Induction Motor Geometric Parameter Optimization Using a Metaheuristic Optimization Method for High-Efficiency Motor Design

Abstract

:1. Introduction

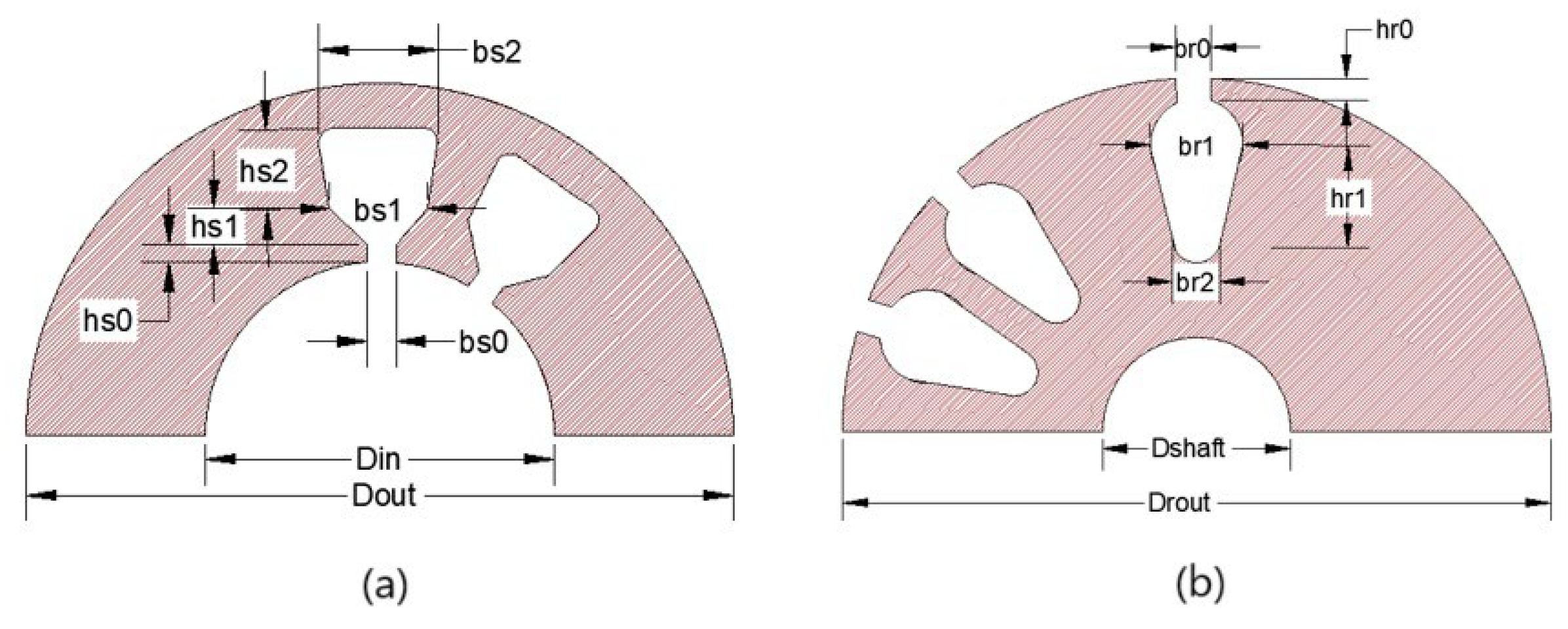

2. Design Calculations for Induction Motors

3. Optimization Methods Used for High-Performance IM Design

3.1. Genetic Algorithm

3.2. Artificial Ecosystem-Based Optimization

3.2.1. Manufacturers

3.2.2. Consumers

- Herbivores are mathematically expressed as follows:

- Carnivores are mathematically formulated as follows:

- Omnivores are mathematically modeled as follows:

3.2.3. Decomposition

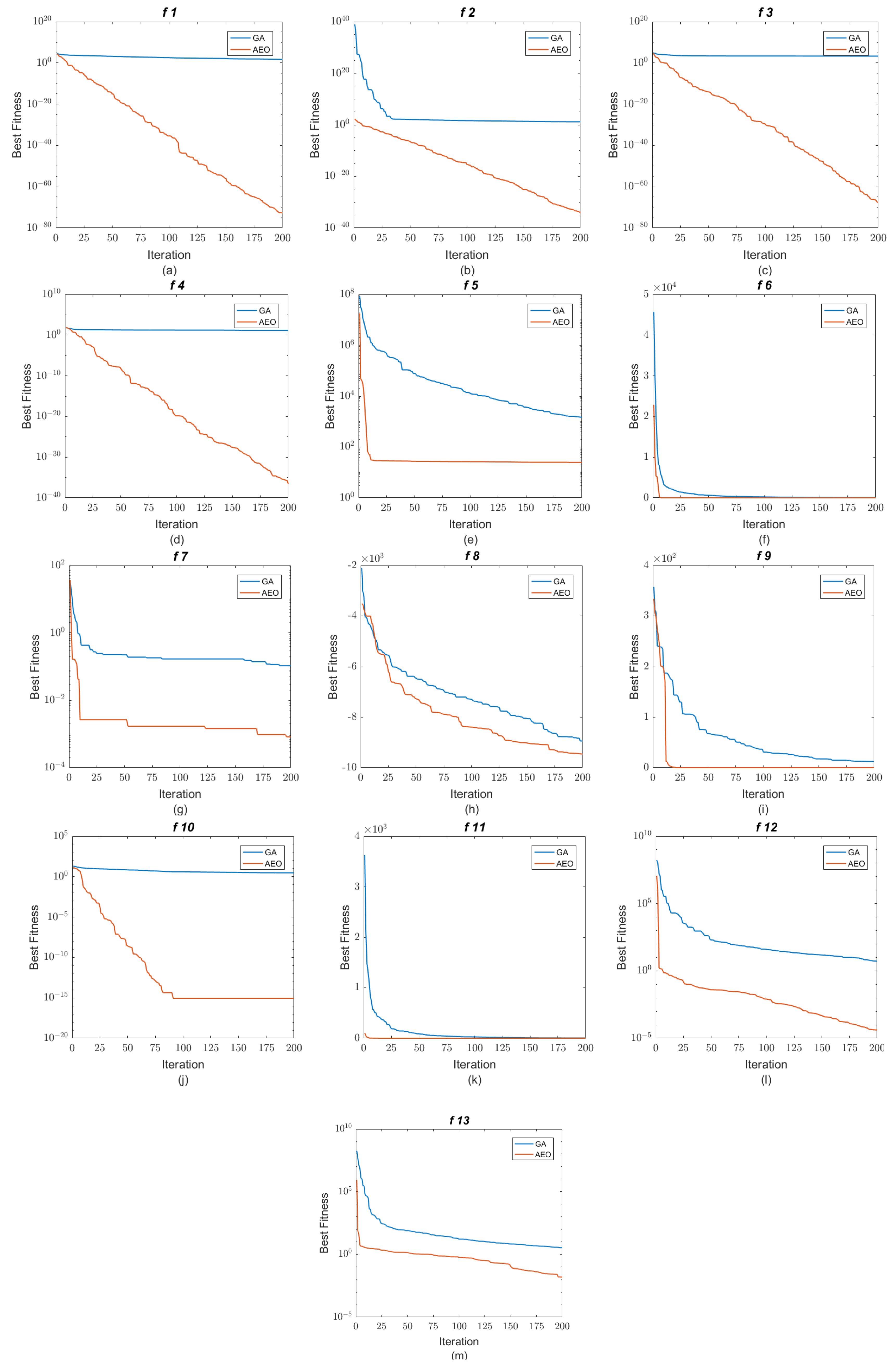

4. Comparison of AEO and GA

5. Design Procedure for an Induction Motor

| Description/Symbols | Units | Values | Description/Symbols | Units | Values |

|---|---|---|---|---|---|

| kW | 5.5 | mm | 2.2 | ||

| Volt | 460 | mm | 1 | ||

| Hz | 60 | mm | 1.5 | ||

| 3 | 28 | ||||

| 4 | 1 | ||||

| 0.895 | 3.42 | ||||

| 0.83 | T | 1.60 | |||

| 36 | T | 1.60 | |||

| 4.50 | 0.75 × | ||||

| T | 0.70 | mm | 1.5 | ||

| T | 1.55 | mm | 1 | ||

| 0.95 | 1.78 × 10−8 | ||||

| 7800 | 2.17 × 10−8 | ||||

| 3.1 × 10−8 |

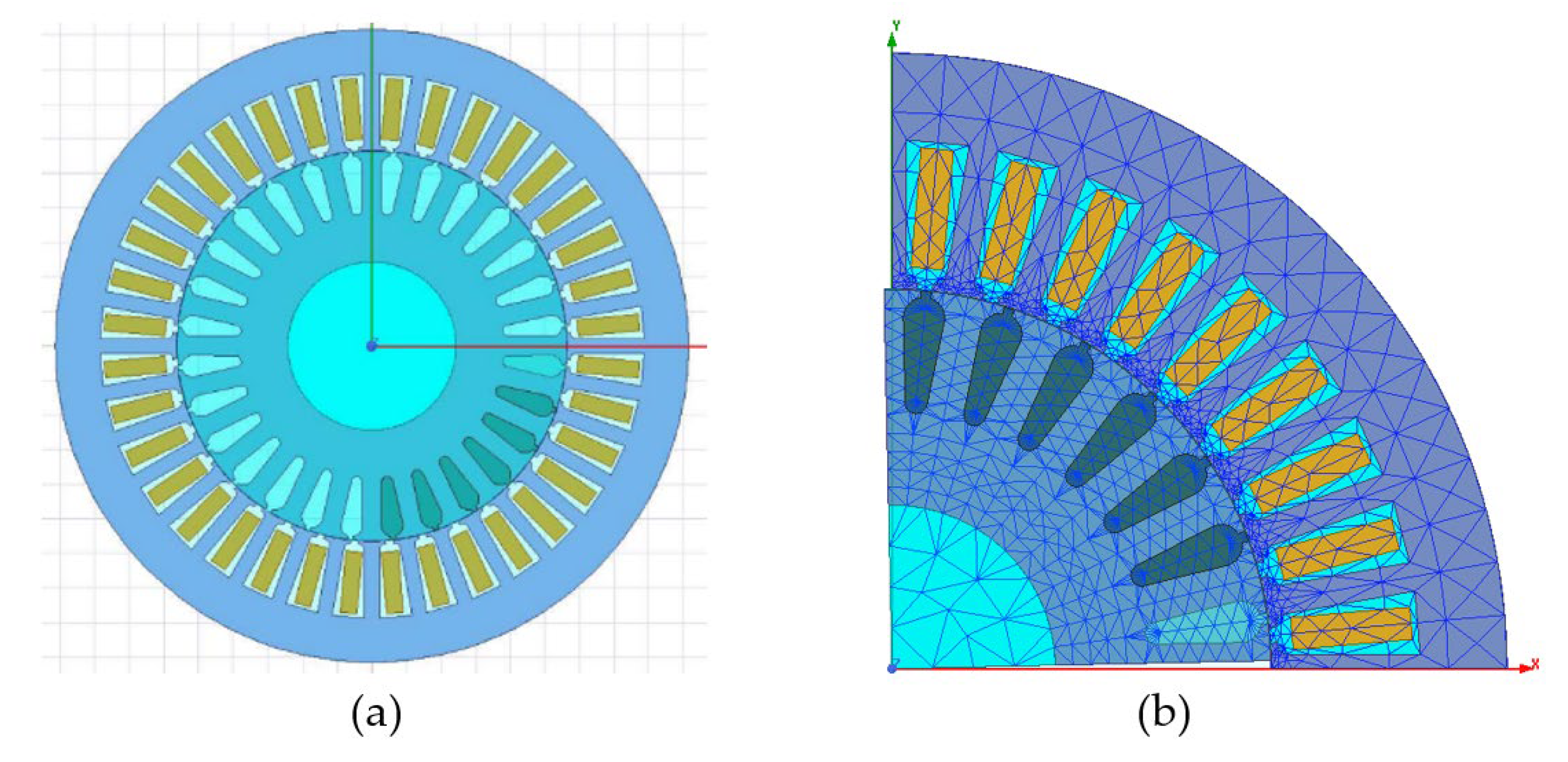

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Renier, B.; Hameyer, K.; Belmans, R. Comparison of standards for determining efficiency of three phase induction motors. IEEE Trans. Energy Convers. 1999, 14, 512–517. [Google Scholar] [CrossRef]

- Zhou, P.; Xu, Y.; Zhang, W. Design Consideration on a Low-Cost Permanent Magnetization Remanufacturing Method for Low-Efficiency Induction Motors. Energies 2023, 16, 6142. [Google Scholar] [CrossRef]

- Mahmouditabar, F.; Baker, N.J. Design Optimization of Induction Motors with Different Stator Slot Rotor Bar Combinations Considering Drive Cycle. Energies 2024, 17, 154. [Google Scholar] [CrossRef]

- Gangsar, P.; Tiwari, R. Signal based condition monitoring techniques for fault detection and diagnosis of induction motors: A state-of-the-art review. Mech. Syst. Signal Process. 2020, 144, 106908. [Google Scholar] [CrossRef]

- Saidur, R. A review on electrical motors energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 877–898. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Sadhu, P.K.; Basak, R.; Sanyal, A. Energy efficient design of three phase induction motor by water cycle algorithm. Ain Shams Eng. J. 2020, 11, 1139–1147. [Google Scholar] [CrossRef]

- Verucchi, C.; Ruschetti, C.; Giraldo, E.; Bossio, G.; Bossio, J. Efficiency optimization in small induction motors using magnetic slot wedges. Electr. Power Syst. Res. 2017, 152, 1–8. [Google Scholar] [CrossRef]

- Danin, Z.; Sharma, A.; Averbukh, M.; Meher, A. Improved Moth Flame Optimization Approach for Parameter Estimation of Induction Motor. Energies 2022, 15, 8834. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, J.; Xin, Y.; Guo, Q.; Yao, Z. Multi-objective structure optimization for interior permanent magnet synchronous motors under complex operating conditions. Struct. Multidiscip. Optim. 2024, 67, 120. [Google Scholar] [CrossRef]

- Mallik, S.; Mallik, K.; Barman, A.; Maiti, D.; Biswas, S.K.; Deb, N.K.; Basu, S. Efficiency and cost optimized design of an induction motor using genetic algorithm. IEEE Trans. Ind. Electron. 2017, 64, 9854–9863. [Google Scholar] [CrossRef]

- Gulbahce, M.O.; Kocabas, D.A. High-speed solid rotor induction motor design with improved efficiency and decreased harmonic effect. IET Electr. Power Appl. 2018, 12, 1126–1133. [Google Scholar] [CrossRef]

- Çunkaş, M.; Akkaya, R. Design optimization of induction motor by genetic algorithm and comparison with existing motor. Math. Comput. Appl. 2006, 11, 193–203. [Google Scholar] [CrossRef]

- Chekroun, S.; Abdelhadi, B.; Benoudjit, A. A New approach design optimizer of induction motor using particle swarm algorithm. AMSE J. Ser. Model. A 2014, 87, 89–108. [Google Scholar]

- Chekroun, S.; Abdelhadi, B.; Benoudjit, A. Design optimization of induction motor using hybrid genetic algorithm «a critical analyze». AMSE J. Ser. Adv. C 2015, 71, 1–23. [Google Scholar]

- Akhtar, M.J.; Behera, R.K. Optimal design of stator and rotor slot of induction motor for electric vehicle applications. IET Electr. Syst. Transp. 2019, 9, 35–43. [Google Scholar] [CrossRef]

- Arslan, M.; Çunkaş, M.; Sağ, T. Determination of induction motor parameters with differential evolution algorithm. Neural Comput. Appl. 2012, 21, 1995–2004. [Google Scholar] [CrossRef]

- Tai, Y.; Liu, Z.; Yu, H.; Liu, J. Efficiency optimization of induction motors using genetic algorithm and Hybrid Genetic Algorithm. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Gupta, A.; Machavaram, R.; Kshatriya, T.; Ranjan, S. Multi-objective design optimization of a three phase squirrel cage induction motor for electric propulsion system using genetic algorithm. In Proceedings of the 2020 IEEE First International Conference on Smart Technologies for Power, Energy and Control (STPEC), Nagpur, India, 25–26 September 2020; pp. 1–6. [Google Scholar]

- Nakhaei, M.R.; Roshanfekr, R. Optimal Design of 3-phase Squirrel Cage Induction Motors Using Genetic Algorithm Based on the Motor Efficiency and Economic Evaluation of the optimal Model. Balk. J. Electr. Comput. Eng. 2021, 9, 59–68. [Google Scholar] [CrossRef]

- Abdulraheem, T.; Asaolu, G.O.; Oladele, T.A.; Bamiduro, H.A.; Ezeah, J.U. Optimization of 20kVA, 3-Phase Induction Motor using Genetic Algorithm. IJSRSET 2017, 3, 151–155. [Google Scholar]

- Boldea, I.; Nasar, S.A. The Induction Machines Design Handbook, 2nd ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar] [CrossRef]

- Upadhyay, K.G. Design of Electrical Machines; New Age International: New Delhi, India, 2011. [Google Scholar]

- Gulbahce, M.O.; Lordoglu, A.; Kocabas, D.A. Increasing the Performance of High-Speed Solid Rotor Induction Motor by Plunge Type Electrical Discharge Machining. Adv. Electr. Comput. Eng. 2023, 23, 79–86. [Google Scholar] [CrossRef]

- Rajini, V.; Nagarajan, V.S. Electrical Machine Design; Pearson Education: Bangalore, India, 2018. [Google Scholar]

- Murthy, K.V. Computer-Aided Design of Electrical Machines; BS Publications: Hyderabad, India, 2008. [Google Scholar]

- Apaydın, H.; Serteller, F.; Oğuz, Y. Implementation of Three Phase Induction Motor Pre-Design Program on Electronic Circuit. Politek. Dergisi. 2023, 27, 1281–1292. [Google Scholar] [CrossRef]

- Ban, B.; Stipetic, S. Robust feasibility verification and region inner-point detection algorithms for geometric shape objects applied to electric machine optimization workflow. Struct. Multidiscip. Optim. 2022, 65, 175. [Google Scholar] [CrossRef]

- Ocak, C. A FEM-Based Comparative Study of the Effect of Rotor Bar Designs on the Performance of Squirrel Cage Induction Motors. Energies 2023, 16, 6047. [Google Scholar] [CrossRef]

- Murty, K.G. Optimization Models for Decision Making: Volume; University of Michigan: Ann Arbor, MI, USA, 2003. [Google Scholar]

- Wang, D.; Tan, D.; Liu, L. Particle swarm optimization algorithm: An overview. Soft Comput. 2018, 22, 387–408. [Google Scholar] [CrossRef]

- Pereira, J.L.J.; Oliver, G.A.; Francisco, M.B.; Cunha, S.S., Jr.; Gomes, G.F. A review of multi-objective optimization: Methods and algorithms in mechanical engineering problems. Arch. Comput. Methods Eng. 2022, 29, 2285–2308. [Google Scholar] [CrossRef]

- Subramani, R.; Vijayalakshmi, C. Multi-Objectıve Optımization Algorithms And Performance Test Functions For Energy Effıcıency: Review. Int. J. Eng. Sci. Res. Technol. 2017, 6, 39–52. [Google Scholar]

- Mirjalili, S.; Lewis, A. The whale optimization algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Ahmadi, S.A. Human behavior-based optimization: A novel metaheuristic approach to solve complex optimization problems. Neural Comput. Appl. 2017, 28 (Suppl. 1), 233–244. [Google Scholar] [CrossRef]

- Valdez, F.; Melin, P.; Castillo, O. A survey on nature-inspired optimization algorithms with fuzzy logic for dynamic parameter adaptation. Expert Syst. Appl. 2014, 41, 6459–6466. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Abdel-Fatah, L.; Sangaiah, A.K. Metaheuristic algorithms: A comprehensive review. In Computational Intelligence for Multimedia Big Data on the Cloud with Engineering Applications; Academic Press: Cambridge, MA, USA, 2018; pp. 185–231. [Google Scholar] [CrossRef]

- Bektaş, Y. Real-time control of Selective Harmonic Elimination in a Reduced Switch Multilevel Inverter with unequal DC sources. Ain Shams Eng. J. 2024, 15, 102719. [Google Scholar] [CrossRef]

- Pandey, H.M.; Chaudhary, A.; Mehrotra, D. A comparative review of approaches to prevent premature convergence in GA. Appl. Soft Comput. 2014, 24, 1047–1077. [Google Scholar] [CrossRef]

- Man, K.F.; Tang, K.S.; Kwong, S. Genetic algorithms: Concepts and applications [in engineering design]. IEEE Trans. Ind. Electron. 1996, 43, 519–534. [Google Scholar] [CrossRef]

- Mitchell, M. Genetic algorithms: An overview. Complex 1995, 1, 31–39. [Google Scholar] [CrossRef]

- Hassanat, A.; Almohammadi, K.; Alkafaween, E.A.; Abunawas, E.; Hammouri, A.; Prasath, V.S. Choosing mutation and crossover ratios for genetic algorithms—A review with a new dynamic approach. Information 2019, 10, 390. [Google Scholar] [CrossRef]

- Patil, V.P.; Pawar, D.D. The optimal crossover or mutation rates in genetic algorithm: A review. Int. J. Appl. Eng. Technol. 2015, 5, 38–41. [Google Scholar]

- Bi, H.; Lu, F.; Duan, S.; Huang, M.; Zhu, J.; Liu, M. Two-level principal–agent model for schedule risk control of IT outsourcing project based on genetic algorithm. Eng. Appl. Artif. Intell. 2020, 91, 103584. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Zhang, Z. Artificial ecosystem-based optimization: A novel nature-inspired meta-heuristic algorithm. Neural Comput. Appl. 2020, 32, 9383–9425. [Google Scholar] [CrossRef]

- Jamil, M.; Yang, X.S. A literature survey of benchmark functions for global optimization problems. Int. J. Math. Model. Numer. Optim. 2013, 4, 150–194. [Google Scholar] [CrossRef]

| Function Name | Description of the Function | Dimension | Range of Values | Optimum Value |

|---|---|---|---|---|

| Sphere | 30 | [−100, 100] | 0 | |

| Schwefel 2.22 | 30 | [−10, 10] | 0 | |

| Schwefel 1.2 | 30 | [−100, 100] | 0 | |

| Schwefel 2.21 | 30 | [−100, 100] | 0 | |

| Rosenbrock | 30 | [−30, 30] | 0 | |

| Step | 30 | [−100, 100] | 0 | |

| Quartic | 30 | [−1.28, 1.28] | 0 |

| Function Name | Description of the Function | Dimension | Range of Values | Optimum Value |

|---|---|---|---|---|

| Schwefel | 30 | [−500, 500] | ||

| Rastrigin | 30 | [−5.12, 5.12] | 0 | |

| Ackley | 30 | [−32, 32] | 0 | |

| Griewank | 30 | [−600, 600] | 0 | |

| Penalized | 30 | [−50, 50] | 0 | |

| Penalized 2 | 30 | [−50, 50] | 0 |

| Function Number | Index | Optimization Techniques | |

|---|---|---|---|

| GA | AEO | ||

| Average | 22.4545 | 4.5414 × 10−66 | |

| Standard Deviation | 5.7000 | 1.0185 × 10−65 | |

| Best Value | 12.9998 | 6.7211 × 10−78 | |

| Average | 0.8488 | 1.8175 × 10−32 | |

| Standard Deviation | 0.1796 | 5.0184 × 10−32 | |

| Best Value | 0.5578 | 2.5352 × 10−38 | |

| Average | 2.895 × 103 | 2.8105 × 10−68 | |

| Standard Deviation | 8.131 × 102 | 6.9181 × 10−68 | |

| Best Value | 1.926 × 103 | 2.1721 × 10−78 | |

| Average | 6.176 | 4.1896 × 10−32 | |

| Standard Deviation | 1.182 | 1.0889 × 10−31 | |

| Best Value | 4.941 | 2.6871 × 10−35 | |

| Average | 3.905 × 102 | 2.5105 × 101 | |

| Standard Deviation | 1.602 × 102 | 7.2142 × 101 | |

| Best Value | 2.146 × 102 | 2.4201 × 101 | |

| Average | 10.16 | 0 | |

| Standard Deviation | 1.532 | 0 | |

| Best Value | 8.526 | 0 | |

| Average | 4.714 × 10−2 | 1.3587 × 10−3 | |

| Standard Deviation | 1.124 × 10−2 | 1.4657 × 10−3 | |

| Best Value | 3.173 × 10−2 | 1.4071 × 10−4 | |

| Average | −9.462 × 103 | −9.7426 × 103 | |

| Standard Deviation | 3.380 × 102 | 5.3122 × 102 | |

| Best Value | −9.918 × 103 | −1.0820 × 104 | |

| Average | 18.950 | 0 | |

| Standard Deviation | 4.540 | 0 | |

| Best Value | 11.69 | 0 | |

| Average | 1.462 | 8.8818 × 10−12 | |

| Standard Deviation | 5.466 × 10−1 | 1.7030 × 10−27 | |

| Best Value | 7.713 × 10−3 | 8.8818 × 10−12 | |

| Average | 1.065 | 0 | |

| Standard Deviation | 3.147 × 10−2 | 0 | |

| Best Value | 1.011 | 0 | |

| Average | 2.060 × 10−1 | 3.7326 × 10−5 | |

| Standard Deviation | 2.078 × 10−1 | 2.1774 × 10−5 | |

| Best Value | 1.680 × 10−2 | 1.3847 × 10−5 | |

| Average | 7.227 × 10−1 | 0.1069 | |

| Standard Deviation | 1.705 × 10−1 | 0.1300 | |

| Best Value | 4.549 × 10−1 | 6.6828 × 10−3 | |

| Description/Symbols | Units | Values | Description/Symbols | Units | Values |

|---|---|---|---|---|---|

| mm | 182.9 | mm | 1.5 | ||

| mm | 112.9 | mm | 6.2 | ||

| mm | 133 | mm | 3.3 | ||

| mm | 0.31 | mm | 1 | ||

| mm | 2.2 | mm | 12.6 | ||

| mm | 6 | mm | 48.6 | ||

| mm | 9.4 | ||||

| mm | 1 | ||||

| mm | 1.5 | ||||

| mm | 19.5 |

| Motor Parameter Name—Units | Matlab Program Calculation Results | Ansys-RMxprt Calculation Results |

|---|---|---|

| Specific Electric Loading—Am | 26,789 | 26,776 |

| Rated Current—A | 9.1059 | 9.097 |

| Magnetization Current—A | 4.2578 | 4.250 |

| Rotor Current—A | 8.0491 | 7.663 |

| Air Gap Flux Density—T | 0.6915 | 0.6918 |

| Stator Teeth Flux Density—T | 1.6714 | 1.6675 |

| Rotor Teeth Flux Density—T | 1.6740 | 1.6542 |

| Stator Yoke Flux Density—T | 1.7841 | 1.8178 |

| Rotor Yoke Flux Density—T | 1.7194 | 1.6379 |

| Air Gap mmf—Aturns | 104.6079 | 120.903 |

| Stator Tooth mmf—Aturns | 88.4325 | 80.875 |

| Rotor Tooth mmf—Aturns | 40.23 | 58.6951 |

| Stator Yoke mmf—Aturns | 246.2024 | 168.834 |

| Rotor Yoke mmf—Aturns | 69.6702 | 20.0847 |

| Stator Phase Resistance—ohm | 0.8273 | 0.9111 |

| Rotor Resistance—ohm | 0.8990 | 0.7915 |

| Stator Phase Leakage Reactance—ohm | 2.2966 | 2.009 |

| Rotor Leakage Reactance—ohm | 3.1794 | 2.1362 |

| Magnetization Reactance—ohm | 58.7326 | 58.52 |

| Stator Core Steel Weigh—kg | 10.1873 | 10.3368 |

| Rotor Core Steel Weight—kg | 5.2155 | 5.7586 |

| Stator Ohmic Loss—W | 205.5864 | 226.205 |

| Rotor Ohmic Loss—W | 173.5334 | 139.481 |

| Iron Core Losses—W | 86.8155 | 80.930 |

| Frictional and Windage Loss—W | 66 | 66.336 |

| Stray Loss—W | 55 | 55 |

| Output Power—W | 5491.1 | 5500.33 |

| Efficiency—% | 90.34 | 90.64 |

| Power Factor | 0.8517 | 0.8296 |

| Rated Torque—Nm | 30.087 | 29.9113 |

| Rated Slip | 0.0302 | 0.0244 |

| Description | Units | Lower | Real Values | Upper |

|---|---|---|---|---|

| 25 | 29 | 35 | ||

| mm | 100 | 112.9 | 120 | |

| mm | 120 | 133 | 150 | |

| mm | 0.3 | 1 | 1.2 | |

| mm | 1 | 1.5 | 2 | |

| mm | 19 | 19.5 | 22 | |

| mm | 2 | 2.2 | 3 | |

| mm | 5 | 6 | 7 | |

| mm | 8 | 9.4 | 12 | |

| mm | 175 | 1829 | 210 |

| Description | Units | Design Parameter Name | Limit |

|---|---|---|---|

| T | 0.75 | ||

| 0.6 | |||

| T | 1.7 | ||

| T | 1.7 | ||

| T | 1.7 | ||

| 0.80 | |||

| 1.2 | |||

| 1.75 | |||

| 7 |

| Description | GA | AEO | ||

|---|---|---|---|---|

| CPU Time (s) | (η)% | CPU Time (s) | (η)% | |

| Average | 111.211 | 91.382 | 52.84 | 91.575 |

| Standard Deviation | 0.1192 | 0.08720 | ||

| Description | Units | M1 | Design Parameter Values | |

|---|---|---|---|---|

| M2 | M3 | |||

| 29 | 27 | 26 | ||

| mm | 112.9 | 115.75 | 118.69 | |

| mm | 133 | 138.84 | 142.59 | |

| mm | 1 | 0.61 | 0.51 | |

| mm | 1.5 | 1.3 | 1.46 | |

| mm | 19.5 | 20.82 | 19.97 | |

| mm | 2.2 | 2.2 | 2.3 | |

| mm | 6 | 5.51 | 6.36 | |

| mm | 9.4 | 9.66 | 8.23 | |

| mm | 182.9 | 204.63 | 198.42 | |

| (Ansys RMxprt) | % | 90.64 | 91.87 | 91.97 |

| (Matlab) | % | 90.34 | 91.45 | 91.61 |

| Optimization running time in the Matlab program | sec | 106.5485 | 52.1754 | |

| Change in efficiency of the M2 and M3 motor designs compared to the M1 motor design | % | 1.22 | 1.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Apaydin, H.; Oyman Serteller, N.F.; Oğuz, Y. Induction Motor Geometric Parameter Optimization Using a Metaheuristic Optimization Method for High-Efficiency Motor Design. Energies 2025, 18, 733. https://doi.org/10.3390/en18030733

Apaydin H, Oyman Serteller NF, Oğuz Y. Induction Motor Geometric Parameter Optimization Using a Metaheuristic Optimization Method for High-Efficiency Motor Design. Energies. 2025; 18(3):733. https://doi.org/10.3390/en18030733

Chicago/Turabian StyleApaydin, Hasbi, Necibe Füsun Oyman Serteller, and Yüksel Oğuz. 2025. "Induction Motor Geometric Parameter Optimization Using a Metaheuristic Optimization Method for High-Efficiency Motor Design" Energies 18, no. 3: 733. https://doi.org/10.3390/en18030733

APA StyleApaydin, H., Oyman Serteller, N. F., & Oğuz, Y. (2025). Induction Motor Geometric Parameter Optimization Using a Metaheuristic Optimization Method for High-Efficiency Motor Design. Energies, 18(3), 733. https://doi.org/10.3390/en18030733