Abstract

The influence of supercritical CO2 on the properties of petroleum has become the focus of academic and industrial attention internationally. CO2 has been shown in laboratory studies and in field applications of shale oil to be an effective oil displacement agent. In this paper, the research progress of the interaction between CO2 and crude oil is investigated from three perspectives: (i) the research methods of the interaction experiment between CO2 and crude oil; (ii) the influence of CO2 on oil property and the primary controlling factors; and (iii) the cause, influence, and harm of CO2-induced asphaltene precipitation. Our current knowledge on this topic is as follows: (1) Physical simulation can investigate the effects of various variables on CO2 displacement, which is in situ and intuitive. Numerical simulation can investigate the displacement principle at the microscopic molecular level and also scale up the results of physical simulation to the macroscopic scale of oilfield production to explore the long-term large-scale injection rules; (2) after entering the formation, CO2 dissolves in crude oil, expands the volume of crude oil, reduces the viscosity, improves the oil–water mobility ratio, reduces the oil–water interfacial tension, and extracts light hydrocarbons to form a miscible displacement zone; (3) after CO2 is injected into the formation and dissolves in crude oil, it occupies the surface space of asphaltenes and causes asphaltenes to precipitate. Under the combined influence of internal and external factors, the precipitation of asphaltenes has a significant impact on the physical properties of the reservoir. Clarifying the influencing factors of CO2 on the property of crude oil has reference significance for understanding the reaction characteristics between supercritical CO2 and formation fluids, providing a theoretical basis for CO2 injection enhanced oil recovery technology, and has reference value for carbon storage research.

1. Introduction

Carbon capture, utilization and storage (CCUS), as a new technology developed to cope with greenhouse gas emission reduction, plays a crucial role in achieving large-scale CO2 emission reduction [1,2,3,4]. A study published by the International Energy Agency (IEA) in 2020 indicates that under sustainable development scenarios, the contribution of CCUS technology to cumulative CO2 emission reductions can reach 15% [5]. CO2-enhanced oil recovery (CO2-EOR) technology has a broad adaptability and significant oil increase effect, which has attracted much attention among many CCUS technologies. As an ideal place for carbon sequestration, oil reservoir can not only achieve long-term effective CO2 sequestration, but also improve oil recovery, with both economic and social environmental benefits [6].

In addition to studying the physical and chemical interaction between CO2 and reservoir rocks, the interaction between CO2 and fluids is also an area of concern. CO2-EOR technology involves dissolving CO2 in the formation oil after injection as an effective displacement agent, leading to a series of changes in the properties of crude oil and enhancing the oil recovery. The critical point of CO2 is 31.1 °C and 7.38 MPa, and it is easy to reach the supercritical state under reservoir conditions. Supercritical CO2 has the viscosity of gas and the solubility of liquid, with good injection performance and solubility. With the injection of supercritical CO2 into the formation, the energy is supplemented to the formation. The full contact of CO2 and the crude oil in the formation can modify the properties of crude oil, which can expand the volume of crude oil, reduce crude oil viscosity, reduce interfacial tension, extract light hydrocarbons in crude oil, and form miscible displacement under certain conditions, so as to improve oil recovery [7,8]. During the miscible contact between CO2 and crude oil, the composition and balance of crude oil will change, resulting in the flocculation, aggregation, precipitation and precipitation of asphaltene, and strong adsorption on the inner surface of reservoir rock, resulting in a series of phenomena such as reservoir pore throat blockage, wettability reversal, permeability reduction and seepage resistance increase [9,10,11].

This paper introduces the research methods and understanding of CO2 injection, discusses the effects of CO2 on properties of crude oil and asphaltene precipitation, analyzes the problems existing in the research methods and conclusions, and puts forward suggestions for the next step to provide scientific guidance for the follow-up research of CO2 injection.

2. Research Methods of CO2 Injection

Currently, the primary research methods are divided into two categories: physical simulation and numerical simulation. Physical simulations generally refer to the temperature and pressure environment of formation circumstances, as well as the creation of physical simulation experiments to replicate the influence of the CO2 displacement process on crude oil [12,13]. The numerical simulation uses the data provided by the physical simulation, and uses the numerical simulation software (PHREEQC v3.7 and TOUGHREACT v3.0) to establish the geological model and geochemical system to study the molecular change state of the CO2 displacement process. The physical simulation data can also be used to simulate the oilfield production process and determine the long-term scale injection rule [14,15].

2.1. Advances in Physical Simulation Experiment Research Methods

The commonly used experimental method for the impact of CO2 displacement on crude oil is the core displacement experiment, which mimics the fluid in the core at formation temperature and pressure in order to thoroughly analyze the CO2 displacement. The core displacement experiment is separated into two parts: a short-core displacement experiment and long -ore displacement experiment, which can investigate the effects of permeability, reservoir temperature, formation pressure, crude oil viscosity, gas injection volume and asphaltene on CO2 displacement. Using data from the quantity of CO2-driven asphaltene deposition in a low permeability reservoir, Hu et al. [16] investigated the influence of formation temperature and displacement pressure on deposition. In order to study the influence of gas injection rate and pressure on crude oil recovery under reservoir conditions, Wang et al. [17] designed a CO2 displacement long-core system experiment. To assess the impact of CO2 displacement, Zhang et al. [18] conducted an indoor core displacement experiment. Following Zhang’s approach, a further considered the effect of asphaltene precipitation on core wettability, Wu [11] investigated assessing wettability changes in the core end face and internal section following displacement. Although many scholars [19,20] have designed core displacement experiments for research, the occurrence condition of oil and water cannot be fully restored during the core displacement experiment. The simulated oil, simulated formation water, and formation fluid used in the experiment are different, and the core position and direction impact the experimental outcomes. The saturation and aging of the core took too long throughout the experiment, and the displacement procedure is extremely challenging [21,22].

The core displacement experiment is influenced by several factors. In order to solve this problem, the impact of CO2 on a particular crude oil property may be further investigated by physical simulation experiments like the Pressure–Volume–Temperature (PVT) experiment, microscopic displacement experiment, and miscible pressure experiment [23,24].

The thin tube experiment, interfacial tension disappearance, and bubble rising instrument are the primary techniques used to ascertain the lowest miscible pressure of CO2 and crude oil. Stalkup [25] proposed to measure the minimum miscibility pressure using a slim tube experiment. In order to compensate for the shortfall of time and high expenditure in the tiny tube experiment, Christiansen and Kim [26] used the bubble riser method to find the minimum miscible pressure. The accuracy of the bubble rising apparatus and interfacial tension loss techniques has to be further demonstrated because they are subjectively influenced. Although the thin tube experiment method is the most reliable laboratory determination method, the length of the thin tube, porosity and permeability and sand filling properties of the thin tube experiment method have certain influence on the experimental results.

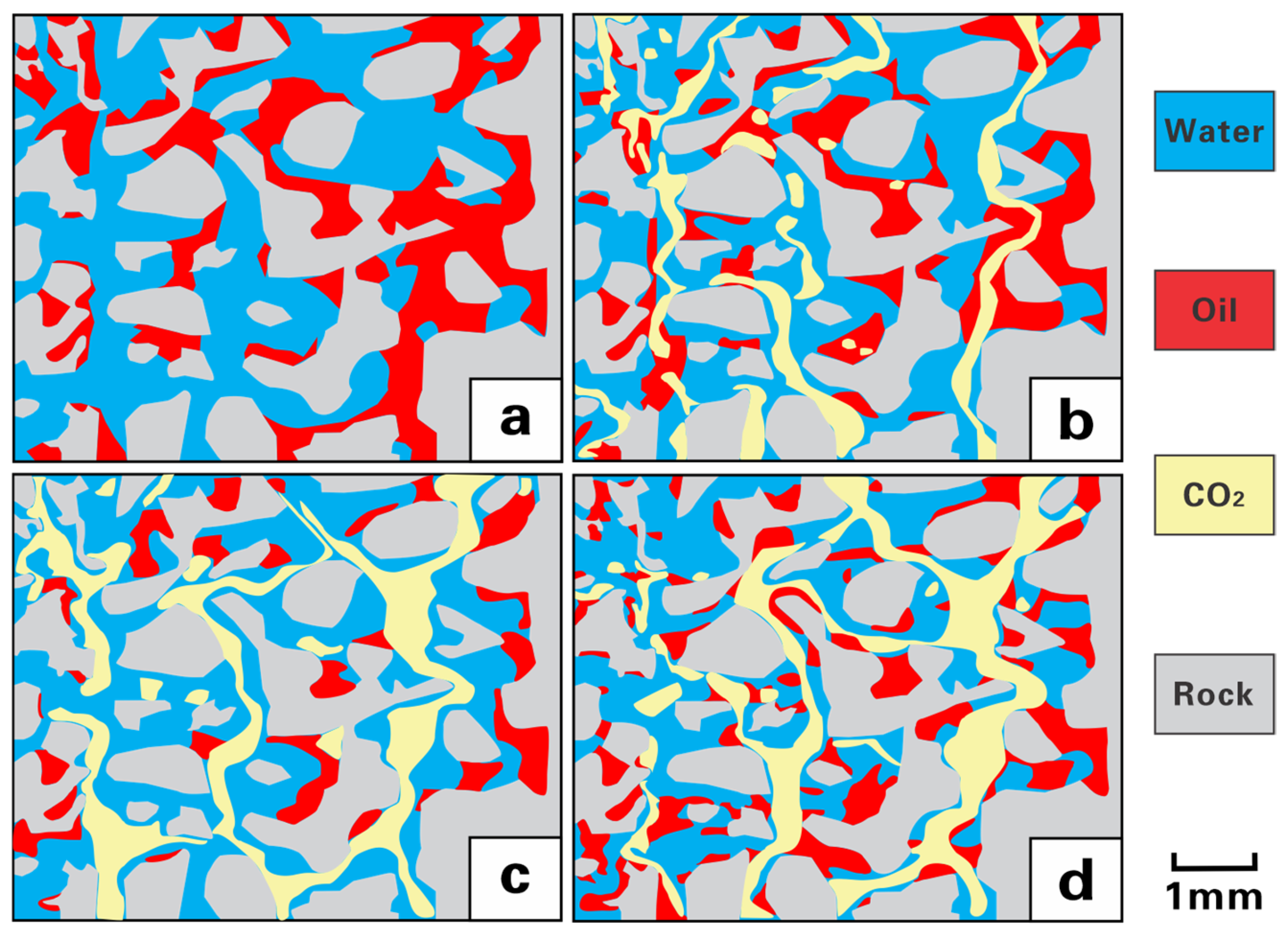

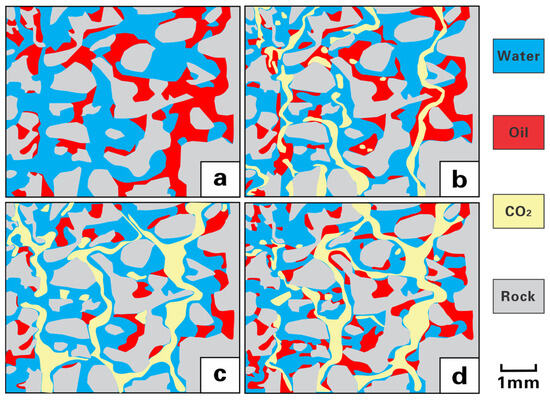

In microscopic oil displacement experiments that involve observing the quartz sand model, the real sandstone model and the etched glass model, the microscopic seepage dynamics of the fluid and the occurrence characteristics of different pore throats can be directly observed (Figure 1). Cui et al. [27] established a visual microscopic model to simulate the displacement process of CO2 in ultra-high water cut reservoirs, and found that CO2 can diffuse into crude oil through a water film. In order to analyze the influence of pore throat distribution on oil displacement efficiency during CO2 displacement, Li et al. [28] used a real sandstone microscopic model to conduct CO2 displacement experiments. Through high-resolution microscopy, Song et al. [29] investigated CO2 saturation and its distribution using two uniform microscopic models, demonstrating the impact of variables like injection rate and micromodel structure on CO2 displacement efficiency. The repeatability of the experimental data is limited, and the etched glass micromodel is unable to replicate the mineral surface in the tiny oil displacement experiment [30,31].

Figure 1.

Microscopic experiment of CO2 injection. (a) After water injection (20 MPa, 0.06 mL/min); (b) after CO2 injection (30 MPa); (c) after CO2 injection (40 MPa); (d) after CO2 injection (50 MPa) [32].

The PVT experiment measures the phase properties of CO2 gas mixed with formation fluid using a PVT fluid analyzer. According to Hao et al. [33], the PVT characteristics of any unknown oil–CO2 mixture in a reservoir can be predicted by regression of the CO2 concentration curve for various oil samples from the reservoir using the bubble point pressure, volume coefficient, swelling coefficient, solubility, or relative viscosity. A new visual PVT device was used by Yang et al. [24] to visually examine the change rule of the gas–liquid interface between CO2 and crude oil. When the crude oil attained saturation under formation pressure, Zhang et al. [34] measured the amount of CO2 injected into it using a PVT fluid analyzer. They then degassed the crude oil to ascertain its asphaltene content, viscosity, and hydrocarbon components. The drawback of the PVT is that the experiment’s reactor only contains three phases: water, gas, and oil. There are no mineral components involved, and the stratification of water and oil during the experiment affects the experimental outcomes [35,36].

Physical simulation experiments directly simulate reservoir conditions through physical models, offering a more realistic representation of the actual enhanced oil recovery (EOR) process. It can directly observe complex phenomena such as multiphase flow, phase behavior changes, and microscopic seepage, thereby revealing detailed mechanisms. Unexpected physical or chemical phenomena may also be observed during the experiment to promote theoretical innovation. However, physical simulation experiments require specialized equipment and materials, and the preparation and operation are time-consuming [37,38]. The cost of a single experiment is high, and the flexibility to adjust parameters is limited. Alcorn et al. [39] indicated that at a larger scale, gravity segregation of fluids with different densities, rock heterogeneities, and fractures influence the flow behavior more; thus, the flow behavior is scale-dependent. The laboratory model struggles to completely restore the scale and heterogeneity of the actual reservoir, and it is difficult to simulate the long-term (decades) oil displacement process. Additionally, the natural variability in core samples can lead to fluctuations in experimental results, resulting in lower consistency in repeated experiments.

2.2. Advances in Numerical Simulation Experimental Research Methods

There are two main simulation methods, molecular dynamics simulation and reservoir numerical simulation, that are used to study the CO2 displacement process through numerical simulation experiments. In order to better observe and comprehend the mutual dissolution of CO2 and crude oil, molecular dynamics simulation is the application of theoretical algorithms and computer techniques to simulate the kinetic behavior of molecular motion, which allows for the study of the impact of CO2 on crude oil at the molecular level and provides an accurate description of the microscopic process of CO2 diffusion in alkanes [40,41,42]. For example, Zhong et al. [43] investigated the microscopic mechanism and process of supercritical CO2 stripping of crude oil from surface of silicon dioxide using molecular dynamics modeling. Wang [44] examined the microscopic mechanism of supercritical CO2 displacement of shale oil and the microscopic process of supercritical CO2 displacement of shale oil using molecular dynamics simulation techniques. Using the molecular dynamics simulation method, Teng [45] investigated the features and characteristics of CO2 swelling/extraction heavy oil and examined the influence of CO2 on the structure and attributes of each heavy oil component. The real composition of crude oil is complicated, and the molecular dynamics simulation mostly shows the reaction of CO2 with a single alkane molecule. There is a lack of molecular-level interaction between multiple components of crude oil and CO2 [46,47].

Reservoir numerical simulation, which can analyze the CO2 injection process from a few days to several decades, is a crucial tool to simulate the actual development process of oil reservoirs and predict the production performance. In order to reduce risk at each stage, Nasralla et al. [48] designed a 3-month CO2 injection model that considered variables including spacing, injection rate, and anticipated duration. Alfarge et al. [49] observed that the diffusion effect of CO2 molecules did not support the oil displacement impact after simulating a continuous infusion of CO2 for 20 years. By simulating the harm caused by asphaltene deposition on reservoir permeability, Zhou [50] established a numerical model of asphaltene deposition to investigate the effect of asphaltene deposition on the development of CO2 displacement. Using numerical modeling, Mahzari et al. [51] investigated the effect of the release of a light hydrocarbon gas phase in reservoirs on the CO2 displacement process. To investigate how porosity, permeability, and gas injection rate affect oil recovery and CO2 storage, Lliguizaca et al. [52] built a numerical simulation mechanism model for CO2 injection development. Using CMG-Winprop v2023.10 phase simulation software, Li [53] performed phase and numerical simulation of CO2 displacement asphaltene precipitation, quantitatively assessed the harm resulting from asphaltene deposition to reservoirs, and used numerical simulation to characterize the amount of asphaltene precipitation, damage to reservoir porosity and permeability, and damage to production capacity. Although the numerical simulation method can effectively simulate the CO2 injection process and production state under high temperature and high-pressure conditions, the biggest problem of this method is that its accuracy depends on the accuracy of physical parameters, and the acquisition of physical parameters is difficult.

Numerical simulation research can quickly adjust parameters for multi-scenario analysis, support sensitivity research and optimization design, and can simulate large-scale reservoirs (kilometers) and long-term spans (decades). Relying on computing resources rather than physical equipment, the cost of a single simulation is much lower than that of experiments, which is suitable for large-scale parameter screening. It can deal with complex geological conditions and coupling processes. However, the accuracy of numerical simulation results is limited by the accuracy of mathematical models and parameters, which need to be calibrated by experimental data [54]. According to Ahammad et al. [55], accurate modeling of the effect of viscosity is one of the most challenging aspects of the CO2-based EOR process. Numerical simulation research may ignore the micro phenomenon, resulting in macro prediction deviation. The simulation of complex phase transitions or chemical reactions still needs to be simplified [56].

Future research directions should focus on utilizing physical experiments to obtain critical data for calibrating numerical model parameters. The experimental scheme is screened by numerical simulation to reduce blind experiments. Combined with microscopic experiments and macroscopic simulations, a cross-scale prediction model can be established. The combination of the two methods can significantly improve the design efficiency and reliability of the CO2 injection scheme and reduce the development risk.

3. Effect of CO2 on Crude Oil Property

After CO2 is dissolved in crude oil, CO2 molecules diffuse into the oil phase, causing volume expansion of crude oil, reduced viscosity, improved oil–water flow ratio, reduced oil–water interfacial tension, extraction of light hydrocarbons and the formation of miscible displacement zones [57,58]. Li [59] and Qian [60] divided the interaction between CO2 and crude oil into two stages: the first stage is that CO2 dissolves into the oil phase at low pressure; the second stage is CO2 extraction of light components in crude oil at higher pressure. Zou et al. [61] categorized the integration of CO2 into the oil phase into four stages: In the first stage, CO2 dissolves into crude oil and expands its volume. In the second stage, CO2 extracts crude oil components to form an oil–gas transition zone, reducing crude oil volume. In the third stage, the interchange of oil and gas components slows down, the CO2 extraction effect is dominant, the oil and gas transition zone nearly vanish, and the volume of crude oil decreased slowly. In the fourth stage, the interchange of components between crude oil and CO2 stops, and the volume of crude oil falls linearly as a result of compression.

3.1. CO2 Dissolved into the Crude Oil System

Because the property of crude oil varies by location, a range of targeted technological techniques will be created during the extraction process to successfully utilize various types of crude oil. Many scientists have utilized oil samples from various places to perform simulated studies on the dissolving of CO2 into crude oil in order to explore phenomena such as volume expansion, viscosity decrease, and interfacial tension reduction. CO2 solubility is a crucial parameter affecting the hydrocarbon viscosity and its swelling which, in turn, enhance its mobility and relative permeability and contribute to the enhanced hydrocarbon recovery. Quantitative experimental methods for the solubility of CO2 include PVT experiments, high-pressure solubility tests and molecular dynamics simulation technology. A PVT experiment refers to the simulation of reservoir conditions in a high-pressure reactor, by changing the pressure and temperature, directly measuring the amount of CO2 dissolved in crude oil. A high-pressure solubility test refers to the use of high temperature and a high-pressure reactor, combined with gas chromatography (GC) or mass spectrometry (MS), to analyze the composition changes of the system after dissolution [62,63]. The solubility parameter δ between pure CO2 and kinds of hydrocarbons at certain temperature and pressure was calculated through the application of molecular dynamics simulation technology and TraPPE-UA force field parameters [41].

In this equation, CED is the cohesion energy density; Evac is vacuum energy; Ebulk is phase energe; V is mole volume.

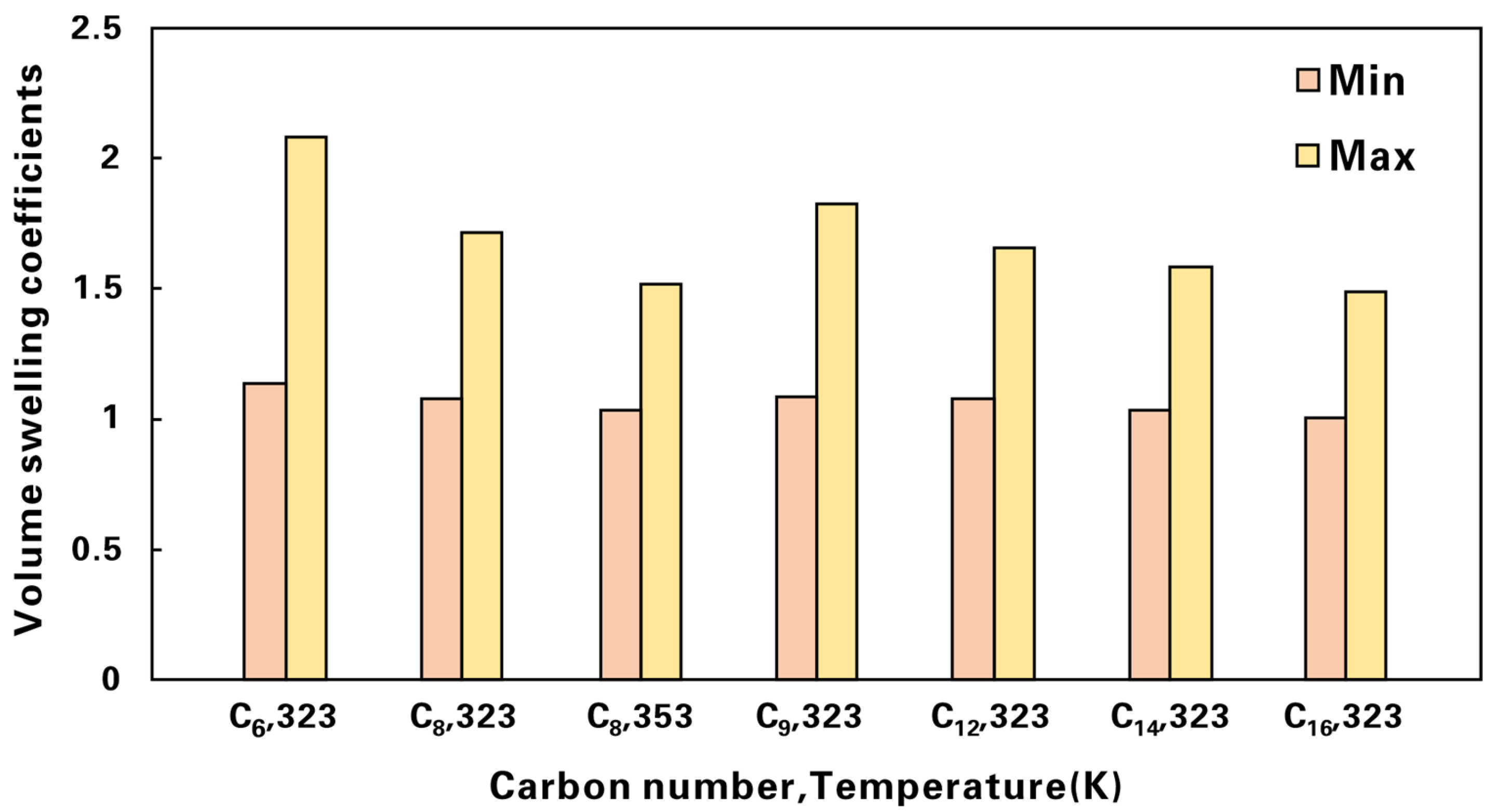

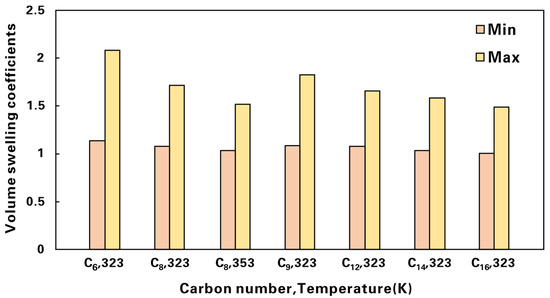

The composition of crude oil is complicated, and differences in the carbon number and structure of hydrocarbon components will influence the dissolution effect of CO2. When the carbon chain length reaches different values, the oil phase exhibits a variety of distribution patterns. Because it is hard to precisely and quantitatively characterize the impacts of each component of crude oil using a single oil field as the research object, many researchers began to investigate the volume expansion effect of a binary system made of various hydrocarbon pure substances and CO2. For example, Zhang et al. [64] used Monte Carlo (MC) simulation to investigate the solubility of CO2 in octane and its effect on the expansion of octane, and discovered that the interaction between CO2 and octane was the primary cause of the expansion of octane, and the expansion coefficient of octane had a linear relationship with the solubility of CO2 in a certain pressure range. By simulating the dissolution mechanism and process of five n-alkane oil droplets in CO2, Wang [65] found that the volume expansion of alkanes decreased with the increase in the chain length of alkanes at the same time, indicating that the solubility of CO2 in alkanes decreased with the increase in the chain length. Shi [40] observed the microscopic process of molecular simulation of CO2 and decane miscibility and concluded that CO2 dissolution would increase the decane molecular distance and extend the molecular chain, resulting in the volume expansion of the decane phase. As CO2 solubility in alkanes is related to pressure, the volume expansion of various alkanes rises as pressure increases. At low pressure, due to the strong contact between decane molecules, CO2 dissolution into decane is severely impeded, and the miscibility between CO2 and decane is weak. As the pressure increases, the interaction between CO2 and decane increases, while the interaction between decane diminishes, increasing the miscibility of CO2 and decane, resulting in volume expansion. Han et al. [66] discovered that the coefficient of volume expansion of an n-hexane–CO2 system decreased with increasing temperature when the system contained a small amount of CO2, but increased with a specific range of increase when the CO2 content reached 75% and the temperature was too high to be beneficial for CO2 dissolution, reducing the volume expansion effect. It is clear that the main reason for the expansion of crude oil is the increase of CO2 dissolution in crude oil and the increase in hydrocarbon molecular spacing. The main control factors are pressure, temperature, and the intrinsic properties of hydrocarbon components, but the influence of alkane molecular structure on the expansion effect is still unknown. Alkanes with low carbon atoms are more conducive to CO2 dissolution under high pressure and optimum temperatures, with a significant coefficient of volume expansion (Figure 2). The volume expansion of crude oil will discharge water in the pore space of the reservoir, reduce the capillary resistance and flow resistance of crude oil in flow, and improve the flow ability of the expanded crude oil, thus facilitating the release of the expanded crude oil from the binding of rocks and becoming mobile oil, which is beneficial to improving the flow environment of crude oil [67,68,69].

Figure 2.

Volume swelling coefficients of different alkanes [40,64,66].

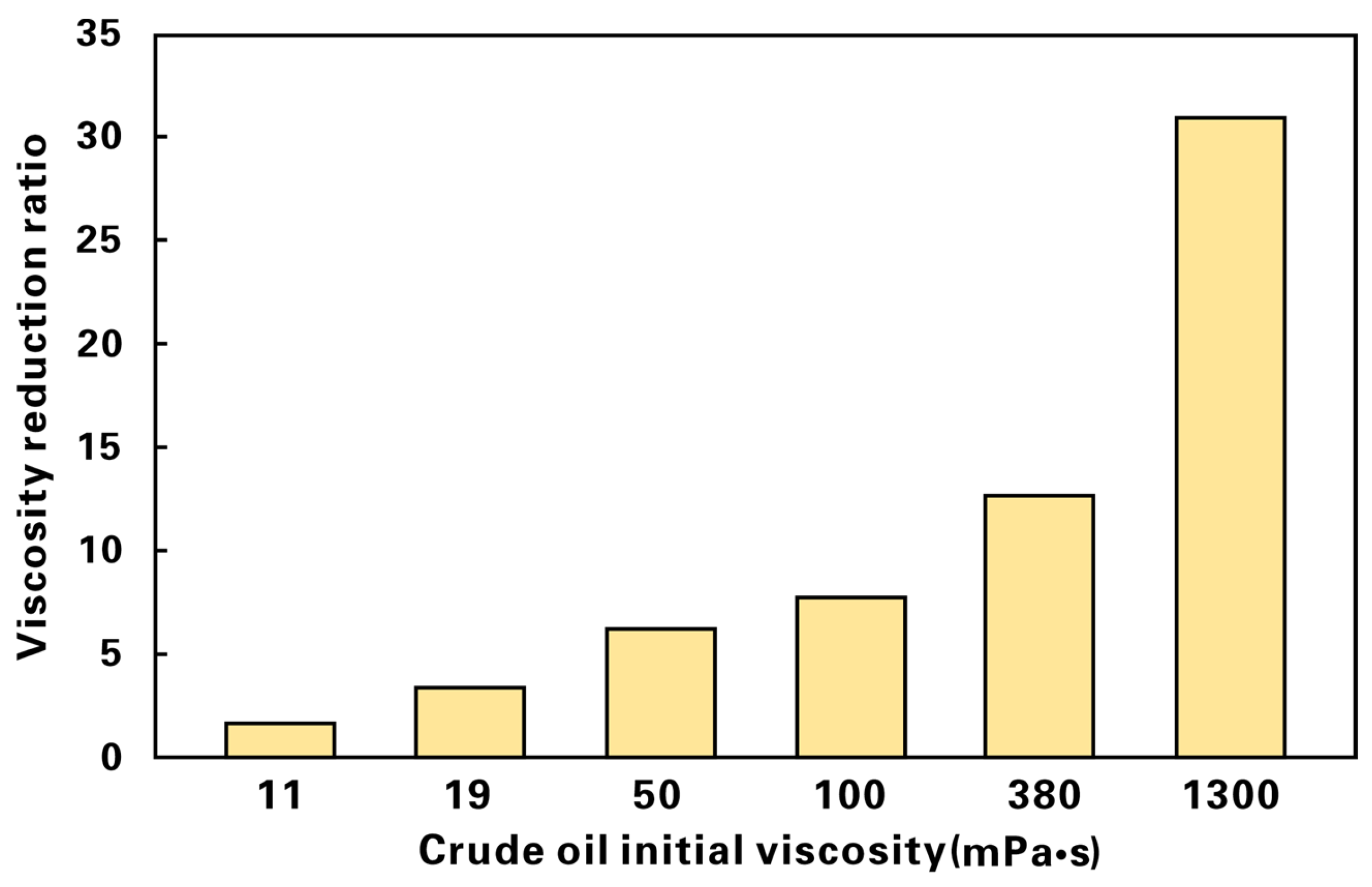

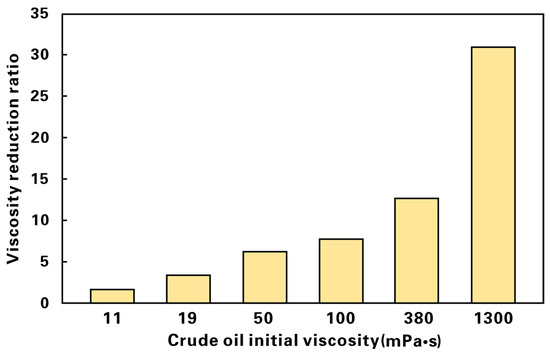

According to molecular dynamics simulation research [70,71], when CO2 is dissolved in crude oil, it enters the intermolecular space, causing swelling, increasing the molecular spacing of the system, reducing the intermolecular strength of the entire system, and weakening the internal friction of crude oil. Furthermore, heavy oil often has a high concentration of colloidal asphaltene. When CO2 is dissolved in crude oil, it destroys the asphaltene association, releases the light components bound by it, and increases the relative quantity of liquid oil, which dilutes the system. The viscosity of crude oil lowers once CO2 is dissolved due to the two effects described above [64,72]. The viscosity reduction of crude oil after dissolving CO2 depends on the pressure, temperature, gasoline ratio and initial viscosity. Wei [73] investigated the viscous-reducing effect of CO2 on Caoqiao crude oil and Tarim crude oil, and discovered that as dissolution pressure increased, solubility of CO2 increased, the effect on swelling and dilution of crude oil was enhanced, the viscosity reduction range of the crude oil system increased, and the viscous-reducing rate of dissolved CO2 crude oil increased with decreasing temperature. In addition, Ted et al. [74] investigated samples from the Cold Lake area and discovered that the viscosity of crude oil under formation pressure reduced with increasing temperature, and the sensitivity of viscosity to temperature declined dramatically as the gas–oil ratio increased. Wang et al. [75] investigated the influence of CO2 on ultra-heavy oil in Xinjiang and discovered that, under low temperature circumstances, the viscosity of ultra-heavy oil saturated with CO2 reduced with increasing reservoir temperature and pressure. When the temperature hits 200 °C, the viscosity of ultra-heavy oil stopped changing with pressure. The higher the initial viscosity of crude oil, the greater the drop in viscosity, that is, the more noticeable the viscosity reduction impact of CO2 on medium oil and heavy oil (Figure 3) [76,77].

Figure 3.

Viscosity reduction ratio of different viscosity crude oil [75,78,79,80,81].

Mobility is defined as the ratio of permeability to viscosity, and reservoir recovery is related to the ratio of oil fluidity [82]. When CO2 is dissolved in crude oil, the viscosity falls and fluidity increases. Water is soluble in CO2, and hydrogen bonds and van der Waals forces occur between water and CO2 molecules, increasing viscosity and decreasing mobility. The combined action of the two processes reduces the gap between crude oil and water mobility, enhances the oil–water flow ratio, and improves water’s oil displacement capability. Meanwhile, the swept area of water drive is also expanded, and the oil displacement efficiency is improved [78,83].

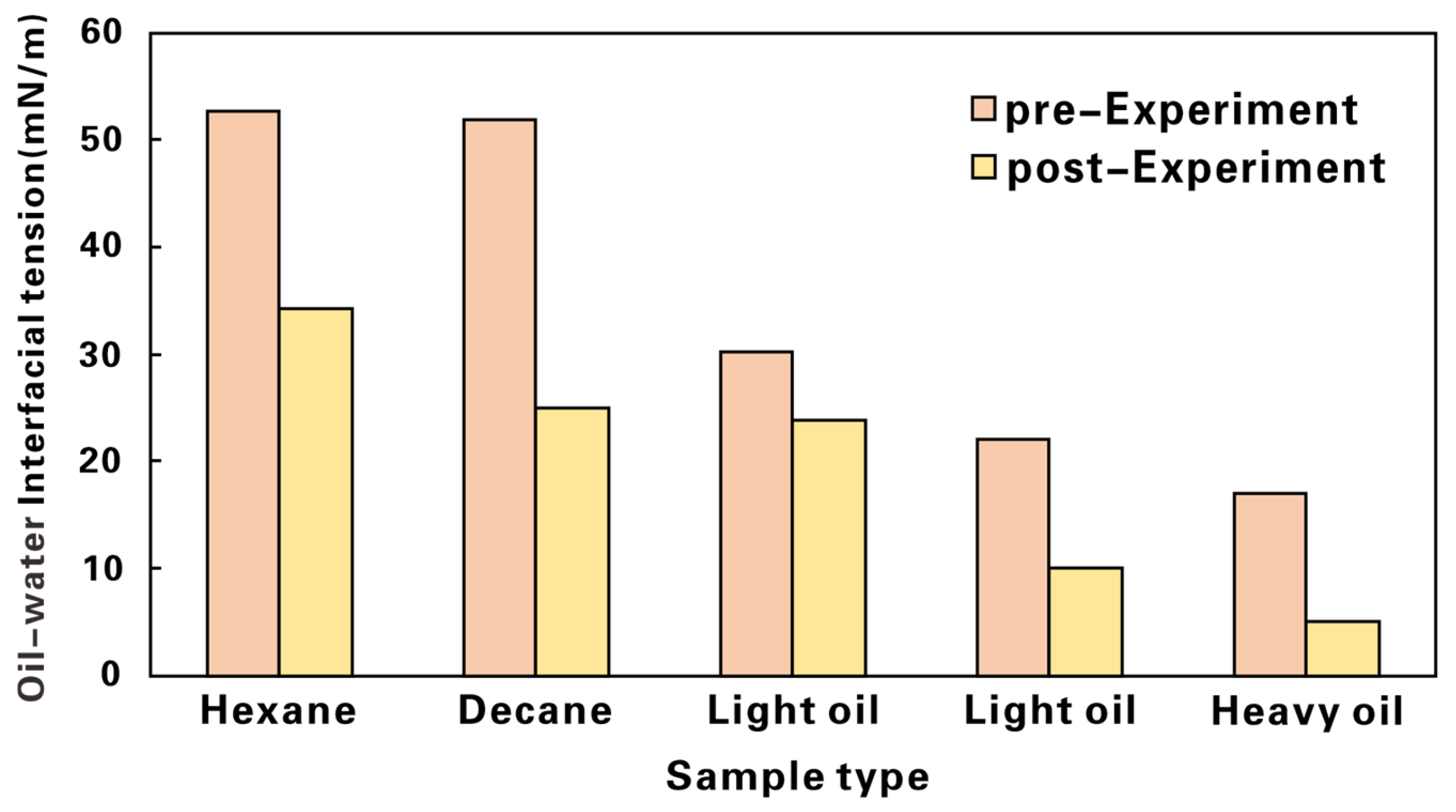

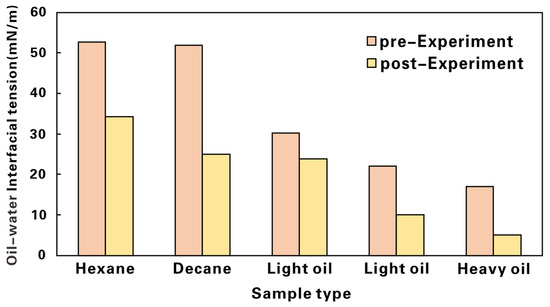

CO2 can dramatically lower oil–water interfacial tension (Figure 4) and residual oil saturation, increasing oil recovery [84,85]. Dai [86] used molecular modeling technology for the first time to explore the interfacial phenomena between oil and CO2 mixtures and water, and the findings indicated that the interfacial tension of oil and water reduced with the concentration of dissolved CO2. Through molecular modeling, Shi [40] discovered when the CO2 molar proportion grew, the surface of the water and decane phases became rougher and uneven, indicating that the anisotropic distribution of interfacial molecules increased. The addition of CO2 caused a change in the orientation of decane molecules at the interface, which had a greater impact on the reduction in decane–water interfacial tension, allowing more space for mutual infiltration between water and CO2, promoting the expansion of the interface region. The coexistence zone between decane and water was enlarged, and intermolecular permeability between the two phases increased, strengthening the link between the two phases and lowering interfacial tension. Wei [73] investigated the changes in oil–water of the Changqing system after CO2 was dissolved and discovered that when gas injection pressure increased, the oil–water interfacial tension reduced. However, the injection pressure should not be too high. High pressure not only suppresses the interaction between oil and water phases but also reduces the solubility of CO2, hindering its dissolution with oil and water.

Figure 4.

Trend of oil–water interfacial tension before and after the experiment [17,40,86,87,88].

3.2. CO2 Extraction of Lightweight Components

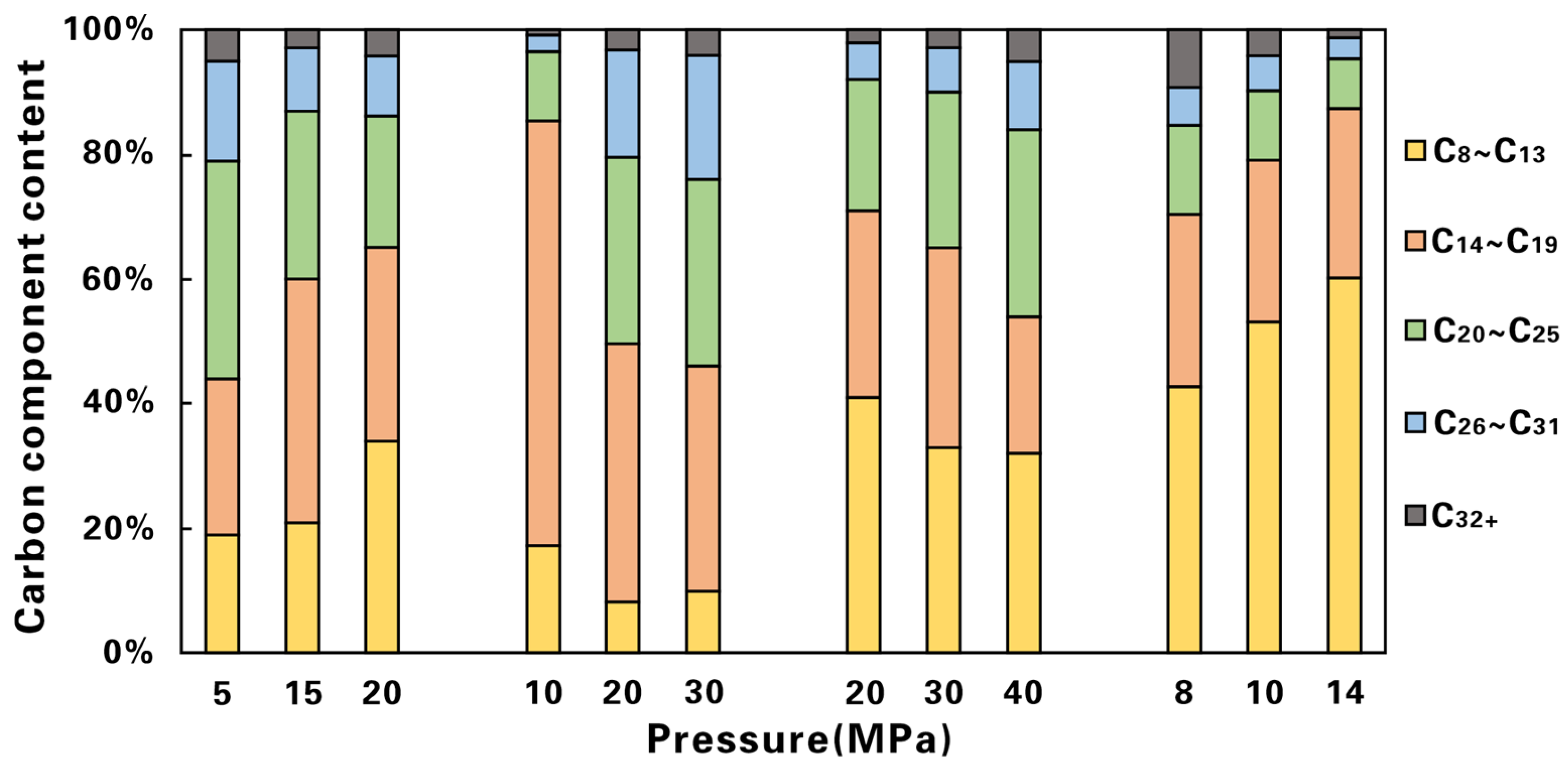

When the displacement pressure progressively rises to the minimum miscible pressure, CO2 dissolves in crude oil and becomes miscible with it after multiple contact and mass transfers. At this moment, CO2 may remove lighter components from crude oil while also forming a specific miscible zone with them. The oil displacement process is approximately a single-phase flow, greatly promoting the oil displacement process [89,90]. Non-polar saturated hydrocarbon molecules are less impacted by adsorption of other components and may be easily removed from crude oil using non-polar CO2. Zhao et al. [91] studied CO2 extraction samples from the Baiyushan Oilfield and discovered that the primary components of CO2 extraction were crude oil with less than C10 components. Under the same formation temperature, CO2 prioritized the extraction of low molecular weight saturated hydrocarbons. With the increased pressure, the extraction capability of supercritical CO2 steadily improved, not only increasing the extraction quantity of low molecular weight saturated hydrocarbons but also expanding the molecular weight range of extraction and improving the extraction capacity for high molecular weight saturated hydrocarbons (Figure 5) [92,93,94]. Qin et al. [95] demonstrated through microscopic displacement experiments that the light components in crude oil were dissolved into the miscible liquid of CO2 and crude oil during the extraction process, typically C2–C6 components and even C10 components, which enriched the light components in the miscible liquid of CO2 and crude oil and caused the components of the miscible liquid of CO2 and crude oil to constantly approach the components of crude oil. Furthermore, CO2 molecules continued to enter the crude oil, causing the crude oil component to be miscible with the CO2. The gap between crude oil and CO2-crude oil is continually reduced as the two technologies work together, and miscibility steadily improves, ultimately achieving the goal of miscibility and better oil recovery. The minimum miscibility pressure depends on the purity of CO2, the composition of crude oil and reservoir temperature. With the increase in reservoir temperature and the molecular weight of C5 to C20 components in crude oil, the minimum miscibility pressure increases [96,97].

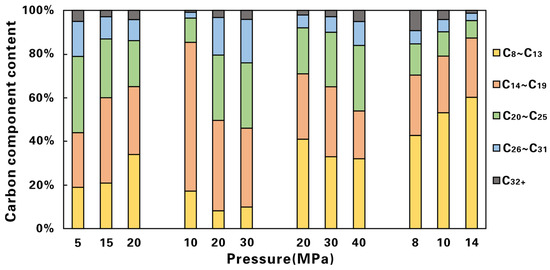

Figure 5.

Extracted oil composition distribution under different extraction pressures [60,94,98,99].

4. Asphaltene Precipitation of CO2 Injection

4.1. Origin of Asphaltene Precipitation

The existence form of asphaltene in crude oil is roughly classified into four types: the solubility parameter model [100], equation of state model [101], colloidal model [102], and scale theory model [103], of which the asphaltene colloidal model is widely recognized. Under reservoir circumstances, macromolecules in crude oil are typically quite stable, with the main body existing in the form of a scattered colloid. The core of the micelle is an asphalt molecule group, with colloid on the perimeter, resulting in micelles scattered throughout the crude oil system. Crude oil can be regarded as a colloidal system, while asphaltene, as a dispersed phase in the entire system, can be in a relatively stable state in the whole system. The fundamental reason is that colloid is used as an adhesive solvent covered in the asphaltene surface, forming a stable coating surface, which plays a strong role in ensuring the stability of asphaltene [104,105]. Colloid, as a colloidal solvent, is the primary medium for dispersing asphaltene in the crude oil system. As the injected CO2 dissolves in the crude oil, a large number of small CO2 molecules occupy the surface space of asphaltene molecular groups, resulting in a relatively low concentration of colloid, which cannot form micelles or the solvent layer of micelles is insufficiently thick, and colloid no longer forms a protective coating on the asphaltene particles. As a result, asphaltene particles collide and interact to create bigger molecular clusters, causing asphalt to flocculate and precipitate [106]. To be clear, some academics have different opinions. For instance, Yang [107] thought that as the amount of CO2 dissolved in the oil sample increases, the asphaltene molecules in the oil phase were surrounded by more CO2 molecules, which was not conducive to the aggregation of asphaltene molecules and the formation of aggregates.

4.2. Main Controlling Factors of Asphaltene Precipitation

CO2 is injected into the formation in a supercritical condition, dissolves in crude oil, and produces the change in crude oil property to produce asphaltene precipitation, which is influenced by both internal and external influences. Internal influences include formation temperature and crude oil properties, whereas external influences include CO2 injection pressure and injection rate [108,109,110,111].

Crude oil composition is the core parameter that determines the stability of asphaltenes. Pressure directly affects the solubility and phase state of CO2. High temperature aggravates thermodynamic instability, but it needs to be coupled with pressure analysis. The CO2 injection rate has a dynamic regulation effect on asphaltene precipitation, but the dynamic process has a weak regulation effect on local supersaturation. The weight of the influencing factors from large to small is as follows: crude oil properties, injection pressure, formation temperature and injection rate [112,113,114].

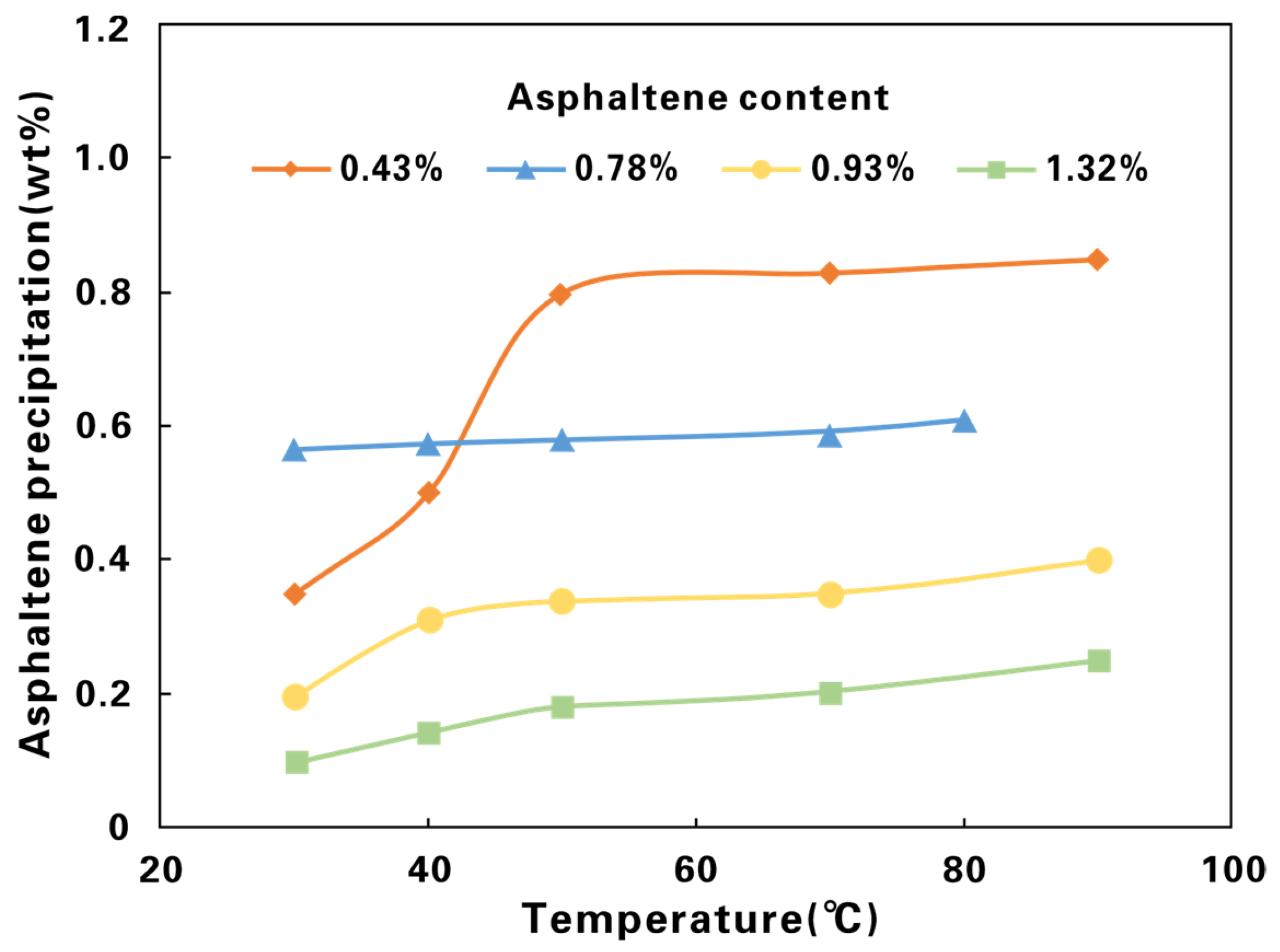

4.2.1. Formation Temperature

The quantity of asphaltene precipitation in the core initially drops and then increases with the increase in formation temperature (Figure 6). On the one hand, when the temperature of the system increases, the internal molecular movement intensifies and the collision probability between asphaltene micelles rises, which promotes the breakdown of asphaltene in oil and lowers precipitation. However, when the system temperature increases, the connection between asphaltene and colloid decreases, resulting in the desorption of certain colloid molecules on the asphaltene surface; thus, aggregation and flocculation occur, which increases precipitation [115,116]. Asphaltene precipitation in various kinds of crude oil can increase or decrease as temperature rises. The change trend of asphaltene precipitation with temperature is mostly determined by whether the collision aggregation trend among asphaltene micelles or the dispersion dissolution trend of asphaltene micelles increases as temperature rises [117,118].

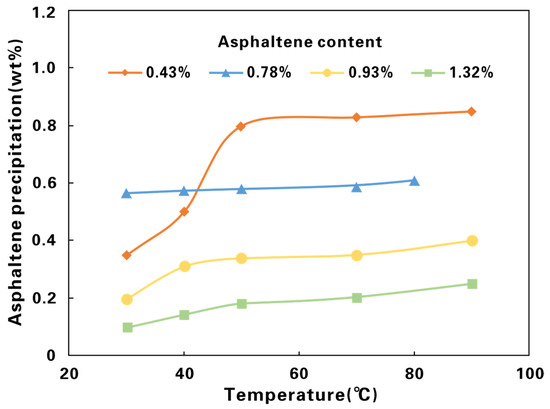

Figure 6.

Amount of asphaltene precipitation with temperature change [50,117,118].

4.2.2. Crude Oil Properties

The asphaltene content of various crude oils is different, and the precipitation of asphaltene increases with the increase in the starting amount of asphaltene in crude oil, that is, there is a positive correlation. The higher the initial concentration of asphaltene in crude oil, the closer the distance of asphaltene coalescence, the simpler it is to coalesce and deposit between asphaltene and asphaltene, resulting in increased asphaltene precipitation [119]. As CO2 is dissolved in crude oil, the volume of crude oil expands and the density decreases. With the decrease in crude oil density, the higher the initial asphaltene content in crude oil and the larger the density difference between asphaltene and crude oil, meaning high molecular weight asphaltene precipitation from crude oil is more likely to occur [120].

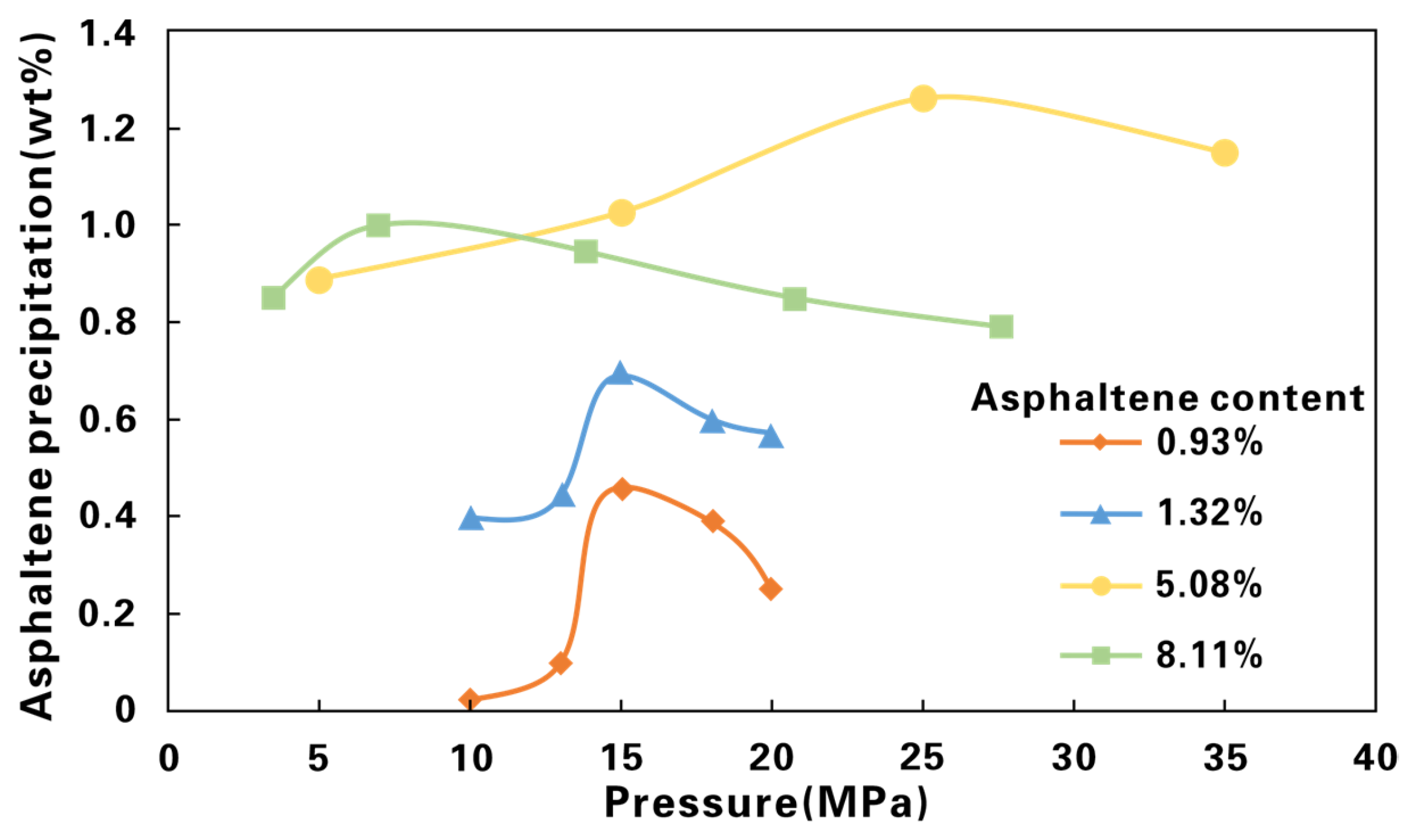

4.2.3. Injection Pressure

The higher the injection pressure, the stronger the dissolution ability of CO2 in crude oil formation and the more small and medium molecular components of crude oil increase. The concentration of colloid as an “asphaltene stabilizer” also decreases, and the more likely it is to cause asphaltene to associate with each other to form precipitation (Figure 7). When CO2 is injected at miscible pressure, the amount of dissolved CO2 in the crude oil reaches a maximum, indicating that asphaltene precipitation is most likely to occur in the miscible zone of CO2 displacement. After reaching the miscible pressure, the pressure increases further, increasing the density of the mixed phase, enhancing the solubility of asphaltene, and decreasing the precipitated asphaltene [121,122].

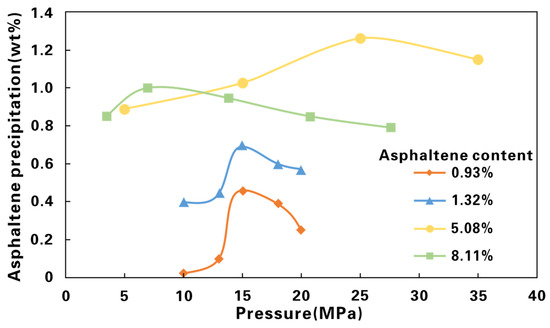

Figure 7.

Amount of asphaltene precipitation with pressure change [11,50,117,121].

4.2.4. Injection Rate

The initial asphaltene precipitation decreases with the increase in injection rate. Asphaltene precipitation is a three-step process that includes emission, flocculation, and precipitation. According to Ali et al. [123], an injection rate of 0.4 mL/min promoted the continuation of the asphaltene precipitation process of crude oil in the core, but an injection rate of 0.8 mL/min did not promote the development of asphaltene precipitation of crude oil. Because of the tiny particle size before flocculation, some of the freshly precipitated asphaltene was removed from the core at a high injection rate, resulting in reduced precipitation of the original asphaltene in the core as the injection rate increased. Ding [124] found that when the injection rate increased from 0.12 mL/min to 0.18 mL/min, the amount of asphaltene precipitation decreased. In addition, Zhang [125] found that different rules showed that the precipitation amount of asphaltene increased first and then decreased with the injection rate rising from 0.1 mL/min to 0.16 mL/min. It can be seen that there is no consensus on the injection rate of CO2 required to create asphaltene precipitation.

4.3. Hazards of Asphaltene Precipitation

Asphaltene, as a polar molecule with a large molecular weight and complex component group content, produces a wide range of asphaltene components due to differences in polycyclic aromatic hydrocarbons and a few heteroatoms, raising concerns about impact of asphaltene on reservoir development, petroleum refining, and the environment. Asphaltene deposition in oil and gas reservoirs, drilling equipment, and surface development equipment will create a variety of issues, including blockage of well pipes, separators, pipelines, and other equipment, significantly reducing production efficiency. Formation obstruction, rock surface wettability reversal, permeability reduction, etc., cause reservoir degradation and reduce real production efficiency [126,127,128,129,130].

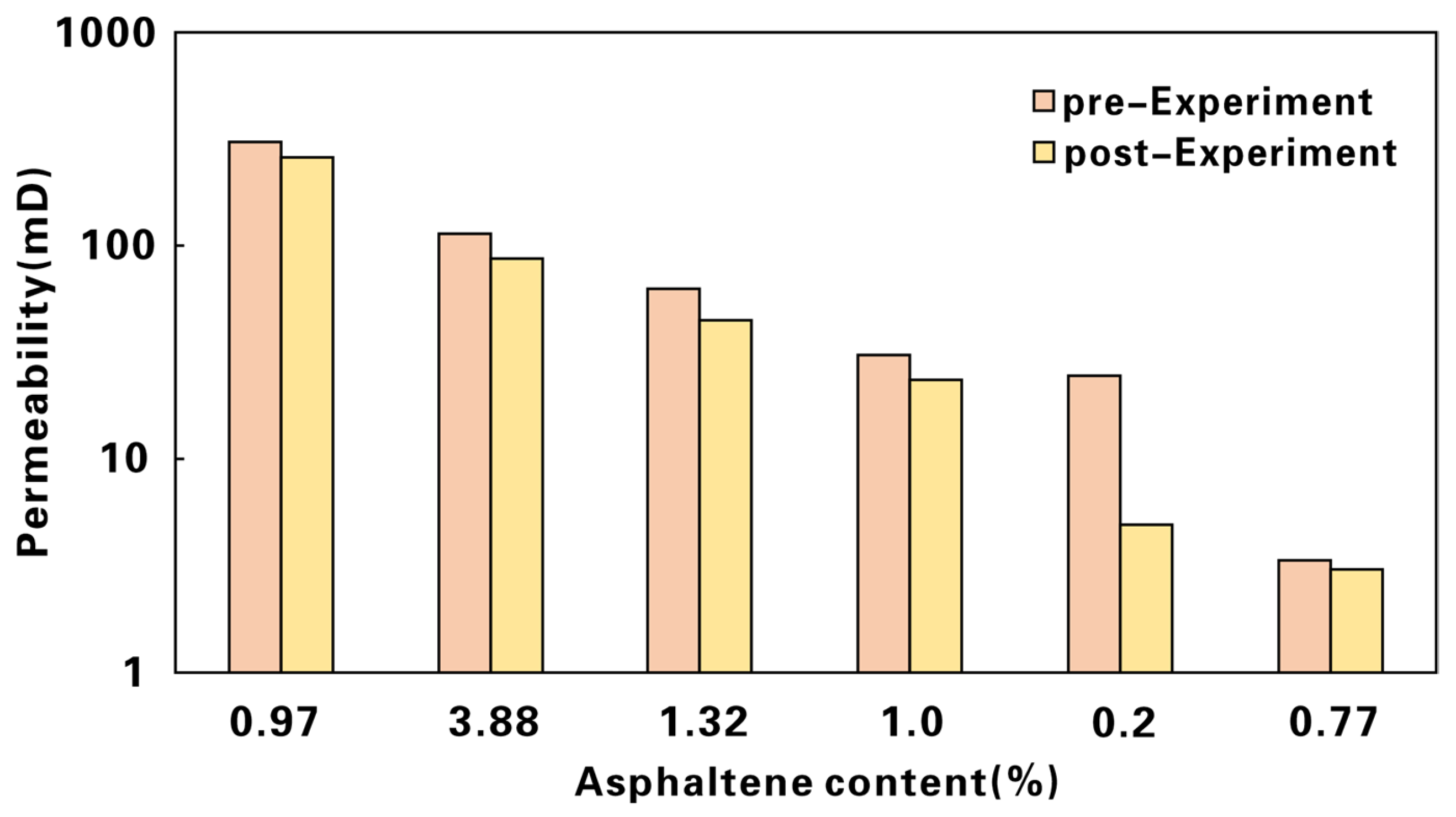

In terms of asphaltene precipitation, it is commonly considered that asphaltene can clog reservoir pores in two ways: (1) asphaltene collects and forms blocks at the throat; (2) asphaltene is adsorbed and deposits on the pore surface of rock [131]. Asphaltene collected at the pore throat blocks a portion of the tiny pore, while absorbed and deposited asphaltene adheres to the surface of the rock with large pores. Asphaltene precipitation alters the spatial organization of pores, reduces porosity and permeability, and degrades reservoir physical characteristics (Figure 8) [132,133].

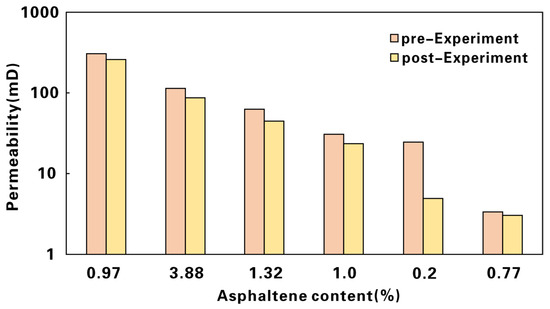

Figure 8.

Trend of permeability before and after the experiment [134,135,136,137,138,139].

Asphaltene precipitation will also affect wettability. Typically, reservoir rocks have hydrophilic properties. After asphaltene is deposited on the rock surface, the adsorption of asphaltene changes the hydrophilic–lipophilic balance of the rock surface due to some non-polar chains of macromolecular chains at both ends of asphaltene molecules, thereby changing the wettability of the rock surface [140,141], but there is no direct evidence that the wetting change ability is proportional to the asphaltene content.

In order to solve the problem of reservoir pore blockage caused by asphaltene precipitation, the measures that can be taken at present include chemical inhibitor injection technology, adjustment of production parameters, solvent deasphalting and asphaltene precipitation removal.

Adding appropriate chemical agents can prevent the further aggregation of asphaltene aggregates, improve the colloidal stability and flow ability of crude oil, and thus effectively inhibit asphaltene deposition [142,143]. Chemical inhibitors mainly include natural fatty acid organics, surface active substances containing benzene rings, vegetable oils or oil processing products, ionic liquids and metal oxide nanoparticles. Karambeigi et al. [144] evaluated the inhibition effect of salicylic acid, phthalic acid, nonylphenol, phenanthrene and benzoic acid on asphaltene deposition. The results showed that the inhibition effect of salicylic acid was better, which could reduce the asphaltene deposition by 34%, mainly through π-π bond and acid–base interaction. Junior et al. [145] found that sweet almond, coconut oil, sandalwood and other vegetable oils are soluble in crude oil, which has the effect of inhibiting asphaltene deposition, and the cost is low. These two chemical inhibitors are environmentally friendly. In recent years, ionic liquids have become a new research direction for inhibiting asphaltene deposition. Bisweswar et al. [146] studied the stabilizing effect of ionic liquid 1-butyl-3-methylimidazolium bromide on asphaltenes during miscible carbon dioxide injection in high-pressure reservoirs. It is believed that there is an acid–base interaction between the aromatic ring in asphaltenes and the ionic liquid cations, and the Br− anion has a higher steric hindrance, which can inhibit the further aggregation of asphaltene aggregates and has a significant inhibitory effect on asphaltene deposition.

Asphaltene deposition can be inhibited to a certain extent by controlling the production pressure drop, adjusting fluid flow rate, conducting heat insulation and controlling heat loss [147]. Pressure drop is one of the reasons for asphaltene deposition in oil wells. Controlling the production pressure drop, as far as possible to make the crude oil flow system in a more stable state, to a certain extent, can inhibit the precipitation of asphaltene [148]. Mahdi et al. [149] studied the influence of throttle valve size on the thermodynamic parameters of fluid in vertical oil wells. It was found that the amount of asphaltene deposition can be reduced under the optimal throttle valve size, and the deposition position in the production process can be changed when the thermodynamic conditions in the string are changed. Gharbi et al. [150] found that the use of insulation rings can avoid excessive heat loss, in addition to keeping the fluid temperature constant, and preventing asphaltene deposition due to a sudden temperature drop.

Solvent deasphalting (SDA) can use propane or butane extraction to remove some asphaltenes from crude oil [151]. Vallejos et al. [152] patented an SSU-SDA process based on the downhole injection of a light solvent under reservoir conditions to generate upgraded crude oils from heavy crude oil reservoirs. After injection of a light solvent (propane), the same well is operated under production conditions, and after separation and circulation of the light solvent, the upgraded hydrocarbon product is obtained.

When cleaning up the asphaltene deposition wells partially or completely blocked by asphaltene deposits, the asphaltene precipitation removal technologies mainly include the mechanical method [153], chemical method [154], thermal method [155], biological method [156] and external force field [157].

5. Conclusions

This article reviews the research methodologies used to study the interaction of CO2 and crude oil, the influence of CO2 on crude oil property, and the precipitate of asphaltene induced by CO2.

- (1)

- Physical simulation based on formation conditions, as well as numerical simulation across spatial scales, can improve the accuracy of physical simulation experimental data and provide a solid foundation for numerical simulation research on molecular reaction mechanisms and long-term large-scale oilfield production. At the same time, the growth of numerical modeling necessitates a significant number of both experimental and field data for feedback in order to anticipate more correctly, avoid potential difficulties, and increase the efficiency of CO2 displacement.

- (2)

- When CO2 enters the formation, it dissolves in crude oil, causing increased crude oil volume, decreased viscosity, increased oil–water flow ratio, and decreased oil–water interfacial tension. With increasing pressure, light hydrocarbons may be removed to form a miscible displacement zone, which aids in crude oil recovery and increases oil displacement efficiency. The temperature and pressure conditions of the interaction between CO2 and crude oil mainly affect the solubility and reactivity degree of CO2, and choosing the proper displacement settings is beneficial to crude oil recovery.

- (3)

- When CO2 is dissolved in crude oil, CO2 molecules occupy the surface space of asphaltene molecular clusters, and the colloid on the surface of asphaltene molecular clusters decreases, causing collisions between asphaltene particles and further association to form larger molecular clusters, resulting in asphalt flocculation and deposition. Asphaltene precipitation is influenced by both internal and external influences. Internal influences include formation temperature and crude oil properties, whereas external influences include CO2 injection pressure and injection rate. Asphaltene precipitation will cause formation clogging, permeability decrease, and wettability inversion on the rock surface, affecting the CO2 displacement work. The measures to deal with asphaltene precipitation include chemical inhibitor injection technology, adjustment of production parameters, solvent deasphalting and asphaltene precipitation removal.

Author Contributions

Conceptualization, S.W. and X.L.; writing—review and editing, S.W. and X.L.; visualization, Y.S. and C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation project (grant no. 42072187), and the Major Science and Technology Project of China National Petroleum Corporation (grant no. 2021DQ-0405).

Data Availability Statement

All relevant data are within the paper.

Conflicts of Interest

X.L., S.W. and C.W. were employed by China National Petroleum Corporation (CNPC). The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The authors declare that this study received funding from China National Petroleum Corporation. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- He, M.Q.; He, M.Q.; Li, T.T.; Huang, X.; Li, X.; Wu, K. Study on Fracture Propagation Behavior and Mechanical Properties of CO2 Fracturing in Shale Reservoirs. In Proceedings of the 2nd International Conference on Advances in Rock Mechanics—TuniRock 2022, Hamammet, Tunisia, 25–27 March 2022. [Google Scholar]

- Hui, G.; Chen, Z.X.; Schultz, R.; Chen, S.N.; Song, Z.J.; Zhang, Z.C.; Song, Y.L.; Wang, H.; Wang, M.M.; Gu, F. Intricate unconventional fracture networks provide fluid diffusion pathways to reactivate pre-existing faults in unconventional reservoirs. Energy 2023, 282, 128803. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhang, S.C.; Zou, Y.S.; Ma, X.F.; Xiong, D.; Liu, L.; Yang, P.; Zhu, D.Y. Experimental Study on CO2 Fracturing of Continental Shale with Dense Laminas. In Proceedings of the 58th U.S. Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024. [Google Scholar] [CrossRef]

- Hamdi, Z.; Cheong, W.C.; Bataee, M.; Partoon, B. Gas Hydrate-Assisted CO2 Storage in Subsurface Systems. In Proceedings of the SPE Symposium and Exhibition—Production Enhancement and Cost Optimisation, Kuala Lumpur, Malaysia, 3–4 September 2024. [Google Scholar] [CrossRef]

- Wang, X.Z.; Yang, H.; Wang, W.; Yao, Z.J.; Liu, Y. Technology and practice of CO2 flooding and storage in low-permeability tight reservoirs. Petroleum Geol. Recovery Effic. 2023, 30, 27–35. [Google Scholar] [CrossRef]

- Zou, C.N.; Wu, S.T.; Yang, Z.; Pan, S.X.; Wang, G.F.; Jiang, X.H.; Guan, M.D.; Yu, C.; Yu, Z.; Shen, Y. Progress, challenge and significance of building a carbon industry system in the context of carbon neutrality strategy. Pet. Explor. Dev. 2023, 50, 190–205. [Google Scholar] [CrossRef]

- Li, H.B.; Yang, Z.M.; Li, R.S.; Zhou, T.Y.; Guo, H.K.; Liu, X.W.; Meng, H. Mechanism of CO2 enhanced oil recovery in shale reservoirs. Pet. Sci. 2021, 18, 1788–1796. [Google Scholar] [CrossRef]

- Massarweh, O.; Abushaikha, A.S. A review of recent developments in CO2 mobility control in enhanced oil recovery. Petroleum 2022, 8, 291–317. [Google Scholar] [CrossRef]

- Mirzayi, B.; Vafaie-Sefti, M.; Mousavi-Dehghani, S.A.; Fasih, M.; Mansoori, G.A. The effects of asphaltene deposition on unconsolidated porous media properties during miscible natural gas flooding. Petrol. Sci. Technol. 2008, 26, 231–243. [Google Scholar] [CrossRef]

- Mohamed, M.; Jocin, A.; Mashhad, F. The impact of asphaltene deposition on fluid flow in sandstone. Petrol. Sci. Eng. 2019, 174, 676–681. [Google Scholar] [CrossRef]

- Wu, R.N. The Study on Asphaltene Precipitation and Reservoir Physical Properties Damage During CO2 Injection in Tight Oil Reservoirs. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2019. [Google Scholar] [CrossRef]

- Tan, Y.S.; Li, Q.; Chen, B.W.; Xu, L.; Yu, T.; Cao, X.M. Experimental investigation of SiO2 nanoparticle–assisted CO2 flooding in carbonate saline aquifers. Energy 2024, 305, 132275. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, G.L.; Tang, M.; Wu, J.; Yang, X.; Zhu, M.; Xie, Z.Z. Experimental study on CO2 flooding characteristics in low-permeability fractured reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 11637–11649. [Google Scholar] [CrossRef]

- Zhao, F.L.; Hao, H.D.; Wang, Z.X.; Hou, J.R.; Fu, Z.F.; Li, W.F.; Wang, P.; Zhang, M.; Lu, G.Y.; Lv, G.Z. Performance Improvement of CO2-EOR By Production Control in a Heterogeneous 3D Model: Experimental and Numerical Simulation. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 17–20 July 2017. [Google Scholar] [CrossRef]

- de Araujo, I.S.; Gomaa, I.; Heidari, Z. Molecular Dynamics Simulation of CO2 Flooding into Mineral Nanopores in the Presence of Residual Oil. In Proceedings of the SPWLA 65th Annual Logging Symposium, Rio de Janeiro, Brazil, 18–22 May 2024. [Google Scholar]

- Hu, J.; He, Y.F.; Ling, D.; Wang, H.M.; Li, H.M.; Li, S.L. Experimental Study on Measuring Asphaltene Precipitation Volume in Carbon Dioxide Flooding Reservoir. Chem. Eng. Mach. 2001, 38, 155–156, 231. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, F.J.; Fan, F.; Zhang, L.F.; Yao, E.D. Study on the Influence of CO2 Finger-Channeling Flooding on Oil Displacement Efficiency and Anti-channeling Method. In Proceedings of the ARMA-CUPB Geothermal International Conference, Beijing, China, 5–8 August 2019. [Google Scholar]

- Zhang, G.Y.; Li, D.; Ja, G.H.; Deng, C.M.; Jia, Z.Z. Laboratory test on CO2 injection displacement in long cores of Huabei oilfield. Pet. Geol. Eng. 2022, 36, 77–81. [Google Scholar] [CrossRef]

- Jin, X.Q.; Chao, C.; Edlmann, K.; Fan, X.F. Understanding the interplay of capillary and viscous forces in CO2 core flooding experiments. J. Hydrol. 2022, 606, 127411. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wang, X.W.; Kang, Y.L.; Guo, C.B.; He, Q.C.; Li, C. Characterization of Stages of CO2-EOR Process in Low-Permeability Oil Reservoirs Based on Core Flooding Experiments. Energies 2024, 17, 5469. [Google Scholar] [CrossRef]

- Zhao, Z.W.; Zhang, S.C.; Zou, Y.S.; Zhang, X.H.; Zhu, D.Y.; Liu, S.K.; Yang, P.; Liu, L. Evaluation of Gas Flooding Effect in Mahu Tight Sandstone Reservoir. In Proceedings of the 58th U.S. Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024. [Google Scholar] [CrossRef]

- Yu, Y.; Beddoe, C.; Xue, Z.Q.; Chakhmakhchev, A.; Hamling, J.; Smith, S.; Bethany, K. Experimental Evaluation of Enhanced Tight Oil Recovery Performance by Microbubble CO2 and Microbubble Rich Gas in North Dakota Plays. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022. [Google Scholar] [CrossRef]

- Zhang, X.; Su, Y.; Li, L.; Hao, Y.; Wang, W.; Liu, J.; Gao, X.; Zhao, A.; Wang, K. Microscopic remaining oil initiation mechanism and formation damage of CO2 injection after waterflooding in deep reservoirs. Energy 2022, 248, 123649. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, Q.; Li, X.; Tsau, J.S.; Barati, R.; Negahban, S. Experimental and Mechanism Study of CO2 and Bakken Oil Interactions at Equilibrium and Non-Equilibrium Conditions. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019. [Google Scholar] [CrossRef]

- Stalkup, F.I. Displacement Behavior of the Condensing/Vaporizing Gas Drive Process. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 27–30 September 1987. [Google Scholar] [CrossRef]

- Christiansen, R.L.; Haines, H.K. Rapid Measurement of Minimum Miscibility Pressure with the Rising-Bubble Apparatus. SPE Reserv. Eng. 1987, 2, 523–527. [Google Scholar] [CrossRef]

- Cui, M.L.; Wang, R.; Lv, C.Y.; Tang, Y.Q. Research on microscopic oil displacement mechanism of CO2 EOR in extra-high water cut reservoirs. J. Pet. Sci. Eng. 2017, 154, 315–321. [Google Scholar] [CrossRef]

- Li, M.; Zhu, Y.S.; Li, W.H.; Yuan, G.W.; Du, C.F. Feasibility Study on Applying CO2-flooding Micro-visualization Technology in Ultra-low Permeability Reservoirs: A Case Study in Ordos Basin. Geoscience 2019, 33, 911–918. [Google Scholar] [CrossRef]

- Song, Y.C.; Zhao, C.Z.; Chen, M.K.; Chi, Y.; Zhang, Y.; Zhao, J.F. Pore-scale visualization study on CO2 displacement of brine in micromodels with circular and square cross sections. Int. J. Greenh. Gas Control 2020, 95, 102958. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.; He, Y.; Tang, J.; Wang, Y.; Qin, J. Microscopic Flow Characteristics of Immiscible CO2 Flooding and CO2 Foam Flooding After Water Flooding in Fractured Porous Media: A Visual Investigation. Transp. Porous Med. 2023, 149, 117–145. [Google Scholar] [CrossRef]

- Wang, C.W.; Su, Y.L.; Wang, W.D.; Li, L.; Hao, Y.M.; Zhu, H.W. Microscopic Visualization Experiment of High Temperature and High-Pressure CO2-C2H6/DME Displacement in Tight Reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 22–25 April 2024. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Li, L.; Su, Y.L.; Zhang, X.; Liu, J.H.; Zhou, X.M.; Luo, W.T. Microscopic mechanism of CO, flooding in low permeability heavy oil reservoir. In Proceedings of the 2022 International Field Exploration and Development Conference, Xi’an, China, 16 November 2022. [Google Scholar]

- Yongmao, H.; Zenggui, W.; Binshan, J.; Yueming, C.; Xiangjie, L.; Petro, X. Laboratory Investigation of CO2 Flooding. In Proceedings of the Nigeria Annual International Conference and Exhibition, Abuja, Nigeria, 2–4 August 2004. [Google Scholar] [CrossRef]

- Zhang, M.L.; Wang, L.; Cui, Q.; Hu, Y.N.; He, S.Q. Experimental study on reservoir physical property change of carbon dioxide flooding. World Pet. Ind. 2023, 30, 90–96. [Google Scholar] [CrossRef]

- Tsau, J.S.; Bui, L.H.; Willhite, G.P. Swelling/Extraction Test of a Small Sample Size for Phase Behavior Study. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar] [CrossRef]

- Wei, B.; Gao, H.; Pu, W.; Zhao, F.; Li, Y.; Jin, F.; Sun, L.; Li, K. Interactions and phase behaviors between oleic phase and CO2 from swelling to miscibility in CO2-based enhanced oil recovery (EOR) process: A comprehensive visualization study. J. Mol. Liq. 2017, 232, 277–284. [Google Scholar] [CrossRef]

- Al-Otaibi, F.M.; Al-Mutairi, S.M.; Kokal, S.L.; Funk, J.J.; Al-Qahtani, J.F. Best Practices for Conducting CO2-EOR Lab Study. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. SPE 151126. [Google Scholar]

- Kokal, S.; Sanni, M.; Alhashboul, A. Design and Implementation of the First CO2-EOR Demonstration Project in Saudi Arabia. In Proceedings of the SPE Annual TechnicalConference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar] [CrossRef]

- Alcorn, Z.P.; Fernø, M.A.; Graue, A. Upscaling CO2 Foam for EOR as CCUS from On- To Offshore. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar] [CrossRef]

- Shi, J.Q. Molecular Simulation Studies of Supercritical CO2 Swelling Oil and Reducing Oil/Water Interfacial Tension. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2015. [Google Scholar]

- Yang, S.Y.; Lian, L.M.; Yang, Y.Z.; Ma, D.S.; Tang, J.; Su, X.F. Molecular Dynamics Simulation of Miscible Process in CO2 and Crude Oil System. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016. [Google Scholar] [CrossRef]

- Kazemi, M.; Takbiri-Borujeni, A.; Hansel, J.R.; Valera, M. Enhanced Oil Recovery of Shale Oil: A Molecular Simulation Study. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019. [Google Scholar] [CrossRef]

- Zhong, Y.L.; Liu, B.; Du, H.J.; You, Y.P.; Ding, G. Study on Supercritical Carbon Dioxide Oil Flooding Mechanism. J. Shengli Coll. China Univ. Pet. 2022, 36, 54–59. [Google Scholar]

- Wang, C. Displacement Mechanism of Shale Oil by Supercritical Carbon Dioxide from Molecular Dynamics Simulations. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2017. [Google Scholar]

- Teng, G.L. Study on Mechanism of Supercritical Carbon Dioxide Enhancing Heavy Oil Recovery. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2021. [Google Scholar]

- Dong, X.H.; Chen, Z.L.; Chen, Z.X.; Wang, J.; Wu, K.L.; Li, R.; Li, L. Vapor-Liquid Equilibria and Diffusion of CO2/n-Decane Mixture in the Nanopores of Shale Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Coskuner, Y.; Yin, X.L.; Erdal, O. Effects of Molecular Level Forces on the Diffusivity Characteristics of Hydrocarbons in Shale Reservoirs. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 26–28 July 2021. [Google Scholar] [CrossRef]

- Ramez, N.; Jeppe, G.; Sameer, A.B.; Reda, A.; Fadi, A.; Nicholas, B.; Nabil, A.B. Comprehensive Piloting Strategy to De-Risk First CO2 EOR Development in Sultanate of Oman. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 12 February 2024. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.; Bai, B. Mechanistic Study for the Applicability of CO2-EOR in Unconventional Liquids Rich Reservoirs. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Zhou, X.Z. Investigation of the Asphaltene Deposition Distribution in CO2 Flooding of Low Permeability Reservoir. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2017. [Google Scholar]

- Pedram, M.; Adrian, J.; Eric, O. Impact of in-situ gas liberation for enhanced oil recovery and CO2 storage in liquid-rich shale reservoirs. Energy Sources 2020, 46, 16124–16144. [Google Scholar] [CrossRef]

- Lliguizaca, J.R.; Landa-Marbán, D.; Gasda, S.E.; Sandve, T.H.; Alcorn, Z.P. Data-Driven Predictions of CO2 EOR Numerical Studies Using Machine Learning in an Open-Source Framework. In Proceedings of the SPE Norway Subsurface Conference, Bergen, Norway, 17 April 2024. [Google Scholar] [CrossRef]

- Li, S.S. Numerical Simulation Study of CO2-EOR in Tight Reservoirs. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2023. [Google Scholar]

- Tong, S.Q.; Sun, W.J. Improve the accuracy of numerical simulation of carbon dioxide flooding and dynamic miscible evaluation method. West-China Explor. Eng. 2019, 31, 52–5459. [Google Scholar]

- Ahammad, M.J.; Rahman, M.A.; Alam, J.M. A Streamline Based Lagrangain Method to Investigate Two-Phase Flow in Hydrocarbon Recovery. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 12 February 2024. [Google Scholar] [CrossRef]

- Zhou, Y.T. Research on Several Problems in Numerical Simulation of CO2 Flooding in Low Permeability. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2020. [Google Scholar]

- Huang, T.; Yang, H.J.; Liao, G.Z.; Zeng, F.H. Optimization of CO2 Flooding Strategy to Enhance Heavy Oil Recovery. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 9–11 June 2015. [Google Scholar] [CrossRef]

- Hao, H.D.; Hou, J.R.; Zhao, F.L.; Huang, H.D.; Wang, Z.X.; Liu, H.Z. Feasibility Study of Gas-EOR Using CO2 and N2 Mixture in a Heavy Oil Reservoir: Experiments and Pilot Test. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 15–18 July 2019. [Google Scholar] [CrossRef]

- Li, B.F.; Ye, J.Q.; Li, Z.M.; Ji, Y.M.; Liu, W. Phase interaction of CO2-oil-water system and its effect on interfacial tension at high temperature and high pressure. Acta Pet. Sin. 2016, 37, 1265–1272, 1301. [Google Scholar] [CrossRef]

- Qian, K.; Yang, S.L.; Dou, H.E.; Wang, Q.; Huang, Y.; Wan, T.; Zhang, Y.X. Interaction of the CO2-oil system and displacement mechanisms during CO2 flooding. Pet. Sci. Bull. 2019, 4, 69–82. [Google Scholar] [CrossRef]

- Zuo, M.; Chen, H.; Xu, C.; Stephenraj, I.R.; Qi, X.; Yu, H.; Liu, X.Y. Study on Dynamic Variation Characteristics of Reservoir Fluid Phase Behavior During CO2 Injection in CO2 Based Enhanced Oil Recovery Process. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Bangkok, Thailand, 9–10 August 2022. [Google Scholar] [CrossRef]

- Ali, K.; Farshid, T.; Christine, C. Experimental Measurement of CO2 Solubility in heavy Oil and Its Diffusion Coefficient calculation at both Static and Dynamic Conditions. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11–13 June 2013. [Google Scholar] [CrossRef]

- Ariza-Quiroga, C.; Aristizabal, J.D.; Martinez Vertel, J.J.; Cundar, C.; Delgadillo, C.; Trujillo-Portillo, M.L.; Sandoval, J.; Maya, G.A.; Osorio, R. Effect of Phase Behavior and Mass Transfer Mechanisms on Crude Oil Recovery and CO2 Storage in a CO2 Injection Process in Colombian Reservoirs. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Port of Spain, Trinidad and Tobago, 14–15 June 2023. [Google Scholar] [CrossRef]

- Zhang, J.F.; Pan, Z.J.; Liu, K.Y.; Burke, N. Molecular Simulation of CO2 Solubility and Its Effect on Octane Swelling. Energy Fuels 2013, 27, 2741–2747. [Google Scholar] [CrossRef]

- Wang, L. Molecular Simulation of Oil Detachment and Erosion Mechanism by Supercritical Carbon Dioxide. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2014. [Google Scholar]

- Han, H.S.; Li, S.; Chen, X.L.; Qin, J.S.; Zeng, B.Q. Main control factors of carbon dioxide on swelling effect of crude hydrocarbon components. Acta Pet. Sin. 2016, 37, 392–398. [Google Scholar] [CrossRef]

- Chen, P.; Kalam, M.Z.; Al Kindi, S.A.; Abolhag, Y.H.; Shtepani, E. Maximize EOR Potential by Optimizing Miscible CO2 Injection Parameters in Carbonate Reservoirs. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar] [CrossRef]

- Zou, J.; Liao, X.; Zhao, X.; Chen, Z.; Zhang, Z. An Experimental Study of the Dynamic Mass Transfer Process During Carbonated Water Injection. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar] [CrossRef]

- Fakher, S.; Elgahawy, Y.; Hesham, A. Oil Swelling Measurement Techniques: Conventional Methods and Novel Pressure-Based Method. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Virtual, 20–22 July 2020. [Google Scholar] [CrossRef]

- Ali, A.; Bahman, Z. Molecular Dynamics Simulations Study on the Shear Viscosity, Density, and Equilibrium Interfacial Tensions of CO2 + Brines and Brines + CO2 + n-Decane Systems. J. Phys. Chem. B 2021, 125, 2707–2718. [Google Scholar] [CrossRef]

- Kang, Y.L.; Zhang, L.; Luo, J.; Guo, Y.C.; Cheng, S.Y.; Wu, D.; Li, K.F.; Guo, S.Q. Molecular dynamics simulation of CO2 dissolution-diffusion in multi-component crude oil. Front. Environ. Sci. 2023, 11, 1243854. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Sun, B.; Shen, Y.; Zhang, J.; Chen, X.; Wang, M. Molecular dynamics simulation on volume swelling of CO2-alkane system. Fuel 2015, 143, 194–201. [Google Scholar] [CrossRef]

- Wei, G.Q. Study on Effective Viscosity of CO2 Dissolved Crude Oil and Crude Oil-water Mixture Systems. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2018. [Google Scholar] [CrossRef]

- Frauenfeld, T.W.; Kissel, G.; Zhou, S. PVT and Viscosity Measurements for Lloydminster-Aberfeldy and Cold Lake Blended Oil Systems. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium and International Horizontal Well Technology Conference, Calgary, AB, Canada, 4–7 November 2002. [Google Scholar] [CrossRef]

- Wang, F.S.; Mou, Z.B.; Liu, P.C.; Zhang, S.F.; Wang, C.; Li, X.L. Experiment and numerical simulation on mechanism of CO2 assisted mining in super heavy oil reservoirs. Pet. Geol. Recovery Effic. 2017, 24, 86–91. [Google Scholar] [CrossRef]

- Farzaneh, S.A.; Seyyed, S.M.; Sohrabi, M. Enhanced Heavy Oil Recovery by Liquid CO2 Injection under Different Injection Strategies. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar] [CrossRef]

- Fakher, S.; Elgahawy, Y.; Abdelaal, H.; Imqam, A. Laboratory Studies on Immiscible CO2 Injection: AData Analysis Screening Criteria. In Proceedings of the 54th U.S. Rock Mechanics/Geomechanics Symposium, Virtual, 26 June–1 July 2020. [Google Scholar]

- Han, W. Research on the Effect of CO2 Huff and Puff of Fractured Horizontal Wells in Tight Oil Reservoirs. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2018. [Google Scholar] [CrossRef]

- Wang, S.L.; Sun, B.C.; Wang, L.; Li, Z.R.; Yang, J. Study and Application of the Stimulation Mechanism of CO2 Huff and Puff. Drill. Prod. Technol. 2004, 27, 91–94. [Google Scholar] [CrossRef]

- Wang, Y.H. Evaluation of CO2 Huff-n-Puff Experiments on Jimusar Shale Oil. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2020. [Google Scholar] [CrossRef]

- Lu, X.W.; Lu, P.L. Mechanism and application status of enhancing oil recovery by CO2 immiscible flooding. Pet. Geol. Eng. 2007, 2, 58–61. [Google Scholar]

- Asghari, K.; Araghi, M.M.; Ahmadloo, F.; Nakutnyy, P. Utilization of CO2 for Improving the Performance of Waterflooding in Heavy Oil Recovery. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 16–18 June 2009. [Google Scholar] [CrossRef]

- Liu, Y. Study on Oil Recovery of CO2 Flooding in Low Permeability Fractured Reservoir. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2018. [Google Scholar] [CrossRef]

- Yekeen, N.; Padmanabhan, E.; Abdulelah, H.; Irfan, S.A.; Okunade, O.A.; Khan, J.A.; Negash, B.M. CO2/brine interfacial tension and rock wettability at reservoir conditions: A critical review of previous studies and case study of black shale from Malaysian formation. J. Pet. Sci. Eng. 2021, 196, 107673. [Google Scholar] [CrossRef]

- Beaton, M.L.; Mashhadi, N.; Dominato, K.R.; Maguire, T.J.; Rupert, K.D.; Mundle, S.O.C. Monitoring CO2 injection and retention in steam-assisted gravity drainage (SAGD) operations. J. Pet. Sci. Eng. 2022, 218, 111050. [Google Scholar] [CrossRef]

- Dai, M. Application of Molecular Simulations to CO2-EOR: Phase-Equilibria and Interfacial Phenomena. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 15–17 November 2011. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, R.; Lun, Z.M.; Lv, C.Y.; Luo, M.; Zhao, C.P.; Pan, W.Y. Interfacial Tension and Oil Displacement Efficiency between CO2 and Crude Oil under High Temperature and High Pressure. Sci. Technol. Eng. 2017, 17, 38–42. [Google Scholar]

- Drexler, S.; Elton, L.C.; Ana, C.J.; Leandro, A.C.; Paulo, C. Effect of CO2 Injection on the Interfacial Tension for a Brazilian Pre-Salt Field. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 29–31 October 2019. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, Q.; Wang, S.; Feng, D.; Wu, K.; Dong, X.; Chen, S.; Chen, Z. Effects of Nanoscale Pore Confinement on CO2 Displacement. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016. [Google Scholar]

- Zuo, M.S.; Chen, H.; Qi, X.Y.; Liu, X.L.; Xu, C.H.; Yu, H.Z.; Brahim, M.S.; Wu, Y.; Liu, H.P. Effects of CO2 injection volume and formation of in-situ new phase on oil phase behavior during CO2 injection for enhanced oil recovery (EOR) in tight oil reservoirs. Chem. Eng. J. 2023, 452, 139454. [Google Scholar] [CrossRef]

- Zhao, J.; An, X.; Qiao, S. The extraction effect of CO2 injection on the flow properties of crude oil. Pet. Sci. Technol. 2019, 37, 710–717. [Google Scholar] [CrossRef]

- Alshuaibi, M.; Farzaneh, S.A.; Sohrabi, M. An experimental and simulation investigation on the effect of different gas mixtures on performance of miscible CO2 injection in HPHT Abu Dhabi reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar] [CrossRef]

- Fan, P.W.; Zhu, W.Y.; Lin, J.S.; Gao, C.; Wang, S.T. Factors and regularity of supercritical CO2 extraction of heavy oil impact. Sci. Technol. Eng. 2017, 17, 31–36. [Google Scholar] [CrossRef]

- Zhang, X.L. The Compositions of Supercritical CO2 Extraction Products and the Occurrence State of Retained Oil in Organic-rich Shales. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2018. [Google Scholar] [CrossRef]

- Qin, J.S.; Zhang, K.; Chen, X.L. Mechanism of the CO2 flooding as reservoirs containing high water. Acta Pet. Sin. 2010, 31, 797–800. [Google Scholar]

- Xianhong, T.; Kuiqian, M.; Shichao, C.; Xiaofeng, T.; Nan, L.; Shiqiang, P.; Na, L.; Wei, Z.; Lijun, Z.; Chen, H. Study on Dynamic Phase Behavior of Oil and Gas System during CO2 Flooding. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 15–19 July 2019. [Google Scholar] [CrossRef]

- Chen, H.; Li, B.; Zhang, X.; Wang, Q.; Wang, X.; Yang, S. Effect of gas contamination and well depth on pressure interval of CO2 near-miscible flooding. J. Pet. Sci. Eng. 2019, 176, 43–50. [Google Scholar] [CrossRef]

- Li, M.T.; Shan, W.W.; Liu, X.G.; Shang, G.H. Laboratory study on miscible oil displacement mechanism of supercritical carbon dioxide. Acta Pet. Sin. 2006, 27, 80–83. [Google Scholar] [CrossRef]

- Qi, G.X. Effect of CO2 extraction on minimum miscibility pressure. Petroleum Reserv. Eval. Dev. 2019, 9, 51–55, 60. [Google Scholar] [CrossRef]

- Hirschberg, A.; de Jone, L.N.G.; Schipper, B.A.; Meijer, J.G. Influence of temperature and pressure on asphaltene flocculation. SPE J. 1984, 24, 283–293. [Google Scholar] [CrossRef]

- Kontogeorgis, G.M.; Voutsas, E.C.; Yakoumis, I.Y.; Tassios, D.P. An equation of state for associating fluids. Ind. Eng. Chem. Res. 1996, 35, 4310–4318. [Google Scholar] [CrossRef]

- Victorov, A.I.; Firoozabadi, A. Thermodynamic micellization model of asphaltene precipitation from petroleum fluids. AIChE J. 1996, 42, 1753–1764. [Google Scholar] [CrossRef]

- Rassamdana, H.; Dabir, B.; Nematy, M.; Farhani, M.; Sahimi, M. Asphalt flocculation and deposition: I. The onset of precipitation. AIChE J. 1996, 42, 10–22. [Google Scholar] [CrossRef]

- Pfeiffer, J.P.; Saal RN, J. Asphaltic bitumen as colloid system. J. Phys. Chem. 1940, 44, 139–149. [Google Scholar] [CrossRef]

- Nghiem, L.X.; Kohse, B.F.; Ali SM, F.; Doan, Q. Asphaltene Precipitation: Phase Behaviour Modelling and Compositional Simulation. In Proceedings of the SPE Asia Pacific Conference on Integrated Modelling for Asset Management, Yokohama, Japan, 25–26 April 2000. [Google Scholar] [CrossRef]

- Soleymanzadeh, A.; Yousefi, M.; Kord, S.; Mohammadzadeh, O. A view on methods of determining onset of asphaltene precipitation. J. Pet. Explor. Prod. Technol. 2019, 9, 1375–1396. [Google Scholar] [CrossRef]

- Yang, H.X. Study on the Viscosity Reduction Mechanism of Heavy Oil under the Impacts of Carbon Dioxide. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2021. [Google Scholar]

- Punase, A.; Prakoso, A.; Hascakir, B. The Polarity of Crude Oil Fractions Affects the Asphaltenes Stability. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23 May 2016. [Google Scholar] [CrossRef]

- Ortiz, R.; Perez, C.; Sánchez, O.; Aybar, U.; Tellez, F.; Mujica, L.; Aguilar, J.; Andrade, A.; Resendiz, T.; Camarillo, L.; et al. Asphaltene-Prevention Work Flow Enhances Oil Production in High-Temperature Fractured Carbonate Reservoirs. SPE Prod. Oper. 2017, 32, 476–490. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, F.; Hou, J.; Lu, G.; Zhang, M.; Wang, Z. Comparative Analysis of CO2, N2, and Gas Mixture Injection on Asphaltene Deposition Pressure in Reservoir Conditions. Energies 2018, 11, 2483. [Google Scholar] [CrossRef]

- Fakher, S.; Ahdaya, M.; Elturki, M.; Imqam, A.; Elgahawy, Y. The Effect of Unconventional Oil Reservoirs’ Nano Pore Size on the Stability of Asphaltene During Carbon Dioxide Injection. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 15–18 July 2019. [Google Scholar]

- Mullins, O.C.; Betancourt, S.S.; Cribbs, M.E.; Dubost, F.X.; Creek, J.L.; Andrews, A.B.; Venkataramanan, L. The Colloidal Structure of Crude Oil and the Structure of Oil Reservoirs. Energy Fuels 2008, 21, 2785–2794. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Huang, S.S.; Dong, M. Asphaltene Deposition During CO2 Flooding. SPE Prod. Facil. 1999, 14, 235–245. [Google Scholar] [CrossRef]

- Dong, Z.X.; Wang, J.; Liu, G.; Lin, M.Q.; Li, M.Y. Experimental study on asphaltene precipitation induced by CO2 flooding. Pet. Sci. 2014, 11, 174–180. [Google Scholar] [CrossRef]

- Tian, J.F.; Chen, Z.L. Adsorption and precipitation mechanism of petroleum asphaltene and its influence factors. Mar. Pet. Geol. 2005, 10, 37–42. [Google Scholar]

- Wu, G.S. Experimental Design and Data Processing; Metallurgical Industry Press: Beijing, China, 1997. [Google Scholar]

- Li, R.T.; Liao, X.W.; Zou, J.D.; Zhang, H.; Zhou, X.Z.; Mu, L.Y.; Peng, D. Experimental and Numerical Studies on Asphaltene Deposition Distribution during CO2 Flooding in Ultra-Low Permeability Reservoirs. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 15–18 July 2019. [Google Scholar] [CrossRef]

- Wang, W.D.; Gong, H.J.; Sang, Q.; Gui, W.Y.; Lv, W. Static Experimental Study on the Effect of CO2 on Asphaltene Precipitation in Crude Oil. In Proceedings of the 2021 International Field Exploration and Development Conference, Qingdao, China, 16–18 September 2021. [Google Scholar]

- Fakher, S. Investigating Factors that May Impact the Success of Carbon Dioxide Enhanced Oil Recovery in Shale Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar] [CrossRef]

- He, Y.F.; Li, D.; Hu, J.; Guo, L.C. Study on the precipitation rules of petroleum asphaltene in carbon dioxide immiscible displacement reservoir. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2011, 26, 28–32. [Google Scholar]

- Moqadam, M.S.; Firoozinia, H.; Kharrat, R.; Ghazanfari, M.H.; Alamatsaz, A.R. Effect of Pressure and CO2 Composition Changes on Distribution of Asphaltene Molecular Weight in Heavy Crude Oil. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 16–18 June 2009. [Google Scholar] [CrossRef]

- Darabi, H.; Abouie, A.; Sepehrnoori, K. Effect of Temperature Variations on Asphaltene Dynamics in Oil Reservoirs. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23–26 May 2016. [Google Scholar] [CrossRef]

- Ali, M.; Dahraj, N.U.; Haider, S.A. Study of Asphaltene Precipitation during CO2 Injection in Light Oil Reservoirs. In Proceedings of the SPE/PAPG Pakistan Section Annual Technical Conference, Islamabad, Pakistan, 24–25 November 2015. [Google Scholar] [CrossRef]

- Ding, C.C. Research and Analysis of the Influencement of Carbon dioxide Flooding on Asphaltene Precipitation. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2013. [Google Scholar]

- Zhang, K. Research of Seepage Rule in Porous Media in CO2 Flooding Under the Influence of Asphaltene Deposition. Master’s Thesis, Changzhou University, Changzhou, China, 2015. [Google Scholar]

- Mahdavi, E.; Zebarjad, F.S.; Ayatollahi, S.; Taghikhani, V. Experimental investigation on the effect of Asphaltene types on the interfacial tension of CO2–hydrocarbon systems. Energy Fuels 2015, 29, 7941–7947. [Google Scholar] [CrossRef]

- Shoushtari, A.B.; Asadolahpour, S.R.; Madani, M. Thermodynamic investigation of asphaltene precipitation and deposition profile in wellbore: A case study. J. Mol. Liq. 2020, 320, 114468. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, Y.; He, M.Q.; Li, X.; Yang, W.P.; Lu, J. Asphaltene precipitation and reservoir damage characteristics of CO2 flooding in different microscopic structure types in tight light oil reservoirs. Fuel 2022, 312, 122943. [Google Scholar] [CrossRef]

- Li, L.; Wang, M.J.; Su, Y.L.; Gao, X.G.; Wang, W.D.; Tu, J.W.; Wang, X.H. Investigation of Asphaltene Precipitation and Reservoir Damage during CO2 Flooding in High-Pressure, High-Temperature Sandstone Oil Reservoirs. SPE J. 2024, 29, 4179–4193. [Google Scholar] [CrossRef]

- Gu, Z.H.; Zhang, C.; Li, P.F.; Li, Z.Y.; Wang, M.J.; Li, Z.M. CO2-Induced In-Situ Targeted Precipitation of Asphaltene in Heavy Oil Reservoirs: Balancing Formation Gas Channeling Regulation and Wellbore Asphaltene Blockage Prevention. SPE J. 2024, 29, 6138–6154. [Google Scholar] [CrossRef]