Environmental Assessment of a Waste-to-Energy Cascading System Integrating Forestry Residue Pyrolysis and Poultry Litter Anaerobic Digestion

Abstract

1. Introduction

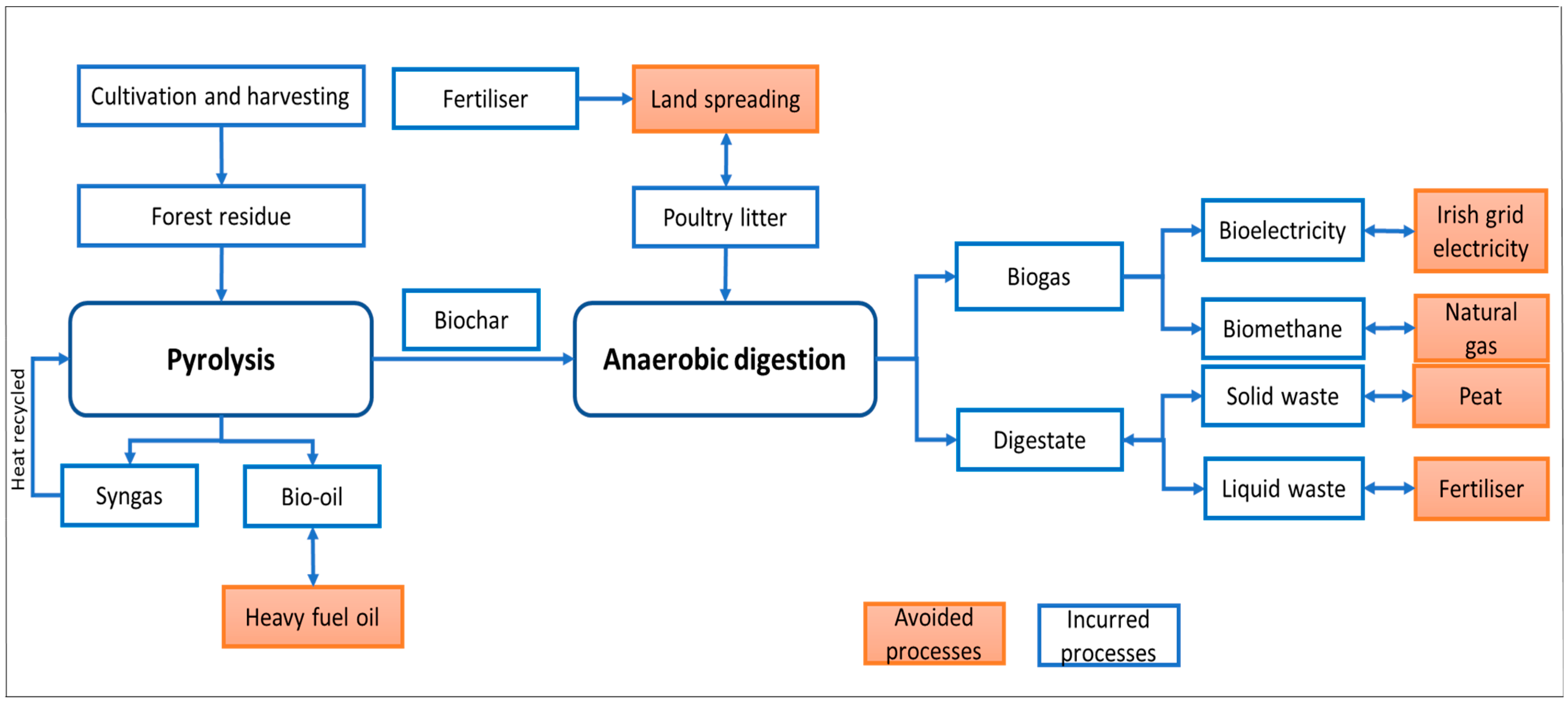

2. Materials and Methods

2.1. Goal and Scope

2.2. Inventory

2.3. Life Cycle Impact Assessment

2.4. Scenario Analysis

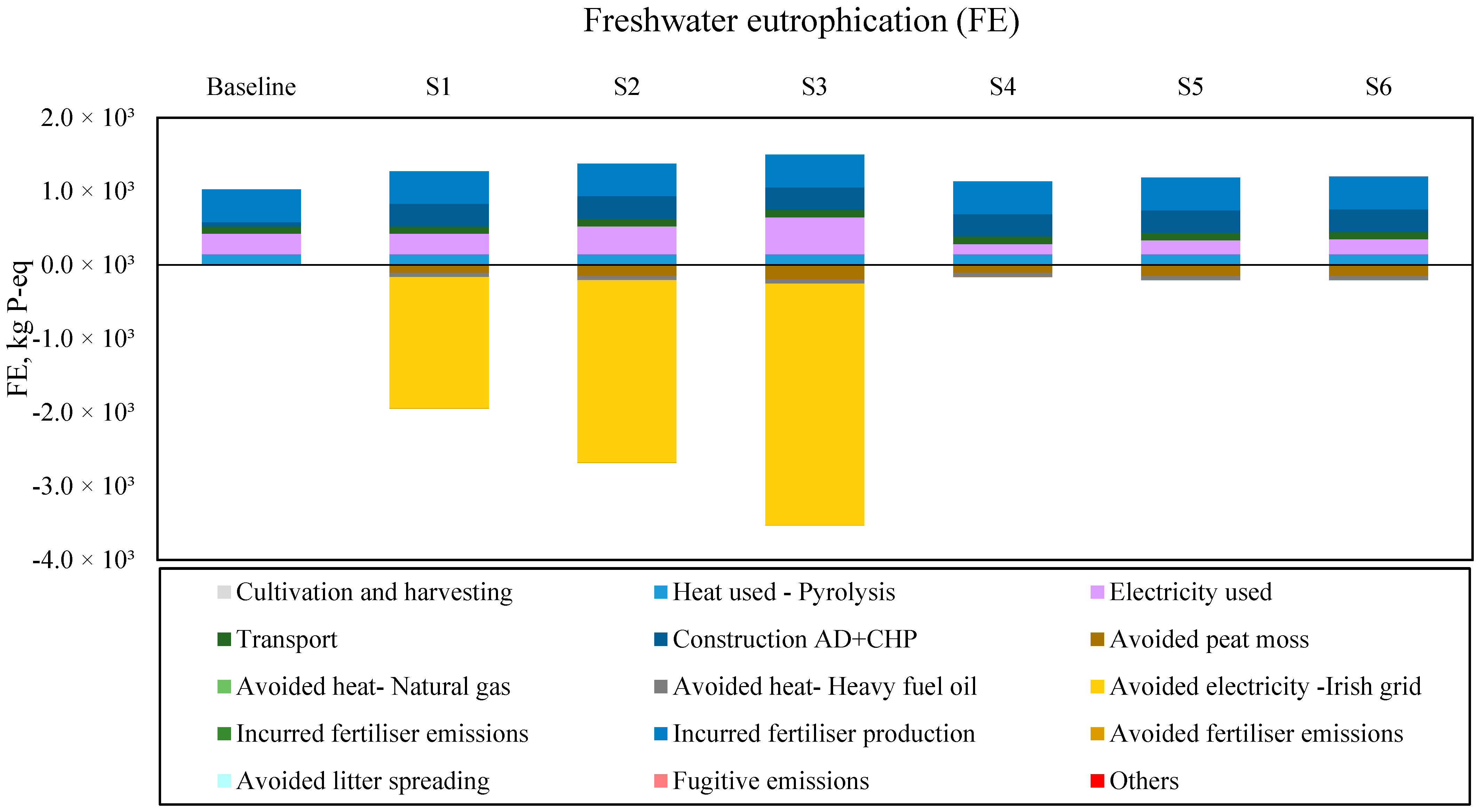

3. Results and Discussion

4. Conclusions, Outlooks, and Limitations of the Study

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | anaerobic digestion |

| BS | baseline scenario |

| CAN | calcium ammonium nitrate |

| CC | climate change |

| CHP | combined heat and power |

| CLT | Cut-to-Length |

| FD | fossil depletion |

| FE | freshwater eutrophication |

| GJ | gigajoule |

| HFO | heavy fuel oil |

| km | kilometre |

| kWh | kilowatt hour |

| LCA | life cycle assessment |

| LCI | life cycle inventory |

| m | metre |

| MWh | megawatt hour |

| OFMSW | organic fraction of municipal solid waste |

| PLT | poultry litter |

| PR | pyrolysis |

| RHI | renewable heat incentive |

| S | scenario |

| t | tonne |

| TA | terrestrial acidification |

| TS | total solid |

References

- Department of Business Enterprise and Innovation (DBEI). Realising the Opportunities for Enterprise in the Bioeconomy and Circular Economy in Ireland. 2019. Available online: https://enterprise.gov.ie/en/publications/publication-files/realising-opportunities-for-enterprise-bioeconomy-and-circular-economy-ireland.pdf (accessed on 23 August 2023).

- Government of Ireland. Bioeconomy Action Plan Consultation and Discussion Document. 2022. Available online: https://www.gov.ie/pdf/?file=https://assets.gov.ie/240374/042b595a-de62-469e-85b9-000f401caed2.pdf#page=null (accessed on 23 August 2023).

- Central Statistics Office (CSO). Meat Supply Balance 2019–2021. 2022. Available online: https://www.cso.ie/en/releasesandpublications/ep/p-msb/meatsupplybalance2021/ (accessed on 17 October 2023).

- ReportLinker. Ireland Poultry Meat Industry Outlook 2022–2026. 2022. Available online: https://www.reportlinker.com/clp/country/1828/726369 (accessed on 17 October 2023).

- ICT Biochain. Fate of Biomasses in Ireland. 2020. Available online: https://bioeconomyfoundation.com/ictbiochain/ (accessed on 17 October 2023).

- Sustainable Energy Authority of Ireland (SEAI). Bioenergy Supply in Ireland 2015–2035. 2017. Available online: https://www.seai.ie/publications/Bioenergy-Supply-in-Ireland-2015-2035.pdf (accessed on 23 August 2023).

- IEA Bioenergy. The Role of Anaerobic Digestion and Biogas in the Circular Economy. 2018. Available online: https://www.ieabioenergy.com/wp-content/uploads/2018/08/anaerobic-digestion_web_END.pdf (accessed on 23 August 2023).

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Mehta, N.; Anderson, A.; Johnston, C.R.; Rooney, D.W. Evaluating the opportunity for utilising anaerobic digestion and pyrolysis of livestock manure and grass silage to decarbonise gas infrastructure: A Northern Ireland case study. Renew. Energy 2022, 196, 343–357. [Google Scholar] [CrossRef]

- Tayibi, S.; Monlau, F.; Bargaz, A.; Jimenez, R.; Barakat, A. Synergy of anaerobic digestion and pyrolysis processes for sustainable waste management: A critical review and future perspectives. Renew. Sustain. Energy Rev. 2021, 152, 111603. [Google Scholar] [CrossRef]

- Kizito, S.; Jjagwe, J.; Mdondo, S.W.; Nagawa, C.B.; Bah, H.; Tumutegyereize, P. Synergetic effects of biochar addition on mesophilic and high total solids anaerobic digestion of chicken manure. J. Environ. Manag. 2022, 315, 115192. [Google Scholar] [CrossRef]

- Indren, M.; Birzer, C.H.; Kidd, S.P.; Hall, T.; Medwell, P.R. Effect of wood biochar dosage and re-use on high-solids anaerobic digestion of chicken litter. Biomass Bioenergy 2021, 144, 105872. [Google Scholar] [CrossRef]

- Jang, H.M.; Choi, Y.K.; Kan, E. Effects of dairy manure-derived biochar on psychrophilic, mesophilic and thermophilic anaerobic digestions of dairy manure. Bioresour. Technol. 2018, 250, 927–931. [Google Scholar] [CrossRef]

- Department of Agriculture, Food and the Marine (DAFM). Forest Statistics Ireland 2022. 2022. Available online: https://www.teagasc.ie/media/website/crops/forestry/advice/Forest-Statistics-Ireland-2022.pdf (accessed on 11 August 2023).

- Cavali, M.; Junior, N.L.; de Almeida Mohedano, R.; Belli Filho, P.; da Costa, R.H.R.; de Castilhos Junior, A.B. Biochar and hydrochar in the context of anaerobic digestion for a circular approach: An overview. Sci. Total Environ. 2022, 822, 153614. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.; Lin, Y. Integrated processes of anaerobic digestion and pyrolysis for higher bioenergy recovery from lignocellulosic biomass: A brief review. Renew. Sustain. Energy Rev. 2017, 77, 1272–1287. [Google Scholar] [CrossRef]

- Motola, V.; Scarlat, N.; Hurtig, O.; Buffi, M.; Georgakaki, A.; Letout, S.; Mountraki, A.; Joanny, G. Clean Energy Technology Observatory: Bioenergy in the European Union—2022. Status Report on Technology Development, Trends, Value Chains and Markets; JRC130730; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- IEA Bioenergy. The Role of Biogas and Biomethane in Pathway to Net Zero. 2022. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/12/2022_12_12-IEA_Bioenergy_position-paper_Final2.pdf (accessed on 23 August 2023).

- Li, H.; Feng, K. Life cycle assessment of the environmental impacts and energy efficiency of an integration of sludge anaerobic digestion and pyrolysis. J. Clean. Prod. 2018, 195, 476–485. [Google Scholar] [CrossRef]

- Wang, J.; Okopi, S.I.; Ma, H.; Wang, M.; Chen, R.; Tian, W.; Xu, F. Life cycle assessment of the integration of anaerobic digestion and pyrolysis for treatment of municipal solid waste. Bioresour. Technol. 2021, 338, 125486. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Antoniou, N.; Barakat, A.; Zabaniotou, A. A new concept for enhancing energy recovery from agricultural residues by coupling anaerobic digestion and pyrolysis process. Appl. Energy 2015, 148, 32–38. [Google Scholar] [CrossRef]

- Torri, C.; Fabbri, D. Biochar enables anaerobic digestion of aqueous phase from intermediate pyrolysis of biomass. Bioresour. Technol. 2014, 172, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Opatokun, S.A.; Lopez-Sabiron, A.M.; Ferreira, G.; Strezov, V. Life cycle analysis of energy production from food waste through anaerobic digestion, pyrolysis and integrated energy system. Sustainability 2017, 9, 1804. [Google Scholar] [CrossRef]

- Fehilytimoney. A Baseline Study Quantifying the Scale of the Poultry Industry and Identifying Environmental Impacts of the Poultry Sector within County Monaghan. 2021. Available online: https://monaghan.ie/wp-content/uploads/2021/08/Baseline%20Study%20Poultry%20Sector%20Co.Monaghan%20July%202021.pdf (accessed on 21 July 2023).

- Beausang, C.; McDonnell, K.; Murphy, F. Anaerobic digestion of poultry litter—A consequential life cycle assessment. Sci. Total Environ. 2020, 735, 139494. [Google Scholar] [CrossRef] [PubMed]

- da Costa, T.P.; Murphy, F.; Roldan, R.; Mediboyina, M.K.; Chen, W.; Sweeney, J.; Capareda, S.; Holden, N.M. Technical and environmental assessment of forestry residues valorisation via fast pyrolysis in Ireland. Biomass Bioenergy 2023, 173, 106766. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; McDonnell, K. Forest biomass supply chains in Ireland: A life cycle assessment of GHG emissions and primary energy balances. Appl. Energy 2014, 116, 1–8. [Google Scholar] [CrossRef]

- Moskalik, T.; Borz, S.A.; Dvořák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber harvesting methods in Eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Schmilewski, G.; Socio-Economic Impact of the Peat and Growing Media Industry on Horticulture in the EU. European Peat and Growing Media Association (EPAGMA): Saterland-Sedelsberg, Germany. 2019. Available online: https://peatlands.org/assets/uploads/2019/06/ipc2008p160-164-schmilewski-socio-economic-impact-of-the-peat-and-growing-media-industry.pdf (accessed on 28 August 2023).

- Harty, M.A.; Forrestal, P.J.; Watson, C.J.; McGeough, K.L.; Carolan, R.; Elliot, C.; Krol, D.; Laughlin, R.J.; Richards, K.G.; Lanigan, G.J. Reducing nitrous oxide emissions by changing N fertiliser use from calcium ammonium nitrate (CAN) to urea-based formulations. Sci. Total Environ. 2016, 563, 576–586. [Google Scholar] [CrossRef]

- Muench, S.; Guenther, E. A systematic review of bioenergy life cycle assessments. Appl. Energy 2013, 112, 257–273. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Sustainable Energy Authority of Ireland (SEAI). Energy in Ireland 2022 Report. 2022. Available online: https://www.seai.ie/publications/Energy-in-Ireland-2022.pdf (accessed on 23 August 2023).

- Government of Ireland. Climate Action 2021. 2021. Available online: https://www.gov.ie/pdf/?file=https://assets.gov.ie/224574/be2fecb2-2fb7-450e-9f5f-24204c9c9fbf.pdf#page=null (accessed on 23 August 2023).

- Ahmadi Moghaddam, E.; Ericsson, N.; Hansson, P.A.; Nordberg, Å. Exploring the potential for biomethane production by willow pyrolysis using life cycle assessment methodology. Energy Sustain. Soc. 2019, 9, 6. [Google Scholar] [CrossRef]

- Caiardi, F.; Belaud, J.P.; Vialle, C.; Monlau, F.; Tayibi, S.; Barakat, A.; Oukarroum, A.; Zeroual, Y.; Sablayrolles, C. Waste-to-energy innovative system: Assessment of integrating anaerobic digestion and pyrolysis technologies. Sustain. Prod. Consum. 2022, 31, 657–669. [Google Scholar] [CrossRef]

- Boldrin, A.; Hartling, K.R.; Laugen, M.; Christensen, T.H. Environmental inventory modelling of the use of compost and peat in growth media preparation. Resour. Conserv. Recycl. 2010, 54, 1250–1260. [Google Scholar] [CrossRef]

- Alengebawy, A.; Mohamed, B.A.; Ghimire, N.; Jin, K.; Liu, T.; Samer, M.; Ai, P. Understanding the environmental impacts of biogas utilization for energy production through life cycle assessment: An action towards reducing emissions. Environ. Res. 2022, 213, 113632. [Google Scholar] [CrossRef]

- Tsapekos, P.; Khoshnevisan, B.; Alvarado-Morales, M.; Symeonidis, A.; Kougias, P.G.; Angelidaki, I. Environmental impacts of biogas production from grass: Role of co-digestion and pretreatment at harvesting time. Appl. Energy 2019, 252, 113467. [Google Scholar] [CrossRef]

- Government of Ireland. Support Scheme for Renewable Heat Scheme Overview. 2019. Available online: https://www.gov.ie/en/publication/8b810d-support-scheme-for-renewable-heat/ (accessed on 16 March 2024).

| Scenario (S) | Cultivation and Harvesting of Forest Residue | PR | AD | Litter Spreading | Irish Grid Electricity | Natural Gas | Peat Moss | Fertiliser | HFO |

|---|---|---|---|---|---|---|---|---|---|

| Displaced Processes | |||||||||

| BS | √ | √ | √ | √ | X | X | X | X | X |

| S1 | √ | √ | √ | √ | √ | X | √ | √ | √ |

| S2 | √ | √ | √ | √ | √ | X | √ | √ | √ |

| S3 | √ | √ | √ | √ | √ | X | √ | √ | √ |

| S4 | √ | √ | √ | √ | X | √ | √ | √ | √ |

| S5 | √ | √ | √ | √ | X | √ | √ | √ | √ |

| S6 | √ | √ | √ | √ | X | √ | √ | √ | √ |

| Inputs | Units | BS | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|---|---|

| Forestry residues (dry) | t | 23,010.11 | 23,010.11 | 23,010.11 | 23,010.11 | 23,010.11 | 23,010.11 | 23,010.11 |

| Energy (PR) | MWh | 56.28 | 56.28 | 56.28 | 56.28 | 56.28 | 56.28 | 56.28 |

| Heat (PR) | GJ | 2.48 × 105 | 2.48 × 105 | 2.48 × 105 | 2.48 × 105 | 2.48 × 105 | 2.48 × 105 | 2.48 × 105 |

| PL-transported | t | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 | 20,000 |

| Calcium ammonium nitrate | t | 190,000 | 190,000 | 190,000 | 190,000 | 190,000 | 190,000 | 190,000 |

| Electricity (AD) | kWh | 1.40 × 106 | 1.40 × 106 | 1.40 × 106 | 1.40 × 106 | 1.40 × 106 | 1.40 × 106 | 1.40 × 106 |

| AD plant | item(s) | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Ammonia stripper | t | 750 | 750 | 925.56 | 1087.55 | 750 | 925.56 | 1087.55 |

| PL transport, litter, lorry | t | 1.00 × 106 | 1.00 × 106 | 1.00 × 106 | 1.00 × 106 | 1.00 × 106 | 1.00 × 106 | 1.00 × 106 |

| transport, solid, lorry | t × km | - | 1,530,000 | 1,942,920 | 2,145,880 | 1,530,000 | 1,942,920 | 2,145,880 |

| transport, biochar, lorry a | t × km | 242,500 | 242,500 | 242,500 | 242,500 | 242,500 | 242,500 | 242,500 |

| CHP unit | item(s) | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Electricity (biogas upgrading) | GJ | - | - | - | - | 1524.61 | 1524.61 | 1524.61 |

| Tap water (biogas upgrading) | t | - | - | - | - | 255.42 | 255.42 | 255.42 |

| Outputs | ||||||||

| Bio-syngas | m3 | 10,191.34 | 10,191.34 | 10,191.34 | 10,191.34 | 10,191.34 | 10,191.34 | 10,191.34 |

| Bio-oil | t | 1853.72 | 1853.72 | 1853.72 | 1853.72 | 1853.72 | 1853.72 | 1853.72 |

| Biomethane b | m3 | 3,080,000 | 3,080,000 | 4,276,225 | 5,662,504 | 3,080,000 | 4,276,225 | 5,662,504 |

| Electricity (avoided) | GJ | - | 33,825.61 | 33,825.61 | 33,825.61 | - | - | - |

| Heat (avoided) | GJ | - | - | - | - | 99,792.45 | 99,792.45 | 99,792.45 |

| Ammonium sulphate (avoided) | t | - | 0.35 | 0.44 | 0.50 | 0.35 | 0.44 | 0.50 |

| Peat moss (avoided) | m3 | - | 38,250 | 48,573 | 53,674 | 38,250 | 48,573 | 53,674 |

| Heavy fuel oil (avoided) | t | - | 1853.72 | 1853.72 | 1853.72 | 1853.72 | 1853.72 | 1853.72 |

| Methane to air (fugitive) | t | 50.74 | 50.74 | 67.45 | 90.28 | 50.74 | 67.45 | 90.28 |

| NH3 litter (avoided) | t | 82.40 | 82.40 | 82.40 | 82.40 | 82.40 | 82.40 | 82.40 |

| NH3 (digestate storage) | t | 2.31 | 2.31 | 3.02 | 4.06 | 2.31 | 3.02 | 4.06 |

| N2O (digestate storage) | t | 9.43 × 10−2 | 9.43 × 10−2 | 1.31 × 10−1 | 1.73 × 10−1 | 9.43 × 10−2 | 1.31 × 10−1 | 1.73 × 10−1 |

| N2O (CHP) | t | 1.40 × 10−4 | 1.40 × 10−4 | 1.94 × 10−4 | 2.57 × 10−4 | - | - | - |

| NOx (CHP) | t | 1.73 × 10−2 | 1.73 × 10−2 | 2.40 × 10−2 | 3.18 × 10−2 | - | - | - |

| Impact Category | Flow | Factor | Units |

|---|---|---|---|

| Climate change (CC) | CO2 | 1 | kg CO2-eq/kg |

| CH4 | 25 | kg CO2-eq/kg | |

| N20 | 298 | kg CO2-eq/kg | |

| Freshwater eutrophication (FE) | P | 1 | kg P-eq/kg |

| PO4 | 0.33 | kg P-eq/kg | |

| H3PO4 | 0.32 | kg P-eq/kg | |

| Terrestrial acidification (TA) | SO2 | 1 | kg SO2-eq/kg |

| NOx | 0.56 | kg SO2-eq/kg | |

| NH3 | 2.45 | kg SO2-eq/kg | |

| Fossil depletion (FD) | Crude oil | 1 | kg oil-eq/kg |

| Natural gas | 1.11 | kg oil-eq/m3 | |

| Mine gas | 1.07 | kg oil-eq/m3 | |

| Hard coal | 0.434 | kg oil-eq/kg | |

| Brown coal | 0.225 | kg oil-eq/kg |

| Impact Category | BS | S1 | S2 | S3 | S4 | S5 | S6 |

|---|---|---|---|---|---|---|---|

| CC | 2.05 × 107 | 9.31 × 106 (54.55%) | 6.64 × 106 (67.61%) | 3.54 × 106 (82.75%) | −2.08 × 106 (110.15%) | −9.18 × 106 (144.80%) | −1.74 × 107 (184.96%) |

| TA | −1.68 × 105 | −2.37 × 105 (29.09%) | −2.53 × 105 (33.60%) | −2.72 × 105 (38.15%) | −1.88 × 105 (10.80%) | −1.86 × 105 (9.42%) | −1.86 × 105 (9.62%) |

| FE | 1.02 × 103 | −6.74 × 102 (165.87%) | −1.31 × 103 (227.53%) | −2.04 × 103 (299.00%) | 9.70 × 102 (5.27%) | 9.79 × 102 (4.32%) | 9.93 × 102 (2.96%) |

| FD | 7.54 × 106 | 5.26 × 106 (30.24%) | 4.65 × 106 (38.27%) | 3.95 × 106 (47.57%) | −3.84 × 106 (105.09%) | −3.09 × 106 (141.01%) | −6.24 × 106 (182.84%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mediboyina, M.K.; Murphy, F. Environmental Assessment of a Waste-to-Energy Cascading System Integrating Forestry Residue Pyrolysis and Poultry Litter Anaerobic Digestion. Energies 2024, 17, 1511. https://doi.org/10.3390/en17071511

Mediboyina MK, Murphy F. Environmental Assessment of a Waste-to-Energy Cascading System Integrating Forestry Residue Pyrolysis and Poultry Litter Anaerobic Digestion. Energies. 2024; 17(7):1511. https://doi.org/10.3390/en17071511

Chicago/Turabian StyleMediboyina, Maneesh Kumar, and Fionnuala Murphy. 2024. "Environmental Assessment of a Waste-to-Energy Cascading System Integrating Forestry Residue Pyrolysis and Poultry Litter Anaerobic Digestion" Energies 17, no. 7: 1511. https://doi.org/10.3390/en17071511

APA StyleMediboyina, M. K., & Murphy, F. (2024). Environmental Assessment of a Waste-to-Energy Cascading System Integrating Forestry Residue Pyrolysis and Poultry Litter Anaerobic Digestion. Energies, 17(7), 1511. https://doi.org/10.3390/en17071511