Melting and Solidification Characteristics of PCM in Oscillated Bundled-Tube Thermal Energy Storage System

Abstract

1. Introduction

2. Mathematical Formulation

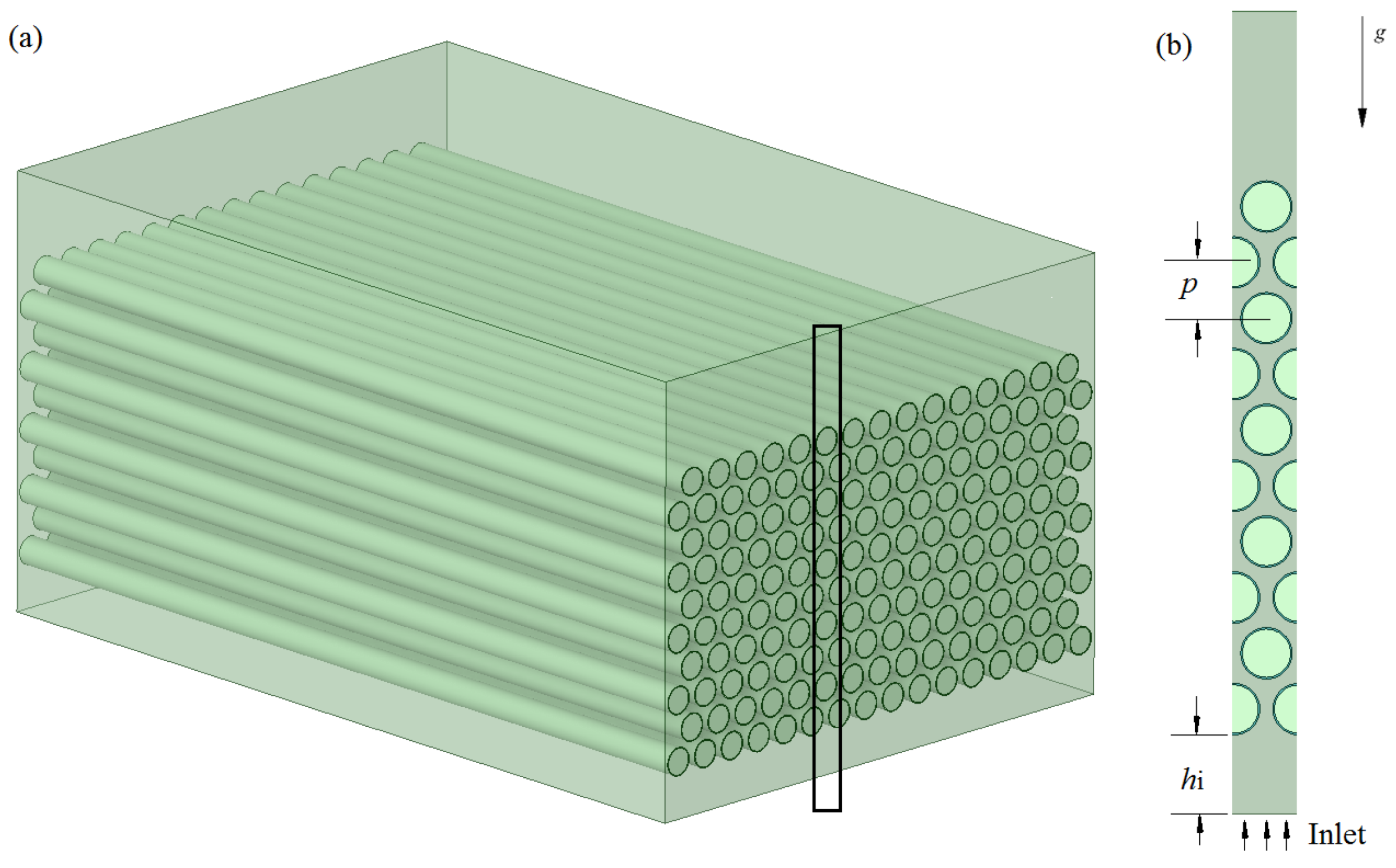

2.1. Problem Description

2.2. Governing Equation

2.3. Initial and Boundary Conditions

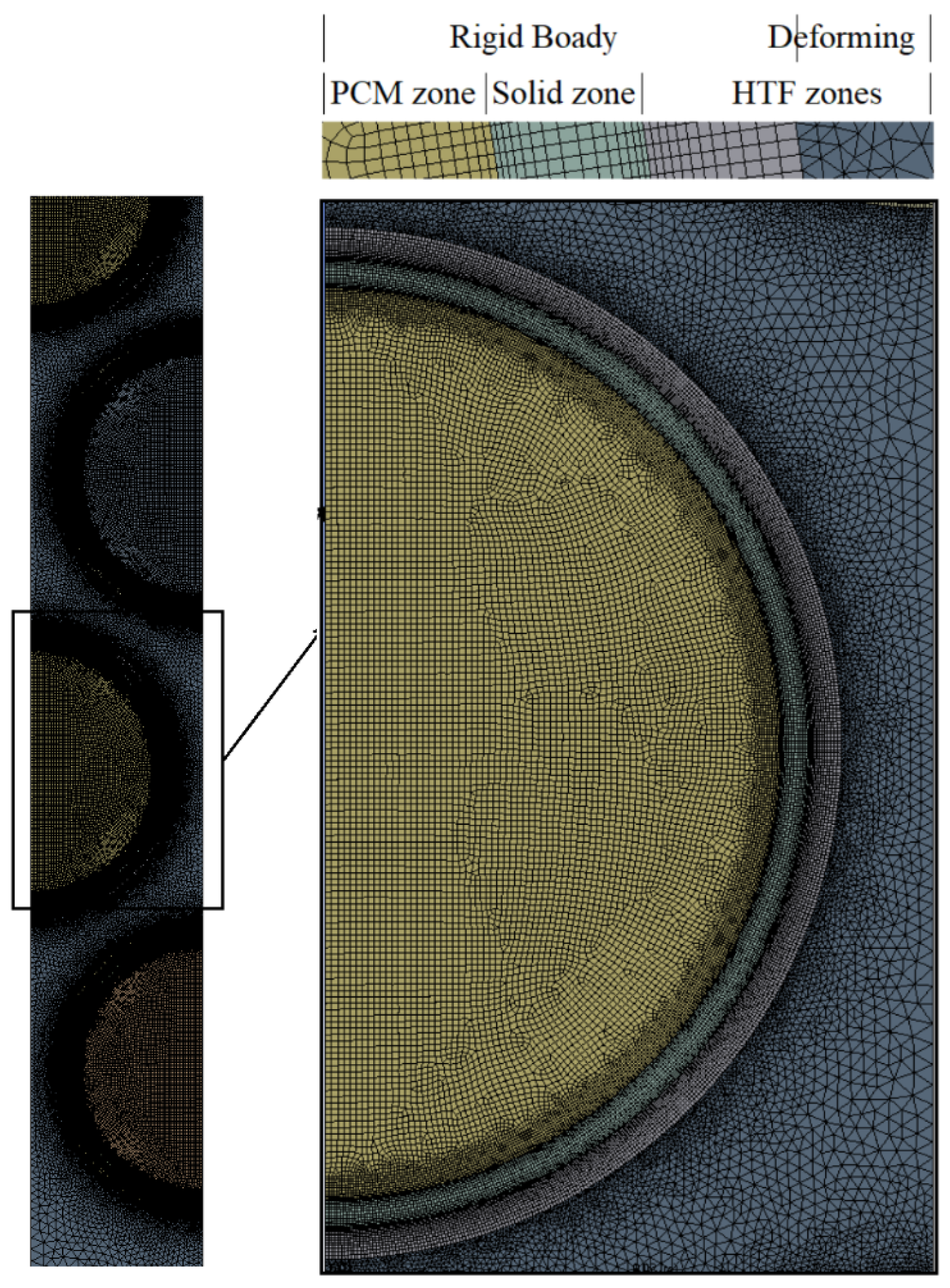

2.4. Dynamic Mesh and Mesh Generation

3. Numerical Considerations

3.1. Numerical Method

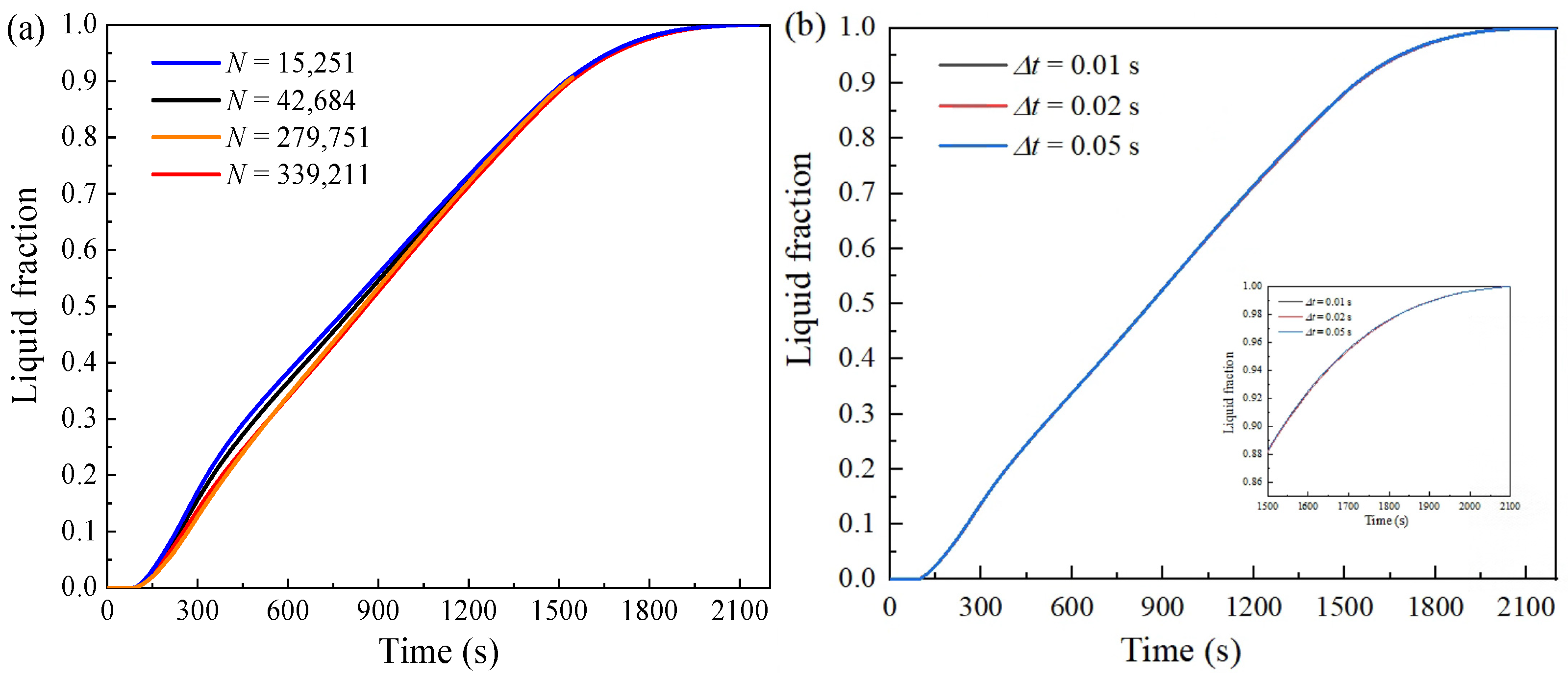

3.2. Independence Analysis

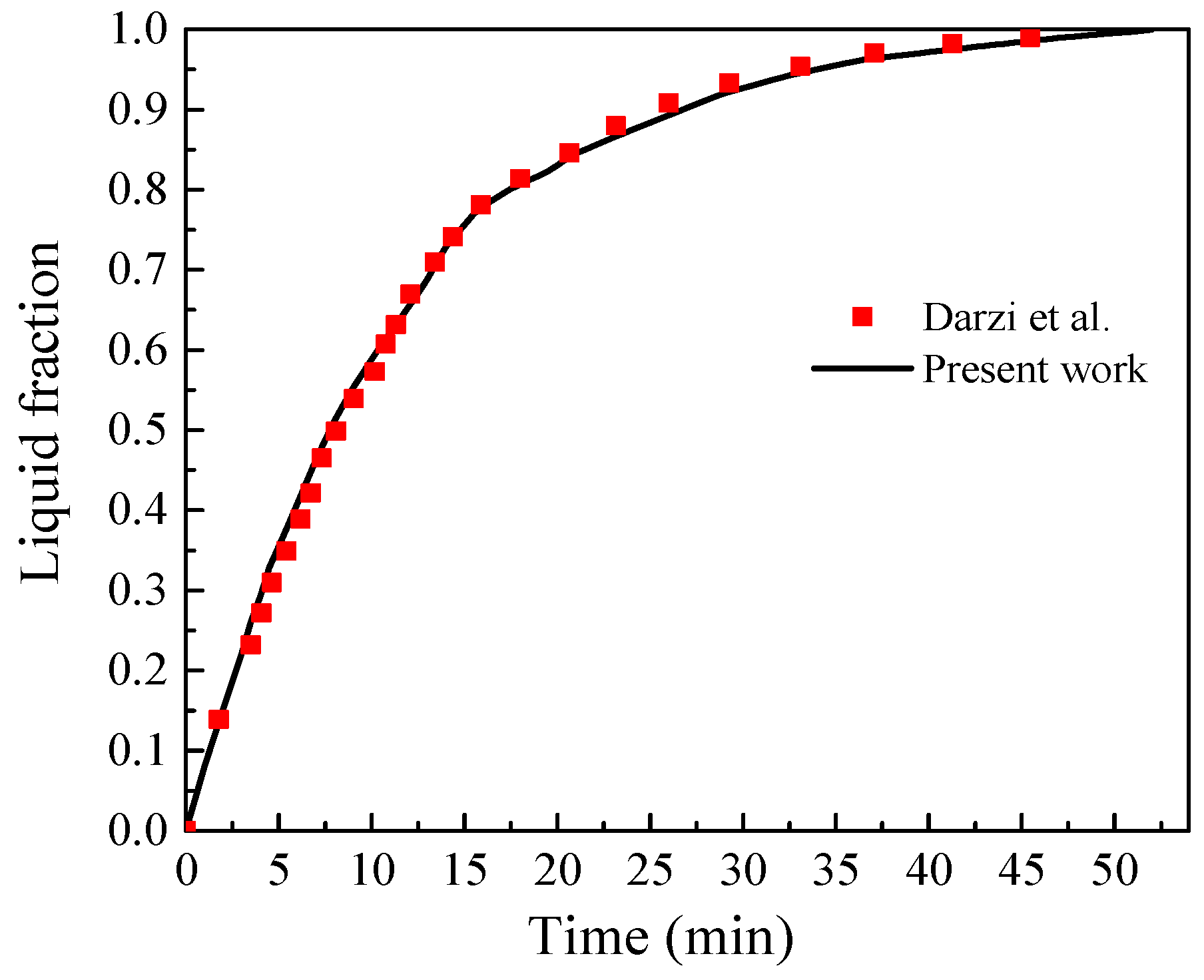

3.3. Model Validation

4. Results and Discussion

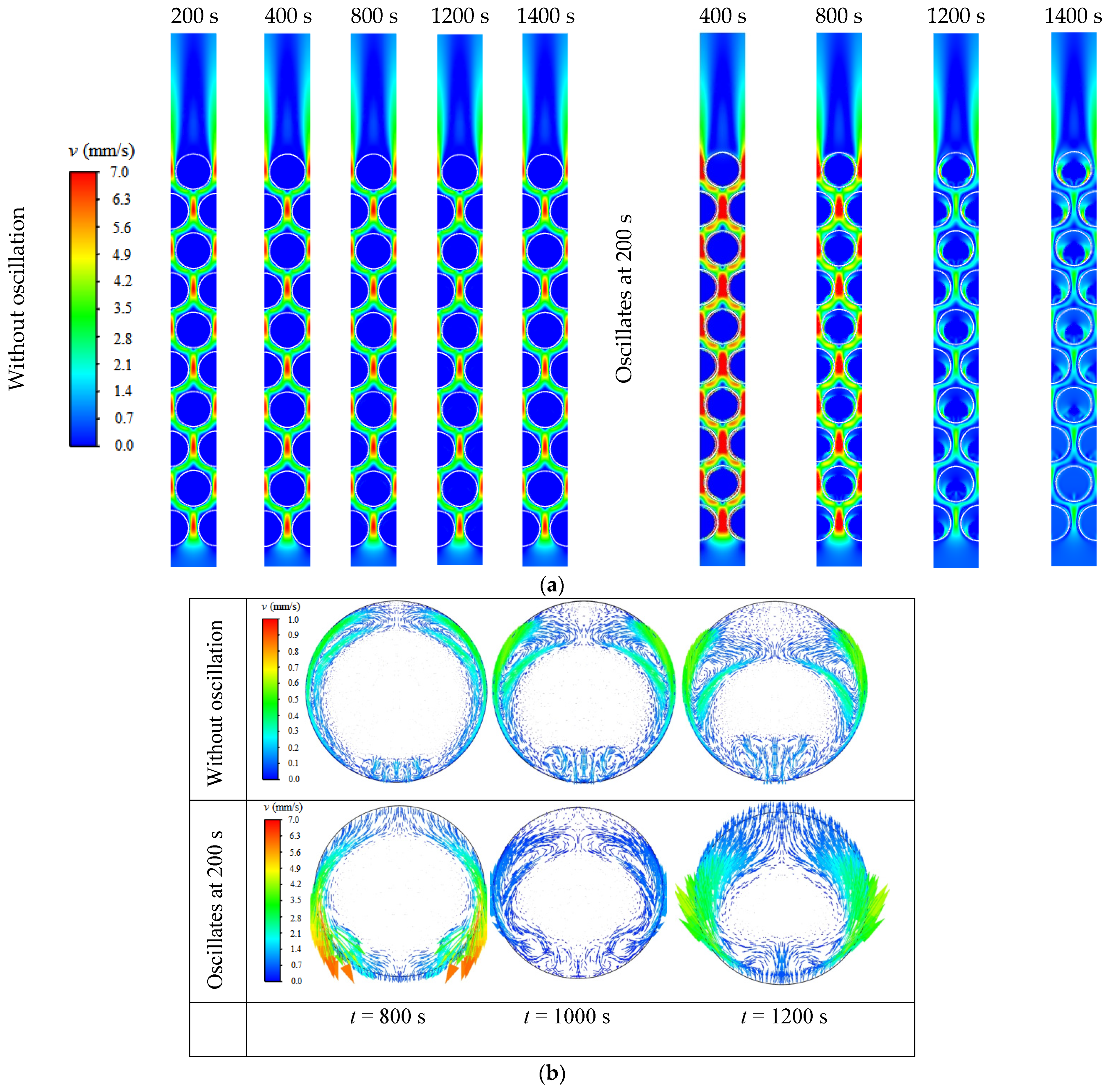

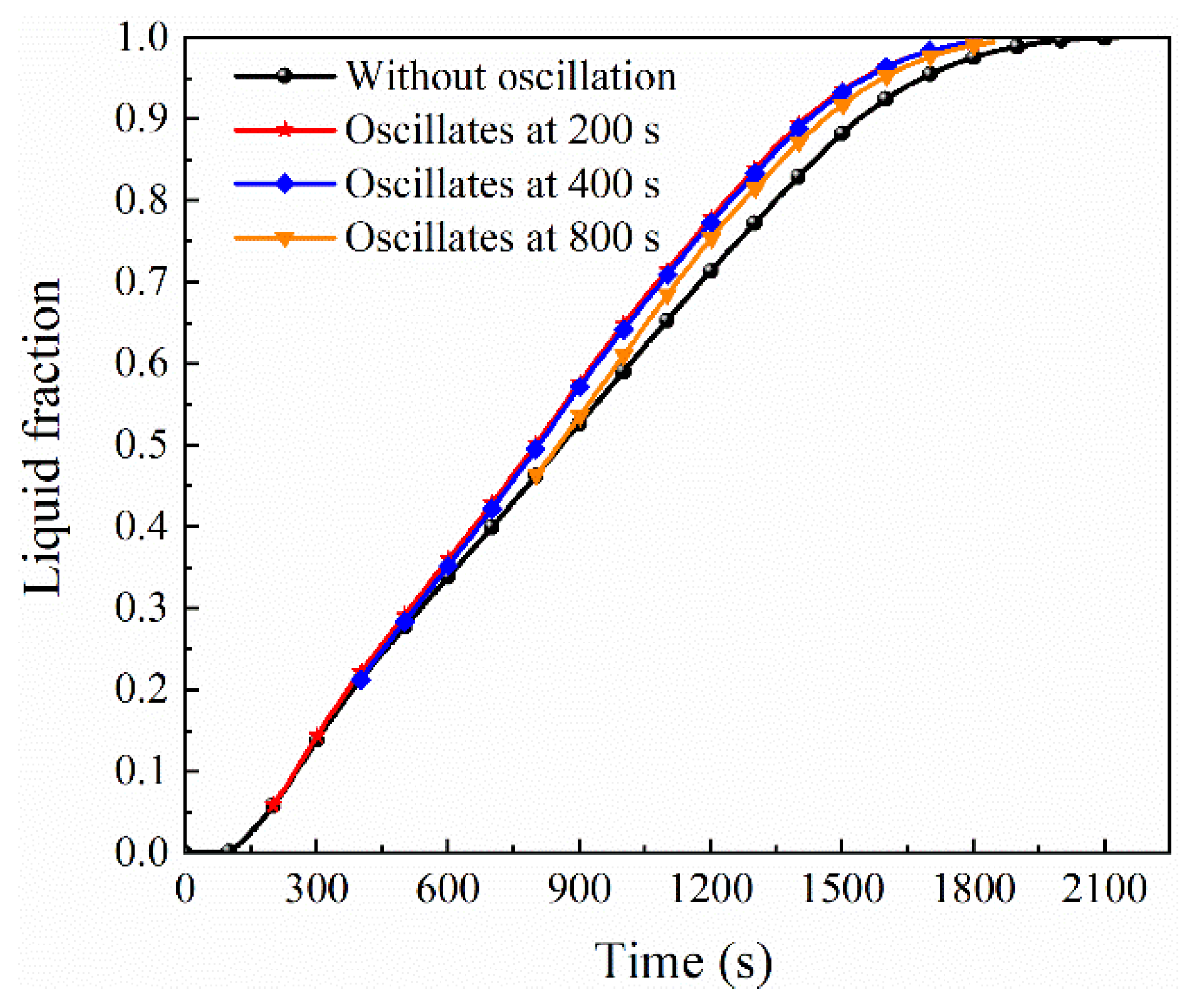

4.1. Effect of Oscillation Time

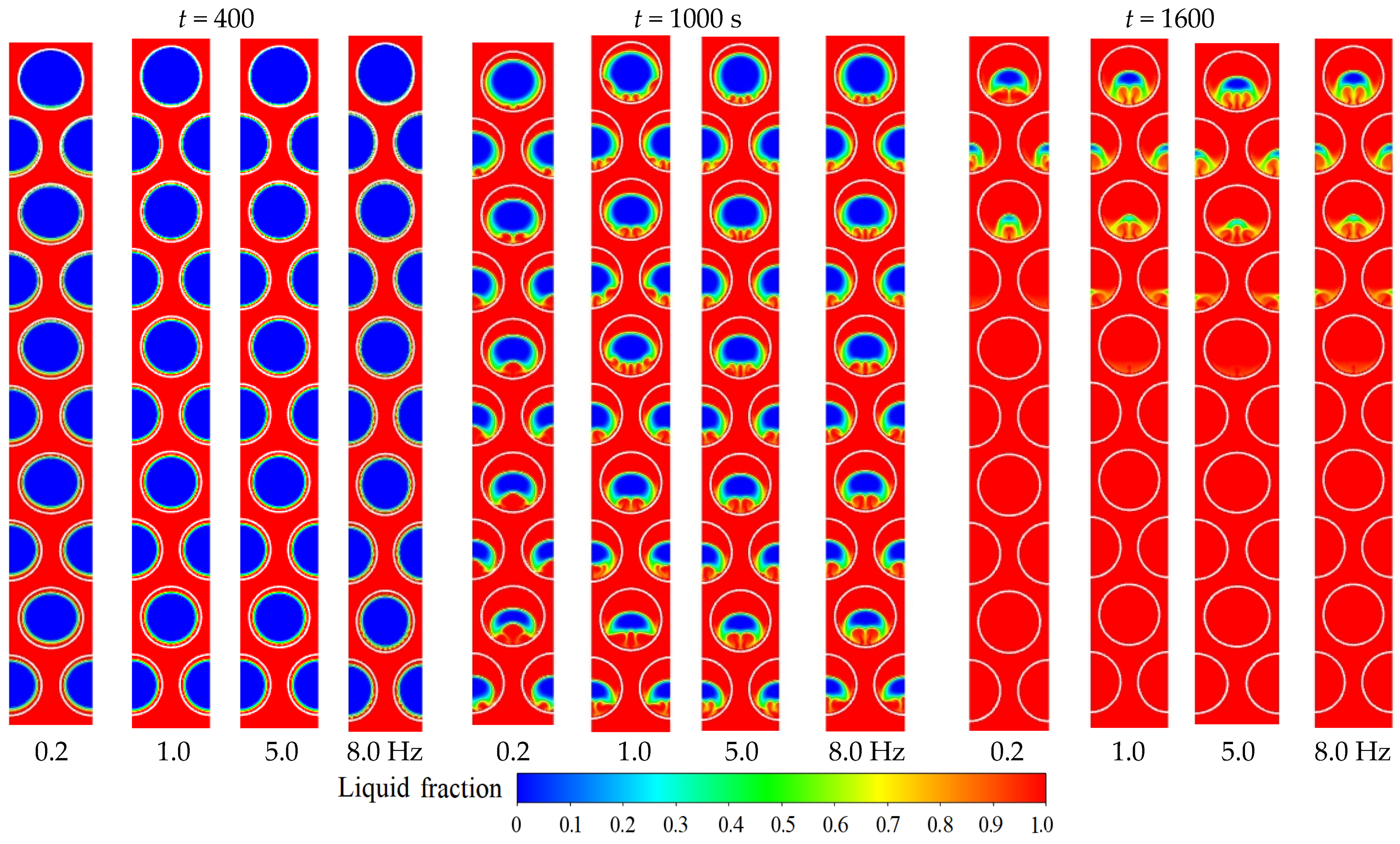

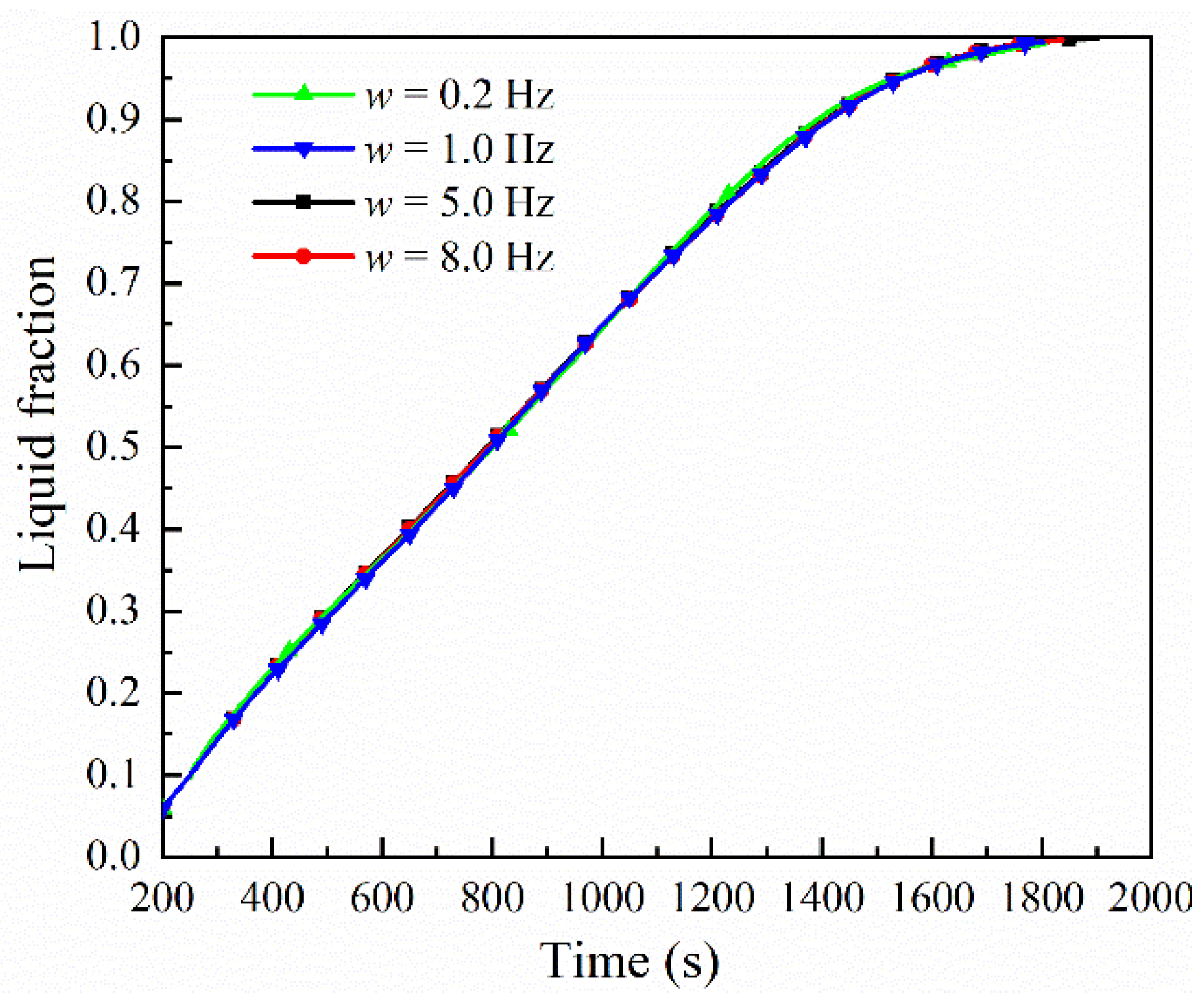

4.2. Effect of Oscillation Frequency

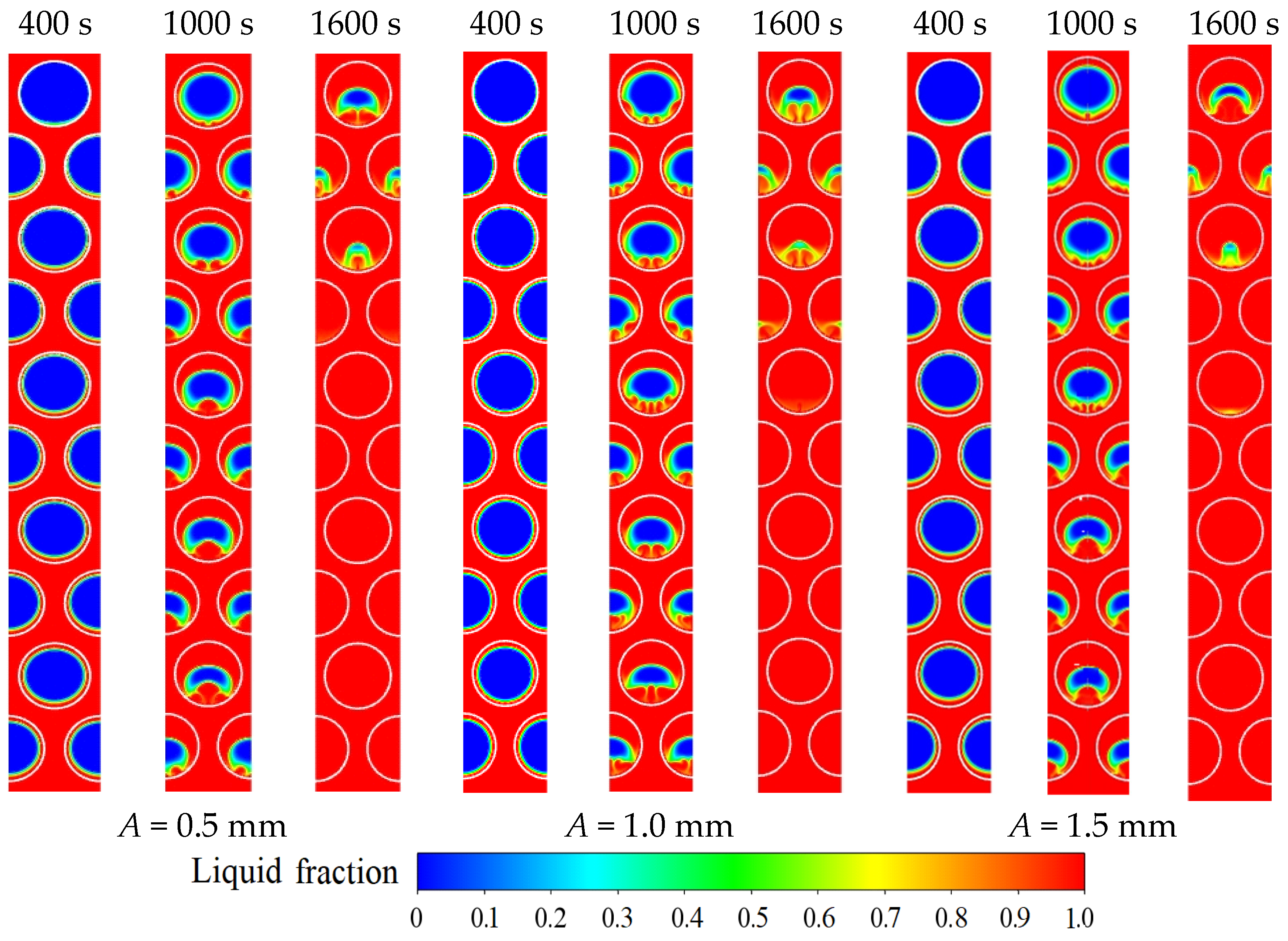

4.3. Effect of Oscillation Amplitude

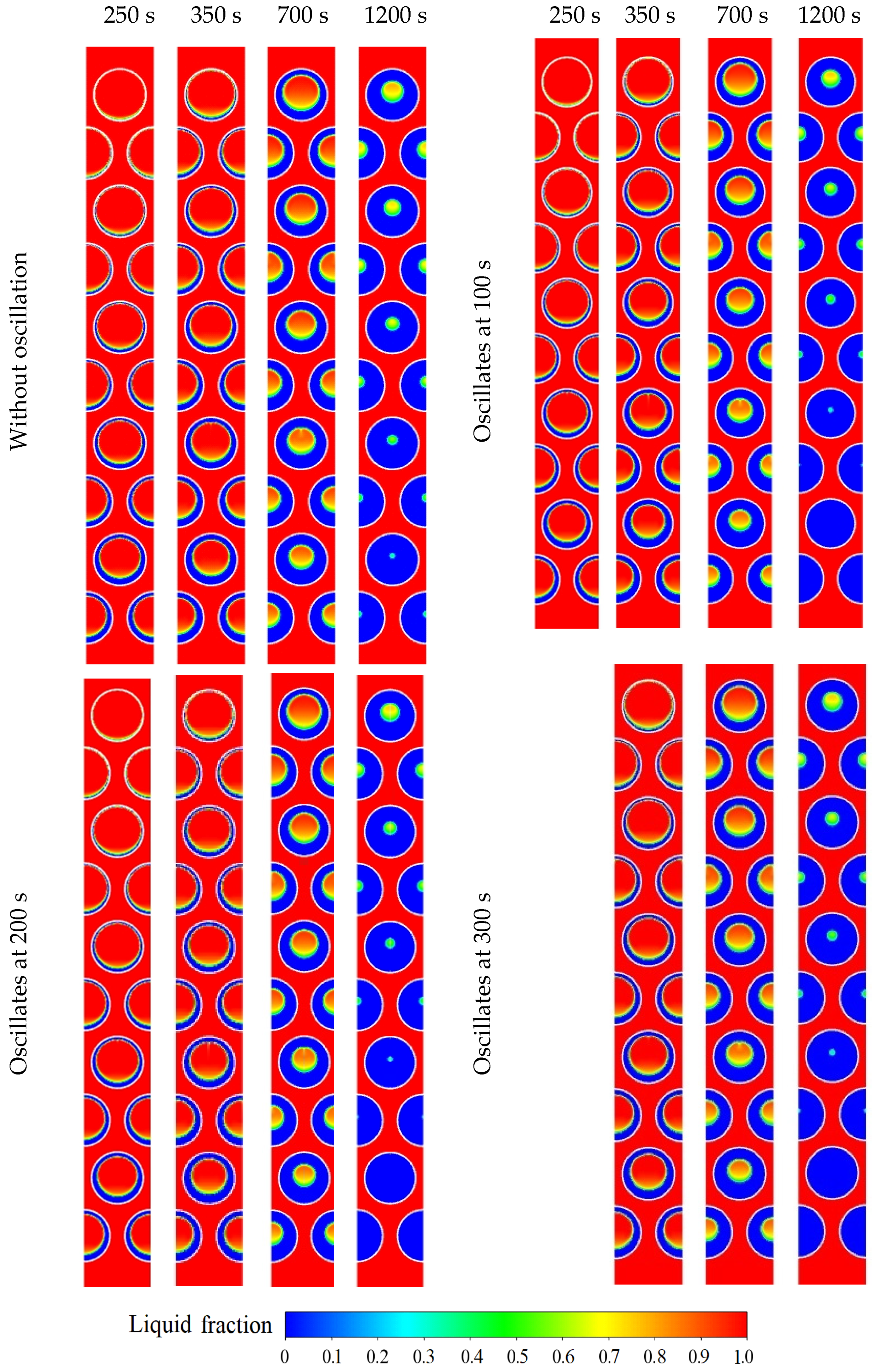

4.4. Solidification Process

5. Conclusions

- (1)

- The oscillation of the tube bundle can shorten the melting time of the TES system since the convection in liquid PCM is enhanced through the movement of tubes. The case with a frequency of 1 Hz and amplitude of 1 mm oscillation starting at t = 200 s has an 8.3% shorter melting time compared to the case without oscillation.

- (2)

- A too early oscillation is not necessary for the melting enhancement as too little liquid PCM is present at the early melting stage and thus convection is negligible. The cases with the oscillation starting at 200 and 400 s show nearly the same melting time, which are 1800 and 1805 s, respectively.

- (3)

- The effect of oscillation frequency on the PCM melting is not significant among all considered cases. A high oscillation frequency can slightly enhance convection at the former melting stage and slightly suppress convection at the later melting stage. The cases with oscillation frequencies of 0.2, 1.0, 5.0 and 8.0 Hz show nearly the same melting times, which are 1797, 1800, 1801 and 1803 s, respectively.

- (4)

- The effect of oscillation amplitude on the PCM melting is important, and a higher oscillation amplitude can further shorten the melting time compared to a lower oscillation amplitude. Due to a large amount of liquid PCM, the increase of oscillation amplitude leads to the significant enhancement of convection. The melting time of cases with oscillation amplitudes of 0.5, 1.0, and 1.5 mm are 1832, 1800 and 1746 s, respectively.

- (5)

- The solidification process can also be accelerated by the oscillation of tubes, and the solidification times of the cases without oscillation, with oscillation starting at 100, 200 and 300 s, are 1444, 1338, 1345 and 1355 s, respectively. The effect of oscillation on solidification becomes significant at the later solidification stage as the liquid fraction curves show clear discrepancies at t > 400 s.

- (6)

- The best phase transition performance can be obtained with the oscillation starting at an early time and a higher oscillation amplitude. The case with oscillation starting at 200 s and an amplitude of 1.5 mm gives the shortest melting time among all cases, which is 1746 s.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Liu, B.; Ding, X.; Wang, F. Research on optimization of energy storage regulation model considering wind–solar and multi-energy complementary intermittent energy interconnection. Energy Rep. 2022, 8, 490–501. [Google Scholar] [CrossRef]

- Mostafavi Tehrani, S.S.; Shoraka, Y.; Nithyanandam, K.; Taylor, R.A. Shell-and-tube or packed bed thermal energy storage systems integrated with a concentrated solar power: A techno-economic comparison of sensible and latent heat systems. Appl. Energy 2019, 238, 887–910. [Google Scholar] [CrossRef]

- Romaní, J.; Gasia, J.; Solé, A.; Takasu, H.; Kato, Y.; Cabeza, L.F. Evaluation of energy density as performance indicator for thermal energy storage at material and system levels. Appl. Energy 2019, 235, 954–962. [Google Scholar] [CrossRef]

- Aftab, W.; Usman, A.; Shi, J.; Yuan, K.; Qin, M.; Zou, R. Phase change material-integrated latent heat storage systems for sustainable energy solutions. Energy Environ. Sci. 2021, 14, 4268–4291. [Google Scholar] [CrossRef]

- Gasia, J.; Maldonado, J.M.; Galati, F.; De Simone, M.; Cabeza, L.F. Experimental evaluation of the use of fins and metal wool as heat transfer enhancement techniques in a latent heat thermal energy storage system. Energy Convers. Manag. 2019, 184, 530–538. [Google Scholar] [CrossRef]

- Rudra Murthy, B.V.; Nidhul, K.; Gumtapure, V. Performance evaluation of novel tapered shell and tube cascaded latent heat thermal energy storage. Sol. Energy 2021, 214, 377–392. [Google Scholar] [CrossRef]

- Kumar, A.; Saha, S.K. Performance study of a novel funnel shaped shell and tube latent heat thermal energy storage system. Renew. Energy 2021, 165, 731–747. [Google Scholar] [CrossRef]

- Sodhi, G.S.; Muthukumar, P. Compound charging and discharging enhancement in multi-PCM system using non-uniform fin distribution. Renew. Energy 2021, 171, 299–314. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, D.; Li, P.; Yuan, Y.; Tan, H. Optimization of exergy efficiency of a cascaded packed bed containing variable diameter particles. Appl. Therm. Eng. 2021, 188, 116680. [Google Scholar] [CrossRef]

- Patil, J.R.; Mahanwar, P.A.; Sundaramoorthy, E.; Mundhe, G.S. A review of the thermal storage of phase change material, morphology, synthesis methods, characterization, and applications of microencapsulated phase change material. J. Polym. Eng. 2023, 43, 354–375. [Google Scholar] [CrossRef]

- Mohamed Moussa, E.I.; Karkri, M. A numerical investigation of the effects of metal foam characteristics and heating/cooling conditions on the phase change kinetic of phase change materials embedded in metal foam. J. Energy Storage 2019, 26, 100985. [Google Scholar] [CrossRef]

- Sadeghi, H.M.; Babayan, M.; Chamkha, A. Investigation of using multi-layer PCMs in the tubular heat exchanger with periodic heat transfer boundary condition. Int. J. Heat Mass Transf. 2020, 147, 118970. [Google Scholar] [CrossRef]

- Siahpush, A.; O’Brien, J.; Crepeau, J. Phase change heat transfer enhancement using copper porous foam. J. Heat Transf. 2008, 130, 082301. [Google Scholar] [CrossRef]

- Safari, V.; Abolghasemi, H.; Kamkari, B. Experimental and numerical investigations of thermal performance enhancement in a latent heat storage heat exchanger using bifurcated and straight fins. Renew. Energy 2021, 174, 102–121. [Google Scholar] [CrossRef]

- Deng, S.; Nie, C.; Wei, G.; Ye, W.-B. Improving the melting performance of a horizontal shell-tube latent-heat thermal energy storage unit using local enhanced finned tube. Energy Build. 2019, 183, 161–173. [Google Scholar] [CrossRef]

- Ye, W.; Jamshideasli, D.; Khodadadi, J.M. Improved Performance of Latent Heat Energy Storage Systems in Response to Utilization of High Thermal Conductivity Fins. Energies 2023, 16, 1277. [Google Scholar] [CrossRef]

- Manoj Kumar, P.; Sudarvizhi, D.; Stalin, P.M.J.; Aarif, A.; Abhinandhana, R.; Renuprasanth, A.; Sathya, V.; Ezhilan, N.T. Thermal characteristics analysis of a phase change material under the influence of nanoparticles. Mater. Today Proc. 2021, 45, 7876–7880. [Google Scholar] [CrossRef]

- Nie, C.; Liu, J.; Deng, S. Effect of geometric parameter and nanoparticles on PCM melting in a vertical shell-tube system. Appl. Therm. Eng. 2021, 184, 116290. [Google Scholar] [CrossRef]

- Amidu, M.A.; Ali, M.; Alkaabi, A.K.; Addad, Y. A critical assessment of nanoparticles enhanced phase change materials (NePCMs) for latent heat energy storage applications. Sci. Rep. 2023, 13, 7829. [Google Scholar] [CrossRef]

- Huang, S.; Lu, J.; Li, Y. Numerical study on the influence of inclination angle on the melting behaviour of metal foam-PCM latent heat storage units. Energy 2022, 239, 122489. [Google Scholar] [CrossRef]

- Nie, C.; Liu, J.; Deng, S. Effect of geometry modification on the thermal response of composite metal foam/phase change material for thermal energy storage. Int. J. Heat Mass Transf. 2021, 165, 120652. [Google Scholar] [CrossRef]

- Andreozzi, A.; Asinari, P.; Barletta, A.; Bianco, V.; Bocanegra, J.A.; Brandão, P.V.; Buonomo, B.; Cappabianca, R.; Celli, M.; Chiavazzo, E.; et al. Heat Transfer and Thermal Energy Storage Enhancement by Foams and Nanoparticles. Energies 2023, 16, 7421. [Google Scholar] [CrossRef]

- Mahdavi, M.; Tiari, S.; Pawar, V. A numerical study on the combined effect of dispersed nanoparticles and embedded heat pipes on melting and solidification of a shell and tube latent heat thermal energy storage system. J. Energy Storage 2020, 27, 101086. [Google Scholar] [CrossRef]

- Khalilmoghadam, P.; Rajabi-Ghahnavieh, A.; Shafii, M.B. A novel energy storage system for latent heat recovery in solar still using phase change material and pulsating heat pipe. Renew. Energy 2021, 163, 2115–2127. [Google Scholar] [CrossRef]

- Nakhchi, M.E.; Hatami, M.; Rahmati, M. A numerical study on the effects of nanoparticles and stair fins on performance improvement of phase change thermal energy storages. Energy 2021, 215, 119112. [Google Scholar] [CrossRef]

- Yang, X.; Wei, P.; Liu, G.; Bai, Q.; He, Y.L. Performance evaluation on the gradient design of pore parameters for metal foam and pin fin-metal foam hybrid structure. Appl. Therm. Eng. 2020, 175, 115416. [Google Scholar] [CrossRef]

- Selvakumar, R.D.; Wu, J.; Alkaabi, A.K. Electrohydrodynamic acceleration of charging process in a latent heat thermal energy storage module. Appl. Therm. Eng. 2024, 242, 122475. [Google Scholar] [CrossRef]

- Yang, C.; Zheng, Z.-J.; Cai, X.; Xu, Y. Experimental study on the effect of rotation on melting performance of shell-and-tube latent heat thermal energy storage unit. Appl. Therm. Eng. 2022, 215, 118877. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P. Numerical investigation of heat transfer performance of a rotating latent heat thermal energy storage. Appl. Energy 2018, 227, 542–554. [Google Scholar] [CrossRef]

- Soltani, H.; Soltani, M.; Karimi, H.; Nathwani, J. Optimization of shell and tube thermal energy storage unit based on the effects of adding fins, nanoparticles and rotational mechanism. J. Clean. Prod. 2022, 331, 129922. [Google Scholar] [CrossRef]

- Qu, X.; Jiang, S.; Qi, X. Experimental investigation on performance improvement of latent heat storage capsule by oscillating movement. Appl. Energy 2022, 316, 119130. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Sun, Y.; Chen, Y.; He, C.; Yin, H.; Xu, Y. Study of the melting performance of shell-and-tube latent heat thermal energy storage unit under the action of rotating finned tube. J. Energy Storage 2023, 62, 106801. [Google Scholar] [CrossRef]

- Huang, X.; Li, F.; Guo, J.; Li, Y.; Du, R.; Yang, X.; He, Y.L. Design optimization on solidification performance of a rotating latent heat thermal energy storage system subject to fluctuating heat source. Appl. Energy 2024, 362, 122997. [Google Scholar] [CrossRef]

- Li, N.; Zhao, Y.; Wang, H.; Chen, Q.; Li, Z.; Ma, Y.; Tang, G. Thermal and hydraulic performance of a compact precooler with mini-tube bundles for aero-engine. Appl. Therm. Eng. 2022, 200, 117656. [Google Scholar] [CrossRef]

- Chen, K.; Guo, L.; Xie, X.; Liu, W. Experimental investigation on enhanced thermal performance of staggered tube bundles wrapped with metallic foam. Int. J. Heat Mass Transf. 2018, 122, 459–468. [Google Scholar] [CrossRef]

- Dubovsky, V.; Ziskind, G.; Letan, R. Analytical model of a PCM-air heat exchanger. Appl. Therm. Eng. 2011, 31, 3453–3462. [Google Scholar] [CrossRef]

- Ezra, M.; Kozak, Y.; Dubovsky, V.; Ziskind, G. Analysis and optimization of melting temperature span for a multiple-PCM latent heat thermal energy storage unit. Appl. Therm. Eng. 2016, 93, 315–329. [Google Scholar] [CrossRef]

- Promoppatum, P.; Yao, S.C.; Hultz, T.; Agee, D. Experimental and numerical investigation of the cross-flow PCM heat exchanger for the energy saving of building HVAC. Energy Build. 2017, 138, 468–478. [Google Scholar] [CrossRef]

- Liu, J.; Xu, C.; Ju, X.; Yang, B.; Ren, Y.; Du, X. Numerical investigation on the heat transfer enhancement of a latent heat thermal energy storage system with bundled tube structures. Appl. Therm. Eng. 2017, 112, 820–831. [Google Scholar] [CrossRef]

- Alhusseny, A.; Al-Zurfi, N.; Nasser, A.; Al-Fatlawi, A.; Aljanabi, M. Impact of using a PCM-metal foam composite on charging/discharging process of bundled-tube LHTES units. Int. J. Heat Mass Transf. 2020, 150, 119320. [Google Scholar] [CrossRef]

- Tang, S.Z.; He, Y.; He, Y.L.; Wang, F.L. Enhancing the thermal response of a latent heat storage system for suppressing temperature fluctuation of dusty flue gas. Appl. Energy 2020, 266, 114870. [Google Scholar] [CrossRef]

- Kang, Z.; Zhou, W.; Qiu, K.; Wang, C.; Qin, Z.; Zhang, B.; Yao, Q. Numerical Simulation of an Indirect Contact Mobilized Thermal Energy Storage Container with Different Tube Bundle Layout and Fin Structure. Sustainability 2023, 15, 5511. [Google Scholar] [CrossRef]

- Pignata, A.; Minuto, F.D.; Lanzini, A.; Papurello, D. A feasibility study of a tube bundle exchanger with phase change materials: A case study. J. Build. Eng. 2023, 78, 107622. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Kean, T.H.; Chow, H.K.; Rajaandra, A.; Rahman, S.; Kaur, J. Performance enhancement of cold thermal energy storage system using nanofluid phase change materials: A review. Int. Commun. Heat Mass Transf. 2018, 94, 85–95. [Google Scholar] [CrossRef]

- Deng, S.; Nie, C.; Jiang, H.; Ye, W.B. Evaluation and optimization of thermal performance for a finned double tube latent heat thermal energy storage. Int. J. Heat Mass Transf. 2019, 130, 532–544. [Google Scholar] [CrossRef]

- Rabienataj Darzi, A.A.; Jourabian, M.; Farhadi, M. Melting and solidification of PCM enhanced by radial conductive fins and nanoparticles in cylindrical annulus. Energy Convers. Manag. 2016, 118, 253–263. [Google Scholar] [CrossRef]

- Dhaidan, N.S.; Khodadadi, J.M.; Al-Hattab, T.A.; Al-Mashat, S.M. Experimental and numerical investigation of melting of NePCM inside an annular container under a constant heat flux including the effect of eccentricity. Int. J. Heat Mass Transf. 2013, 67, 455–468. [Google Scholar] [CrossRef]

- Li, Z.; Yu, X.; Wang, L.; Lu, Y.; Huang, R.; Chang, J.; Jiang, R. Effects of fluctuating thermal sources on a shell-and-tube latent thermal energy storage during charging process. Energy 2020, 199, 117400. [Google Scholar] [CrossRef]

| k (W/m·K) | ρ (kg/m3) | cp (J/kg·K) | Ts (K) | Tl (K) | L (J/kg) | μ (Pa·s) | β (K−1) | |

|---|---|---|---|---|---|---|---|---|

| Paraffin | 0.2 | 850/760 | 2000 | 302.15 | 309.15 | 165,000 | 0.0254 | 0.00005 |

| Water | 0.6 | 998.2 | 4182 | - | - | - | 0.001 | - |

| Copper | 387.6 | 8978 | 381 | - | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Xiao, Y.; Chen, D.; Ye, C.; Nie, C. Melting and Solidification Characteristics of PCM in Oscillated Bundled-Tube Thermal Energy Storage System. Energies 2024, 17, 1973. https://doi.org/10.3390/en17081973

Liu J, Xiao Y, Chen D, Ye C, Nie C. Melting and Solidification Characteristics of PCM in Oscillated Bundled-Tube Thermal Energy Storage System. Energies. 2024; 17(8):1973. https://doi.org/10.3390/en17081973

Chicago/Turabian StyleLiu, Jiangwei, Yuhe Xiao, Dandan Chen, Chong Ye, and Changda Nie. 2024. "Melting and Solidification Characteristics of PCM in Oscillated Bundled-Tube Thermal Energy Storage System" Energies 17, no. 8: 1973. https://doi.org/10.3390/en17081973

APA StyleLiu, J., Xiao, Y., Chen, D., Ye, C., & Nie, C. (2024). Melting and Solidification Characteristics of PCM in Oscillated Bundled-Tube Thermal Energy Storage System. Energies, 17(8), 1973. https://doi.org/10.3390/en17081973