A Holistic Framework for Developing Expert Systems to Improve Energy Efficiency in Manufacturing

Abstract

:1. Introduction

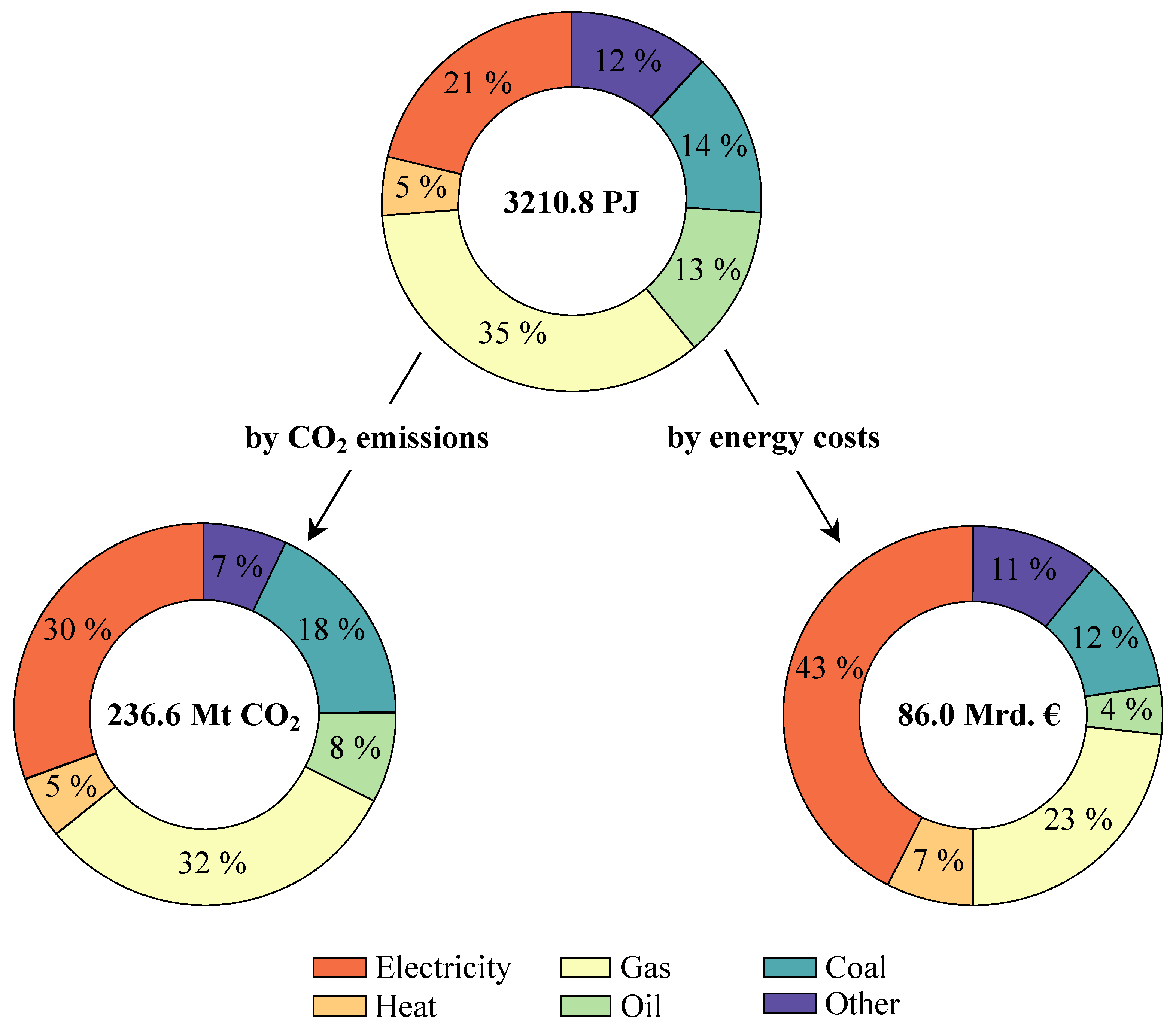

2. Fundamentals

2.1. Energy Management

2.2. Knowledge Management

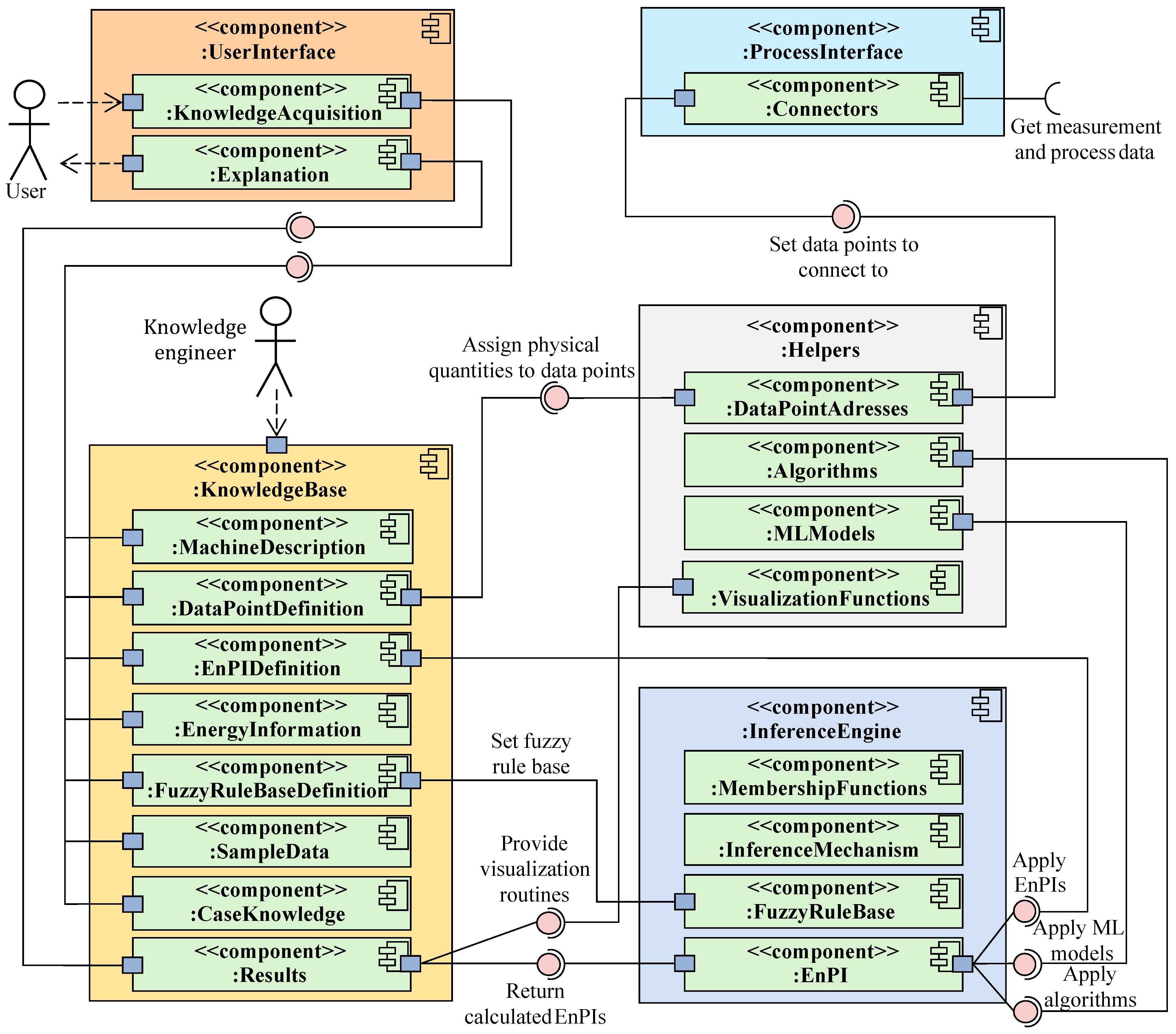

2.3. Expert Systems

- The knowledge base encompasses an explicit representation of knowledge used for problem-solving [25]. It can be divided into different parts [22,26]:

- –

- Domain-specific knowledge covers general knowledge about a specific field, which is independent of a specific problem. Ref. [12] refers to this part as the system’s long-term memory.

- –

- Case-specific knowledge corresponds to problem-specific facts, data and parameters. Ref. [12] refers to this part as the system’s short-term memory.

- –

- Intermediate and final results are ultimately derived knowledge that arises within problem-solving processes.

- The human-machine interface serves as the communication environment between humans (experts and other users) and the ES [12].

- The knowledge acquisition module enables experts to enrich the ES with new knowledge or to modify existing knowledge [12].

- The explanation module ensures transparency in the decision-making process of the ES. This helps to make the solutions found comprehensible and verifiable, thus increasing their acceptance. Moreover, it provides benefits in terms of knowledge transfer and distribution within knowledge management [22].

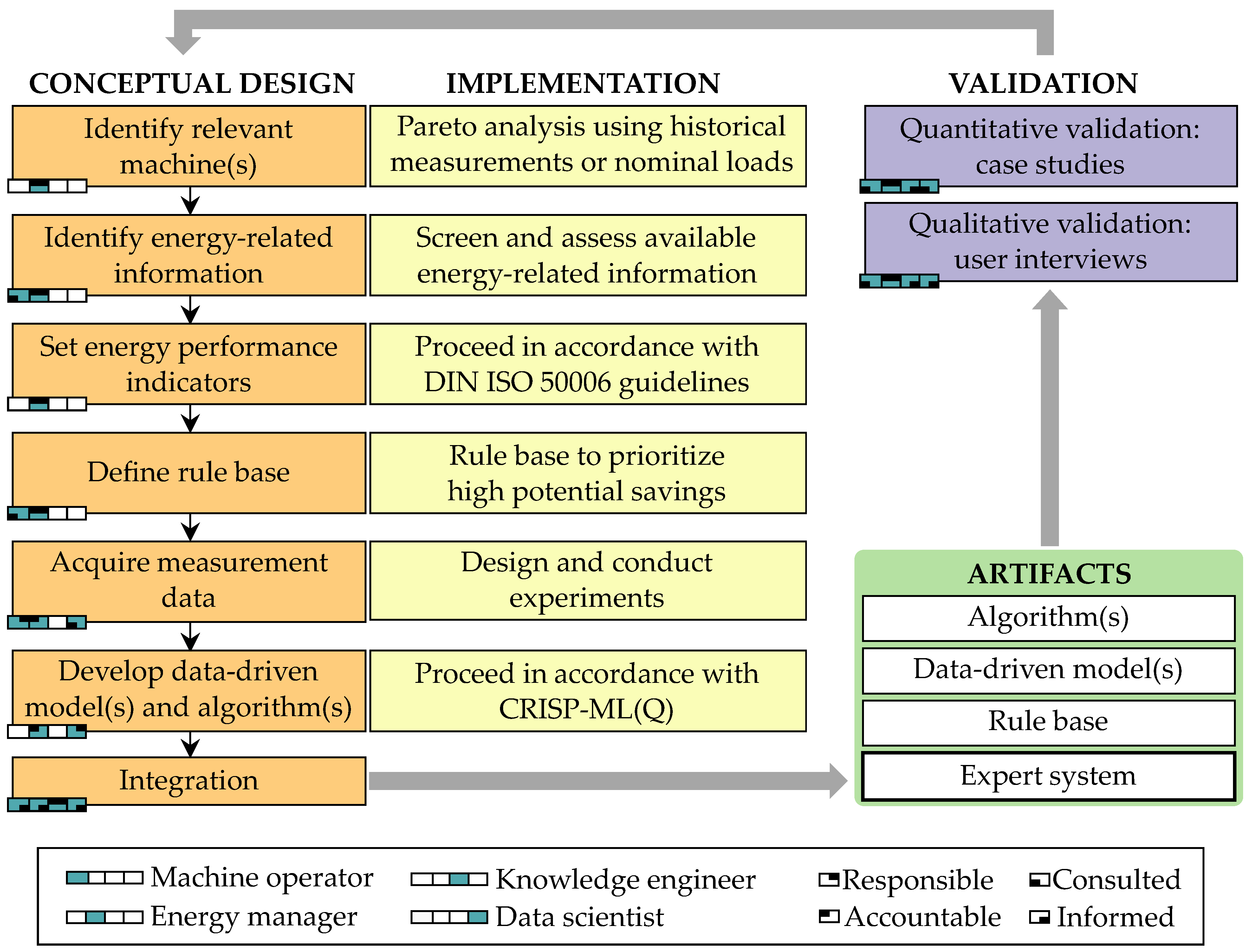

3. Methodology

3.1. Environment

3.2. Methodological Framework

4. Computational Implementation

5. Application

5.1. Relevant Machines and Energy-Related Information

5.2. Energy Performance Indicators and Rule Base

5.3. Data Acquisition and Algorithm Development

5.4. Integration and Validation

6. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CRISP-ML(Q) | CRoss-Industry Standard Process model for the development of Machine Learning applications with Quality assurance methodology |

| DSR | Design Science Research |

| EMAS | Eco-Management and Audit Scheme |

| EMS | Environmental management system |

| EnB | Energy baseline |

| EnEfG | Energy Efficiency Act |

| EnMS | Energy management system |

| EnPI | Energy performance indicator |

| ERP | Enterprise Resource Planning |

| ES | Expert system |

| ESS | Expert system shell |

| ESS4EE | Expert System Shell for Energy Efficiency |

| EU | European Union |

| MES | Manufacturing Execution Systems |

| ML | Machine Learning |

| PDCA | Plan-Do-Check-Act |

| RACI | Responsible Accountable Consulted Informed |

| SCADA | Supervisory Control and Data Acquisition |

| SEU | Significant energy use |

References

- European Parliament, Council of the European Union. Regulation (EU) 2021/1119. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32021R1119 (accessed on 7 December 2024).

- Metreau, E.; Kouame, Y. GDP Ranking. Available online: https://datacatalog.worldbank.org/search/dataset/0038130/gdp_ranking (accessed on 7 December 2024).

- Gütschow, J.; Jeffery, L.; Gieseke, R.; Günther, A. The PRIMAP-Hist National Historical Emissions Time Series (1850–2017). Available online: https://dataservices.gfz-potsdam.de/pik/showshort.php?id=escidoc:4736895 (accessed on 8 February 2025).

- Federal Office of Justice. Federal Climate Action Act: KSG. Available online: https://www.gesetze-im-internet.de/ksg/KSG.pdf (accessed on 8 February 2025).

- Energieeffizienz in Zahlen: Entwicklungen und Trends in Deutschland 2022. Available online: https://www.bmwk.de/Redaktion/DE/Publikationen/Energie/energieeffizienz-in-zahlen-2022.pdf?__blob=publicationFile&v=7 (accessed on 8 February 2025).

- Ioshchikhes, B. Supplementary Material | A Holistic Framework for Developing Expert Systems to Improve Energy Efficiency in Manufacturing. Available online: https://tudatalib.ulb.tu-darmstadt.de/handle/tudatalib/4396.2 (accessed on 22 February 2025).

- European Parliament, Council of the European Union. Directive (EU) 2023/1791. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=OJ:JOL_2023_231_R_0001 (accessed on 8 February 2025).

- ABB Ltd. Accelerating Ambition: How Global Industry Is Speeding Up Investment in Energy Efficiency. Available online: https://www.energyefficiencymovement.com/wp-content/uploads/2022/04/ABB-Energy-Efficiency-Survey-Report-2022.pdf (accessed on 8 December 2024).

- International Energy Agency. Energy Efficiency 2024. Available online: https://www.iea.org/reports/energy-efficiency-2024 (accessed on 8 December 2024).

- Ioshchikhes, B.; Frank, M.; Weigold, M. A Systematic Review of Expert Systems for Improving Energy Efficiency in the Manufacturing Industry. Energies 2024, 17, 4780. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Frank, M.; Elserafi, G.; Magin, J.; Weigold, M. Developing Expert Systems for Improving Energy Efficiency in Manufacturing: A Case Study on Parts Cleaning. Energies 2024, 17, 3417. [Google Scholar] [CrossRef]

- Buccieri, G.P.; Balestieri, J.A.P.; Matelli, J.A. Energy efficiency in Brazilian industrial plants: Knowledge management and applications through an expert system. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 577. [Google Scholar] [CrossRef]

- Li, P.; Lu, Y.; Qian, Y.; Wang, Y.; Liang, W. An explanatory parametric model to predict comprehensive post-commissioning building performances. Build. Environ. 2022, 213, 108897. [Google Scholar] [CrossRef]

- Bundesministerium der Justiz. Gesetz zur Steigerung der Energieeffizienz in Deutschland: (Energieeffizienzgesetz—EnEfG). Available online: https://www.gesetze-im-internet.de/enefg/BJNR1350B0023.html (accessed on 11 December 2024).

- ISO 50001:2018; Energiemanagementsysteme—Anforderungen mit Anleitung zur Anwendung. Deutsche Fassung EN ISO 50001:2018; DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2018.

- European Parliament, Council of the European Union. Consolidated text: Regulation (EC) No 1221/2009. Available online: http://data.europa.eu/eli/reg/2009/1221/2023-07-12 (accessed on 2 February 2025).

- VDI 4602 BLATT 1; Energy Management–Fundamentals. VDI Verein Deutscher Ingenieure e.V.: Düsseldorf, Germany, 2018.

- Aamodt, A.; Nygård, M. Different roles and mutual dependencies of data, information, and knowledge—An AI perspective on their integration. Data Knowl. Eng. 1995, 16, 191–222. [Google Scholar] [CrossRef]

- North, K. Wissensorientierte Unternehmensführung: Wertschöpfung durch Wissen, 5th ed.; Gabler Verlag: Wiesbaden, Germany, 2011. [Google Scholar] [CrossRef]

- Rehäuser, J.; Krcmar, H. Wissensmanagement im Unternehmen. In Wissensmanagement; Schreyögg, G., Conrad, P., Eds.; De Gruyter: Berlin, Germany; Boston, MA, USA, 1996; pp. 1–40. [Google Scholar] [CrossRef]

- DeTore, A.W. An introduction to expert systems. J. Insur. Med. 1989, 21, 233–236. [Google Scholar]

- Puppe, F. Einführung in Expertensysteme, 2nd ed.; Studienreihe Informatik: New York, NY, USA; Springer: Berlin, Germany, 1991. [Google Scholar]

- Lutz, B.; Moldaschl, M. Expertensysteme und Industrielle Facharbeit: Ein Gutachten über Denkbare Qualifiktorische Auswirkungen von Expertensystemen in der Fertigenden Industrie; Erstellt im Auftrag der Enquete-Kommission “Technikfolgenabschätzung und -Bewertung” des Deutschen Bundestages; Forschungsberichte aus dem Institut für Sozialwissenschaftliche Forschung e.V., Campus Verl.: Frankfurt am Main, Germany, 1989. [Google Scholar]

- Jackson, P. Introduction to Expert Systems, 3rd ed.; Addison-Wesley Longman Publishing Co., Inc.: Redwood City, CA, USA, 1998. [Google Scholar]

- Styczynski, Z.A.; Rudion, K.; Naumann, A. Einführung in Expertensysteme; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Wehking, K.H. Technisches Handbuch Logistik 2; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Frank, M.; Joseph, T.M.; Weigold, M. Improving Energy Efficiency in Manufacturing: A Novel Expert System Shell. arXiv 2024. [Google Scholar] [CrossRef]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Design Science in Information Systems Research. Manag. Inf. Syst. Q. 2004, 28, 75–105. [Google Scholar] [CrossRef]

- Vom Brocke, J.; Hevner, A.; Maedche, A. (Eds.) Design Science Research Cases; Progress in IS; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Ferreira, B.; Silva, W.; Barbosa, S.D.; Conte, T. Technique for representing requirements using personas: A controlled experiment. IET Softw. 2018, 12, 280–290. [Google Scholar] [CrossRef]

- Roth, A. (Ed.) Einführung und Umsetzung von Industrie 4.0: Grundlagen, Vorgehensmodell und Use Cases aus der Praxis; Springer Gabler: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Thiede, S. Energy Efficiency in Manufacturing Systems; Sustainable Production, life Cycle Engineering and Management; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- ISO 50006:2023; Energiemanagementsysteme—Bewertung der Energieleistung anhand von Energieleistungskennzahlen und energetischen Ausgangsbasen. DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2024.

- Liao, S.H. Expert system methodologies and applications—A decade review from 1995 to 2004. Expert Syst. Appl. 2005, 28, 93–103. [Google Scholar] [CrossRef]

- Studer, S.; Bui, T.B.; Drescher, C.; Hanuschkin, A.; Winkler, L.; Peters, S.; Müller, K.R. Towards CRISP-ML(Q): A Machine Learning Process Model with Quality Assurance Methodology. Mach. Learn. Knowl. Extr. 2021, 3, 392–413. [Google Scholar] [CrossRef]

- Smith, M.L.; Erwin, J.; Diaferio, S. Role & responsibility charting (RACI). Project Management Forum (PMForum). 2005, Volume 5, p. 12. Available online: https://pmicie.org/files/22/PM-Toolkit/85/racirweb31.pdf (accessed on 8 February 2025).

- Ioshchikhes, B.; Yoldas, C.; Horn, L.; Asl, N.A.; Zimmer, L.; Wigandt, A. Expert System Shell for Energy Efficiency (ESS4EE). Available online: https://github.com/Borika95/ESS4EE (accessed on 14 February 2025).

- Kluyver, T.; Ragan-Kelley, B.; Pérez, F.; Granger, B.; Bussonnier, M.; Frederic, J.; Kelley, K.; Hamrick, J.; Grout, J.; Corlay, S.; et al. Jupyter Notebooks—A publishing format for reproducible computational workflows. In Proceedings of the Positioning and Power in Academic Publishing: Players, Agents and Agendas, Göttingen, Germany, 7–9 June 2016; IOS Press: Amsterdam, The Netherlands, 2016; pp. 87–90. [Google Scholar] [CrossRef]

- Abele, E.; Schneider, J.; Beck, M.; Maier, A. ETA—die Modell-Fabrik: Energieeffizienz Weiter Gedacht. Available online: http://tubiblio.ulb.tu-darmstadt.de/105750/ (accessed on 14 February 2025).

- Sossenheimer, J. Hybrides Energiemessstellenkonzept zum Ganzheitlichen Energiemonitoring von Fertigungsmaschinen und Komponenten; Shaker Verlag: Düren/Maastricht, Germany, 2023. [Google Scholar]

- Walther, J. Hierarchical Electrical Load Forecasting of Industrial Production Systems in the Manufacturing Industry Based on Deep Learning. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2022. [Google Scholar] [CrossRef]

- Erlach, K.; Westkämper, E. (Eds.) Energiewertstrom: Der Weg zur Energieeffizienten Fabrik; Fraunhofer Verl.: Stuttgart, Germany, 2009. [Google Scholar]

- Seevers, J.P.; Jurczyk, K.; Meschede, H.; Hesselbach, J.; Sutherland, J.W. Automatic Detection of Manufacturing Equipment Cycles Using Time Series. J. Comput. Inf. Sci. Eng. 2020, 20, 031005. [Google Scholar] [CrossRef]

- VDMA 34179:2019-04; Messvorschrift zur Bestimmung des Energie- und Medienbedarfs von Werkzeugmaschinen in der Serienfertigung. Verband Deutscher Maschinen- und Anlagenbau e.V.: Frankfurt am Main, Germany, 2019.

- Dehning, P.; Blume, S.; Dér, A.; Flick, D.; Herrmann, C.; Thiede, S. Load profile analysis for reducing energy demands of production systems in non-production times. Appl. Energy 2019, 237, 117–130. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man-Mach. Stud. 1975, 7, 1–13. [Google Scholar] [CrossRef]

- Ioshchikhes, B. ES4EE_ETAFactory. Available online: https://github.com/Borika95/ES4EE_ETAFactory (accessed on 8 February 2025).

- POWER ANALYZER UMG 604-PRO. Available online: https://www.janitza.com/us/umg-604-pro.html (accessed on 23 January 2025).

- Ioshchikhes, B.; Heller, P.; Weigold, M. Machining Cycle Detection Based Expert System for Improving Energy Efficiency in Manufacturing. In Sustainable Manufacturing as a Driver for Growth; Kohl, H., Seliger, G., Dietrich, F., Mur, S., Eds.; Lecture Notes in Mechanical Engineering; Springer Nature: Cham, Switzerland, 2025; pp. 659–667. [Google Scholar] [CrossRef]

| Persona | Role and Contribution |

|---|---|

| Machine operator | Brings practical expertise from direct involvement in manufacturing processes, ensuring feasibility and applicability of proposed solutions. |

| Energy manager | Analyzes energy usage within manufacturing processes, identifies inefficiencies, and prioritizes areas for improvement. |

| Knowledge engineer | Collects, structures, and represents expert knowledge in a usable format for the expert system, combining practical and scientific insights. |

| Data scientist | Develops data-driven models and algorithms to automate the analysis of energy and process data, generating actionable insights. |

| Premise (IF) | Consequent (THEN) | |

|---|---|---|

| 1.1 | is high AND is high | is very high |

| 1.2 | is medium AND is high | is high |

| 1.3 | is low AND is high | is medium |

| ⋮ | ||

| 1.9 | is low AND is low | is very low |

| 2.1 | is high AND is low | is very high |

| 2.2 | is medium AND is low | is high |

| 2.3 | is low AND is low | is medium |

| ⋮ | ||

| 2.9 | is low AND is high | is very low |

| 3.1 | is high AND is high AND is high | is very high |

| 3.2 | is medium AND is high AND is high | is very high |

| 3.3 | is low AND is high AND is high | is high |

| 3.4 | is high AND is medium AND is high | is high |

| ⋮ | ||

| 3.27 | is low AND is low AND is low | is very low |

| Machine | Job | NPEF | NPTF | NPTR | n | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| m | i | in % | in % | in % | in kWh | in 1 | in (kWh)2 | in 1 | in 1 | in 1 |

| EMAG VLC100 Y | 38.01 | 58.47 | 0.05 | 0.70 | 0.70 | |||||

| OP 10 | 0.63 | 12 | 9.45 × 10−6 | 0.24 | ||||||

| OP 11 | 0.15 | 19 | 5.20 × 10−7 | 0.30 | ||||||

| MAFAC JAVA | 4.97 | 54.00 | 0.69 | 0.30 | 0.70 | |||||

| OP 20 | 0.26 | 8 | 6.59 × 10−4 | 0.15 | ||||||

| IVA RH 655 | 3.59 | 48.73 | 92.09 | 0.30 | 0.30 | |||||

| OP 30 | 0.49 | 2 | 1.27 × 10−4 | 0.50 | ||||||

| EMAG VLC100 GT | 37.15 | 66.01 | 0.03 | 0.92 | 0.92 | |||||

| OP 40 | 0.18 | 30 | 6.96 × 10−5 | 0.30 | ||||||

| OP 41 | 0.41 | 16 | 1.43 × 10−5 | 0.30 | ||||||

| MAFAC KEA | 23.80 | 41.06 | 13.89 | 0.30 | 0.50 | |||||

| OP 50 | 0.09 | 11 | 3.08 × 10−1 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ioshchikhes, B.; Zink, R.; Ozen, O.; Weigold, M. A Holistic Framework for Developing Expert Systems to Improve Energy Efficiency in Manufacturing. Energies 2025, 18, 1406. https://doi.org/10.3390/en18061406

Ioshchikhes B, Zink R, Ozen O, Weigold M. A Holistic Framework for Developing Expert Systems to Improve Energy Efficiency in Manufacturing. Energies. 2025; 18(6):1406. https://doi.org/10.3390/en18061406

Chicago/Turabian StyleIoshchikhes, Borys, Robin Zink, Oskay Ozen, and Matthias Weigold. 2025. "A Holistic Framework for Developing Expert Systems to Improve Energy Efficiency in Manufacturing" Energies 18, no. 6: 1406. https://doi.org/10.3390/en18061406

APA StyleIoshchikhes, B., Zink, R., Ozen, O., & Weigold, M. (2025). A Holistic Framework for Developing Expert Systems to Improve Energy Efficiency in Manufacturing. Energies, 18(6), 1406. https://doi.org/10.3390/en18061406