Current Research Status and Prospects of Electrode Boilers Under the Background of the “Dual Carbon” Goals

Abstract

1. Introduction

2. The Fundamental Principle of the Electrode Boiler

2.1. Types of Electrode Boilers

2.2. Operating Mechanism of Immersion-Type Electrode Boilers

- (1)

- The electrodes heat the boiler water: the three-phase electrode is directly immersed in the boiler water, and when electrified, the boiler water, characterized by high thermal resistance, is instantly heated, generating high-quality steam.

- (2)

- Water circulation within the boiler: the water from the outer drum of the boiler is pumped into the inner drum via a circulation pump to maintain the concentration of the boiler water within the inner drum.

- (3)

- External feedwater supply: during normal operation or in a hot standby state, external feedwater is required to maintain a constant water level in the outer drum of the boiler, ensuring that the boiler operates reliably.

3. Development of Electrode Boilers in the Context of the “Dual Carbon” Goals

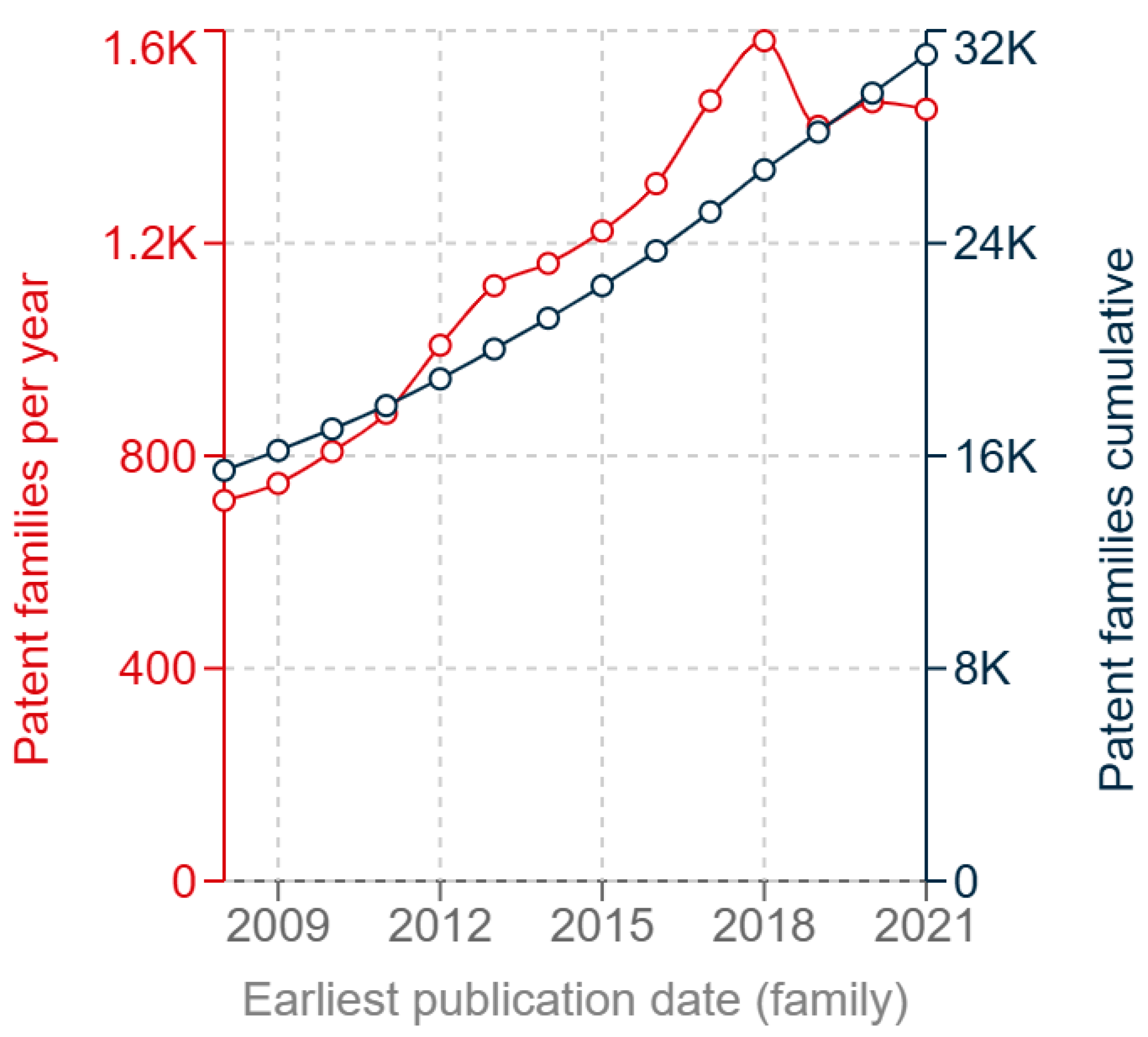

3.1. The Evolution of Electrode Boilers in China

3.2. The Technological Advancements of Relevant Enterprises in China

4. Current Status of Application of and Research on Electrode Boilers in the Context of the “Dual Carbon” Goals

4.1. Application of Electrode Boilers in Nuclear Power Plants

4.2. Thermal Energy Storage Technology of Electrode Boilers

4.3. Clean Heating

4.4. Maintaining Stable Grid Operation

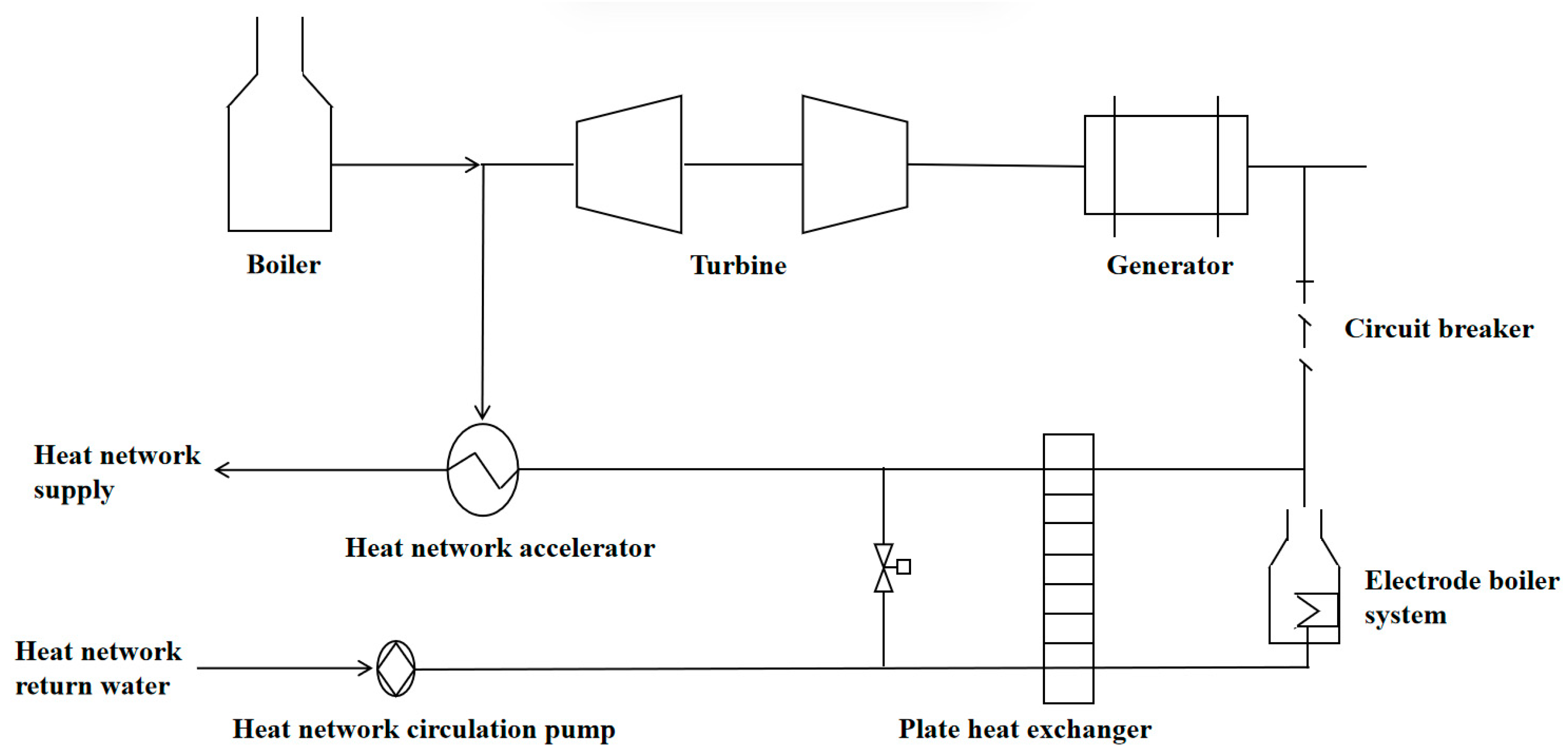

4.5. Grid Peak-Shaving and Renewable Energy Consumption

5. Issues Requiring Urgent Resolution in Electrode Boiler Technology

5.1. Issues Related to Electrode Materials and Corrosion

5.2. Issues Related to Boiler Water Treatment

5.3. Issues Related to Electric Field Distribution in Boilers

5.4. Issues Related to Monitoring and Control

6. Summary and Outlook

- In recent years, numerous scholars have conducted in-depth studies on the mechanisms behind wind curtailment, proposing various strategies to enhance system integration capacity through the use of electrode boilers. Future research should focus on optimizing the parameter configurations of electrode boilers for different application scenarios, while also exploring strategies for absorbing energy from other renewable resources. Moreover, it is crucial to strengthen the connection between theoretical research and practical applications, supporting experimental validation and the dissemination of new technologies.

- The electrode boiler plays a key role in peak-shaving for combined heat and power (CHP) units and in the absorption of new energy. Future CHP systems are expected to be more modular, with electrode boilers serving as flexible and scalable components. Future efforts should prioritize the development of heat-power decoupling technologies, optimize the integration of energy storage systems (especially novel storage technologies), and refine control strategies between the CHP unit and the electrode boiler. Advanced control methods, such as fuzzy logic and neural networks, should be incorporated to enable intelligent control of the electrode boiler. These advancements will enhance system flexibility, stability, economic efficiency, and energy utilization.

- It is recommended that further research be conducted on electrode materials to reduce dependence on imported materials. Key areas of focus should include the development of novel electrode materials, additives, and protective coatings, aiming to balance high heat generation efficiency with cost-effectiveness and corrosion resistance. For example, superconducting materials, known for their unique properties, like zero resistance and strong magnetism, reduce energy losses during transmission. Their high conductivity also enhances durability, extending the lifespan of the electrodes, making them promising candidates for electrode applications. In the future, electrode materials may incorporate self-cleaning technologies through intelligent surface treatment processes, enabling automatic cleaning during operation, thus extending their lifespan while maintaining high performance. Given that corrosion and wear of electrodes are inevitable during boiler operation, the thermal efficiency in corrosive environments should be thoroughly considered when developing new materials.

- Efficient, low-cost monitoring and assessment of changes in electrode boiler water composition and corrosion are critical. With advancements in Industry 4.0 and IoT technology, there is increasing emphasis on intelligence and automation across various sectors. Research should focus on leveraging these advanced technologies to achieve more accurate and efficient remote control and minimizing control delays as much as possible.

- With the support of renewable resources such as wind and solar energy, electrode boilers will play an increasingly significant role in clean heating. In the future, the size of electrode boilers may be further reduced to meet the heating needs of residential and small commercial spaces, allowing for seamless integration with existing heating infrastructures (e.g., district heating systems) and building energy management systems (BEMS). Furthermore, electrode boilers will evolve beyond standalone heating devices, integrating with other green technologies such as photovoltaic power generation, heat pumps, and smart grids to form comprehensive energy solutions.

- In the future, electrode boilers may integrate with novel thermal storage materials (e.g., phase-change materials and ceramic storage) to improve storage efficiency and thermal energy density. This will further enhance the electrode boiler’s capabilities in energy storage and heat recovery.

- Strengthening collaboration between enterprises and universities, as well as among enterprises, is essential. Interdisciplinary and cross-regional knowledge integration is a key driver of modern technological development and is crucial for addressing significant engineering challenges.

- In addition to the applications of electrode boilers discussed in Chapter 3, considering their advantages and the specific needs of various industries, I have outlined some potential applications in Table 5.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Z.-Y.; Yao, S.; Yang, S.-P.; Wang, X.-L. Under goals of carbon peaking and carbon neutrality: Status, problems, and suggestions of CCUS in China. Huan Jing Ke Xue = Huanjing Kexue 2023, 44, 1128–1138. [Google Scholar]

- Yang, Q.; Sun, Y.; Zhou, H.; Ling, C. Research review of carbon capture, utilization and storage technology in China’s typical industries. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2023, 51, 101–110. [Google Scholar]

- Liu, F.; Guan, J.; Qi, Z.; Fang, M.; Shen, Z.; Li, C. Technology route selection for carbon capture utilization and storage in coal fired power plants. J. Huazhong Univ. Sci. Technol 2022, 50, 1–13. [Google Scholar]

- Al-Mulali, U.; Tang, C.F.; Ozturk, I. Estimating the environment Kuznets curve hypothesis: Evidence from Latin America and the Caribbean countries. Renew. Sustain. Energy Rev. 2015, 50, 918–924. [Google Scholar] [CrossRef]

- Chandran, V.; Sharma, S.; Madhavan, K. Electricity consumption–growth nexus: The case of Malaysia. Energy Policy 2010, 38, 606–612. [Google Scholar] [CrossRef]

- Chang, C.-C.; Carballo, C.F.S. Energy conservation and sustainable economic growth: The case of Latin America and the Caribbean. Energy Policy 2011, 39, 4215–4221. [Google Scholar] [CrossRef]

- Fodha, M.; Zaghdoud, O. Economic growth and pollutant emissions in Tunisia: An empirical analysis of the environmental Kuznets curve. Energy Policy 2010, 38, 1150–1156. [Google Scholar] [CrossRef]

- Kivyiro, P.; Arminen, H. Carbon dioxide emissions, energy consumption, economic growth, and foreign direct investment: Causality analysis for Sub-Saharan Africa. Energy 2014, 74, 595–606. [Google Scholar] [CrossRef]

- Rui, Q. Influencing Factors and Scenario Prediction of Carbon Emissions in China. Sci. Technol. Ecnony Mark. 2023, 12, 46–49. [Google Scholar]

- Suo, H.-X. Development and Reform Commission Pushes for Coal Power Retrofit Plan. China Business Daily. 22 July 2024, p. A04. Available online: https://finance.sina.com.cn/jjxw/2024-07-20/doc-incetcst7510379.shtml (accessed on 12 September 2024).

- Guan, D.; Meng, J.; Reiner, D.-M.; Zhang, N.; Shan, Y.; Mi, Z.; Shao, S.; Liu, Z.; Zhang, Q.; Davis, S.-J. Structural decline in China’s CO2 emissions through transitions in industry and energy systems. Nat. Geosci. 2018, 11, 551–555. [Google Scholar] [CrossRef]

- Tan, B.; Song, H.; Si, S.; Lu, X.-M.; Liu, Z.-P.; Zhang, Y.-L.; Xu, Y. The technology and practice for clean combustion of coal. Coal Sci. Technol. 2022, 50 (Suppl. S2), 393–402. [Google Scholar]

- Qin, B.-Y.; Zhou, X.-Y.; Ding, T.; Shi, W.; Li, H.-Y.; Wen, Y. Review on development of global carbon market and prospect of China’s carbon market construction. Autom. Electr. Power Syst. 2022, 46, 186–199. [Google Scholar]

- Ren, D.-W.; Hou, J.-M.; Xiao, J.-Y.; Jin, Y.; Jin, C.; Hui, D. Exploration of key technologies for energy storage in the cleansing transformation of energy and power. High Volt. Eng. 2021, 47, 2751–2759. [Google Scholar]

- Zhou, Q.; Ma, Y.-H.; Shen, C.-Y.; Zhang, Z.-Z.; Zhang, Y.-Q.; Yang, S.-Y. Reflection and suggestions on sustainable development of new energy in northwest China in new era. Power Syst. Clean Energy 2020, 36, 78–84. [Google Scholar]

- Yuan, X.-F. Study on Mechanism Modeling and Dynamic Characteristics of Submerged Electrode Boiler System. Master’s Thesis, North China Electric Power University, Beijing, China, 2019. [Google Scholar]

- Wang, Z.; Chen, W.-B.; Ye, Y.-H. Application of regenerative electrode boilers in heating systems. Sci. Technol. Innov. Her. 2018, 15, 88–89. [Google Scholar]

- Xie, H.-B.; Dai, S.; Xu, D.; Hu, L.-X. Study on the impact of district heating network characteristics on the effectiveness of wind power curtailment reduction. Electr. Power Autom. Equip. 2020, 40, 24–31. [Google Scholar]

- Wang, K. Discussion on the flexibility peak-shaving and decoupling technology for heating units under the “Dual-Carbon” targets. Saf. Technol. Spec. Equip. 2023, 8–10. [Google Scholar] [CrossRef]

- Xu, Z.-P.; Chen, J.; Zhang, J.-X.; Arafat, A. Wind curtailment consumption coordination heating strategy based on electrode boiler and thermal power plant. Mod. Electron. Tech. 2023, 46, 169–175. [Google Scholar]

- Han, W.-Q. Research on combined heating mode of photothermal and electrode boiler. Sol. Energy 2019, 53–57. [Google Scholar] [CrossRef]

- Luo, G.-X.; Wang, J.-X. Electric Heat Boiler. Ind. Boil. 1987, 22+48–54. [Google Scholar] [CrossRef]

- Wang, H.; Dong, H.-M.; Du, Q.; Wei, G.-H. Current situation and outlook of electrode boilers in China. J. Eng. Therm. Energy Power 2023, 38, 1–12. [Google Scholar]

- Wang, Z.; Dai, G.-P.; Zhang, D.-C.; Huang, Y.-T.; Ceng, N. Research on the insulation performance of the boiler shell for immersion electrode boilers. Technol. Wind 2019, 162–163. [Google Scholar] [CrossRef]

- Guo, F.; Xia, Q.-Y.; Liu, Y. Theory and application of immersion-type electrode boiler. Energy Res. Manag. 2012, 2, 65–67. [Google Scholar] [CrossRef]

- Jiang, X.; Zhou, Y.-X. Study on electric field distribution characteristics of electrodes in submerged electrode boiler. Comput. Simul. 2022, 39, 248–252. [Google Scholar]

- Zheng, Z. Study on Electrode Corrosioncharacteristics of High Voltage Electrodeboiler. Master’s Thesis, Xinjiang University, Xinjiang, China, 2021. [Google Scholar]

- Electrode Boiler Technology in Typical Cases and Application Characteristics of Wind Power Heating in Xinjiang. In Proceedings of the National Thermal Power Plant Unit Flexibility Retrofit Technology Exchange Seminar; China Thermal Power Industry Technology Innovation Strategic Alliance, National Thermal Power Engineering Technology Research Center: Beijing, China, 2018; p. 5.

- Chen, W.-P.; Dai, G.-P.; Chen, C.; Ye, Y.-H. A review of the research and development of high-voltage electrode boiler technology. Technol. Econ. Guide 2019, 27, 65–66. [Google Scholar]

- Xu, H.-G.; Luo, W. Research on the utilization of waste heat from thermal drainage and centralized heating and cooling in nuclear power plants. Fluid Mach. 2024, 52, 100–104. [Google Scholar]

- Yao, M.-J.; Ye, Q. Academician of the Chinese Academy of Engineering: Nuclear Power Promotes the Achievement of the ’Dual Carbon’ Goals. China Energy News. 8 September 2023, p. 4. Available online: http://paper.people.com.cn/zgnyb/html/2023-09/08/node_2225.htm (accessed on 15 September 2024).

- Deng, Z.-L. Consideration on environmental protection of new energy development and utilization under the background of carbon peak carbon neutrality. Leather Manuf. Environ. Technol. 2023, 4, 41–44. [Google Scholar]

- He, L.; Hu, Z.-H. Thermal Energy Storage Technology: A cost-effective energy solution. Science and Technology Daily. 28 May 2024, p. 006. Available online: https://digitalpaper.stdaily.com/http_www.kjrb.com/kjrb/html/2024-05/28/node_7.htm (accessed on 21 September 2024).

- Rao, Y.-F.; Si, X.-Z.; Gu, Q.-F.; Yang, H.-J. Energy Storage Technology Development Trend and Technology Status Analysis. Electr. Energy Manag. Technol. 2020, 7–15. [Google Scholar] [CrossRef]

- Yang, Y.-C.; Zhang, Y.; Mo, K. Development and Outlook of New Technologies for Energy Storage. China Heavy Equip. 2022, 27–32. [Google Scholar] [CrossRef]

- Shen, X.-T.; Li, Q.; Yue, L.-W. Multiple Countries Accelerate the Development of Advanced Energy Storage Technologies. People’s Daily. 19 July 2022, p. 017. Available online: http://world.people.com.cn/n1/2022/0719/c1002-32478817.html (accessed on 21 September 2024).

- Ma, W.-S. The Analysis of Energy Consumption Characteristics and Research on Optimal Load Dispatch of Cogeneration Units. Master’s Thesis, Northeast Electric Power University, Jilin, China, 2023. [Google Scholar]

- Wang, Z.-X.; Zhang, J.-J.; Dong, B.; Shi, L.-N.; Li, S.; Yang, F.; Gu, J.-G. Research on technology and policy of flexibility renovation for coal-fired power plants under carbon peaking and carbon neutrality goal. Electr. Power Technol. Environ. Prot. 2024, 40, 213–220. [Google Scholar]

- Liu, Z.-X.; Zhang, Y.-J.; Gao, T.-T.; Hou, Y.; Bian, J.-C. Analysis of Flexibility Improvement Technology for Thermal Power Generating Units under the “Dual Carbon” Goal. Power Stn. Aux. Equip. 2023, 44, 40–45. [Google Scholar]

- Zhang, T.-Y. A Brief Analysis of the Application of Electric Boilers and Boiler Room Design. China Plant Eng. 2023, 120–122. [Google Scholar] [CrossRef]

- Zhang, C.-F.; Ding, X.-Y.; Gao, X.-F.; Qu, S.-J.; Chuai, Z.-Y.; Cheng, Y.-S.; Li, X.-J.; Lan, Y. Research and Analysis on the Implementation Plan of Promoting “Clean Energy+Clean Heating”. Jilin Electr. Power 2022, 50, 13–16. [Google Scholar]

- Shan, Q.; Yang, X.-F.; Wu, X.-H.; Sun, D.-L.; Yu, C.-Y.; Liu, G.-H. Research on modeling and simulation of ground source heat pump heating system with seasonal solar thermal Research on modeling and simulation of ground source heat pump heating system with seasonal solar thermal. Renew. Energy Resour. 2022, 40, 1028–1037. [Google Scholar]

- Ma, Q.; Lu, Y.; Wang, M.; Ren, Y.-C.; Chai, R. Analysis of the current status of heating research based on clean heating methods. East China Sci. Technol. 2023, 89–91. [Google Scholar] [CrossRef]

- Xu, Z.-J.; Zhao, D.-P. Research on Clean Heating from Wind Power Based on Cogeneration. In Innovation Practices in Power Enterprise Management in China (2019); Jilin Electric Power Co., Ltd. Bai Cheng Power Plant: Baicheng, China, 2020; p. 4. [Google Scholar]

- Yuan, H.; Liu, Y.-H.; Sun, J.; Ge, J. Energy Storage Capacity Optimization Allocation Methods for Grid-Connected New Energy under Dual-Carbon Background. Power Syst. Clean Energy 2024, 40, 134–140. [Google Scholar]

- Zhang, D.; Feng, K.-H.; Shi, Z.-Y.; Yu, Q.-X. Current States and Recommendations for Grid Integration of New Energy in China. Sol. Energy 2024, 89–97. [Google Scholar] [CrossRef]

- Yang, X.-S. Analysis of New Energy Grid Integration and Energy Storage Technologies. Xinjiang Youse Jinshu 2023, 46, 96–97. [Google Scholar]

- Wang, Z. Research on Energy Storage Planning and Operation Control Technology of New Power System under the Background of “Dual Carbon”. Mod. Ind. Econ. Informationization 2024, 14, 183–184+188. [Google Scholar]

- Yang, J.-W.; Zhang, N.; Wang, Y.; Kang, C.-Q. Multi-energy System Towards Renewable Energy Accommodation: Review and Prospect. Autom. Electr. Power Syst. 2018, 42, 11–24. [Google Scholar]

- Liu, F.-L.; Wang, F.; Yan, J.-M.; Xu, G.-Y.; Bi, T.-S. In Estimating maximum penetration level of renewable energy based on frequency stability constrains in power grid. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 4–7 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 607–611. [Google Scholar]

- Ji, Z.-G. An Investigation into the Current Status and Development Trends of the Wind Power Industry in China. China Plant Eng. 2020, 217–218. [Google Scholar] [CrossRef]

- Sun, K. Renewable Energy Development in the First Three Quarters Continues to Improve; Energy Supply and Demand Situation Remains Stable. State Grid News. 22 November 2022, p. 005. Available online: http://211.160.252.154/202211/22/#page=6 (accessed on 4 October 2024).

- Zhang, Z.-G.; Kang, C.-Q. Challenges and Prospects for Constructing the New-type Power System Towards a Carbon Neutrality Future. Proc. CSEE 2022, 42, 2806–2819. [Google Scholar]

- Shi, H.-J. The Need for Further Improvement in Wind Power Consumption Capacity. Electr. Age 2024, 9, 3. [Google Scholar]

- Wang, G. Strategic Role and Development Recommendations of Energy Storage under the Carbon Neutrality Goal. Vitality 2021, 20, 107–108. [Google Scholar]

- Zhang, J.-H.; Zhang, J.-H.; Mu, G.; Ge, Y.-F.; Yan, G.-G.; Shi, S.-J. Hierarchical Optimization Scheduling of Deep Peak Shaving for Energy-storageAuxiliary Thermal Power Generating Units. Power Syst. Technol. 2019, 43, 3961–3970. [Google Scholar]

- Li, J.-H.; An, C.-Y.; Li, C.-P.; Zhang, J.-X.; Liu, R.-T. Multi-Objective Optimization Scheduling Method Considering Peak Regulating Market Transactions for Energy Storage-New Energy-Thermal Power. Trans. China Electrotech. Soc. 2023, 38, 6391–6406. [Google Scholar]

- Xu, B.; Cui, H.-L. Experimental study on deep peak shaving performance of combined electrode boiler of cogeneration unit. Ningxia Electr. Power 2022, 60–65. [Google Scholar] [CrossRef]

- Sun, M.-M.; Wang, L. Economic Analysis of Peak Regulation Method in Heat Grid with Electrode Boiler for Energy Storage. J. Shenyang Inst. Eng. (Nat. Sci.) 2019, 15, 327–331. [Google Scholar]

- Liu, R.-F.; He, Y.-K.; Qi, X.-F.; Wang, R.; Liu, Q.; Luo, K.-Y. Cost Characteristics and Social Cost Comparison of Energy Storage and Other Flexible Regulation Resources. China Power Enterp. Manag. 2019, 35–37. [Google Scholar] [CrossRef]

- Miao, C.-H.; Bai, Z.-H.; Wang, W.; Sun, F.-C.; Zhang, P.; Yang, P. Economic comparison and analysis of typical regenerative electric heating projects. Power Demand Side Manag. 2018, 20, 36–39. [Google Scholar]

- Zhang, X.-H. The Study of Technology and Application about Acquiring Heat Energy by Electricity. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2003. [Google Scholar]

- Chu, H.-C. Research on Accommodating Curtailed Wind Power Based on Wind Power Heating. Master’s Thesis, Dalian University of Technology, Dalian, China, 2015. [Google Scholar]

- Liu, D.-J. Study on Deep Peak-Shaving Technology for Thermal Power Units. China Plant Eng. 2020, 181–183. [Google Scholar] [CrossRef]

- Xu, F.; Min, Y.; Chen, L.; Chen, Q.; Hu, W.; Zhang, W.-L.; Wang, X.-H.; Hou, Y.-H. Combined Electricity-Heat Operation System Containing Large Capacity Thermal Energy Storage. Proc. CSEE 2014, 34, 5063–5072. [Google Scholar]

- Xu, Y.-K. The Design and Analysis of Game Theorymechanism About Thermal Power Plantparticipation in Wind Power Heating. Master’s Thesis, Xiangtan University, Xiangtan, China, 2016. [Google Scholar]

- Chen, Y.-X. Research on CHP Units’ Operating Characteristic and the Wind Power Accommodation Capacity Using the Electrical Boiler to Compensatepower Peak Load. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2016. [Google Scholar]

- Zhao, Q.-X.; Chen, X.-L.; Shao, H.-S.; Wang, Y.-G. Technical Innovation & Development in Industrial Boiler. Ind. Boil. 2016, 1–23. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Wang, L. Electric design of auxiliary steam boiler. Electr. Power 2011, 44, 62–65. [Google Scholar]

- Zhao, C.-L.; Xiu, H.-X. Briefly Introduce Auxiliary Boiler Selection in Nuclear Power Plant. Appl. Energy Technol. 2010, 25–27. [Google Scholar] [CrossRef]

- Zhou, X.-L.; Bai, M.; Na, E.-s. Feasibility Analysis of Electric Start-up Boiler for 1000MW Thermal Power Units. Power Syst. Eng. 2016, 32, 37–39+43. [Google Scholar]

- Ning, F.-Q. Crevice Corrosion Behaviors of Nickel-Based Alloy 690 and 405 Stainless Steel in High Temperature High Pressure Water. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2021. [Google Scholar]

- Yang, J.-Q.; Wang, S.-Z.; Wang, J.-H.; Xu, H.-D. Oxidation Behaviors of Four Candidate Materials for the Advanced Ultra-Supercritical Water Power Plant in Supercritical Water at 700 °C. J. Xi’an Jiaotong Univ. 2021, 55, 18–26. [Google Scholar]

- Zheng, Z.; Zhou, Y.-X.; Li, Y.-Y. AC Corrosion Behavior of Several Metallic Materials as Candidate for Boiler Electrode. J. Chiness Soc. Corros. Prot. 2023, 43, 202–208. [Google Scholar]

- Li, Z.-L.; Yang, Y. Mechanism, influence factors and risk evaluation of metal alternating current corrosion. CIESC J. 2011, 62, 1790–1799. [Google Scholar]

- Liu, X.; Chi, J.; Dong, B.; Sun, Y. Recent progress in decoupled H2 and O2 production from electrolytic water splitting. ChemElectroChem 2019, 6, 2157–2166. [Google Scholar] [CrossRef]

- Lee, J.; Kang, Y.; Kim, J.-S.; Park, J.; Lee, J.-J.; Kim, B.-K. Electrochemical descaling of metal oxides from stainless steel using an ionic liquid–acid solution. ACS Omega 2020, 5, 15709–15714. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.-M.; Liang, Y.-L.; Wang, Z.-Y.; Lu, Y. Constant Pressure Expansion Water Supply and Exhaust Device for High Temperature Circulating Hot Water System of Electrode Boiler, Has Solenoid Valve That Is Connected to Pure Water Make-Up. Pump. Patent CN208671388-U, 29 March 2019. [Google Scholar]

- Gong, Y.; Hu, Z.; Liu, T.-T. Application of automatic monitoring system of the hardness of water quality on the steam boiler’s water treatment equipment on the oil field. Foreign Electron. Meas. Technol. 2006, 63–65. [Google Scholar] [CrossRef]

- Wang, X.; Tong, W.; Li, C.-G.; Jiao, Y.-Q.; Di, X.-M.; Wang, Q.; Wang, J.-P. Application of Intelligent Water Quality Detection System in Boiler Water Quality Analysis. Sino-Glob. Energy 2022, 27, 96–100. [Google Scholar]

- Olatinwo, S.O.; Joubert, T.-H. Energy efficient solutions in wireless sensor systems for water quality monitoring: A review. IEEE Sens. J. 2018, 19, 1596–1625. [Google Scholar] [CrossRef]

- Zhang, Y. Operating Principles, Application Prospects, and Demonstration Effects of High-Voltage Electrode Thermal Storage Boilers. J. Shandong Ind. Technol. 2017, 4+42. [Google Scholar] [CrossRef]

- Yuan, X.-F.; Ma, J.; Zhang, Q.; Mo, R.-C. Study on improving operation flexibility of heating unit by using electrode boiler. Electr. Power Sci. Eng. 2018, 34, 42–48. [Google Scholar]

- He, X.; Ruan, Y.; Wang, W. Three-Dimensional Transient Electric Field Characteristics of High Pressure Electrode Boilers. Electronics 2024, 13, 1615. [Google Scholar] [CrossRef]

- Wu, X.-L.; Wang, L.-L.; Zhang, W.-W.; Gu, Z.-F. Analysis and application of order degree in intelligent manufacturing line control system based on information characterization. Comput. Integr. Manuf. Syst. 2021, 27, 1741–1748. [Google Scholar]

- Jiang, Y.; Li, Y.-N.; Fan, J.-L. Model Predictive Control-based Setpoint Regulation in Industrial Processes. Control Eng. China 2018, 25, 980–984. [Google Scholar]

- Hu, Y.-W.; He, W.-F.; Ren, L.-F.; Chen, Y.-H. Analysis of Fault Detection of Electrode Boiler Equipment Based on Grey Model. Mach. Build. Autom. 2023, 52, 229–232. [Google Scholar]

- Chen, W.-B.; Ceng, N.; Zhang, D.-C.; Wang, S.-G.; Huang, Y.-T. Conductivity Prediction and Control Methods for Electrode Boilers Based on Artificial Neural Networks. Electron. Technol. Softw. Eng. 2019, 71–72. [Google Scholar] [CrossRef]

| Project | Key Achievements |

|---|---|

| Xinjiang Altay City Clean Energy Heating Demonstration Project, China | This project, developed by Beijing Reeter Ai Energy Technology Co., Ltd. and Heng’an Power in China, includes four 120 MW high-temperature hot-water boilers, thermal storage support, a 4500 m2 electric boiler house, and six 2000 m3 thermal storage tanks. The system utilizes off-peak electricity for thermal storage at night, releasing heat during the day. The electrode boiler’s outlet water temperature reaches 140 °C, and the thermal storage can retain heat at 130 °C. Annually, the system consumes 158 million kWh, saving 55,400 tons of coal and reducing CO2 emissions by 138,000 tons. |

| Yunnan Jinding Zinc Industry Co., Ltd. Fluidized Bed Boiler Environmental Retrofit Project, China | A core piece of equipment, an electrode boiler, was successfully commissioned, achieving a thermal efficiency of 99.58%. This led to a significant reduction in energy consumption and pollutant emissions. Additionally, the system’s intelligent control improves automation levels and enhances the working conditions for operators. |

| Gansu 2 Million m2 Centralized Heating Project | This project utilizes four high-pressure electrode boilers and three thermal storage tanks for centralized heating. Unlike coal-fired boilers, the electrode boilers operate without combustion, eliminating exhaust and carbon emissions, thus ensuring clean heating. The system’s high thermal efficiency minimizes energy loss, and by storing heat during off-peak hours and releasing it during peak hours, it capitalizes on the peak–valley price difference, significantly reducing operational costs—an advantage that traditional boilers cannot offer. |

| Jet-Type Electrode Boilers | Immersion-Type Electrode Boilers | |

|---|---|---|

| Principle | Boiler water is sprayed directly onto the electrode for heating; the electrode is not immersed in the water, and there is no direct contact between the electrode and the metal shell, eliminating the need for insulation of the metal shell. | The electrode, connected to a high-voltage power source, is immersed in the boiler water for heating. Due to indirect contact between the electrode and the metal shell via the boiler water, insulation for the metal shell is required. |

| Power Requirements | Three-phase four-wire system with the neutral point grounded | The three-phase electrodes within the boiler are nearly symmetrical, so no special requirements exist for the power supply lines. |

| Steam Quality | High salt content | Low salt content |

| Circulating Water Volume | A large volume of water is required, as heating power is mainly sustained by the volume of water sprayed onto the electrodes. | A smaller volume of circulating water is needed, primarily to compensate for evaporation losses. |

| Insulation Needs | The outer shell is electrically charged and requires insulation devices. | The outer shell is not electrically charged and does not require insulation. |

| Boiler Water Conductivity | High, approximately 1700 μS/cm | Low, around 20–20 μS/cm |

| Operation and Maintenance | More complex; requires regular pollution discharge and water replenishment, with strict water quality requirements. | Simpler, with fewer maintenance requirements. |

| Space Requirement | Larger | Smaller |

| Year | Key Events Related to Electrode Boilers |

|---|---|

| 1905 | European scientists invented the world’s first low-pressure electrode boiler. |

| 1926 | Sweden’s Z&I Company pioneered the submerged electrode boiler, significantly improving control precision and enabling direct connection to high-voltage power sources (6–20 kV), marking the birth of high-pressure electrode boilers. |

| 1940s | European researchers developed the jet-type electrode boiler, which reduced the insulation requirements and began to be applied in industrial production. |

| 1970s to 1980s | With the rapid expansion of nuclear power plants abroad, electrode boilers gained widespread application in nuclear power construction due to their notable performance with regard to environmental and safety-related factors. |

| 1983 | With the rapid expansion of nuclear power plants abroad, electrode boilers gained widespread application in nuclear power construction due to their notable performance with regard to environmental and safety-related factors. |

| 1990s | China introduced nuclear technology from Westinghouse for the first time, and jet-type electrode boilers began to be applied on a large scale in the country. |

| 2009 to present | The Chinese high-pressure electrode boiler market has continuously advanced along two main lines: the “localization of overseas brands” and the “independence of domestic manufacturers”. |

| Issue | Potential Solutions |

|---|---|

| Electrode Materials and Corrosion | Improve the study of corrosion mechanisms; develop new electrode materials, additives, and protective coatings. |

| Boiler Water Treatment | Enhance research on the characteristics of electrode boiler water under different conditions; develop faster and more accurate intelligent monitoring and dosing systems. |

| Research on In-Boiler Electric Field Distribution | Improve the study of electric field distribution in electrode boilers under various conditions; explore methods to avoid or correct electric field issues. |

| Monitoring and Control | Expand the scope of monitoring and control; develop more accurate and efficient systems by integrating modern intelligent technologies. |

| Potential Applications | |

|---|---|

| Hydrogen Production and Utilization | Electrode boilers can be integrated with hydrogen production systems (e.g., electrolysis units) to provide the high temperatures required for enhanced electrolysis efficiency, or they can utilize hydrogen as an energy source to improve overall energy performance. Additionally, electrode boilers can serve as a hydrogen-powered heat sources, enabling the integration of hydrogen with thermal energy systems. |

| Zero-Carbon and Smart Building Systems | Electrode boilers can adjust their operation based on real-time climate conditions, energy prices, and building demands. They can also be integrated with other in-building energy systems (e.g., heat pumps, solar energy, and energy storage) to optimize energy management and reduce carbon emissions. |

| Seawater Desalination | Electrode boilers can supply stable thermal energy for seawater desalination, particularly when paired with renewable energy sources. This not only reduces carbon emissions but also enhances the economic viability of desalination processes. By integrating with solar, wind, and other renewable energy sources, electrode boilers offer low-carbon, efficient desalination solutions. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Hu, R.; Zhang, Y.; Dong, H.; Du, Q. Current Research Status and Prospects of Electrode Boilers Under the Background of the “Dual Carbon” Goals. Energies 2025, 18, 769. https://doi.org/10.3390/en18040769

Zhao Z, Hu R, Zhang Y, Dong H, Du Q. Current Research Status and Prospects of Electrode Boilers Under the Background of the “Dual Carbon” Goals. Energies. 2025; 18(4):769. https://doi.org/10.3390/en18040769

Chicago/Turabian StyleZhao, Zheng, Rui Hu, Yu Zhang, Heming Dong, and Qian Du. 2025. "Current Research Status and Prospects of Electrode Boilers Under the Background of the “Dual Carbon” Goals" Energies 18, no. 4: 769. https://doi.org/10.3390/en18040769

APA StyleZhao, Z., Hu, R., Zhang, Y., Dong, H., & Du, Q. (2025). Current Research Status and Prospects of Electrode Boilers Under the Background of the “Dual Carbon” Goals. Energies, 18(4), 769. https://doi.org/10.3390/en18040769