Research on Nuclear Magnetic Resonance Displacement Experiment on Gas–Water Mutual Drive Based on Rock Physical Property Differences

Abstract

1. Introduction

2. Materials and Methods

2.1. Core Sample Selection

2.2. CT Scanning and Electron Microscopy Analysis

2.3. Three-Dimensional Confocal Microscopy Analysis

2.4. Core Physical Property Classification

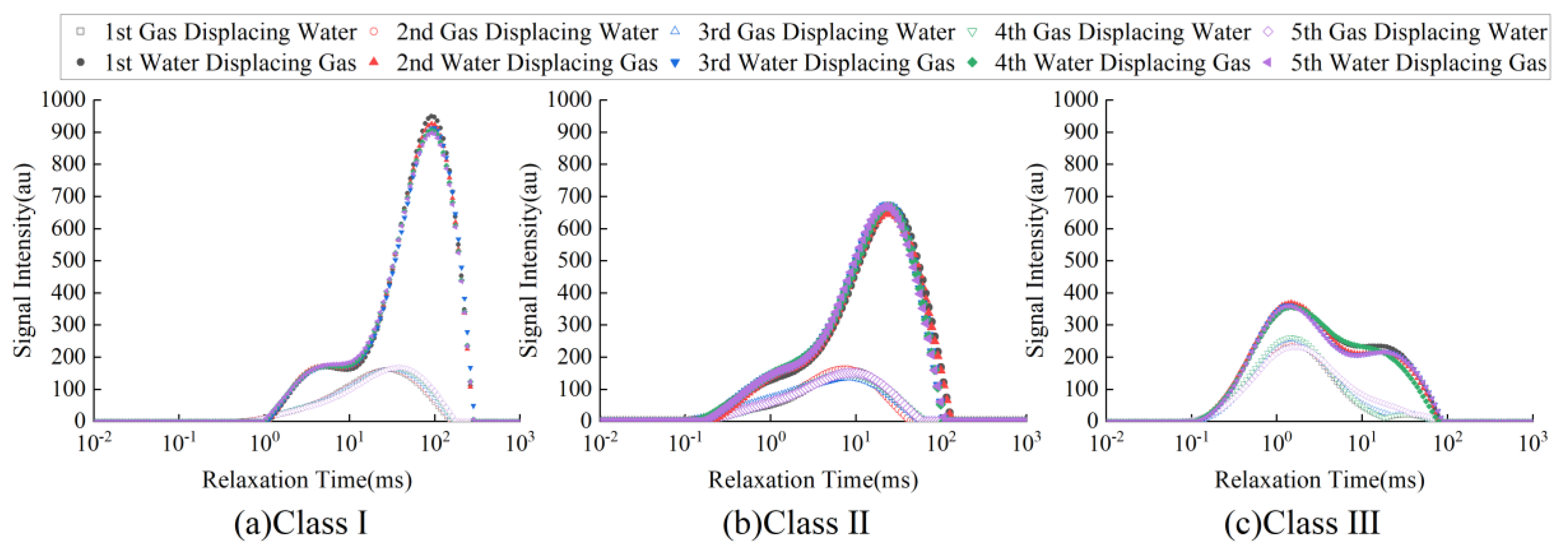

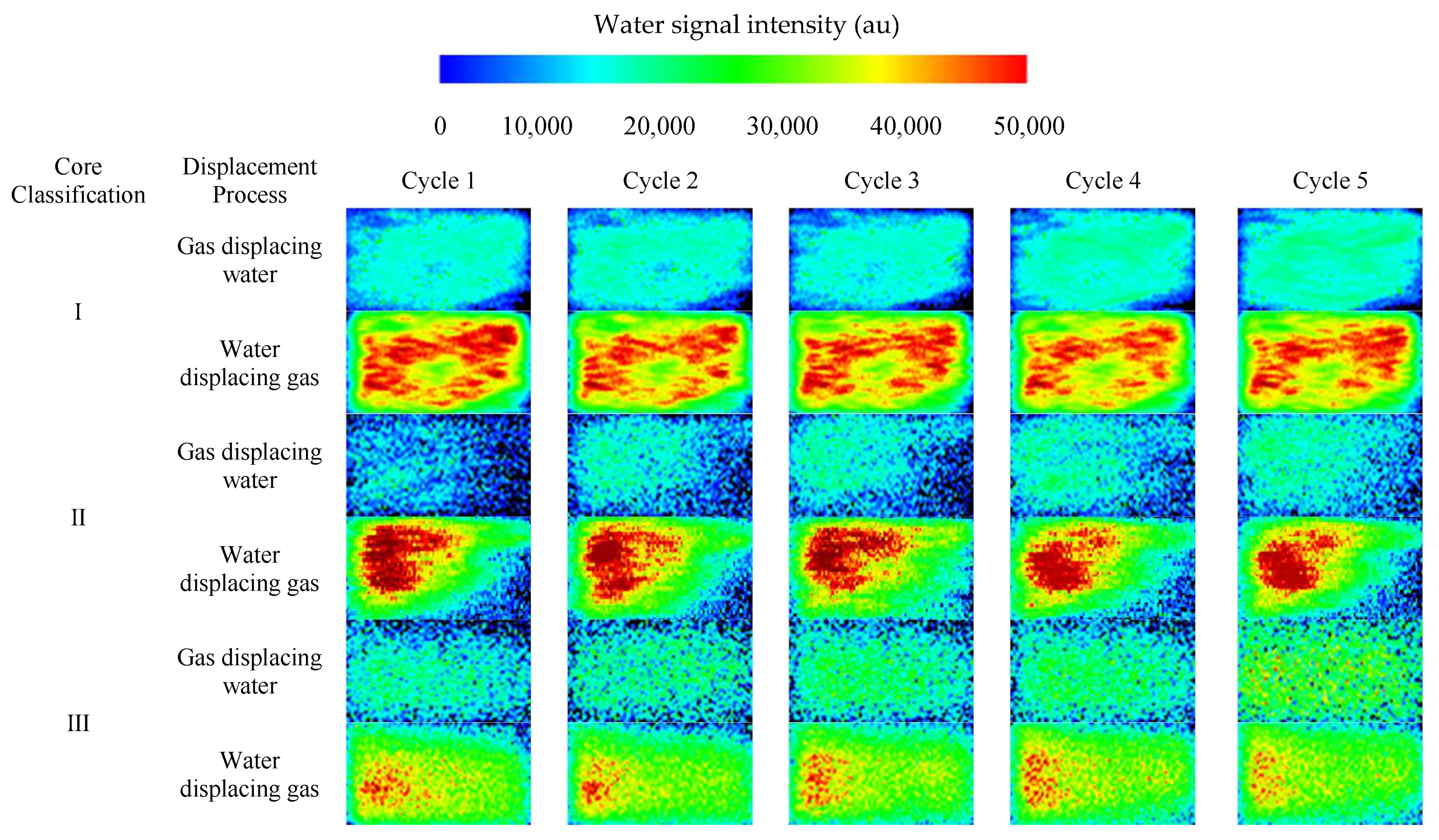

- High-permeability cores (Class I): Permeability ≥ 100 mD, porosity > 20%, uniform pore structure, mainly composed of dissolution pores and intergranular pores, with low clay mineral content.

- Medium-permeability cores (Class II): Permeability 20–100 mD, porosity 15–20%, heterogeneous pore structure, containing moderate amounts of clay minerals.

- Low-permeability cores (Class III): Permeability < 20 mD, porosity < 15%, heterogeneous pore structure, containing significant amounts of clay minerals.

2.5. NMR Displacement Experiment Design

- Sample preparation: Representative core samples were selected, including Class I (permeability 221 mD), Class II (permeability 82.4 mD), and Class III (permeability 4.92 mD) reservoirs. Physical property analyses such as for porosity and permeability were performed, and mineral compositions were confirmed.

- Initial saturation measurement: NMR technology was used to measure the initial saturation of the cores and determine the initial distribution of gas and water.

- Displacement process:

- Gas displacing water experiment: Gas was injected into the core to gradually replace the water, simulating the gas–water displacement process. Gas–water distribution, phase changes, and displacement efficiency were recorded. The experiment utilized methane gas under simulated reservoir conditions (42 megapascals, 95 degrees Celsius). To ensure capillary-dominated flow, the gas injection rate was maintained at 1 milliliters per minute.

- Water displacing gas experiment: After gas had displaced the water, water was injected to drive the gas forward, and the effect of water displacing gas was studied.

- Multi-cycle Injection and production: Five cycles of gas–water mutual drive were designed. Each cycle consisted of gas displacing water and water displacing gas. The dynamic changes in the gas–water phases in each cycle were observed, simulating the displacement conditions in the gas–water transition zone of a gas storage reservoir.

3. Results and Analysis

3.1. Rock Physical Properties and Pore Structure Analysis

3.2. Multi-Cycle Gas–Water Mutual Drive Experiment Results

4. Discussion

4.1. Relationship Between Core Pore Structure and Gas–Water Mutual Drive

- Influence of Pore Size on Displacement Process

- 2.

- Influence of Pore Connectivity on Displacement Process

- 3.

- Influence of Pore Morphology on Displacement Process

4.2. Influence of Rock Physical Property Differences on Gas–Water Mutual Drive

- Influence of Permeability on Gas–Water Mutual Drive

- 2.

- Influence of Porosity on Gas–Water Mutual Drive

- 3.

- Relationship Between Heterogeneity of Pore Structure and Displacement Efficiency

4.3. Influence of Mineral Composition on Gas–Water Mutual Drive

4.4. Comparison with Research Results of Others

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Zhang, M.; Zhou, F.; Fei, H.; Yu, S.; Su, H.; Liang, T.; Chen, Z. Experiment and Prediction of Enhanced Gas Storage Capacity in Depleted Gas Reservoirs for Clean Energy Applications. Renew. Energy 2024, 237, 121894. [Google Scholar] [CrossRef]

- Yang, H.; He, Q.; Chao, M.; Ping, Z.; Li, H.; Yu, F.; Renze, L.; Li, Z.; Duan, C. Injection-mining scheme optimization of underground gas storage based on agent model. Geoenergy Sci. Eng. 2024, 244, 213406. [Google Scholar] [CrossRef]

- Mao, S.; Chen, B.; Malki, M.; Chen, F.; Morales, M.; Ma, Z.; Mehana, M. Efficient prediction of hydrogen storage performance in depleted gas reservoirs using machine learning. Appl. Energy 2024, 361, 122914. [Google Scholar] [CrossRef]

- Ramey, H.J. Correlations of Surface and Interfacial Tensions of Reservoir Fluids; Society of Petroleum Engineers: Richardson, TX, USA, 1973. [Google Scholar]

- Khalil, Z.; Saad, M. On a fully nonlinear degenerate parabolic system modeling immiscible gas–water displacement in porous media. Nonlinear Anal. -Real World Appl. 2011, 12, 1591–1615. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, S. Experimental and theoretical characterization of methane and CO2 sorption hysteresis in coals based on Langmuir desorption. Int. J. Coal Geol. 2017, 171, 49–60. [Google Scholar] [CrossRef]

- Hamza, A.; Hussein, I.A.; Al-Marri, M.J.; Mahmoud, M.A.; Shawabkeh, R.A.; Aparicio, S. CO2 enhanced gas recovery and sequestration in depleted gas reservoirs: A review. J. Pet. Sci. Eng. 2021, 196, 107685. [Google Scholar] [CrossRef]

- Dabbaghi, E.; Ng, K.W. Effects of CO2 on the mineralogy, mechanical, and transport properties of rocks. Renew. Sustain. Energy Rev. 2024, 199, 114519. [Google Scholar] [CrossRef]

- Wang, Y.D.; Armstrong, R.T.; Mostaghimi, P. Enhancing resolution of digital rock images with super resolution convolutional neural networks. J. Pet. Sci. Eng. 2019, 182, 106261. [Google Scholar] [CrossRef]

- Niu, Y.; Jackson, S.J.; Alqahtani, N.; Mostaghimi, P.; Armstrong, R.T. Paired and unpaired deep learning methods for physically accurate super-resolution carbonate rock images. Transp. Porous Media 2022, 144, 825–847. [Google Scholar] [CrossRef]

- Buono, G.; Caliro, S.; Macedonio, G. Exploring microstructure and petrophysical properties of microporous volcanic rocks through 3D multiscale and super-resolution imaging. Sci. Rep. 2023, 13, 6651. [Google Scholar] [CrossRef]

- Fang, F.; Shen, W.; Gao, S.; Liu, H.; Wang, Q.; Li, Y. Experimental Study on the Physical Simulation of Water Invasion in Carbonate Gas Reservoirs. Appl. Sci. 2017, 7, 697. [Google Scholar] [CrossRef]

- Lu, Z.; Sha, A.M.; Wang, W.T. Permeability evaluation of clay-quartz mixtures based on low-field NMR and fractal analysis. Appl. Sci. 2020, 10, 1585. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, Q.; Yang, H.; Liu, J.; Luan, G.; Hu, P.; Yu, Z. Gas–Water Two-Phase Displacement Mechanism in Coal Fractal Structures Based on a Low-Field Nuclear Magnetic Resonance Experiment. Sustainability 2023, 15, 15440. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Zhao, Y.; Wang, Z.; Song, Y.; Lv, J. Study of displacement behavior and dispersion characteristics based on low-field NMR in the context of CO2 geological sequestration and enhanced methane recovery. Fuel 2024, 373, 132332. [Google Scholar] [CrossRef]

- Gu, J.; Lyu, H.; Chen, G. Research on the characteristics of pore water distribution of calcium carbonate waste soil based on NMR tests. Bull. Eng. Geol. Environ. 2025, 84, 60. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, M.; Yang, H.; Hu, P.; Gu, Q. Dynamic evolution process and application of gas displacement by water injection in gas-bearing coal bodies. Int. J. Heat Mass Transfer. 2024, 224, 125352. [Google Scholar] [CrossRef]

- Cong, Y.; Zhai, C.; Yu, X.; Xu, J.; Sun, Y. Quantification of liquid nitrogen injection efficiency and phase change expansion boost laws in coal seam borehole. Int. J. Heat Mass Transfer. 2024, 220, 125010. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Liang, X.; Wang, S.; Ma, Z. Ecological risk assessment of soil and water loss by thermal enhanced methane recovery: Numerical study using two-phase flow simulation. J. Clean. Prod. 2021, 334, 130183. [Google Scholar] [CrossRef]

- Huang, Z.; Li, X.; Li, S.; Zhao, K.; Zhang, R. Investigation of the hydraulic properties of deep fractured rocks around underground excavations using high-pressure injection tests. Eng. Geol. 2018, 245, 180–191. [Google Scholar] [CrossRef]

- Kozhevnikov, E.; Turbakov, M.; Riabokon, E.; Gladkikh, E.; Guzev, M. Rock permeability evolution during cyclic loading and colloid migration after saturation and drying. Adv. Geo-Energy Res. 2024, 11, 208–219. [Google Scholar] [CrossRef]

- Khan, M.Y.; Mandal, A. The impact of permeability heterogeneity on water-alternating-gas displacement in highly stratified heterogeneous reservoirs. J. Pet. Explor. Prod. Technol. 2022, 12, 871–897. [Google Scholar] [CrossRef]

- Cecilia, J.A.; García-Sancho, C.; Franco, F. Montmorillonite based porous clay heterostructures: Influence of Zr in the structure and acidic properties. Microporous Mesoporous Mater. 2013, 176, 95–102. [Google Scholar] [CrossRef]

- AlKharraa, H.; Wolf, K.H.; Alquraishi, A.A.; Mahmoud, M.A.; Deshenenkov, I.S.; AlDuhailan, M.A.; Alarifi, S.A.; Alqahtani, N.B.; Kwak, H.; Zitha, P.L. Impact of clay mineralogy on the petrophysical properties of tight sandstones. Geoenergy Sci. Eng. 2023, 227, 211883. [Google Scholar] [CrossRef]

| Core Class | Permeability (mD) | Porosity (%) | Clay Content (%) |

|---|---|---|---|

| I | ≥100 | >20 | <5 |

| II | 20–100 | 15–20 | 5–15 |

| III | <20 | <15 | >15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, J.; Wu, T.; Zhou, C.; Yu, X.; Gao, J.; Chen, H. Research on Nuclear Magnetic Resonance Displacement Experiment on Gas–Water Mutual Drive Based on Rock Physical Property Differences. Energies 2025, 18, 1338. https://doi.org/10.3390/en18061338

Pang J, Wu T, Zhou C, Yu X, Gao J, Chen H. Research on Nuclear Magnetic Resonance Displacement Experiment on Gas–Water Mutual Drive Based on Rock Physical Property Differences. Energies. 2025; 18(6):1338. https://doi.org/10.3390/en18061338

Chicago/Turabian StylePang, Jin, Tongtong Wu, Chunxi Zhou, Xinan Yu, Jiaao Gao, and Haotian Chen. 2025. "Research on Nuclear Magnetic Resonance Displacement Experiment on Gas–Water Mutual Drive Based on Rock Physical Property Differences" Energies 18, no. 6: 1338. https://doi.org/10.3390/en18061338

APA StylePang, J., Wu, T., Zhou, C., Yu, X., Gao, J., & Chen, H. (2025). Research on Nuclear Magnetic Resonance Displacement Experiment on Gas–Water Mutual Drive Based on Rock Physical Property Differences. Energies, 18(6), 1338. https://doi.org/10.3390/en18061338