Integration of Piezoelectric Energy Harvesting Systems into Building Envelopes for Structural Health Monitoring with Fiber Optic Sensing Technology

Abstract

1. Introduction

2. Materials and Methods

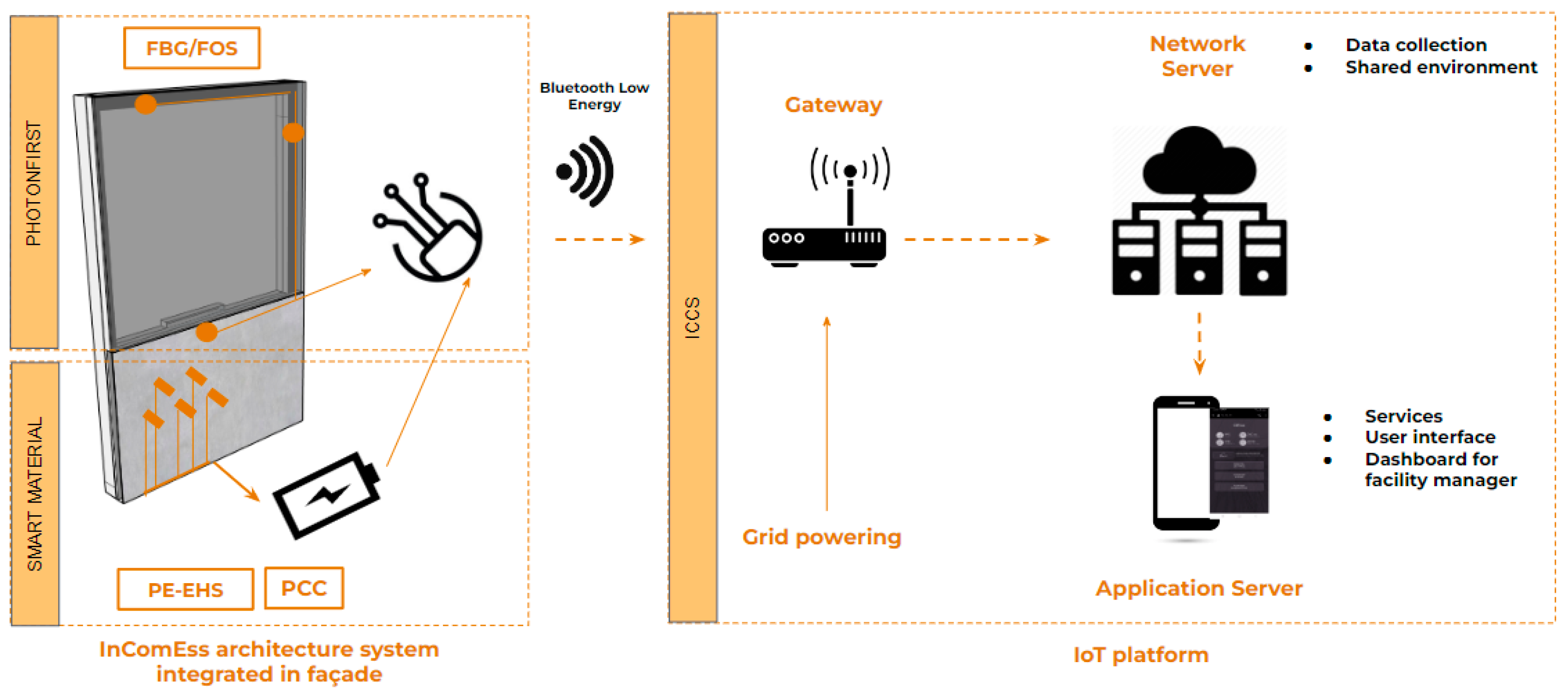

- Analysis and design of the InComEss architecture system and components for integration into the façade—The InComEss system architecture is composed of a set of components analyzed to understand the impact of façade integrability. PE-EHS, FBG along FOS, FOS monadgator, PCC/PCB, and supercapacitor are the physical components to be embedded in the façade. Additionally, the digital component, represented by the IoT gateway for data gathering and transmitting in the IoT platform, is analyzed for its design for façade structural health monitoring. The aim is to adapt and integrate the InComEss architecture within the façade components and relative requirements. This paper underlines the study of PE-EHSs. An in-depth investigation of possible applications within the façade’s components is carried out to define the possible configuration of PE-EHSs, considering several key factors, including aesthetic considerations to ensure visual integration, energy efficiency for sustainable performance, replicability for widespread application, and maintenance considerations to facilitate long-term functionality and ease of upkeep. Multiple distinct configurations are developed with the primary objective of identifying the optimal integration for the façade system;

- Preliminary PE-EHS testing activities—The PE-EHS configurations designed are tested preliminarily in small real environments with the objective of analyzing their voltage production and defining the PE-EHS configurations for the ventilated façade integration. The comprehensive evaluation of these tests addresses the final configuration and specific testing activities to be developed in a controlled lab environment;

- Final PE-EHS configurations and tests in a laboratory of the InComEss architecture system—The PE-EHS final configurations are identified. Testing activities in the controlled lab environment include collecting voltage data for analysis of piezoelectric energy production and overall system performance to identify the results achievable by the overall system in different façade stress conditions. The InComEss architecture system’s components (PE-EH, FBG-FOS, PCC/PCB, IoT gateway, and IoT platform) are validated individually and together to evaluate the stand-alone system reliability. In particular, the PCC circuit’s capability to charge the supercapacitor is tested based on the voltage generated by the PE-EHS integrated into the ventilated façade. The FOS monadgator power consumption is monitored during testing activity. The air velocity employed in the tests during laboratory activities is chosen to reflect the typical wind load forces experienced by high-rise buildings, which serves as the primary reference point for this research. Initial tests using a fan within a range of 5 m/s to 8 m/s are conducted to identify a suitable minimum air velocity. Ultimately, a minimum velocity of 5 m/s is adopted for subsequent testing. Furthermore, to ensure consistency with standardized practices and serviceability of the façade, the wind load range during the experiments corresponds to air velocities ranging from 9.03 m/s to 31.30 m/s. These values align with the specifications outlined in the EN 13830 standard [46], which governs test service conditions for façades. By adhering to this established standard, the obtained results maintain relevance and applicability to real-world building environments;

- Results and test analysis—The laboratory tests for the PE-EHS are analyzed based on testing conditions to comprehend the piezoelectric configuration’s potential for voltage generation. The InComEss system and its integration into the façade are analyzed to wrap up potentialities and limitations for the application. For the lab test, knowing this voltage (U) and the capacitance (C), the stored energy (E) generated by the PE-EHS is calculated as follows:

- InComEss components—The research is based on component development within the project [45]:

- ○

- A PE patch [47,48] is a Macro-Fiber Composite (MFC) PZT, model M8514P2, with a dimension of 18 × 100 mm bonded to a substrate carrier beam made of 1 mm (tb) FR-4 made by glass-reinforced epoxy laminate material and with a dimension of 35 × 110 mm (Wb × Lb). The bluff body is a hollow cylinder made of a polymeric material with a diameter of 10 mm (Df) and a length of 70 mm (Lc). The InComEss system architecture’s energy generation is achieved by integrating a piezoelectric cantilever, constructed from Poly(vinylidene fluoride (PVDF) tapes, into a façade. Given the challenge of inducing significant deformation through vibration alone on a piezoelectric patch with dimensions of 18 cm in length and 5 cm in width, a polymeric wheel designed to rotate with wind is developed and subjected to simulation. The strategy entails attaching permanent magnets to both the wheel and the piezoelectric cantilever, leveraging magnetic repulsion to induce deformation as the wheel turns under typical direct wind conditions (2–5 m/s). The design process utilizes SolidWorks for the wheel’s conception, while Ansys is employed for simulation purposes, with the goal of maximizing output voltage. Through initial analysis and simulation, several solutions are validated, including the reduction in blade inclination from 45° to 30°, the integration of an air channel within the façade’s ventilated cavity to focus airflow and enhance the initial force generated, and the reduction in the wheel’s weight to enable its activation by lower air pressures. These adjustments are implemented and tested on the cantilevers to determine their impact. For the development of the piezoelectric tapes used on the cantilever, PVDF homopolymer pellets, specifically Kynar 720 from Arkema, are converted into tapes using a twin-screw extruder coupled with a flat die. After that, silver ink is applied to both sides of the tapes to create electrodes. The tapes were then poled using a DC power supply to achieve a target piezoelectric coefficient (d33) of up to 20 pC/N. After polarization, the tapes are aligned on a fiberglass composite to construct the piezoelectric generator, with the aim of optimizing the mechanical-to-electrical energy conversion efficiency. The output voltage, both in laboratory and real-world conditions, is measured to evaluate the piezoelectric performance of the developed PVDF cantilever and wheel, utilizing different energy measuring systems for voltage (reported in the Section 2). These output voltages serve as a basis for comparison because, for the façade integration, a dedicated PCB is developed, which is solely capable of voltage acquisition. Consequently, the output voltage provides a comparative analysis between the ideal scenario (laboratory conditions) and the real-world simulation on a ventilated façade;

- ○

- An FOS monadgator based on a low-energy-consumption solution to data gathering and transmission of the InComEss system architecture is used. The FOS monadgator-powered consumption is measured for a full cycle (start-up, FBG data collection, data transfer);

- ○

- A supercapacitor based on the screen-printing method with a capacitance of 125 mF and a voltage of 5 V is used. The equivalent series resistance (ESR) of this module is 26 Ohm;

- ○

- A PCB/PCC is used to have all the components integrated and communicate with each other. The Power Conditioning Circuit is composed of a rectifier to transform the alternate voltage of the piezoelectrics into a direct current and an actively controlled switched regulator to convert the voltage into a usable value. The load resistance is variable since the PCC is powering an active circuit. There is a minimum voltage needed to start harvesting energy; below that threshold, the PCC does not operate. Based on in-field data analysis, a current of ~4 mA is necessary to reach a ~5 V threshold to charge the supercapacitor, and consequently, the resistance is R = U/I = 5 V/0.004 A = 1250 Ohm. The PCC needs a power of 20 mW to run. No more technical information can be disclosed due to confidentiality issues;

- ○

- An IoT gateway, which has been recently proposed for a real-time vehicle monitoring application [49], is customized to support the integration with the FOS node for data collection and transmission to the IoT platform;

- ○

- An IoT platform is customized for façade structural health monitoring, visualization, exploring, and alerting.

- Energy measuring system for voltage:

- ○

- For configurations A1, A2, and C2 in a real environment at Focchi premises, a custom-built data acquisition system specifically designed for the project is used. The system consists of a low-voltage drop diode bridge rectifier that converts the AC that usually comes from the PEG into a DC voltage. This DC voltage is used to charge up a low-leakage foil capacitor. The rising voltage across this capacitor is measured using a very-high-input impedance op amp so that no discharging effect as a result of the measurement chain occurs. No more technical information can be disclosed due to confidentiality issues;

- ○

- For configuration D in a real environment at CENTI premises, a BK Precision 2194 oscilloscope is used;

- ○

- For configuration D in lab tests, a data-logger Keysight 34907A with 16 bits of digital input and output, 3 active channels, and 7 Hz for the channel is used.

- Prefabricated façade—A unitized façade system for a multifactional façade is selected [25] to improve solutions in the same product development;

- Test activities and method statement—In preliminary test activities, real conditions in a small environment or wind velocity generated by a fan of 2–3 m/s are used. In the laboratory tests, a specific method statement is adopted based on stress conditions of the façade using wind airflow and rain forces; see Appendix A. The tests are conducted with a fan at 600 mm and with nozzles simulating rain in correspondence with façade joints with a continuous flow rate of 2 l/min·sqm and at 400 mm from the façade. The PE-EHS is situated behind the façade cladding, replicating its intended integration within a ventilated façade system. While wind load conditions are adopted to check the PE-EHS voltage generated by airflow within the chamber, the rain exposure induces vibrations in the external cladding, exploiting this dynamic interplay between rain-induced vibrations in the cladding and the PE-EHS, in addition to utilizing the airflow within the ventilated cavity. To simulate rain within the controlled laboratory environment, a system employing a series of nozzles corresponding to the typical joint locations in a façade is utilized. Two types of rain tests are conducted:

- ○

- Dynamic Rain Test: This test simulates wind gusts by generating pulsating pressure variations every 3 s. The pressure fluctuates between 750 Pa and 250 Pa, mimicking the dynamic nature of wind-induced pressure changes;

- ○

- Static Rain Test: This test aims to understand the behavior under constant rain conditions. A constant pressure of 600 Pa is maintained throughout the test duration.

3. Results

3.1. Preliminary PE-EHS Configurations and Tests

3.2. Final PE-EHS Configurations and Tests of InComEss System Architecture

4. Discussion

- PE-EHS integration into a façade:

- ○

- The feasibility of integrating PE-EHS within a building envelope’s ventilated cavity is confirmed by configurations “C1”, “C2”, and “D”, as the lab integration into a full-scale façade demonstrates. This opens doors for real-world implementations;

- ○

- Balancing architectural requirements with energy harvesting efficiency remains a challenge. While exposed configurations may offer higher energy output, as demonstrated in the preliminary test in the case of perpendicular airflow against the wheel’s blades, they often fall short of aesthetic acceptability. Finding an optimal balance is crucial.

- PE-EHS energy generation:

- ○

- In the lab test, configurations “C1” and “C2” demonstrate the potential to combine the vortex effect with cladding vibration for enhanced energy harvesting, especially during wind–rain events. The voltage generated would have been capable of activating the PCC (5 V) and starting to charge the supercapacitor. Additionally, these configurations are promising because their combination, parallel with 2/3 PE-EHS, could increase the power generation and consequently activate within wind conditions comparable to the fan test;

- ○

- Configuration “D” showed unexpected performance variations compared to preliminary tests. The discrepancies observed between the wind tunnel and laboratory testing environments can be attributed largely to the wind direction during testing. Performance appears sensitive to wind direction and airflow stability, confirming preliminary tests’ boundary conditions even under higher wind loads. In the controlled setting of the wind tunnel, the wind direction aligned perfectly with the rotational direction of the wheel, maximizing its efficiency. However, in the laboratory environment, the fan simulates real-world wind conditions where the wind typically blows perpendicular to the façade. This necessitates the airflow entering the ventilated cavity from the bottom, leading to a reduction in air velocity compared to the wind tunnel scenario. This difference in air velocity directly impacts the performance of the proposed PE-EHS system activated by wheel rotation. In laboratory tests with non-parallel and turbulent airflow, the wheel struggled to initiate rotation at wind velocities between 5 and 8 m/s. This highlights the need for a more stable wind regime, even at lower speeds. This is also the reason why configuration “D” did not achieve the expected 5 V planned for the PCC. Lower air velocity translates to reduced rotational force on the wheel, consequently decreasing the efficiency of energy harvesting. Addressing this challenge is crucial for ensuring the system’s effectiveness in real-world applications, with further activities needed to optimize wheel design to improve further responsiveness and performance at lower air velocities and to investigate alternative airflow channeling strategies within the ventilated cavity to enhance air velocity and maintain efficient wheel rotation despite the perpendicular wind direction recommended to identify blind spots and improve performance in variable wind conditions.

- InComEss system architecture:

- ○

- The data collection and transmission functionality of the InComEss architecture for building envelope monitoring was successfully demonstrated using a battery-replacing energy harvesting solution based on the PE-EHS;

- ○

- The low energy generated by the PE-EHS did not allow for validation of the self-powered system to supply the FOS monadgator and enable continuous data collection. Additional PE-EHS units are required to achieve self-powered functionality. The PE-EHS can produce sufficient voltage in an open circuit, but this voltage drops significantly once connected to the PCC due to its low internal resistance. This was observed in lab testing for C1, where the peak voltage dropped from 14 V to 1.4 V upon connection to the PCB, falling short of the minimum required voltage to charge the supercapacitor and power the FOS. The wheel configuration never reached this voltage during testing. The maximum power generated was 4 mA × 1.4 V = 5.6 mW, which needed 20 mW, not enough to start the charging of the supercapacitor and consequently run the FOS monadgator. Power management was part of the InComEss project, but the selection of alternative on-market power management with lower power consumption could support lower starting voltages and, consequently, the adoption of PE-EHSs.

- Testing procedure:

- ○

- While the testing procedure appears adequate for SHM sensing (not the focus of this paper), it requires further refinement, small environments, further tests, and parameter optimization for PE-EHS evaluation. Addressing the identified challenges and establishing robust testing protocols is crucial for future iterations.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sequence | Test | Activity—Range Values | Test Time |

|---|---|---|---|

| 1A | Air—infiltration | Test pressure: + 600 Pa (Class A4) | 45′ |

| 1B | Air—exfiltration | Test pressure: −600 Pa (Class A4) | 1 h 15′ |

| 2 | Rain—test static | Test pressure: 600 Pa (Class R7) | 55′ |

| 3A | Wind—pression | Test pressure: +1750 Pa | 8′ |

| 3B | Wind—depression | Test pressure: −2000 Pa | 8′ |

| 4A | Air—infiltration | Test pressure: + 600 Pa (Class A4) | 8′ |

| 4B | Air—exfiltration | Test pressure: −600 Pa (Class A4) | 8′ |

| 5 | Rain—test static | Test pressure: 600 Pa (Class R7) | 1 h 5′ |

| 6 | Rain—test dynamic | Dynamic water penetration test with fan with a pulse every 3 s from 750 Pa to 250 Pa | 36′ |

| 7A | Building movement—vertical | 1. Vertical offset of the intermediate unit: uz = ±7 [mm]—2 cycles | n.a. |

| 7B | Building movement—horizontal | 2. Horizontal offset of the intermediate beam: uz = ±7 [mm]—2 cycles | n.a. |

| 8A | Air—infiltration | Test pressure: + 600 Pa (Class A4) | 7′30″ |

| 8B | Air—exfiltration | Test pressure: −600 Pa (Class A4) | 7′30″ |

| 9 | Rain—test static | Test pressure: 600 Pa (Class R7) | 1 h |

| 10A | Wind—pression | Test pressure: 2625 Pa | 2′ |

| 10B | Wind—depression | Test pressure: −3000 Pa | 2′ |

| 11 | Fan excitation | Dynamic test | 1 h 35′ |

| 12A | Impact test—hard body | 6 J (1.224 mm height with 0.5 kg steel ball)10 J (1.020 mm height with 1.0 kg steel ball) | n.a. |

| 12B | Impact test—soft body | 120 J (245 mm height)500 J (1020 mm height) | n.a. |

| 12C | Impact test—double type | 343 J (700 mm height) | n.a. |

References

- Blum, D.; Candanedo, J.; Chen, Z.; Fierro, G.; Gori, V.; Johra, H.; Madsen, H.; Marszal-Pomianowska, A.; O’Neill, Z.; Pradhan, O.; et al. Data-Driven Smart Buildings: State-of-the-Art Review; CSIRO: Newcastle, Australia, 2023; 103p. [Google Scholar]

- Karimi, R.; Farahzadi, L.; Sepasgozar, S.M.E.; Sargolzaei, S.; Sepasgozar, S.M.E.; Zareian, M.; Nasrolahi, A.; Karimi, R.; Farahzadi, L.; Sepasgozar, S.M.E.; et al. Smart Built Environment Including Smart Home, Smart Building and Smart City: Definitions and Applied Technologies. In Advances and Technologies in Building Construction and Structural Analysis; IntechOpen: London, UK, 2021; ISBN 978-1-83881-141-9. [Google Scholar]

- Politecnico di Milano; Energy & Strategy Group. Smart Building Report 2022; Efficienza Energetica e Trasformazione Digitale nel Settore degli Edifici; Dipartimento di Ingegneria Gestionale Collana Quaderni AIP: Milan, Italy, 2022. [Google Scholar]

- Verbeke, S.; Aerts, D.; Reynders, G.; Ma, Y.; Waide, P. Final Report on the Technical Support to the Development of a Smart Readiness Indicator for Buildings: Summary; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-19978-6. [Google Scholar]

- Zaffagnini, T.; Pracucci, A. Dalla Città Intelligente Alla Responsive City. Applicativi IoT e Tecnologie Innovative Human-Centric Based per Edifici Intelligenti Di Nuova Generazione. L’Ufficio Tec. 2023, 1–2, 17. [Google Scholar]

- Intelligent Buildings—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/intelligent-buildings (accessed on 29 January 2024).

- Smart Readiness Indicator. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/smart-readiness-indicator_en (accessed on 29 January 2024).

- Energy Performance of Buildings Directive. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en (accessed on 29 January 2024).

- European Parliament. Directive (EU) 2018/ of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency; European Parliament: Strasbourg, France, 2018. [Google Scholar]

- Actions to Digitalise the Energy Sector. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_6228 (accessed on 29 January 2024).

- Overview Article-Smart Buildings and Smart Technologies in Europe: State of Play and Perspectives|BUILD UP. Available online: https://build-up.ec.europa.eu/en/resources-and-tools/articles/overview-article-smart-buildings-and-smart-technologies-europe-state (accessed on 29 January 2024).

- The EU Smart Building Innovation Platform|SMARTBUILT4EU Project|Fact Sheet|H2020. Available online: https://cordis.europa.eu/project/id/956936 (accessed on 29 January 2024).

- Intelligent Building Energy Assets Control for Comfort, Energy and Flexibility Optimisation|iBECOME Project|Fact Sheet|H2020. Available online: https://cordis.europa.eu/project/id/894617/it (accessed on 29 January 2024).

- Zeng, Z.; Zhao, R.; Yang, H. Micro-Sources Design of an Intelligent Building Integrated with Micro-Grid. Energy Build. 2013, 57, 261–267. [Google Scholar] [CrossRef]

- Shinisha, A.; Devi, S.; Murugasan, D.; Solomon Simon, E. Future Nano-Grid Technologies and Its Implementation Challenges for Smart Cities. IOP Conf. Ser. Mater. Sci. Eng. 2020, 955, 012002. [Google Scholar] [CrossRef]

- Saeed, M.; Fangzong, W.; Kalwar, B.; Iqbal, S. A Review on Microgrids’ Challenges & Perspectives. IEEE Access 2021, 9, 166502–166517. [Google Scholar] [CrossRef]

- Shakeri, M.; Pasupuleti, J.; Amin, N.; Rokonuzzaman, M.; Low, F.W.; Yaw, C.T.; Asim, N.; Samsudin, N.A.; Tiong, S.K.; Hen, C.K.; et al. An Overview of the Building Energy Management System Considering the Demand Response Programs, Smart Strategies and Smart Grid. Energies 2020, 13, 3299. [Google Scholar] [CrossRef]

- Khan, S.; Sudhakar, K.; Hazwan Yusof, M.; Sundaram, S. Review of Building Integrated Photovoltaics System for Electric Vehicle Charging. Chem. Rec. 2024, 24, e202300308. [Google Scholar] [CrossRef] [PubMed]

- Fiorotti, R.; Yahyaoui, I.; Rocha, H.R.O.; Honorato, Í.; Silva, J.; Tadeo, F. Demand Planning of a Nearly Zero Energy Building in a PV/Grid-Connected System. Renew. Energy Focus 2023, 45, 220–233. [Google Scholar] [CrossRef]

- Wei, W.; Ye, L.; Fang, Y.; Wang, Y.; Chen, X.; Li, Z. Optimal Allocation of Energy Storage Capacity in Microgrids Considering the Uncertainty of Renewable Energy Generation. Sustainability 2023, 15, 9544. [Google Scholar] [CrossRef]

- Saavedra, E.; Mascaraque, L.; Calderon, G.; del Campo, G.; Santamaria, A. The Smart Meter Challenge: Feasibility of Autonomous Indoor IoT Devices Depending on Its Energy Harvesting Source and IoT Wireless Technology. Sensors 2021, 21, 7433. [Google Scholar] [CrossRef]

- Sonbul, O.S.; Rashid, M. Towards the Structural Health Monitoring of Bridges Using Wireless Sensor Networks: A Systematic Study. Sensors 2023, 23, 8468. [Google Scholar] [CrossRef] [PubMed]

- Shokoor, F.; Shafik, W. Harvesting Energy Overview for Sustainable Wireless Sensor Networks. J. Smart Cities Soc. 2023, 2, 165–180. [Google Scholar] [CrossRef]

- Arnesano, M.; Bueno, B.; Pracucci, A.; Magnagni, S.; Casadei, O.; Revel, G.M. Sensors and Control Solutions for Smart-IoT Façade Modules. In Proceedings of the 2019 IEEE International Symposium on Measurements & Networking (M&N), Catania, Italy, 8–10 July 2019; pp. 1–6. [Google Scholar]

- Giovanardi, M.; Baietta, A.; Belletti, F.; Magnani, S.; Casadei, O.; Pracucci, A. Exploiting the Value of Active and Multifunctional Façade Technology through the IoT and AI. Appl. Sci. 2024, 14, 1145. [Google Scholar] [CrossRef]

- Pracucci, A.; Dugué, A.; Richet, N.; Abdullah, T.; Başer, E.; Caneva, S.; Deneyer, A.; Dias, P.; Diygu, C.; Fakhari, M.; et al. IWG5 White Paper. IWG 5 Buildings. 2023. Available online: https://www.iwg5-buildings.eu/wp-content/uploads/2023/09/IWG5_Active-Module_white-paper_v3_Final.pdf (accessed on 27 March 2024).

- Guardigli, L.; Fornace, F.D.; Casadei, O.; Frani, F.; Nicolini, L.; Revel, G.M.; Arnesano, M. Development of a Curtain Wall Prototype with Dynamic Behaviour (SmartSkin). TECHNE-J. Technol. Archit. Environ. 2018, 16, 218–225. [Google Scholar] [CrossRef]

- Pracucci, A.; Vandi, L.; Magnani, S.; Baietta, A.; Casadei, O.; Uriarte, A.; Vavallo, M. Prefabricated Plug-and-Play Unitized Façade System for Deep Retrofitting: The RenoZEB Case Study. In Proceedings of the The 9th Annual Edition of Sustainable Places (SP 2021), Rome, Italy, 29 September–1 October 2021; p. 9. [Google Scholar]

- Infinite Building Renovation-Industrialised Envelope Solutions. Available online: https://infinitebuildingrenovation.eu/ (accessed on 16 June 2023).

- Thulasi, V.; Lakshmi, P.; Sahithya, A. High Performance of W-Shaped Piezo Electric Energy Harvester for Smart Building Application. Integr. Ferroelectr. 2024, 240, 149–162. [Google Scholar] [CrossRef]

- Zhou, W.; Du, D.; Cui, Q.; Lu, C.; Wang, Y.; He, Q. Recent Research Progress in Piezoelectric Vibration Energy Harvesting Technology. Energies 2022, 15, 947. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, C.; Lai, L.; Dong, X.; Li, Y. Design, Manufacture and Test of Piezoelectric Cantilever-Beam Energy Harvesters with Hollow Structures. Micromachines 2021, 12, 1090. [Google Scholar] [CrossRef]

- Doria, A.; Fanti, G.; Filipi, G.; Moro, F. Development of a Novel Piezoelectric Harvester Excited by Raindrops. Sensors 2019, 19, 3653. [Google Scholar] [CrossRef] [PubMed]

- Doria, A.; Medè, C.; Fanti, G.; Desideri, D.; Maschio, A.; Moro, F. Development of Piezoelectric Harvesters with Integrated Trimming Devices. Appl. Sci. 2018, 8, 557. [Google Scholar] [CrossRef]

- Doria, A.; Medè, C.; Desideri, D.; Maschio, A.; Codecasa, L.; Moro, F. On the Performance of Piezoelectric Harvesters Loaded by Finite Width Impulses. Mech. Syst. Signal Process. 2018, 100, 28–42. [Google Scholar] [CrossRef]

- Students Harness Vibrations from Wind for Electricity. Available online: https://news.cornell.edu/stories/2010/05/researchers-harness-energy-wind-vibrations (accessed on 29 April 2020).

- Solaripedia|Green Architecture & Building|Projects in Green Architecture & Building. Available online: https://www.solaripedia.com/13/285/3171/solar_ivy_leaves.html (accessed on 29 April 2020).

- The 10th Annual Year in Ideas-Interactive Feature-NYTimes.Com. Available online: http://archive.nytimes.com/www.nytimes.com/interactive/2010/12/19/magazine/ideas2010.html#Turbine-Free_Wind_Power (accessed on 29 April 2020).

- Raudaschl, M.; Levak, T.; Riewe, R.; Triantafyllidis, G.; Drnda, E.; Popek, S.; Schlegl, D.; Funke-Kaiser, D.; Lund, A. Piezoelectric Textile Façade for the Energy Supply of Active Sensor Technology with Regard to Data Management for Circular Economy in Building Construction. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012037. [Google Scholar] [CrossRef]

- Structural Health Monitoring—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/chemical-engineering/structural-health-monitoring (accessed on 29 January 2024).

- Ferreira, P.M.; Machado, M.A.; Carvalho, M.S.; Vidal, C. Embedded Sensors for Structural Health Monitoring: Methodologies and Applications Review. Sensors 2022, 22, 8320. [Google Scholar] [CrossRef] [PubMed]

- Valinejadshoubi, M.; Bagchi, A.; Moselhi, O. Structural Health Monitoring of Buildings and Infrastructure. World Acad. Sci. Eng. Technol.-Int. J. Civ. Environ. Eng. 2016, 10, 731–738. [Google Scholar]

- Preethichandra, D.M.G.; Suntharavadivel, T.G.; Kalutara, P.; Piyathilaka, L.; Izhar, U. Influence of Smart Sensors on Structural Health Monitoring Systems and Future Asset Management Practices. Sensors 2023, 23, 8279. [Google Scholar] [CrossRef] [PubMed]

- Bremer, K.; Wollweber, M.; Weigand, F.; Rahlves, M.; Kuhne, M.; Helbig, R.; Roth, B. Fibre Optic Sensors for the Structural Health Monitoring of Building Structures. Procedia Technol. 2016, 26, 524–529. [Google Scholar] [CrossRef]

- InComEss. Available online: https://www.incomess-project.com (accessed on 29 January 2024).

- EN 13830:2003; Curtain Walling—Product Standard. SIST: Ljubljana, Slovenia, 2003. Available online: https://standards.iteh.ai/catalog/standards/cen/51c14384-e4c8-49ba-8658-6aac20f9ae1f/en-13830-2003 (accessed on 27 March 2024).

- Smart Material Company. Available online: https://www.smart-material.com/EH-MFC-generatorsV2.html (accessed on 26 February 2024).

- MacroFiberCompositeTM P2 Type. Available online: https://www.smart-material.com/MFC-product-P2V2.html (accessed on 26 February 2024).

- Vlachos, M.; Lopardo, R.; Amditis, A. Real Time Vehicle Status Monitoring under Moving Conditions Using a Low Power IoT System. J. Internet Things 2023, 4, 235–261. [Google Scholar] [CrossRef]

- Schabowicz, K.; Zawiślak, Ł.; Staniów, P. Efficiency of Ventilated Façades in Terms of Airflow in the Air Gap. Stud. Geotech. Mech. 2021, 43, 224–236. [Google Scholar] [CrossRef]

- Rahiminejad, M.; Khovalyg, D. Review on Ventilation Rates in the Ventilated Air-Spaces behind Common Wall Assemblies with External Cladding. Build. Environ. 2021, 190, 107538. [Google Scholar] [CrossRef]

- Tommasino, D.; Moro, F.; de Pablo Corona, E.; Vandi, L.; Baietta, A.; Pracucci, A.; Doria, A. Optimization of a Piezoelectric Wind-Excited Cantilever for Energy Harvesting from Façades. In Proceedings of the Advances in Italian Mechanism Science; Niola, V., Gasparetto, A., Quaglia, G., Carbone, G., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 848–856. [Google Scholar]

- Che Tempo Faceva a Poggio Torriana a Novembre 2021-Archivio Meteo Poggio Torriana » ILMETEO.It. Available online: https://www.ilmeteo.it/portale/archivio-meteo/Poggio+Torriana/2021/Novembre (accessed on 26 February 2024).

- Che Tempo Faceva a Poggio Torriana a Dicembre 2021-Archivio Meteo Poggio Torriana. Available online: https://www.ilmeteo.it/portale/archivio-meteo/Poggio+Torriana/2021/Dicembre (accessed on 26 February 2024).

- Che Tempo Faceva a Poggio Torriana a Giugno 2023-Archivio Meteo Poggio Torriana. Available online: https://www.ilmeteo.it/portale/archivio-meteo/Poggio+Torriana/2023/Giugno (accessed on 26 February 2024).

- Ansys 2023 R2 Release Highlights|Ansys Latest Release. Available online: https://www.ansys.com/products/release-highlights (accessed on 1 February 2024).

| PE-EHS “A1” Configuration | PE-EHS “A2” Configuration | ||

|---|---|---|---|

| Time | PE Voltage [V] | Time | PE Voltage [V] |

| 8:00 | 0.5476 | 8:00 | 0.5094 |

| 10:00 | 0.5473 | 10:00 | 0.3357 |

| 12:00 | 0.5449 | 12:00 | 0.5380 |

| 14:00 | 0.5442 | 14:00 | 0.5191 |

| 16:00 | 0.5419 | 16:00 | 0.4768 |

| 18:00 | 0.5417 | 18:00 | 0.5283 |

| PE-EHS “C2” Configuration | |

|---|---|

| Time | PE Voltage [V] |

| 08:00 | 0.6195 |

| 10:00 | 0.6140 |

| 12:00 | 0.6299 |

| 14:00 | 0.6427 |

| 16:00 | 0.6400 |

| 18:00 | 0.6321 |

| # | Description | Working Principle | Testing Facility | AFS [m/s] | PE Voltage [V] | ||

|---|---|---|---|---|---|---|---|

| DAF | IAF | RE | |||||

| A1 | PE-EHS cantilever with cylinder to enable vortex effect without cladding | X | Focchi premises | 0.5–3 | Max. 0.55 Min. 0.54 | ||

| A2 | PE-EHS cantilever with cylinder to enable vortex effect with cladding | X | Focchi premises | 0.5–3 | Max. 0.54 Min. 0.34 | ||

| C1 | PE-EHS vertical cantilever with cylinder to enable vortex effect and position in external cladding to exploit cladding vibration | X | X | Lab chamber fan excitation 490 mm | 5–8 | Max. 4.18 Min. 4.30 | |

| Lab chamber fan excitation 1490 mm | 5–8 | Max. 4.74 Min. 3.96 | |||||

| Lab chamber (Rain—dynamic) | 9.03–31.30 | Max. 30.45 Min. 25.46 | |||||

| C2 | PE-EHS horizontal cantilever with cylinder to enable vortex effect and position in external cladding to exploit cladding vibration | X | X | Focchi premises | 0.5–3 | Max. 0.64 Min. 0.61 | |

| Lab chamber fan excitation 490 mm | 5–8 | Max. 2.75 Min. 2.40 | |||||

| Lab chamber fan excitation 1490 mm | 5–8 | Max. 4.27 Min. 3.78 | |||||

| Lab chamber (Rain—dynamic) | 9.03–31.30 | Max. 13.25 Min. 11.00 | |||||

| D | PE-EHS cantilever with magnet activated by magnet installed in a wheel rotating | X | CENTI premise | 2–5 | Max. 20 Min. 4 | ||

| Lab chamber fan excitation 490 mm | 5–8 | Max. 0.54 Min. 0.13 | |||||

| Lab chamber fan excitation 1490 mm | 5–8 | Max. 0.71 Min. 0.27 | |||||

| Lab chamber (Rain—dynamic) | 9.03–31.30 | Max. 0.65 Min. 0.45 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pracucci, A.; Vandi, L.; Belletti, F.; Melo, A.R.A.; Vlachos, M.; Amditis, A.; Calcagni, M.T.; Esteves, D.S. Integration of Piezoelectric Energy Harvesting Systems into Building Envelopes for Structural Health Monitoring with Fiber Optic Sensing Technology. Energies 2024, 17, 1789. https://doi.org/10.3390/en17071789

Pracucci A, Vandi L, Belletti F, Melo ARA, Vlachos M, Amditis A, Calcagni MT, Esteves DS. Integration of Piezoelectric Energy Harvesting Systems into Building Envelopes for Structural Health Monitoring with Fiber Optic Sensing Technology. Energies. 2024; 17(7):1789. https://doi.org/10.3390/en17071789

Chicago/Turabian StylePracucci, Alessandro, Laura Vandi, Francesco Belletti, Amanda Ramos Aragão Melo, Marios Vlachos, Angelos Amditis, Maria Teresa Calcagni, and David Seixas Esteves. 2024. "Integration of Piezoelectric Energy Harvesting Systems into Building Envelopes for Structural Health Monitoring with Fiber Optic Sensing Technology" Energies 17, no. 7: 1789. https://doi.org/10.3390/en17071789

APA StylePracucci, A., Vandi, L., Belletti, F., Melo, A. R. A., Vlachos, M., Amditis, A., Calcagni, M. T., & Esteves, D. S. (2024). Integration of Piezoelectric Energy Harvesting Systems into Building Envelopes for Structural Health Monitoring with Fiber Optic Sensing Technology. Energies, 17(7), 1789. https://doi.org/10.3390/en17071789