Abstract

The ongoing challenge to ensure a sustainable and affordable energy supply forces industrial companies to transform their energy system. This transformation usually leads to an increase in topological complexity, which in turn results in increased operational complexity. Existing approaches from the field of supervisory and optimal control are capable of mastering complex operational problems. However, due to the complex and non-transparent implementation, there is still no industrial penetration, which hinders the necessary transformation of energy systems. This work aims at establishing trust in these control approaches and presents a procedure model for the systematic development of application-oriented operating strategies for industrial energy heating systems. It combines research approaches from the fields of sequencing control and approximate MPC to extract rule-based operating strategies, which are inherently easy to understand and implementable. By splitting the procedure model into five phases, expert knowledge can be integrated in a targeted manner. The procedure model is validated by the exemplary application to an industrial heating supply system. As part of an optimization study, the operating strategy developed is compared with both an MPC strategy and a baseline strategy. While the conventional MPC approach represents the upper limit of optimality, the operating strategy developed is able to achieve comparable results. Compared to the baseline strategy, a relative reduction in operating costs of 5.4% to 37.0% is achieved.

1. Introduction

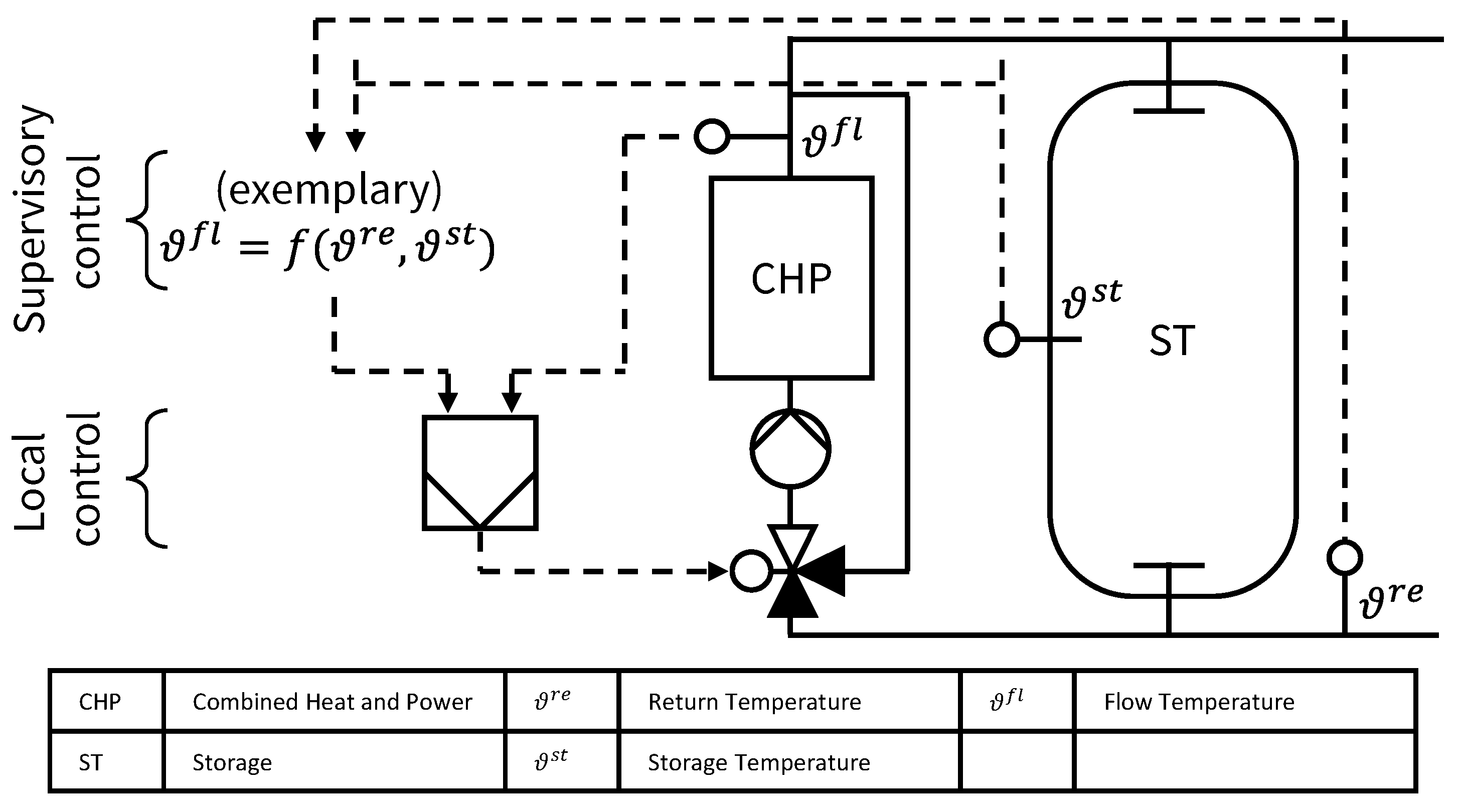

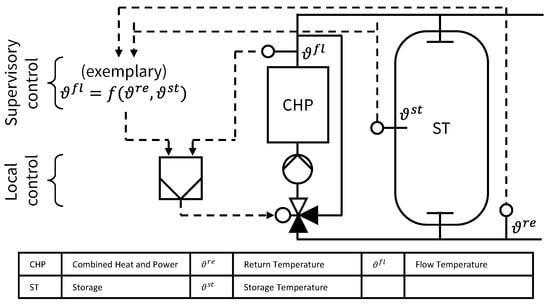

The commitment towards climate neutrality and the latest developments in the energy markets underline the complexity of the task to ensure a resilient, sustainable and affordable energy supply. This particularly applies to industrial companies, as the industrial sector accounts for 38% of the total final energy demand [1]. Due to the high relative share, transformation of industrial energy systems is a necessity to achieve climate goals. Potential transformative measures are the increase in energy efficiency or the utilization of renewable energies (e.g., via electrification) [2]. Typically the transformation of energy systems leads to an inevitable increase in topological complexity, which is accompanied by an increased operational complexity [3]. Therefore, the development of operating strategies, which are capable of mastering complex operating tasks, is essential [4,5]. Roth defines the task of operating strategies as the control of complex systems or multiple interacting systems such that operating options are selected according to overarching objectives [6]. For the control of industrial energy supply systems, overarching objectives are of economical or ecological nature. The operating options again depend on the application. Here, Salsbury defines central plants, distribution systems and terminal units as main groups [7]. Central plants contain energy converters like CHP plants, HP or CT to provide heating, cooling or electricity. In terms of thermal energy, typically water or water-based distribution systems are used to transport the provided energy to its destination. The actual application of the energy is controlled by the so-called terminal units. For heating or cooling supply systems, relevant components are radiators or heat exchangers in combination with control valves. These terminal units are typically controlled by local control functions like PID or hysteresis controllers. In addition to local control functions, supervisory control functions have gained relevance. According to Salsbury, supervisory control functions operate at a higher level than local control functions in the conceptual hierarchy of an operating strategy. More specifically, a supervisory control function may apply different setpoints or mode changes to local control functions [7]. The specification of setpoints through a supervisory control function is illustrated in Figure 1. At the local level, a conventional controller (e.g., PID controller) influences a control valve such that the desired flow temperature is achieved. At the supervisory level, a supervisory control function defines as a function of the return temperature as well as the ST temperature . In addition to the specification of setpoints, a supervisory control function may also decide on mode changes like the on/off status of one or multiple converters (also referred to as sequencing control). The nature of the supervisory control function depends on the application. Wang et al. differentiate supervisory control functions in model-based methods, model-free methods, hybrid methods and performance map-based methods [8]. Within model-based methods, a model of the underlying system is used to decide on specific actions. An example of model-based supervisory control is MPC. Within model-free methods, no specific model is used to decide on actions. Hybrid methods combine model-based and model-free methods or different types of models. An example of a hybrid method is a reinforcement learning approach, where physical models and black-box models are combined. Performance map-based methods rely on expert knowledge. Here, simulation results or operational data are used to construct a performance map, which decides on the actions during operation. Although the topic of supervisory control plays an important role in research, the above-mentioned approaches are not yet widely used in industry. According to a survey conducted by Royapoor et al., practitioners from industry see a lack of academias’ direct engagement, and the complexity and performance uncertainty of the approaches as the greatest obstacles to their adoption [9]. Despite the reluctance to use supervisory control concepts, we are not aware of any research that focuses on increasing industrial penetration. Following Mandasini et al., who state that the validity and trustworthiness of scientific research outcomes is increased by applying structured approaches, we argue that a procedural development process can increase practitioners’ acceptance [10]. Therefore, the main goal of this work is to contribute to the development of application-oriented operating strategies, which are implementable for industrial energy systems, to eventually increase the industrial penetration. Application orientation should be ensured by the following two criteria. Firstly, the ability to formulate rule-based operating strategies, as these are easily implementable into a state-of-the-art PLC and understandable to the operators. Secondly, the ability to integrate and rely on expert knowledge throughout the development process. During the course of this work, a procedure model is outlined which considers the above-mentioned aspects. It combines existing research approaches in a structured way to create a framework for the development of application-oriented operating strategies. We argue that it provides an important methodological approach to enable operators of industrial energy systems to apply sophisticated operating strategies and thus close the gap between the increasingly complicated and non-transparent operating strategies from science and operators’ reality. It can be applied during the commissioning of new systems, extension of existing systems or improvement in general, e.g., in the course of energy consulting. By splitting the procedure model into five phases, the competencies and expert knowledge of different stakeholders (e.g., energy management department, energy consulting firms as well as plant or automation engineering department) can be combined in a targeted manner. Within Section 2, the applied scientific methods for the development of the procedure model are presented. Section 3 illustrates the mentioned procedure model. It is applied to an industrial heating supply system as an example in Section 4. The focus lies on modeling aspects while still outlining the remaining phases of the procedure model. Throughout an optimization study, a performance assessment of the developed operating strategy is conducted. In Section 5, we close with a discussion on the advantages and disadvantages of the presented approach as well as a conclusion and an outlook on further research activities.

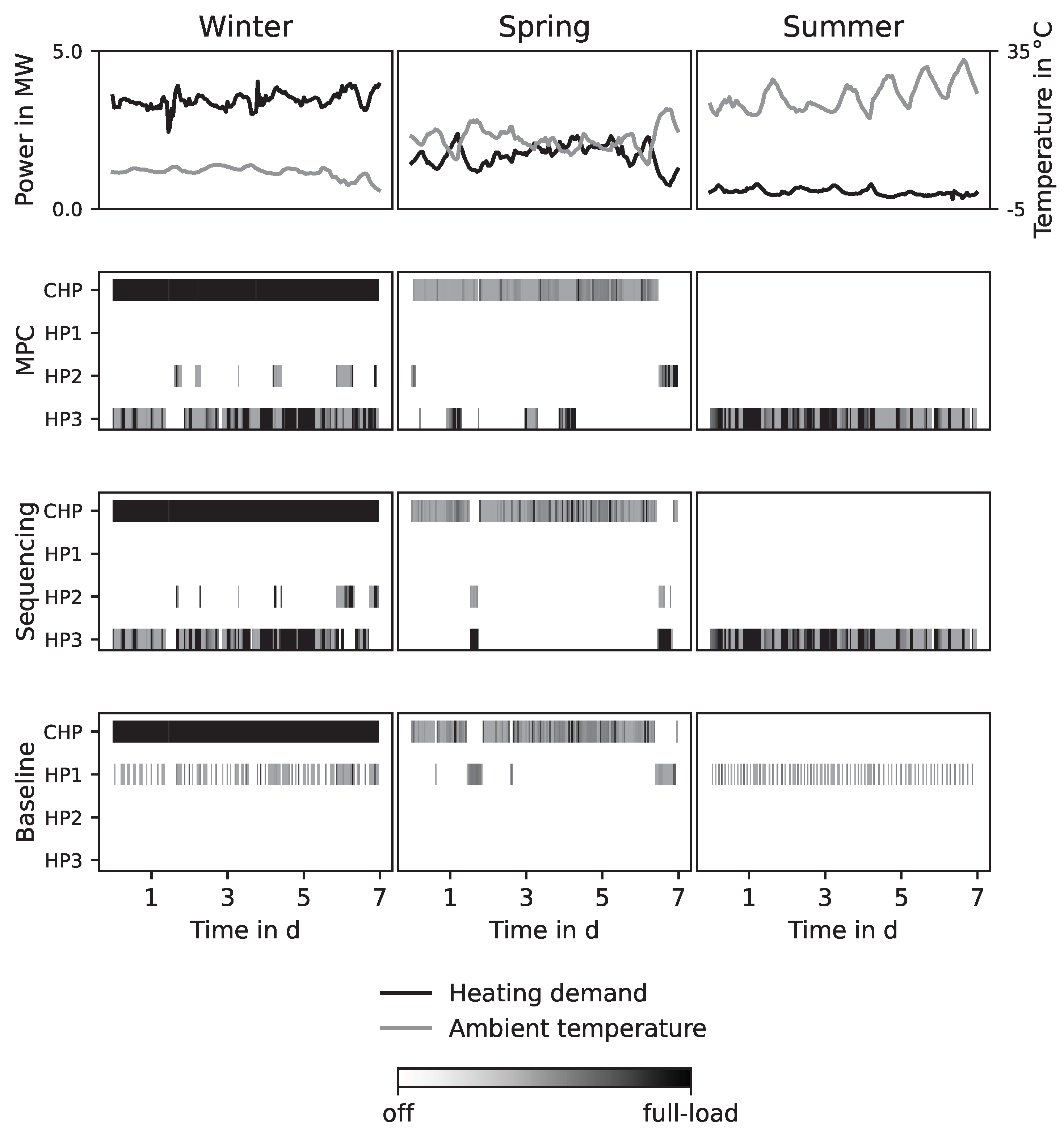

Figure 1.

Exemplary distinction between local and supervisory control functions.

2. Methodology

This section portrays the applied methodology for the development of the procedure model presented in Section 3. Since the formulation of rule-based operating strategies is relevant for application orientation, the corresponding methods are derived from sequencing control and approximate MPC. In the Section 2.1 and Section 2.2, we describe the mentioned methods and related scientific work.

2.1. Sequencing Control

The aim of sequencing control is to optimize the operation of multiple converters by deciding on their prioritization. The advantage is that the resulting operating strategy is generally already formulated rule-based. In academia, these approaches are often applied to chiller systems, for example, in [11,12,13,14]. In [11], Huang et al. developed a method which optimizes the load distribution between multiple chillers as well as the condenser setpoint temperature. This is performed by optimizing the value of so-called critical points. If the cooling load exceeds the critical point, the next chiller is activated. The method is subsequently applied to a simulation case study of three chillers, indicating energy efficiency gains especially during transition periods. Despite addressing a similar problem (load distribution and water temperature), Karami et al. present a different approach. In [12], they use a physical simulation model in combination with a particle swarm optimization to optimize the chilled water temperature setpoint, the condenser water temperature setpoint as well as the chiller sequence. The results indicate maximum energy savings of up to 13.6%. To deal with measurement uncertainties, Zhuang et al. developed a risk-based approach to optimize chiller sequencing control [13]. The results show that the generated operating strategy is able to improve reliability of the chiller sequence control while decreasing energy consumption. In summary, it can be said that the sequence control approaches presented are able to generate advantages with regard to the chosen optimization objective. At the same time, the approaches typically require that the factors influencing the sequence are defined during model formulation. This can be a challenge, especially for complex systems.

2.2. Approximate MPC

Approximate MPC approaches generally use physical models (e.g., MILP models) to create an optimal schedule. The schedule is then analyzed to extract rules that approximate the model (and its optimization). In [15], Stoffel et al. conduct a comparative study of advanced operating strategies including different MPCs, reinforcement learning as well as approximate MPC approaches. The approaches are applied to the example of a ventilation system and compared with regard to energy savings as well as qualitative criteria. As a result, Stoffel et al. find an energy saving potential of about 5% for the approximate MPC algorithm, whereas the conventional MPC approach reaches an energy saving potential of about 8%. Regarding qualitative criteria, Stoffel et al. state an advantage of approximate MPC in the fields of data quality dependence as well as transferability. At the same time, disadvantages with regard to adaptability and know-how dependence are outlined. An algorithmic approach, which appears to be suitable for sequencing control problems, is presented in [16]. Here, Domahidi et al. present an approach to approximate binary decisions (e.g., load, deload) by the so-called adaboost algorithm. More systematic approaches are presented in [17,18]. In [17], Drgona et al. develop a neural network approximation of detailed MPC building operating strategies. The main steps are a linearization of the building model, MPC performance evaluation as well as model selection, training and tuning. In [18], Maier et al. illustrate a similar approach which is reduced to four steps including clustering, operation optimization, rule mining as well as evaluation and interpretation. Here, the approach is applied to an HP system, deciding between five specific operating modes. To approximate the optimal schedule, random forest models are applied. To summarize, a lot of research has been conducted on approximating optimal operating strategies and on specific algorithms to solve this problem. Nevertheless, the approaches typically lack generalization, especially with respect to the optimal operating strategies. Moreover, the integration of expert knowledge (e.g., in the context of approximation) is hardly considered.

3. Results

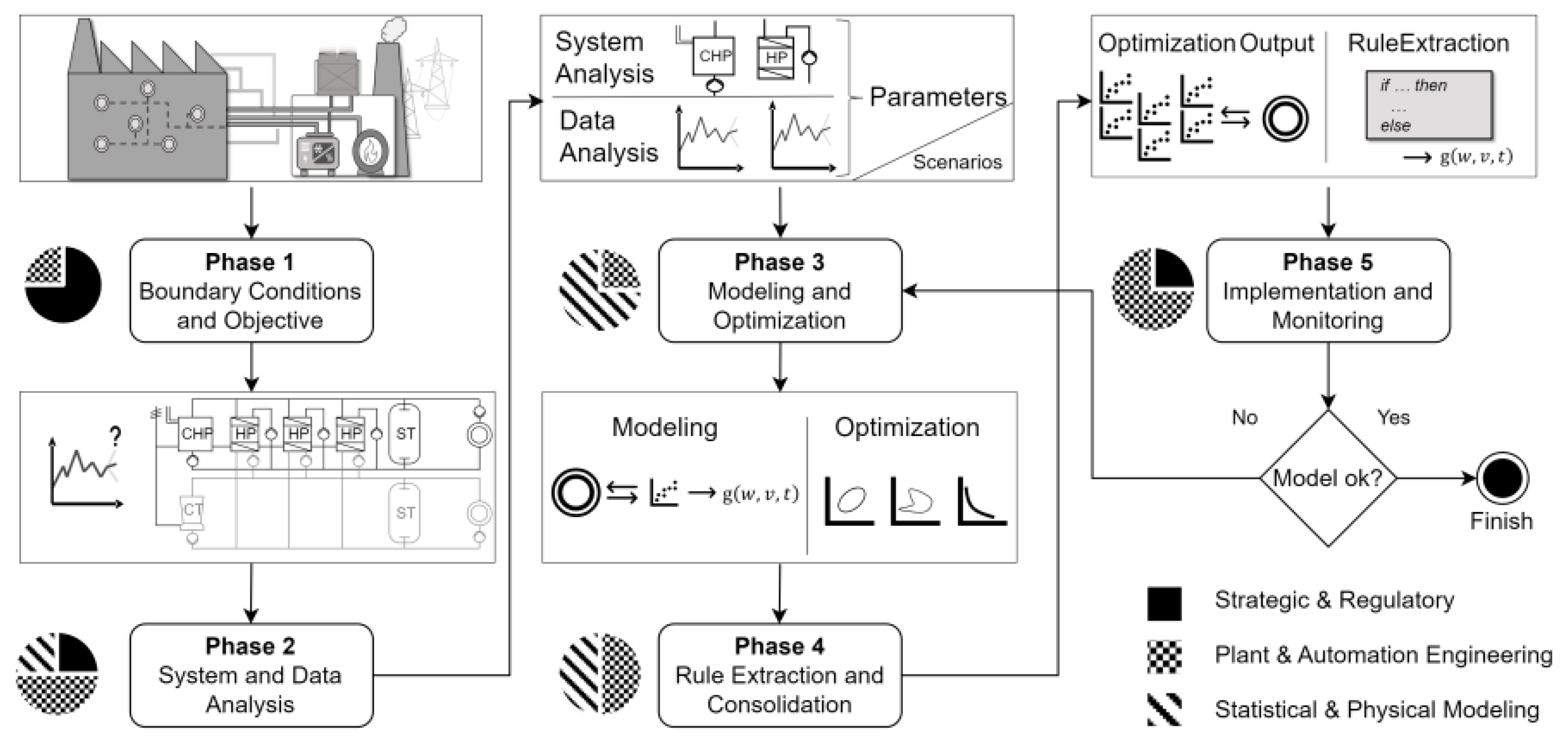

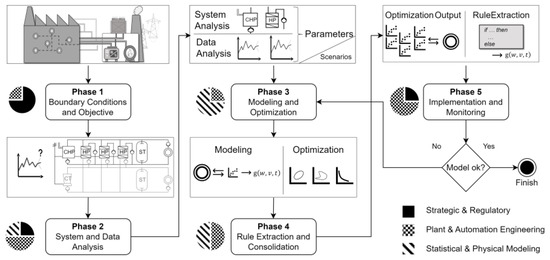

This section presents the procedure model we developed. It is illustrated in Figure 2 and aims at supporting users throughout the development of application-oriented operating strategies. The required competencies are segmented into the fields of strategy and regulation, plant and automation engineering and statistical and physical modeling. As the rule-based nature of the operating strategy is seen as a main requirement, phases two (Section 3.2) to four (Section 3.4) are inspired by the approximate MPC and sequencing control approaches, described in Section 2.2, and presented in [18]. Section 3.1, Section 3.2, Section 3.3 and Section 3.4 describe each phase with its main findings as well as the contribution of each stakeholder. Section 4.5 presents the implementation and monitoring phase.

Figure 2.

Flow chart of the procedure model and qualitative distribution of necessary competencies.

3.1. Phase 1: Boundary Conditions and Objective

The goal of the first phase is to develop a common understanding of the underlying task. For that, it is necessary to specify the boundary conditions. This means that it is determined for which system the operating strategy is to be developed and which components (e.g., inverters or storage systems) fall within the scope of application. In addition, the objective must be defined. Thus, the question of ecological, economical or even hybrid objectives must be answered. Here, company- or site-specific aspects like energy-related taxes and incentives as well as types of energy sourcing must be considered. The aforementioned aspects underline that this phase is mainly characterized by strategic and regulatory tasks. In practice, it is likely that this phase will be led by the energy management department and/or energy consulting firms, bringing together specialist departments if necessary.

3.2. Phase 2: System and Data Analysis

The second phase is divided into two subtasks: system analysis and data analysis. The aim of the system analysis is to obtain a detailed understanding of the underlying technical system to determine the scope for action of the operating strategy. For this purpose, possible operating modes (e.g., heat- or electricity-led) must be determined for all components. Additionally, it is necessary to specify operating ranges with regard to the minimal load as well as continuous or discrete control characteristics. Finally, the factors influencing the performance of the components must be determined. These may be system internal such as the predominant demand and therefore the utilization rate of the converters, or system external such as ambient conditions. Once the influencing factors have been identified, the data analysis must be carried out. The goal is to determine scenarios which are representative for the subsequent application of the operating strategy. This can also include the extrapolation of influencing factors which may change in the future, like energy prices or demands. The second phase concludes with the definition of scenarios that may require an adjustment or reformulation of the operating strategy, as rule-based approaches generally have disadvantages in terms of adaptability. The described tasks and findings emphasize the importance of expert knowledge during the second phase. As a profound understanding of the technical system and its operating behavior is necessary, expertise in the field of plant engineering as well as statistics is required.

3.3. Phase 3: Modeling and Optimization

In the third phase, optimized schedules for the technical system are created. This is performed by developing a system model which is then optimized for each scenario. Both the modeling and the optimization are based on the interim results of the second phase (Section 3.2). It is mandatory that the system model represents the technical system’s behavior as well as the scope of action of the operating strategy. Therefore, experts from the field of plant and automation engineering will still be enrolled in the third phase, even though the main tasks are from the field of statistical and physical modeling. It should be noted that expertise in the field of statistical and physical modeling is not very widespread in industrial companies—especially with regard to energy systems. Therefore, companies may rely on external expertise (e.g., energy consulting firms) in this phase.

3.4. Phase 4: Rule Extraction and Consolidation

Within the fourth phase, the operating strategy is created based on the optimized schedules of phase three. For that, machine learning-based approaches are most frequently applied in the literature. Even if these approaches are numerically efficient, expert knowledge can still be integrated in this phase. To achieve a balance between the quality and complexity of the operating strategy, it can be advantageous to consider only a subset of the total operating states. The factors that influence the selection of certain operating states can also be narrowed down using the findings from earlier phases. The outlined tasks require profound competencies in statistics and data-driven approaches. At the same time, a solid understanding of the underlying technical system is necessary.

3.5. Phase 5: Implementation and Monitoring

The actual implementation of the derived operating strategy is conducted in phase five. This phase is based on expertise from the field of automation engineering. However, due to disadvantages of rule-based approaches in terms of adaptability, it is necessary to conduct a monitoring of the strategy during operation. This may include an assessment of the model quality of the third phase (Section 3.3) and a review of whether certain events (e.g., significant changes in energy procurement) may require a reformulation of the operating strategy.

4. Application and Evaluation

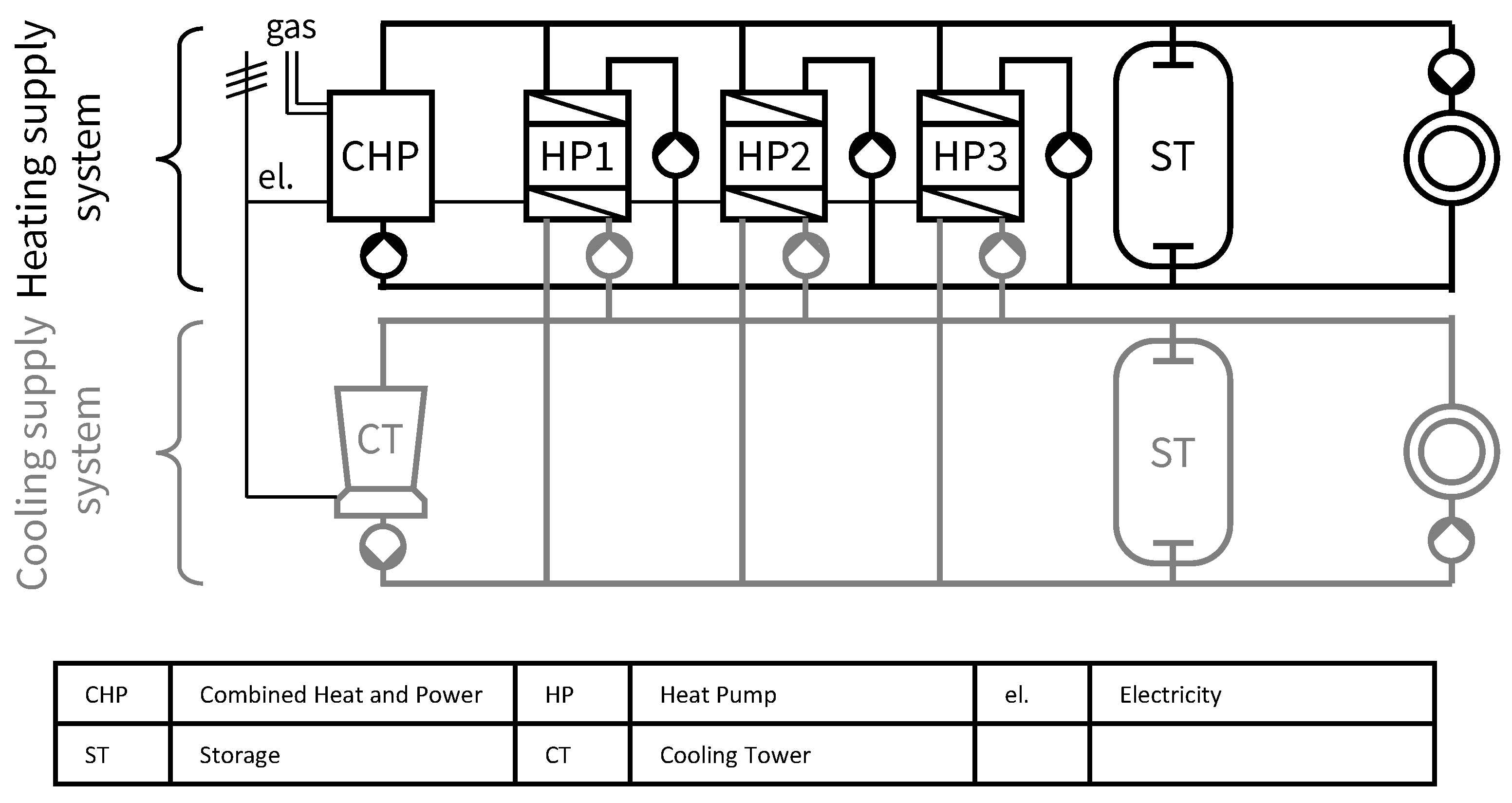

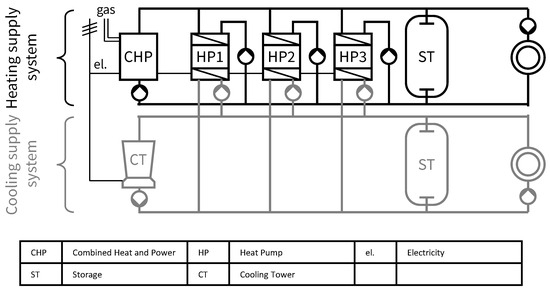

Within the following section, the procedure model is applied to the example of an industrial heating supply system, illustrated in Figure 3. While phase three (Section 3.3) is focused, the remaining phases are still conducted as examples.

Figure 3.

Use case of an industrial heating supply system.

4.1. Boundary Condition and Objective

The heating supply system consists of one CHP and three HPs as converters, and a buffer storage as well as a network for heat distribution. The HPs are connected to a cooling supply system to use industrial waste heat as an energy source. The cooling supply system is also equipped with a CT. However, throughout this exemplary application, the operating strategy focuses on the heating supply system, determining the optimal converter utilization regarding economic objectives. Here, operating expenses are influenced by the use of the final energies natural gas and electricity. Regarding energy sourcing, conventional supply contracts including peak and off-peak tariffs are assumed. As the heating supply system is a part of a larger industrial site, the CHP’s generated electricity leads to a reduced electricity purchase, not to grid feed-in.

4.2. System and Data Analysis

This phase builds on the interim results of the previous phase. Due to the technical system design and the focus on the heating supply system, it is assumed that all converters (CHP and HP) are operated heat led. Therefore, the operating strategy must decide on the optimal converter control sequence within the heating supply system. As the defined objective is primarily influenced by the amount and temporal course of the purchased final energies, the temporal utilization of the converters as well as their efficiencies are of key interest. Here, the part load as well as thermal efficiencies are important. The thermal efficiencies are influenced by the required flow temperatures. In heating networks, these are typically adjusted according to the ambient air temperature. The system analysis carried out clarifies the scope of action of the operating strategy. Key parameters of the heating supply system are outlined in Table 1.

Table 1.

Parameters of the converters within the industrial heating supply system.

By analyzing the influences on the objective, influencing factors are determined. These are the predominant heating demand due to part load efficiencies, the flow and ambient temperature due to thermal efficiencies as well as final energy prices. As both the heating requirement and the flow temperature depend on the ambient temperature, a total of ten representative days are selected for the latter.

4.3. Modeling and Optimization

As stated in Section 3.3, the modeling and optimization phase must consider not only the technical system’s behavior but also the scope of action of the operating strategy. Therefore, the following subsection is divided into two paragraphs: the operating strategy model formulation and the technical system model formulation. The actual optimization will not be described in detail, as commonly available frameworks and solvers are applied.

4.3.1. Operating Strategy Model Formulation

Subsequently, a model formulation for the optimization of sequencing control problems is outlined. In contrast to existing sequencing control approaches, the presented model formulation does not rely on the definition of specific influencing factors beforehand. Because of this, the model formulation can be applied to a broad range of technical systems (see Section 2). The model formulation is characterized by the definition of two variables. Firstly, by the binary variable , which defines whether converter is at priority at time step . Secondly, by the binary variable , which defines whether the activation of a specific converter is allowed with regard to the sequencing control approach. In addition to the variables mentioned, Equation (1) ensures that each priority within the sequence is occupied by exactly one converter. On the other hand, Equation (2) ensures that each converter occupies exactly one priority.

The activation of a specific converter through is limited by in Equation (3). Based on this, a converter can only operate once it is set to the given priority. Additionally, as stated in Equation (4), activation is dependent on the relative utilization of the less prioritized converter, with and .

Finally, can then be used to control the activation of a specific converter as illustrated in Equation (5). Here, the heating power of a specific converter is limited by and M, with and large enough.

4.3.2. Technical System Model Formulation

Within this paragraph, the model formulation of the technical system is described. The model is formulated as a MILP, simplifying the system’s behavior to power and energy balances. The general system behavior of the CHP is outlined in Equations (6) and (7). Here, not only efficiencies ( and ) but also a simplified part load behavior is considered. This is carried out by penalizing the system’s power balance through the binary variable . Thus, defines whether the CHP is activated from time step to .

Further part load constraints are defined in Equations (8)–(11). Here, is influenced by the binary variable , which defines the activation status of the CHP. The activation status, in turn, determines the allowed operating range (Equations (10) and (11)). Here, defines the minimal relative utilization with and .

The interaction between the operating strategy and the technical system is illustrated by Equation (12). Here, the relative utilization variable from the prior subsection is defined as the fraction of the actual and rated gas consumption of the CHP. The CHP is therefore regarded as an entry of the converter set .

As displayed by Equations (13) and (14), the system behavior of the HP is modeled according to the CHP. However, the thermal efficiency of the HP is influenced by the COP and, therefore, the flow temperatures of the heating and cooling network ( and ). The ideal COP is adjusted by the correction factor .

Even though not being within the scope of the operating strategy, the influences on the CT’s operation still need to be considered, as they influence the objective. As displayed in Equation (15), the CT’s system behavior is modeled depending on its EER. The EER, however, is modeled as a linear function of the ambient temperature, assuming dry cooling.

The heat storage is implemented by a basic energy balance, displayed in Equation (16). Here, represents the predominant heating demand and the duration of one time step. The same holds true for the cool storage and network.

Finally, Equation (17) defines the objective function. As stated beforehand, the objective is to minimize operating expenses, which are influenced by the final energy prices of electricity and natural gas .

4.4. Rule Extraction and Consolidation

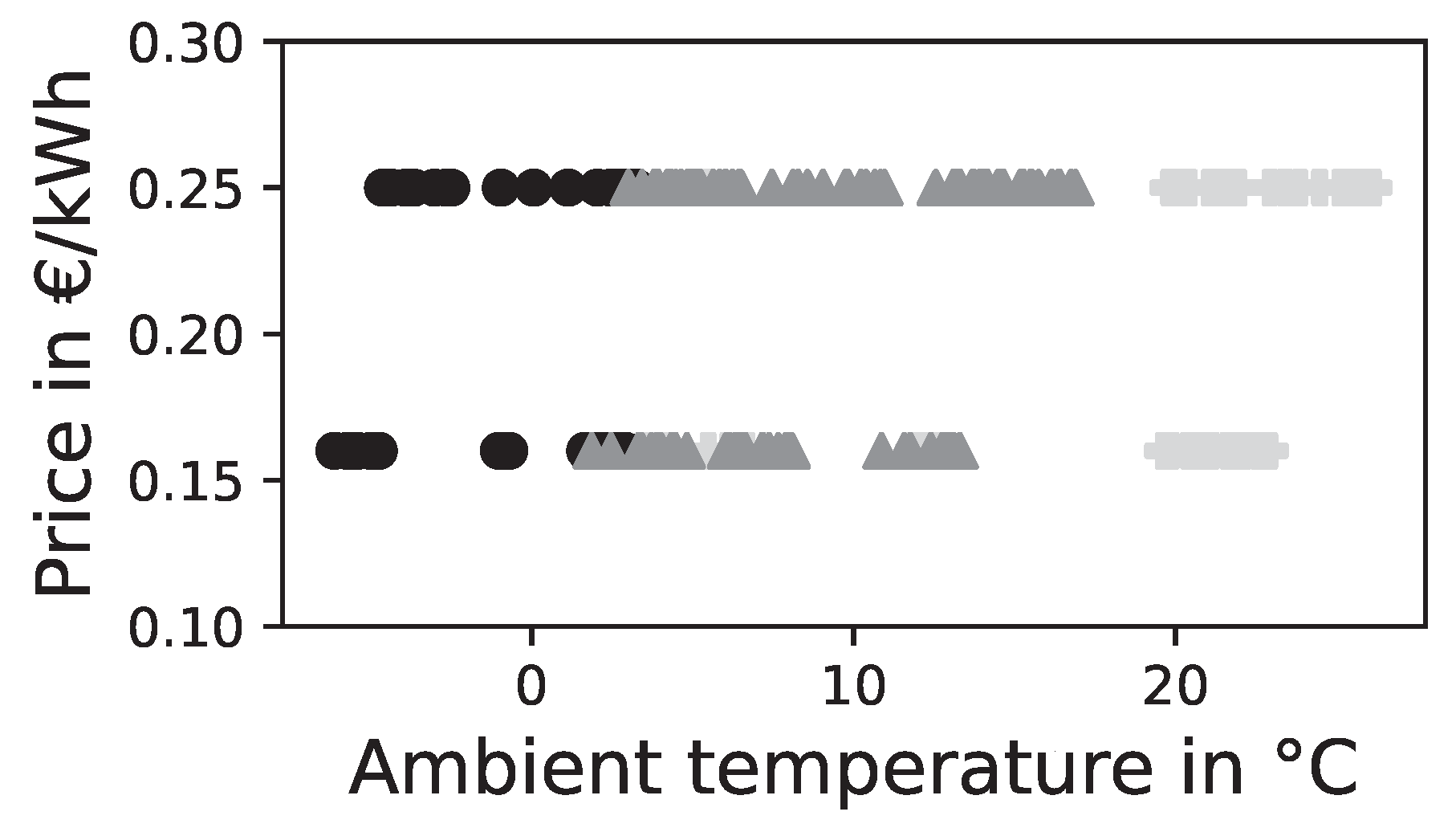

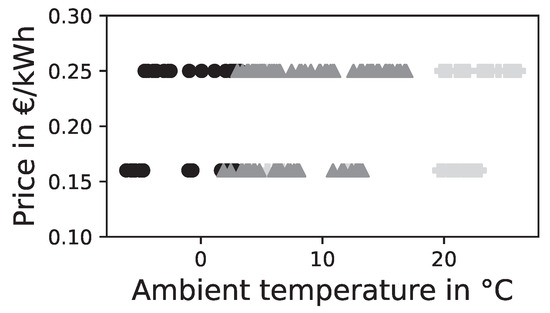

Throughout this section, the rule extraction and consolidation of the operating strategy will be described. As the technical system model considered is rather simple, we do not apply complex machine learning approaches but rely on information gathered in prior phases. In phase two (Section 4.2), final energy prices and the ambient temperature are already identified as the main influencing factors. Therefore, it can be analyzed as to which converter sequence is chosen based on those factors. This is illustrated in Figure 4. It can be observed that the selected converter sequence (highlighted by different shades of gray) is mainly influenced by the ambient temperature and less by the electricity price. Even if there are some outliers, the ambient temperature is chosen as the only influencing factor. Within Table 2, the sequence sets are displayed. Here, not only the converter priority but also the appropriate temperature interval is defined.

Figure 4.

Selected sequence sets based on the electricity price and ambient temperature.

Table 2.

Sequence sets used to approximate the optimal schedules.

4.5. Implementation and Monitoring

In this exemplary application, the operating strategy is not implemented on a PLC of the actual system. However, the operating strategy outlined beforehand could be implemented by three if/else conditions.

4.6. Evaluation

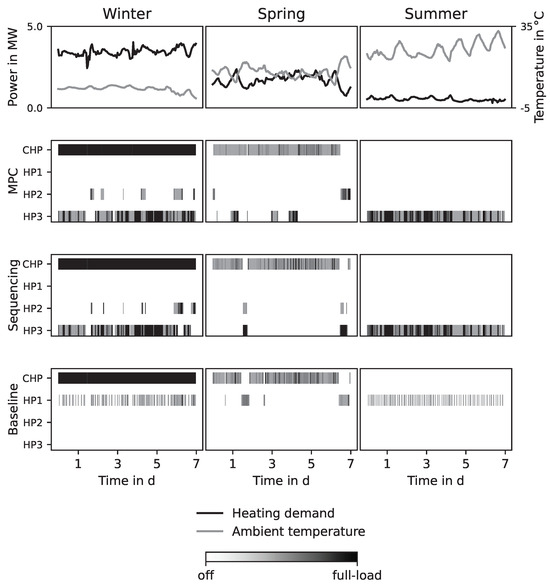

To evaluate the performance of the developed operating strategy, we conducted an optimization study, which is accessible via GitHub [19]. The applied data sets are accessible via TUdatalib [20]. The following operating strategies are compared: the baseline strategy, sequencing strategy and MPC strategy. We apply these strategies to a winter, spring and summer scenario, each with a duration of one week. Within the baseline strategy, a simple decision rule is implemented, which is defined based on qualitative assumptions. Below the heating-threshold temperature of 15 °C, the CHP is used as the prioritized converter. Above the heating-threshold temperature, the HPs are prioritized with descending rating. The sequencing strategy is the strategy outlined beforehand, including the sequence sets and their corresponding temperature intervals. The MPC strategy represents a conventional optimization approach. The scope for action is not limited to sequencing control, i.e., the load can be divided between several inverters in parallel. Figure 5 illustrates the system behavior throughout the optimization study. For each scenario and operating strategy, the converter utilization is outlined. It can be observed that the converter utilization of the MPC strategy and sequencing strategy is quite similar in all scenarios. Nevertheless, differences are apparent during the spring scenario. Here, the MPC strategy splits the load between the CHP and HP3. As load splitting between multiple converters is not in the scope of action for sequencing control approaches, the sequencing strategy changes between the utilization of the CHP and the HP. Comparing the aforementioned operating strategies with the baseline strategy outlines, it is shown that a prioritization of HP1 does lead to unfavorable system behavior. During the winter and summer scenario, the residual heating demand is not high enough for a sufficient utilization of HP1. Therefore, a high number of start-up cycles can be observed, which negatively influences the efficiency. The aforementioned aspects can also be observed in a quantitative assessment. Table 3 shows the relative reduction in operating expenses of the MPC strategy and sequencing strategy in comparison to the baseline strategy. During winter and summer, the performance benefits of both operating strategies are almost identical. During the spring scenario, the MPC strategy has considerable advantages over the sequencing strategy. However, both operating strategies lead to a significant reduction in operating expenses with regard to the baseline strategy.

Figure 5.

System behavior throughout the optimization study.

Table 3.

Relative reduction in operating expenses compared to the baseline strategy.

The optimization study outlines the importance of considering the system behavior during the development of operating strategies. At least for the given heating supply system, the developed rule-based operating strategy was able to reduce the operating expenses substantially, compared to the baseline. However, it must be noted that the illustrated approach has some limitations. Due to the applied sequencing control approach, the operating strategy will lead to suboptimal solutions because of load splitting. Additionally, a high number of influencing factors may lead to quite complex strategies, adversely affecting the implementation of rule-based operating strategies. Lastly, significant system changes may require the reformulation of the operating strategies.

5. Conclusions

In this article, we present a five-phase procedure model for the development of application-oriented operating strategies. It allows the inclusion of practitioners’ knowledge from the domains of strategy and regulation, plant and automation engineering, and statistical and physical modeling. By applying it to an exemplary industrial heating supply system, the usability is validated. With special focus on Section 3.3, we show in an optimization study that the derived operating strategy can outperform the baseline strategy with minimal implementation effort (three if/else conditions). As the presented approach was applied to a rather isolated technical system, we want to focus on more complex systems in the future. Here, the complexity with regard to multiple operating modes (e.g., heat- and electricity-led CHP) as well as the operation of storage are of particular interest. By increasing the complexity of the underlying technical system, an increased complexity of the relating operating strategy can be assumed. Thus, the rule extraction and consolidation of phase four (Section 3.4) becomes more challenging. Therefore, in future work, we want to focus on algorithmic aspects of phase four by determining which approaches are best suited for the proposed model formulation. Additionally, as flexible energy sourcing becomes increasingly important for industrial companies, we want to evaluate how rule-based operating strategies can contribute to that. The overarching goal of the aforementioned investigations is to identify the changes and limitations of rule-based operating strategies. We are aware of the benefits of pure algorithmic approaches, such as MPC. However, we consider the development and implementation of rule-based operating strategies as a way to gain confidence in even more promising, but not in detail comprehensible, operating strategies such as black-box approaches (e.g., reinforcement learning) and thus contribute to the common goal of an affordable and sustainable energy supply.

Author Contributions

L.T.: conceptualization, investigation, methodology, software and writing—original draft; M.F.: methodology, software, investigation, writing—original draft and writing—review and editing; M.W.: supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Economic Affairs and Climate Action (BMWK) grant number 03EN2048A.

Data Availability Statement

All applied data sets are accessible via TUdatalib [20]. The conducted optimization study is reproducibly published via GitHub [19].

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CT | Cooling Tower |

| COP | Coefficient of Performance |

| CHP | Combined Heat and Power |

| EER | Energy Efficiency Ratio |

| HP | Heat Pump |

| PID | Proportional–Integral–Derivative |

| MPC | Model Predictive Control |

| ST | Storage |

| PLC | Programmable Logic Controller |

| MILP | Mixed-Integer Linear Programming |

Symbols

The following symbols are used in this manuscript:

| Converter | |

| Priority | |

| Time step | |

| Binary variable for converter priority declaration at time step | |

| Binary variable for converter priority activation at time step | |

| Relative utilization of less prioritized converter | |

| Heating power | |

| M | Nominal power value |

| Thermal efficiency | |

| Electrical efficiency | |

| Binary variable for part load behavior | |

| Binary variable for part load behavior adaption | |

| Minimal relative utilization | |

| Flow temperature | |

| Correction factor for COP |

References

- International Energy Agency. Global Energy and Climate Model: Net Zero Emissions by 2050 Scenario (NZE); IEA: Paris, France, 2022. [Google Scholar]

- International Energy Agency. Industry; IEA: Paris, France, 2022. [Google Scholar]

- Lund, H.; Østergaard, P.A.; Nielsen, T.B.; Werner, S.; Thorsen, J.E.; Gudmundsson, O.; Arabkoohsar, A.; Vad Mathiesen, B. Perspectives on fourth and fifth generation district heating. Energy 2021, 227, 120520. [Google Scholar] [CrossRef]

- Fridgen, G.; Keller, R.; Körner, M.F.; Schöpf, M. A holistic view on sector coupling. Energy Policy 2020, 147, 111913. [Google Scholar] [CrossRef]

- Weidlich, I. Wärmenetze. In Erneuerbare Energien: Systemtechnik ·Wirtschaftlichkeit· Umweltaspekte; Kaltschmitt, M., Streicher, W., Wiese, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1203–1226. ISBN 978-3-662-61190-6. [Google Scholar]

- Roth, M. Betriebsstrategie. In Energiemanagement im Kraftfahrzeug; Liebl, J., Lederer, M., Rohde-Brandenburger, K., Biermann, J.W., Roth, M., Schäfer, H., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2014; pp. 323–365. ISBN 978-3-658-04450-3. [Google Scholar]

- Salsbury, T.I. A Survey of Control Technologies in the Building Automation Industry. IFAC Proc. Vol. 2005, 38, 90–100. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Z. Supervisory and Optimal Control of Building HVAC Systems: A Review. HVAC&R Res. 2008, 14, 3–32. [Google Scholar]

- Royapoor, M.; Antony, A.; Roskilly, T. A review of building climate and plant controls, and a survey of industry perspectives. Energy Build. 2018, 158, 453–465. [Google Scholar] [CrossRef]

- Mandasini, A.A. Improving the Validity of Scientific Research Results through Research Methodology Management. Kontigensi J. Ilm. Manaj. 2022, 10, 439–447. [Google Scholar] [CrossRef]

- Huang, S.; Zuo, W.; Sohn, M. A New Method for the Optimal Chiller Sequencing Control. In Proceedings of the Building Simulation 2015: 14th Conference of IBPSA, Hyderabad, India, 7–9 December 2015. [Google Scholar]

- Karami, M.; Wang, L. Particle Swarm optimization for control operation of an all-variable speed water-cooled chiller plant. Appl. Therm. Eng. 2018, 130, 962–978. [Google Scholar] [CrossRef]

- Zhuang, C.; Wang, S.; Shan, K. A risk-based robust optimal chiller sequencing control strategy for energy-efficient operation considering measurement uncertainties. Appl. Energy 2020, 280, 115983. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, C.; Pan, X.; Yan, D. Design and operation optimization of multi-chiller plants based on energy performance simulation. Energy Build. 2020, 222, 110100. [Google Scholar] [CrossRef]

- Stoffel, P.; Maier, L.; Kümpel, A.; Schreiber, T.; Müller, D. Evaluation of advanced control strategies for building energy systems. Energy Build. 2023, 280, 112709. [Google Scholar] [CrossRef]

- Domahidi, A.; Ullmann, F.; Morari, M.; Jones, C.N. Learning decision rules for energy efficient building control. J. Process Control 2014, 24, 763–772. [Google Scholar] [CrossRef]

- Drgoňa, J.; Picard, D.; Kvasnica, M.; Helsen, L. Approximate model predictive building control via machine learning. Appl. Energy 2018, 218, 199–216. [Google Scholar] [CrossRef]

- Maier, L.M.; Henn, S.; Mehrfeld, P.; Müller, D. Approximate Optimal Control for Heat Pumps in Building Energy Systems. In Proceedings of the 34th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Taormina, Italy, 28 June–2 July 2021. [Google Scholar]

- Frank, M.; Theisinger, L.; Weigold, M. Systematic Development of application-oriented Operating Strategies at the Example of an Industrial Heating Supply System (Version 1.0.0) [Computer software]. 2024. Available online: https://github.com/MichaelGeFr/MDPI_Energies_2024_Operating_Strategies (accessed on 10 April 2024).

- Frank, M.; Theisinger, L.; Weigold, M. Systematic Development of application-oriented Operating Strategies at the Example of an Industrial Heating Supply System. 2024. Available online: https://tudatalib.ulb.tu-darmstadt.de/handle/tudatalib/4208 (accessed on 10 April 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).