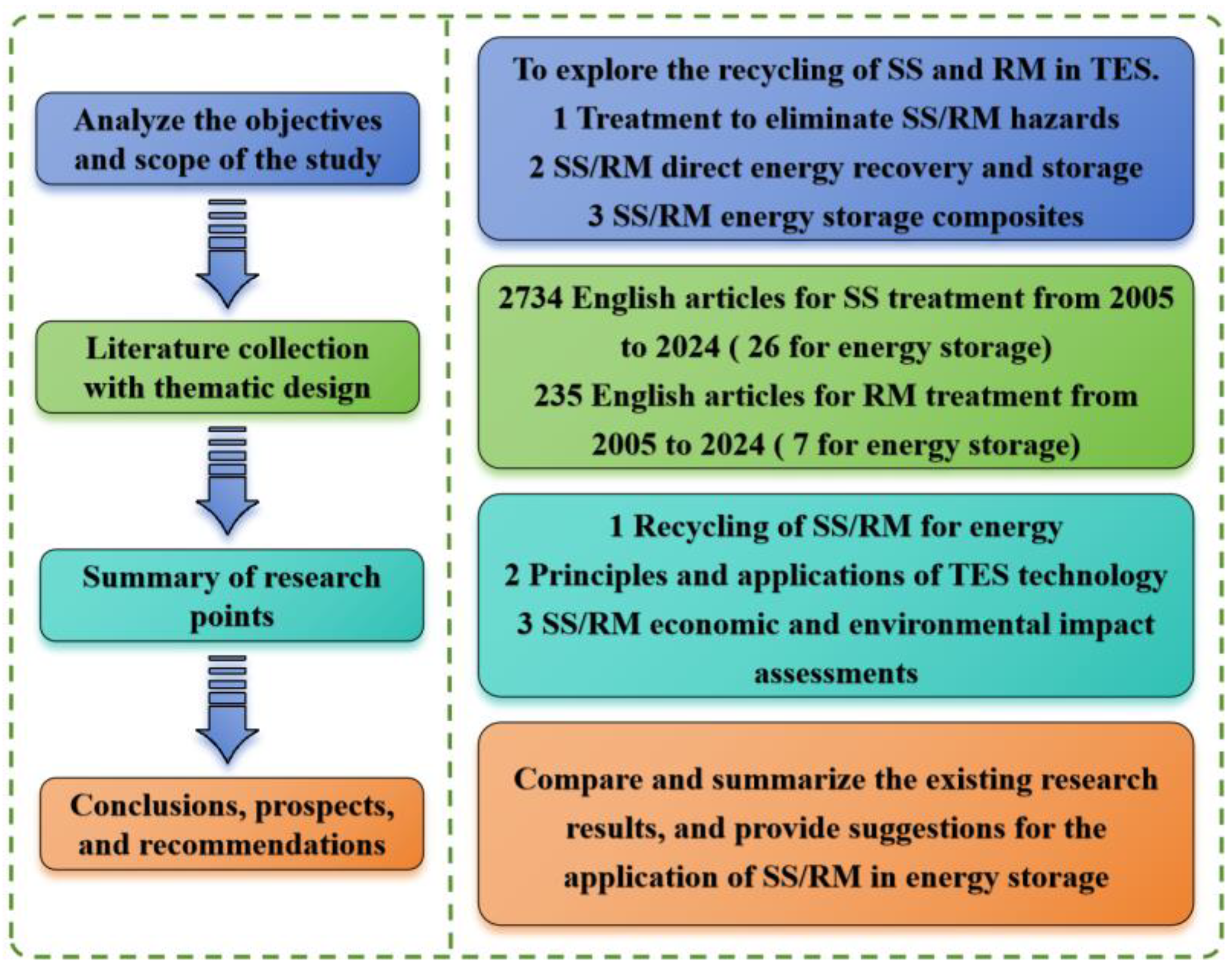

A Mini Review on Sewage Sludge and Red Mud Recycling for Thermal Energy Storage

Abstract

:1. Introduction

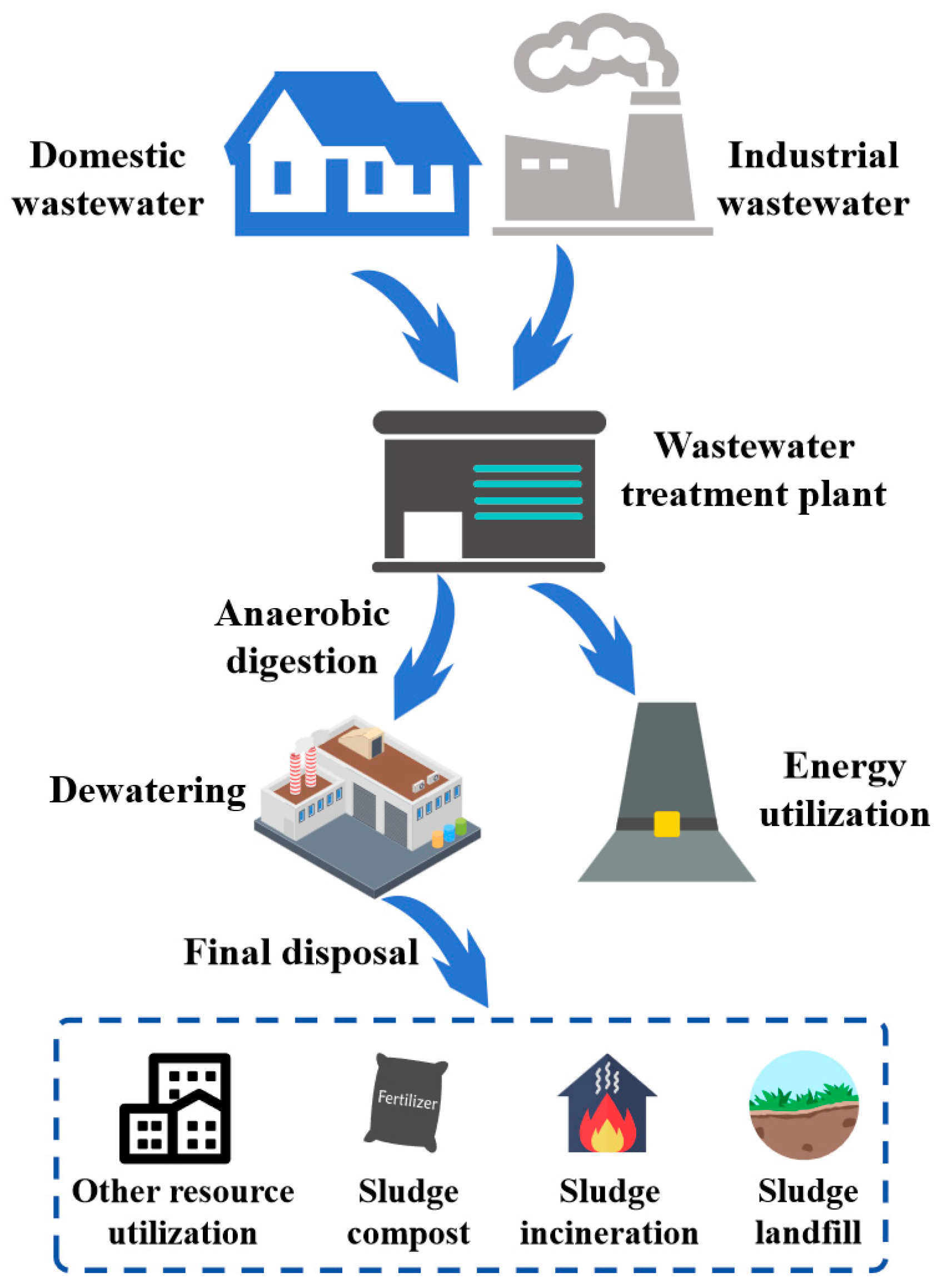

2. Basic Property, Recycling Options, and Challenges

2.1. Basic Property

2.1.1. Sewage Sludge

| Ref. | SiO2 | Al2O3 | P2O5 | CaO | Fe2O3 | MgO | K2O | Na2O | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| [62] | 24.95% | 37.04% | 17.31% | 7.75% | 5.75% | 2.59% | 1.69% | 1.57% | 0.07% |

| [82] | 10.30% | 5.04% | 2.42% | 34.10% | 15.40% | 1.14% | 0.45% | 1.27% | 27.70% |

| [83] | 27.27% | 24.21% | 16.97% | 6.95% | 10.22% | 2.45% | 2.07% | 0.32% | |

| [84] | 30.22% | 16.82% | 13.05% | 8.31% | 22.24% | 3.25% | 1.88% | 3.08% | |

| [84] | 43.95% | 17.98% | 12.09% | 6.16% | 12.48% | 2.65% | 2.42% | 1.54% |

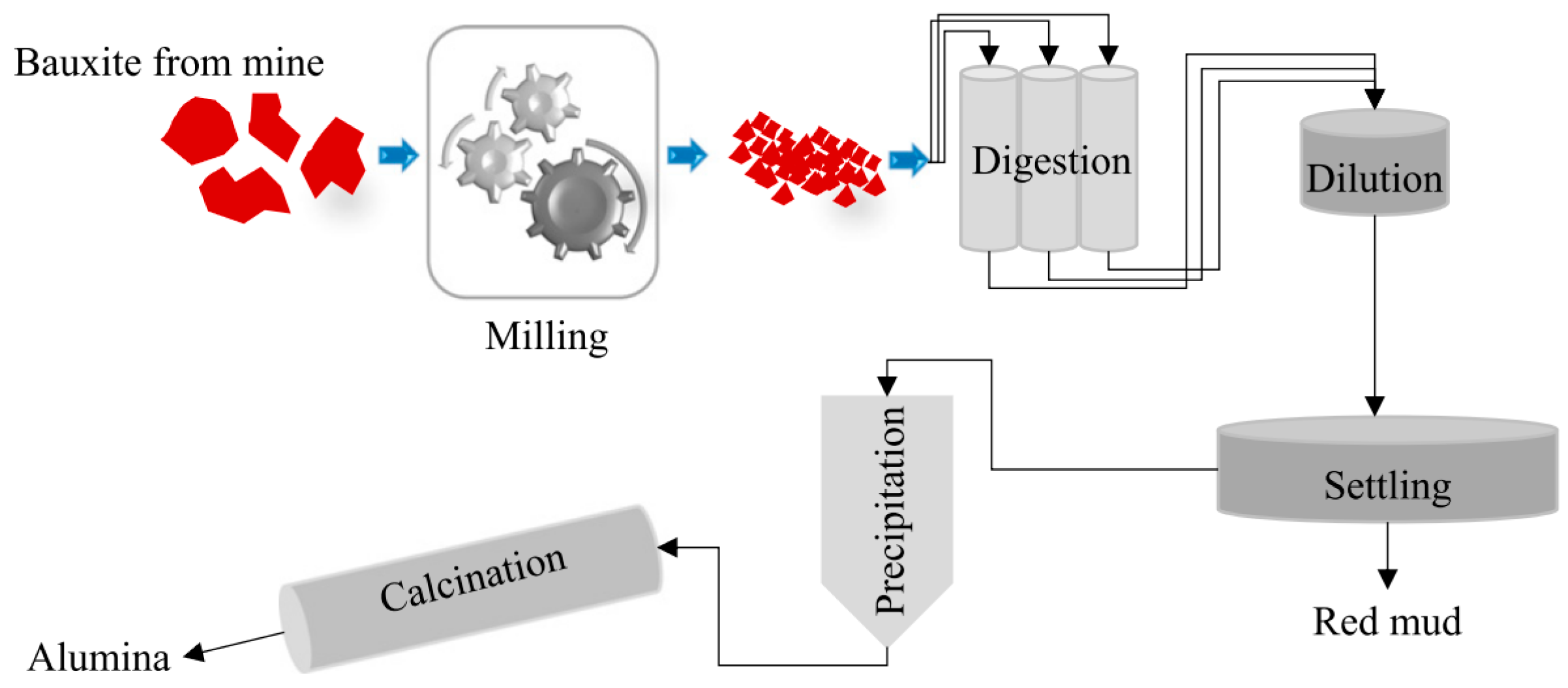

2.1.2. Red Mud

2.2. Recycling Options

- (1)

- Organic matter transformation and soil improvement

- (2)

- Carbon capture and utilization

- (3)

- Circular economy and resource recovery

- (4)

- Intelligent monitoring and optimal managementUsing advanced monitoring technology, big data analysis, and artificial intelligence, the sludge treatment process can be intelligently monitored and optimized to improve treatment efficiency and reduce carbon emissions [101].

- (5)

- Energy storage applicationsThe organic components in SS and RM can be used as excellent TES materials after specific treatment [102]. This application method not only improves energy efficiency, but also further reduces carbon emissions in the sludge treatment process, opening up a new means of carbon emission reduction and the utilization of SS and RM.

2.3. Challenges

- (1)

- Technical problems

- (2)

- Treatment costThe treatment cost of SS and RM is high, including the pretreatment, transportation, storage, and subsequent utilization, which increases the economic burden of TES technology’s application [110,111,112]. In 2021, the cost of SS collection and treatment services in cities around the world varied significantly, with costs ranging from as low as 0.1 USD/m3 to as high as 16 USD/m3 [113]. RM costs 11.08 USD/ton, and the accumulation and storage of RM comes with a significant maintenance fee [7].

- (3)

- Environmental protection standardsWhen handling and using these substances, environmental protection standards must be strictly followed to prevent secondary pollution to the environment. Therefore, effective measures need to be taken to control the emission of pollutants in TES applications [114].

- (4)

- Market acceptanceAs the TES technology of SS and RM is relatively new, the market acceptance of it may not be high, and it is necessary to increase publicity efforts to improve public awareness and acceptance [106].

3. Recycling for Thermal Energy Storage

3.1. Sewage Sludge

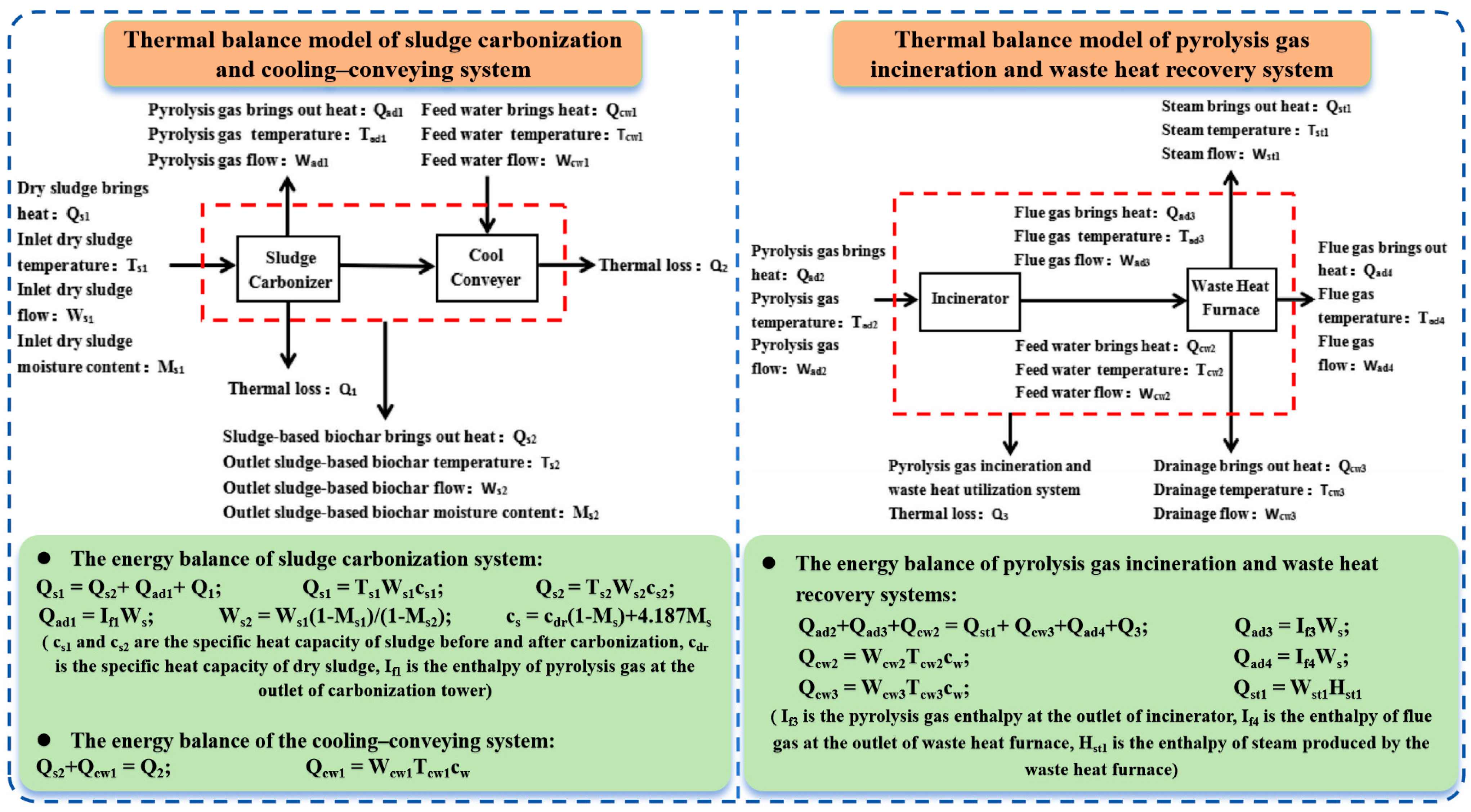

3.1.1. Direct Energy Recovery and Storage

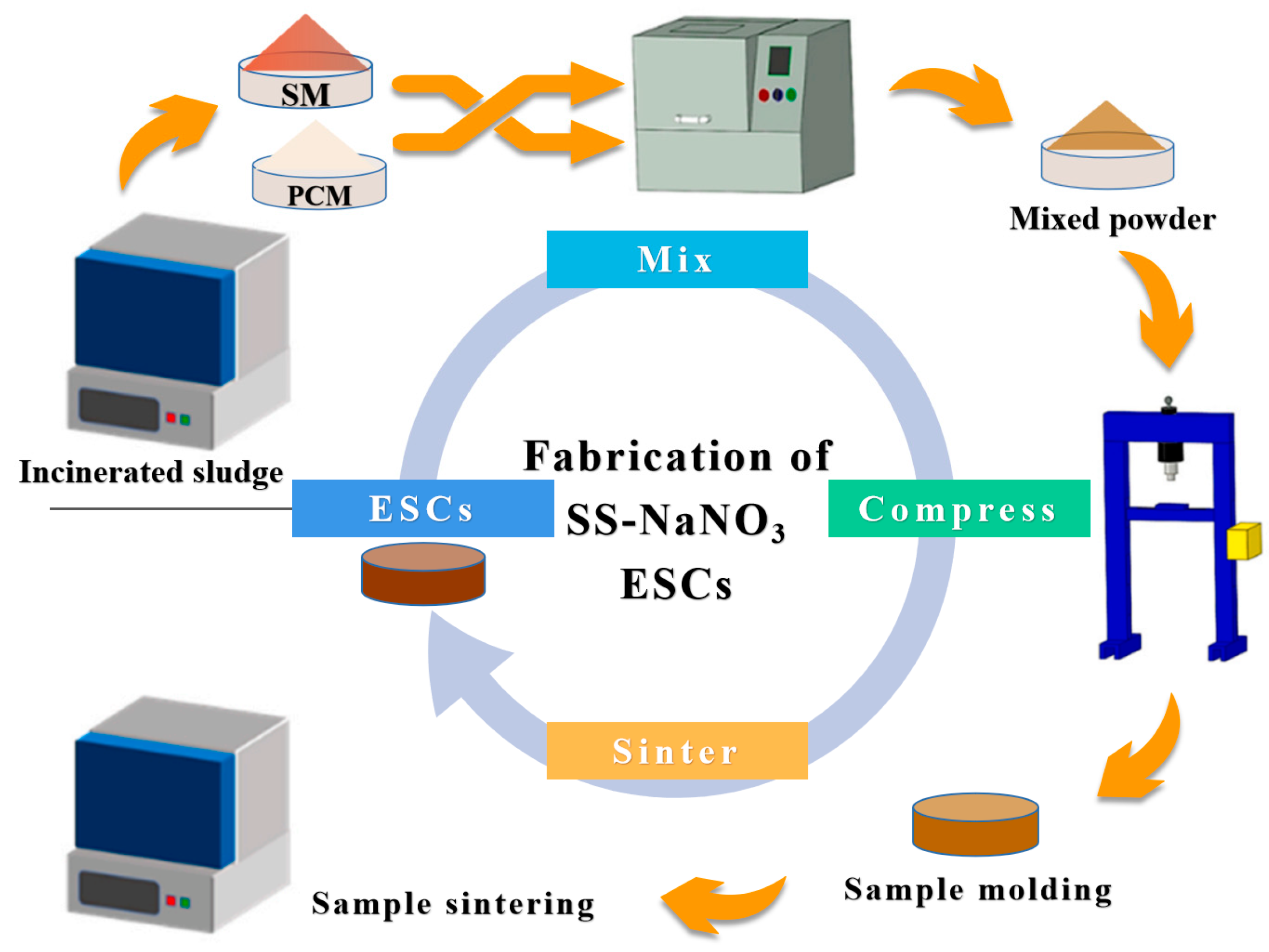

3.1.2. Sewage Sludge Energy Storage Composites

3.2. Red Mud

3.2.1. Direct Thermal Energy Storage

3.2.2. Red Mud Energy Storage Composites

3.3. Analysis and Comparisons

3.3.1. Benefits of Sewage Sludge and Red Mud in Energy Storage

- (1)

- (2)

- (3)

- Environmental friendliness: The effective utilization of SS and RM helps reduce the discharge and accumulation of these wastes, thereby reducing their potential impact on the environment. By using them in energy storage systems, we can reduce the exploitation and consumption of natural resources, mitigating the risks of environmental pollution and ecological destruction [103].

- (4)

- Innovative technology application: The application of SS and RM in energy storage systems represents a technological innovation. This application approach not only contributes to the development and progress of related technologies but also brings new solutions and ideas to the field of energy storage.

3.3.2. Comparisons of Energy Storage Composites

4. Conclusions

- (1)

- SS and RM, as solid waste, exhibit significant resource recovery potential in TES technology and carbon reduction. Sludge treatment has the potential to achieve an 83.48% reduction in carbon emissions compared to conventional cement. Microwave-assisted biomass pyrolysis to prepare biofuels, by using high-temperature pretreated RM as additives, increases the energy recovery efficiency from 4.71% to 9.98%.

- (2)

- However, SS and RM also face several challenges, like high collection and treatment cost, environmental risks, and practical application difficulties in TES applications. The cost of SS collection and treatment services in cities around the world varies significantly, with costs ranging from 0.1 USD/m3 to 16 USD/m3. The accumulation and storage of RM comes with a significant maintenance fee, costing 11.08 USD/ton.

- (3)

- The composition of SS and RM is complex, and its physical and chemical properties may affect the binding effect with PCMs. How to select the appropriate PCM, and how to achieve a uniform mixing and close binding with the SM, is the key technology in the preparation process. In addition, factors such as the material stability, thermal conductivity, and phase transition temperature need to be considered during the preparation process, which require in-depth research and precise control.

- (4)

- With the improvement in environmental awareness and the increase in energy demand, the TES application of SS and RM has broad prospects. A thermal balance model of the sludge pyrolysis–carbonization–cooling–conveying system, pyrolysis gas incineration–waste heat recovery system, and flue gas treatment and deodorization system can save energy and reduce consumption by 52.2%, compared with the typical sludge drying and incineration process.

- (5)

- SS and RM have great potential in the field of TES, but also face many challenges. Through continuous exploration and innovation, we can overcome these challenges, promote the development of resource utilization and TES technology, and contribute to environmental protection and energy utilization.

5. Future Perspective and Recommendations

- Future perspectives:

- (1)

- The focus will be on improving the energy storage capacity and thermal stability of SS/RM-based materials, which involves exploring novel processing techniques and additives that can enhance the material’s phase change behavior and thermal conductivity.

- (2)

- There will be a growing interest in developing a cost-effective and environmentally friendly SS/RM energy storage system, which includes the utilization of renewable energy sources for material processing, as well as the implementation of waste reduction and recycling strategies throughout the manufacturing cycle.

- (3)

- The integration of SS/RM-based TES systems into various applications will be explored. Potential areas of application include building energy management, solar energy systems, and industrial heat recovery.

- Recommendations:

- (1)

- Encourage further research and development efforts to enhance the performance and scalability of SS/RM-based TES materials, which includes exploring new material formulations, processing techniques, and additives that can improve the material’s properties.

- (2)

- Promote the development of sustainable production processes that minimize environmental impact and maximize resource utilization. This includes the use of renewable energy for material processing, waste reduction strategies, and recycling initiatives.

- (3)

- Foster collaboration between research institutions, industries, and policymakers to accelerate the development and deployment of SS/RM-based thermal energy storage solutions, which includes sharing knowledge, resources, and best practices to overcome challenges and achieve common goals.

Author Contributions

Funding

Conflicts of Interest

References

- Castellanos, H.G.; Aryanfar, Y.; Keçebaş, A.; Assad, M.E.H.; Islam, S.; Naveed, Q.N.; Lasisi, A. A new paradigm for mining energy from industrial sludge: A low-cost fuel. J. Water Process Eng. 2024, 59, 104987. [Google Scholar] [CrossRef]

- Rahman, T.; Jahromi, H.; Roy, P.; Adhikari, S.; Hassani, E.; Oh, T.-S. Hydrothermal liquefaction of municipal sewage sludge: Effect of red mud catalyst in ethylene and inert ambiences. Energy Convers. Manag. 2021, 245, 114615. [Google Scholar] [CrossRef]

- Zhou, P.; Li, D.; Zhang, C.; Ping, Q.; Wang, L.; Li, Y. Comparison of different sewage sludge pretreatment technologies for improving sludge solubilization and anaerobic digestion efficiency: A comprehensive review. Sci. Total Environ. 2024, 921, 171175. [Google Scholar] [CrossRef]

- Hu, M.; Ma, J.; Jiang, Z.; Wang, J.; Pan, Z.; Hu, Z.T.; Tang, S.; Beims, R.; Xu, C. New insights into nitrogen control strategies in sewage sludge pyrolysis toward environmental and economic sustainability. Sci. Total Environ. 2023, 882, 163326. [Google Scholar] [CrossRef]

- Sharma, A.K.; Ghodke, P.K.; Chen, W.-H. Progress in green adsorbent technologies from sewage sludge for wastewater remediation and carbon capture: A sustainable approach towards clean environment. Curr. Opin. Green Sustain. Chem. 2024, 46, 100883. [Google Scholar] [CrossRef]

- Svobodova-Sedlackova, A.; Calderon, A.; Fernandez, A.I.; Chimenos, J.M.; Berlanga, C.; Yucel, O.; Barreneche, C.; Rodriguez, R. Mapping the research landscape of bauxite by-products (red mud): An evolutionary perspective from 1995 to 2022. Heliyon 2024, 10, e24943. [Google Scholar] [CrossRef]

- Yan, P.; Chen, B.; Aminul Haque, M.; Liu, T. Influence of red mud on the engineering and microstructural properties of sustainable ultra-high performance concrete. Constr. Build. Mater. 2023, 396, 132404. [Google Scholar] [CrossRef]

- Wu, P.; Liu, X.; Zhang, Z.; Wei, C. Properties of red mud-filled and modified resin composites. Constr. Build. Mater. 2023, 409, 133984. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, J.; Li, H.; Zhao, P.; Chen, Q. Recycling red mud from the production of aluminium as a red cement-based mortar. Waste Manag. Res. 2017, 35, 500–507. [Google Scholar] [CrossRef]

- Kumar, M.; Dutta, S.; You, S.; Luo, G.; Zhang, S.; Show, P.L.; Sawarkar, A.D.; Singh, L.; Tsang, D.C.W. A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge. J. Clean. Prod. 2021, 305, 127143. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Mousavi, S.A.; Darvishi, P. Performance and recent development in sewage sludge-to-bioenergy using microbial fuel cells: A comprehensive review. Int. J. Hydrogen Energy 2024, 50, 1432–1455. [Google Scholar] [CrossRef]

- Anagnostopoulos, A.; Navarro, M.E.; Stefanidou, M.; Seferlis, P.; Gaidajis, G.; Ding, Y. Effect of carbon on the performance of red mud-molten salt composites for thermal management and waste heat recovery applications. J. Energy Storage 2021, 44, 103363. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Wang, X.; Guo, H.; Zhu, T.; Zhao, Y.; Lu, X.; Zhang, Y.; Ni, B.-J.; Liu, Y. Medium-chain fatty acids production from sewage sludge through anaerobic fermentation: A critical review. Chem. Eng. J. 2023, 477, 147138. [Google Scholar] [CrossRef]

- Liang, L.; Wang, Y.; Li, N.; Yan, B.; Chen, G.; Hou, L. Breaking rate-limiting steps in a red mud-sewage sludge carbon catalyst activated peroxymonosulfate system: Effect of pyrolysis temperature. Sep. Purif. Technol. 2022, 299, 121805. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Zhang, X.; Yang, X.; Niu, S.; Zheng, Z.; Dong, B.; Hur, J.; Dai, X. Aging and mitigation of microplastics during sewage sludge treatments: An overview. Sci. Total Environ. 2024, 922, 171338. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, P.; Yang, S.; Zhou, Y.; Du, W.; Wang, Y.; Deng, C.; Wang, S. Thermodynamic analysis of SOFC–CCHP system based on municipal sludge plasma gasification with carbon capture. Appl. Energy 2023, 336, 120822. [Google Scholar] [CrossRef]

- Chang, H.; Zhao, Y.; Li, X.; Damgaard, A.; Christensen, T.H. Review of inventory data for the biological treatment of sewage sludge. Waste Manag. 2023, 156, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Zhang, H.; Xu, C.; Yan, G.; Wang, H.; Liu, G.-H.; Qi, L. Evaluation of ultimate biochemical carbon separation technology based on ultra-short sludge retention time activated sludge system. J. Environ. Chem. Eng. 2024, 12, 112057. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Mašláni, A.; Van Oost, G.; Fathi, J.; Hlína, M.; Mates, T.; Pohořelý, M.; Jeremiáš, M. Integration of thermal plasma with CCUS to valorize sewage sludge. Energy 2024, 288, 129896. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Ye, Y.; Hao Ngo, H.; Guo, W.; Woong Chang, S.; Duc Nguyen, D.; Fu, Q.; Wei, W.; Ni, B.; Cheng, D.; Liu, Y. A critical review on utilization of sewage sludge as environmental functional materials. Bioresour Technol. 2022, 363, 127984. [Google Scholar] [CrossRef] [PubMed]

- de Sousa Cordeiro, E.; Scaratti, G.; de Souza, D.C.S.; Nickel, C.D.M.; José, H.J.; de Fátima Peralta Muniz Moreira, R.; De Noni, A. Red mud as catalyst for the treatment of pharmaceuticals compounds by advanced oxidation processes—A review. Environ. Nanotechnol. Monit. Manag. 2024, 21, 100938. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, W.; Zhou, P.; Liu, Y.; Lei, X.; Li, B.; Ning, P. Research on red mud-limestone modified desulfurization mechanism and engineering application. Sep. Purif. Technol. 2021, 272, 118867. [Google Scholar] [CrossRef]

- Singh, V.; Bano, S.; Chauhan, V.B.; Pal, P.; Kumar, A.; Srivastava, J.B. Red mud as a sustainable road construction material: An experimental investigation. Constr. Build. Mater. 2024, 411, 134549. [Google Scholar] [CrossRef]

- Niu, A.; Lin, C. Trends in research on characterization, treatment and valorization of hazardous red mud: A systematic review. J. Environ. Manag. 2024, 351, 119660. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Wang, Z.; Guo, J.; Qi, J.; Liu, S.; Zhu, H.; Li, B.; Liu, Z. Catalytic degradation of antibiotic sludge to produce formic acid by acidified red mud. Environ. Res. 2024, 245, 117970. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Li, X.; Liu, W.; Zhai, S.; Xu, Q.; Huan, C.; Nie, S.; Ouyang, Q.; Wang, H.; Wang, A. Carbon source recovery from waste sludge reduces greenhouse gas emissions in a pilot-scale industrial wastewater treatment plant. Environ. Sci. Ecotechnol. 2023, 14, 100235. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Yan, K.; Wang, Z.; Gao, Y.; Li, K.; Peng, J. Does anaerobic digestion improve environmental and economic benefits of sludge incineration in China? Insight from life-cycle perspective. Resour. Conserv. Recycl. 2023, 188, 106688. [Google Scholar] [CrossRef]

- Xie, J.; Zhuge, X.; Liu, X.; Zhang, Q.; Liu, Y.; Sun, P.; Zhao, Y.; Tong, Y. Environmental sustainability opportunity and socio-economic cost analyses of phosphorus recovery from sewage sludge. Environ. Sci. Ecotechnol. 2023, 16, 100258. [Google Scholar] [CrossRef]

- Huang, B.; Zhuge, Y.; Rameezdeen, R.; Xing, K.; Huang, G.; Liu, Y. Integrated carbon assessment for sludge-derived concrete: Modelling and a comparative study. J. Clean. Prod. 2024, 435, 140304. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, W.; Zhu, Y.; Shao, Y.; Shao, Y.; Zhang, X. Preparation and characterisation of sodium nitrate/stone-sawing mud shape-stabilized phase change materials for medium-high temperature thermal energy storage. J. Energy Storage 2022, 56, 106047. [Google Scholar] [CrossRef]

- Thonon, M.; Fraisse, G.; Zalewski, L.; Pailha, M. Simultaneous charging and discharging processes in latent heat thermal energy storage: A review. Therm. Sci. Eng. Prog. 2024, 47, 102299. [Google Scholar] [CrossRef]

- Chen, R.; Cai, G.; Dong, X.; Mi, D.; Puppala, A.J.; Duan, W. Mechanical properties and micro-mechanism of loess roadbed filling using by-product red mud as a partial alternative. Constr. Build. Mater. 2019, 216, 188–201. [Google Scholar] [CrossRef]

- Ogugua, P.C.; Su, H.; Wang, E. Synergistic blending of biomass, sewage sludge, and coal for enhanced bioenergy production: Exploring residue combinations and optimizing thermal conversion parameters. J. Environ. Manag. 2024, 352, 120035. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Zhao, Y.; Bisinella, V.; Damgaard, A.; Christensen, T.H. Climate change impacts of conventional sewage sludge treatment and disposal. Water Res. 2023, 240, 120109. [Google Scholar] [CrossRef]

- Li, Q.; Cong, L.; Zhang, X.; Dong, B.; Zou, B.; Du, Z.; Xiong, Y.; Li, C. Fabrication and thermal properties investigation of aluminium based composite phase change material for medium and high temperature thermal energy storage. Sol. Energy Mater. Sol. Cells 2020, 211, 110511. [Google Scholar] [CrossRef]

- Cai, Z.; Li, Y.; Li, S.; Wu, H.; Bai, C.; Tan, J.; Xu, X.; Yin, Y.; Wang, W. Novel high thermal conductivity alumina/salt composites for thermal energy storage: Effect of wettability on microstructure and properties. J. Eur. Ceram. Soc. 2024, 44, 3953–3964. [Google Scholar] [CrossRef]

- Mahroug, I.; Doppiu, S.; Dauvergne, J.-L.; Palomo del Barrio, E. Li4(OH)3Br/MgO shape stabilized composite as novel high temperature thermal energy storage material. J. Energy Storage 2022, 52, 104921. [Google Scholar] [CrossRef]

- Li, C.; Li, Q.; Cong, L.; Jiang, F.; Zhao, Y.; Liu, C.; Xiong, Y.; Chang, C.; Ding, Y. MgO based composite phase change materials for thermal energy storage: The effects of MgO particle density and size on microstructural characteristics as well as thermophysical and mechanical properties. Appl. Energy 2019, 250, 81–91. [Google Scholar] [CrossRef]

- Li, Y.; Song, Y.; Wu, D.; Zhang, C.; Zhu, H. Highly active and stable Ca(OH)2-based thermochemical energy storage materials enabling direct solar absorption. J. Energy Storage 2024, 84, 110885. [Google Scholar] [CrossRef]

- Zhelezny, V.; Ivchenko, D.; Hlek, Y.; Khliyeva, O.; Shestopalov, K. Experimental study of phase transition heat of composite thermal energy storage materials paraffin wax/expanded graphite. J. Energy Storage 2024, 77, 110174. [Google Scholar] [CrossRef]

- Li, W.; Gao, C.; Hou, A.; Qiu, J.; Wang, S. One-pot in situ synthesis of expandable graphite-encapsulated paraffin composites for thermal energy storage. Chem. Eng. J. 2024, 481, 148541. [Google Scholar] [CrossRef]

- Wang, M.; Liu, S.; Gao, W.; Zhou, M. Synthesis and characterization of Capric acid-Lauric acid/expanded vermiculite as a phase change composite for thermal energy storage. J. Energy Storage 2024, 78, 110091. [Google Scholar] [CrossRef]

- Wang, T.; Zhao, S.; Liu, S.; Li, J.; Xin, Y.; Lu, Q.; Chen, H.; Liang, C. Effect of porous carbon on thermal and physical properties of composite pure alkane/expanded vermiculite phase change energy storage materials. J. Energy Storage 2022, 54, 105220. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, W.; Shao, Y.; Zhang, T.; Shao, Y.; Tian, C.; Ma, J.; Yang, Y.; Chu, L.; Zhu, Y. Gold tailings-solar salt shape-stabilized phase change materials for medium-high temperature thermal energy storage. J. Energy Storage 2024, 76, 109810. [Google Scholar] [CrossRef]

- Wu, S.; Zhou, Y.; Gao, W.; Zhang, Z.; Liu, A.; Cai, R.; Wu, C.; Peng, X.; Li, S.; Li, C.; et al. Preparation and properties of shape-stable phase change material with enhanced thermal conductivity based on SiC porous ceramic carrier made of iron tailings. Appl. Energy 2024, 355, 122256. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Xu, Q.; Luo, Q.; Xuan, Y. MXene reconciles concurrent enhancement of thermal conductivity and mechanical robustness of SiC-based thermal energy storage composites. DeCarbon 2023, 1, 100005. [Google Scholar] [CrossRef]

- Luo, Q.; Liu, X.; Yao, H.; Wang, H.; Xu, Q.; Tian, Y.; Wang, J.; Jin, Y.; Xuan, Y.; Ding, Y. Fast and stable solar/thermal energy storage via gradient SiC foam-based phase change composite. Int. J. Heat Mass Transf. 2022, 194, 123012. [Google Scholar] [CrossRef]

- Xiong, Y.; Tian, X.; Li, X.; Ren, J.; Xu, Q.; Wu, Y.; Ding, Y. Effects of expanded graphite on NaNO3/semi-coke ash shape-stable phase change composites for thermal energy storage. J. Energy Storage 2023, 72, 108648. [Google Scholar] [CrossRef]

- Yaxuan, X.; Chenhua, Y.; Jing, R.; Yuting, W.; Qian, X.; Binjian, N.; Chuan, L.; Yulong, D. Waste semicoke ash utilized to fabricate shape-stable phase change composites for building heating and cooling. Constr. Build. Mater. 2022, 361, 129638. [Google Scholar] [CrossRef]

- Gao, J.-m.; Ma, S.; Wang, B.; Ma, Z.; Guo, Y.; Cheng, F. Template-free facile preparation of mesoporous silica from fly ash for shaped composite phase change materials. J. Clean. Prod. 2023, 384, 135583. [Google Scholar] [CrossRef]

- Naresh, R.; Parameshwaran, R.; Ram, V.V.; Srinivas, P.V. Study on thermal energy storage properties of bio-based n-dodecanoic acid/fly ash as a novel shape-stabilized phase change material. Case Stud. Therm. Eng. 2022, 30, 101707. [Google Scholar] [CrossRef]

- Chen, P.; Jiang, D.; Chen, Y.; Xu, Y.; Wang, B.; Jiang, C. Preparation and thermal properties of phase change energy storage composite material based on modified fly ash. Ceram. Int. 2023, 49, 35651–35664. [Google Scholar] [CrossRef]

- Mert, M.S.; Mert, H.H.; Arıcı, M. Development and properties of n-octadecane / kaolinite composites as form-stabilized phase change materials for energy storage. J. Clean. Prod. 2023, 410, 137304. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, H.; Wang, C.; Zhou, Y. Kaolinite nanotube-stearic acid composite as a form-stable phase change material for thermal energy storage. Appl. Clay Sci. 2021, 201, 105930. [Google Scholar] [CrossRef]

- Gautam, A.; Saini, R.P. A review on sensible heat based packed bed solar thermal energy storage system for low temperature applications. Sol. Energy 2020, 207, 937–956. [Google Scholar] [CrossRef]

- Mohan, G.; Venkataraman, M.B.; Coventry, J. Sensible energy storage options for concentrating solar power plants operating above 600 °C. Renew. Sustain. Energy Rev. 2019, 107, 319–337. [Google Scholar] [CrossRef]

- Koçak, B.; Fernandez, A.I.; Paksoy, H. Review on sensible thermal energy storage for industrial solar applications and sustainability aspects. Sol. Energy 2020, 209, 135–169. [Google Scholar] [CrossRef]

- Sharma, A.; Pitchumani, R.; Chauhan, R. Solar air heating systems with latent heat storage—A review of state-of-the-art. J. Energy Storage 2022, 48, 104013. [Google Scholar] [CrossRef]

- Opolot, M.; Zhao, C.; Liu, M.; Mancin, S.; Bruno, F.; Hooman, K. A review of high temperature (≥500 °C) latent heat thermal energy storage. Renew. Sustain. Energy Rev. 2022, 160, 112293. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, S.; Hu, D.; Zhang, Y.; Lv, H.; Liu, C.; Chen, Y.; Sun, J. Paraffin/red mud phase change energy storage composite incorporated gypsum-based and cement-based materials: Microstructures, thermal and mechanical properties. J. Hazard. Mater. 2019, 364, 608–620. [Google Scholar] [CrossRef]

- Xiong, Y.; Song, C.; Ren, J.; Jin, Y.; Nie, B.; Xu, Q.; Wu, Y.; Li, C.; Li, H.; Ding, Y. Sludge-incinerated ash based shape-stable phase change composites for heavy metal fixation and building thermal energy storage. Process Saf. Environ. Prot. 2022, 162, 346–356. [Google Scholar] [CrossRef]

- Li, Y.; Jia, X.; Li, X.; Liu, P.; Zhang, X.; Guo, M. Study on the potential of sludge-derived humic acid as energy storage material. Waste Manag. 2023, 162, 55–62. [Google Scholar] [CrossRef]

- Anagnostopoulos, A.; Elena Navarro, M.; Sharma, S.; Ahmad, A.; Maksum, Y.; Ding, Y. From waste to value: Utilising waste foundry sand in thermal energy storage as a matrix material in composites. Sol. Energy 2024, 268, 112294. [Google Scholar] [CrossRef]

- Wang, Z.; Li, X.; Liu, H.; Li, J.; Vodnar, D.C.; Lin, C.S.K.; Wang, Q. Life cycle assessment of traditional and innovative sludge management scenarios in Australia: Focusing on environmental impacts, energy balance, and economic benefits. Resour. Conserv. Recycl. 2024, 204, 107496. [Google Scholar] [CrossRef]

- Lin, C.; Liu, Y.; Li, Y.-Y.; Liu, J. Achieving rapid start-up of mainstream partial nitritation by sludge treatment using high salinity. Chem. Eng. J. 2024, 483, 149290. [Google Scholar] [CrossRef]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Benavente, V.; Perez, C.; Jansson, S. Co-hydrothermal carbonization of microalgae and digested sewage sludge: Assessing the impact of mixing ratios on the composition of primary and secondary char. Waste Manag. 2024, 174, 429–438. [Google Scholar] [CrossRef]

- Rao, B.; Su, J.; Xu, S.; Pang, H.; Xu, P.; Zhang, Y.; Zhu, J.; Tu, H. Thermal and non-thermal mechanism of microwave irradiation on moisture content reduction of municipal sludge. Water Res. 2022, 226, 119231. [Google Scholar] [CrossRef]

- Sanchez-Sanchez, C.; Moreno-Rodriguez, E.; Ortiz-Cruz, J.A.; Moeller-Chavez, G.E. Development of aerobic granular sludge for real industrial/municipal wastewater treatment. Water Sci. Technol. 2023, 87, 2328–2344. [Google Scholar] [CrossRef]

- Oh, J.Y.; Choi, S.D.; Kwon, H.O.; Lee, S.E. Leaching of polycyclic aromatic hydrocarbons (PAHs) from industrial wastewater sludge by ultrasonic treatment. Ultrason. Sonochem 2016, 33, 61–66. [Google Scholar] [CrossRef]

- Santos, M.T.; Lopes, P.A. Sludge recovery from industrial wastewater treatment. Sustain. Chem. Pharm. 2022, 29, 100803. [Google Scholar] [CrossRef]

- Traina, F.; Capodici, M.; Torregrossa, M.; Viviani, G.; Corsino, S.F. PHA and EPS production from industrial wastewater by conventional activated sludge, membrane bioreactor and aerobic granular sludge technologies: A comprehensive comparison. Chemosphere 2024, 355, 141768. [Google Scholar] [CrossRef]

- Wang, X.; Yi, K.; Pang, H.; Liu, Z.; Li, X.; Zhang, W.; Zhang, C.; Liu, S.; Huang, J.; Zhang, C. An overview of quorum sensing in shaping activated sludge forms: Mechanisms, applications and challenges. Sci. Total Environ. 2024, 927, 171886. [Google Scholar] [CrossRef]

- Lu, J.; Lu, Q.; Hu, Q.; Qiu, B. Recovery of organic matters by activated sludge from municipal wastewater: Performance and characterization. Environ. Res. 2024, 252, 118829. [Google Scholar] [CrossRef]

- Sakaveli, F.; Petala, M.; Tsiridis, V.; Karas, P.A.; Karpouzas, D.G.; Darakas, E. Effect of attapulgite on anaerobic digestion of primary sludge and downstream valorization of produced biosolids. Renew. Energy 2023, 217, 119211. [Google Scholar] [CrossRef]

- Cheikhwafa, J.; Glinska, K.; Torrens, E.; Bengoa, C. Effect of temperature on hydrothermal liquefaction of high lipids and carbohydrates content municipal primary sludge. Heliyon 2024, 10, e24731. [Google Scholar] [CrossRef]

- Ngo, P.L.; Young, B.R.; Brian, K.; Baroutian, S. Thermal hydrolysis of primary sludge and waste activated sludge mixture: Biogas production and formation of inhibitors. J. Clean. Prod. 2023, 428, 139354. [Google Scholar] [CrossRef]

- Yang, H.; Li, Q. Modifying humus-phosphorus-arsenic interactions in sludge composting: The strengthening of phosphorus availability and arsenic efflux detoxification mechanisms. J. Hazard. Mater. 2024, 470, 134131. [Google Scholar] [CrossRef]

- Guven, H.M.; Ates, H. A holistic approach to the recovery of valuable substances from the treatment sludge formed from chemical precipitation of fruit processing industry wastewater. Sci. Total Environ. 2024, 917, 170372. [Google Scholar] [CrossRef]

- Zhang, X.; Ye, P.; Wu, Y. Enhanced technology for sewage sludge advanced dewatering from an engineering practice perspective: A review. J. Environ. Manag. 2022, 321, 115938. [Google Scholar] [CrossRef]

- Wu, Z.; Jiang, Y.; Guo, W.; Jin, J.; Wu, M.; Shen, D.; Long, Y. The long-term performance of concrete amended with municipal sewage sludge incineration ash. Environ. Technol. Innov. 2021, 23, 101574. [Google Scholar] [CrossRef]

- Fang, Z.; Liu, F.; Li, Y.; Li, B.; Yang, T.; Li, R. Influence of microwave-assisted pyrolysis parameters and additives on phosphorus speciation and transformation in phosphorus-enriched biochar derived from municipal sewage sludge. J. Clean. Prod. 2021, 287, 125550. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, R.; Xiong, Z.; Li, X.; Chen, J.; Yao, H. Transformation of phosphorous during incineration of sewage sludge: Influence of steam and mineral. Fuel 2021, 303, 121307. [Google Scholar] [CrossRef]

- Liu, X.; Han, Y.; He, F.; Gao, P.; Yuan, S. Characteristic, hazard and iron recovery technology of red mud - A critical review. J. Hazard. Mater. 2021, 420, 126542. [Google Scholar] [CrossRef]

- Xue, S.; Li, M.; Jiang, J.; Millar, G.J.; Li, C.; Kong, X. Phosphogypsum stabilization of bauxite residue: Conversion of its alkaline characteristics. J. Environ. Sci. 2019, 77, 1–10. [Google Scholar] [CrossRef]

- Nganda, A.; Srivastava, P.; Lamba, B.Y.; Pandey, A.; Kumar, M. Advances in the fabrication, modification, and performance of biochar, red mud, calcium oxide, and bentonite catalysts in waste-to-fuel conversion. Environ. Res. 2023, 232, 116284. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Z.; Zhu, H.; Wang, Z.; Guo, J.; Zhang, X.; Yu, H.; Yue, X.; Ning, P.; Li, B. The roles of red mud as desulfurization and denitrification in flue gas: A review. J. Environ. Chem. Eng. 2023, 11, 109770. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Liu, Z. Red mud-based catalysts for the catalytic removal of typical air pollutants: A review. J. Environ. Sci. 2023, 127, 628–640. [Google Scholar] [CrossRef]

- Occhicone, A.; Graziuso, S.G.; De Gregorio, E.; Montagnaro, F.; Ricciotti, L.; Tarallo, O.; Roviello, G.; Ferone, C. Synthesis and characterization of new acid-activated red mud-metakaolin geopolymers and comparison with their alkaline counterparts. J. Clean. Prod. 2024, 435, 140492. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Z.; Wang, K.; Wang, F.; Jiang, H.; Liang, M.; Wei, J.; Airey, G. Sustainable utilization of bauxite residue (Red Mud) as a road material in pavements: A critical review. Constr. Build. Mater. 2021, 270, 121419. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Karimi, Z.; Allahverdi, A. Recycling of Red Mud for Value-Added Applications: A Comprehensive Review. Encycl. Renew. Sustain. Mater. 2020, 2, 561–582. [Google Scholar]

- Liu, Y.; Li, W.; Zhang, Z.-Y.; Zhou, J.; Yin, X.; Zhu, X.; Wang, X. Preparation of non-sintered building materials with a high content of red mud using magnesium oxychloride cement. Constr. Build. Mater. 2023, 408, 133501. [Google Scholar] [CrossRef]

- Ram Kumar, B.A.V.; Ramakrishna, G. Performance evaluation of red mud as a construction material—A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Wang, M.; Liu, X. Applications of red mud as an environmental remediation material: A review. J. Hazard. Mater. 2021, 408, 124420. [Google Scholar] [CrossRef]

- Khan, A.Z.; Malik, S.; Mehmood, M.A.; Shahid, A.; Shahzad, T.; Zhao, X.-Q.; Bai, F.-W.; Liu, C.-G. Two-stage algal cultivation for the biotransformation of urban wastewater’s pollutants into multiple bioproducts in a circular bioeconomy paradigm. Energy Convers. Manag. 2022, 273, 116400. [Google Scholar] [CrossRef]

- Yadav, A.; Garg, V.K. Biotransformation of bakery industry sludge into valuable product using vermicomposting. Bioresour Technol. 2019, 274, 512–517. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Ganeshan, P.; Gohil, N.; Kumar, V.; Singh, V.; Rajendran, K.; Harirchi, S.; Solanki, M.K.; Sindhu, R.; Binod, P.; et al. Advanced approaches for resource recovery from wastewater and activated sludge: A review. Bioresour Technol. 2023, 384, 129250. [Google Scholar]

- Nguyen, M.D.; Thomas, M.; Surapaneni, A.; Moon, E.M.; Milne, N.A. Beneficial reuse of water treatment sludge in the context of circular economy. Environ. Technol. Innov. 2022, 28, 102651. [Google Scholar]

- Ferrer, I.; Passos, F.; Romero, E.; Vázquez, F.; Font, X. Optimising sewage sludge anaerobic digestion for resource recovery in wastewater treatment plants. Renew. Energy 2024, 224, 120123. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.; Hu, J.; Pu, C. Intelligent management of carbon emissions of urban domestic sewage based on the Internet of Things. Environ. Res. 2024, 251, 118594. [Google Scholar] [CrossRef]

- Yu, K.; Jia, M.; Tian, W.; Yang, Y.; Liu, Y. Enhanced thermo-mechanical properties of cementitious composites via red mud-based microencapsulated phase change material: Towards energy conservation in building. Energy 2024, 290, 130301. [Google Scholar] [CrossRef]

- Song, C.; Li, C.; Zhu, D.; Chen, W.; Ai, L.; Huang, N.; Yang, L.; Guo, C.; Liu, F. Waste utilization of sewage sludge and red mud based on chemical looping catalytic oxidation. Fuel 2023, 332, 125990. [Google Scholar] [CrossRef]

- Wei, R.; Zhang, F.; Wang, X.; Meng, D.; Meng, K.; Long, H. A novel approach for the resource utilization of zinc-bearing dust and sludge via the blast furnace main trough. Waste Manag. 2023, 172, 127–139. [Google Scholar] [CrossRef]

- Ren, C.; Hu, D.; Chen, Y.; Guo, L. Thermodynamic and environmental analysis of auto-thermal supercritical water co-gasification polygeneration system of sewage sludge with coal. Energy Convers. Manag. 2023, 288, 117127. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A. Energy and resources recovery from excess sewage sludge: A holistic analysis of opportunities and strategies. Resour. Conserv. Recycl. Adv. 2023, 19, 200184. [Google Scholar] [CrossRef]

- Hamalainen, A.; Kokko, M.; Tolvanen, H.; Kinnunen, V.; Rintala, J. Towards the implementation of hydrothermal carbonization for nutrients, carbon, and energy recovery in centralized biogas plant treating sewage sludge. Waste Manag. 2024, 173, 99–108. [Google Scholar] [CrossRef]

- Fan, Y.; Hornung, U.; Dahmen, N. Hydrothermal liquefaction of sewage sludge for biofuel application: A review on fundamentals, current challenges and strategies. Biomass Bioenergy 2022, 165, 106570. [Google Scholar] [CrossRef]

- Yang, Y.; Xiao, P.; Wen, M.; Liu, T.; Yang, J.; Dai, S.; Zhao, Y.; Huang, Q.; Liu, Z.; Li, B. A review on the modified red mud for biomass catalytic pyrolysis: Preparation, mechanisms and perspectives. J. Anal. Appl. Pyrolysis 2024, 178, 106430. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, X.; Liang, W.; Yao, S.; Li, J.; Wang, C.; Yue, G. Red mud-based perovskite oxygen carrier preparation for chemical looping gasification of municipal sludge. Waste Manag. 2024, 177, 169–176. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Y.; Wang, H.; Zhang, Z.; Shen, X.; Liu, H. Enhancing the sustainable production of cost-effective ceramics with high strength using kaolin, sewage sludge and blast-furnace slag. Chem. Eng. J. 2024, 480, 148184. [Google Scholar] [CrossRef]

- Mazzeo, D.E.C.; Dombrowski, A.; Oliveira, F.A.; Levy, C.E.; Oehlmann, J.; Marchi, M.R.R. Endocrine disrupting activity in sewage sludge: Screening method, microbial succession and cost-effective strategy for detoxification. J. Environ. Manag. 2023, 330, 117207. [Google Scholar] [CrossRef]

- Medeiros, D.L.; Santos, C.; Ribeiro, R.; Tommaso, G. The dissolved methane recovery from treated sewage in upflow anaerobic sludge blanket (UASB) reactors: The energy demand, carbon footprint and financial cost. J. Environ. Manag. 2023, 343, 118258. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, Y.; Liu, M.; Xia, Y.; Yang, Y. Sodium gluconate as a retarder modified sewage sludge ash-based geopolymers: Mechanism and environmental assessment. J. Clean. Prod. 2023, 419, 138317. [Google Scholar] [CrossRef]

- Guo, F.; Liu, W.; Chen, W.; Wang, F.; Zhang, H.; Jiang, X.; Gardy, J. Migration and transformation of phosphorus and toxic metals during sludge incineration with Ca additives. J. Environ. Manag. 2024, 352, 119910. [Google Scholar] [CrossRef]

- Peng, B.; Zhu, Y.; Tang, L. Study on the fate of phosphorus, fluorine and chlorine in sludge during incineration. Fuel 2024, 358, 130331. [Google Scholar] [CrossRef]

- Lin, J.; Liu, S.; Han, Z.; Ma, R.; Cui, C.; Sun, S. Scaled-up microwave pyrolysis of sludge for hydrogen-rich biogas and life cycle assessment: Parameters synergistic optimization, carbon footprint analysis and technology upgrade. Chem. Eng. J. 2023, 452, 139551. [Google Scholar] [CrossRef]

- Quan, L.M.; Kamyab, H.; Yuzir, A.; Ashokkumar, V.; Hosseini, S.E.; Balasubramanian, B.; Kirpichnikova, I. Review of the application of gasification and combustion technology and waste-to-energy technologies in sewage sludge treatment. Fuel 2022, 316, 123199. [Google Scholar] [CrossRef]

- Dutta, N.; Giduthuri, A.T.; Usman Khan, M.; Garrison, R.; Ahring, B.K. Improved valorization of sewage sludge in the circular economy by anaerobic digestion: Impact of an innovative pretreatment technology. Waste Manag. 2022, 154, 105–112. [Google Scholar] [CrossRef]

- Cai, J.; Zhou, H.; Zhang, T.; Shi, Z.; Meng, Q. Sensitivity analysis of structural parameters of a low-temperature heat pump sludge drying system. Appl. Therm. Eng. 2022, 207, 118172. [Google Scholar] [CrossRef]

- Liu, T.; Wen, C.; Zhou, K.; Li, C.; Zhu, Y.; Wang, D.; Li, R.; Jing, Z. Influence of collaborative disposal of sewage sludge in the fly ash partitioning and PM10 emission from a subcritical coal-fired boiler. Fuel 2023, 331, 125871. [Google Scholar] [CrossRef]

- Kostowski, W.; Tańczuk, M.; Majchrzyk, M.; Banasik, A.; Klimanek, A. Generation of renewable hydrogen from sewage sludge —Quantitative and energy-based technology evaluation. Int. J. Hydrogen Energy 2024, 52, 983–994. [Google Scholar] [CrossRef]

- Meng, Z.; Xiong, H.; Zhu, C.; Xu, G. Study on the process technology of energy saving and consumption reducing for municipal sludge-based biochar. Renew. Energy 2024, 220, 119606. [Google Scholar] [CrossRef]

- Peltola, P.; Ruottu, L.; Larkimo, M.; Laasonen, A.; Myohanen, K. A novel dual circulating fluidized bed technology for thermal treatment of municipal sewage sludge with recovery of nutrients and energy. Waste Manag. 2023, 155, 329–337. [Google Scholar] [CrossRef]

- Hu, M.; Hu, H.; Ye, Z.; Tan, S.; Yin, K.; Chen, Z.; Guo, D.; Rong, H.; Wang, J.; Pan, Z.; et al. A review on turning sewage sludge to value-added energy and materials via thermochemical conversion towards carbon neutrality. J. Clean. Prod. 2022, 379, 134657. [Google Scholar] [CrossRef]

- Liew, C.S.; Kiatkittipong, W.; Lim, J.W.; Lam, M.K.; Ho, Y.C.; Ho, C.D.; Ntwampe, S.K.O.; Mohamad, M.; Usman, A. Stabilization of heavy metals loaded sewage sludge: Reviewing conventional to state-of-the-art thermal treatments in achieving energy sustainability. Chemosphere 2021, 277, 130310. [Google Scholar] [CrossRef]

- Khan, U.; Bilal, M.; Adil, H.M.; Darlington, N.; Khan, A.; Khan, N.; Ihsanullah, I. Hydrogen from sewage sludge: Production methods, influencing factors, challenges, and prospects. Sci. Total Environ. 2024, 919, 170696. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Zhang, L.; Gong, Q.; Liu, X.; Li, X.; Zhang, Q.; Peng, Y. Rapid cultivation and enrichment of anammox bacteria solely using traditional activated sludge as inoculum and biocarrier in low-strength real sewage treatment. Bioresour Technol. 2022, 358, 127354. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; An, Z.; Cui, W.; Tang, X.; Sun, D.; Wang, C. Effect of surface modification of sludge hydropyrolysis residue on the heat storage performance of composite hydrated salt. J. Energy Storage 2024, 78, 109928. [Google Scholar] [CrossRef]

- Han, Y.; Zheng, J.; Wei, L.; Zhu, L. Waste to functions: Construction of a novel solar-thermal conversion material based on sludge-derived carbon dots via Ca-in-situ-functionalization for efficient solar-driven water evaporation. Chem. Eng. J. 2024, 484, 149763. [Google Scholar] [CrossRef]

- Sun, J.; Tao, J.; Huang, H.; Ma, R.; Sun, S. Promotion of bio-oil production from the microwave pyrolysis of cow dung using pretreated red mud as a bifunctional additive: Parameter optimization, energy efficiency evaluation, and mechanism analysis. Environ. Res. 2023, 236, 116806. [Google Scholar] [CrossRef] [PubMed]

- Wen, H.; Gao, J.; Yang, Y.; Zhao, M.; Gu, L.; Yu, H.; Liu, E. Effect of red mud on combustion behavior and heavy metal stabilization of Refuse Derived Fuel (RDF). J. Environ. Chem. Eng. 2023, 11, 111106. [Google Scholar] [CrossRef]

- Chai, Z.; Chen, X.; Fang, M.; Min, X.; Huang, Z.; Wang, Q.; Liu, C.; Liu, Y.; Huang, F. Fabrication and properties of high-thermal-storage RTO ceramics using bauxite tailings and red mud. Ceram. Int. 2023, 49, 31342–31350. [Google Scholar] [CrossRef]

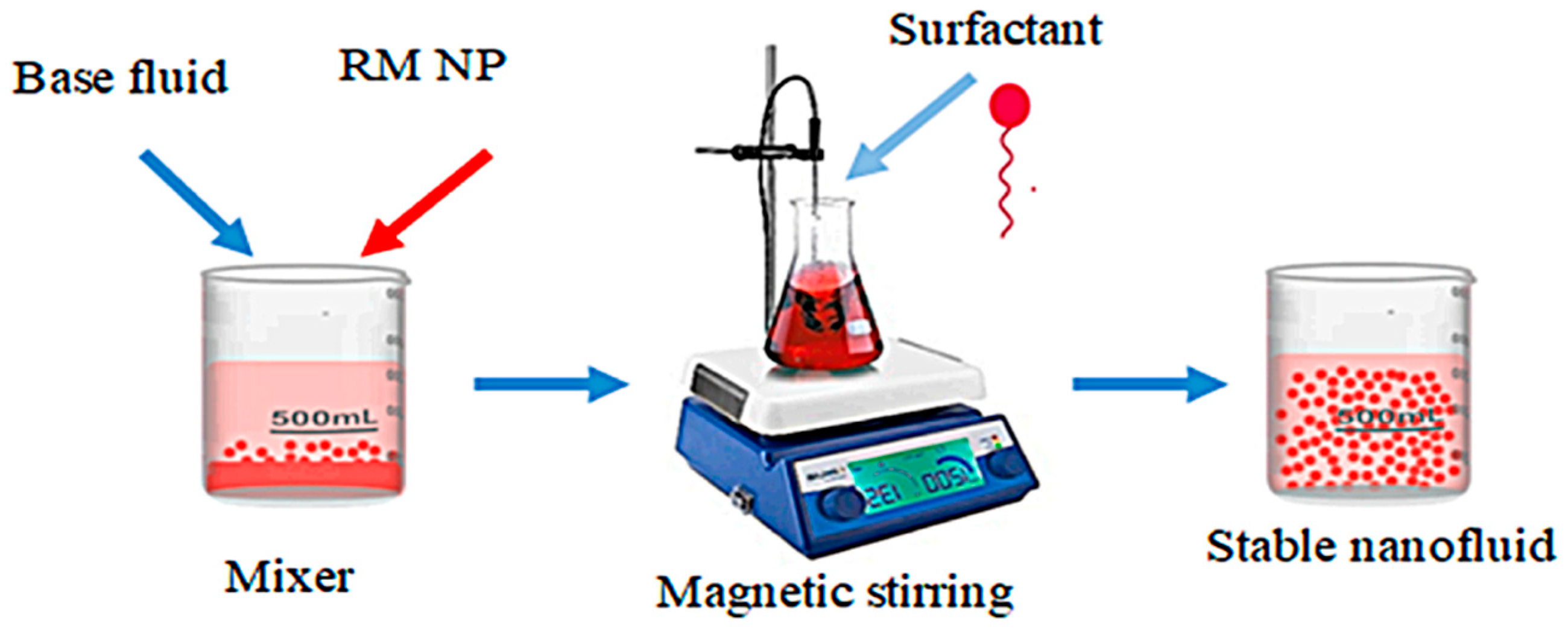

- Praveen Kumar, K.; Khedkar, R.; Sharma, P.; Elavarasan, R.M.; Paramasivam, P.; Wanatasanappan, V.V.; Dhanasekaran, S. Artificial intelligence-assisted characterization and optimization of red mud-based nanofluids for high-efficiency direct solar thermal absorption. Case Stud. Therm. Eng. 2024, 54, 104087. [Google Scholar] [CrossRef]

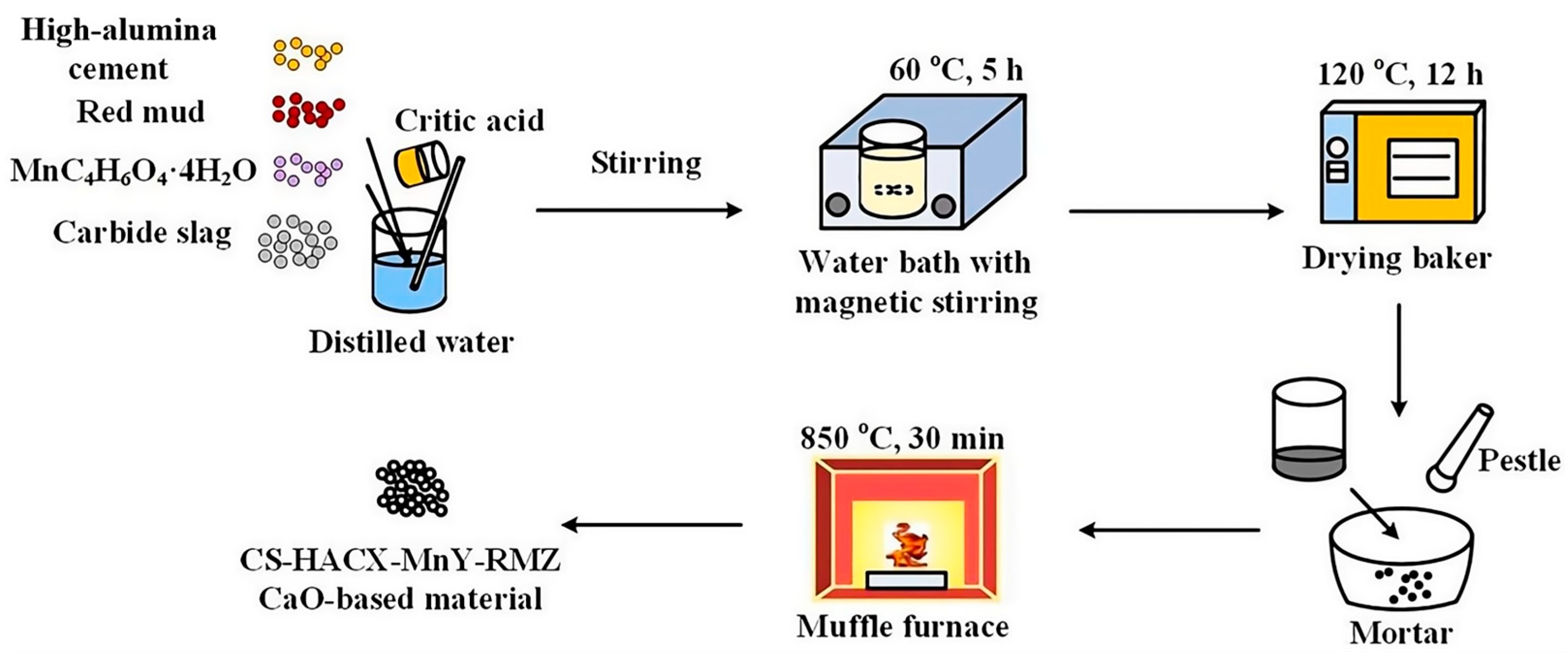

- Yang, Y.; Li, Y.; Zhang, C.; He, Z.; Zhao, J. Thermochemical heat storage and optical properties of red mud/Mn co-doped high alumina cement-stabilized carbide slag in CaO/CaCO3 cycles. Fuel Process. Technol. 2022, 236, 107419. [Google Scholar] [CrossRef]

- Afolabi, L.O.; Ariff, Z.M.; Megat-Yusoff, P.S.M.; Al-Kayiem, H.H.; Arogundade, A.I.; Afolabi-Owolabi, O.T. Red-mud geopolymer composite encapsulated phase change material for thermal comfort in built-sector. Sol. Energy 2019, 181, 464–474. [Google Scholar] [CrossRef]

- Anagnostopoulos, A.; Navarro, M.E.; Stefanidou, M.; Ding, Y.; Gaidajis, G. Red mud-molten salt composites for medium-high temperature thermal energy storage and waste heat recovery applications. J. Hazard. Mater. 2021, 413, 125407. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, G.; Fishlock, S.J.; Roy, J.S.; Pritam, A.; Banerjee, D.; Deshmukh, S.; Ghosh, S.; McLaughlin, J.A.; Roy, S.S. Effective Utilization of Waste Red Mud for High Performance Supercapacitor Electrodes. Glob. Chall 2019, 3, 1800066. [Google Scholar] [CrossRef]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive utilization status of red mud in China: A critical review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- Tarpani, R.R.Z.; Azapagic, A. Life cycle sustainability assessment of advanced treatment techniques for urban wastewater reuse and sewage sludge resource recovery. Sci. Total Environ. 2023, 869, 161771. [Google Scholar] [CrossRef]

- Xiong, Y.; Li, S.; Ren, J.; Zhang, A.; Xu, Q.; Wu, Y.; Zhao, Y.; Ding, Y. Effect of carbon capture on desulfurization gypsum/carbide slag phase-change composites for waste removal and renewable energy storage. J. Environ. Chem. Eng. 2024, 12, 112484. [Google Scholar] [CrossRef]

- Li, C.; Li, Q.; Ge, R.; Lu, X. A novel one-step ultraviolet curing fabrication of myristic acid-resin shape-stabilized composite phase change material for low temperature thermal energy storage. Chem. Eng. J. 2023, 458, 141355. [Google Scholar] [CrossRef]

- Yu, Q.; Jiang, Z.; Cong, L.; Lu, T.; Suleiman, B.; Leng, G.; Wu, Z.; Ding, Y.; Li, Y. A novel low-temperature fabrication approach of composite phase change materials for high temperature thermal energy storage. Appl. Energy 2019, 237, 367–377. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, H.; Ren, J.; Nevzat, A.; Xu, Q.; Nie, B.; Li, C.; Ding, Y. Carbide slag recycling to fabricate shape-stable phase change composites for thermal energy storage. J. Energy Storage 2023, 60, 106694. [Google Scholar] [CrossRef]

- Xiong, Y.; Yang, Y.; Zhang, A.; Ren, J.; Xu, Q.; Wu, Y.; Zhao, Y.; Ding, Y. Investigation on low-carbon shape-stable phase change composite by steel slag and carbide slag for solar thermal energy storage. J. Energy Storage 2024, 76, 109736. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Nian, H. Expanded Vermiculite: A Promising Natural Encapsulation Material of LiNO3, NaNO3, and KNO3 Phase Change Materials for Medium-Temperature Thermal Energy Storage. Adv. Eng. Mater. 2018, 20, 1800135. [Google Scholar] [CrossRef]

- Yaxuan, X.; Huixiang, W.; Yuting, W.; Jinhua, Z.; Haimeng, L.; Qian, X.; Xingxing, Z.; Chuan, L.; Yulong, D. Carbide slag based shape-stable phase change materials for waste recycling and thermal energy storage. J. Energy Storage 2022, 50, 104256. [Google Scholar] [CrossRef]

- Xiong, Y.; Fan, Y.; Wu, Y.; Ren, J.; Li, X.; Yao, C.; Zhao, Y.; Xu, Q.; Ding, Y. Low-carbon shape-stable phase change composite utilizing semi-coke ash for building thermal energy storage. Sol. Energy Mater. Sol. Cells 2024, 270, 112823. [Google Scholar] [CrossRef]

| Distinguish | Sintered RM | Bayer RM | Combined RM |

|---|---|---|---|

| Preparation method | Hematite powder is sintered to form solid lumps at high temperatures. | Raw materials reacted with alkaline solutions through chemical reactions, and then prepared by precipitation, filtration, and drying. | By mixing sintered RM and Bayer RM in a certain proportion, which combines the characteristics of the two RMs to obtain better material properties. |

| Material Performance | High stability and mechanical strength; Lower porosity and a higher density; Good thermal conductivity. | High purity and finer particle size; Good plasticity and machinability; Low density and thermal conductivity. | High stability and mechanical strength; Low density and good machinability. |

| Thermal storage performance | With high density and thermal conductivity, can effectively absorb and conduct heat, and release heat quickly. | The TES performance is relatively weak, but can still absorb and release a certain amount of heat. | In terms of heat storage performance, it shows good comprehensive characteristics, with high heat conduction performance and certain heat storage capacity. |

| RM Type | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | Na2O | K2O | TiO2 | Burn Vectors |

|---|---|---|---|---|---|---|---|---|---|

| Sintered RM | 3~20 | 2.0~8.0 | 10.0~20.0 | 30.0~60.0 | — | 2.0~10.0 | — | 0.01~10 | 10.0~15.0 |

| Bayer RM | 20~23 | 46.0~49.0 | 5.0~7.0 | 7.0~10.0 | 1.2~1.6 | 2.0~2.5 | 0.2~0.4 | 2.5~3.0 | 6.0~10.0 |

| Combined RM | 20~20.5 | 43.7~46.8 | 5.4~7.5 | 6.1~7.5 | — | 2.8~3.0 | 0.5~0.7 | 6.1~7.7 | — |

| Compare Content | Sintered RM | Bayer RM |

|---|---|---|

| Average particle size (µm) | 28.5 | 14.8 |

| Density (g/cm3) | 3.26 | 2.70 |

| Specific gravity | 2.47 | 2.64 |

| Mass loss in heat treatment (%) | 6.5 | 3.2 |

| Bond strength (kPa) | 287 | 14.6 |

| Stability and water conductivity | Better | Weaker |

| Main applications | Road construction, building materials, cement production, environmental protection, and desulfurization | The main filling material for the dam body construction of the storage yard, the production of cement, the manufacture of ceramics and refractories. |

| ESCs | PCM, wt.% | Operating Temperature Range, °C | Latent Heat, J/g | TES Density, J/g | Thermal Conductivity, W/(m·K) | Mechanical Strength, MPa | Ref. |

|---|---|---|---|---|---|---|---|

| NaNO3/SS incinerated ash | 50 | 100–400 | 60.33 | 409.25 | 0.955 | 139.65 | [62] |

| Solar salt/RM | 50 | 25–400 | 58 | / | 0.77–0.83 | / | [137] |

| Paraffin/RM | 55 | 50–100 | 40 | / | / | / | [61] |

| Solar salt/RM | 60 | 25–500 | 65.47 | / | / | / | [12] |

| NaNO3/Desulfurization gypsum-carbide slag (7:3) | 50 | 100–400 | 77.38 | 483.2 | 1.548 | 134.1 | [141] |

| Myristic acid/Resin | 60 | 25–100 | / | 210.8 | / | 25–34 | [142] |

| NaNO3/Ca(OH)2 | 60 | 140–340 | 102.8 | 417 | / | 108 | [143] |

| NaNO3/Semi-coke ash | 47 | 100–400 | 69.54 | 424.91 | 1.844 | 113.82 | [49] |

| Na2CO3/Carbide slag | 47.5 | 100–900 | 81.10 | 993 | 0.62 | 22.02 | [144] |

| NaNO3/Steel slag-carbide slag (5:5) | 50 | 100–400 | 74.1 | 371.1 | 1.263 | 131.2 | [145] |

| KNO3/expanded vermiculite | 87 | 243.1–325.1 | 83.8 | / | 0.33 | / | [146] |

| Na2CO3/Carbide slag | 50 | 100–400 | 59.61 | 447 | 0.93 | 73.6 | [147] |

| Li4(OH)3Br/MgO | 70 | 40–350 | 149 | / | 0.626 | / | [38] |

| n-octadecane/Kaolinite | 30 | 25–600 | 81.8 | / | / | / | [54] |

| Na2CO3/Semi-coke ash | 47.5 | 100–900 | 62.9 | 961.58 | 1.306 | 23.57 | [148] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Zhang, A.; Zhao, Y.; Xu, Q.; Ding, Y. A Mini Review on Sewage Sludge and Red Mud Recycling for Thermal Energy Storage. Energies 2024, 17, 2079. https://doi.org/10.3390/en17092079

Xiong Y, Zhang A, Zhao Y, Xu Q, Ding Y. A Mini Review on Sewage Sludge and Red Mud Recycling for Thermal Energy Storage. Energies. 2024; 17(9):2079. https://doi.org/10.3390/en17092079

Chicago/Turabian StyleXiong, Yaxuan, Aitonglu Zhang, Yanqi Zhao, Qian Xu, and Yulong Ding. 2024. "A Mini Review on Sewage Sludge and Red Mud Recycling for Thermal Energy Storage" Energies 17, no. 9: 2079. https://doi.org/10.3390/en17092079