ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems

Abstract

:1. Introduction

Contributions

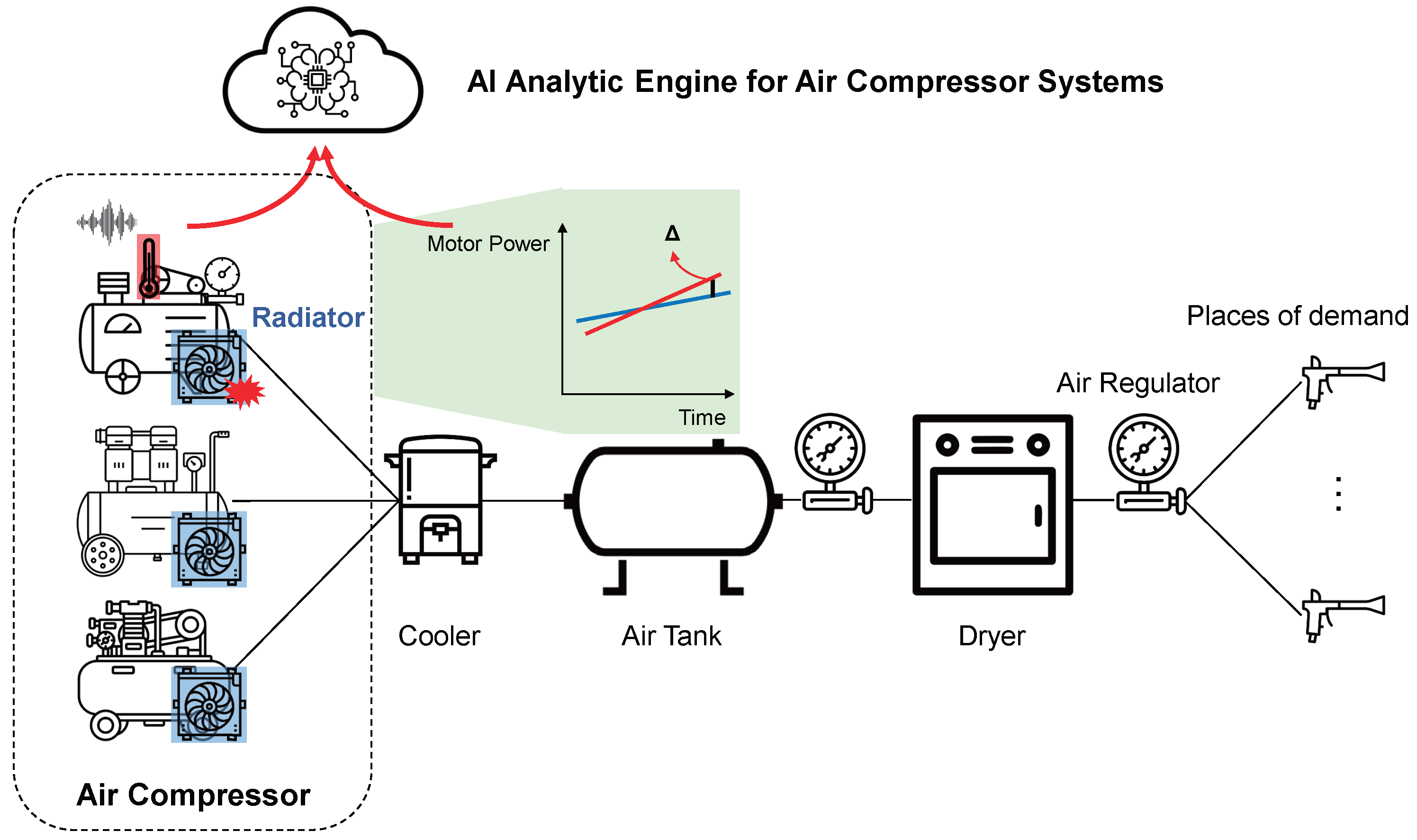

2. System Model

2.1. Proposed Idea

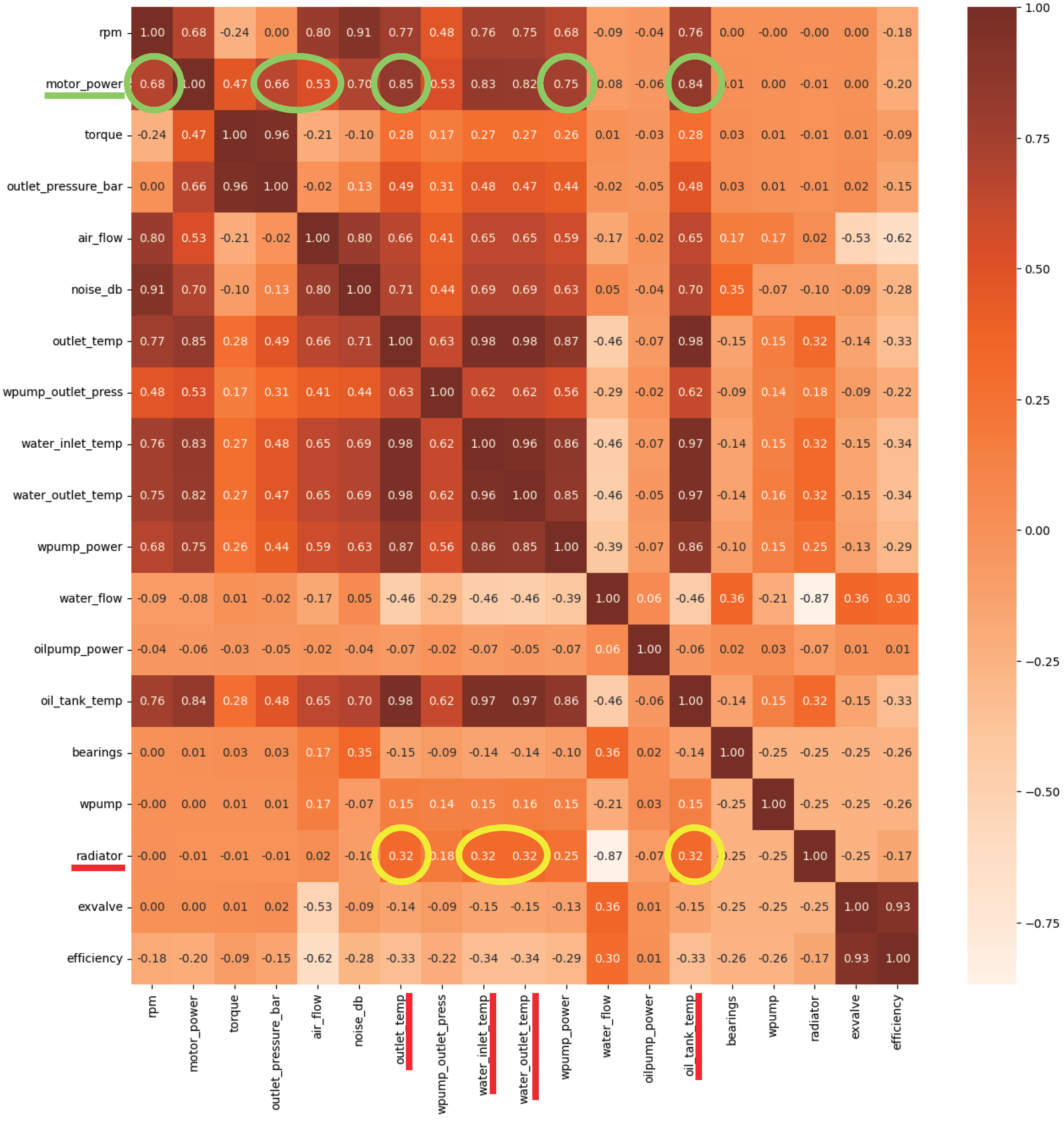

2.2. Correlation Analysis and Feature Extraction

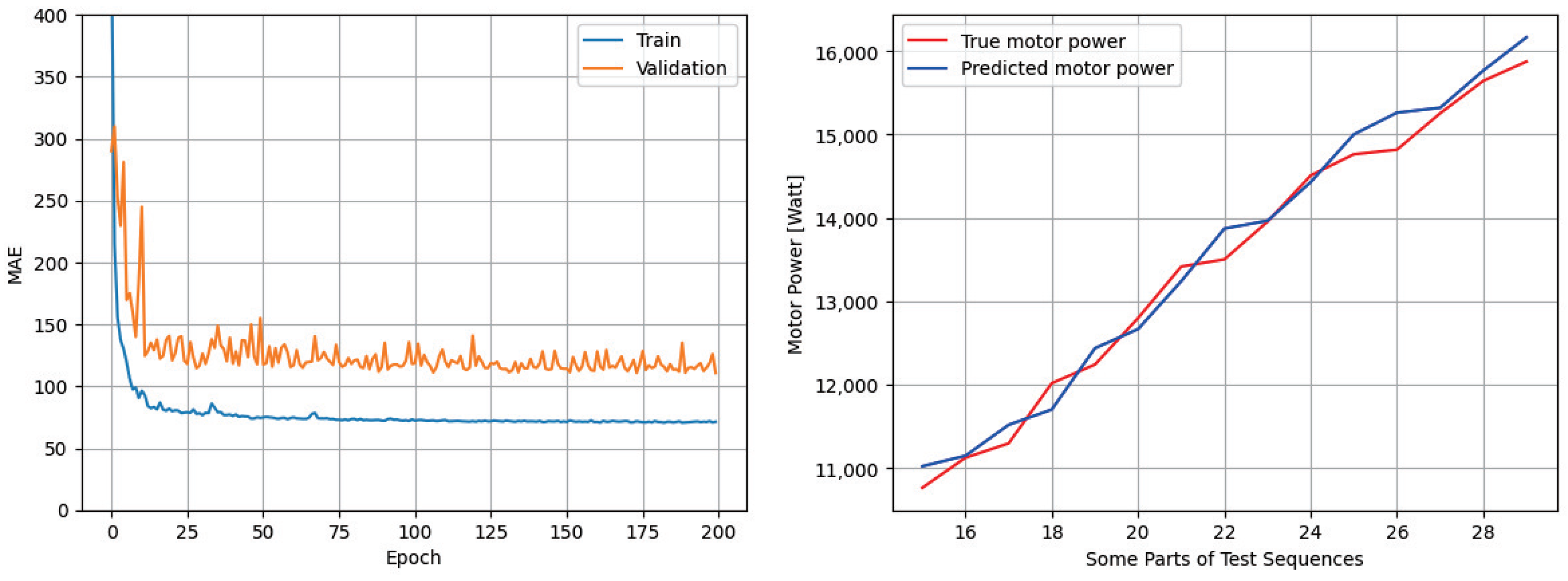

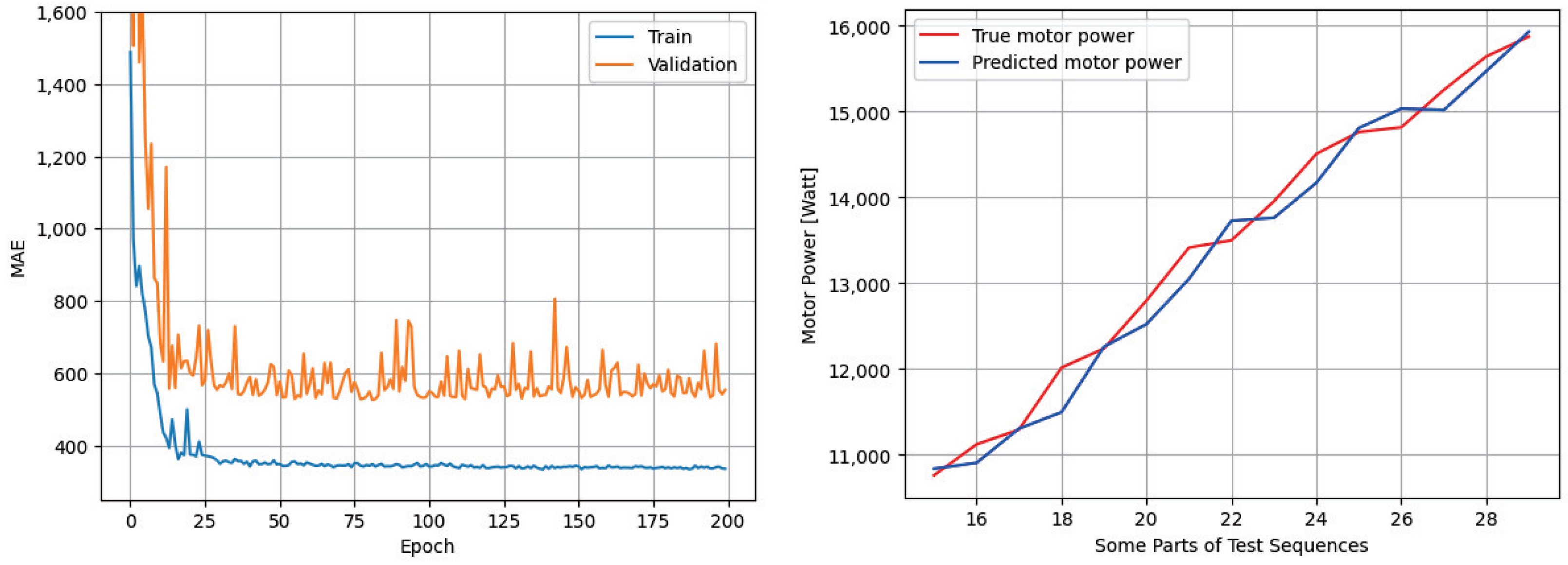

2.3. Proposed LSTM-Based Motor Power Prediction Model

2.4. Proposed ML-Based Radiator Fault Detection Model

3. Numerical Results

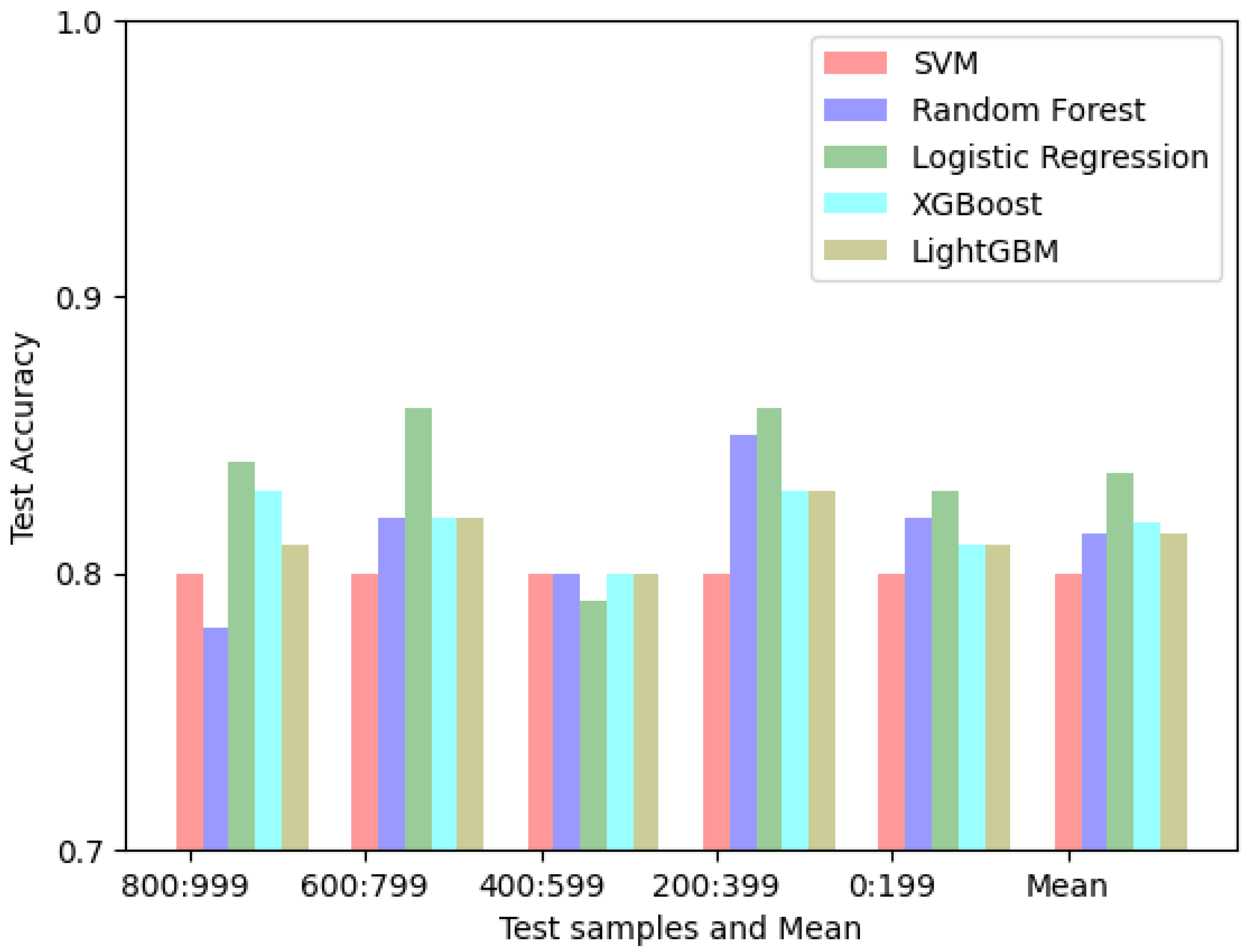

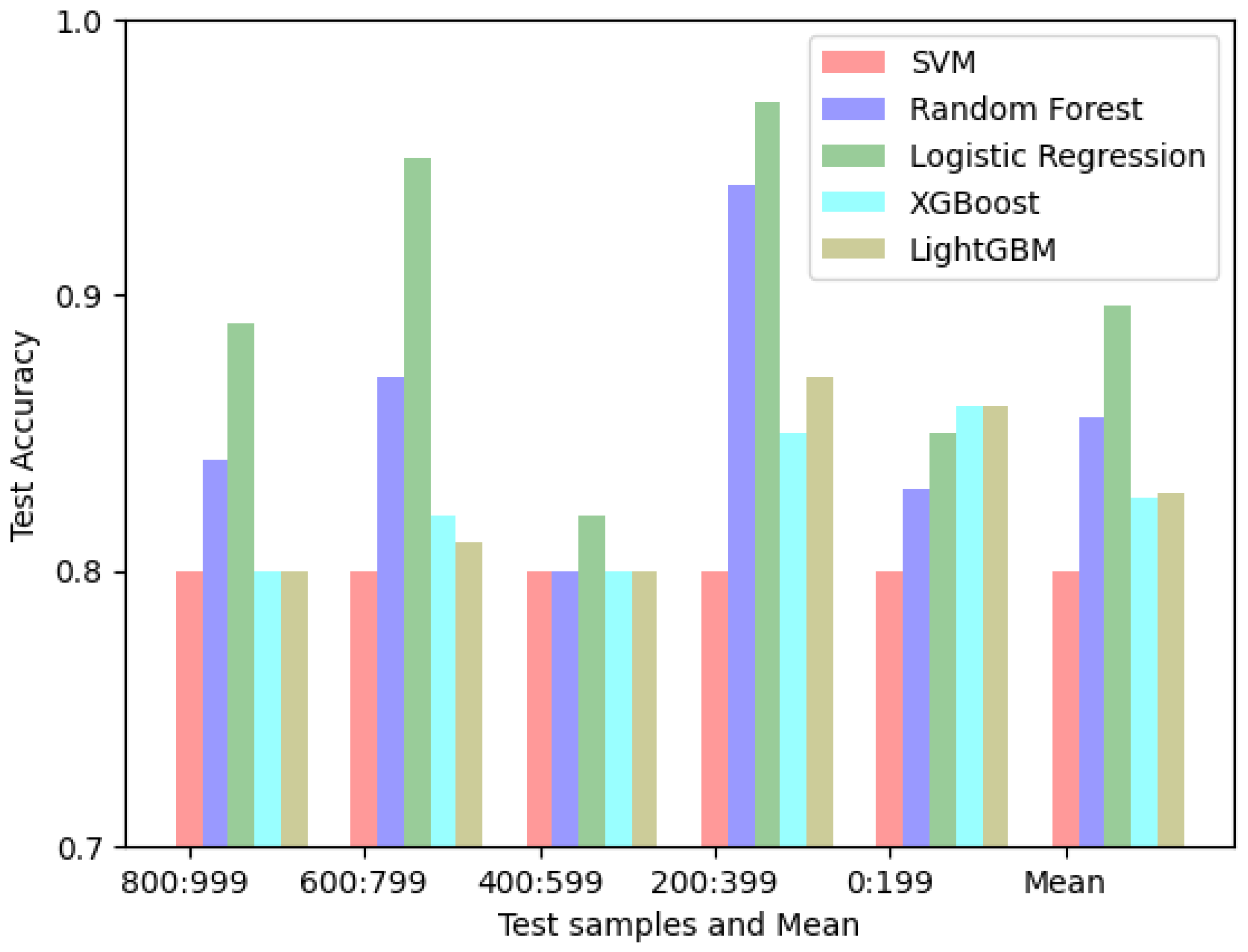

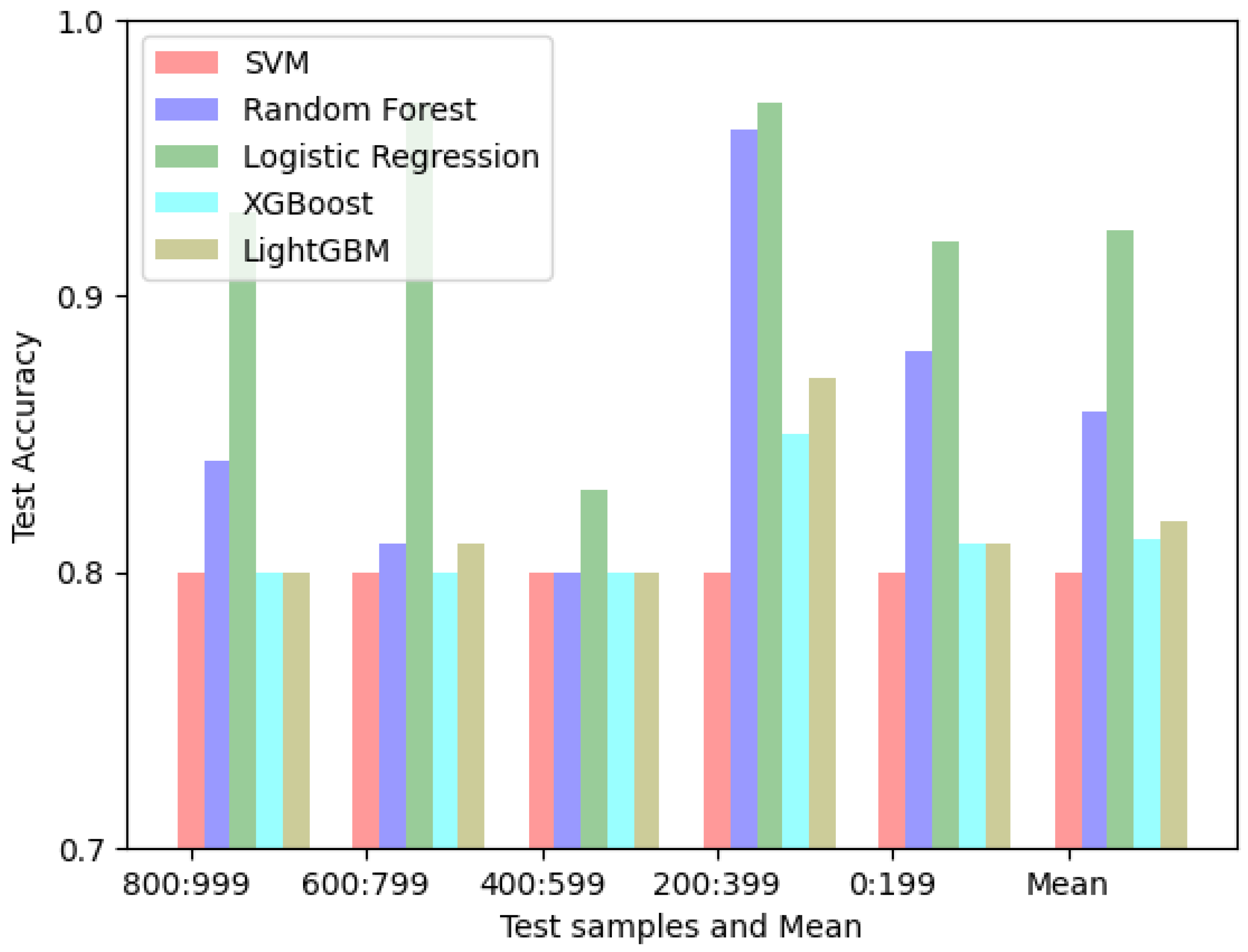

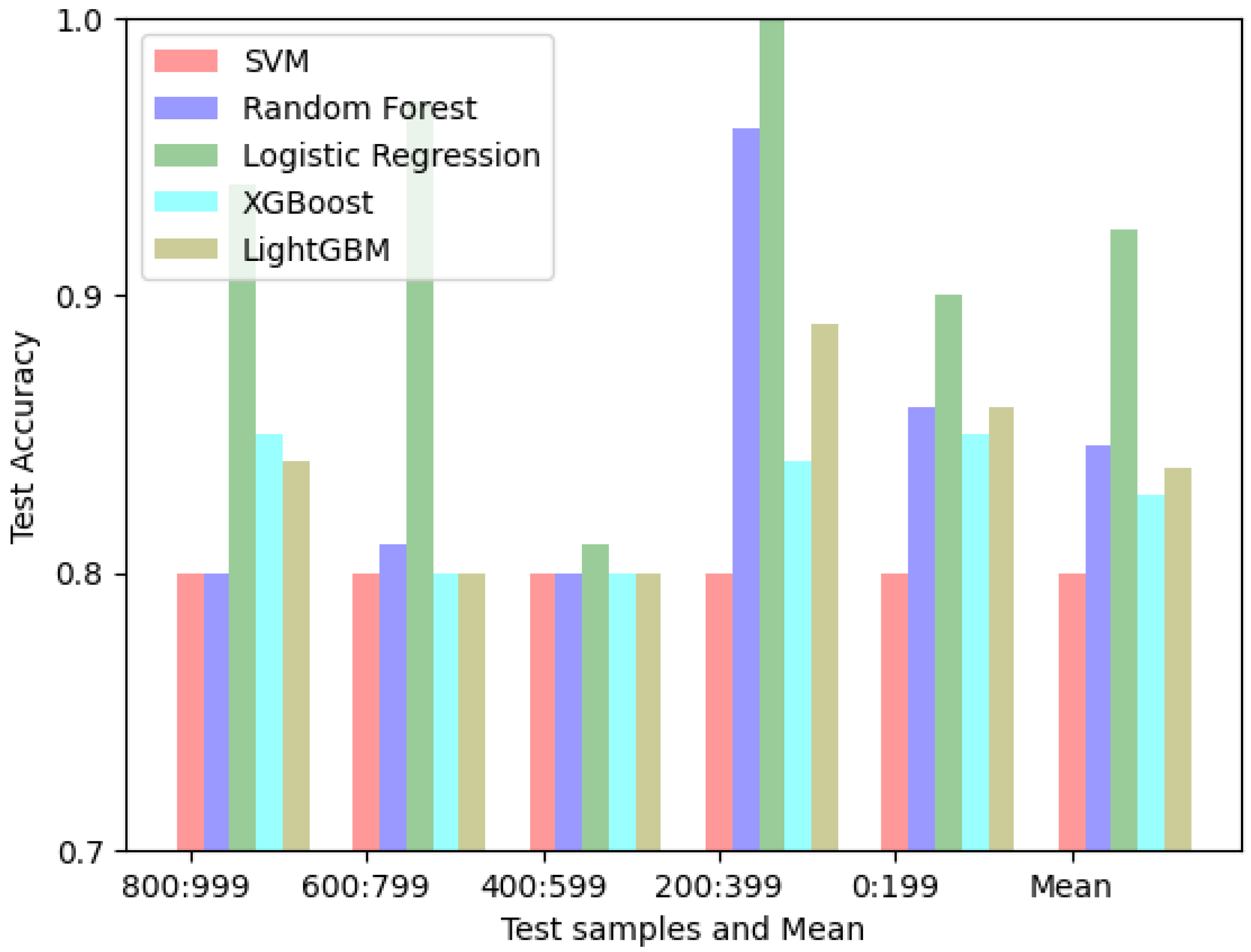

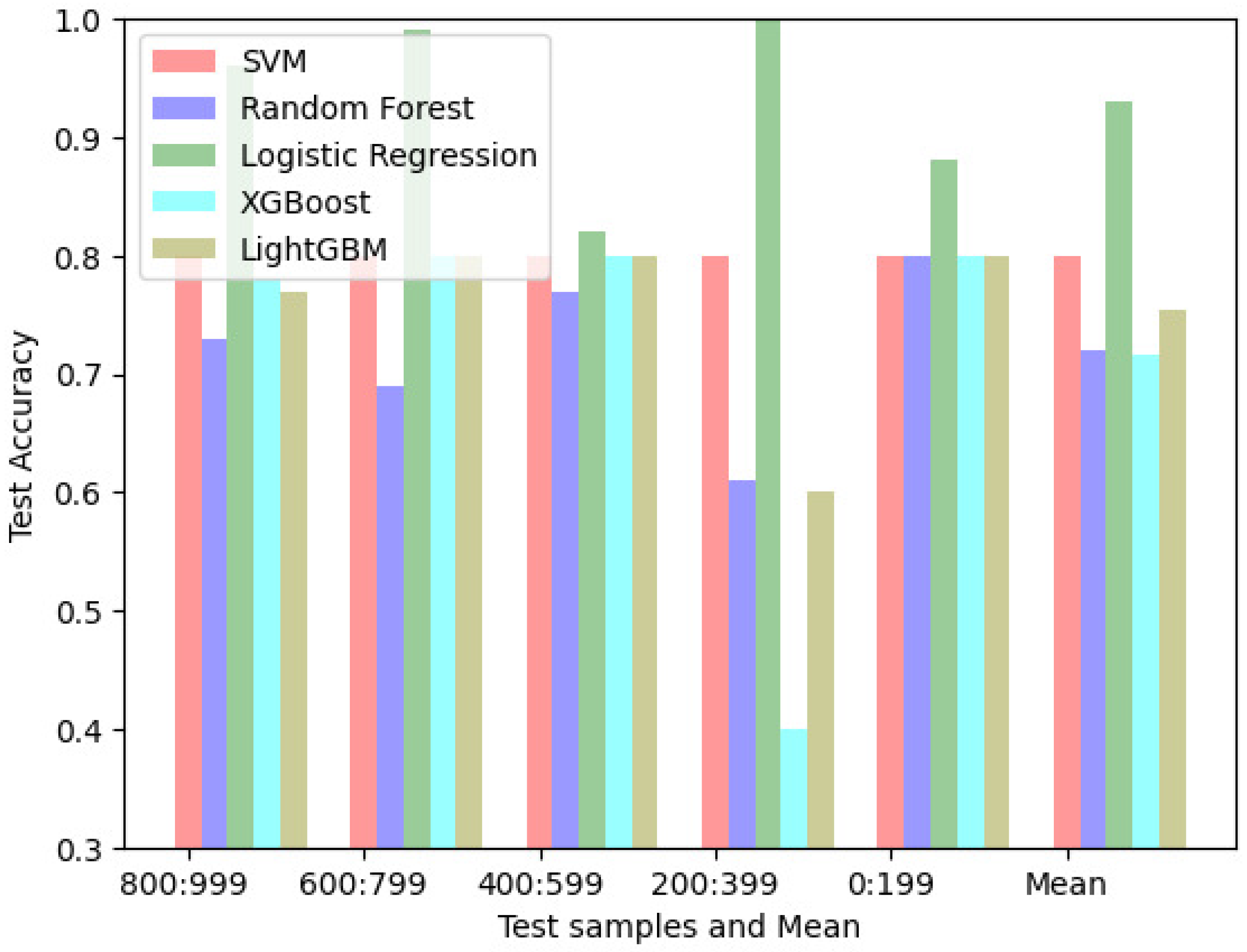

3.1. Performance Comparison among ML Models

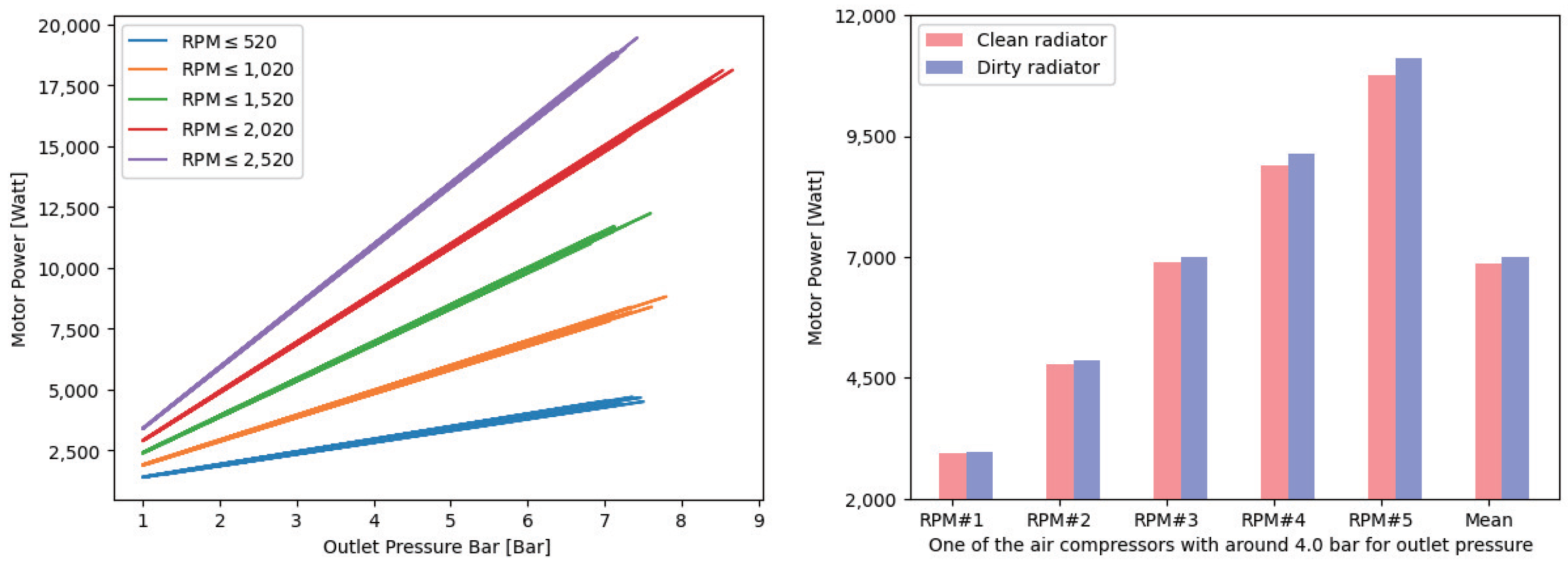

3.2. Energy Saving Effects of Removing a Dirty Radiator

3.3. The Limitations and Shortcomings of the Proposed Models

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| CBAM | Convolutional Block Attention Module |

| DL | Deep Learning |

| GBM | Gradient Boosting Machine |

| LAMDA | Learning Methodology for Multivariable Data Analyses |

| LSTM | Long Short-Term Memory |

| MA | Moving Average |

| MAE | Mean Absolute Error |

| MAPE | Mean Average Percentage Error |

| ML | Machine learning |

| OPEX | OPerational EXpenditure |

| OVA | One-Versus-All |

| RPM | Revolutions Per Minute |

| RUL | Remaining Useful Life |

| SVM | Support Vector Machine |

| XGBoost | eXtreme Gradient Boosting |

References

- Saidur, R.; Rahim, N.A.; Hasanuzzaman, M. A review on compressed-air energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 1135–1153. [Google Scholar] [CrossRef]

- Yuan, C.Y.; Zhang, T.; Rangarajan, A.; Dornfeld, D.; Ziemba, B.; Whitbeck, R. A decision-based analysis of compressed air usage patterns in automotive manufacturing. J. Manuf. Syst. 2006, 25, 293–300. [Google Scholar] [CrossRef]

- Panda, C.; Singh, T.R. ML-based vehicle downtime reduction: A case of air compressor failure detection. Eng. Appl. Artif. Intell. 2023, 122, 106031. [Google Scholar] [CrossRef]

- Cerrada, M.; Montalvo, D.; Zambrano, X.; Cabrera, D.; Sánchez, R.V. Fault diagnosis in reciprocating compressor bearings: An approach using LAMDA applied on current signals. IFAC-PapersOnLine 2022, 55, 199–204. [Google Scholar] [CrossRef]

- Loukopoulos, P.; Zolkiewski, G.; Bennett, I.; Sampath, S.; Pilidis, P.; Li, X.; Mba, D. Abrupt fault remaining useful life estimation using measurements from a reciprocating compressor valve failure. Mech. Syst. Signal Process. 2019, 121, 359–372. [Google Scholar] [CrossRef]

- Lee, J.-G.; Kim, D.-H.; Lee, J.H. Proactive Fault Diagnosis of a Radiator: A Combination of Gaussian Mixture Model and LSTM Autoencoder. Sensors 2023, 23, 8688. [Google Scholar] [CrossRef] [PubMed]

- Air Compressor Predictive Maintenance Using Machine Learning. Available online: https://www.neuraldesigner.com/blog/air-compressor/ (accessed on 20 January 2024).

- Predictive Maintenance Dataset—Air Compressor. Available online: https://www.kaggle.com/datasets/afumetto/predictive-maintenance-dataset-air-compressor (accessed on 20 January 2024).

- Guo, J.; Wang, Z.; Li, H.; Yang, Y.; Huang, C.-G.; Yazdi, M.; Kang, H.S. A hybrid prognosis scheme for rolling bearings based on a novel health indicator and nonlinear Wiener process. Reliab. Eng. Syst. Saf. 2024, 245, 110014. [Google Scholar] [CrossRef]

- Guo, J.; Yang, Y.; Li, H.; Dai, L.; Huang, B. A parallel deep neural network for intelligent fault diagnosis of drilling pumps. Eng. Appl. Artif. Intell. 2024, 133, 108071. [Google Scholar] [CrossRef]

- Gribbestad, M.; Hassan, M.U.; Hameed, I.A. Transfer Learning for Prognostics and Health Management (PHM) of Marine Air Compressors. J. Mar. Sci. Eng. 2021, 9, 47. [Google Scholar] [CrossRef]

- Drakaki, M.; Karnavas, Y.L.; Tziafettas, I.A.; Linardos, V.; Tzionas, P. Machine learning and deep learning based methods toward Industry 4.0 predictive maintenance in induction motors: A state of the art survey. J. Ind. Eng. Manag. 2022, 15, 31–57. [Google Scholar] [CrossRef]

- Lee, D.; Chen, M.-H.; Lai, G.-W. Achieving energy savings through artificial-intelligence-assisted fault detection and diagnosis: Case study on refrigeration systems. Case Stud. Therm. Eng. 2022, 40, 102499. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Z.; Chen, Y.; Li, H.; Liu, C.; Lu, J.; Li, R. Sensor Fault Detection Combined Data Quality Optimization of Energy System for Energy Saving and Emission Reduction. Processes 2022, 10, 347. [Google Scholar] [CrossRef]

- Rodriguez, P.C.; Marti-Puig, P.; Caiafa, C.F.; Serra-Serra, M.; Cusidó, J.; Solé-Casals, J. Exploratory Analysis of SCADA Data from Wind Turbines Using the K-Means Clustering Algorithm for Predictive Maintenance Purposes. Machines 2023, 11, 270. [Google Scholar] [CrossRef]

- Shi, T.; Peng, X. Performance Assessment and Optimization of the Ultra-High Speed Air Compressor in Hydrogen Fuel Cell Vehicles. Appl. Sci. 2024, 14, 1232. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, W.; Jia, G.; Li, G.; Cai, M. Energy Analysis of Precooling Air Compressor System. Entropy 2022, 24, 1035. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, S.; Kara, S.; Kornfeld, B. Energy Efficiency of Compressed Air Systems. Procedia CIRP 2014, 15, 313–318. [Google Scholar] [CrossRef]

- Liu, E.; Lv, L.; Yi, Y.; Xie, P. Research on the Steady Operation Optimization Model of Natural Gas Pipeline Considering the Combined Operation of Air Coolers and Compressors. IEEE Access 2019, 7, 83251–83265. [Google Scholar] [CrossRef]

- Bayoumi, M.A.; Esawy, A.M.; Salim, O.M. New symbolic model for multi-compressor operation based on multi-objective Jaya optimization for life/energy saving. Ain. Shams Eng. J. 2023, 14, 102245. [Google Scholar] [CrossRef]

- Ong, K.S.H.; Niyato, D.; Yuen, C. Predictive Maintenance for Edge-Based Sensor Networks: A Deep Reinforcement Learning Approach. In Proceedings of the IEEE 6th World Forum on Internet of Things (WF-IoT), New Orleans, LA, USA, 2–16 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Choi, B.S.; Kim, H.; Jeon, S.H. LSTM-based Time Series Forecasting of Pulmonary Function Test for COPD Early Diagnosis. J. Korean Inst. Commun. Inf. Sci. (J-KICS) 2024, 49, 346–355. [Google Scholar] [CrossRef]

| Estimation Metric | Channels | Test Rate | ||

|---|---|---|---|---|

| MAPE 1 | Motor power, Outlet temp., Water inlet temp., Water outlet temp., Oil tank temp. | |||

| Motor power | ||||

| Scenarios | Features | Accuracy of ML Models | ||||

|---|---|---|---|---|---|---|

| SVM | Random Forest | Logistic Regression | XGBoost | Light GBM | ||

| ML1 | RPM, Motor power, Outlet temp., Water inlet temp., Water outlet temp., Oil tank temp. | |||||

| ML2 | RPM, Motor power, Noise db, Outlet temp. | |||||

| ML3 | RPM, Motor power, Outlet pressure bar, Noise db, Outlet temp. | |||||

| ML4 | RPM, Motor power, Outlet pressure bar, Outlet temp., Wpump power, Oil tank temp. | |||||

| ML5 | RPM, Motor power, Outlet pressure bar, Air flow, Outlet temp., Wpump power | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, S.H.; Yoo, S.; Yoo, Y.-S.; Lee, I.-W. ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems. Energies 2024, 17, 1428. https://doi.org/10.3390/en17061428

Jeon SH, Yoo S, Yoo Y-S, Lee I-W. ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems. Energies. 2024; 17(6):1428. https://doi.org/10.3390/en17061428

Chicago/Turabian StyleJeon, Seung Hyun, Sarang Yoo, Yoon-Sik Yoo, and Il-Woo Lee. 2024. "ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems" Energies 17, no. 6: 1428. https://doi.org/10.3390/en17061428

APA StyleJeon, S. H., Yoo, S., Yoo, Y.-S., & Lee, I.-W. (2024). ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems. Energies, 17(6), 1428. https://doi.org/10.3390/en17061428