A Review on Phase-Change Materials (PCMs) in Solar-Powered Refrigeration Systems

Abstract

:1. Introduction

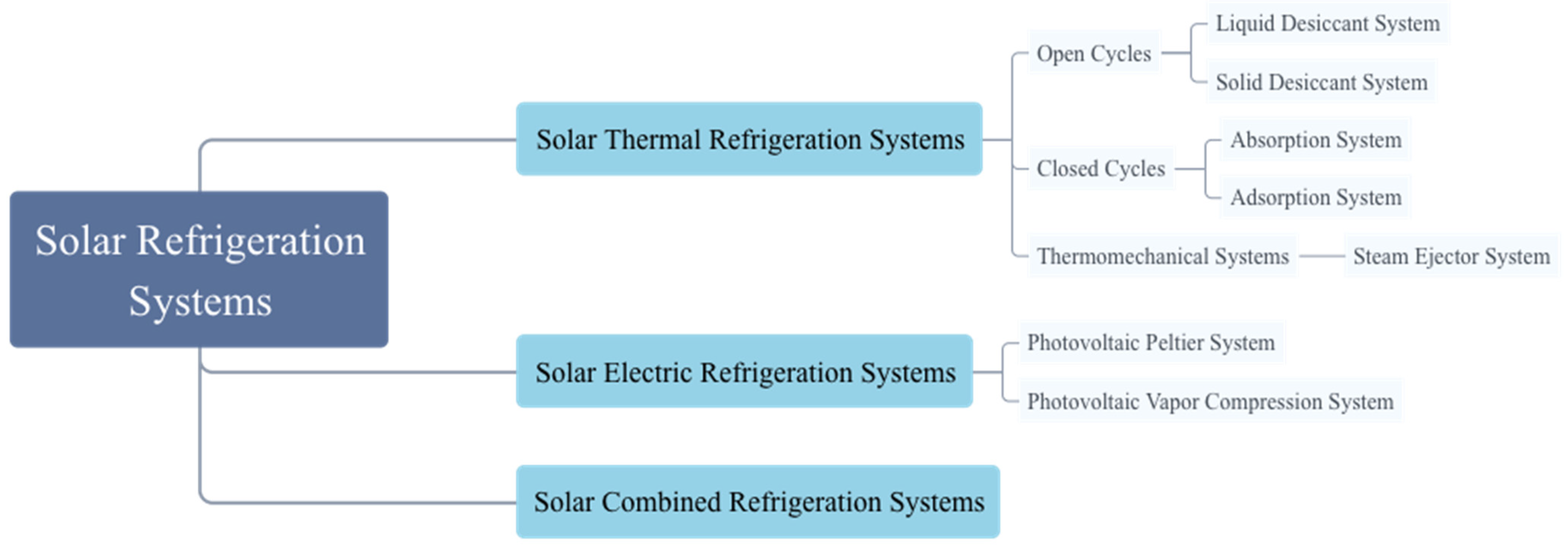

2. Classification of Solar Refrigeration Systems

2.1. Solar Thermal Refrigeration

2.1.1. Open Adsorption Cycle

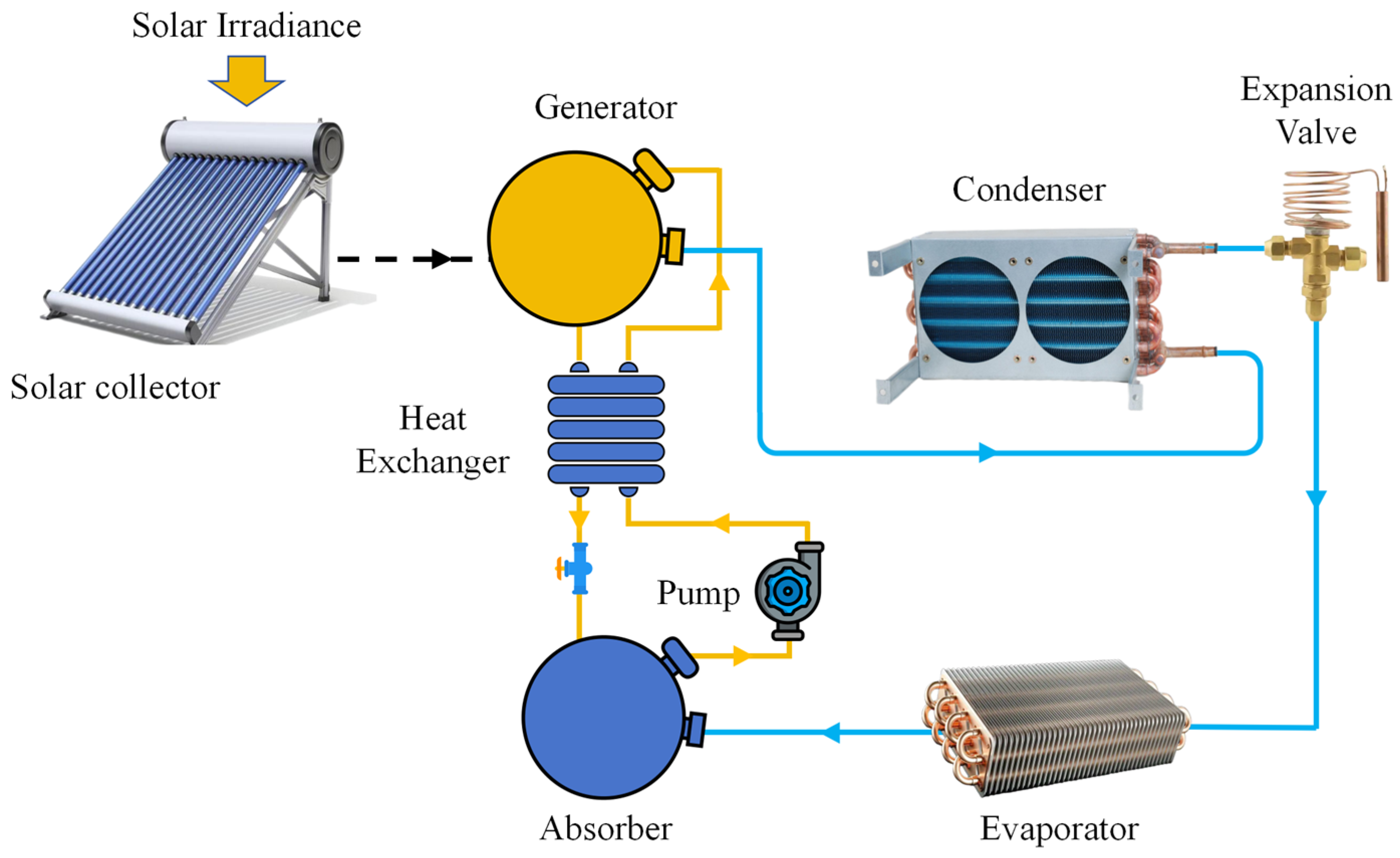

2.1.2. Closed Absorption Cycle

2.1.3. Thermomechanical Refrigeration System

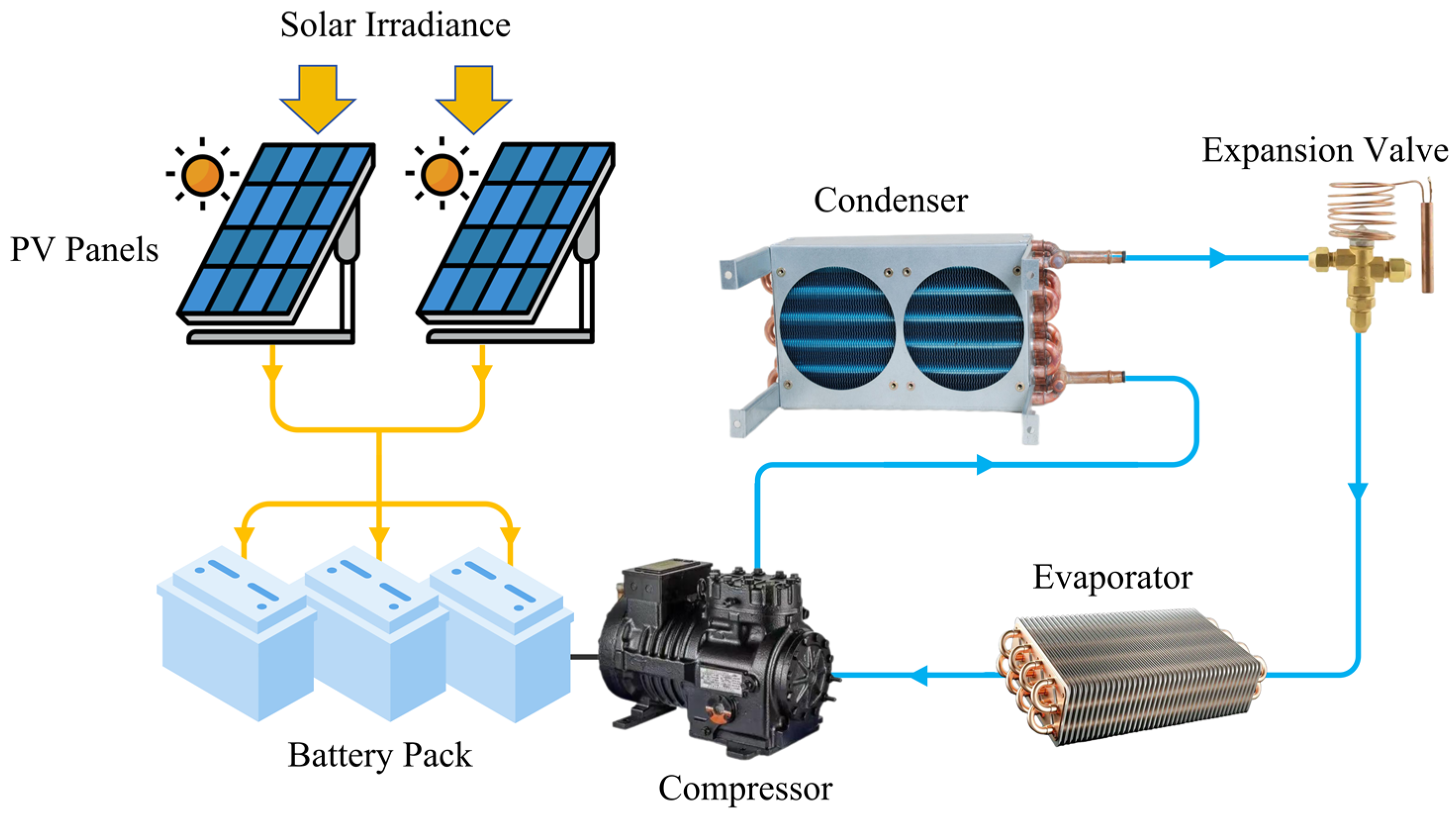

2.2. Solar Electric Refrigeration

2.3. Solar Combined Refrigeration

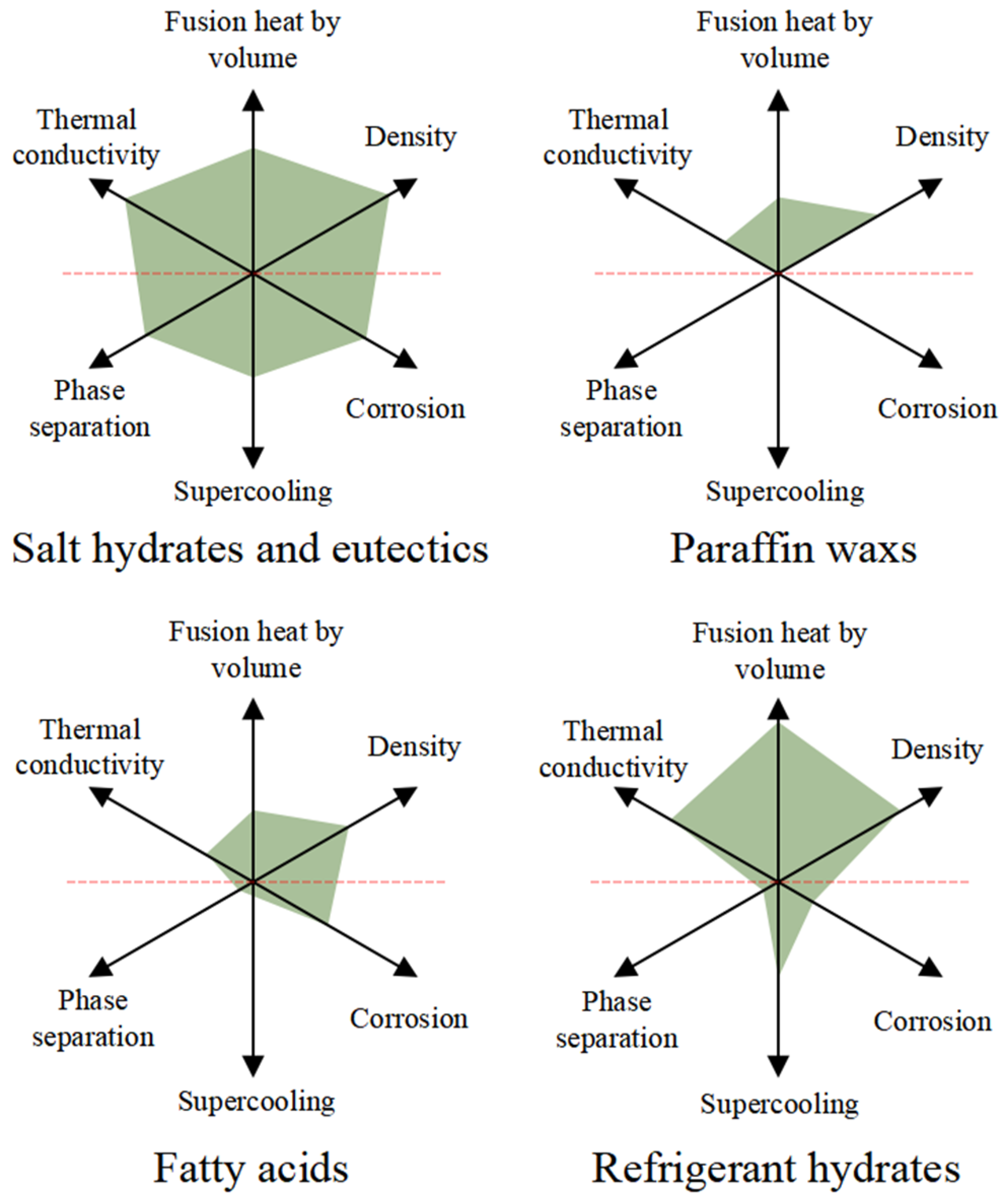

3. PCMs

4. PCM-Integrated Solar Vapor Compression Refrigeration System

4.1. Photovoltaic Panels

4.1.1. Effect of Photovoltaic Panel Temperature on COP

4.1.2. Methods of Integrating PCM with Photovoltaic Panels

4.1.3. Selection of PCM

4.2. Condenser

4.3. Evaporator

5. PCM-Integrated Solar Thermal Absorption Refrigeration System

5.1. Solar Collector

5.2. Absorber

5.3. Generator

6. Conclusions

- Phase-change temperature and latent heat are the most critical parameters for PCM selection. Ideally, the PCM should have a phase-change temperature that aligns with the system’s operating range and a high latent heat to maximize energy storage.

- Choosing the right PCM depends on whether a component is intended to absorb or release heat. For evaporators, using a PCM with a phase-change temperature above the evaporation temperature ensures sufficient heat absorption; for condensers, a phase-change temperature below the condensation temperature aids effective heat release.

- In addition to phase-change temperature and latent heat, supercooling can significantly affect a system’s performance and must be considered during PCM selection and design.

- Microencapsulation technology enhances the heat transfer surface area of inorganic phase-change materials (PCMs) while mitigating their inherent phase separation challenges. Concurrently, the incorporation of nucleating agents effectively addresses the pronounced supercooling phenomenon in these materials by promoting controlled crystallization during phase transition processes.

- Organic PCMs, often chosen for their low supercooling, remain prevalent despite lower thermal conductivity. Inorganic PCMs feature higher thermal conductivity but may suffer from more pronounced supercooling. Currently, organic PCMs are still predominant in practical applications.

- Much of the existing literature focuses on improving the thermal conductivity of PCMs by introducing nanoparticles or employing microencapsulation techniques. However, these methods can be expensive, limiting their economic feasibility.

- PCMs experience volumetric changes during phase transitions, potentially causing deformation or structural stress on storage tanks and containers, thereby reducing their service life.

- Although a direct contact integration of PCMs is broadly validated in research, actual integration strategies remain relatively narrow, suggesting the need for innovative designs to optimize heat transfer and encapsulation.

- While adding PCMs raises initial costs, it confers significant advantages, including enhanced energy efficiency, better performance under fluctuating weather conditions, and partial mitigation of the inherent intermittency of solar energy.

- Experimental and numerical investigations on phase-change material integration across multiple components within the same solar cooling system remain insufficiently explored in the current literature.

- Although integrating PCMs in both the condenser and evaporator enhances the temperature gradient for heat transfer and elevates system performance, inherent limitations in existing integration approaches frequently amplify thermal resistance, leading to significant energy dissipation.

- The integration of phase-change materials with solar collectors remains relatively uncommon in current practice, with existing implementations often necessitating solution pump operation that introduces additional electrical power consumption.

- The incorporation of phase-change materials (PCMs) in generator units presents significant theoretical advantages, as their superior thermal exchange properties effectively mitigate energy losses, thereby enhancing overall system efficiency.

7. Outlook

- While organic PCMs dominate current applications, their widespread use stems largely from the stability challenges that plague inorganic counterparts—particularly phase separation. Nonetheless, many inorganic salt solutions outshine organics in terms of thermal performance, thanks to their higher thermal conductivity. Bridging the gap in phase separation and other drawbacks could unlock significant potential for inorganic PCMs.

- Research on eutectic materials remains comparatively sparse, presenting a promising area for innovation. Further investigation into eutectic mixtures could broaden the range of operating temperatures and provide specialized solutions for diverse refrigeration and thermal storage needs.

- Embedding nanoparticles in PCMs can markedly boost thermal conductivity but often at a high cost. Future studies should aim to develop more cost-effective additives, balancing affordability with the desired performance gains.

- Current PCM integration methods across various systems are relatively limited and uniform. Exploring novel designs—potentially involving new heat exchanger geometries or hybrid approaches—could further improve heat transfer efficiency and reliability.

- The existing one-size-fits-all integration strategies may not accommodate varying operational or climatic demands. Modular or detachable PCM systems could adapt to shifting loads or seasonal changes, enhancing both system resilience and practical utility. A representative application involves integrating phase-change material (PCM) behind photovoltaic panels, where automated regulation enables heat absorption during peak operating temperatures, followed by detachment upon complete phase transition to facilitate thermal dissipation.

- Phase transition in PCMs is typically accompanied by volumetric changes that can induce mechanical stress on storage containers, shortening their lifespan. Ongoing research should focus on reducing or managing this expansion, whether through advanced encapsulation techniques or by modifying the PCM’s intrinsic properties.

- The majority of current experimental and modeling efforts address small-scale solar refrigeration units, such as household refrigerators or commercial freezers. Extending PCM integration to large-scale or industrial refrigeration systems represents an important frontier with the potential to substantially increase energy savings and system stability on a bigger stage.

- Future research should prioritize experimental and numerical investigations into concurrent PCM integration across multiple system components to enhance integration methodology flexibility while simultaneously advancing solar cooling system performance.

Funding

Conflicts of Interest

References

- Mondal, M.A.H.; Denich, M. Assessment of renewable energy resources potential for electricity generation in Bangladesh. Renew. Sustain. Energy Rev. 2010, 14, 2401–2413. [Google Scholar]

- Yüksel, I. Global warming and renewable energy sources for sustainable development in Turkey. Renew. Energy 2008, 33, 802–812. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook 2022; IEA: Paris, France, 2022. [Google Scholar]

- Tabor, H. Use of solar energy for cooling purposes. Sol. Energy 1962, 6, 136–142. [Google Scholar]

- James, S.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar]

- Coulomb, D. Refrigeration and cold chain serving the global food industry and creating a better future: Two key IIR challenges for improved health and environment. Trends Food Sci. Technol. 2008, 19, 413–417. [Google Scholar]

- International Energy Agency (IEA). Electricity 2024; IEA: Paris, France, 2024. [Google Scholar]

- UNESCAP. Share of Total Energy Consumption from Renewable Sources in Bangladesh from 2005 to 2015; Bangladesh Statistics: Dhaka, Bangladesh, 2017. [Google Scholar]

- Khan, M.M.A.; Saidur, R.; Al-Sulaiman, F.A. A review for phase change materials (PCMs) in solar absorption refrigeration systems. Renew. Sustain. Energy Rev. 2017, 76, 105–137. [Google Scholar]

- Patil, B.; Salunke, N.; Diware, V.; Ar, S.R.; Ansari, K.B. Stability assessment of emerging phase change materials for solar thermal storage in absorption refrigeration: A review. Int. J. Green Energy 2024, 22, 253–280. [Google Scholar] [CrossRef]

- Anyanwu, E.E. Review of solid adsorption solar refrigerator I: An overview of the refrigeration cycle. Energy Convers. Manag. 2003, 44, 301–312. [Google Scholar]

- Totla, N.B.; Arote, S.S.; Gaikwad, S.V.; Jodh, S.P.; Kattimani, S.K. Comparison of the performances of NH3-H2O and LiBr-H2O vapour absorption refrigeration cycles. Int. J. Eng. Res. Appl. 2016, 6, 8–13. [Google Scholar]

- Xu, X.; Li, Y.; Yang, S.; Chen, G. A review of fishing vessel refrigeration systems driven by exhaust heat from engines. Appl. Energy 2017, 203, 657–676. [Google Scholar]

- Nikbakhti, R.; Wang, X.; Hussein, A.K.; Iranmanesh, A. Absorption cooling systems—Review of various techniques for energy performance enhancement. Alex. Eng. J. 2020, 59, 707–738. [Google Scholar]

- Wouagfack, P.A.N.; Tchinda, R. Finite-time thermodynamics optimization of absorption refrigeration systems: A review. Renew. Sustain. Energy Rev. 2013, 21, 524–536. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. Review of solar refrigeration and cooling systems. Energy Build. 2013, 67, 286–297. [Google Scholar] [CrossRef]

- Huang, B.J.; Chang, J.M.; Petrenko, V.A.; Zhuk, K.B. A solar ejector cooling system using refrigerant R141b. Sol. Energy 1998, 64, 223–226. [Google Scholar] [CrossRef]

- Gosney, W.B. Principle of Refrigeration; Cambridge University Press: Cambridge, UK, 1982. [Google Scholar]

- Tassou, S.A.; Lewis, J.; Ge, Y.; Hadawey, A.; Chaer, I. A review of emerging technologies for food refrigeration application. Appl. Therm. Eng. 2010, 30, 263–276. [Google Scholar] [CrossRef]

- Cao, Z.H. A New Refrigeration Method—A Discussion on Semiconductor Refrigeration Technology. Clean Air Cond. Technol. 2017, 1, 106–107. [Google Scholar]

- Xie, B.B.; Zhang, L. Comprehensive Study on the Operating Conditions of Semiconductor Refrigeration Systems. Shandong Ind. Technol. 2015, 68. [Google Scholar] [CrossRef]

- Kobayashi, E.; Watabe, Y.; Hao, R.; Ravi, T.S. High Efficiency Heterojunction Solar Cells on n-type Kerfless Monocrystalline Silicon Wafers by Epitaxial Growth. Appl. Phys. Lett. 2015, 106, 96. [Google Scholar] [CrossRef]

- Richter, A.; Hermle, M.; Glunz, S.W. Reaction of the Limiting Efficiency for Crystalline Silicon Solar Cells. IEEE J. Photovohaics 2013, 3, 1184–1191. [Google Scholar] [CrossRef]

- Ma, X.Y.; Zheng, D.Y.; Zhu, X.J. Design and Experimental Analysis of Solar Semiconductor Refrigeration Box. Sci. Technol. Innov. 2017, 32, 145–146. [Google Scholar]

- Miranda, A.G.; Chen, T.S.; Hong, C.W. Feasibility study of a green energy powered thermoelectric chip based air conditioner for electric vehicles. Energy 2013, 59, 633–641. [Google Scholar]

- Abdul-Wahab, S.A.; Elkamel, A.; Al-Damkhi, A.M.; Al-Habsi, I.A.; Al-Rubai’Ey’, H.S.; Al-Battashi, A.K.; Al-Tamimi, A.R.; Al-Mamari, K.H.; Chutani, M.U. Design and experimental investigation of portable solar thermoelectric refrigerator. Renew. Energy 2009, 34, 30–34. [Google Scholar]

- Song, C.; Zhu, J.; Yang, X. Innovative Design and Experiments of a Semiconductor Cooling and Heating Box Driven by Solar Energy. IOP Conf. Ser. Mater. Sci. Eng. 2019, 677, 032108. [Google Scholar]

- Tamm, G.; Goswami, D.Y.; Lu, S.; Hasan, A.A. Theoretical and experimental investigation of an ammonia-water power and refrigeration thermodynamic cycle. Sol. Energy 2004, 76, 217–228. [Google Scholar]

- Tang, L.; Zeng, D.; Ling, Z. Research progress on phase change cold storage materials and system applications. Chem. Ind. Prog. 2023, 42, 4322–4339. [Google Scholar]

- Li, S.K.; Lin, Y.; Pan, F. Research progress in thermal energy storage and conversion technology. Energy Storage Sci. Technol. 2022, 11, 1551–1562. [Google Scholar]

- Yataganbaba, A.; Ozkahraman, B.; Kurtbas, I. Worldwide trends on encapsulation of phase change materials: A bibliometric analysis (1990–2015). Appl. Energy 2017, 185, 720–731. [Google Scholar]

- Shchegolkov, A.; Shchegolkov, A.; Demidova, A. The Use of Nanomodified Heat Storage Materials for Thermal Stabilization in the Engineering and Aerospace Industry as a Solution for Economy. MATEC Web Conf. 2018, 224, 03012. [Google Scholar]

- Shchegolkov, A.; Shchegolkov, A.; Dyachkova, T.; Semenov, A. The heat storage material based on paraffin-modified multilayer carbon nanotubes with Nickel-zinc ferrite. IOP Conf. Series Mater. Sci. Eng. 2017, 312, 012023. [Google Scholar]

- Tatsidjodoung, P.; Le, P.N.; Luo, L. A review of potential materials for thermal energy storage in building applications. Renew. Sustain. Energy Rev 2013, 18, 327–349. [Google Scholar]

- Oro, E.; Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar]

- Elsayed, M.; Mansour, M.S.; Eid, M.; Abdel-Raouf, M. Thermal behavior of frozen products paired with PCM during winter and summer power outages. Case Stud. Therm. Eng. 2024, 53, 103956. [Google Scholar]

- Rahimi, M.; Ranjbar, A.A.; Hosseini, M.J. Experimental Investigation on PCM/Fin Slab Incorporation in a Evaporator Side of a Household Refrigerator. Energy Rep. 2023, 10, 407–418. [Google Scholar]

- Wang, L.B.; Liu, L.N.; Li, H.S.; Bu, X.B.; Gong, Y.L. Optimization of Working Fluid and Operation Condition for Organic Rankine Vapor Compressor Refrigeration System Driven by Solar Energy. Adv. NR Energy 2017, 5, 386–393. [Google Scholar]

- Aung, Z.T.; Mon, M.; Nu, S.S. Theoretical study on energy-saving of steam compression air conditioning system using solar thermal energy. In Proceedings of the 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Chiang Mai, Thailand, 28 June–1 July 2016. [Google Scholar]

- Hans, R.; Kaushik, S.C.; Manikandan, S. Experimental study and analysis on novel thermo-electric cooler driven by solar photovoltaic system. Appl. Sol. Energy 2016, 52, 205–210. [Google Scholar]

- Dhawan, S.; Sinha, R.; Chaturvedi, S.; Parvez, Y.; Haq, A.U. Development and Performance Analysis of an Automated Solar-Powered Thermoelectric Refrigeration System. Appl. Sol. Energy 2023, 59, 226–238. [Google Scholar]

- Richard, G.; Peter, E.; Bill, B. Thermodynamics. In Mechanical Engineering Systems; IIE Core Textbooks Series; Butterworth-Heinemann: Oxford, UK, 2001; pp. 7–111. [Google Scholar]

- Neha, K.; Sanjay, K.S.; Sanjay, K. A comparative study of different materials used for solar photovoltaics technology. Mater. Today Proc. 2022, 66, 3522–3528. [Google Scholar]

- Green, M.A.; Emery, K.; Hishikawa, Y.H.; Warta, W.; Dunlop, E. Solar cell efficiency tables (version 49). Prog. Photovolt. Res. Appl. 2016, 25, 3–13. [Google Scholar]

- Yu, T.W.K.P.; Lam, K.H.; Chan, L.S.H. Thermal management in photovoltaic cells using phase change materials. Renew. Energy 2011, 36, 2085–2091. [Google Scholar]

- Lee, D.J.C.; Barlow, D.D.W.K.; Chan, C.K.L. Performance improvement of solar cells using phase change materials for temperature control. Energy Procedia 2014, 57, 1822–1831. [Google Scholar]

- Rosenthal, A.H.; Gonçalves, B.P.; Beckwith, J.A.; Gulati, R.; Compere, M.D.; Boetcher, S.K.S. Phase-change material to thermally regulate photovoltaic panels to improve solar to electric efficiency. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, IMECE 2015, Houston, TX, USA, 13–19 November 2015; Volume 57502, p. V08BT10A00. [Google Scholar]

- Huang, M.J. Two Phase Change Material with Different Closed Shape Fins in Building Integrated Photovoltaic System Temperature Regulation. In Proceedings of the World Renewable Energy Congress-Sweden, Linköping, Sweden, 8–13 May 2011; Volume 57, pp. 2938–2945. [Google Scholar]

- Biwole, P.H.; Eclache, P.; Kuznik, F. Improving the Performance of Solar Panels by the Use of Phase-Change Materials. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; pp. 2953–2960. [Google Scholar]

- Radziemska, E.; Klugmann, E. Thermally affected parameters of the current-voltage characteristics of silicon photocell. Energy Convers 2002, 43, 1889–1900. [Google Scholar]

- Krauter, S. Increased electrical yield via water flow over the front of photovoltaic panels. Sol. Energy Mater. Sol. Cells 2004, 82, 131–137. [Google Scholar]

- Krauter, S.; Araújo, R.G.; Schroer, S.; Hanitsch, R.; Salhi, M.J.; Triebel, C.; Lemoine, R. Combined photovoltaic and solar thermal systems for facade integration and building insulation. Sol. Energy 1999, 67, 239–248. [Google Scholar]

- Boudhina, N.; Jebali, R. Effects of Temperature on the Efficiency of Photovoltaic Modules: A Comparative Study. Energy Rep. 2019, 5, 797–804. [Google Scholar]

- Radziemska, E. Performance Analysis of a Photovoltaic-Thermal Integrated System. Int. J. Photoenergy 2009, 2009, 732093. [Google Scholar]

- Xiao, L.; Fu, X.; Zhou, H.; Qi, W.; Zhang, X.; Meng, W. Design and Experimental Study of PV/TEG/PCM Thermal Control Solar Hybrid Power Generation System. J. Chuxiong Norm. Univ. 2022, 37, 15–19. [Google Scholar]

- Ma, T.; Zhao, J.; Li, Z. Mathematical modelling and sensitivity analysis of solar photovoltaic panel integrated with phase change material. Appl. Energy 2018, 228, 1147–1158. [Google Scholar]

- Sharma, S.; Tahir, A.; Reddy, K.; Mallick, T.K. Performance enhancement of a Building-Integrated Concentrating Photovoltaic system using phase change material. Sol. Energy Mater. Sol. Cell 2016, 149, 29–39. [Google Scholar]

- Maghrabie, H.M.; Mohamed, A.S.A.; Fahmy, A.M.; Samee, A.A. Performance Augmentation of PV Panels Using Phase Change Material Cooling Technique: A Review. SVU-Int. J. Eng. Sci. Appl. 2021, 2, 1–13. [Google Scholar] [CrossRef]

- Malvi, C.S.; Dixon-Hardy, D.W.; Crook, R. Energy balance model of combined photovoltaic solar-thermal system incorporating phase change material. Sol. Energy 2011, 85, 1440–1446. [Google Scholar]

- Kazemian, A.; Hosseinzadeh, M.; Sardarabadi, M.; Passandideh-Fard, M. Experimental study of using both ethylene glycol and phase change material as coolant in photovoltaic thermal systems (PVT) from energy, exergy and entropy generation viewpoints. Energy 2018, 162, 210–223. [Google Scholar] [CrossRef]

- Fayaz, H.; Rahim, N.A.; Hasanuzzaman, M.; Nasrin, R.; Rivai, A. Numerical and experimental investigation of the effect of operating conditions on performance of PVT and PVT-PCM, Renew. Energy 2019, 143, 827–841. [Google Scholar]

- Hasan, A.; McCormack, S.J.; Huang, M.J. Evaluation of Phase Change Materials for Thermal Regulation Enhancement of Building Integrated Photovoltaics. Sol. Energy 2010, 84, 1601–1612. [Google Scholar] [CrossRef]

- Ahmadi, R.; Monadinia, F.; Maleki, M. Passive/active photovoltaic-thermal (PVT) system implementing infiltrated phase change material (PCM) in PS-CNT foam. Sol. Energy Mater. Sol. Cells 2021, 222, 110942. [Google Scholar] [CrossRef]

- Refaey, H.; Abdo, S.; Saidani-Scott, H.; El-Shekeil, Y.; Bendoukha, S.; Barhoumi, N.; Abdelrahman, M. Thermal Regulation of Photovoltaic Panels Using PCM with Multiple Fins Configuration: Experimental Study with Analysis. Therm. Sci. Eng. Prog. 2024, 49, 102457. [Google Scholar] [CrossRef]

- Al Arni, S.; Mahdi, J.M.; Abed, A.M.; Hammoodi, K.A.; Hasan, H.A.; Homod, R.Z.; Ben Khedher, N. Novel Multi-Layer Nano-Modified PCM Configuration for Efficient Thermal Management of Photovoltaic-Thermal Systems. J. Energy Storage 2024, 103, 114352. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Norton, B. Energy and cost saving of a photovoltaic-phase change materials (PV-PCM) system through temperature regulation and performance enhancement of photovoltaics. Energies 2014, 7, 1318–1331. [Google Scholar] [CrossRef]

- Browne, M.C.; Norton, B.; McCormack, S.J. Heat retention of a photovoltaic/thermal collector with PCM. Sol. Energy 2016, 133, 533–548. [Google Scholar] [CrossRef]

- Venkitaraj, K.P.; Suresh, S. Experimental study on thermal and chemical stability of pentaerythritol blended with low melting alloy as possible PCM for latent heat storage. Exp. Therm. Fluid Sci. 2017, 88, 73–87. [Google Scholar] [CrossRef]

- Sarcinella, A.; Cunha, S.; Aguiar, J.; Frigione, M. Thermo-chemical characterization of organic phase change materials (PCMs) obtained from lost wax casting industry. Sustainability 2024, 16, 7057. [Google Scholar] [CrossRef]

- Ryu, H.W.; Woo, S.W.; Shin, B.C.; Kim, S.D. Prevention of supercooling and stabilization of inorganic salt hydrates as latent heat storage materials. Sol. Energy Mater. Sol. Cells 1992, 27, 161–172. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Raheem Junaidi, M.A. Influence of advanced composite phase change materials on thermal energy storage and thermal energy conversion. J. Therm. Anal. Calorim. 2025, 1–22. [Google Scholar] [CrossRef]

- Kamaraj, D.; Senthilkumar, S.R.R.; Ramalingam, M.; Vanaraj, R.; Kim, S.-C.; Prabakaran, M.; Kim, I.-S. A review on the effective utilization of organic phase change materials for energy efficiency in buildings. Sustainability 2024, 16, 9317. [Google Scholar] [CrossRef]

- Wu, S.Y.; Wang, H.; Xiao, S.; Zhu, D.S. An investigation of melting/freezing characteristics of nanoparticle-enhanced phase change materials. J. Therm. Anal. Calorim. 2012, 110, 1127–1131. [Google Scholar] [CrossRef]

- Wu, S.; Zhu, D.; Zhang, X.; Huang, J. Preparation and melting/freezing characteristics of Cu/paraffin nanofluid as phase-change material (PCM). Energy Fuels 2010, 24, 1894–1898. [Google Scholar] [CrossRef]

- Jiang, M.H. The influence of operating conditions on the performance of chiller units. Refrig. Technol. 2021, 41, 78–82. [Google Scholar]

- Wang, F.; Maidment, G.; Missenden, J.; Tozer, R. The novel use of phase change materials in refrigeration plant. Part 1: Experimental investigation. Appl. Therm. Eng. 2007, 27, 2893–2901. [Google Scholar] [CrossRef]

- Wang, F.; Maidment, G.; Missenden, J.; Tozer, R. The novel use of phase change materials in refrigeration plant. Part 2: Dynamic simulation model for the combined system. Appl. Therm. Eng. 2007, 27, 2902–2910. [Google Scholar] [CrossRef]

- Wang, F.; Maidment, G.; Missenden, J.; Tozer, R. The novel use of phase change materials in refrigeration plant. Part 3: Pcm for control and energy savings. Appl. Therm. Eng. 2007, 27, 2911–2918. [Google Scholar] [CrossRef]

- Cheng, W.L.; Zhang, R.M.; Xie, K.; Liu, N.; Wang, J. Heat conduction enhanced shapestabilized paraffin/HDPE composite PCMs by graphite addition: Preparation an thermal properties. Sol. Energy Mater. Sol. Cells 2010, 94, 1636–1642. [Google Scholar] [CrossRef]

- Cheng, W.L.; Mei, B.J.; Liu, Y.N.; Huang, Y.H.; Yuan, X.D. A novel household refrigerator with shape-stabilized PCM (Phase Change Material) heat storage condensers: An experimental investigation. Energy 2011, 36, 5797–5804. [Google Scholar]

- Cheng, W.L.; Yuan, X.D. Numerical analysis of a novel household refrigerator with shape-stabilized PCM (phase change material) heat storage condensers. Energy 2013, 59, 265–276. [Google Scholar]

- Alasiri, A.; Nasser, M. Comparative analysis of PCM configurations for energy-efficient air conditioning systems: A case study in Riyadh, Saudi Arabia. Case Stud. Therm. Eng. 2025, 65, 105691. [Google Scholar]

- Ismail, M.; Hassan, H. Enhancing Air Conditioning System Performance via Dual Phase Change Materials Integration: Seasonal Efficiency and Capsulation Structure Impact. Int. J. Thermophys. 2024, 45, 115. [Google Scholar]

- Cavargna, A.; Mongibello, L.; Iasiello, M.; Bianco, N. Analysis of a Phase Change Material-Based Condenser of a Low-Scale Refrigeration System. Energies 2023, 16, 3798. [Google Scholar] [CrossRef]

- Said, M.A.; Hassan, H. Impact of Energy Storage of New Hybrid System of Phase Change Materials Combined with Air-Conditioner on Its Heating and Cooling Performance. J. Energy Storage 2021, 36, 102400. [Google Scholar] [CrossRef]

- Said, M.A.; Hassan, H. An experimental work on the effect of using new technique of thermal energy storage of phase change material on the performance of air conditioning unit. Energy Build. 2018, 173, 353–364. [Google Scholar]

- Yu, H. Modeling and Simulation of Evaporators in HVAC Systems. Ph.D. Thesis, Shandong University, Jinan, China, 2006. [Google Scholar] [CrossRef]

- Bista, S.; Hosseini, S.E.; Owens, E.; Phillips, G. Performance improvement and energy consumption reduction in refrigeration systems using phase change material (PCM). Appl. Therm. Eng. 2018, 142, 723–735. [Google Scholar]

- Salah, B.; Sifeddine, R. Phase Change Materials for Enhancing Heat Transfer in Evaporator Systems. Energy Convers. Manag. 2015, 93, 267–276. [Google Scholar]

- Maiorino, A.; Del Duca, M.G.; Mota-Babiloni, A.; Greco, A.; Aprea, C. The thermal performances of a refrigerator incorporating a phase change material. Int. J. Refrig. 2019, 100, 255–264. [Google Scholar]

- Joybari, M.M.; Haghighat, F.; Moffat, J.; Sra, P. Heat and Cold Storage Using Phase Change Materials in Domestic Refrigeration Systems: The State-of-the-Art Review. Energy Build. 2015, 106, 111–124. [Google Scholar]

- Mselle, B.D.; Vérez, D.; Zsembinszki, G.; Borri, E.; Cabeza, L.F. Performance Study of Direct Integration of Phase Change Material into an Innovative Evaporator of a Simple Vapour Compression System. Appl. Sci. 2020, 10, 4649. [Google Scholar] [CrossRef]

- Arsana, M.E.; Temaja, I.W.; Widiantara, I.B.G.; Sukadana, I.B.P. Corn oil phase change material (PCM) in frozen food cooling machine to improve energy efficiency. J. Phys. Conf. Ser. 2020, 1450, 012107. [Google Scholar]

- Ghorbani, B.; Mehrpooya, M. Concentrated Solar Energy System and Cold Thermal Energy Storage (Process Development and Energy Analysis). Sustain. Energy Technol. Assess. 2020, 37, 100607. [Google Scholar]

- Jokiel, M.; Sevault, A.; Banasiak, A.; NÆSS, E. Cold Storage Using Phase Change Material in Refrigerated Display Cabinets: Experimental Investigation. In Proceedings of the PCM2021 13th IIR, Phase Change Materials and Slurries for Refrigeration and Air Conditioning Conference, Vicenza, Italy, 1–3 September 2021; pp. 1–13. [Google Scholar]

- Cheralathan, M.; Velraj, R.; Renganarayanan, S. Performance analysis on industrial refrigeration system integrated with encapsulated PCM-based cool thermal energy storage system. Int. J. Energy Res. 2007, 31, 1398–1413. [Google Scholar]

- Li, G.; Hwang, Y.; Radermacher, R. Review of cold storage materials for air conditioning application. Int. J. Refrig. 2012, 22, 108–120. [Google Scholar]

- Zhang, Y.; Li, Y.; Zhang, W. A review of phase change materials and their applications in energy storage systems. Energy 2012, 47, 98–108. [Google Scholar]

- Chen, H.; Zhao, X.; Li, Y. Enhancement of heat transfer in phase change material based thermal storage using graphene nanomaterials. Int. J. Heat Mass Transf. 2016, 98, 869–876. [Google Scholar]

- Zhang, Q.; Lu, J.; Wang, H.; Han, X. Phase change materials for thermal energy storage: A review. Renew. Sustain. Energy Rev. 2012, 16, 2247–2257. [Google Scholar]

- Zhu, Y.; Shen, Z.; Xia, Y.; Bao, W. Development and performance of encapsulated phase change material for thermal energy storage. Renew. Energy 2015, 73, 60–66. [Google Scholar]

- Ullah, K.R.; Saidur, R.; Ping, H.W.; Akikur, R.; Shuvo, N. A review of solar thermal refrigeration and cooling methods. Renew. Sustain. Energy Rev. 2013, 24, 499–513. [Google Scholar]

- Boopathi, R.V.; Shanmugam, V. A review and new approach to minimize the cost of solar assisted absorption cooling system. Renew. Sustain. Energy Rev. 2012, 16, 6725–6731. [Google Scholar]

- Xu, S.M.; Huang, X.D.; Du, R. An investigation of the solar powered absorption refrigeration system with advanced energy storage technology. Sol. Energy 2011, 85, 1794–1804. [Google Scholar]

- Shirazi, A.; Pintaldi, S.; White, S.D.; Morrison, G.L.; Rosengarten, G.; Taylor, R.A. Solarassisted absorption air-conditioning systems in buildings: Control strategies and operational modes. Appl. Therm. Eng. 2016, 92, 246–260. [Google Scholar] [CrossRef]

- Wang, S.G.; Wang, R.Z. Recent developments of refrigeration technology in fishing vessels. Renew. Energy 2005, 30, 589–600. [Google Scholar] [CrossRef]

- Serale, G.; Baronetto, S.; Goia, F.; Perino, M. Characterization and Energy Performance of a Slurry PCM-based Solar Thermal Collector: A Numerical Analysis. Energy Procedia 2014, 48, 223–232. [Google Scholar]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar]

- Brancato, V.; Frazzica, A.; Sapienza, A.; Freni, A. Identification and characterization of promising phase change materials for solar cooling applications. Sol. Energy Mater. Sol. Cells. 2017, 160, 225–232. [Google Scholar]

- Agyenim, F.; Smyth, M.; Eames, P. A review of phase change material energy storage; selection of materials suitable for energy storage in the 100–130 °C temperature range. In Proceedings of the World Renewable Energy Congress (WREC 2005), Aberdeen, UK, 22–27 May 2005; pp. 384–389. [Google Scholar]

- Agyenim, F. The use of enhanced heat transfer phase change materials (PCM) to improve the coefficient of performance (COP) of solar powered LiBr/H2O absorption cooling systems. Renew. Energy 2016, 87, 229–239. [Google Scholar]

- Chopra, K.; Pathak, A.K.; Tyagi, V.V.; Pandey, A.K.; Sari, A.; Sarid, A. Thermal Performance of Phase Change Material Integrated Heat Pipe Evacuated Tube Solar Collector System: An Experimental Assessment. Energy Convers. Manag. 2020, 203, 112205. [Google Scholar]

- Naghavi, M.S.; Ong, K.S.; Badruddin, I.A.; Mehrali, M.; Silakhori, M.; Metselaar, H.S.C. Theoretical Model of an Evacuated Tube Heat Pipe Solar Collector Integrated with Phase Change Material. Energy 2015, 91, 911–924. [Google Scholar] [CrossRef]

- Abokersh, M.H.; El-Morsi, M.; Sharaf, O.; Abdelrahman, W. An Experimental Evaluation of Direct Flow Evacuated Tube Solar Collector Integrated with Phase Change Material. Energy 2017, 139, 1111–1125. [Google Scholar]

- Li, Z.; Ge, Z.; Jing, A. Thermal management of PCM-based solar thermal collectors: System design and optimization. Renew. Energy 2018, 120, 407–417. [Google Scholar]

- Yousef, A.; Sharma, Q.; Tahir, K. PCM-based thermal energy storage systems for solar collectors: A review on performance, heat transfer, and integration. Renew. Sustain. Energy Rev. 2015, 48, 423–437. [Google Scholar]

- Li, A.; Duan, S.P.; Han, R.B.; Wang, C.Y. Investigation on the Dynamic Thermal Storage/Release of the Integrated PCM Solar Wall Embedded with an Evaporator. Renew. Energy 2022, 200, 1506–1516. [Google Scholar]

- Srikhirin, P.; Aphornratana, S.; Chungpaibulpatana, S. A review of absorption refrigeration technologies. Renew. Sustain. Energy Rev. 2001, 5, 343–372. [Google Scholar]

- Jeong, S.; Sang, K.; Koo, K.K.; Ziegler, F. Heat transfer performance of a coiled tube absorber with working fluid of ammonia/water/discussion. ASHRAE Trans. 1998, 104, 1577. [Google Scholar]

- Matsuda, A.; Choi, K.H.; Hada, K.; Kawamura, T. Effect of pressure and concentration on performance of a vertical falling-film type of absorber and generator using lithium bromide aqueous solutions. Int. J. Refrig. 1994, 17, 538–542. [Google Scholar]

- Zhang, H.; Zhang, S.; Wu, W.; Wang, S. Performance enhancement of absorption refrigeration system integrated with phase change material. Appl. Therm. Eng. 2014, 63, 306–315. [Google Scholar]

- Ji, X.; Liu, G.; Li, Q.; Wu, J.; Xiao, R. Performance and volume expansion of PCM-based thermal storage systems for absorption refrigeration. Energy 2016, 97, 448–457. [Google Scholar]

- Ponshanmugakumar, S.B.A.; Deepak, P.; Sivaraman, H.; Vignesh, K.R. Numerical investigation on vertical generator integrated with phase change materials in vapour absorption refrigeration system. Appl. Mech. Mater. 2015, 766–767, 468–473. [Google Scholar] [CrossRef]

- Lorente, S.; Bejan, A.; Niu, J.L. Constructal design of latent thermal energy storage with vertical spiral heaters. Int. J. Heat Mass Transf. 2015, 81, 283–288. [Google Scholar] [CrossRef]

- He, Q.; Zhang, W. A study on latent heat storage exchangers with the hightemperature phase-change material. Int. J. Energy Res. 2001, 25, 331–341. [Google Scholar] [CrossRef]

- Migla, L.; Bogdanovics, R.; Lebedeva, K. Performance Improvement of a Solar-Assisted Absorption Cooling System Integrated with Latent Heat Thermal Energy Storage. Energies 2023, 16, 5307. [Google Scholar] [CrossRef]

- Soliman, A.S.; Zhu, S.; Xu, L.; Dong, J.; Cheng, P. Design of an H2O-LiBr absorption system using PCMs and powered by automotive exhaust gas. Appl. Therm. Eng. 2021, 191, 116881. [Google Scholar] [CrossRef]

| Comparison Dimension | Solid Adsorption Refrigeration Systems | Liquid Absorption Refrigeration Systems |

|---|---|---|

| Temperature of the heat source | 20–90 °C | 80–150 °C |

| COP | 0.3–0.6 | 0.6–1.2 |

| Structural complexity | Simple (no pump) | Complex (requires pump) |

| Operating mode | Intermittent | Contiguity |

| Applicable scenarios | Small, decentralized | Large-scale central air conditioning |

| Environmental | Using natural refrigerants such as water, methanol, ammonia, etc., which are not destructive to the ozone layer | Ammonia is environmentally friendly; lithium bromide needs to be corrosion resistant |

| Maintenance cost | Lower | Higher (pumps, corrosion maintenance) |

| Technology maturity | In the pipeline | Mature and standardized |

| Thermophysical Parameters | Organic PCMs | Inorganic PCMs | Eutectic PCMs |

|---|---|---|---|

| Latent heat (kJ/kg) | 120–250 | 150–400 | 100–300 |

| Thermal conductivity (W/m·K) | 0.1–0.3 | 0.5–1.5 | 0.5–8.5 |

| Phase transition temperature (°C) | −20–150 | 20–800 | Can be adjusted by changing the ratio of components |

| Parameters | Organic PCMs | Inorganic PCMs | Eutectic PCMs |

|---|---|---|---|

| Cycling stability | Latent heat decay <5% after 500 cycles | Susceptible to phase separation and subcooling, up to 20% degradation after 100 cycles | Phase separation inhibited by encapsulation or thickening agents, <10% decay over 300 cycles |

| Chemical stability | Non-corrosive, acid- and alkali-resistant | Partially hydrated salts tend to corrode metal containers | Reduced corrosion risk through cladding |

| Thermal stability | Decomposition temperature >200 °C | Decompose easily at high temperatures | Can be adjusted by changing the ratio of components |

| Research Study | Type | PCM | Density (Solid) | Density (Liquid) | Specific Heat Capacity (Solid) | Specific Heat Capacity (Liquid) | Thermal Conductivity (Solid) | Thermal Conductivity (Liquid) | Latent Heat of Fusion | Melting Point | Performance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kJ/kg·K] | [kJ/kg·K] | [W/m·K] | [W/m·K] | [kJ/kg] | [°C] | ||||

| [55] | Organic | Mixture of stearic acid and lauric acid | / | / | / | / | / | / | / | 42.9 °C | Reduced maximum temperature of PV plate from 61.6 °C to 48.9 °C |

| [61] | Organic | A44 | 805 | 805 | 2.15 | / | / | 0.18 | 242.0 | 44.0 | 12.91% (numerical simulation) and 12.75% (experimental) increase in maximum electrical efficiency with 1000 W/m2 radiation. |

| [63] | Organic | PA | 805 | 805 | / | / | / | 0.4 | 124.6 | 47.0 | A 6.8% lower temperature and 14% higher power generation efficiency at 1100 W/m2 radiation. |

| [64] | Organic | Wax (RT42) | 880 | 770 | / | 2 | 0.2 | 0.2 | 165.0 | 38–43 | At a radiation intensity of 850 W/m2, the power generation is increased to 737.4 W-h/m2 and the PV plate temperature is reduced to 60.2 °C, which is 19.4% lower than that of the uncooled plate. |

| Organic | Wax | 860 | / | / | 2 | / | 0.2 | 160.0 | 32–38 | ||

| Organic | Wax (RT31) | / | 760 | / | 2 | 0.2 | 0.2 | 165.0 | 29–34 | ||

| [65] | Organic | Wax (RT26) | 880 | 760 | / | 2 | / | 0.2 | 180 | 25–26 | The electrical efficiency of the PV plate increased to 16.1% within 100 min, and the temperature of the PV plate reduced by 5 °C compared to the single-layer PCM. |

| [62] | Organic | Wax (RT20) | 880 | / | 2.0 | / | 0.2 | 0.2 | 140.3 | 21.2 | Maximum temperature reduction of 14 °C at 1000 W/m2 radiation for 30 min. |

| Organic | Mixture of capric–lauric acid | 880 | 863 | / | / | 0.139 | 0.139 | 171.9 | 20.8 | Maximum temperature reduction of 16.5 °C at 1000 W/m2 radiation for 30 min. | |

| Organic | Mixture of capric–palmitic acid | 883 | 840 | / | / | 0.143 | 0.143 | 196.1 | 22.3 | Maximum temperature reduction of 16.5 °C at 1000 W/m2 radiation for 30 min. | |

| Organic | Commercial blend (SP22) | 1490 | 1430 | 2.5 | / | 0.6 | 0.6 | 182.0 | 23.0 | Maximum temperature reduction of 14 °C at 1000 W/m2 radiation for 30 min. | |

| Inorganic | CaCl2·6H2O | 1710 | / | 1.4 | / | 1.090 | 1.090 | 213.1 | 29.2 | Maximum temperature reduction of 18 °C at 1000 W/m2 radiation for 30 min. |

| Research Study | Type | PCM | Density (Solid) | Density (Liquid) | Specific Heat Capacity (Solid) | Specific Heat Capacity (Liquid) | Thermal Conductivity (Solid) | Thermal Conductivity (Liquid) | Latent Heat of Fusion | Melting Point | Performance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kJ/kg·K] | [kJ/kg·K] | [W/m·K] | [W/m·K] | [kJ/kg] | [°C] | ||||

| [81] | Organic | SSPCM | 957 | / | / | / | 0.31 | / | 133.1 | 44.0 | A 12% higher COP and 6.5 °C lower condensing temperature |

| [85] | Organic | RT35HC | 880 | / | 2000 | / | 0.2 | / | 240.0 | 35.0 | Reduced temperature fluctuations; the COP of the system averages about 1.82 |

| [86] | Organic | SP24E | 1500 | 1400 | / | / | 0.6 | / | 180.0 | 25.0 | The COP was increased by 50% with a power saving of 6.85% |

| [83] | Inorganic | SP31 | 1350 | 1250 | 2 | 2 | 0.5 | 0.5 | 210.0 | 30.0 | Annual energy consumption reduced by up to 8.6% with a maximum COP of 5.63 |

| [84] | Inorganic | SP24E (summer) | 1500 | 1400 | 2 | 2 | 0.5 | 0.5 | 180.0 | 25.0 | An 11.8% reduction in energy consumption |

| Inorganic | SP11gel (winter) | 1330 | 1320 | 2 | 2 | 0.5 | / | 155.0 | 12.5 | Reduction in energy consumption by 12.8 per cent | |

| [87] | Inorganic | SP24E | 1500 | 1400 | / | / | 0.6 | / | 180.0 | 25.0 | Energy consumption is reduced by about 9.8% to 11.2% |

| Research Study | Type | PCM | Density (Solid) | Density (Liquid) | Specific Heat Capacity (Solid) | Specific Heat Capacity (Liquid) | Thermal Conductivity (Solid) | Thermal Conductivity (Liquid) | Latent Heat of Fusion | Melting Point | Performance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kJ/kg·K] | [kJ/kg·K] | [W/m·K] | [W/m·K] | [kJ/kg] | [°C] | ||||

| [93] | Organic | Wax | 880 | 770 | / | / | 0.20 | 0.20 | / | 5.0 | COP increased by 8–10%. |

| [94] | Organic | Corn oil esters | / | / | / | / | / | / | / | −15.0 | CCOP increased by 6% and compressor power consumption reduced by 4%. |

| [86] | Organic | PCM10HC | / | / | / | / | 0.2 | / | 200.0 | 12.0 | The COP increased by 13.5% and the power saving was 3.9%. |

| [95] | Organic | Diethylene glycol | 1200 | 1320 | 4.86 | / | / | / | 247.0 | −10.0 | PCM stores cold during the day and releases it at night. |

| [96] | Inorganic | H2O | 917 | 1000 | 2.01 | 4.18 | 2.2 | 0.58 | 334.0 | 0 | When the compressor stops working, the PCM is able to utilize its latent heat of phase change to maintain a low cabinet temperature. |

| [97] | Inorganic | H2O | 917 | 1000 | 2.01 | 4.18 | 2.2 | 0.56 | 333.6 | 0 | Cooling capacity is stored during the nighttime trough hours and released during the daytime peak hours, thereby taking advantage of peak and valley tariff differences and reducing operating costs. |

| Research Study | Type | PCM | Density (Solid) | Density (Liquid) | Specific Heat Capacity (Solid) | Specific Heat Capacity (Liquid) | Thermal Conductivity (Solid) | Thermal Conductivity (Liquid) | Latent Heat of Fusion | Melting Point | Performance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kJ/kg·K] | [kJ/kg·K] | [W/m·K] | [W/m·K] | [kJ/kg] | [°C] | ||||

| [112] | Organic | Erythritol | 1480 | 1300 | 1.4 | 1.4 | 0.7 | 0.3 | 339.8 | 117.7 | The performance of the heat collector can be significantly improved. |

| [113] | Organic | SA-67 | 1100 | 1190 | 2.01 | 2.47 | 1.1 | 1.2 | 244.2 | 67.1 | Thermal efficiency upgraded from 55.46% to 87.80. |

| [114] | Organic | Wax | 990 | 916 | 2.76 | 2.48 | 0,35 | 0.17 | 174.0 | 64.0 | Systems with integrated PCMs exhibit higher thermal efficiency at different water flow rates and are insensitive to changes in water flow rate. |

| [115] | Organic | Wax | 920 | 795 | 2.3 | 2.3 | 0.21 | 0.21 | 189.0 | 58–62 | System efficiency increased by approximately 14%. |

| [116] | Organic | Caprylic acid and lauric acid | 2000 | 2000 | 2 | 2 | 0.2 | 0.3 | 130.0 | 21.0 | In the active heat release mode, the ratio of heat release to heat storage increased by 30.12%. |

| Research Study | Type | PCM | Density (Solid) | Density (Liquid) | Specific Heat Capacity (Solid) | Specific Heat Capacity (Liquid) | Thermal Conductivity (Solid) | Thermal Conductivity (Liquid) | Latent Heat of Fusion | Melting Point | Performance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kJ/kg·K] | [kJ/kg·K] | [W/m·K] | [W/m·K] | [kJ/kg] | [°C] | ||||

| [124] | Organic | Erythritol | 1480 | 1300 | 1.4 | 1.4 | 0.7 | 0.3 | 339.8 | 117.7 | By optimizing the use of PCMs, the overall performance of the system can be improved and the system can achieve an average annual solar utilization of 0.58. |

| [125] | Organic | Wax | 800 | 800 | 1.25 | / | 0.2 | 0.2 | 125 | 30 | The use of vertical spiral heaters significantly improves the melting efficiency of PCMs. |

| [127] | Organic | RT90HC | 850 | / | 2.0 | / | 0.2 | / | 170.0 | 91.0 | Electricity consumption reduced by 6.2%, and heat delivery time increased by 27.8%. |

| [128] | Organic | RT82 | 950 | / | 2.0 | 2.0 | 0.2 | 0.2 | 176.0 | 82.0 | A 170% increase in COP. |

| Organic | RT100 | / | / | 1.8 | 2.4 | 0.2 | 0.2 | 168.0 | 105.0 | ||

| Inorganic | MgCl2·6H2O | 1570 | 1450 | 2.3 | 2.6 | 0.70 | 0.57 | 167.0 | 118.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Liang, C.; Liu, H.; Gong, L.; Bao, M.; Shen, S. A Review on Phase-Change Materials (PCMs) in Solar-Powered Refrigeration Systems. Energies 2025, 18, 1547. https://doi.org/10.3390/en18061547

Guo Y, Liang C, Liu H, Gong L, Bao M, Shen S. A Review on Phase-Change Materials (PCMs) in Solar-Powered Refrigeration Systems. Energies. 2025; 18(6):1547. https://doi.org/10.3390/en18061547

Chicago/Turabian StyleGuo, Yali, Chufan Liang, Hui Liu, Luyuan Gong, Minle Bao, and Shengqiang Shen. 2025. "A Review on Phase-Change Materials (PCMs) in Solar-Powered Refrigeration Systems" Energies 18, no. 6: 1547. https://doi.org/10.3390/en18061547

APA StyleGuo, Y., Liang, C., Liu, H., Gong, L., Bao, M., & Shen, S. (2025). A Review on Phase-Change Materials (PCMs) in Solar-Powered Refrigeration Systems. Energies, 18(6), 1547. https://doi.org/10.3390/en18061547