Decarbonisation of Natural Gas Grid: A Review of GIS-Based Approaches on Spatial Biomass Assessment, Plant Siting and Biomethane Grid Injection

Abstract

:1. Introduction

2. Review Method

3. Results and Discussion

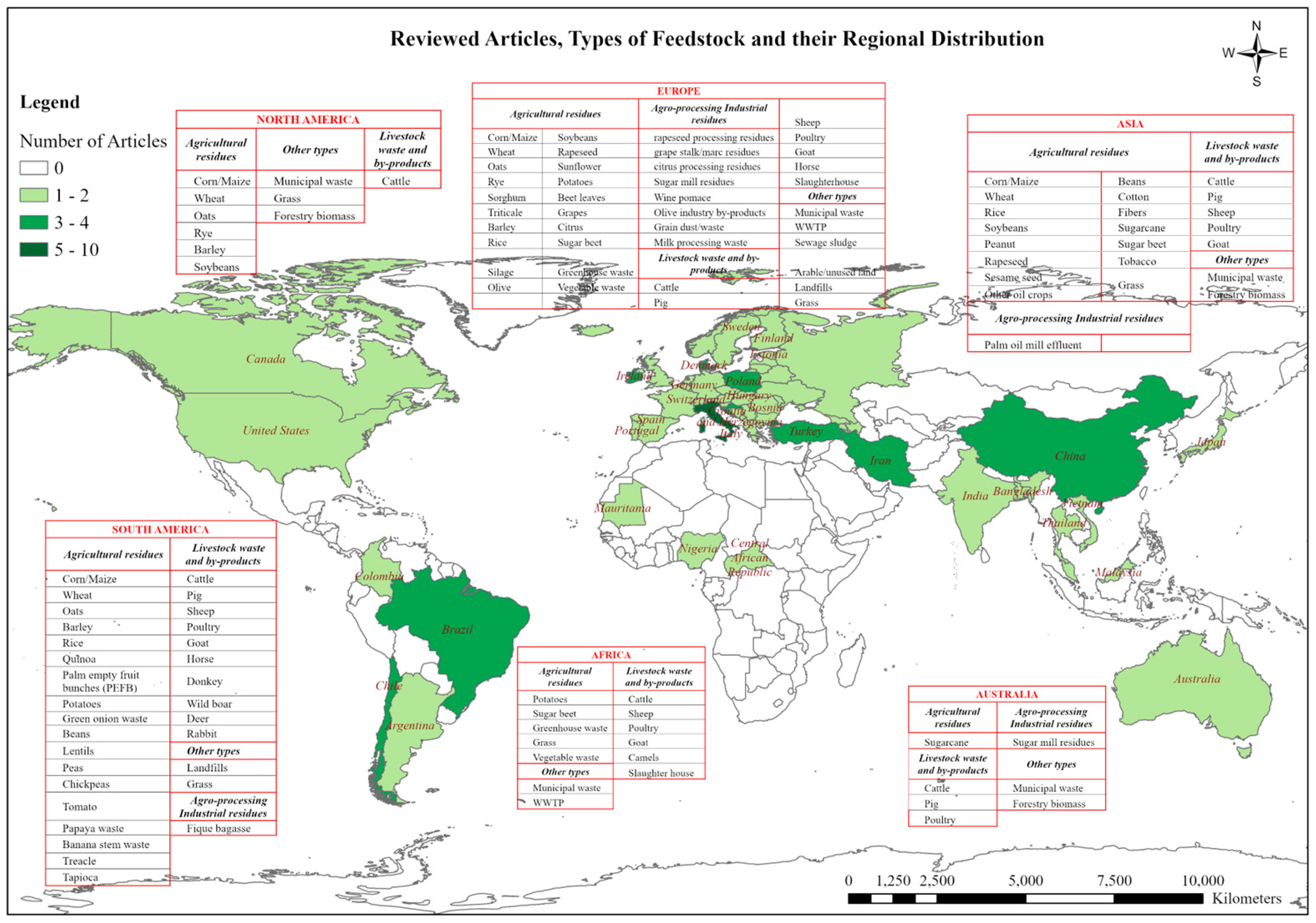

3.1. Biomass for Biogas Production

3.1.1. Livestock Waste

3.1.2. Crop Residues

3.1.3. Energy Crops

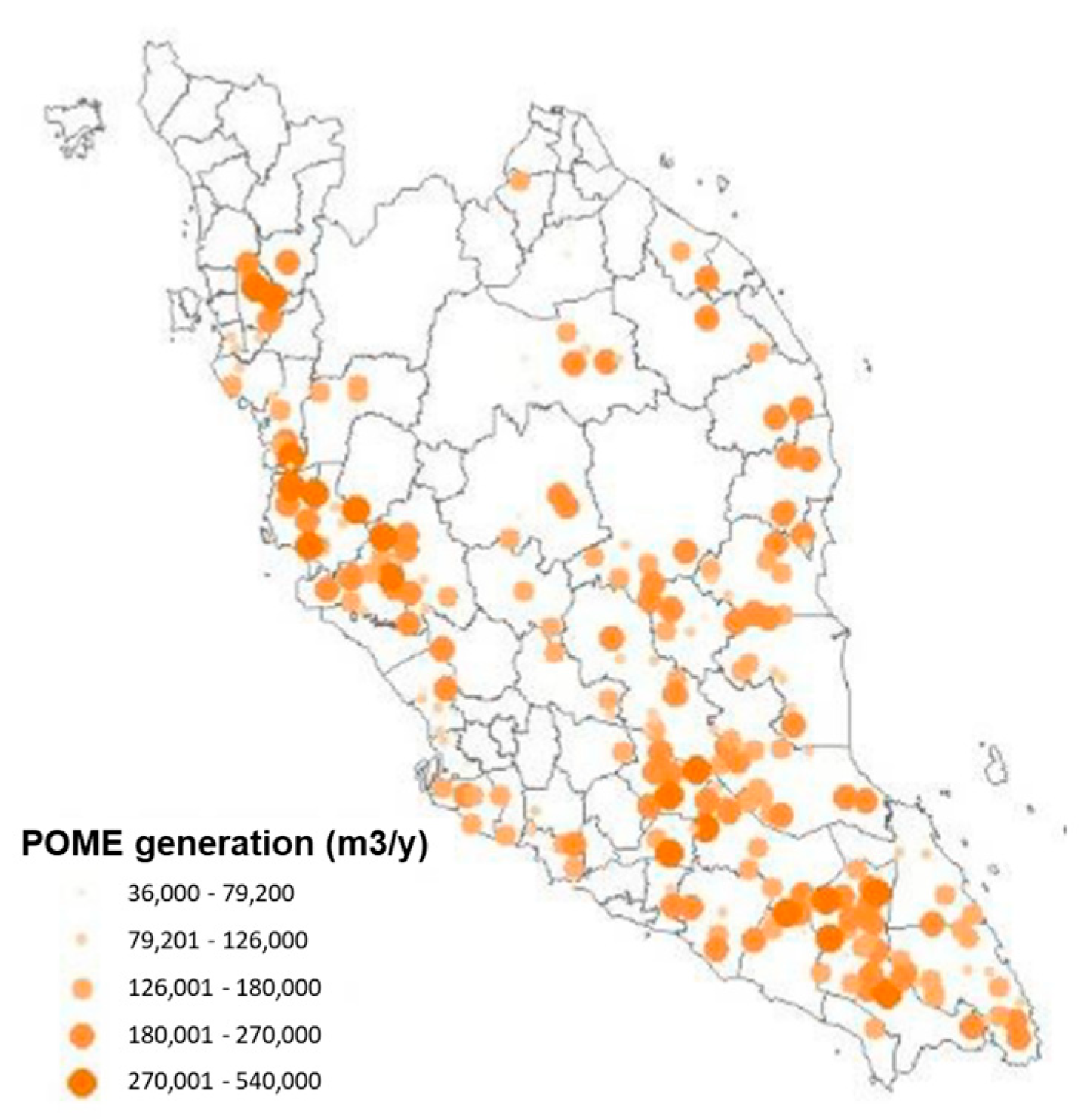

3.1.4. Industrial By-Products

3.1.5. Municipal Solid Waste (MSW)

3.1.6. Sewage Sludge (SS) and Wastewater Treatment Plant Sludge (WWTPS)

3.1.7. Landfills

3.1.8. Aquatic Biomass

3.2. GIS-Based Approaches on Biomass Assessments

3.2.1. Administrative Division-Based Biomass Assessment

| Study Scale | GIS Methodologies | Sources of Feedstocks | Reference | |

|---|---|---|---|---|

| 1 | National | Spatial analysis, Thematic Mapper | Agricultural residues (multi crops); livestock; food and garden | [27] |

| 2 | Regional | Spatial analysis, Raster analysis (100 m), raster overlay | Agricultural residues (multi crops); livestock; food and garden; agro-industrial sub products | [37] |

| 3 | National | Thematic mapper | Agricultural residues (multi crops); livestock | [24] |

| 4 | Regional | Image analysis, Spatial analysis | Agricultural residues (single crop); livestock; food and garden | [11] |

| 5 | Regional | Spatial analysis, Thematic mapper | Livestock; energy crops; energy crops (grass silage) | [26] |

| 6 | National | Thematic mapper | Livestock; food and garden; slaughterhouse waste, milk processing waste | [38] |

| 7 | Regional | Thematic mapper | Agricultural residues (multi crops); livestock | [39] |

| 8 | Regional | Spatial analysis, Thematic mapper | Industrial by-products (citrus pulp) | [40] |

| 9 | Regional | Thematic mapper | Grass (waste grass, riverbanks and roadsides grass, natural and rural areas) | [41] |

| 10 | National | Spatial analysis, Thematic mapper | Livestock; food and garden | [36] |

| 11 | Regional | Spatial analysis, Thematic mapper | Industry by-products (olive pomace) | [35] |

| 12 | Regional | Thematic mapper | Agricultural residues (multi crops); livestock; food-processing wastes (citrus pulp, olive pomace and whey), forage crops (corn silage) | [42] |

| 13 | National | Thematic mapper | Livestock; slaughterhouses | [34] |

| 14 | Regional | Thematic mapper | Agricultural residues (multi crops); livestock; food and garden; WWTP; energy crops; residue grass, industry waste | [30] |

| 15 | National | Thematic mapper | Agricultural residues (multi crops); livestock | [23] |

| 16 | National | Spatial analysis, Thematic mapper | Livestock; grass silage | [43] |

| 17 | National | Spatial analysis, Thematic mapper | Livestock | [18] |

| 18 | Regional | Spatial analysis, Thematic mapper | Municipal waste (household-generated, industrial waste and commercial waste) | [29] |

| 19 | National | Spatial Analysis, Thematic Mapper | Agricultural residues (multi crops); forestry waste; livestock; municipal solid waste; sewage; industrial waste | [44] |

| 20 | Regional | Spatial Analysis, Thematic Mapper | Livestock waste | [45] |

3.2.2. Location-Based Biomass Assessment

- Extraction (from secondary spatial data sources) or mapping (self-digitised data) the locations of feedstock sources (e.g., locations of animal farms, industries, etc.);

- Combine other required non-spatial data (e.g., number of animals, production statistics, etc.) with the location layers and calculate the biomass and energy potential using the field calculator or spatial statistical tools and relevant equations.

- Calculate the biomass and energy potential using non-spatial data (e.g., production statistics, number of animals, etc.) using other statistical methods or mathematical models;

- Combine the results with the location shapefile using the Join Attributes method and represent the results using thematic mapper and appropriate symbolising methods.

| Study Scale | GIS Methodologies | Feedstock Types Studied | Reference | |

|---|---|---|---|---|

| 1 | Regional | SA, TM | Livestock | [47] |

| 2 | National | SA, TM | Aquatic macrophyte biomass | [33] |

| 3 | Regional | SA, TM | Industrial residues | [48] |

| 4 | Regional | SA, TM | Livestock | [49] |

| 5 | Regional | SA, TM | Livestock | [50] |

| 6 | Regional | SA, TM | Livestock; slaughterhouse waste | [12] |

| 7 | Regional | SA, TM | Livestock | [19] |

| 8 | National | SA, TM | Livestock, crop by-products | [51] |

| 9 | National | SA, TM | Landfills | [32] |

| 10 | Regional | SA, TM | Industrial residues (sugar, wine, vegetable and olive oil industries) | [10] |

| 11 | Regional | SA, TM | Municipal solid waste (waste transfer stations) | [52] |

| 12 | Regional | SA, TM | Agricultural residues (multi crops) | [53] |

3.2.3. Grid-Based Biomass Assessment

- Extraction (from secondary spatial data sources) or mapping (self-digitised data) the areas/locations of feedstock sources (e.g., crop-cultivating areas, locations of animal farms, industries, etc.);

- Combine other required non-spatial data (e.g., number of animals, production statistics, etc.) and calculate the geometrics to identify the extent of cultivated lands of feedstock sources;

- Create a rectangular grid layer covering the study area with the required resolution;

- Clip the feedstock layers with the grid layer to obtain the biomass in each cell separately;

- Calculate the biomass availability and energy potential using field calculator or spatial statistics and relevant equations within each grid;

- Calculate the aggregate biomass and energy potential using attribute joining and spatial statistics.

3.2.4. Cluster-Based Biomass Assessment

- Extraction (from secondary spatial data sources) or mapping (self-digitised data) the locations of feedstock sources (locations of animal farms, industries, etc.);

- Combine other required non-spatial data (e.g., number of animals, production statistics, etc.) with the location layers and calculate the biomass potential using field calculator or spatial statistics and relevant equations;

- Develop a density map by employing interpolation tools with predefined search radius to identify the clusters of densely distributed areas of biomass (Figure 6).

3.3. Biogas Plant Siting

3.3.1. Identification of Exclusive and Selective Criteria (Constraints and Preference Criteria)

Environmental Criteria

Economic Criteria

Social Criteria

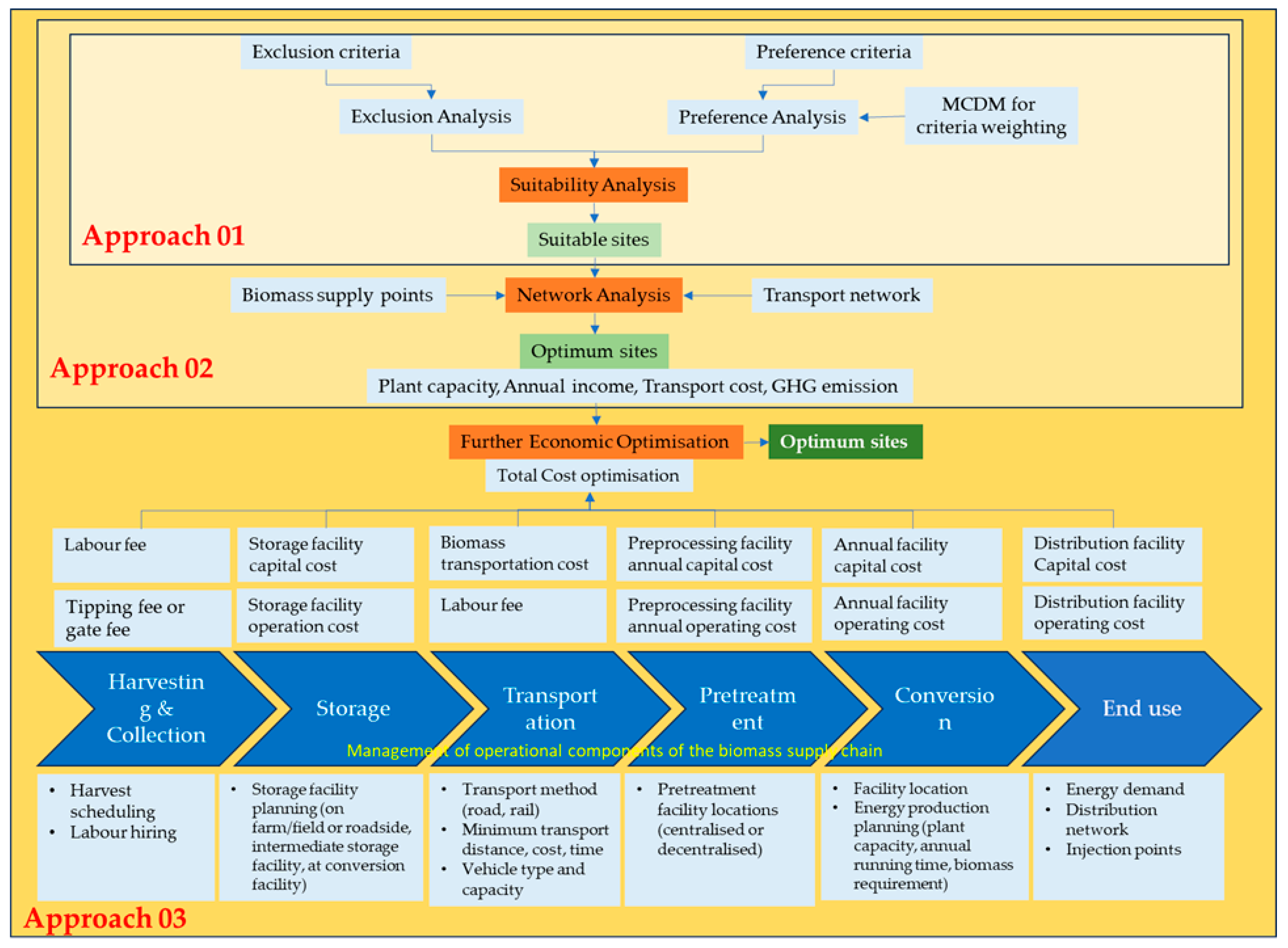

3.3.2. GIS-Based Approaches on Selecting and Optimising the Biogas Plant Locations

- Suitability Analysis (Multi-Criteria Analysis)

- Optimality Analysis (Network Analysis)

Suitability Analysis

Exclusion Analysis

Preference Analysis and Criteria Weighting

Land Suitability Analysis

Optimality Analysis

- To identify the most suitable location for a biogas plant while minimising transportation costs among the potential sites in the study area [81];

- To assign each biomass source to potential plants, considering all accessible roads within a specific distance, defining the biomass supply areas and avoiding the competition for biomass between biogas plants [61];

- To minimise the distance between biomass sources and biogas facilities and maximise the profit of the entire supply chain [50].

- Defining the road network (geometry, road parameters: maximum speed, one- or two-way or forbidden roads);

- Defining the origin–destination matrix (feedstock supply points and candidate sites);

- Identifying the transport model parameters (problem type (cost function, % of market), travel setting (cutoff (maximum biomass travel distance) and maximum number of facilities).

3.4. Identification of Biomethane Injection Points

4. Conclusions

5. Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| GIS | Geographic Information System |

| GHG | Greenhouse gas |

| STEPS | Stated Policies Scenario |

| EJ | Exajoule |

| AD | Anaerobic digestion |

| MT | Million tonnes |

| IEA | International Energy Agency |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analysis |

| MWel | Megawatt electricity |

| kW | Kilowatt |

| PJ | Petajoule |

| DM | Dry matter |

| VS | Volatile solids |

| MSW | Municipal solid waste |

| OFMSW | Organic fraction of MSW |

| SS | Sewage sludge |

| WWTPS | Wastewater treatment plant sludge |

| t/year | Tonnes per year |

| C/N ratio | Carbon/Nitrogen ratio |

| MCA | Multi-criteria analysis |

| AHP | Analytic Hierarchy Process |

| NA | Network analysis |

| LAM | Location allocation model |

| SA | Spatial analysis |

| EA | Euclidean allocation |

| CA | Cluster Analysis |

| FWOD | Fuzzy weighted Overlap Dominance |

| SAF | Service Area Function |

| ZSA | Zonal statistics analysis |

| VRP Solver | Vehicle Routing Problem Solver |

| BWM | Best worst method |

| CRITIC | Criteria Importance Through Intercriteria Correlation |

| MABAC | Multi-attributive Border Approximation Area Comparison |

| MILP | Mixed-Integer Linear Programming |

References

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- International Energy Agency. Greenhouse Gas Emissions from Energy Data Explorer. 2024. Available online: https://www.iea.org/data-and-statistics/data-tools/greenhouse-gas-emissions-from-energy-data-explorer (accessed on 23 October 2024).

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector; IEA: Paris, France, 2021; Available online: https://iea.blob.core.windows.net/assets/deebef5d-0c34-4539-9d0c-10b13d840027/NetZeroby2050-ARoadmapfortheGlobalEnergySector_CORR.pdf (accessed on 16 January 2024).

- International Energy Agency. World Energy Outlook 2023; IEA: Paris, France, 2023; Available online: https://iea.blob.core.windows.net/assets/614bb748-dc5e-440b-966a-adae9ea022fe/WorldEnergyOutlook2023.pdf (accessed on 16 January 2024).

- International Energy Agency. World Energy Outlook 2024; IEA: Paris, France, 2024; Available online: https://iea.blob.core.windows.net/assets/5e9122fc-9d5b-4f18-8438-dac8b39b702a/WorldEnergyOutlook2024.pdf (accessed on 18 January 2024).

- Wall, D.M.; Dumont, M.; Murphy, J. GREEN GAS: Facilitating a Future Green Gas Grid Through the Production of Renewable Gas, IEA Bioenergy Task 37; IEA Bioenergy: Paris, France, 2018; Available online: https://www.ieabioenergy.com/wp-content/uploads/2018/04/green_gas_web_end.pdf (accessed on 18 December 2023).

- International Energy Agency. Outlook for Biogas and Biomethane: Prospects for Organic Growth; IEA: Paris, France, 2020; Available online: https://iea.blob.core.windows.net/assets/03aeb10c-c38c-4d10-bcec-de92e9ab815f/Outlook_for_biogas_and_biomethane.pdf (accessed on 24 December 2023).

- ENEA Australia Pty Ltd.; Deloitte Financial Advisory Pty Ltd. Australia’s Bioenergy Roadmap: Appendix–Market Activity and Opportunities; ARENA: Sydney, Australia, 2021. Available online: https://arena.gov.au/assets/2021/11/appendix-market-activity-and-opportunities-australias-bioenergy-roadmap.pdf (accessed on 6 June 2024).

- International Energy Agency. Renewables 2023: Analysis and Forecast to 2028; IEA: Paris, France, 2024; Available online: https://iea.blob.core.windows.net/assets/96d66a8b-d502-476b-ba94-54ffda84cf72/Renewables_2023.pdf (accessed on 12 November 2024).

- Lovrak, A.; Pukšec, T.; Grozdek, M.; Duić, N. An integrated Geographical Information System (GIS) approach for assessing seasonal variation and spatial distribution of biogas potential from industrial residues and by-products. Energy 2022, 239, 122016. [Google Scholar] [CrossRef]

- Brahma, A.; Saikia, K.; Hiloidhari, M.; Baruah, D.C. GIS based planning of a biomethanation power plant in Assam, India. Renew. Sustain. Energy Rev. 2016, 62, 596–608. [Google Scholar] [CrossRef]

- Chukwuma, E.C.; Okey-Onyesolu, F.C.; Ani, K.A.; Nwanna, E.C. GIS bio-waste assessment and suitability analysis for biogas power plant: A case study of Anambra state of Nigeria. Renew. Energy 2021, 163, 1182–1194. [Google Scholar] [CrossRef]

- Laasasenaho, K.; Lensu, A.; Lauhanen, R.; Rintala, J. GIS-data related route optimization, hierarchical clustering, location optimization, and kernel density methods are useful for promoting distributed bioenergy plant planning in rural areas. Sustain. Energy Technol. Assess. 2019, 32, 47–57. [Google Scholar] [CrossRef]

- Lovrak, A.; Pukšec, T.; Duić, N. A Geographical Information System (GIS) based approach for assessing the spatial distribution and seasonal variation of biogas production potential from agricultural residues and municipal biowaste. Appl. Energy 2020, 267, 115010. [Google Scholar] [CrossRef]

- Jayarathna, L.; Kent, G.; O’Hara, I.; Hobson, P. A Geographical Information System based framework to identify optimal location and size of biomass energy plants using single or multiple biomass types. Appl. Energy 2020, 275, 115398. [Google Scholar] [CrossRef]

- Biosantech, T.A.S.; Rutz, D.; Janssen, R.; Drosg, B. 2-Biomass resources for biogas production. In The Biogas Handbook; Wellinger, A., Murphy, J., Baxter, D., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 19–51. [Google Scholar]

- Gerber, P.J.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J.; Falcucci, A.; Tempio, G. Tackling Climate Change Through Livestock–A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013. [Google Scholar]

- Yalcinkaya, S.; Ruhbas, Y. Spatiotemporal analysis framework for identifying emerging hot spots and energy potential from livestock manure in Turkey. Renew. Energy 2022, 193, 278–287. [Google Scholar] [CrossRef]

- Casas, R.; Casas, F.; Bustos, J. Design of profitable networks of biogas plants in Chile. SN Appl. Sci. 2021, 3, 1–23. [Google Scholar] [CrossRef]

- Soha, T.; Papp, L.; Csontos, C.; Munkacsy, B. The importance of high crop residue demand on biogas plant site selection, scaling and feedstock allocation—A regional scale concept in a Hungarian study area. Renew. Sustain. Energy Rev. 2021, 141, 110822. [Google Scholar] [CrossRef]

- Wang, S.; Yin, C.; Jiao, J.; Yang, X.; Shi, B.; Richel, A. StrawFeed model: An integrated model of straw feedstock supply chain for bioenergy in China. Resour. Conserv. Recycl. 2022, 185, 106439. [Google Scholar] [CrossRef]

- Sharmin, S.; Yabar, H.; Richards, D. Green Energy Optimization in Dinajpur, Bangladesh: A Path to Net Neutrality. Sustainability 2023, 15, 1336. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Brzozowska, A.; Stebila, J. Agricultural Residue Management for Sustainable Power Generation: The Poland Case Study. Appl. Sci. 2021, 11, 5907. [Google Scholar] [CrossRef]

- Bidart, C.; Frohling, M.; Schultmann, F. Livestock manure and crop residue for energy generation: Macro-assessment at a national scale. Renew. Sustain. Energy Rev. 2014, 38, 537–550. [Google Scholar] [CrossRef]

- Kulichkova, G.I.; Ivanova, T.S.; Köttner, M.; Volodko, O.I.; Spivak, S.I.; Tsygankov, S.P.; Blume, Y.B. Plant feedstocks and their biogas production potentials. Open Agric. J. 2020, 14, 219–234. [Google Scholar] [CrossRef]

- O’Shea, R.; Wall, D.M.; Kilgallon, I.; Browne, J.D.; Murphy, J.D. Assessing the total theoretical, and financially viable, resource of biomethane for injection to a natural gas network in a region. Appl. Energy 2017, 188, 237–256. [Google Scholar] [CrossRef]

- Dzene, L.; Bodescu, F. Evaluation of Biomass Availability For Biogas Production At Regional Level. Environ. Clim. Technol. 2009, 3, 54–62. [Google Scholar] [CrossRef]

- Akther, A.; Ahamed, T.; Noguchi, R.; Genkawa, T.; Takigawa, T. Site suitability analysis of biogas digester plant for municipal waste using GIS and multi-criteria analysis. Asia-Pac. J. Reg. Sci. 2019, 3, 61–93. [Google Scholar] [CrossRef]

- Safieddin, A.S.M.; Asakereh, A.; Soleymani, M. An analysis of renewable electricity generation potential from municipal solid waste: A case study (Khuzestan Province, Iran). Biomass Convers. Biorefinery 2023, 13, 89–97. [Google Scholar] [CrossRef]

- Bedoić, R.; Smoljanić, G.; Pukšec, T.; Čuček, L.; Ljubas, D.; Duić, N. Geospatial analysis and environmental impact assessment of a holistic and interdisciplinary approach to the biogas sector. Energies 2021, 14, 5374. [Google Scholar] [CrossRef]

- Hohn, J.; Lehtonen, E.; Rasi, S.; Rintala, J. A Geographical Information System (GIS) based methodology for determination of potential biomasses and sites for biogas plants in southern Finland. Appl. Energy 2014, 113, 1–10. [Google Scholar] [CrossRef]

- Veiga, A.P.B.; Silva, R.S.; Martins, G. Geographic Information Systems based approach for assessing the locational feasibility for biomethane production from landfill gas and injection in pipelines in Brazil. Eng. Sanit. E Ambient. 2022, 27, 41–46. [Google Scholar] [CrossRef]

- Rohl, M.; Roth, S.; Schutz, W.; Zehnsdorf, A.; Herbes, C. Biogas production from submerged macrophytesa case study of regional biomass potentials in Germany. Energy Sustain. Soc. 2019, 9, 1–12. [Google Scholar]

- Ali, M.M.; Ndongo, M.; Bilal, B.; Yetilmezsoy, K.; Youm, I.; Bahramian, M. Mapping of biogas production potential from livestock manures and slaughterhouse waste: A case study for African countries. J. Clean. Prod. 2020, 256, 120499. [Google Scholar] [CrossRef]

- Valenti, F.; Arcidiacono, C.; Chinnici, G.; Cascone, G.; Porto SM, C. Quantification of olive pomace availability for biogas production by using a GIS-based model. Biofuels Bioprod. Biorefin. 2017, 11, 784–797. [Google Scholar] [CrossRef]

- Zareei, S. Evaluation of biogas potential from livestock manures and rural wastes using GIS in Iran. Renew. Energy 2018, 118, 351–356. [Google Scholar] [CrossRef]

- Zubaryeva, A.; Zaccarelli, N.; Del Giudice, C.; Zurlini, G. Spatially explicit assessment of local biomass availability for distributed biogas production via anaerobic co-digestion—Mediterranean case study. Renew. Energy 2012, 39, 261–270. [Google Scholar] [CrossRef]

- O’Shea, R.; Kilgallon, I.; Wall, D.; Murphy, J.D. Quantification and location of a renewable gas industry based on digestion of wastes in Ireland. Appl. Energy 2016, 175, 229–239. [Google Scholar] [CrossRef]

- Villamar, C.A.; Rivera, D.; Aguayo, M. Anaerobic co-digestion plants for the revaluation of agricultural waste: Sustainable location sites from a GIS analysis. Waste Manag. Res. 2016, 34, 316–326. [Google Scholar] [CrossRef]

- Valenti, F.; Porto SM, C.; Chinnici, G.; Cascone, G.; Arcidiacono, C. Assessment of citrus pulp availability for biogas production by using a GIS-based model: The case study of an area in southern Italy. Chem. Eng. Trans. 2017, 58, 529–534. [Google Scholar] [CrossRef]

- Mattioli, A.; Boscaro, D.; Dalla, V.F.; Correale, S.F.; Pezzuolo, A.; Sartori, L.; Bolzonella, D. Biogas from Residual Grass: A Territorial Approach for Sustainable Bioenergy Production. Waste Biomass Valorizat. 2017, 8, 2747–2756. [Google Scholar] [CrossRef]

- Valenti, F.; Liao, W.; Porto SM, C. A GIS-based spatial index of feedstock-mixture availability for anaerobic co-digestion of Mediterranean by-products and agricultural residues. Biofuels Bioprod. Biorefin. 2018, 12, 362–378. [Google Scholar] [CrossRef]

- Keogh, N.; Corr, D.; O’Shea, R.; Monaghan RF, D. The gas grid as a vector for regional decarbonisation-a techno economic case study for biomethane injection and natural gas heavy goods vehicles. Appl. Energy 2022, 323, 119590. [Google Scholar] [CrossRef]

- De Sousa, L.V.; Lora, E.E.; de Lisboa, F.C.; Dovichi, F.B.; Del Olmo, O.A. Holistic assessment of Brazil’s bioenergetic potential. Biofuels Bioprod. Biorefin. 2023, 18, 675–685. [Google Scholar] [CrossRef]

- Uyan, M.; Ertunç, E. GIS-based optimal site selection of the biogas facility installation using the Best-Worst Method. Process Saf. Environ. Prot. 2023, 180, 1003–1011. [Google Scholar] [CrossRef]

- Hoo, P.Y.; Patrizio, P.; Leduc, S.; Hashim, H.; Kraxner, F.; Tan, S.T.; Ho, W.S. Optimal Biomethane Injection into Natural Gas Grid—Biogas from Palm Oil Mill Effluent (POME) in Malaysia. Energy Procedia 2017, 105, 562–569. [Google Scholar] [CrossRef]

- Rodrigues, C.; Rodrigues, A.C.; Vilarinho, C.; Alves, M.; Alonso, J.M. Spatial multicriteria gis-based analysis to anaerobic biogas plant location for dairy waste and wastewater treatment and energy recovery (Barcelos, NW Portugal). In Innovation, Engineering and Entrepreneurship; Springer: Cham, Switzerland, 2019; Volume 505, pp. 626–632. [Google Scholar] [CrossRef]

- Famoso, F.; Prestipino, M.; Brusca, S.; Galvagno, A. Designing sustainable bioenergy from residual biomass: Site allocation criteria and energy/exergy performance indicators. Appl. Energy 2020, 274, 115315. [Google Scholar] [CrossRef]

- Worawimut, C.; Vivanpatarakij, S.; Watanapa, A.; Wiyaratn, W.; Assabumrungrat, S. Geographical information system based planning and economic assessment of centralized and decentralized biogas plants for electricity generation. Chem. Eng. Trans. 2020, 80, 349–354. [Google Scholar] [CrossRef]

- Durmaz, Y.G.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Siegrist, A.; Bowman, G.; Burg, V. Energy generation potentials from agricultural residues: The influence of techno-spatial restrictions on biomethane, electricity, and heat production. Appl. Energy 2022, 327, 120075. [Google Scholar] [CrossRef]

- Billal, M.M.; Sebastian, R.M.; Kumar, A. The development of an integrated GIS-based optimization framework for power generation from municipal solid waste-to-energy facilities. J. Clean. Prod. 2024, 434, 139865. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, Y.; Ma, K. A method for determining the optimal number and location of biomass energy facilities. J. Environ. Manag. 2023, 348, 119313. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Chang, S.; Cai, W.; Wang, C.; Fu, J.; Hui, J.; Yu, L.; Zhu, W.; Huang, G.; Kumar, A.; et al. Spatial distribution of usable biomass feedstock and technical bioenergy potential in China. GCB Bioenergy 2020, 12, 54–70. [Google Scholar] [CrossRef]

- Bojesen, M.; Birkin, M.; Clarke, G. Spatial competition for biogas production using insights from retail location models. Energy 2014, 68, 617–628. [Google Scholar] [CrossRef]

- Bojesen, M.; Skov-Petersen, H.; Gylling, M. Forecasting the potential of Danish biogas production—Spatial representation of Markov chains. Biomass Bioenergy 2015, 81, 462–472. [Google Scholar] [CrossRef]

- Sahoo, K.; Mani, S.; Das, L.; Bettinger, P. GIS-based assessment of sustainable crop residues for optimal siting of biogas plants. Biomass Bioenergy 2018, 110, 63–74. [Google Scholar] [CrossRef]

- Scarlat, N.; Fahl, F.; Dallemand, J.F.; Monforti, F.; Motola, V. A spatial analysis of biogas potential from manure in Europe. Renew. Sustain. Energy Rev. 2018, 94, 915–930. [Google Scholar] [CrossRef]

- Hoo, P.Y.; Hashim, H.; Ho, W.S.; Yunus, N.A. Spatial-economic optimisation of biomethane injection into natural gas grid: The case at southern Malaysia. J. Environ. Manag. 2019, 241, 603–611. [Google Scholar] [CrossRef]

- Ferrari, G.; Marinello, F.; Lemmer, A.; Ranzato, C.; Pezzuolo, A. Network analysis for optimal biomethane plant location through a multidisciplinary approach. J. Clean. Prod. 2022, 378, 134484. [Google Scholar] [CrossRef]

- Jayarathna, L.; Kent, G.; O’Hara, I.; Hobson, P. Geographical information system based fuzzy multi criteria analysis for sustainability assessment of biomass energy plant siting: A case study in Queensland, Australia. Land. Use Policy 2022, 114, 105986. [Google Scholar] [CrossRef]

- Wang, M.M.; Ji, L.; Xie, Y.L. Strategic planning and optimal tactical management of regional bioethanol supply-chain system with high spatial resolution and uncertainties. Biofuels Bioprod. Biorefin. 2024, 18, 464–481. [Google Scholar] [CrossRef]

- Wang, R.; Cai, W.J.; Yu, L.; Li, W.; Zhu, L.; Cao, B.W.; Li, J.; Shen, J.X.; Zhang, S.H.; Nie, Y.Y.; et al. A high spatial resolution dataset of China’s biomass resource potential. Sci. Data 2023, 10, 1–15. [Google Scholar] [CrossRef]

- Zhao, G.; Jiang, P.; Zhang, H.; Li, L.; Ji, T.; Mu, L.; Lu, X.; Zhu, J. Mapping out the regional low-carbon and economic biomass supply chain by aligning geographic information systems and life cycle assessment models. Appl. Energy 2024, 369, 123599. [Google Scholar] [CrossRef]

- Venier, F.; Yabar, H. Renewable energy recovery potential towards sustainable cattle manure management in Buenos Aires Province: Site selection based on GIS spatial analysis and statistics. J. Clean. Prod. 2017, 162, 1317–1333. [Google Scholar] [CrossRef]

- Calvert, K.; Mabee, W. Spatial analysis of biomass resources within a socio-ecologically heterogeneous region: Identifying opportunities for a mixed feedstock stream. ISPRS Int. J. Geo-Inf. 2014, 3, 209–232. [Google Scholar] [CrossRef]

- Sliz-Szkliniarz, B.; Vogt, J. A GIS-based approach for evaluating the potential of biogas production from livestock manure and crops at a regional scale: A case study for the Kujawsko-Pomorskie Voivodeship. Renew. Sustain. Energy Rev. 2012, 16, 752–763. [Google Scholar] [CrossRef]

- Valenti, F.; Porto SM, C.; Chinnici, G.; Cascone, G.; Arcidiacono, C.; Dale, B.E.; Liao, W. Spatial analysis of feedstock supply and logistics to establish regional biogas power generation: A case study in the region of Sicily. Renew. Sustain. Energy Rev. 2018, 97, 50–63. [Google Scholar] [CrossRef]

- Dao, K.M.; Yabar, H.; Mizunoya, T. Unlocking the Energy Recovery Potential from Sustainable Management of Bio-Resources Based on GIS Analysis: Case Study in Hanoi, Vietnam. Resources 2020, 9, 133. [Google Scholar] [CrossRef]

- De Jesus, R.H.G.; Barros, M.V.; Salvador, R.; De Souza, J.T.; Piekarski, C.M.; De Francisco, A.C. Forming clusters based on strategic partnerships and circular economy for biogas production: A GIS analysis for optimal location. Biomass Bioenergy 2021, 150, 106097. [Google Scholar] [CrossRef]

- Escalante, H.; Castro, L.; Gauthier-Maradei, P.; De la Vega, R.R. Spatial decision support system to evaluate crop residue energy potential by anaerobic digestion. Bioresour. Technol. 2016, 219, 80–90. [Google Scholar] [CrossRef]

- Akca, M.S.; Sarikaya, O.V.; Doker, M.F.; Ocak, F.; Kirlangicoglu, C.; Karaaslan, Y.; Satoglu, S.I.; Altinbas, M. A detailed GIS based assessment of bioenergy plant locations using location-allocation algorithm. Appl. Energy 2023, 352, 121932. [Google Scholar] [CrossRef]

- Guido, R.E.; Rodríguez, C.R.; Javi, V.M.; Oviedo, O.A. A multicriteria GIS-based approach for mapping biomass agricultural residues availability for biopower plants. Clean Technol. Environ. Policy 2024, 26, 1989–2006. [Google Scholar] [CrossRef]

- Cioabla, A.E.; Ionel, I.; Dumitrel, G.A.; Popescu, F. Comparative study on factors affecting anaerobic digestion of agricultural vegetal residues. Biotechnol. Biofuels 2012, 5, 39. [Google Scholar] [CrossRef]

- Bertasini, D.; Battista, F.; Rizzioli, F.; Frison, N.; Bolzonella, D. Decarbonization of the European natural gas grid using hydrogen and methane biologically produced from organic waste: A critical overview. Renew. Energy 2023, 206, 386–396. [Google Scholar] [CrossRef]

- Labatut, R.A.; Pronto, J.L. Chapter 4—Sustainable Waste-to-Energy Technologies: Anaerobic Digestion. In Sustainable Food Waste-to-Energy Systems; Trabold, T.A., Babbitt, C.W., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 47–67. [Google Scholar]

- Rajlakshmi Jadhav, D.A.; Dutta, S.; Sherpa, K.C.; Jayaswal, K.; Saravanabhupathy, S.; Mohanty, K.T.; Banerjee, R.; Kumar, J.; Rajak, R.C. Chapter 7—Co-digestion processes of waste: Status and perspective. In Bio-Based Materials and Waste for Energy Generation and Resource Management; Hussain, C.M., Kushwaha, A., Bharagava, R.N., Goswami, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 207–241. [Google Scholar]

- Melis, E.; Asquer, C.; Carboni, G.; Scano, E.A. Chapter 4—Role of Cannabis sativa L. in energy production: Residues as a potential lignocellulosic biomass in anaerobic digestion plants. In Current Applications, Approaches, and Potential Perspectives for Hemp; García-Tejero, I.F., Durán-Zuazo, V.H., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 111–199. [Google Scholar]

- Rolewicz-Kalinska, A.; Oniszk-Poplawska, A.; Wesolowska, J.; Rynska, E.D. Conditions for the development of anaerobic digestion technologies using the organic fraction of municipal solid waste: Perspectives for Poland. Environ. Dev. Sustain. 2016, 18, 1279–1296. [Google Scholar] [CrossRef]

- Nosratinia, M.; Tofigh, A.A.; Adl, M. Determining optimal locations for biogas plants: Case study of Tehran province for utilization of bovine and aviculture wastes. J. Renew. Energy Environ. 2021, 8, 36–44. [Google Scholar] [CrossRef]

- Metson, G.S.; Feiz, R.; Lindegaard, I.; Ranggard, T.; Quttineh, N.H.; Gunnarsson, E. Not all sites are created equal—Exploring the impact of constraints to suitable biogas plant locations in Sweden. J. Clean. Prod. 2022, 349, 131390. [Google Scholar] [CrossRef]

- Tulun, S.; Arsu, T.; Gurbuz, E. Selection of the most suitable biogas facility location with the geographical information system and multi-criteria decision-making methods: A case study of Konya Closed Basin, Turkey. Biomass Convers. Biorefinery 2023, 13, 3439–3461. [Google Scholar] [CrossRef]

- Ankathi, S.; Watkins, D.; Sreedhara, P.; Zuhlke, J.; Shonnard, D.R. GIS-Integrated Optimization for Locating Food Waste and Manure Anaerobic Co-digestion Facilities. Acs Sustain. Chem. Eng. 2021, 9, 4024–4032. [Google Scholar] [CrossRef]

- Dima, F.A.F.; Li, Z.F.; Mang, H.P.; Zhu, L.X. Feasibility Analysis of Biogas Production by Using GIS and Multicriteria Decision Aid Methods in the Central African Republic. Sustainability 2022, 14, 13418. [Google Scholar] [CrossRef]

- Chukwuma, E.C. Facility location allocation modelling for bio-energy system in Anambra State of Nigeria: Integration of GIS and location model. Renew. Energy 2019, 141, 460–467. [Google Scholar] [CrossRef]

- Guler, D.; Charisoulis, G.; Buttenfield, B.P.; Yomralioglu, T. Suitability modeling and sensitivity analysis for biomass energy facilities in Turkey. Clean. Technol. Envir 2021, 23, 2183–2199. [Google Scholar] [CrossRef]

- Yabe, N. Environmental and economic evaluations of centralized biogas plants running on cow manure in Hokkaido, Japan. Biomass Bioenergy 2013, 49, 143–151. [Google Scholar] [CrossRef]

- Franco, C.; Bojesen, M.; Hougaard, J.L.; Nielsen, K. A fuzzy approach to a multiple criteria and Geographical Information System for decision support on suitable locations for biogas plants. Appl. Energy 2015, 140, 304–315. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Sutherland, J.W. A GIS-based method for identifying the optimal location for a facility to convert forest biomass to biofuel. Biomass Bioenergy 2011, 35, 3951–3961. [Google Scholar] [CrossRef]

- Rodríguez, R.; Gauthier-Maradei, P.; Escalante, H. Fuzzy spatial decision tool to rank suitable sites for allocation of bioenergy plants based on crop residue. Biomass Bioenergy 2017, 100, 17–30. [Google Scholar] [CrossRef]

- Kordi, M.; Brandt, S.A. Effects of increasing fuzziness on analytic hierarchy process for spatial multicriteria decision analysis. Comput. Environ. Urban. Syst. 2012, 36, 43–53. [Google Scholar] [CrossRef]

- Jelokhani-Niaraki, M.; Malczewski, J. A group multicriteria spatial decision support system for parking site selection problem: A case study. Land. Use Policy 2015, 42, 492–508. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strat. Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Franco, A.C.; Franco, L.S.; Tesser, D.P.; Salvador, R.; Piekarski, C.M.; Picinin, C.T.; Puglieri, F.N. Benefits and barriers for the production and use of biomethane. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–17. [Google Scholar] [CrossRef]

- Clean Energy Regulator. Biomethane Method Package 2022—Simple Method Guide: User Guide for Biomethane Projects. 2022. Available online: https://cer.gov.au/document_page/biomethane-method-package-simple-method-guide (accessed on 26 January 2025).

- Swinbourn, R.; Li, C.; Wang, F. A Comprehensive Review on Biomethane Production from Biogas Separation and its Techno-Economic Assessments. ChemSusChem 2024. [Google Scholar] [CrossRef] [PubMed]

- European Biogas Association. Transparency Register: 18191445640-83; European Biogas Association: Brussels, Belgium, 2021; Available online: https://www.europeanbiogas.eu/wp-content/uploads/2021/11/Renewable-Energy-Directive_EBA-Position.pdf (accessed on 26 January 2025).

- International Energy Agency. Biomethane: A Global Stocktake; IEA: Paris, France, 2024; Available online: https://iea.blob.core.windows.net/assets/33c29a6e-a2f2-4e20-9fa1-e057263c893a/IEA_Biomethanewebinar_GergelyMOLNAR.pdf (accessed on 26 January 2025).

| Criteria | Include | Exclude |

|---|---|---|

| Timeline and publication source | 2008–2024 | Articles published in conference/seminar proceedings and non-peer-reviewed papers. |

| Language | Research papers published in English. | Papers published in other languages. |

| Methodology | Articles used GIS-based methods. | Mathematical modelling and statistical analysis. |

| Data | Studies based on spatial data. | Studies based on non-spatial data. |

| Review Objectives | Number of Articles |

|---|---|

| 1. To review GIS-based applications on biomass assessment | 57 |

| 2. To review GIS-based methods used for selecting or optimising biogas plant locations | 36 |

| 3. To review the GIS application for facilitating biomethane grid injection | 06 |

| Corn/Maize | Green onion waste | Palm | Papaya waste |

| Wheat | Beans | Olive | Banana stem waste |

| Oats | Lentils | Soybeans | Tricale |

| Rye | Peas | Peanut | Tapicoa |

| Sorghum | Chickpeas | Rapeseed | Cotton |

| Triticale | Beet leaves | Sesame seed | Sugarcane |

| Barley | Grapes | Sunflower | Sugar beet |

| Rice | Citrus | Potatoes | Tobacco |

| Quinoa | Tomato | Grass |

| Energy Crop | Methane Yield (m3/tVSadded) 1 | Energy Crop | Methane Yield (m3/tVSadded) |

|---|---|---|---|

| Maize (whole crop) | 205–450 | Sorghum | 207–387 |

| Wheat (grain) | 384–426 | Peas | 390 |

| Oats (grain) | 250–295 | Sunflower | 154–400 |

| Rye (grain) | 283–492 | Potatoes | 276–400 |

| Grass | 298–467 | Sugar beet | 236–381 |

| Barley | 353–658 | Straw | 242–324 |

| Triticale | 337–555 | Leaves | 417–453 |

| Industrial Type | Number of Articles |

|---|---|

| Sugar mill residues | 6 |

| Slaughterhouse waste | 6 |

| Olive industry by-products | 4 |

| Citrus processing residues | 3 |

| Grain mill residues | 3 |

| Milk-processing waste | 3 |

| Other food industrial residues | 3 |

| Rapeseed-processing residues | 2 |

| Wine industry residues | 2 |

| Palm oil mill effluent | 2 |

| Fique bagasse | 1 |

| Study Scale | GIS Methods | Feedstock Types Studied | Grid Size | Reference | |

|---|---|---|---|---|---|

| 1 | National | Spatial analysis | Agricultural residues (multi crops); livestock; food and garden; forest biomass; grass residues, shrubbery residues, energy crop (sweet sorghum) | 1 km × 1 km | [54] |

| 2 | National | Spatial analysis | Agricultural residues (multi crops); livestock; food and garden | 1 km × 1 km | [14] |

| 3 | Regional | Spatial analysis | Agricultural residues (single crop); forest biomass (softwood sawmill residues, softwood forest harvest residues, softwood pulp logs) | 1 km × 1 km | [15] |

| 4 | National | Spatial analysis | Livestock | 1 km × 1 km | [55] |

| 5 | National | Spatial analysis | Livestock | 1 km × 1 km | [56] |

| 6 | Regional | Raster analysis | Agricultural residues (multi crops) | 30 m × 30 m | [57] |

| 7 | National | Spatial analysis | Livestock | 1 km × 1 km | [58] |

| 8 | Regional | Spatial analysis | Agricultural residues (single crop); livestock; food waste | 10 km × 10 km | [59] |

| 9 | Regional | Spatial analysis | Agricultural residues (multi crops); livestock | 1 km × 1 km | [60] |

| 10 | Regional | Spatial analysis | Agricultural residues (single crop); livestock; food and garden; forest waste (native forestry residues, plantation softwood residues), urban waste (biosolids, solid waste) | 1 km × 1 km | [61] |

| 11 | Regional | Spatial Analysis | Agricultural residues (multi crops) | 3 km × 3 km | [62] |

| 12 | National | Spatial Analysis | Agricultural residues (multi crops); forestry residues; energy crops | 1 km × 1 km | [63] |

| 13 | Regional | Spatial Analysis | Agricultural residues (multi crops) | 1.2 km × 1.2 km | [64] |

| Study Scale | GIS Methods | Feedstock Types Studied | Reference | |

|---|---|---|---|---|

| 1 | Regional | Spatial analysis, Kernel Density | Agricultural residues (multi crops); livestock; food and garden; WWTP; industrial waste | [31] |

| 2 | Regional | Spatial mapping, Spatial Statistics (Incremental Spatial Autocorrelation), Hotspot Analysis | Livestock | [65] |

| 3 | Regional | Spatial Analysis, Zonal Statistics | Agricultural residues (multi crops); forest biomass; underutilised round-wood, grassland residues | [66] |

| 4 | Regional | Spatial analysis, Focal Statistic-sum tool | Agricultural residues (multi crops); livestock | [67] |

| 5 | Regional | heatmap (hotspot analysis) | Agricultural residues (multi crops); livestock; food industrial by-products (citrus processing plants, olive farms, dairy processing plants) | [68] |

| 6 | Regional | Spatial analysis, Kernel Density | Livestock; sewage sludge; biowaste (municipal, shops, tourist centres, vocational schools) | [13] |

| 7 | Regional | Cluster analysis, spatial statistics | Livestock | [69] |

| 8 | Regional | Cluster analysis (GIS, R) | Livestock | [70] |

| 9 | Regional | Neighborhood functions (focal statistics) | Agricultural residues (multi crops) | [71] |

| 10 | National | Cluster Analysis | Agricultural residues (multi crops); livestock | [23] |

| 11 | Regional | Spatial Analysis, Kernel Density | Livestock; sewage sludge | [72] |

| 12 | Regional | Spatial Analysis, Cluster Analysis | Agricultural residues (multi crops) | [73] |

| Method | Advantages | Disadvantages |

|---|---|---|

| Admin-based | Easy to calculate using non-spatial data. | Actual spatial distribution cannot be presented. |

| Location-based | Provide the precise locations of biomass resources. | It cannot be applied to area-based biomass sources such as crop residues. |

| Cluster-based | Densely distributed areas of biomass can be identified. | Output raster does not represent the exact locations and quantities of biomass. |

| Grid-based | Can apply for multiple biomass assessments. | Low-resolution grid size will affect the results. |

| Environmental Criteria | Suitability | Criteria Type | Excluded Buffer (m) Distance | References | |

|---|---|---|---|---|---|

| Minimum | Maximum | ||||

| Environmental protected/sensitive areas (Nature reserves, forests, etc.) | Boolean | Exclusive | 50 | 5000 | [12,22,29,36,37,39,47,48,50,52,53,57,61,65,67,69,71,72,73,80,81,82,83] |

| Waterbodies | Boolean | Exclusive | 30 | 1000 | [12,22,28,29,36,37,39,47,48,50,53,57,60,61,62,65,67,69,70,71,72,73,82,83,84,85,86] |

| Wetlands | Boolean | Exclusive | 50 | 1000 | [12,28,48,50,52,53,57,72,73] |

| Coastal areas | Boolean | Exclusive | 100 | 3000 | [29,50,72] |

| Soil conservation areas | Fuzzy | Selective | [71,84] | ||

| Nitrate vulnerable zone | Fuzzy | Selective | [60] | ||

| Wind direction | Fuzzy | Selective | [81] | ||

| Slope | Fuzzy | Selective | <5% | 20% | [12,22,28,29,37,47,48,52,53,57,60,61,62,69,73,80,82,84,85,86,87] |

| Altitude | Fuzzy | Selective | <500 m a.s.l * | [37,47,48,53,80] | |

| Floodplains | Boolean | Exclusive | 50 | 1000 | [12,22,28,29,36,57,60,67,69,71,72,85] |

| Landslide areas/Mass movement areas | Fuzzy | Selective | [60,71] | ||

| Volcanic hazard areas | Boolean | Exclusive | [71] | ||

| Mining areas | Boolean | Exclusive | 1000 | [52,57,61,71,72,73,80] | |

| Economic Criteria | Suitability | Criteria Type | References |

|---|---|---|---|

| Biomass potential | Fuzzy | Selective | All articles |

| Seasonality of biomass availability | [10,31,57,60,61,83] | ||

| Distance to access roads | Fuzzy | Selective | All articles |

| Distance to railways | Fuzzy | Selective | [29,36,37,52,57,60,61,67,69,86] |

| Distance to power line | Fuzzy | Selective | [12,22,28,37,45,47,52,61,67,72,73,80,81,82,83] |

| Distance to gas pipelines | Fuzzy | Selective | [31,37,47,52,57,61,67,70,73,80] |

| Energy demand | Fuzzy | Selective | [61] |

| Workforce potential/unemployment rate | Fuzzy | Selective | [48,61] |

| Land value | Fuzzy | Selective | [28] |

| Organic carbon in the soil | Fuzzy | Selective | [60] |

| Transport cost | Fuzzy | Selective | [53] |

| Social Criteria | Suitability | Criteria Type | Excluded Buffer (m) | References | |

|---|---|---|---|---|---|

| Minimum | Maximum | ||||

| Built-up areas | Boolean | Exclusive | 300 | 5000 | [22,29,36,47,48,61,67,72,80,81,83,84] |

| Settlements (urban/rural) | Boolean | Exclusive | 30 | 2000 | [12,22,28,29,39,45,47,50,52,53,57,60,62,65,69,70,72,73,80,81,82,84,85,86] |

| Distance to public and commercial places | Boolean | Exclusive | 1000 | [22,28,52,65,69,72,81,83,84] | |

| Airports | Boolean | Exclusive | 500 | 1000 | [29,36,52,61,69,81] |

| Military zones | Boolean | Exclusive | [81] | ||

| Power/water/pump station | Boolean | Exclusive | 100 | 500 | [22,47,52,61,69,82] |

| Industrial areas | Boolean | Exclusive | [28,37,47,48,60,72,73,81,82,84] | ||

| Population density/exposed | Fuzzy | Selective | [48,53,60,61,86,88] | ||

| GDP per capita | Fuzzy | Selective | [48,60] | ||

| Agricultural lands | Fuzzy | Selective | 50 | [28,29,37,48,50,72] | |

| Arable lands | Fuzzy | Selective | [48,53] | ||

| Land use/land cover (classes) | Fuzzy | Selective | [10,45,47,52,60,61,71,82,83,84,87] | ||

| Archeological/Cultural sites | Boolean | Exclusive | 50 | [37,50,53,61] | |

| Visual impact | Fuzzy | Selective | [60,61] | ||

| Country | Main Approach | Techniques | Minimum Transport Distance or Distance from the Road | Number of Suitable Sites | Considered End-Product | Reference | |

|---|---|---|---|---|---|---|---|

| 1 | Poland | Approach 01: Suitability analysis | SA, EA | 40 km | 41 | Electricity; biomethane injection; heat | [67] |

| 2 | Italy | Approach 01: Suitability analysis | AHP, MCA | - | Suitable areas | Electricity | [37] |

| 3 | Finland | Approach 02: Optimality analysis | SA, NA | 10, 40 km | 49 | Biomethane injection | [31] |

| 4 | Denmark | Approach 02: Optimality analysis | p-median solver, LAM | 30 km | 10 | - | [55] |

| 5 | Denmark | Approach 02: Optimality analysis | AHP, FWOD, LAM | 30–40 km | 20 | CHP | [88] |

| 6 | Colombia | Approach 01: Suitability analysis | FAHP, MCA, TP | 25 km | 168 | - | [71] |

| 7 | Chile | Approach 01: Suitability analysis | AHP, map algebra, MCA | - | 178 | - | [39] |

| 8 | Bangladesh | Approach 01: Suitability analysis | AHP, MCA | - | 1 | Electricity | [28] |

| 9 | Argentina | Approach 01: Suitability analysis | SA, SS | 20 km * | 90, 46, 39 | Electricity | [65] |

| 10 | Nigeria | Approach 02: Optimality analysis | LAM, OF | 10 km | 3 | - | [85] |

| 11 | United States | Approach 02: Optimality analysis | MCIEA, LAM | 50 km | 1 to 25 | - | [57] |

| 12 | Italy | Approach 01: Suitability analysis | SA | - | 4 | Electricity | [68] |

| 13 | Nigeria | Approach 01: Suitability analysis | AHP, MCA | - | Suitable areas | Electricity | [12] |

| 14 | Turkey | Approach 03: Optimality analysis | OF, SA, AHP, MOMILP | 60 and 40 km | 12 | Electricity | [50] |

| 15 | Italy | Approach 02: Optimality analysis | AHP, MCA, NA | - | 3 | Electricity | [48] |

| 16 | United States | Approach 03: Optimality analysis | NA, OF, MILP | 13 miles | 1 | Electricity | [83] |

| 17 | Brazil | Approach 01: Suitability analysis | AHP, CA, MCA | 15 km * | 2 | - | [70] |

| 18 | Turkey | Approach 01: Suitability analysis | BWM, FMCA, WLC | - | Suitable areas | - | [86] |

| 19 | Croatia | Approach 01: Suitability analysis | SM | 20 km * | 2 | CHP | [10] |

| 20 | Iran | Approach 01: Suitability analysis | AHP, MCA | 10 km * | Suitable areas | - | [80] |

| 21 | Hungary | Optimality analysis (suitability analysis is not included) | LAM | 40 km | Suitable Livestock farms | - | [20] |

| 22 | Central African Republic | Approach 01: Suitability analysis | ELECTRE TRI, MCDA | - | 1 | Electricity | [84] |

| 23 | Italy | Approach 02: Optimality analysis | AHP, MCA, LAM | 30 km | 93 | Biomethane injection | [60] |

| 24 | Australia | Approach 02: Optimality analysis | AHP, heat map, FMCA, SAF, ZSA | 40 km | 57 | Electricity | [61] |

| 25 | Sweden | Approach 02: Optimality analysis | SM, Modified optimisation model | - | 105 | - | [81] |

| 26 | Switzerland | Approach 02: Optimality analysis | SA, LAM | 20 km | Suitable areas | Electricity; heat; biomethane | [51] |

| 27 | Iran | Approach 01: Suitability analysis | FAHP, MCA | - | Suitable areas | Electricity | [29] |

| 28 | Bangladesh | Approach 01: Suitability analysis | AHP, MCA | - | 21 | Electricity | [22] |

| 29 | Turkey | Approach 01: Suitability analysis | CRITIC, MABAC, FUCOM, MCA | - | 1 | - | [82] |

| 30 | Turkey | Approach 02: Optimality Analysis | AHP, VRP solver, LAM | 40 km, 100 km | 5, 14, 24 | Electricity | [72] |

| 31 | Canada | Approach 03: Optimality Analysis | AHP, MCA, LA, MILP | 100 km | 30 | Electricity | [52] |

| 32 | Argentina | Approach 03: Optimality Analysis | CA, MCA, Simulation | 60 km | 5 | Electricity | [73] |

| 33 | China | Approach 02: Optimality Analysis | AHP, MCA, LAM | 40 km | 30 | Heat | [53] |

| 34 | Turkey | Approach 01: Suitability Analysis | BWM, MCA | - | Suitable areas | - | [45] |

| 35 | China | Approach 03: Optimality Analysis | FMCA, TSP, CCP, MILP | 50 km | 6 | Biofuel | [62] |

| 36 | China | Approach 02: Optimality Analysis | SA, NA, SAF | - | 1 | - | [64] |

| Criteria for Biomethane Injection Points | Maximum Distance from Natural Gas Grid to Biogas Plants | Network Pressure | Country | Reference |

|---|---|---|---|---|

| Distance to biogas plants | 2 km | - | Croatia | [30] |

| Digester, annual operation and maintenance cost of digester upgrading unit, annual operation and maintenance cost upgrading injection into the net, 45 bar maximum network pressure and 1 km length, annual operation and maintenance cost of injection | - | 45 bar max. | Chile | [24] |

| Network pressure | - | the minimum pressure in excess of 16 bar | Ireland | [26] |

| Natural gas grid and district gas gates, gas demand | - | - | Malaysia | [46] |

| Gas demand and seasonal variation at Compressed Natural Gas (CNG) station, Network pressure | 3.9 barg. | Ireland | [43] | |

| Network pressure | 1 km | - | Switzerland | [51] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesthrige, T.G.; Kaparaju, P. Decarbonisation of Natural Gas Grid: A Review of GIS-Based Approaches on Spatial Biomass Assessment, Plant Siting and Biomethane Grid Injection. Energies 2025, 18, 734. https://doi.org/10.3390/en18030734

Mesthrige TG, Kaparaju P. Decarbonisation of Natural Gas Grid: A Review of GIS-Based Approaches on Spatial Biomass Assessment, Plant Siting and Biomethane Grid Injection. Energies. 2025; 18(3):734. https://doi.org/10.3390/en18030734

Chicago/Turabian StyleMesthrige, Thanuja Gelanigama, and Prasad Kaparaju. 2025. "Decarbonisation of Natural Gas Grid: A Review of GIS-Based Approaches on Spatial Biomass Assessment, Plant Siting and Biomethane Grid Injection" Energies 18, no. 3: 734. https://doi.org/10.3390/en18030734

APA StyleMesthrige, T. G., & Kaparaju, P. (2025). Decarbonisation of Natural Gas Grid: A Review of GIS-Based Approaches on Spatial Biomass Assessment, Plant Siting and Biomethane Grid Injection. Energies, 18(3), 734. https://doi.org/10.3390/en18030734