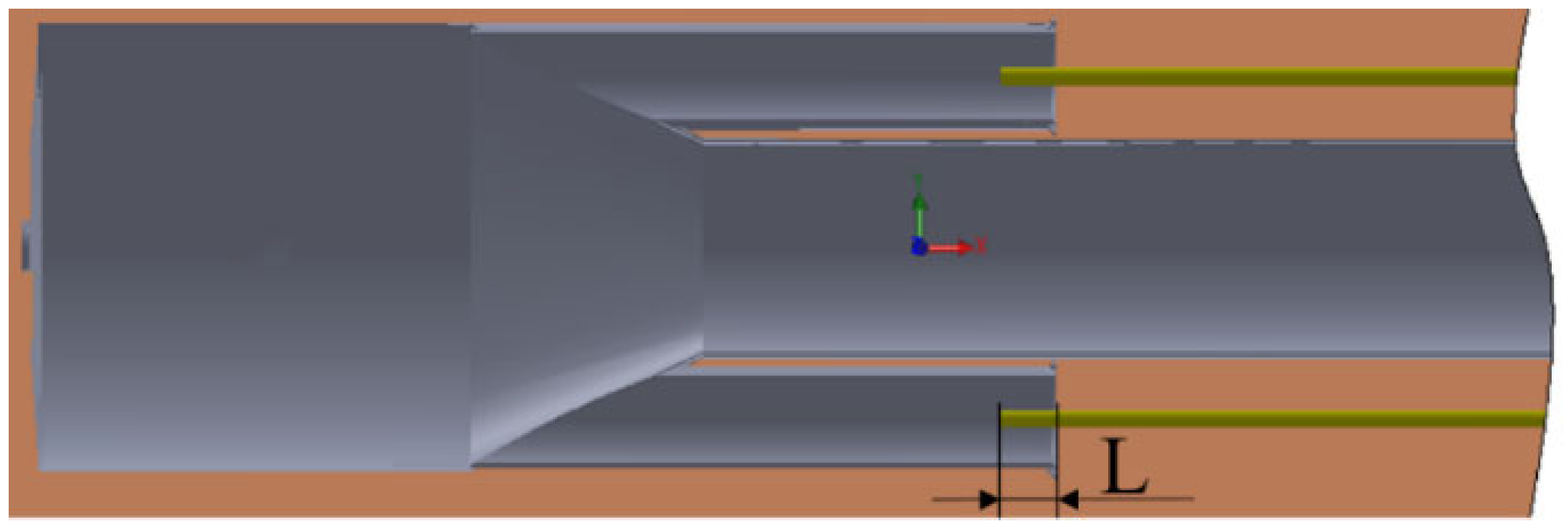

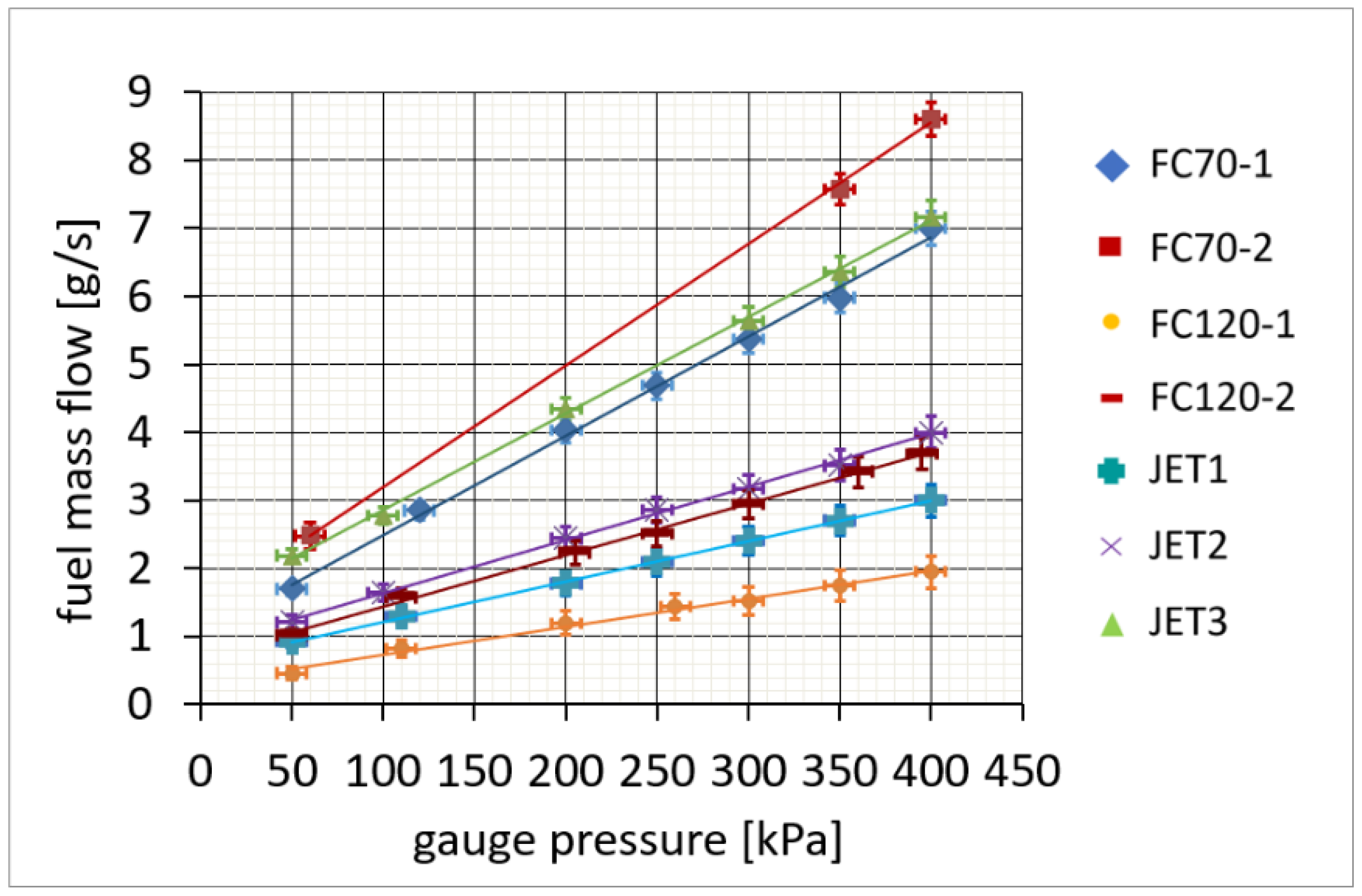

- Jets with cross-sectional diameters of 1.35 mm, 1.55 mm and 2 mm for JET1, JET2 and JET3, respectively;

- Full cone swirls with a spray angle of 70°—FC70-1 and FC70-2;

- Full cone swirls with a spray angle of 120°—FC120-1 and FC120-2.

3. Research Results

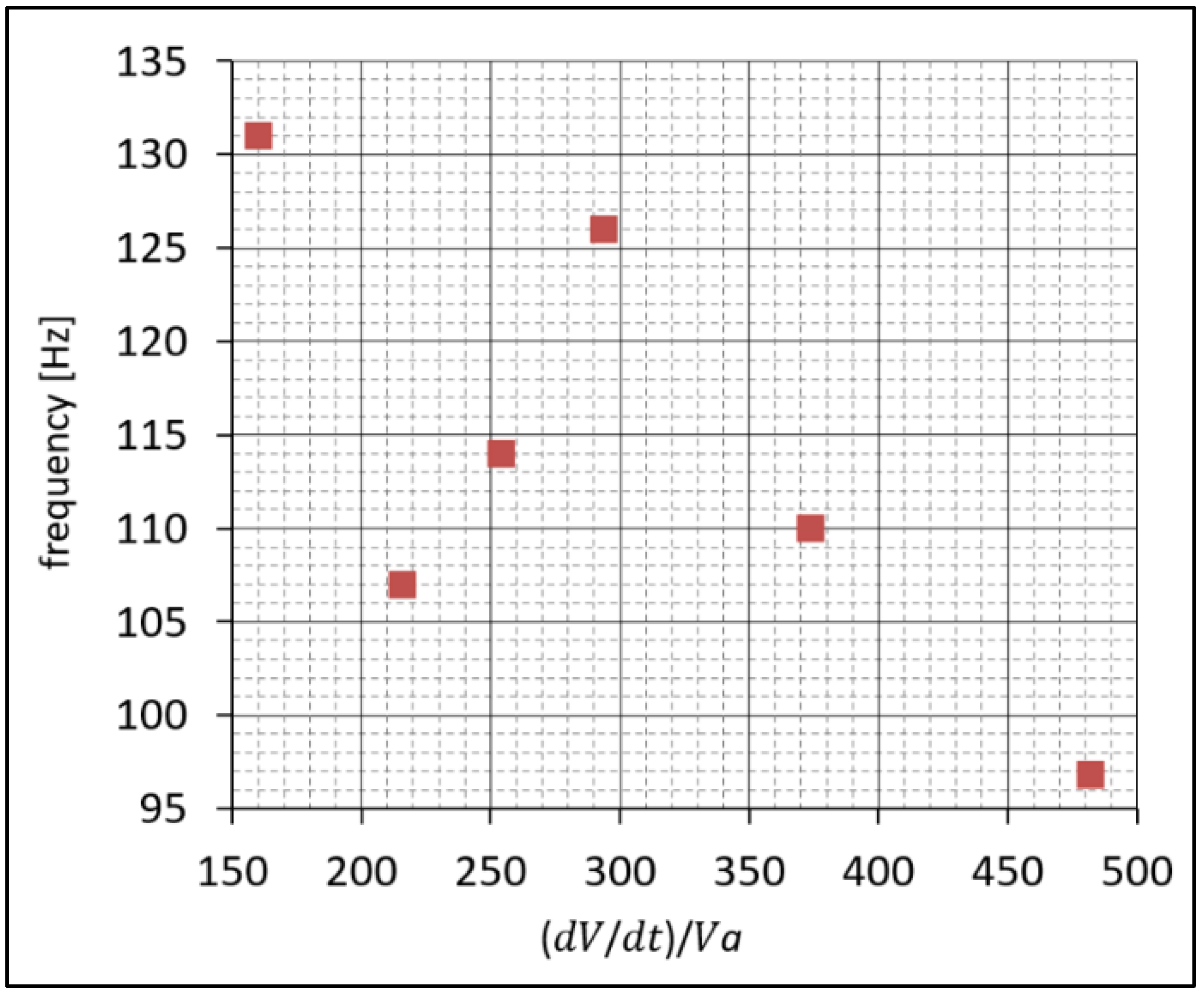

- is the frequency assuming ¼ standing wave along the length of the entire engine;

- is the operating frequency of the Helmholtz resonator;

- c is the speed of sound;

- is the engine length;

- is the inlet–outlet cross-sectional area;

- is the length of the inlet–outlet pipe;

- is the combustion chamber volume.

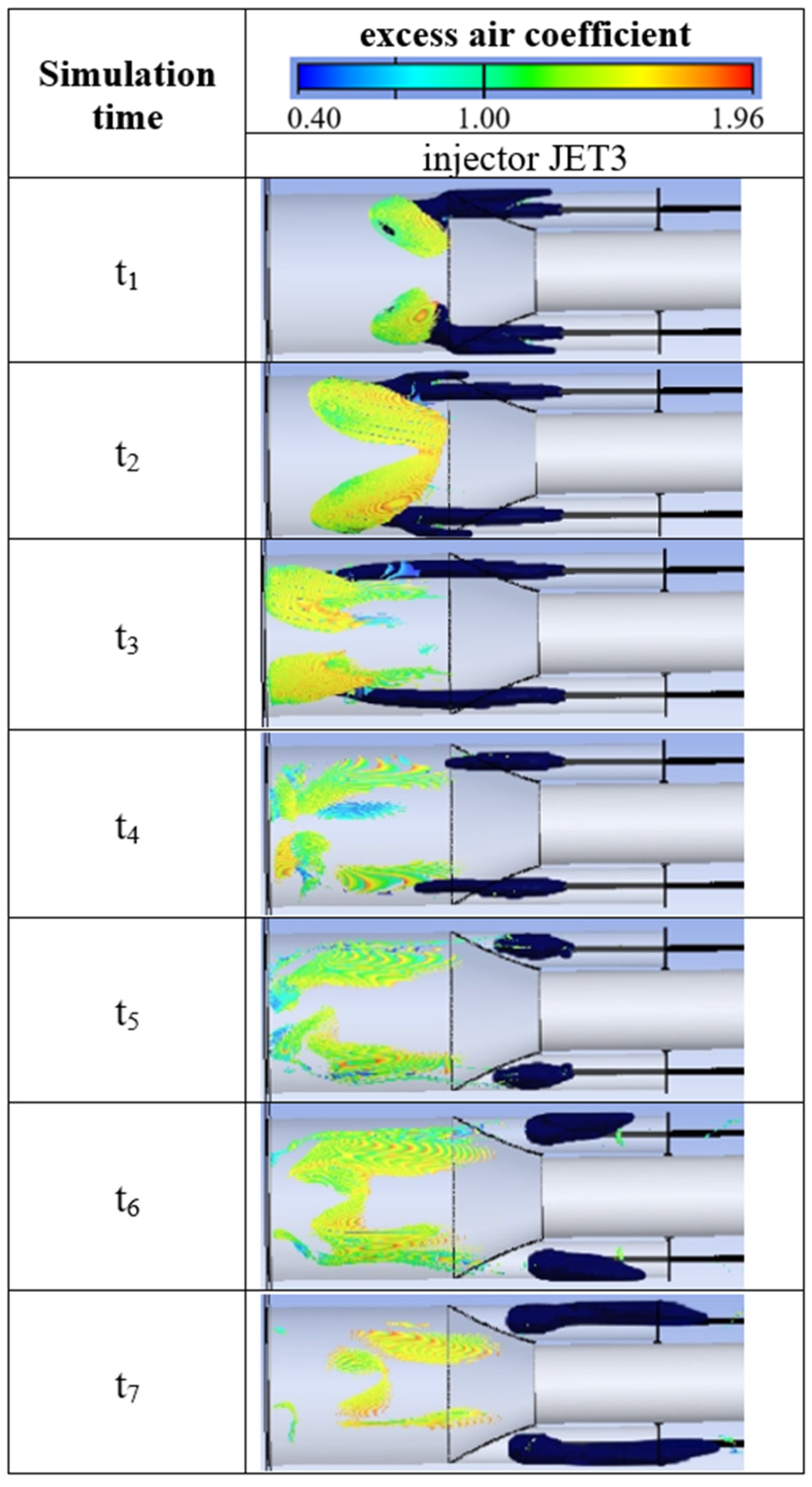

4. Numerical Research

- (a)

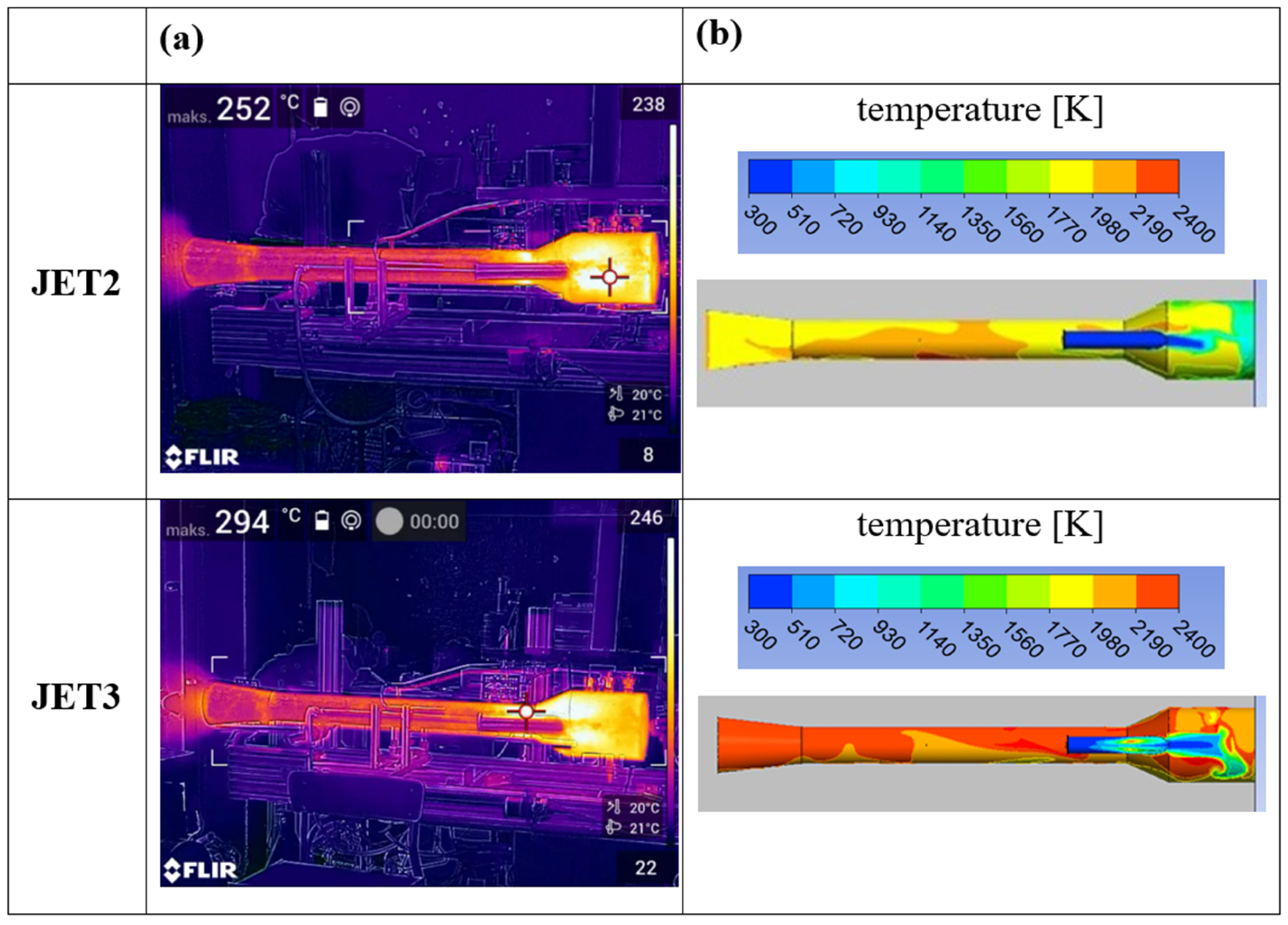

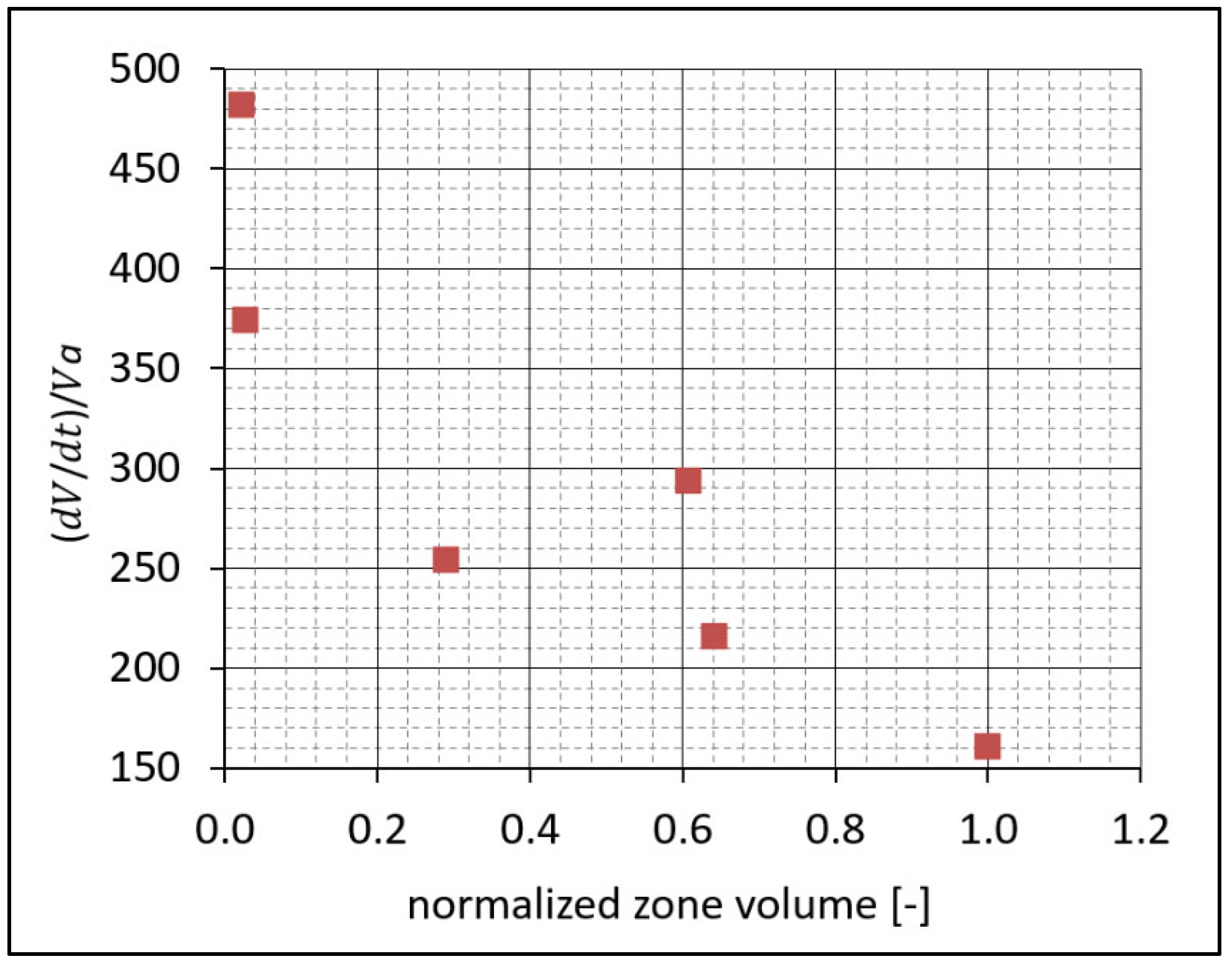

- For JET2 and JET3 swirl injectors placed at L = 125 mm;

- (b)

- For the FC120-1 injector at an angle of 90° to the longitudinal axis of the engine, on L = 255 mm where

- ◦

- ◦

- ;

- (c)

- For FC70-1, FC70-2 injectors located at L = 260 mm.

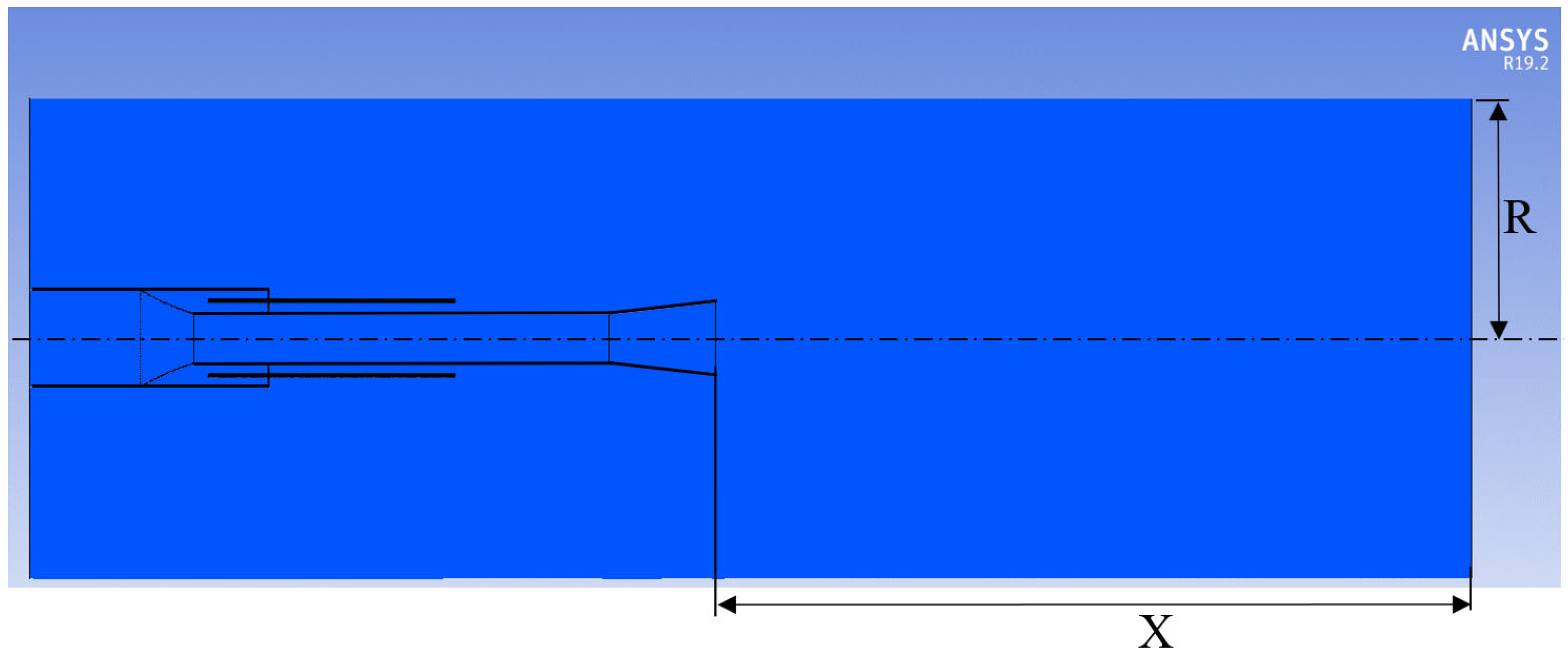

- X = 1600 mm, which is 10 maximum diameters of the outlet diffuser;

- R = 500 mm, which is 5 radii of the combustion chamber.

- The dynamic nature of the stochastic phenomena occurring in the combustion chamber makes the actual flow through it asymmetric. In such cases, the use of symmetry may lead to erroneous results or even to the lack of pulsation; although during the experimental tests, the chamber worked in a given configuration.

- In the vicinity of the planes, the mesh is filled with pentagonal elements. The transitions from these elements to hexagonal elements are a source of low-quality volume, which can distort the flow field inside the tested combustor. In addition, control over the size and quality of these elements is very limited. The use of the plane of symmetry passing through the centre of the combustion chamber forces the use of these elements in places that are particularly important from the point of view of calculations.

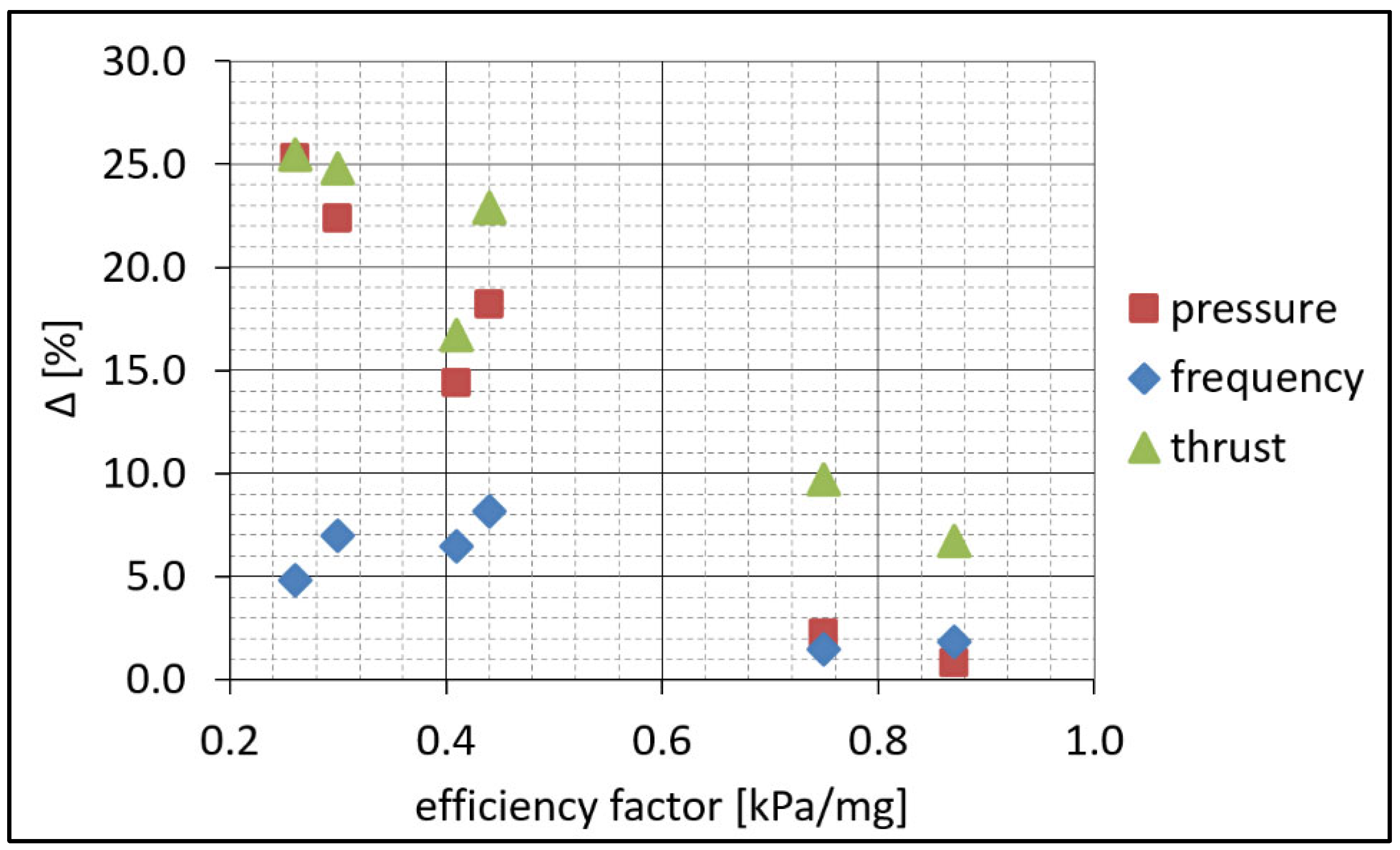

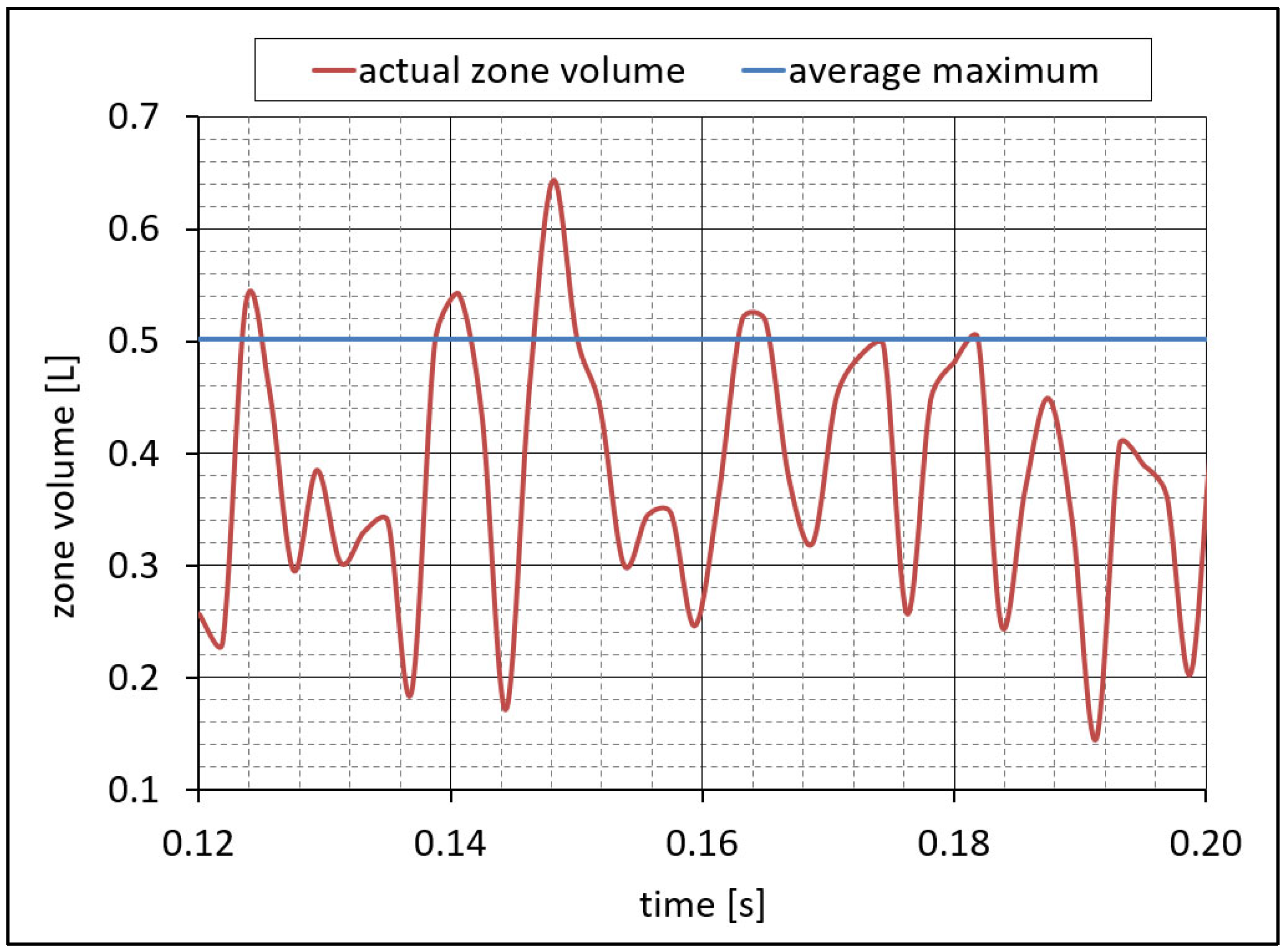

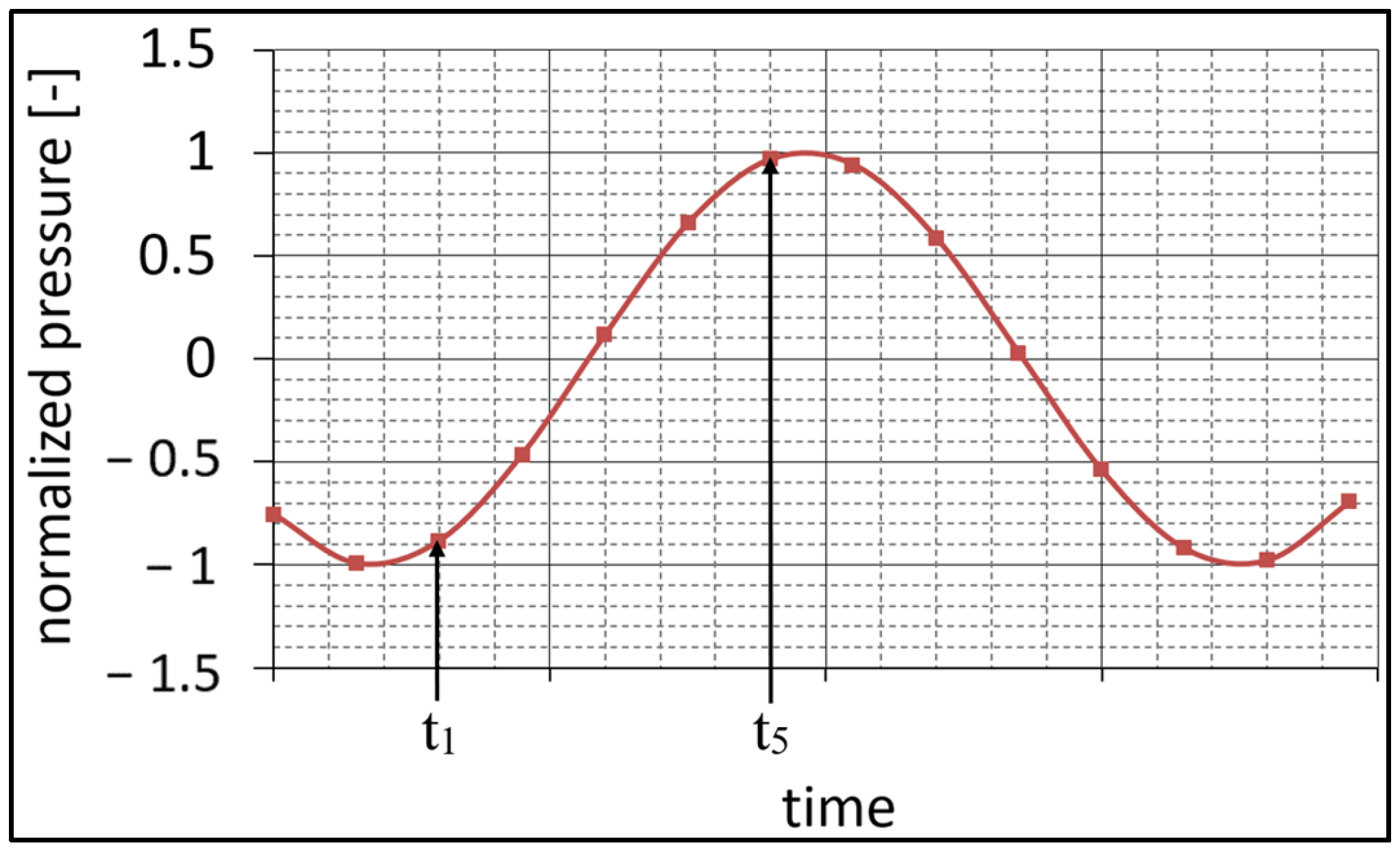

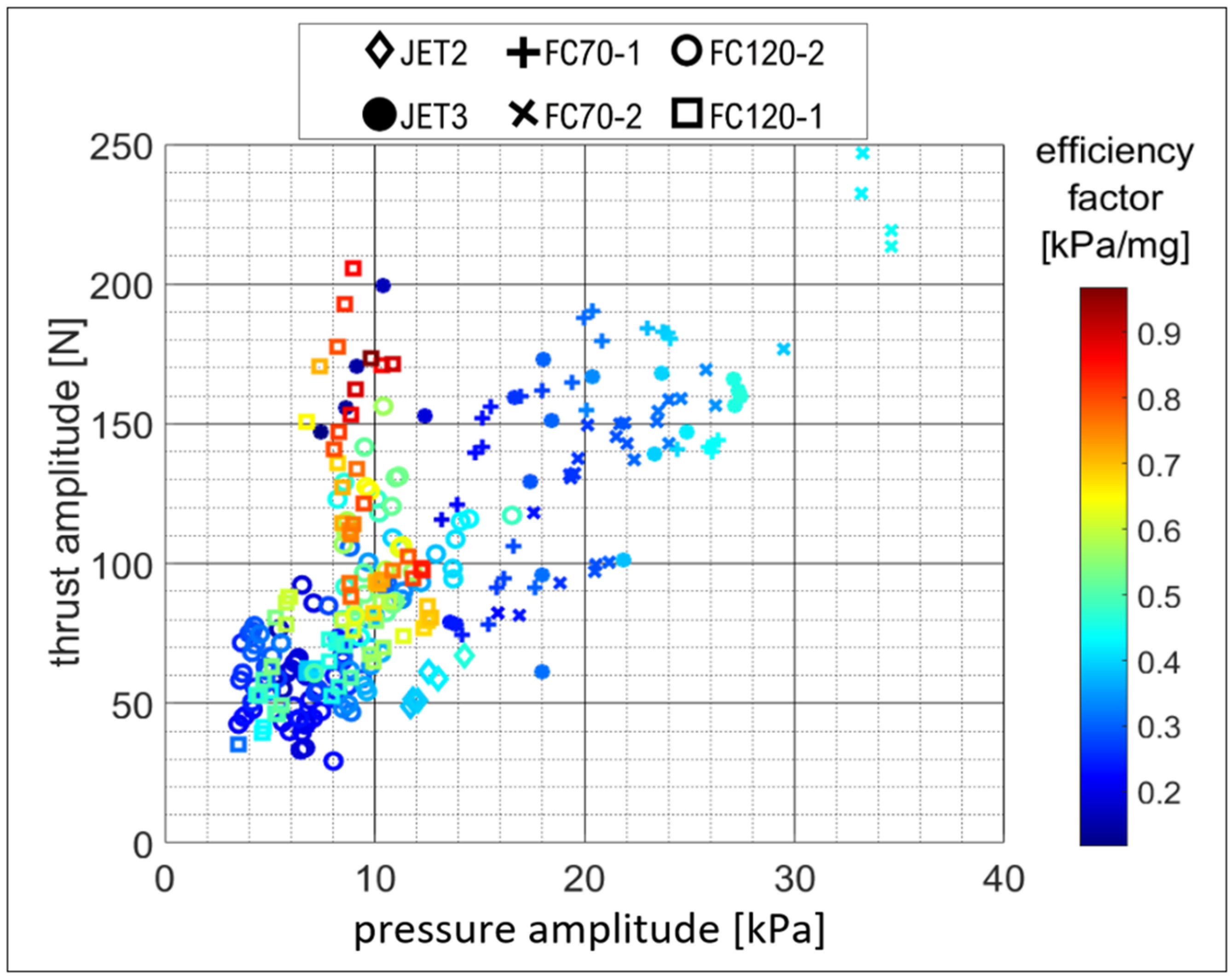

- Amplitude of pressure pulsation inside the combustion chamber;

- Pulsation frequency;

- Thrust.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Klimstra, J. Smart Power Generation, 3rd ed.; Avain: Helsinki, Finland, 2011. [Google Scholar]

- Peters, N. Turbulent Combustion; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Karczewski, M.; Chojnowski, J.; Szamrej, G. A Review of Low-CO2 Emission Fuels for a Dual-Fuel RCCI Engine. Energies 2021, 14, 5067. [Google Scholar] [CrossRef]

- Singh, R.I.; Kumar, R. Current status and experimental investigation of oxy-fired fluidized bed. Renew. Sustain. Energy Rev. 2016, 61, 398–420. [Google Scholar] [CrossRef]

- Kuiken, K. Gas-and Dual-Fuel Engines: For Ship Propulsion, Power Plants and Cogeneration; Book I, Principles; Target Global Energy Training, Nederland: Onnen, IA, USA, 2016. [Google Scholar]

- Karczewski, M.; Szamrej, G.; Chojnowski, J. Experimental Assessment of the Impact of Replacing Diesel Fuel with CNG on the Concentration of Harmful Substances in Exhaust Gases in a Dual Fuel Diesel Engine. Energies 2022, 15, 4563. [Google Scholar] [CrossRef]

- Kyprianidis, K.G.; Nalianda, D.; Dahlquist, E. A NOx Emissions Correlation for Modern RQL Combustors. Energy Proced. 2015, 75, 2323–2330. [Google Scholar] [CrossRef][Green Version]

- Laranci, P.; Zampilli, M.; D’Amico, M.; Bartocci, P.; Bidini, G.; Fantozzi, F. Geometry optimization of a commercial annular RQL combustor of a micro gas turbine for use with natural gas and vegetal oils. Energy Procced. 2017, 126, 875–882. [Google Scholar] [CrossRef]

- Kowalewicz, A. Podstawy Procesów Spalania; WNT: Warszawa, Poland, 2000. [Google Scholar]

- Zbicinski, I.; Kudra, T.; Liu, X. Pulse Combustion Drying, Modern Drying Technology; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2014. [Google Scholar]

- Anand, V.; Gutmark, E. A review of pollutants emissions in various pressure gain combustors. Int. J. Spray Combust. 2019, 11. [Google Scholar] [CrossRef]

- Available online: https://wave-engine.com/ (accessed on 2 February 2023).

- Choutapalli, I.M.; Krothapalli, A.; Alkislar, M.B. Pulsed-Jet Ejector Thrust Augumentor Characteristics. J. Propuls. Power 2012, 28, 293–306. [Google Scholar] [CrossRef]

- Available online: http://auerpolska.com/kociol-pulsacyjny-pulsator-20-kw (accessed on 15 June 2022).

- Available online: https://vespaddd.com.pl/produkty/sprzet-zamglawiacze-zamglawiacze-spalinowe/zamglawiacz-igeba-tf-35 (accessed on 15 June 2022).

- Available online: https://zamglawiacze.com/8-zamglawiacze (accessed on 15 June 2022).

- Kudra, T. Pulse-combustion drying: Status and potentials. Dry. Technol. 2008, 26, 1409–1420. [Google Scholar] [CrossRef]

- Kudra, T.; Benali, M.; Zbicinski, I. Pulse Combustion Drying: Aerodynamics, Heat Transfer, and Drying Kinetics. Dry. Technol. 2003, 21, 629–655. [Google Scholar] [CrossRef]

- Available online: https://www.pulsedry.com/ (accessed on 2 February 2023).

- Meng, X.; De Jong, W.; Kudra, T. A state-of-the-art review of pulse combustion: Principles, modeling, applications and R&D issues. Renew. Sustain. Energy Rev. 2016, 55, 73–114. [Google Scholar]

- Reynst, F.H. Pulsating Combustion; Pergamon Press: Oxford, MI, USA, 1961. [Google Scholar]

- Wójcicki, S. Możliwości rozwojowe silników pulsacyjnych. Technol. Lotnicza 1957, 6, 160–165. [Google Scholar]

- Wójcicki, S. Silniki Pulsacyjne, Strumieniowe, Rakietowe, Wydaw; Ministerstwa Obrony Narodowej: Warszawa, Poland, 1962. [Google Scholar]

- Tharratt, C.E. The Propulsive Duct. Aircr. Eng. Aerosp. Technol. 1966, 38, 23–25. [Google Scholar] [CrossRef]

- Tharratt, C.E. The Propulsive Duct. Aircr. Eng. Aerosp. Technol. 1965, 37, 327–337. [Google Scholar] [CrossRef]

- Tharratt, C.E. The Propulsive Duct. Aircr. Eng. Aerosp. Technol. 1965, 37, 359–371. [Google Scholar] [CrossRef]

- Lockwood, R.M. Hiller Pulse Reactor Lift Engine; Report No. ARD 308; Hiller Aircraft Company: Firebaugh, CA, USA, 1963. [Google Scholar]

- Anand, V.; Jodele, J.; Prise, E. Dynamic Features of Internal and External Flowfields of Pulsejet Engines. AIAA J. 2020, 58, 4204–4211. [Google Scholar] [CrossRef]

- Anand, V.; Jodele, J.; Knight, E.; Prisell, E.; Lyrsell, O.; Gutmark, E. Dependence of Pressure, Combustion and Frequency Characteristics on Valved Pulsejet Combustor Geometries. Flow Turbul. Combust. 2017, 100, 829–848. [Google Scholar] [CrossRef]

- Anand, V.; Jodele, J.; Shaw, V.; Russel, A.; Prisell, E.; Lyrsell, O.; Gutmark, E. Visualization of Valved Pulsejet Combustors and Evidence of Compression Ignition. Flow Turbul. Combust. 2021, 106, 901–924. [Google Scholar] [CrossRef]

- Gieras, M.; Trzeciak, A. A new approach to the phenomenon of pulsed combustion. Exp. Therm. Fluid Sci. 2023, 144, 110845. [Google Scholar] [CrossRef]

- Paxson, D.E.; Zheng, F.; Kuznetsov, A.V.; Roberts, W.L. Comparison Between Numerically Simulated and Experimentally Measured Flowfield Quantities behind a Pulsejet. In Proceedings of the 44th Joint Propulsion Conference and Exhibit, Hartford, CT, USA, 21–23 July 2008. Paper NASA/TM-2008-215432. [Google Scholar]

- Zbiciński, I.; Smucerowicz, I.; Strumiłło, C.; Kasznia, J.; Stawczyk, J.; Murlikiewicz, K. Optimization and Neural Modelling of Pulse Combustors for Drying Applications. Dry. Technol. 1999, 17, 610–631. [Google Scholar] [CrossRef]

- Zhonghua, W.; Mujumdar, A.S. Pulse combustion characteristics of various gaseous fuels. Energ. Fuel. 2008, 22, 915–924. [Google Scholar] [CrossRef]

- Yao, X.; Ming, Z.; Tiezhu, G.; Peng, D.; Yudong, H. Simulation on Operational Characteristics of a Valveless Self-excited Pulse Combustor of the Helmholtz-type. In Proceedings of the 2014 International Conference on Mechatronics, Control and Electronic Engineering, Shenyang, China, 29–31 August 2014; pp. 319–322. [Google Scholar] [CrossRef][Green Version]

- Yungster, S.; Paxson, D.E.; Perkins, H.D. Effect of Fuel Injection and Mixing Characteristics on Pulse-Combustor Performance at High-Pressure. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. Paper AIAA 2014-3728. [Google Scholar]

- Nekoufar, K. Spray Modeling in Pulse Jet Engine and Surveying the Distribution and Fuel-Air Mixture in Combustion. Adv. Environ. Biol. 2013, 7, 2241–2250. [Google Scholar]

- Barr, P.; Keller, J.; Bramlette, T.; Westbrook, C.; Dec, J. Pulse combustor modeling demonstration of the importance of characteristic times (associated with acoustics, fluid mixing, chemical kinetics). Combust. Flame 1990, 82, 252–269. [Google Scholar] [CrossRef]

- Available online: http://www.pulse-jets.com/valveless/ (accessed on 15 November 2022).

- Available online: http://plans-for-everything.com/hen_pulse_jet_plans.html (accessed on 15 June 2022).

- Available online: http://plans-for-everything.com/downloads/pulse_jets/PJE%20OgorelecValveless.pdf (accessed on 15 June 2022).

- Available online: https://www.youtube.com/watch?v=DLcK6q1KiQM (accessed on 15 June 2022).

- Available online: http://aardvark.co.nz/pjet/ (accessed on 15 June 2022).

- Temple, K.A. Thermal and Internal Acoustic Model of a Helmholtz Type Pulse Combustion Furnace. Ph.D Thesis, ProQuest Dissertations Publishing, Purdue University, West Lafayette, IN, USA, 1996. [Google Scholar]

- Geng, T.; Schoen, M.A.; Kuznetsov, A.V.; Roberts, W.L. Combined numerical and experimental investigation of a 15-cm valveless pulsejet. Flow Turbul. Combust. 2007, 78, 17–33. [Google Scholar] [CrossRef]

- Zheng, F. Computational Investigation of High Speed Pulsejets. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2009. [Google Scholar]

- Ansys Inc. ANSYS Fluent Theory Guide; Ansys Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Kordylewski, W.; Bulewicz, E.; Dyjakon, A.; Słupek, S.; Miller, R.; Wanik, A. Spalanie i Paliwa: Praca Zbiorowa; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2001. [Google Scholar]

- Szkarowski, A. Spalanie Gazów: Teoria, Praktyka, Ekologia; WNT: Warszawa, Poland, 2014. [Google Scholar]

- Gieras, M.; Klemens, R.; Rarata, G.; Wolański, P. Determination of explosion parameters of methane-air mixtures in the chamber of 40 dm3 at normal and elevated temperature. J. Loss Prevent. Proc. 2006, 19, 263–270. [Google Scholar] [CrossRef]

- Sustek, J.; Janovsky, B. Comparison of empirical and semi-empirical equations for vented gas explosion with experimental data. J. Loss Prevent. Proc. 2013, 26, 1549–1557. [Google Scholar] [CrossRef]

- Mokhtar, K.M.; Kasmani, R.M.; Hassan, C.R.C.; Hamid, M.D.; Emami, S.D.; Nor, M.I.M. Reliability and applicability of empirical equations in predicting the reduced explosion pressure of vented gas explosions. J. Loss Prevent. Proc. 2020, 63, 104023. [Google Scholar] [CrossRef]

- Rui, S.; Wang, Q.; Chen, F.; Li, Q.; Guo, J.; Wang, J.; Wang, C. Effect of vent area on the vented methane-air deflagrations in a 1 m3 rectangular vessel with and without obstacles. J. Loss Prevent. Proc. 2022, 74, 104642. [Google Scholar] [CrossRef]

| Mesh 1 4,800,000 Elements | Mesh 2 7,200,000 Elements | |

|---|---|---|

| Maximum y+ | 366 | 245 |

| Maximum domain CFL | 2.2 | 1.4 |

| Time per iteration [s] | 15.5 | 28.7 |

| Combustion chamber pressure amplitude [kPa] | 40.1 | 39.6 |

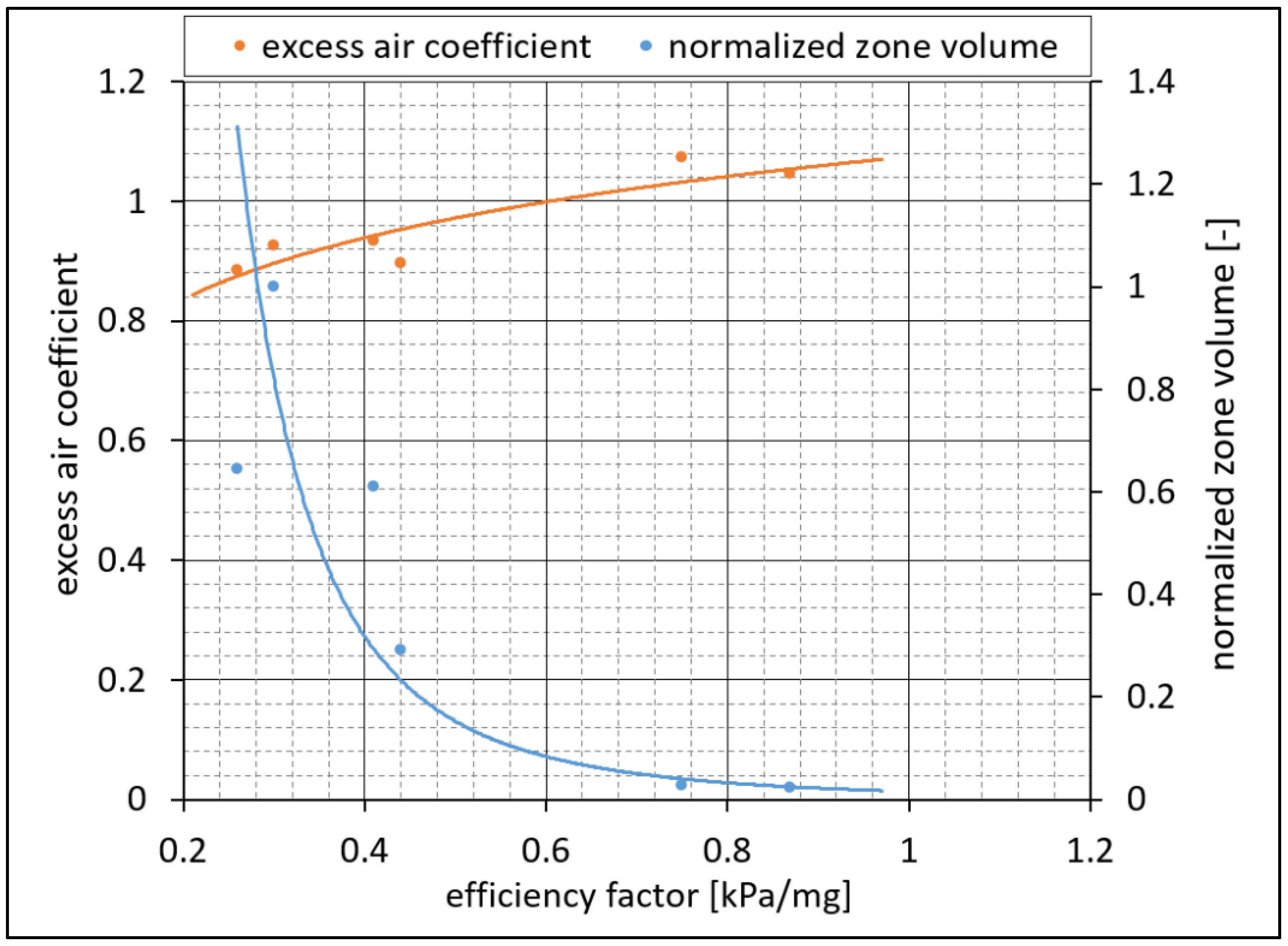

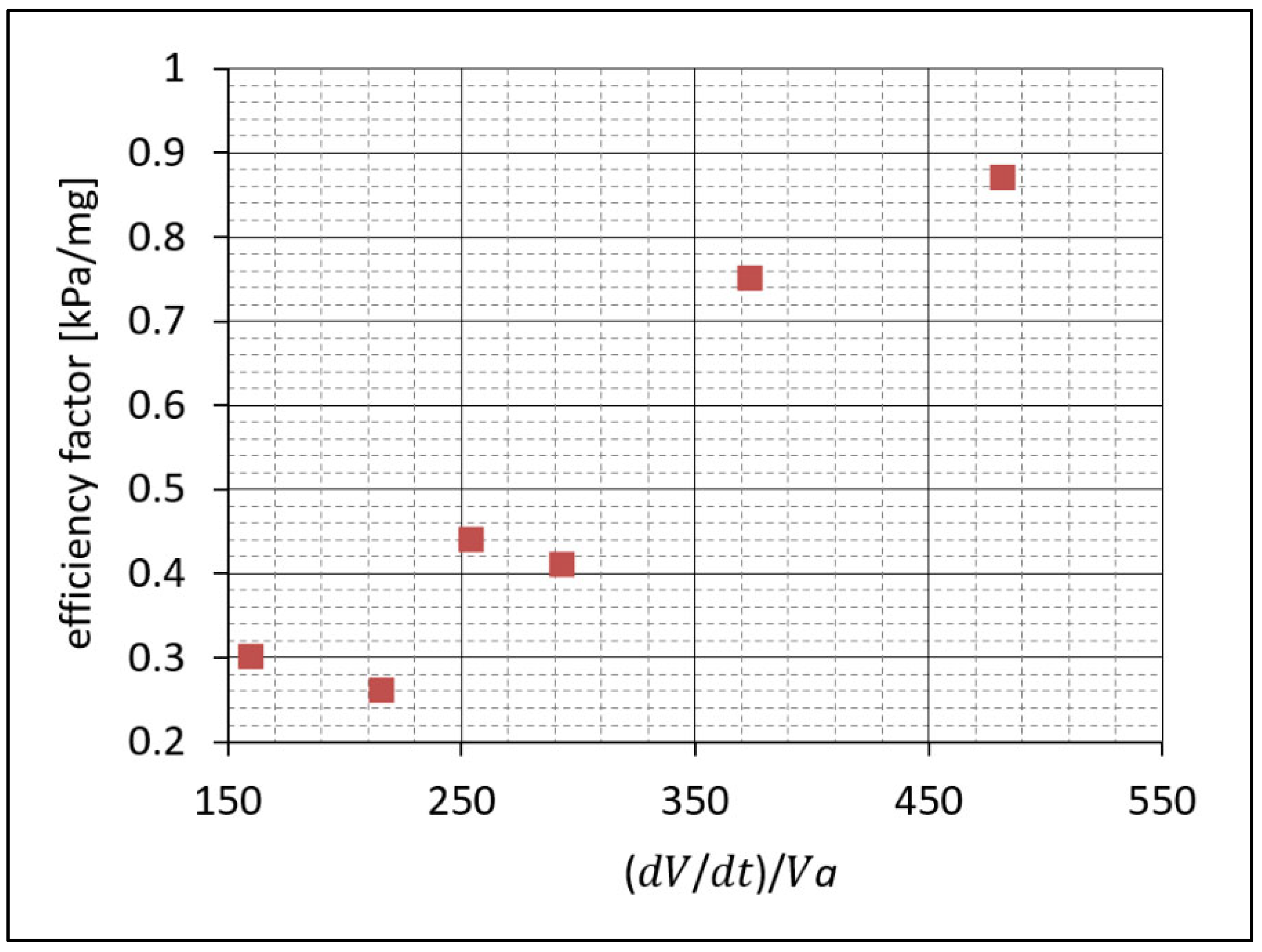

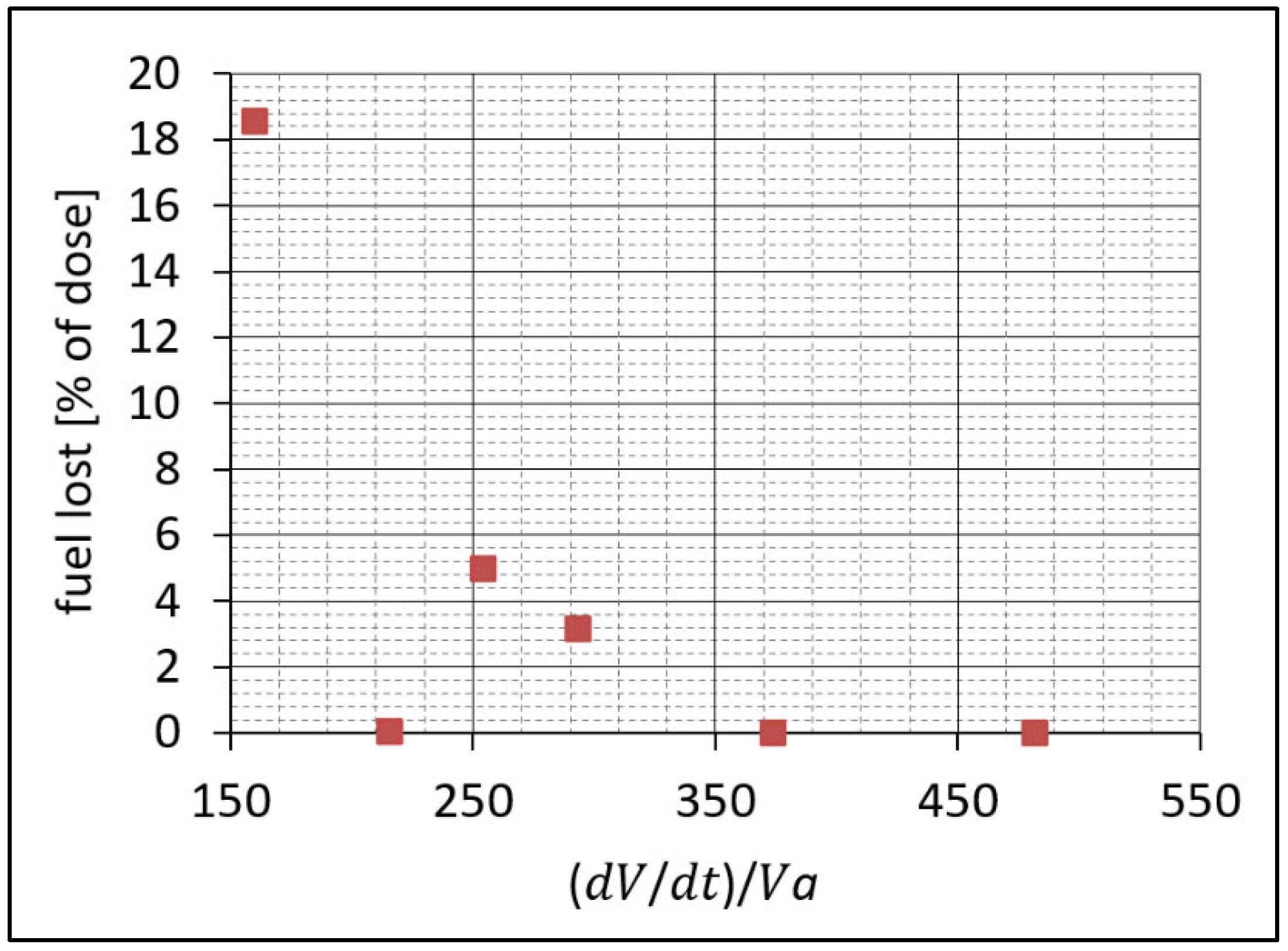

| Injector | Position | Dose [mg/Cycle] | Efficiency Factor [kPa/mg] | Fuel Losses [mg/Cycle] | Fuel Losses [% of Dose] |

|---|---|---|---|---|---|

| JET2 | L = 125 mm | 30 | 0.41 | 3.2 | |

| JET3 | L = 125 mm | 57 | 0.30 | 11 | 18.5 |

| FC70-1 | L = 260 mm | 65 | 0.26 | 0.009 | |

| FC70-2 | L = 260 mm | 78 | 0.44 | 3.9 | 5.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gieras, M.; Trzeciak, A.M. New Aspects of the Pulse Combustion Process. Energies 2024, 17, 1427. https://doi.org/10.3390/en17061427

Gieras M, Trzeciak AM. New Aspects of the Pulse Combustion Process. Energies. 2024; 17(6):1427. https://doi.org/10.3390/en17061427

Chicago/Turabian StyleGieras, Marian, and Adrian Marek Trzeciak. 2024. "New Aspects of the Pulse Combustion Process" Energies 17, no. 6: 1427. https://doi.org/10.3390/en17061427

APA StyleGieras, M., & Trzeciak, A. M. (2024). New Aspects of the Pulse Combustion Process. Energies, 17(6), 1427. https://doi.org/10.3390/en17061427