The Potential of a Thermoelectric Heat Dissipation System: An Analytical Study

Abstract

1. Introduction

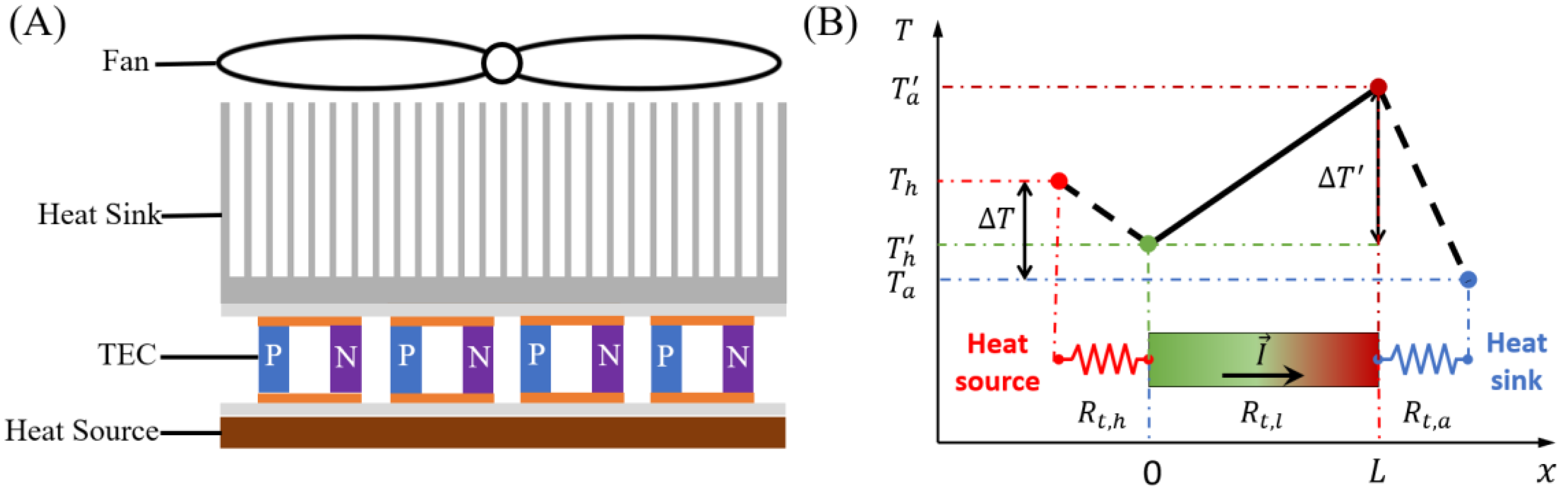

2. Analytical Model

2.1. Theoretical Model Development

- A.

- Conventional heat dissipation system

- B.

- Thermoelectric heat dissipation system

2.2. Maximum Heat Dissipation Density

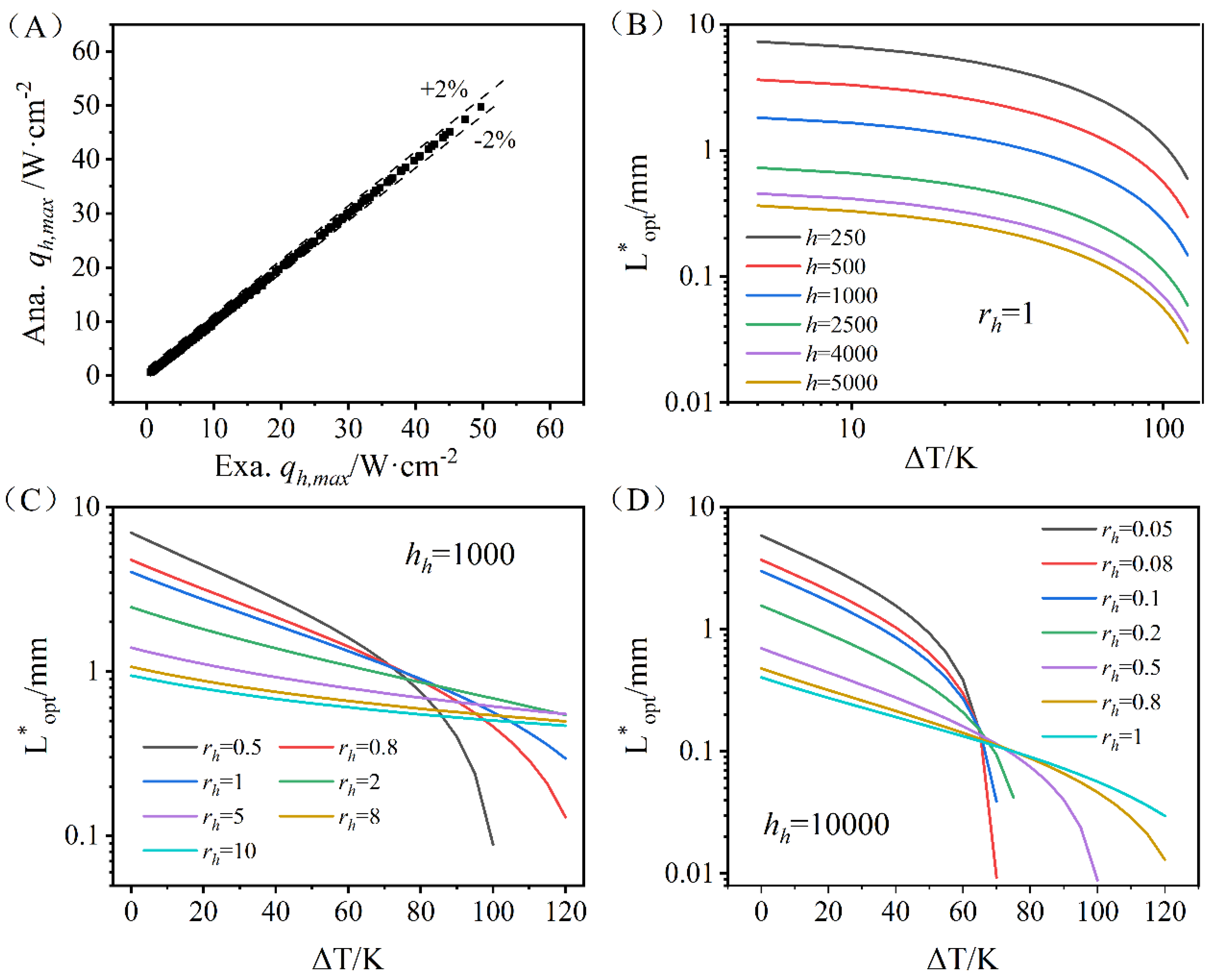

2.3. Optimal Engineering Leg Length

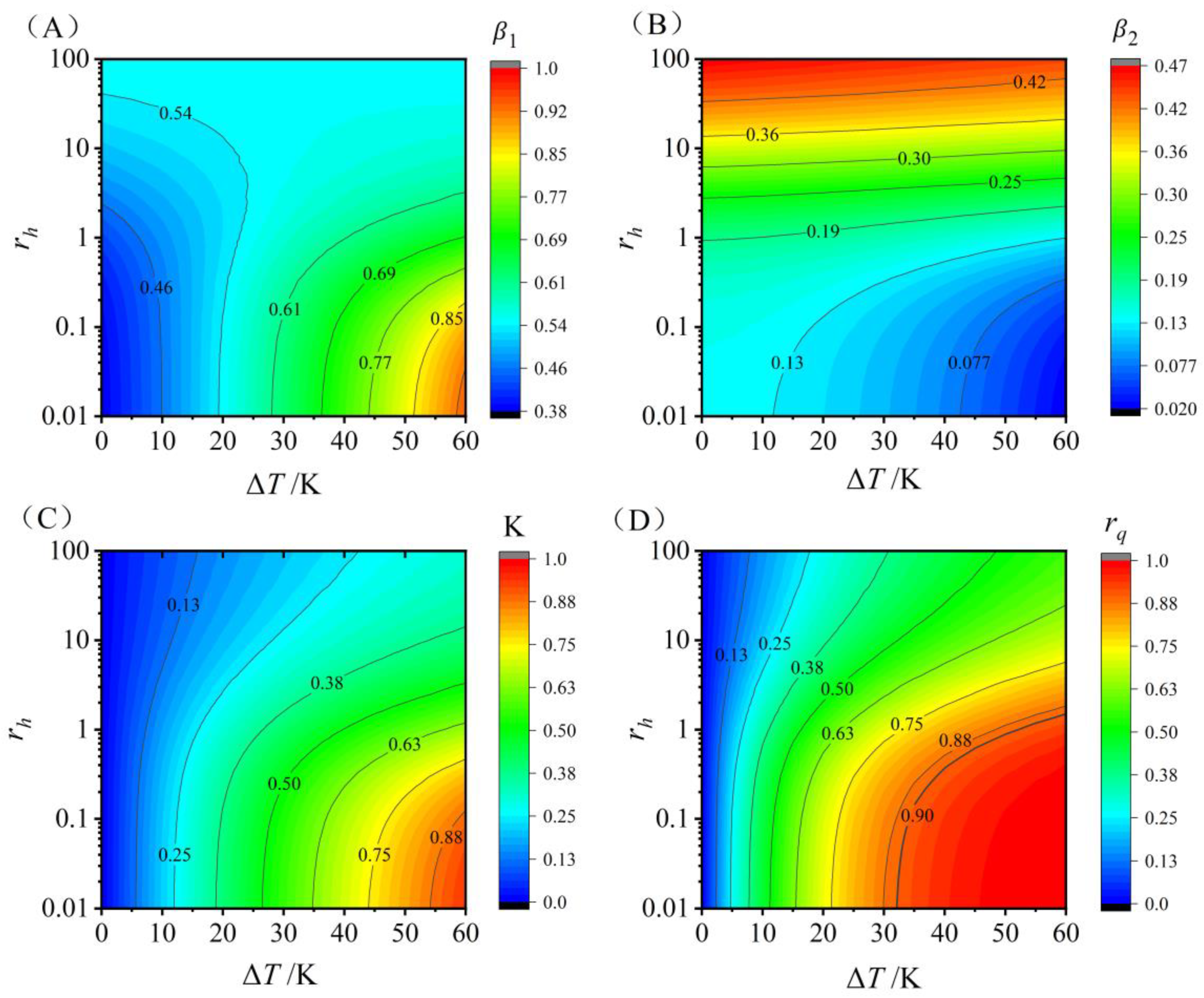

2.4. Dimensionless Evaluation Index

- (1)

- When and can be determined, we define the dimensionless evaluation index as follows:

- (2)

- For finite values of , the heat dissipation density due to thermal conduction is given by the following equation:

- (3)

- When is finite and both and , the maximum heat dissipation density can be expressed as follows:

3. Results and Discussion

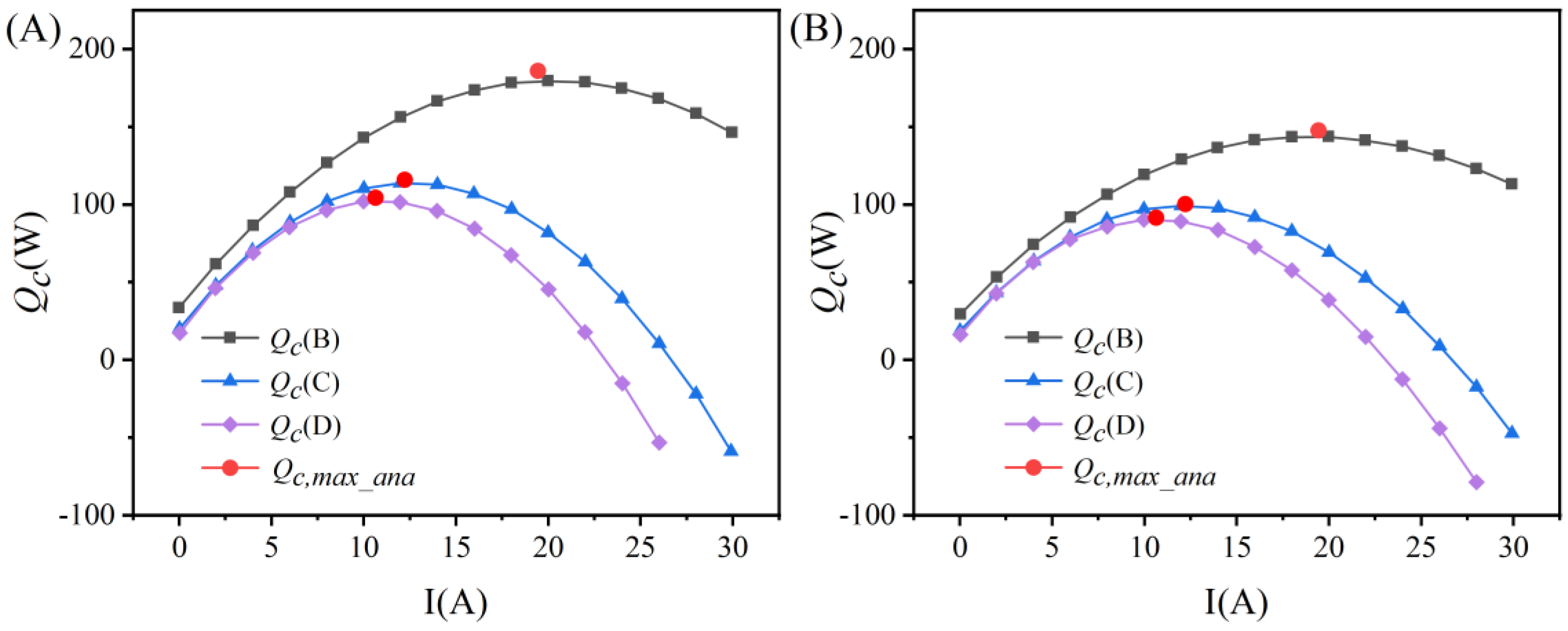

3.1. Maximum Heat Dissipation Density Analysis

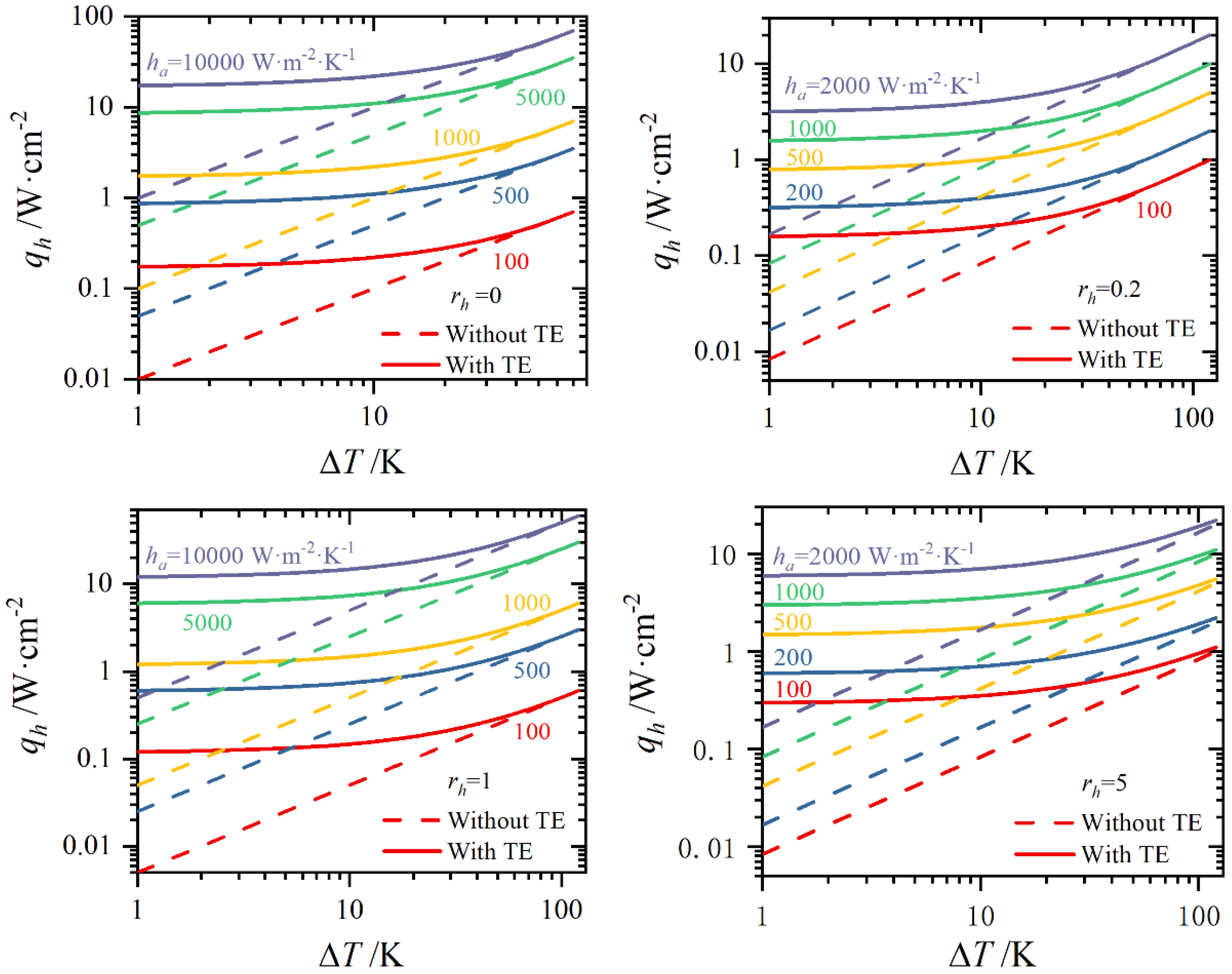

3.2. Heat Dissipation Density Under Different rh and ΔT

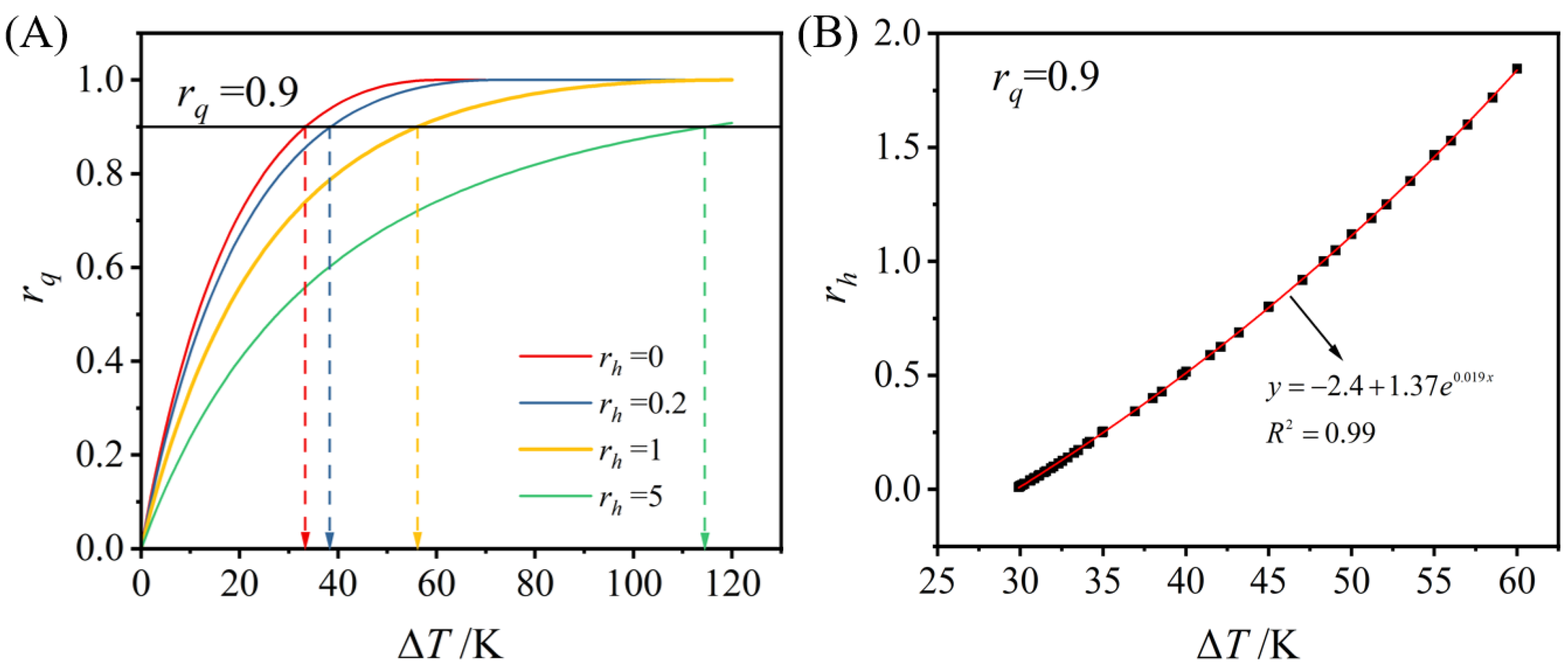

3.3. Dimensionless Evaluation Index Under Different rh and ΔT

4. Conclusions

- (1)

- For a given heat source temperature, heat sink temperature, and external heat transfer conditions, an optimal engineering leg length () exists that maximizes system heat dissipation. The selection of is strongly influenced by the system’s total heat transfer coefficient, decreasing as the coefficient increases. Enhancing the heat transfer coefficient on the heat sink side is critical for improving the performance of thermoelectric heat dissipation systems.

- (2)

- Thermoelectric heat dissipation systems demonstrate superior performance under small temperature differences (). However, for moderate temperature differences (), substantial performance is achieved when . This study provides theoretical guidance for designing and operating thermoelectric heat dissipation systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Nomenclature | |

| q | heat flux |

| S | Seebeck coefficient |

| Z | figure of merit |

| T | temperature |

| L | leg length |

| A | leg cross-section area |

| As | substrate area |

| Qc | heat dissipation power |

| P | electric power |

| COP | coefficient of performance |

| rh | heat transfer coefficient ratio |

| FF | fill factor |

| L* | engineering leg length |

| N | number of TE couples |

| I* | dimensionless electric current |

| Rt,l | leg thermal resistance |

| Rt, a | heat sink side thermal resistance |

| Rt,h | heat source side thermal resistance |

| h | heat transfer coefficient |

| f | dimensionless thermal resistance parameter |

| ΔT | temperature difference between the heat source and heat sink side |

| TE | thermoelectric module |

| TEC | thermoelectric cooler |

| Greek Letters | |

| σ | electrical conductivity |

| κ | thermal conductivity |

| SUBSCRIPTS | |

| max | maximum point |

| opt | optimal |

| com | common |

| h | heat source |

| a | ambient |

References

- Zhang, Q.H.; Deng, K.F.; Wilkens, L.; Reith, H.; Nielsch, K. Micro-thermoelectric devices. Nat. Electron. 2022, 5, 333–347. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Mui, Y.C.; Tarin, M. Analysis of thermoelectric cooler performance for high power electronic packages. Appl. Therm. Eng. 2010, 30, 561–568. [Google Scholar] [CrossRef]

- Sun, W.; Liu, W.-D.; Liu, Q.F.; Chen, Z.G. Advances in thermoelectric devices for localized cooling. Chem. Eng. J. 2022, 450, 138389. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.J.; Wang, J.J.; Zhang, M.; Jia, M.; Wang, Q. Man-portable cooling garment with cold liquid circulation based on thermoelectric refrigeration. Appl. Therm. Eng. 2022, 200, 117730. [Google Scholar] [CrossRef]

- Zaferani, S.H.; Sams, M.W.; Ghomashchi, R.; Chen, Z.G. Thermoelectric coolers as thermal management systems for medical applications: Design, optimization, and advancement. Nano Energy 2021, 90, 106572. [Google Scholar] [CrossRef]

- Han, K.; Lou, Z.K.; Xi, X.M.; Cui, W.; Song, C. Low-temperature properties of the ytterbium-doped fiber laser cooled by the thermoelectric cooler. Opt. Fiber Technol. 2022, 73, 103036. [Google Scholar] [CrossRef]

- Sun, Y.T.; Zhou, L.; Meng, F.K.; Wang, Z. Performance analysis of four-stage thermoelectric cooler for focal plane infrared detectors. Int. J. Refrig. 2024, 165, 290–302. [Google Scholar] [CrossRef]

- Shen, L.M.; Pu, X.W.; Sun, Y.J.; Chen, J. A study on thermoelectric technology application in net zero energy buildings. Energy 2016, 113, 9–24. [Google Scholar] [CrossRef]

- Han, X.; Pang, M.; Teng, C.C.; Cao, M. Analysis and optimization of effect factors of refrigeration performance of portable micro-refrigerator. Appl. Therm. Eng. 2024, 246, 122948. [Google Scholar] [CrossRef]

- Elarusi, A.; Attar, A.; Lee, H. Optimal Design of a Thermoelectric Cooling/Heating System for Car Seat Climate Control (CSCC). J. Electron. Mater. 2016, 46, 1984–1995. [Google Scholar] [CrossRef]

- Lyu, Y.; Siddique, A.R.M.; Majid, S.H.; Biglarbegian, M.; Gadsden, S.A.; Mahmud, S. Electric vehicle battery thermal management system with thermoelectric cooling. Energy Rep. 2019, 5, 822–827. [Google Scholar] [CrossRef]

- Wu, H.; Shi, X.-L.; Duan, J.G.; Liu, Q.; Chen, Z.G. Advances in Ag2Se-based thermoelectrics from materials to applications. Energy Environ. Sci. 2023, 16, 1870–1906. [Google Scholar] [CrossRef]

- Scheele, M.; Oeschler, N.; Veremchuk, I.; Reinsberg, K.G.; Kreuziger, A.M.; Kornowski, A.; Broekaert, J.; Klinke, C.; Weller, H. ZT enhancement in solution-grown Sb(2-x)BixTe3 nanoplatelets. ACS Nano 2010, 4, 4283–4291. [Google Scholar] [CrossRef]

- Cao, Y.Q.; Zhao, X.B.; Zhu, T.J.; Zhang, X.B.; Tu, J.P. Syntheses and thermoelectric properties of Bi2Te3/Sb2Te3 bulk nanocomposites with laminated nanostructure. Appl. Phys. Lett. 2008, 92, 143106. [Google Scholar] [CrossRef]

- Crane, D.T.; Lorimer, A.; Hannemann, C.; Reifenberg, J.; Miller, L.; Scullin, M. A System-Level Approach to Thermoelectric Material Property Optimization. J. Electron. Mater. 2015, 44, 2113–2117. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, D.; Feng, J.; Min, Y.; Li, J.; Ling, Y.; Li, H.; Zhao, D.; Liu, R.; Sun, R. Simultaneous optimization of cooling temperature difference and efficiency for multi-stage thermoelectric device. Appl. Energy 2024, 373, 123878. [Google Scholar] [CrossRef]

- Fabián-Mijangos, A.; Min, G.; Álvarez-Quintana, J. Enhanced performance thermoelectric module having asymmetrical legs. Energy Convers. Manag. 2017, 148, 1372–1381. [Google Scholar] [CrossRef]

- Huang, Y.-X.; Wang, X.-D.; Cheng, C.-H.; Lin, D.T.W. Geometry optimization of thermoelectric coolers using simplified conjugate-gradient method. Energy 2013, 59, 689–697. [Google Scholar] [CrossRef]

- Jeong, E.S. Optimization of thermoelectric modules for maximum cooling capacity. Cryogenics 2021, 114, 103241. [Google Scholar] [CrossRef]

- Pietrzyk, K.; Ohara, B.; Watson, T.; Gee, M.; Avalos, D.; Lee, H. Thermoelectric module design strategy for solid-state refrigeration. Energy 2016, 114, 823–832. [Google Scholar] [CrossRef]

- Wang, T.H.; Wang, Q.H.; Leng, C.; Wang, X.D. Parameter analysis and optimal design for two-stage thermoelectric cooler. Appl. Energy 2015, 154, 1–12. [Google Scholar] [CrossRef]

- He, Y.J.; Cao, C.; Wu, J.; Chen, G. Investigations on coupling between performance and external operational conditions for a semiconductor refrigeration system. Int. J. Refrig. 2020, 109, 172–179. [Google Scholar] [CrossRef]

- Venkatesan, K.; Venkata Ramanan, M. Design and performance evaluation of thermoelectric heat dissipation system integrated with PCM (phase change material). Int. J. Ambient. Energy 2022, 43, 8750–8762. [Google Scholar] [CrossRef]

- Zhu, K.; Deng, B.; Qian, X.; Wang, Y.; Li, H.; Jiang, P.; Yang, R.; Liu, W. A general White–Box strategy for designing thermoelectric heat dissipation system. InfoMat 2022, 4, e12324. [Google Scholar] [CrossRef]

- Muneeshwaran, M.; Tsai, M.-K.; Wang, C.-C. Heat transfer augmentation of natural convection heat sink through notched fin design. Int. Commun. Heat Mass Transf. 2023, 142, 106676. [Google Scholar] [CrossRef]

- Liu, Y.; Su, Y. Experimental investigations on COPs of thermoelectric module frosting systems with various hot side cooling methods. Appl. Therm. Eng. 2018, 144, 747–756. [Google Scholar] [CrossRef]

- Siahmargoi, M.; Rahbar, N.; Kargarsharifabad, H.; Sadati, S.E.; Asadi, A. An Experimental Study on the Performance Evaluation and Thermodynamic Modeling of a Thermoelectric Cooler Combined with Two Heatsinks. Sci. Rep. 2019, 9, 20336. [Google Scholar] [CrossRef]

- Astrain, D.; Aranguren, P.; Martínez, A.; Rodríguez, A.; Pérez, M.G. A comparative study of different heat exchange systems in a thermoelectric refrigerator and their influence on the efficiency. Appl. Therm. Eng. 2016, 103, 1289–1298. [Google Scholar] [CrossRef]

- Alzuguren, I.; Aranguren, P.; Casi, Á.; Erro, I.; Rodríguez, A. Thermoelectrics working in favor of the natural heat flow to actively control the heat dissipation. Int. Commun. Heat Mass Transf. 2024, 156, 107607. [Google Scholar] [CrossRef]

- Nair, V.; Baby, A.; Anoop, M.B.; Indrajith, S.; Murali, M.; Nair, M.B. A comprehensive review of air-cooled heat sinks for thermal management of electronic devices. Int. Commun. Heat Mass Transf. 2024, 159, 108055. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Zhao, F.Y.; Tang, J.F. Performance analysis and assessment of thermoelectric micro cooler for electronic devices. Energy Convers. Manag. 2016, 124, 202–211. [Google Scholar] [CrossRef]

- Qiu, J.; Yan, Y.; Luo, T.; Tang, K.; Yao, L.; Zhang, J.; Zhang, M.; Su, X.; Tan, G.; Xie, H.; et al. 3D Printing of highly textured bulk thermoelectric materials: Mechanically robust BiSbTe alloys with superior performance. Energy Environ. Sci. 2019, 12, 3106–3117. [Google Scholar] [CrossRef]

| Type | Z (1/K) | S (V/K) | Rt,h1 (K/W) | Rt,h2 (K/W) | Rt,m (K/W) | Rt,a (K/W) |

|---|---|---|---|---|---|---|

| TB-127-2.0-1.15(B) | 0.00257 | 0.0523 | 0.03823 | 0.15186 | 0.6458 | 0.04684 |

| TEC2-12712(C) | 0.00259 | 0.0507 | 0.03823 | 0.15186 | 1.1791 | 0.04684 |

| TB-127-1.4-1.05(D) | 0.00258 | 0.0523 | 0.03823 | 0.15186 | 1.3273 | 0.04684 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Shi, R.; Zhu, K. The Potential of a Thermoelectric Heat Dissipation System: An Analytical Study. Energies 2025, 18, 555. https://doi.org/10.3390/en18030555

Li X, Shi R, Zhu K. The Potential of a Thermoelectric Heat Dissipation System: An Analytical Study. Energies. 2025; 18(3):555. https://doi.org/10.3390/en18030555

Chicago/Turabian StyleLi, Xuechun, Rujie Shi, and Kang Zhu. 2025. "The Potential of a Thermoelectric Heat Dissipation System: An Analytical Study" Energies 18, no. 3: 555. https://doi.org/10.3390/en18030555

APA StyleLi, X., Shi, R., & Zhu, K. (2025). The Potential of a Thermoelectric Heat Dissipation System: An Analytical Study. Energies, 18(3), 555. https://doi.org/10.3390/en18030555