Cryogenics in Renewable Energy Storage: A Review of Technologies

Abstract

:1. Introduction

2. Methods and Materials

3. Theoretical Background

3.1. Principle of Cryogenic Systems

3.2. Performance Metrics in Cryogenic Energy Storage Systems

3.2.1. Round-Trip Efficiency

3.2.2. Liquid Yield

3.2.3. Exergy and Exergy Efficiency

3.2.4. Specific Consumption

3.3. Thermodynamics of Cryogenic Systems

3.4. Integration with Renewable Energy Sources

4. Cryogenic Systems for Energy Storage

4.1. Cryogenic CO2 Storage

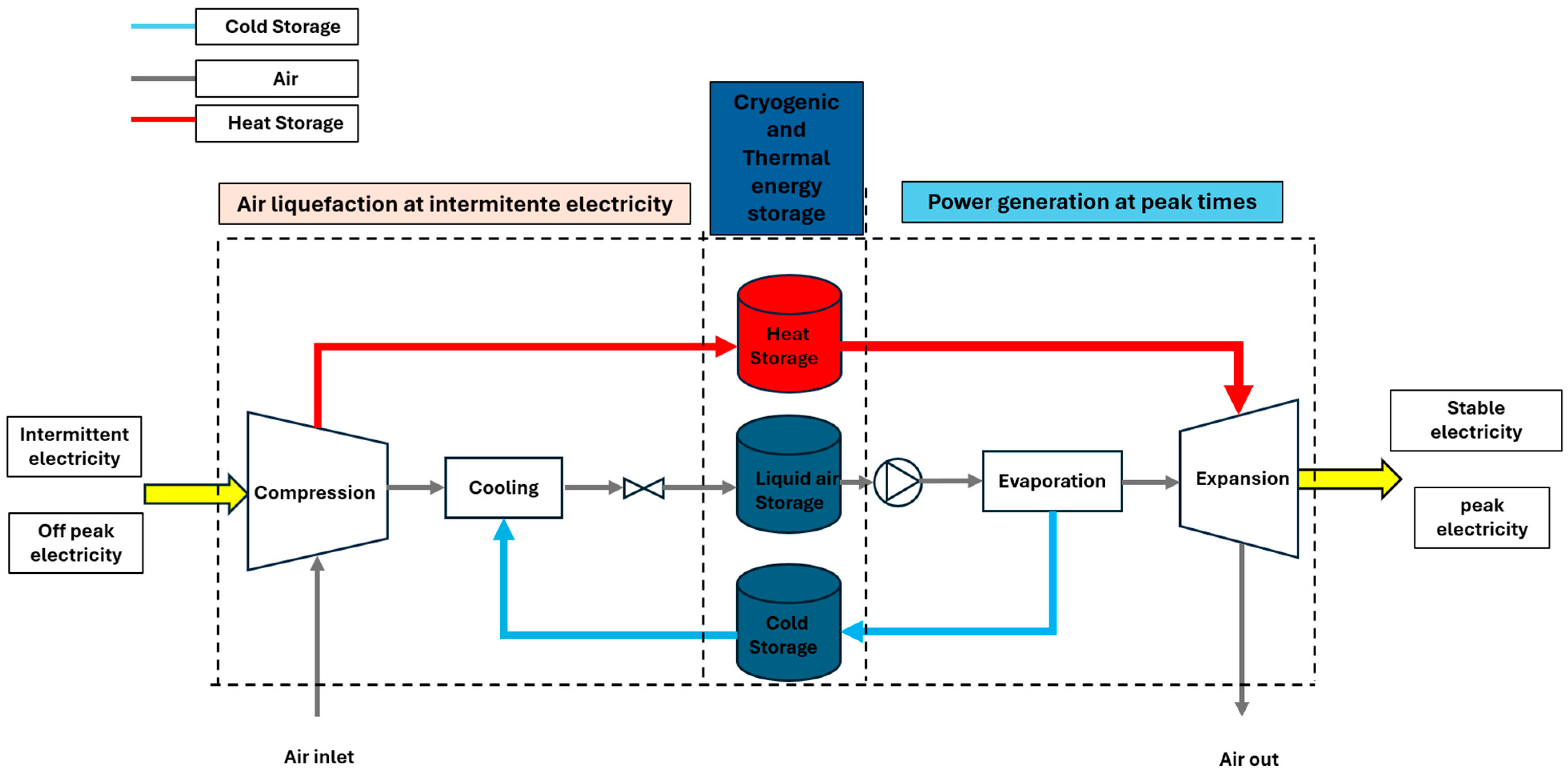

4.2. Liquid Air Energy Storage (LAES)

4.3. Cryogenic Hybrid Systems

LAES Technological Integrations

- Liquefied Natural Gas (LNG) Regasification: The utilization of residual cold generated during the LNG regasification process presents an opportunity to reduce the energy consumption associated with air liquefaction in LAES systems, significantly improving the overall system efficiency [40,79,80,81,83,84,85]. This integration enables optimized use of thermal resources, but its thermodynamic limits are defined by the heat transfer rate between LNG and liquefied air, which directly influences the efficiency of the air liquefaction process. The system efficiency is strongly dependent on factors such as the LNG temperature and the heat transfer rate, as a higher thermal differential between the two fluids can enhance heat transfer efficiency. However, this thermal differential also presents challenges related to thermal control and flow rate management, as a significant temperature difference may result in difficulties in maintaining stable operating conditions. Furthermore, thermodynamic limitations, such as the need to ensure an optimal thermal balance, are critical for minimizing energy losses that could compromise the overall system effectiveness [40,79,80,81,83,84,85].

5. Energy Efficiency in Cryogenic Systems

5.1. LAES Systems

5.2. CO2 Cryogenic Systems

5.3. Hybrid Cryogenic Systems

6. Comparative Analysis of Energy Storage Technologies

6.1. Scalability

6.2. Environmental Impact

6.3. Energy Efficiency

6.4. Financial Cost

7. Challenges and Opportunities in the Development of Cryogenic Energy Storage Systems

7.1. Technical Challenges

7.2. Opportunities for Improvement

7.3. Future Prospects

8. Key Studies Utilized

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gornjak, I.; Kokalj, F.; Samec, N. The Impact of Financial Support Mechanisms and Geopolitical Factors on the Profitability of Investments in Solar Power Plants in Slovenia. Energies 2024, 17, 5714. [Google Scholar] [CrossRef]

- Bai, W.; Lu, J.; Wang, J.; Fu, X.; Fu, Y.; Huang, Y.; Wang, X.; Shi, X. Numerical Simulation Study of Salt Cavern CO2 Storage in Power-to-Gas System. Energies 2024, 17, 5786. [Google Scholar] [CrossRef]

- Gandhi, A.; Zantye, M.S.; Hasan, M.F. Integration of cryogenic energy storage with renewables and power plants: Optimal strategies and cost analysis. Energy Convers. Manag. 2022, 269, 116165. [Google Scholar] [CrossRef]

- Popov, D.; Fikiin, K.; Stankov, B.; Alvarez, G.; Youbi-Idrissi, M.; Damas, A.; Evans, J.; Brown, T. Cryogenic heat exchangers for process cooling and renewable energy storage: A review. Appl. Therm. Eng. 2019, 153, 275–290. [Google Scholar] [CrossRef]

- Lieskoski, S.; Koskinen, O.; Tuuf, J.; Björklund-Sänkiaho, M. A review of the current status of energy storage in Finland and future development prospects. J. Energy Storage 2024, 93, 112327. [Google Scholar] [CrossRef]

- Morgan, R.; Nelmes, S.; Gibson, E.; Brett, G. An analysis of a large-scale liquid air energy storage system. Proc. Inst. Civ. Eng.-Energy 2015, 168, 135–144. [Google Scholar] [CrossRef]

- Elalfy, D.A.; Gouda, E.; Kotb, M.F.; Bureš, V.; Sedhom, B.E. Comprehensive review of energy storage systems technologies, objectives, challenges, and future trends. Energy Strategy Rev. 2024, 54, 101482. [Google Scholar] [CrossRef]

- Carraro, G.; Danieli, P.; Boatto, T.; Lazzaretto, A. Conceptual review and optimization of liquid air energy storage system configurations for large scale energy storage. J. Energy Storage 2023, 72, 108225. [Google Scholar] [CrossRef]

- Vecchi, A.; Li, Y.; Ding, Y.; Mancarella, P.; Sciacovelli, A. Liquid air energy storage (LAES): A review on technology state-of-the-art, integration pathways and future perspectives. Adv. Appl. Energy 2021, 3, 100047. [Google Scholar] [CrossRef]

- Borri, E.; Tafone, A.; Romagnoli, A.; Comodi, G. A Review on Liquid Air Energy Storage: History, State of the Art and Recent Developments; Elsevier Ltd.: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Rabi, A.M.; Radulovic, J.; Buick, J.M. Comprehensive Review of Liquid Air Energy Storage (LAES) Technologies. Energies 2023, 16, 6216. [Google Scholar] [CrossRef]

- Damak, C.; Leducq, D.; Hoang, H.M.; Negro, D.; Delahaye, A. Liquid Air Energy Storage (LAES) as a large-scale storage technology for renewable energy integration—A review of investigation studies and near perspectives of LAES. Int. J. Refrig. 2020, 110, 208–218. [Google Scholar] [CrossRef]

- O’Callaghan, O.; Donnellan, P. Liquid air energy storage systems: A review. Renew. Sustain. Energy Rev. 2021, 146, 111113. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Odoi-Yorke, F. Liquid air energy storage (LAES)—Systematic review of two decades of research and future perspectives. J. Energy Storage 2024, 102, 114022. [Google Scholar] [CrossRef]

- Smith, E.M. Storage of Electrical Energy Using Supercritical Liquid Air. Proc. Inst. Mech. Eng. 1977, 191, 289–298. [Google Scholar] [CrossRef]

- Kishimoto, K.; Hasegawa, K.; Asano, T.J.M.J.G. Development of Generator of Liquid Air Storage Energy System. Mitsubishi Juko Giho 1998, 35, 117–120. [Google Scholar]

- Araki, H.; Nakabaru, M.; Chino, K. Simulation of heat transfer in the cool storage unit of a liquid–air energy storage system. Heat Transf.—Asian Res. 2002, 31, 284–296. [Google Scholar] [CrossRef]

- Morgan, R.E. Liquid air energy storage—From theory to demonstration. Int. J. Environ. Stud. 2016, 73, 469–480. [Google Scholar] [CrossRef]

- Chen, H.; Ding, Y.; Peters, T.; Berger, F. Method of Storing Energy and a Cryogenic Energy Storage System. U.S. Patent 15/053,840, 23 June 2016. [Google Scholar]

- Peng, X.; She, X.; Li, C.; Luo, Y.; Zhang, T.; Li, Y.; Ding, Y. Liquid air energy storage flexibly coupled with LNG regasification for improving air liquefaction. Appl. Energy 2019, 250, 1190–1201. [Google Scholar] [CrossRef]

- Evans, J. Large Scale Energy Storage CryoHub Developing Cryogenic Energy Storage at Refrigerated Warehouses as an Interactive Hub to Integrate Renewable Energy in Industrial Food Refrigeration and to Enhance Power Grid Sustainability Deliverable D8.1 Report on the Barriers to Uptake of Renewable and Low Carbon Technologies. 2017. Available online: https://ior.org.uk/public/downloads/S5YWv/D08.01%20Report%20on%20the%20barriers%20to%20uptake%20of%20renewable%20and%20low%20carbon%20technologies%20S1a.pdf (accessed on 17 March 2025).

- Zhang, T.; She, X.; Nie, B.; Kildahl, H.; Ding, Y. Integration of liquid air energy storage with ammonia synthesis process for resource efficiency and cost-effectiveness. J. Energy Storage 2024, 97, 112637. [Google Scholar] [CrossRef]

- Peng, X.; She, X.; Cong, L.; Zhang, T.; Li, C.; Li, Y.; Wang, L.; Tong, L.; Ding, Y. Thermodynamic study on the effect of cold and heat recovery on performance of liquid air energy storage. Appl. Energy 2018, 221, 86–99. [Google Scholar] [CrossRef]

- Hamdy, S.; Morosuk, T.; Tsatsaronis, G. Cryogenics-based energy storage: Evaluation of cold exergy recovery cycles. Energy 2017, 138, 1069–1080. [Google Scholar] [CrossRef]

- Borri, E.; Tafone, A.; Comodi, G.; Romagnoli, A. Improving liquefaction process of microgrid scale Liquid Air Energy Storage (LAES) through waste heat recovery (WHR) and absorption chiller. Energy Procedia 2017, 143, 699–704. [Google Scholar] [CrossRef]

- Abdo, R.F.; Pedro, H.T.; Koury, R.N.; Machado, L.; Coimbra, C.F.; Porto, M.P. Performance evaluation of various cryogenic energy storage systems. Energy 2015, 90, 1024–1032. [Google Scholar] [CrossRef]

- Mishra, R.S.; Kumar, D. Thermodynamic Performance Analysis of Claude Cryogenic System. 2017. Available online: https://ijrei.com/controller/aviation/%5B2%5D%20vol-1,%20issue-5.pdf (accessed on 17 March 2025).

- Borri, E.; Tafone, A.; Romagnoli, A.; Comodi, G. A preliminary study on the optimal configuration and operating range of a ‘microgrid scale’ air liquefaction plant for Liquid Air Energy Storage. Energy Convers. Manag. 2017, 143, 275–285. [Google Scholar] [CrossRef]

- Elsman, E.B.; Mokkink, L.B.; Terwee, C.B.; Beaton, D.; Gagnier, J.J.; Tricco, A.C.; Baba, A.; Butcher, N.J.; Smith, M.; Hofstetter, C.; et al. Guideline for reporting systematic reviews of outcome measurement instruments (OMIs): PRISMA-COSMIN for OMIs 2024. J. Clin. Epidemiol. 2024, 173, 111422. [Google Scholar] [CrossRef]

- Kandezi, M.S.; Naeenian, S.M.M. Investigation of an efficient and green system based on liquid air energy storage (LAES) for district cooling and peak shaving: Energy and exergy analyses. Sustain. Energy Technol. Assess. 2021, 47, 101396. [Google Scholar] [CrossRef]

- Incer-Valverde, J.; Hamdy, S.; Morosuk, T.; Tsatsaronis, G. Improvement perspectives of cryogenics-based energy storage. Renew. Energy 2021, 169, 629–640. [Google Scholar] [CrossRef]

- Peng, X.; She, X.; Li, Y.; Ding, Y. Thermodynamic analysis of Liquid Air Energy Storage integrated with a serial system of Organic Rankine and Absorption Refrigeration Cycles driven by compression heat. Energy Procedia 2017, 142, 3440–3446. [Google Scholar] [CrossRef]

- Gandhi, A.; Zantye, M.S.; Hasan, M.F. Cryogenic energy storage: Standalone design, rigorous optimization and techno-economic analysis. Appl. Energy 2022, 322, 119413. [Google Scholar] [CrossRef]

- Lim, Y.; Al Atabi, M.; Williams, R.A. Liquid air as an energy storage: A review. J. Eng. Sci. Technol. 2016, 11, 496–515. [Google Scholar]

- Dadsetani, R.; Sheikhzadeh, G.A.; Safaei, M.R.; Alnaqi, A.A.; Amiriyoon, A. Exergoeconomic optimization of liquefying cycle for noble gas argon. Heat Mass Transfer. 2019, 55, 1995–2007. [Google Scholar] [CrossRef]

- Akhoundi, M.; Deymi-Dashtebayaz, M.; Tayyeban, E.; Khabbazi, H. Parametric study and optimization of the precooled Linde–Hampson (PCLH) cycle for six different gases based on energy and exergy analysis. Chem. Pap. 2023, 77, 5343–5356. [Google Scholar] [CrossRef]

- Lopez, M.F.G.; Hernandez, S.C.; Mendez, H.D.L.; Aldaco, A.T.; Leyte, R.L. Análisis Exergético A Un Ciclo Linde Simple Para Licuar Aire. In Avances en Ciencias y Técnicas del Frío-12. Actas del XII Congreso Ibérico y X Congreso Iberoamericano de Ciencias y Técnicas del Frío CYTEF 2024; Editorial electrónica UMH in Elche, Ed.; Series: Advances in Sciences and Techniques of Refrigeration; Miguel Hernandez University: Alicante, Spain, 2024; Available online: https://revistas.innovacionumh.es/index.php/cytef2024/article/view/2683 (accessed on 17 March 2025)ISSN 3045-5057.

- Van Sciver, S.W. Helium Cryogenics; Springer: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Krieger Publishing Co.: Malabar, FL, USA, 2013; ISBN 9781483100364. [Google Scholar]

- Xie, C.; Hong, Y.; Ding, Y.; Li, Y.; Radcliffe, J. An economic feasibility assessment of decoupled energy storage in the UK: With liquid air energy storage as a case study. Appl. Energy 2018, 225, 244–257. [Google Scholar] [CrossRef]

- Rodrigues, E.M.G.; Godina, R.; Santos, S.F.; Bizuayehu, A.W.; Contreras, J.; Catalão, J.P.S. Energy storage systems supporting increased penetration of renewables in islanded systems. Energy 2014, 75, 265–280. [Google Scholar] [CrossRef]

- Aminnaji, M.; Qureshi, M.F.; Dashti, H.; Hase, A.; Mosalanejad, A.; Jahanbakhsh, A.; Babaei, M.; Amiri, A.; Maroto-Valer, M. CO2 Gas hydrate for carbon capture and storage applications—Part 1. Energy 2024, 300, 131579. [Google Scholar] [CrossRef]

- Shamsi, S.S.M.; Barberis, S.; Maccarini, S.; Traverso, A. Large scale energy storage systems based on carbon dioxide thermal cycles: A critical review. Renew. Sustain. Energy Rev. 2024, 192, 114245. [Google Scholar] [CrossRef]

- Dewevre, F.; Lacroix, C.; Loubar, K.; Poncet, S. Carbon dioxide energy storage systems: Current researches and perspectives. Renew. Energy 2024, 224, 120030. [Google Scholar] [CrossRef]

- Zafar, A.; Matuszek, K.; MacFarlane, D.R.; Zhang, X. Recent Progress and Future Perspectives of Ionic Liquid-Based Carbon Dioxide Capture and Conversion. Green Energy Environ. 2024. [Google Scholar] [CrossRef]

- Prasad, A.; Kumar, R.; Sundaramurthy, S.; Suresh, A.; Ayub, R.; Khan, M.A. A review on assessing innovative materials and technologies for carbon dioxide conversion to valuables. Carbon Capture Sci. Technol. 2024, 13, 100287. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, T.; Tian, Z.; Gao, W.; Yang, K. A comprehensive parametric, energy and exergy analysis of a novel physical energy storage system based on carbon dioxide Brayton cycle, low-temperature thermal storage, and cold energy storage. Energy Convers. Manag. 2020, 226, 113563. [Google Scholar] [CrossRef]

- He, Q.; Liu, H.; Hao, Y.; Liu, Y.; Liu, W. Thermodynamic analysis of a novel supercritical compressed carbon dioxide energy storage system through advanced exergy analysis. Renew. Energy 2018, 127, 835–849. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, X.; Jia, W.; Li, H.; Yang, X. Justification of CO2 as the working fluid for a compressed gas energy storage system: A thermodynamic and economic study. J. Energy Storage 2020, 27, 101132. [Google Scholar] [CrossRef]

- Uemura, Y.; Kawasaki, T.; Obara, S. Analysis of the performance of an electricity generation system using the CO2 hydrate formation and dissociation process for heat recover. Energy 2021, 218, 119412. [Google Scholar] [CrossRef]

- Dashti, H.; Underschultz, J.; Garnett, A.; Honari, V.; Sedaghat, M.; Rudolph, V. A Review of Recent Advances in Cost-Effective Infrastructure System Design of the CO2 Distribution to CCS Injection Wells. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018. [Google Scholar] [CrossRef]

- Asgharian, H.; Marques, D.L.; Iov, F.; Liso, V.; Nielsen, M.P.; Thellufsen, J.Z.; Lund, H. The role of cryogenic carbon capture in future carbon-neutral societies. Int. J. Greenh. Gas Control. 2024, 135, 104161. [Google Scholar] [CrossRef]

- Enayatizadeh, H.; Arjomand, A.; Tynjälä, T.; Inkeri, E. Cryogenic carbon capture design through CO2 anti-sublimation for a gas turbine exhaust: Environmental, economic, energy, and exergy analysis. Energy 2024, 304, 132244. [Google Scholar] [CrossRef]

- Wanison, R.; Sripuangchai, P.; Phermkorn, P.; Soisuwan, T.; Kammuang-lue, N.; Terdtoon, P.; Tippayawong, N.; Mona, Y.; Suttakul, P.; Sakulchangsatjatai, P. Performance analysis of precooling systems for cryogenic carbon capture: A comparative study of theoretical, numerical, and experimental methods. Results Eng. 2024, 23, 102763. [Google Scholar] [CrossRef]

- De Guido, G. Cryogenic CO2 capture from oxy-combustion flue gas by a hybrid distillation + physical absorption process. Chem. Eng. Res. Des. 2023, 199, 639–658. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, Y.; Dong, Y.; Wen, C.; Yang, Y. High-pressure supersonic carbon dioxide (CO2) separation benefiting carbon capture, utilisation and storage (CCUS) technology. Appl. Energy 2023, 339, 120975. [Google Scholar] [CrossRef]

- Bose, D.; Bhattacharya, R.; Kaur, T.; Pandya, R.; Sarkar, A.; Ray, A.; Mondal, S.; Mondal, A.; Ghosh, P.; Chemudupati, R.I. Innovative approaches for carbon capture and storage as crucial measures for emission reduction within industrial sectors. Carbon Capture Sci. Technol. 2024, 12, 100238. [Google Scholar] [CrossRef]

- Ramadhan, R.; Mon, M.T.; Tangparitkul, S.; Tansuchat, R.; Agustin, D.A. Carbon capture, utilization, and storage in Indonesia: An update on storage capacity, current status, economic viability, and policy. Energy Geosci. 2024, 5, 100335. [Google Scholar] [CrossRef]

- Ding, H.; Dong, Y.; Zhang, Y.; Wen, C.; Yang, Y. Mass, energy and economic analysis of supersonic CO2 separation for carbon capture, utilization and storage (CCUS). Appl. Energy 2024, 373, 123856. [Google Scholar] [CrossRef]

- Buckingham, J.; Reina, T.R.; Duyar, M.S. Recent advances in carbon dioxide capture for process intensification. Carbon Capture Sci. Technol. 2022, 2, 100031. [Google Scholar] [CrossRef]

- Quale, S.; Rohling, V. The European Carbon dioxide Capture and Storage Laboratory Infrastructure (ECCSEL). Green Energy Environ. 2016, 1, 180–194. [Google Scholar] [CrossRef]

- Hüttermann, L.; Span, R.; Maas, P.; Scherer, V. Investigation of a liquid air energy storage (LAES) system with different cryogenic heat storage devices. Energy Procedia 2019, 158, 4410–4415. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, Y.; Han, Y.; Yan, H.; Du, W.; Qian, F.; Wang, M. An integrated system based on liquid air energy storage, closed Brayton cycle and solar power: Energy, exergy and economic (3E) analysis. J. Energy Storage 2024, 94, 112496. [Google Scholar] [CrossRef]

- Hossain, S.S.; Akhtar, F. Recent progress of geopolymers for carbon dioxide capture, storage and conversion. J. CO2 Util. 2023, 78, 102631. [Google Scholar] [CrossRef]

- Tan, H.; Ding, Z.; Wen, N. Numerical study on the thermodynamic performance of a packed bed cryogenic energy storage system. Appl. Therm. Eng. 2022, 214, 118903. [Google Scholar] [CrossRef]

- Nazir, M.S.; Abdalla, A.N.; Metwally, A.S.M.; Imran, M.; Bocchetta, P.; Javed, M.S. Cryogenic-Energy-Storage-Based Optimized Green Growth of an Integrated and Sustainable Energy System. Sustainability 2022, 14, 5301. [Google Scholar] [CrossRef]

- Kalavani, F.; Mohammadi-Ivatloo, B.; Zare, K. Optimal stochastic scheduling of cryogenic energy storage with wind power in the presence of a demand response program. Renew. Energy 2019, 130, 268–280. [Google Scholar] [CrossRef]

- Legrand, M.; Rodríguez-Antón, L.M.; Martinez-Arevalo, C.; Gutiérrez-Martín, F. Integration of liquid air energy storage into the spanish power grid. Energy 2019, 187, 115965. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, X.-L.; He, Y.-L.; Xue, X.-D.; Mei, S.-W. Thermodynamic analysis of hybrid liquid air energy storage systems based on cascaded storage and effective utilization of compression heat. Appl. Therm. Eng. 2020, 164, 114526. [Google Scholar] [CrossRef]

- He, T.; Lv, H.; Shao, Z.; Zhang, J.; Xing, X.; Ma, H. Cascade utilization of LNG cold energy by integrating cryogenic energy storage, organic Rankine cycle and direct cooling. Appl. Energy 2020, 277, 115570. [Google Scholar] [CrossRef]

- Kheshti, M.; Zhao, X.; Liang, T.; Nie, B.; Ding, Y.; Greaves, D. Liquid air energy storage for ancillary services in an integrated hybrid renewable system. Renew. Energy 2022, 199, 298–307. [Google Scholar] [CrossRef]

- Wang, C.; Akkurt, N.; Zhang, X.; Luo, Y.; She, X. Techno-economic analyses of multi-functional liquid air energy storage for power generation, oxygen production and heating. Appl. Energy 2020, 275, 115392. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Analysis and assessment of novel liquid air energy storage system with district heating and cooling capabilities. Energy 2017, 141, 792–802. [Google Scholar] [CrossRef]

- Antonelli, M.; Barsali, S.; Desideri, U.; Giglioli, R.; Paganucci, F.; Pasini, G. Liquid air energy storage: Potential and challenges of hybrid power plants. Appl. Energy 2017, 194, 522–529. [Google Scholar] [CrossRef]

- Cetin, T.H.; Kanoglu, M.; Yanikomer, N. Cryogenic energy storage powered by geothermal energy. Geothermics 2019, 77, 34–40. [Google Scholar] [CrossRef]

- Li, Y.; Cao, H.; Wang, S.; Jin, Y.; Li, D.; Wang, X.; Ding, Y. Load shifting of nuclear power plants using cryogenic energy storage technology. Appl. Energy 2014, 113, 1710–1716. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Jin, Y.; Ding, Y. An integrated solar-cryogen hybrid power system. Renew. Energy 2012, 37, 76–81. [Google Scholar] [CrossRef]

- Nabat, M.H.; Zeynalian, M.; Razmi, A.R.; Arabkoohsar, A.; Soltani, M. Energy, exergy, and economic analyses of an innovative energy storage system; liquid air energy storage (LAES) combined with high-temperature thermal energy storage (HTES). Energy Convers. Manag. 2020, 226, 113486. [Google Scholar] [CrossRef]

- Ansarinasab, H.; Hajabdollahi, H.; Fatimah, M. Conceptual design of LNG regasification process using liquid air energy storage (LAES) and LNG production process using magnetic refrigeration system. Sustain. Energy Technol. Assess. 2021, 46, 101239. [Google Scholar] [CrossRef]

- Brett, G.; Barnett, M. The application of liquid air energy storage for large scale long duration solutions to grid balancing. EPJ Web Conf. 2014, 79, 03002. [Google Scholar] [CrossRef]

- Li, Y.; Chen, H.; Ding, Y. Fundamentals and applications of cryogen as a thermal energy carrier: A critical assessment. Int. J. Therm. Sci. 2010, 49, 941–949. [Google Scholar] [CrossRef]

- Tan, H.; Wen, N.; Shao, B. Comparative study on the globally optimal performance of cryogenic energy storage systems with different working media. Energy Storage Sav. 2023, 2, 421–434. [Google Scholar] [CrossRef]

- Luyao, L.; Sixian, W.; Zhang, D.; Luwei, Y.; Yuan, Z.; Junjie, W. Performance analysis of liquid air energy storage utilizing LNG cold energy. IOP Conf. Series Mater. Sci. Eng. 2017, 171, 012032. [Google Scholar] [CrossRef]

- Lee, I.; Park, J.; Moon, I. Conceptual design and exergy analysis of combined cryogenic energy storage and LNG regasification processes: Cold and power integration. Energy 2017, 140, 106–115. [Google Scholar] [CrossRef]

- Li, J.; Fan, X.; Li, Y.; Wang, Z.; Gao, Z.; Ji, W.; Chen, L.; Wang, J. A novel system of liquid air energy storage with LNG cold energy and industrial waste heat: Thermodynamic and economic analysis. J. Energy Storage 2024, 86, 111359. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, L.; Ding, X.; Li, M.; Gao, C. Performance study on a new solar aided liquid air energy storage system integrated with organic Rankine cycle and thermoelectric generator. J. Energy Storage 2023, 59, 106566. [Google Scholar] [CrossRef]

- Zhang, Q.; Heuberger, C.F.; Grossmann, I.E.; Sundaramoorthy, A.; Pinto, J.M. Optimal Scheduling of Air Separation with Cryogenic Energy Storage. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2015; pp. 2267–2272. [Google Scholar] [CrossRef]

- Xie, C.; Li, Y.; Ding, Y.; Radcliffe, J. Evaluating Levelized Cost of Storage (LCOS) Based on Price Arbitrage Operations: With Liquid Air Energy Storage (LAES) as an Example. Energy Procedia 2019, 158, 4852–4860. [Google Scholar] [CrossRef]

- Mohammadi-Ivatloo, B.; Karimi, A.; Kalavani, F. Stochastic optimal sizing of integrated cryogenic energy storage and air liquefaction unit in microgrid. Renew. Energy 2019, 136, 15–22. [Google Scholar] [CrossRef]

- Zamani-Gargari, M.; Kalavani, F.; Abapour, M.; Mohammadi-Ivatloo, B. Reliability assessment of generating systems containing wind power and air separation unit with cryogenic energy storage. J. Energy Storage 2018, 16, 116–124. [Google Scholar] [CrossRef]

- Heo, J.Y.; Park, J.H.; Lee, J.I. Exergetic Analysis of Integrated Layout for Liquid Air Energy Storage Applied to APR1400 Using Mechanical Drive Steam Turbines. In Proceedings of the Korean Nuclear Society Autumn Academic Conference, Daejeon, Republic of Korea, 24–25 October 2019; Available online: http://hdl.handle.net/10203/269152 (accessed on 17 March 2025).

- Wang, S.; Xue, X.; Zhang, X.; Guo, J.; Zhou, Y.; Wang, J. The Application of Cryogens in Liquid Fluid Energy Storage Systems. Phys. Procedia 2015, 67, 728–732. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Tafone, A.; Romagnoli, A.; Borri, E.; Comodi, G. New parametric performance maps for a novel sizing and selection methodology of a Liquid Air Energy Storage system. Appl. Energy 2019, 250, 1641–1656. [Google Scholar] [CrossRef]

- Guizzi, G.L.; Manno, M.; Tolomei, L.M.; Vitali, R.M. Thermodynamic analysis of a liquid air energy storage system. Energy 2015, 93, 1639–1647. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Deng, S.; Li, H.; Kitamura, Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew. Sustain. Energy Rev. 2019, 101, 265–278. [Google Scholar] [CrossRef]

- Pellegrini, L.A.; De Guido, G.; Ingrosso, S. Thermodynamic Framework for Cryogenic Carbon Capture. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 475–480. [Google Scholar] [CrossRef]

- Alsanousie, A.A.; Attia, A.E.; Elhelw, M.; Elsamni, O.A. Towards nearly zero emissions natural gas-fired power plants using cryogenic carbon dioxide capture technology. Int. J. Greenh. Gas Control. 2023, 127, 103928. [Google Scholar] [CrossRef]

- Oh, D.-J.; Kim, N.-K.; Song, S.-W.; Kim, Y.-D.; Kim, M.-H. Investigation of fatigue performance for new membrane-type LNG CCS at cryogenic temperature. Mar. Struct. 2018, 62, 90–105. [Google Scholar] [CrossRef]

- Kim, T.-Y.; Yoon, S.-W.; Kim, J.-H.; Kim, M.-H. Fatigue and Fracture Behavior of Cryogenic Materials Applied to LNG Fuel Storage Tanks for Coastal Ships. Metals 2021, 11, 1899. [Google Scholar] [CrossRef]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Balta-Ozkan, N.; Goglio, P.; Hu, Y.; Varga, L.; McCabe, L. Techno-environmental analysis of battery storage for grid level energy services. Renew. Sustain. Energy Rev. 2020, 131, 110018. [Google Scholar] [CrossRef]

- Neigum, K.; Wang, Z. Technology, economic, and environmental analysis of second-life batteries as stationary energy storage: A review. J. Energy Storage 2024, 103, 114393. [Google Scholar] [CrossRef]

- Amir, M.; Deshmukh, R.G.; Khalid, H.M.; Said, Z.; Raza, A.; Muyeen, S.; Nizami, A.-S.; Elavarasan, R.M.; Saidur, R.; Sopian, K. Energy storage technologies: An integrated survey of developments, global economical/environmental effects, optimal scheduling model, and sustainable adaption policies. J. Energy Storage 2023, 72, 108694. [Google Scholar] [CrossRef]

- Roushenas, R.; Razmi, A.R.; Soltani, M.; Torabi, M.; Dusseault, M.; Nathwani, J. Thermo-environmental analysis of a novel cogeneration system based on solid oxide fuel cell (SOFC) and compressed air energy storage (CAES) coupled with turbocharger. Appl. Therm. Eng. 2020, 181, 115978. [Google Scholar] [CrossRef]

- Weber, N.d.A.B.; Hunt, J.D.; Zakeri, B.; Schneider, P.S.; Parente, F.S.A.; Marques, A.D.; Junior, A.O.P. Seasonal pumped hydropower storage role in responding to climate change impacts on the Brazilian electrical sector. J. Energy Storage 2024, 87, 111249. [Google Scholar] [CrossRef]

- Tafone, A.; Borri, E.; Cabeza, L.F.; Romagnoli, A. Environmental performance of a multi-energy liquid air energy storage (LAES) system in cogeneration asset—A life cycle assessment-based comparison with lithium ion (Li-ion) battery. Heliyon 2024, 10, e39193. [Google Scholar] [CrossRef]

- Collath, N.; Winner, H.; Frank, A.; Durdel, A.; Jossen, A. Suitability of late-life lithium-ion cells for battery energy storage systems. J. Energy Storage 2024, 87, 111508. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Fu, L.; Zhang, Z.; Tang, M.; Feng, J.; Jiang, S.; Lei, Y.; Zhang, D.; Shen, B. Photovoltaic-driven liquid air energy storage system for combined cooling, heating and power towards zero-energy buildings. Energy Convers. Manag. 2024, 300, 117959. [Google Scholar] [CrossRef]

- Houssainy, S.; Janbozorgi, M.; Ip, P.; Kavehpour, P. Thermodynamic analysis of a high temperature hybrid compressed air energy storage (HTH-CAES) system. Renew. Energy 2018, 115, 1043–1054. [Google Scholar] [CrossRef]

- Bassam, A.M.; Elminshawy, N.A.; Oterkus, E.; Amin, I. Hybrid compressed air energy storage system and control strategy for a partially floating photovoltaic plant. Energy 2024, 313, 133706. [Google Scholar] [CrossRef]

- Beltrami, F. The impact of hydroelectric storage in Northern Italy’s power market. Energy Policy 2024, 191, 114192. [Google Scholar] [CrossRef]

- Highview Power Storage. Cryogen: A Mature Product; Now a New Means of Energy Storage; Highview Power: London, UK, 2011. [Google Scholar]

- Yazdani, S.; Deymi-Dashtebayaz, M.; Salimipour, E. Comprehensive comparison on the ecological performance and environmental sustainability of three energy storage systems employed for a wind farm by using an emergy analysis. Energy Convers. Manag. 2019, 191, 1–11. [Google Scholar] [CrossRef]

- Hamdy, S.; Morosuk, T.; Tsatsaronis, G. Exergetic and economic assessment of integrated cryogenic energy storage systems. Cryogenics 2019, 99, 39–50. [Google Scholar] [CrossRef]

- Tan, H.; Wen, N.; Ding, Z.; Li, Y. Optimization of a cryogenic liquid air energy storage system and its optimal thermodynamic performance. Int. J. Energy Res. 2022, 46, 15156–15173. [Google Scholar] [CrossRef]

- Hüttermann, L.; Span, R. Investigation of storage materials for packed bed cold storages in liquid air energy storage (LAES) systems. Energy Procedia 2017, 143, 693–698. [Google Scholar] [CrossRef]

- Ren, S.; Gundersen, T.; Liu, Z.; Feng, X. Performance improvement of liquid air energy storage: Introducing Stirling engine and solar energy. Energy Convers. Manag. 2023, 296, 117666. [Google Scholar] [CrossRef]

- Liu, X.; Fan, K.; Huang, X.; Ge, J.; Liu, Y.; Kang, H. Recent advances in artificial intelligence boosting materials design for electrochemical energy storage. Chem. Eng. J. 2024, 490, 151625. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Ahmadi, P.; Adib, M.; Izadi, A. Techno-economic assessment of an efficient liquid air energy storage with ejector refrigeration cycle for peak shaving of renewable energies. Renew. Energy 2023, 214, 96–113. [Google Scholar] [CrossRef]

| Authors | Years | Title | Main Topics Covered |

|---|---|---|---|

| Gandhi et al. [33] | 2022 | Cryogenic energy storage: Standalone design, rigorous optimization and techno-economic analysis | The article investigates the optimization of cryogenic energy storage (CES) systems, addressing challenges related to thermodynamic properties and complex modeling. The optimization approach achieved 52% efficiency and a levelized cost of storage (LCOS) of 144.82 EUR/MWh; however, it reveals that, when accounting for all direct and indirect costs, the LCOS could exceed 251.18 EUR/MWh. |

| Mousavi et al. [120]. | 2023 | Techno-economic assessment of an efficient liquid air energy storage with ejector refrigeration cycle for peak shaving of renewable energies | The article examines the integration of a CCHP system with LAES to enhance its efficiency. Utilizing the Organic Rankine Cycle (ORC) and an ejector refrigeration system, the system optimizes LAES performance while fulfilling heating and cooling requirements. Energy and exergy analyses reveal that the system generated 34,927 kWh of electricity, 424 kW of cooling power, and 729 kW of heating power, achieving 13% higher efficiency compared to the standalone LAES. The return on investment is 2.98 years, considering California as a case study. |

| Rabi et al. [11] | 2023 | Comprehensive Review of Liquid Air Energy Storage (LAES) Technologies | The article examines Liquid Air Energy Storage (LAES) as an alternative to large-scale systems like CAES and PHES, noting its high volumetric energy density and ability to overcome geographical constraints. It includes thermodynamic and economic analyses, highlighting the potential of hybrid solutions with waste energy recovery to optimize LAES efficiency. |

| Tan et al. [116] | 2022 | Optimization of a cryogenic liquid air energy storage system and its optimal thermodynamic performance | The article explores Liquid Air Energy Storage (LAES) for large-scale electricity storage using a process model combining the Linde liquefaction process and an open Rankine cycle. Performance optimization was conducted via single-factor analysis and genetic algorithm (GA) in MATLAB. The study examined the impact of charging, storage, and discharging pressures and compressor/turbine isentropic efficiency. GA optimization achieved a 53.33% round-trip efficiency, 86.96% liquefaction ratio, 81% energy efficiency, and a 10.02% reduction in compressor power consumption. |

| Gandhi et al. [3] | 2022 | Integration of cryogenic energy storage with renewables and power plants: Optimal strategies and cost analysis | The article explores cryogenic energy storage (CES) as a solution to the intermittence of renewable energy sources, highlighting its high technological readiness and moderate efficiency. It employs a mixed-integer nonlinear programming (MINLP) model to calculate daily storage costs across different annual scenarios. The study addresses key issues related to the integration of CES with renewable sources, the amount of storage required for the transition to renewable energy, and optimal storage designs for various energy scenarios. |

| O’Callaghan et al. [13] | 2021 | Liquid air energy storage systems: A review | The article reviews Liquid Air Energy Storage (LAES) systems, covering liquefaction, power generation, integrated systems, and practical demonstrations. It identifies the gap between existing literature and the optimal performance of large-scale systems. The article suggests that future research should investigate LAES systems under dynamic conditions, aiming to optimize the design and assess their operational and economic viability at a large scale. |

| Borri et al. [10] | 2021 | A review on liquid air energy storage: History, state of the art and recent developments | The article explores Liquid Air Energy Storage (LAES), highlighting its high volumetric energy density and potential for integration with thermal systems. It discusses air liquefaction, low round-trip efficiency (50–60%), and suggests that hybrid solutions with waste energy recovery are promising for optimizing the techno–economic performance of LAES. |

| Incer-Valverde et al. [31] | 2021 | Improvement perspectives of cryogenics-based energy storage | The article evaluates an adiabatic cryogenic energy storage system (100 MW/400 MWh) using exergy analysis to identify improvements in inefficiencies, costs, and environmental impacts. Simulation in Aspen Plus® indicates that the heat exchangers are the main cost drivers and that increasing the temperature difference is necessary to minimize costs. The expander and the second heat exchanger are the primary sources of avoidable inefficiencies. The applied recommendations render the technology both thermodynamically and economically viable. |

| Legrand et al. [68] | 2019 | Integration of liquid air energy storage into the Spanish power grid | The article presents a transient thermodynamic model of a 100 MW LAES plant, incorporating a packed-bed cold storage system to optimize efficiency. Thermocline affects the cycle’s efficiency. The economic study, based on simulations, analyzes renewable integration scenarios and calculates the levelized cost of energy. The results show that storing photovoltaic energy during daytime peak hours and discharging at night reduces costs to 150 EUR/MWh and 50 EUR/MWh, respectively. |

| Damak et al. [12] | 2020 | Liquid Air Energy Storage (LAES) as a large-scale storage technology for renewable energy integration—A review of investigation studies and near perspectives of LAES | The article reviews the properties of cryogens, different CES processes, and key ways to integrate the system with other facilities to enhance energy efficiency, particularly through combining refrigerated warehouses and thermal energy recovery from cryogen evaporation. |

| Vecchi et al. [9] | 2021 | Liquid air energy storage (LAES): A review on technology state-of-the-art, integration pathways and future perspectives | The article discusses Liquid Air Energy Storage (LAES) as a solution for decarbonizing the energy system and mitigating the volatility of renewable energy sources, with a capacity range of 10–100 MW and storage of GWh. It highlights the advantages of LAES, such as high energy density and ease of deployment, as well as its evolution since 1977. The paper proposes a methodology for comparing literature results, reviews the operation of LAES within the energy system, and suggests future research directions based on over 120 references. |

| Agyekum et al. [14] | 2024 | Liquid air energy storage (LAES)—Systematic review of two decades of research and future perspectives | The article emphasizes the importance of electrical energy storage systems in optimizing grids with higher penetration of renewable energy sources, presenting a literature review from 2000 to 2023. The review highlights improvements in cycle efficiency, with some configurations achieving up to 70%, and the potential for integration with gas power plants and renewable energy sources. Heat recovery, including Rankine cycles and heat pumps, contributes to enhanced efficiency. The study suggests future research directions. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semedo, A.; Garcia, J.; Brito, M. Cryogenics in Renewable Energy Storage: A Review of Technologies. Energies 2025, 18, 1543. https://doi.org/10.3390/en18061543

Semedo A, Garcia J, Brito M. Cryogenics in Renewable Energy Storage: A Review of Technologies. Energies. 2025; 18(6):1543. https://doi.org/10.3390/en18061543

Chicago/Turabian StyleSemedo, Arian, João Garcia, and Moisés Brito. 2025. "Cryogenics in Renewable Energy Storage: A Review of Technologies" Energies 18, no. 6: 1543. https://doi.org/10.3390/en18061543

APA StyleSemedo, A., Garcia, J., & Brito, M. (2025). Cryogenics in Renewable Energy Storage: A Review of Technologies. Energies, 18(6), 1543. https://doi.org/10.3390/en18061543