Study on the Mechanical and Permeability Characteristics of Gypsum Rock under the Condition of Crude Oil Immersion

Abstract

1. Introduction

2. Preparation of Samples and Tests

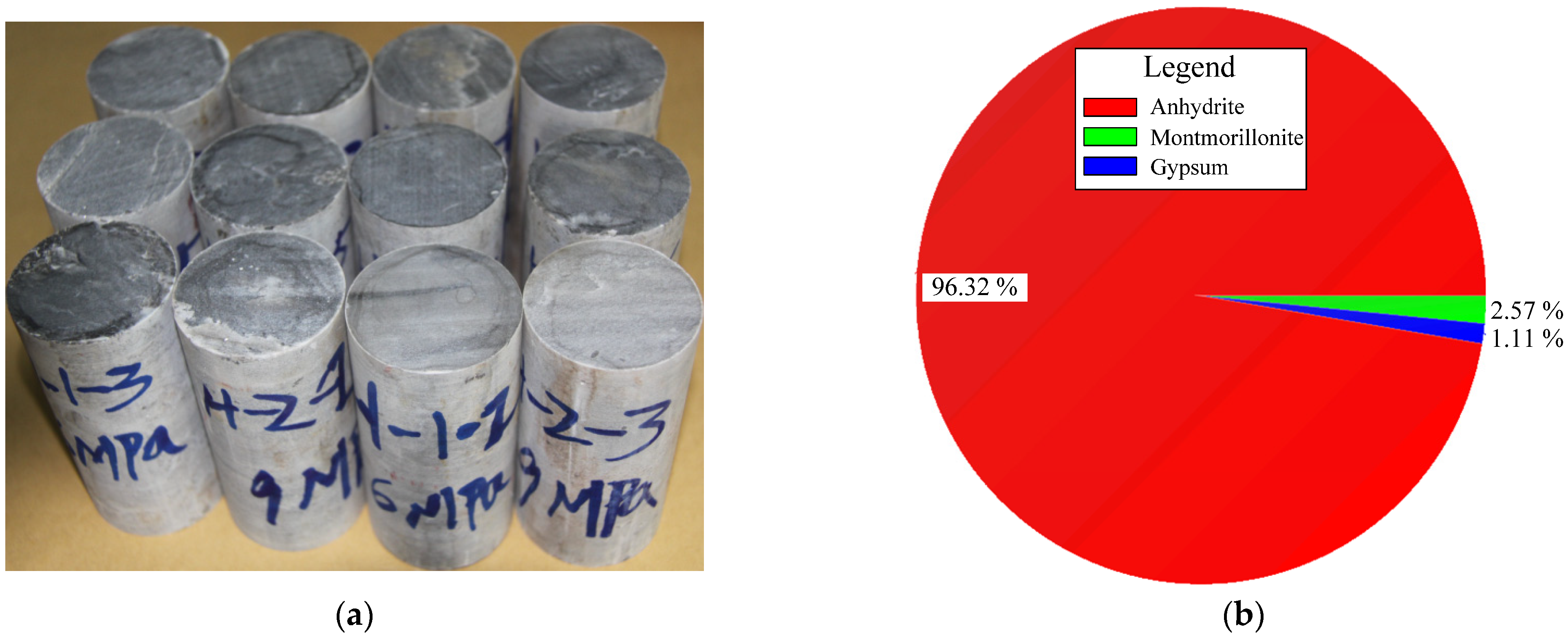

2.1. Sample Preparation

2.2. Crude Oil Soaking

2.3. Rock Mechanics Testing

2.4. Permeability Test

2.5. Pore Distribution Test

3. Results and Discussion

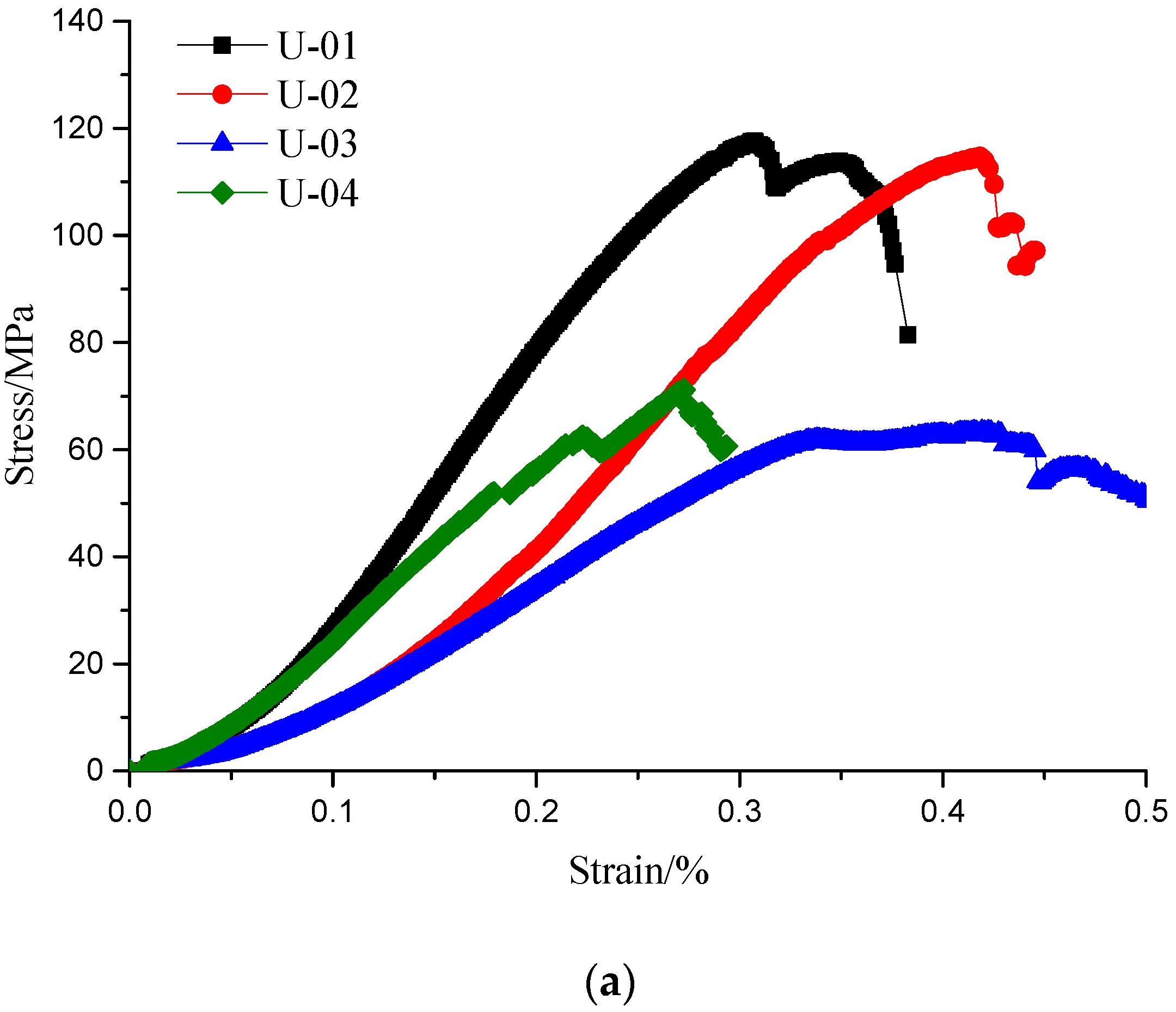

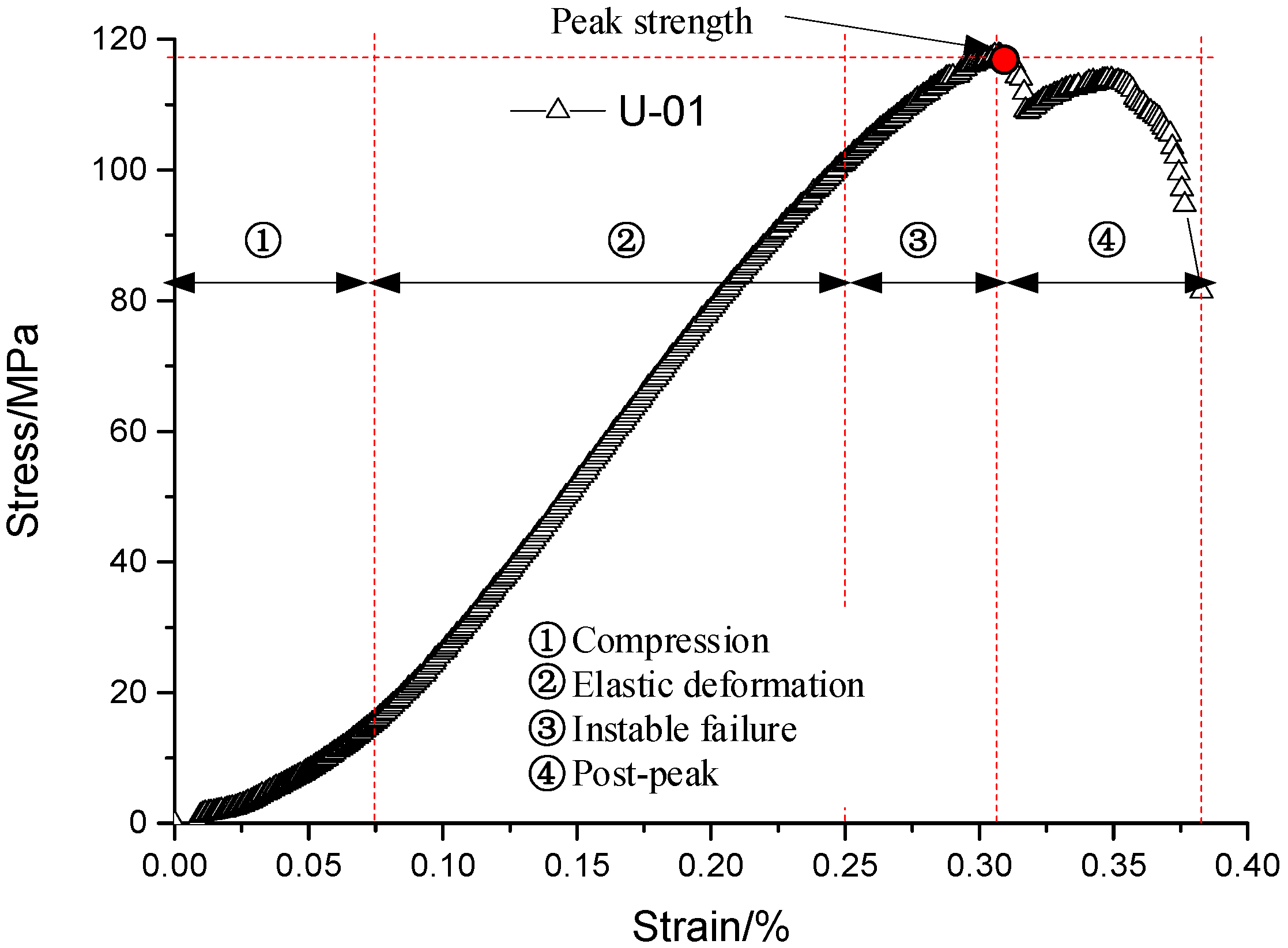

3.1. Uniaxial Compression Test

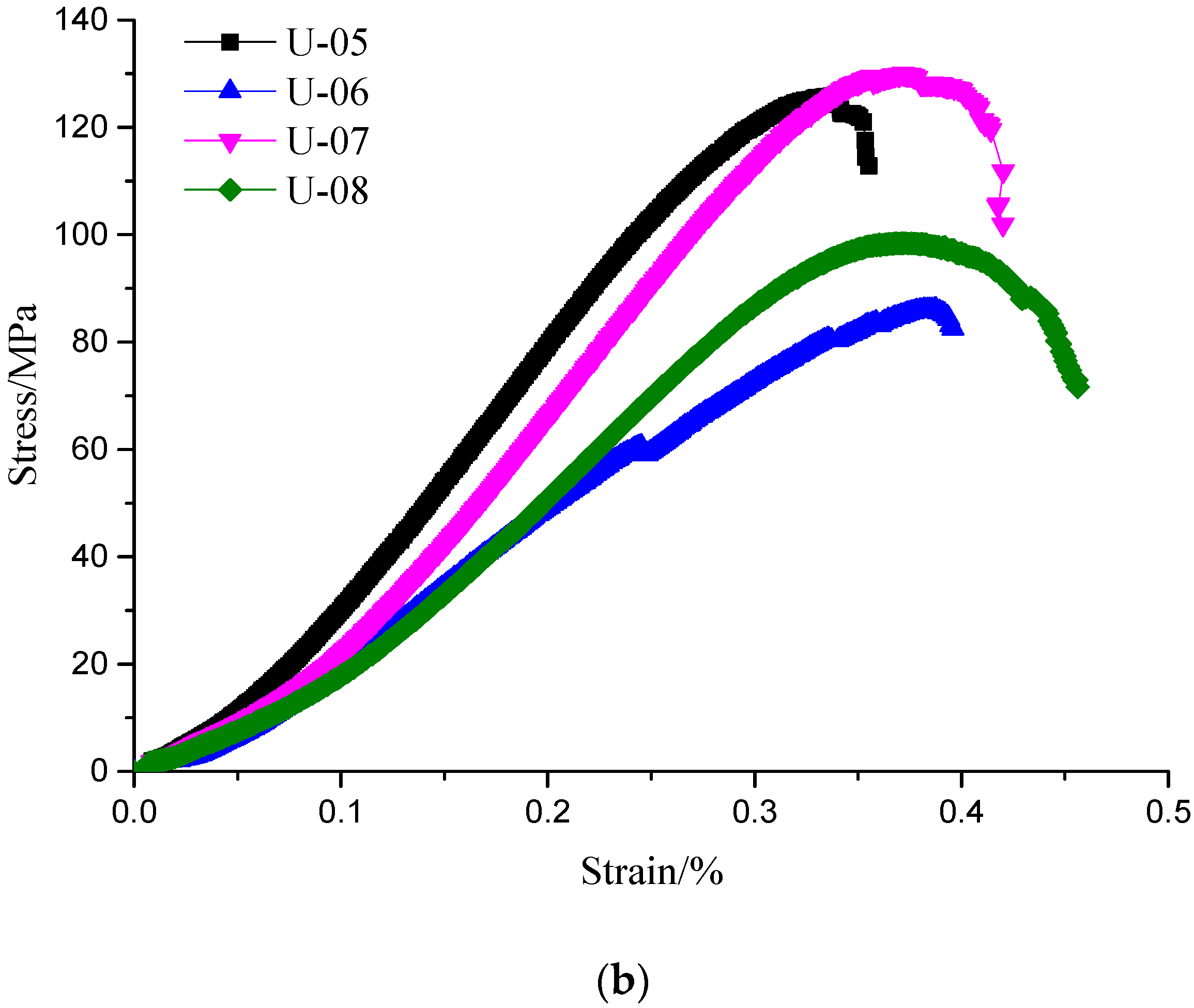

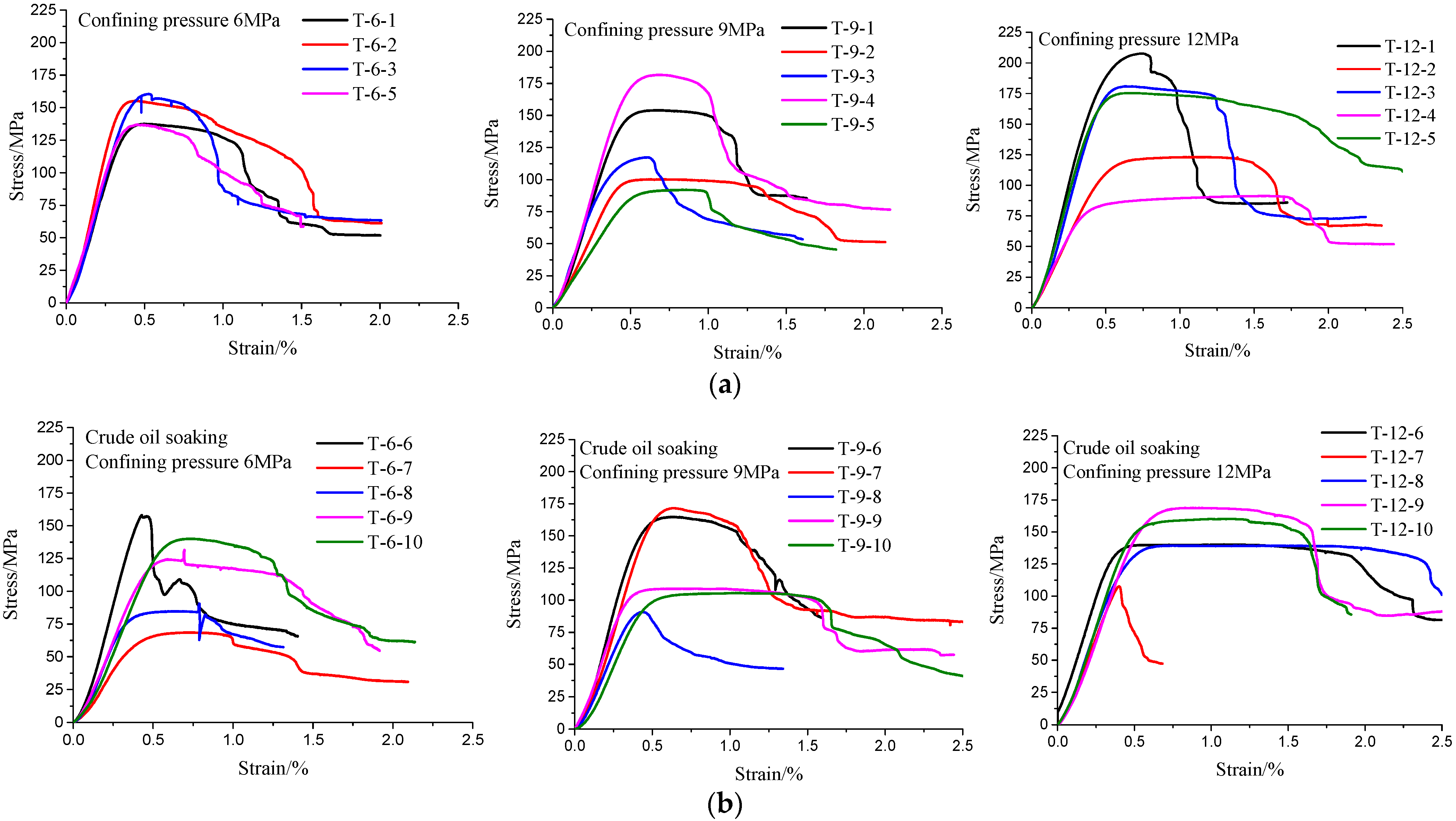

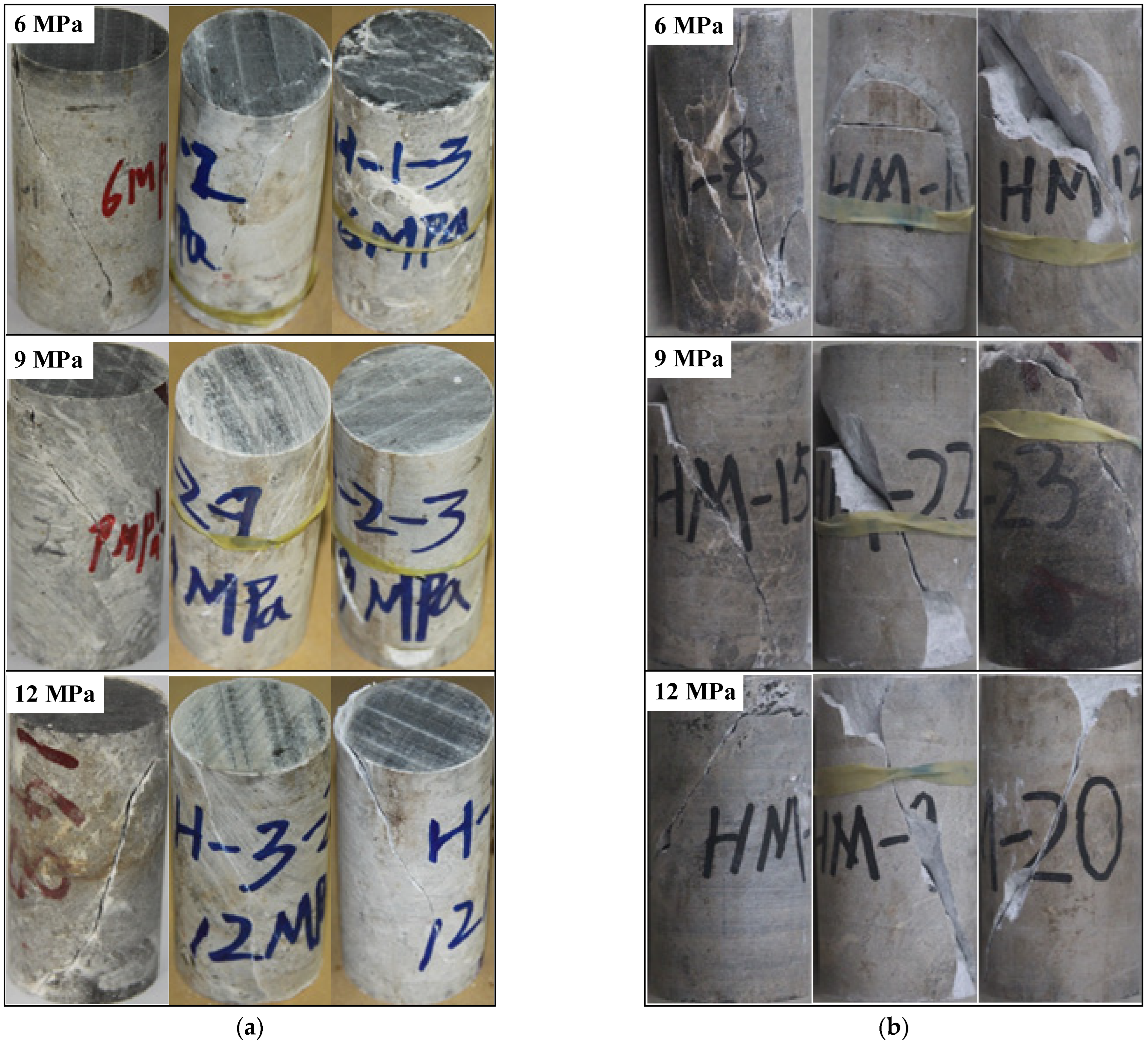

3.2. Triaxial Compression Tests

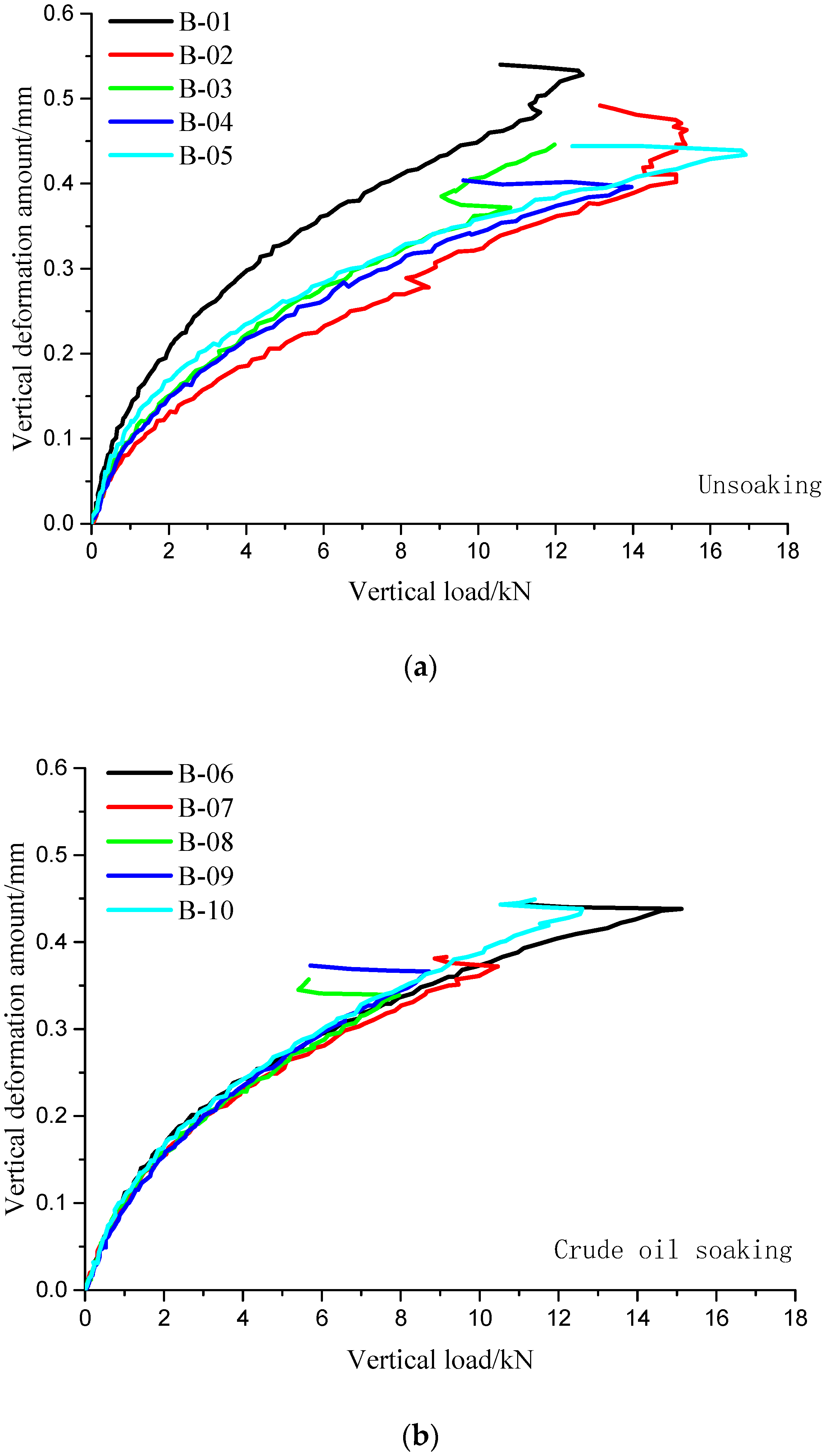

3.3. Brazilian Splitting Tests

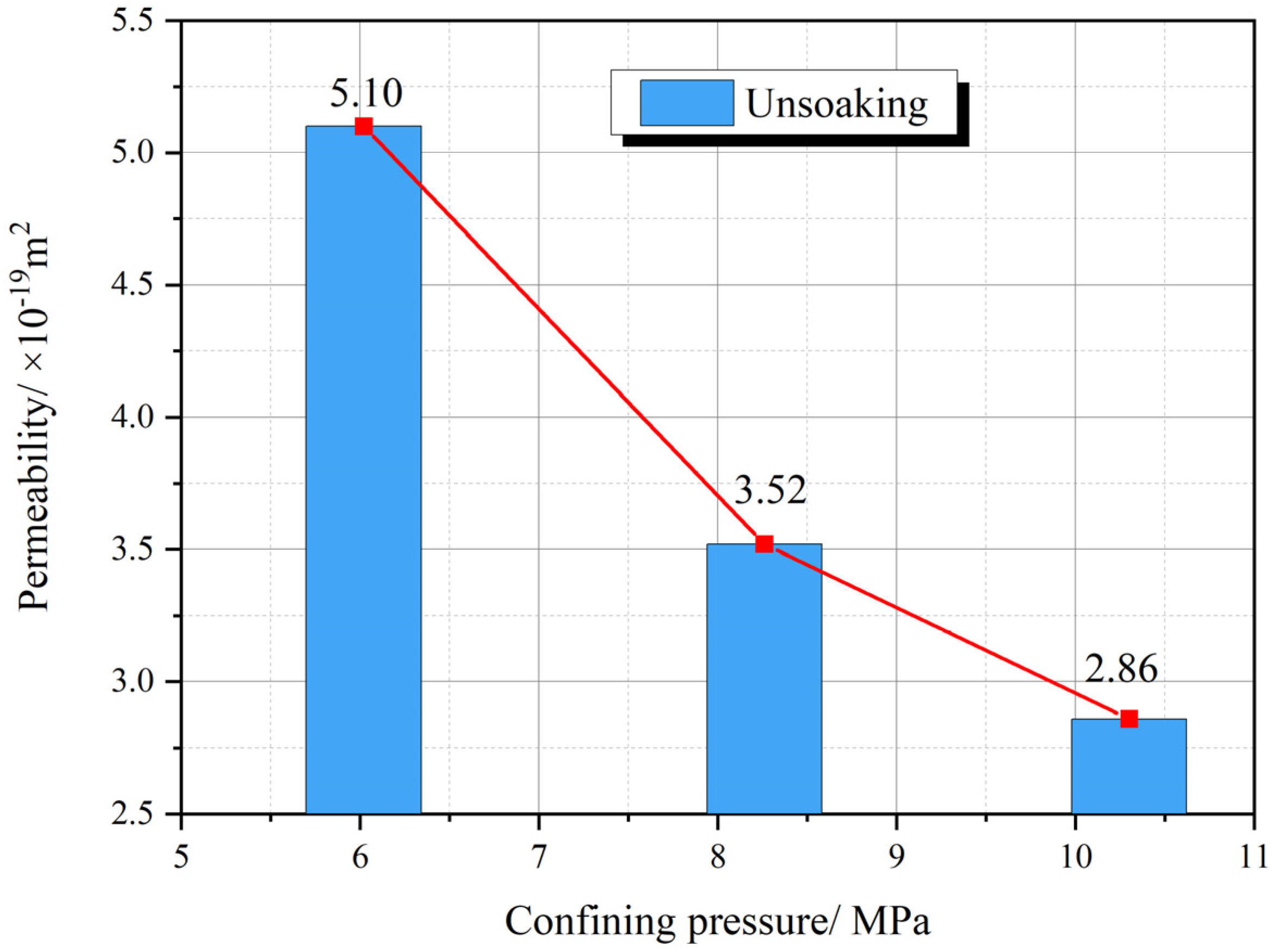

3.4. Permeability Tests

4. Conclusions

- (1)

- During the uniaxial compression experiment, the failure of the gypsum sample experienced a compaction stage, linear elastic stage, plastic deformation stage, and post-peak stage. Crude oil increases the post-peak strength and plastic deformation ability of the sample. The uniaxial compressive strength and elastic modulus of gypsum rock increased by 20% and 34.49%, respectively.

- (2)

- During the triaxial compression experiment, the gypsum sample after crude oil immersion had better plastic deformation ability, and the sample after the failure test had stronger fragmentation. The cohesion of crude oil-soaked samples increased by about 14% compared with that of unsoaked samples, the internal friction angle decreased by about 7.2%, and the peak strength of differential stress under the same confining pressure had little difference.

- (3)

- In the process of the Brazil splitting experiment, the load–deformation relationship curve of crude oil-soaked samples has better normalization. The average tensile strength of gypsum rock before and after crude oil immersion is 7.00 MPa and 5.42 MPa, respectively, which decreases by 22.6%. This is mainly because crude oil erosion intensifies the development of micro-cracks in the sample and significantly reduces the tensile strength of the sample.

- (4)

- The permeability of gypsum rock can reach the level of 10−19 m2, and the permeability of gypsum sample after immersion is even lower. This is mainly because the adhesion and blockage of pores by resins and asphaltenes in crude oil cause the permeability of gypsum samples to decrease.

- (5)

- The results show that crude oil erosion is beneficial to oil storage in the goaf of the Xiaxin gypsum mine, but the properties of gypsum rock vary greatly in different areas. Subsequent studies may require comparative analysis of gypsum rocks from different regions to obtain results that are generally applicable nationwide or even worldwide.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclatures

| A | Sample cross-sectional area [m2] | t | Test time [s] |

| k | Permeability [m2] | Vup | Volume of upstream pressure chambers [m3] |

| L | Sample length [m] | Vdown | Volume of downstream pressure chambers [m3] |

| pp | initial pulse pressure [Pa] | δ | Gas compressive coefficient |

| ∆p | Pressure difference between upstream and downstream [Pa] | μ | Gas dynamic viscosity [Pa·s] |

References

- Ministry of Natural Resources. Report on reserves of China’s major mineral resources published by Ministry of Natural Resources. Geol. China 2018, 45, 1315–1316. [Google Scholar]

- Yin, S.; Zhou, W.; Shan, Y.; Ding, W.; Xie, R.; Guo, C. Assessment of the geostress field of deep-thick gypsum cap rocks: A case study of Paleogene Formation in the southwestern Tarim Basin, NW China. J. Pet. Sci. Eng. 2017, 154, 76–90. [Google Scholar] [CrossRef]

- Jin, Z.; Zhou, Y.; Yun, J. Distribution of gypsum-salt cap rocks and near-term hydrocarbon exploration targets in the marine sequences of China. Oil Gas Geol. 2010, 31, 715–724. [Google Scholar]

- Kamal, M.S.; Hussein, I.; Mahmoud, M.; Sultan, A.S.; Saad, M.A.S. Oilfield scale formation and chemical removal: A review. J. Pet. Sci. Eng. 2018, 171, 127–139. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, H.; Liu, Q.; Zhou, B.; Zhang, D.; Wang, J.; Lu, L.; Luo, H.; Meng, Q.; Wu, X. Significance of gypsum-salt rock series for marine hydrocarbon accumulation. Pet. Res. 2017, 2, 222–232. [Google Scholar] [CrossRef]

- Yılmaz, I.; Sendır, H. Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng. Geol. 2002, 66, 211–219. [Google Scholar] [CrossRef]

- Caselle, C.; Bonetto, S.; Colombero, C.; Comina, C. Mechanical properties of microcrystalline branching selenite gypsum samples and influence of constituting factors. J. Rock Mech. Geotech. Eng. 2019, 11, 228–241. [Google Scholar] [CrossRef]

- Kong, L.; Ostadhassan, M.; Li, C.; Tamimi, N. Can 3-D Printed Gypsum Samples Replicate Natural Rocks? An Experimental Study. Rock Mech. Rock Eng. 2018, 51, 3061–3074. [Google Scholar] [CrossRef]

- Meng, T.; Zhang, D.; Hu, Y.; Jianlin, X.; Sufang, S.; Xiaoming, L. Study of the deformation characteristics and fracture criterion of the mixed mode fracture toughness of gypsum interlayers from Yunying salt cavern under a confining pressure. J. Nat. Gas Sci. Eng. 2018, 58, 1–14. [Google Scholar] [CrossRef]

- Sadeghiamirshahidi, M.; Vitton, S.J. Analysis of drying and saturating natural gypsum samples for mechanical testing. J. Rock Mech. Geotech. Eng. 2019, 11, 219–227. [Google Scholar] [CrossRef]

- Liu, S.; Yang, S.; Shan, F.; Huang, T.; Yin, S.; Liu, X.X. Rock mechanics properties experiment and analysis of deep gypsum cap rocks. Fault-Block Oil Gas Field 2018, 25, 635–638. [Google Scholar]

- Hoxha, D.; Giraud, A.; Homand, F. Modelling long-term behaviour of a natural gypsum rock. Mech. Mater. 2005, 37, 1223–1241. [Google Scholar] [CrossRef]

- Hoxha, D.; Homand, F.; Auvray, C. Deformation of natural gypsum rock: Mechanisms and questions. Eng. Geol. 2006, 86, 1–17. [Google Scholar] [CrossRef]

- Auvray, C.; Homand, F.; Hoxha, D. The influence of relative humidity on the rate of convergence in an underground gypsum mine. Int. J. Rock Mech. Min. Sci. 2008, 45, 1454–1468. [Google Scholar] [CrossRef]

- Liang, W.; Yang, X.; Gao, H.; Zhang, C.; Zhao, Y.; Dusseault, M.B. Experimental study of mechanical properties of gypsum soaked in brine. Int. J. Rock Mech. Min. Sci. 2012, 53, 142–150. [Google Scholar] [CrossRef]

- Meng, T.; Hu, Y.; Fang, R.; Fu, Q.; Yu, W. Weakening mechanisms of gypsum interlayers from Yunying salt cavern subjected to a coupled thermo-hydro-chemical environment. J. Nat. Gas Sci. Eng. 2016, 30, 77–89. [Google Scholar] [CrossRef]

- Salih, N.; Mohammed, A. Characterization and modeling of long-term stressestrain behavior of water confined pre-saturated gypsum rock in Kurdistan Region, Iraq. J. Rock Mech. Geotech. Eng. 2017, 9, 741–748. [Google Scholar] [CrossRef]

- Du, A. Study on Stability and Sealing of Surrounding Rock of Deep Anhydrite Cavern. Master’s Thesis, China University of Geosciences, Beijing, China, 2022. [Google Scholar]

- Liu, S.; Wang, H.; Du, A.; Zhang, B. Tightness Analysis of Anhydrite Mine-Out Used for Underground Crude Oil Storage Considering Seepage–Stress Coupling: A Case Study. Energies 2022, 15, 2929. [Google Scholar] [CrossRef]

- Wang, H.-X.; Zhang, B.; Fu, D.; Ndeunjema, A. Stability and airtightness of a deep anhydrite cavern group used as an underground storage space: A case study. Comput. Geotech. 2018, 96, 12–24. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, H.; Wang, L.; Xu, N. Stability analysis of a group of underground anhydrite caverns used for crude oil storage considering rock tensile properties. Bull. Eng. Geol. Environ. 2019, 78, 6249–6265. [Google Scholar] [CrossRef]

- Zhang, G.; Li, H.; Wang, M.; Li, X. Crack initiation of granite under uniaxial compression tests: A comparison study. J. Rock Mech. Geotech. Eng. 2020, 12, 656–666. [Google Scholar] [CrossRef]

- Donggui, M. Study on Damage Evolution Law and Stability of Surrounding Rock in Underground Oil Storage Space of Abandoned Gypsum Mine. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2022. [Google Scholar]

- Han, P.; Zhang, C.; Wang, X.; Wang, L. Study of mechanical characteristics and damage mechanism of sandstone under long-term immersion. Eng. Geol. 2023, 315, 107020. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Wang, L.; Yu, X.; Shi, L.; Fu, D. Experimental investigation on the long-term interactions of anhydrite rock, crude oil, and water in a mine-out space for crude-oil storage. Eng. Geol. 2020, 265, 105414. [Google Scholar] [CrossRef]

- Professional Standard Compilation Group of People’s Republic of China. Specifications for Rock Tests in Water Conservancy and Hydroelectric Engineering; China Standards Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Sun, Z.G.; Jiang, D.Y.; Xie, K.N.; Wang, K.; Li, L.; Jiang, X. Thermal damage study of Beishan granite based on low field magnetic resonance. J. China Coal Soc. 2020, 45, 1081–1088. [Google Scholar]

| Confining Pressure (MPa) | Original Sample Number | Peak Strengths (MPa) | Average (MPa) | Oi Soaking Sample Number | Peak Strengths (MPa) | Average (MPa) |

|---|---|---|---|---|---|---|

| 6 | T-6-1 | 137.52 | 147.52 | T-6-6 | 157.96 | 117.74 |

| T-6-2 | 155.13 | T-6-7 | 68.51 | |||

| T-6-3 | 160.48 | T-6-8 | 90.56 | |||

| T-6-5 | 136.95 | T-6-9 | 131.59 | |||

| T-6-10 | 140.08 | |||||

| 9 | T-9-1 | 154.02 | 129.01 | T-9-6 | 164.88 | 128.38 |

| T-9-2 | 100.15 | T-9-7 | 171.61 | |||

| T-9-3 | 117.29 | T-9-8 | 90.81 | |||

| T-9-4 | 181.61 | T-9-9 | 109.01 | |||

| T-9-5 | 91.97 | T-9-10 | 105.57 | |||

| 12 | T-12-1 | 207.58 | 155.65 | T-12-6 | 140.27 | 143.22 |

| T-12-2 | 123.15 | T-12-7 | 107.58 | |||

| T-12-3 | 180.83 | T-12-8 | 139.37 | |||

| T-12-4 | 91.29 | T-12-9 | 168.72 | |||

| T-12-5 | 175.41 | T-12-10 | 160.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, T.; Shang, X.; Xie, D.; Yan, D.; Li, M.; Zhang, C. Study on the Mechanical and Permeability Characteristics of Gypsum Rock under the Condition of Crude Oil Immersion. Energies 2024, 17, 1712. https://doi.org/10.3390/en17071712

Jiang T, Shang X, Xie D, Yan D, Li M, Zhang C. Study on the Mechanical and Permeability Characteristics of Gypsum Rock under the Condition of Crude Oil Immersion. Energies. 2024; 17(7):1712. https://doi.org/10.3390/en17071712

Chicago/Turabian StyleJiang, Tingting, Xiurui Shang, Dongzhou Xie, Dairong Yan, Mei Li, and Chunyang Zhang. 2024. "Study on the Mechanical and Permeability Characteristics of Gypsum Rock under the Condition of Crude Oil Immersion" Energies 17, no. 7: 1712. https://doi.org/10.3390/en17071712

APA StyleJiang, T., Shang, X., Xie, D., Yan, D., Li, M., & Zhang, C. (2024). Study on the Mechanical and Permeability Characteristics of Gypsum Rock under the Condition of Crude Oil Immersion. Energies, 17(7), 1712. https://doi.org/10.3390/en17071712