Review of Explosion Mechanism and Explosion-Proof Measures for High-Voltage Cable Intermediate Joints

Abstract

1. Introduction

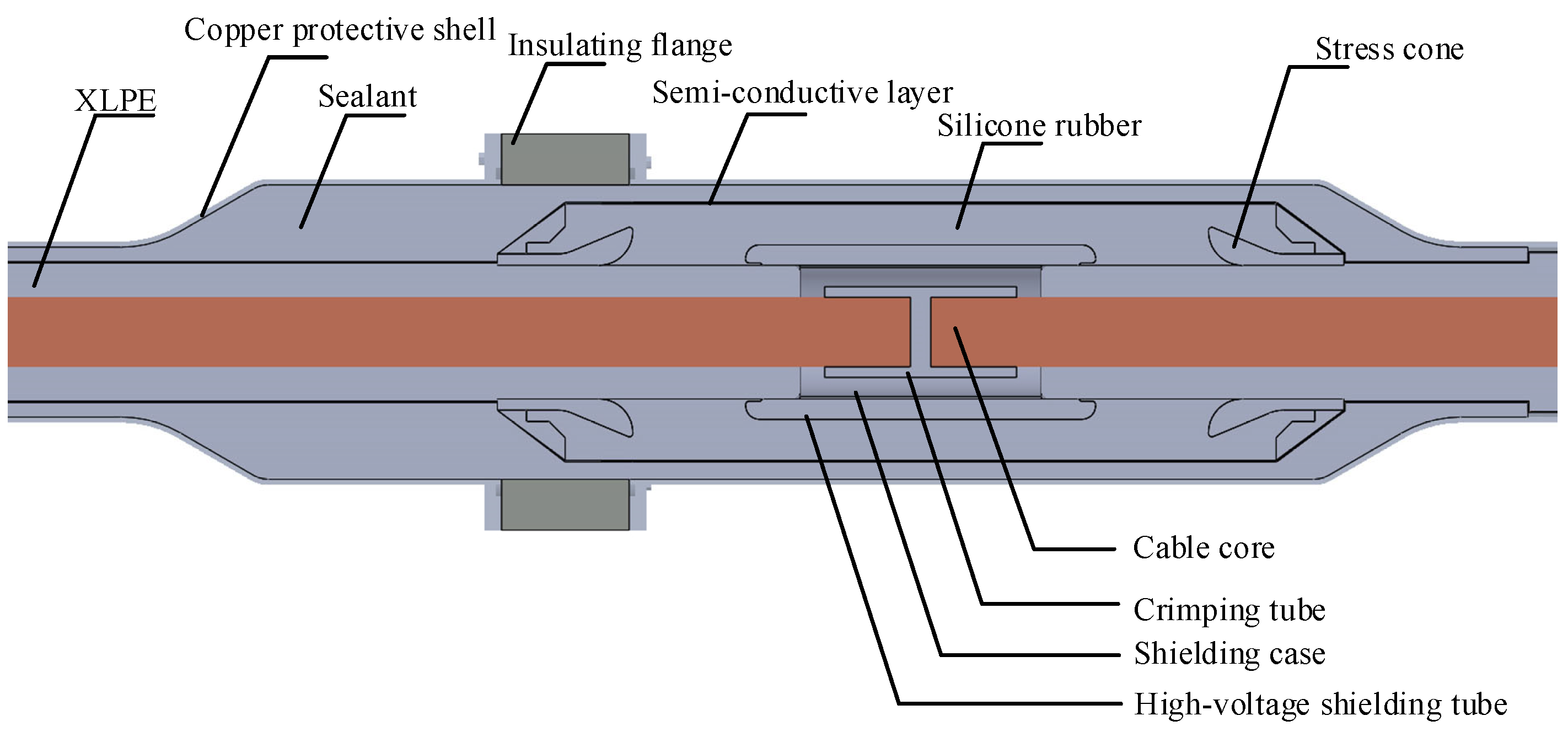

2. Composition of Cable Systems and Structure of Cable Joints

3. Spatial and Temporal Process of Cable Joint Explosion

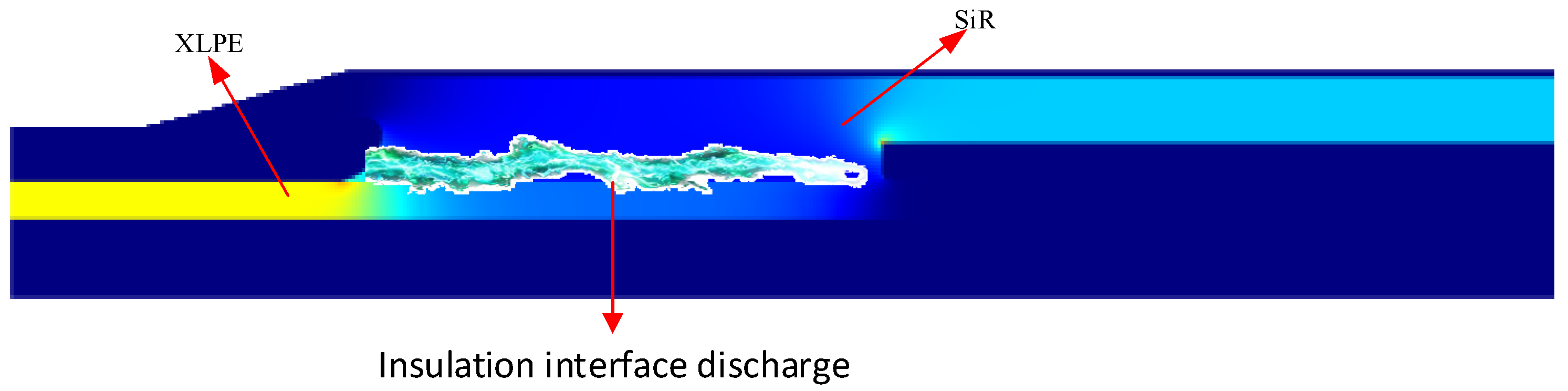

4. Partial Discharge in Cable Joints

4.1. Electric Field Distribution and Weak Points Inside a High-Voltage Cable Joint

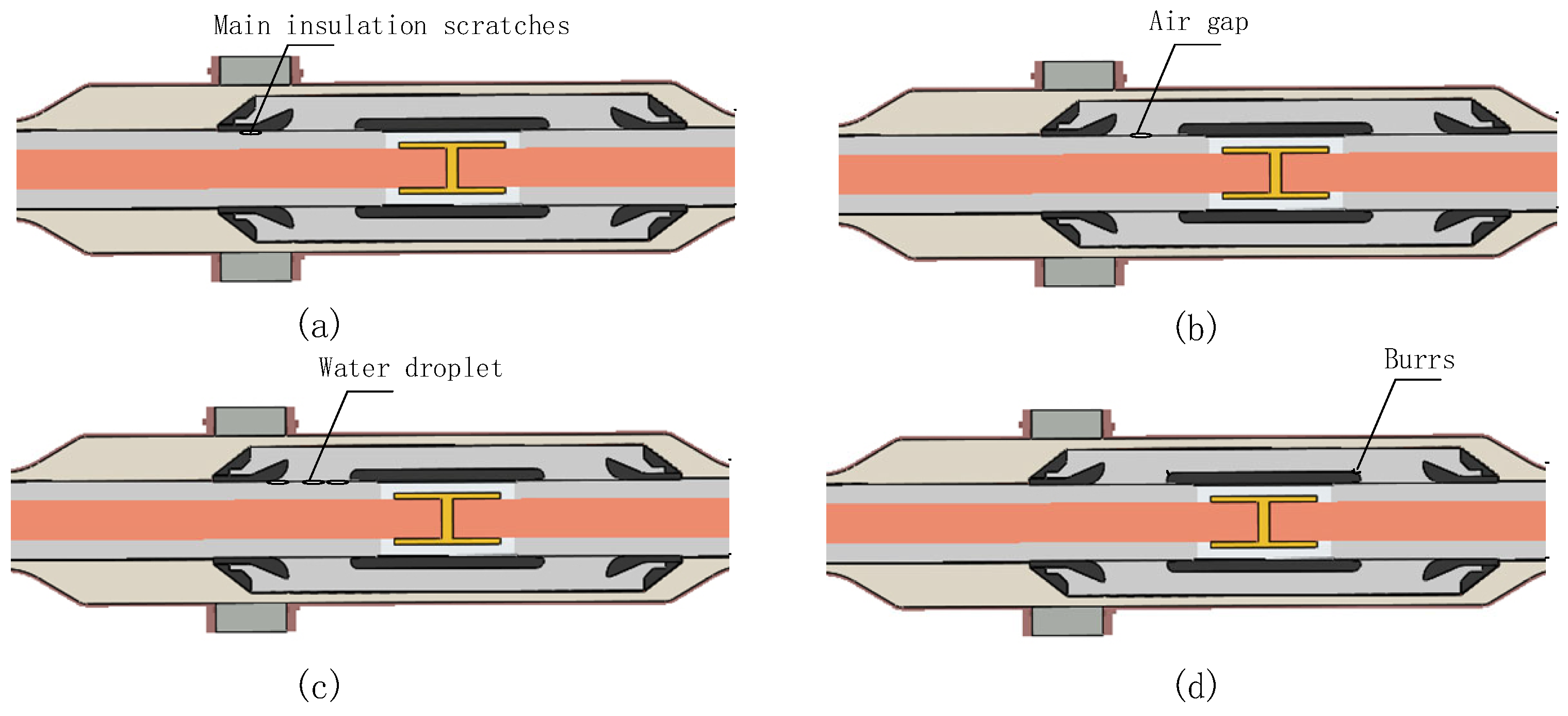

4.2. The Causes of Partial Discharge in Cable Joints

4.3. Detection Methods for Cable Joint Defects

5. Arc Breakdown in Cable Joints

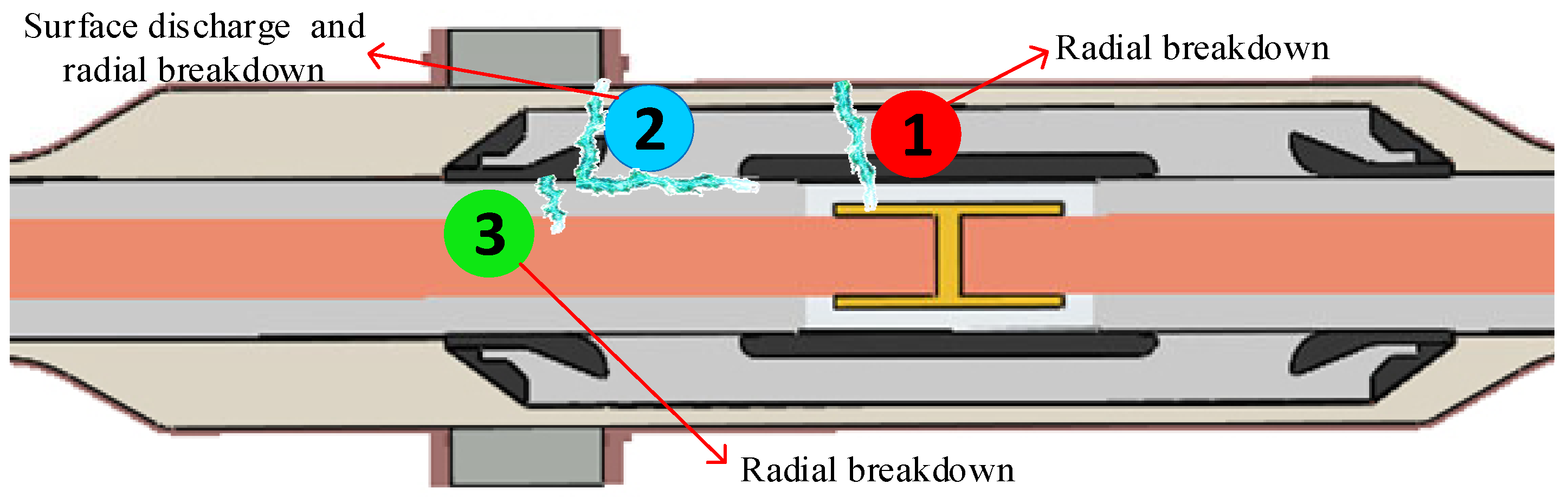

5.1. Arc Breakdown Path and Arc Simulation Models

- Cassie model:

- 2.

- Mayr model:

- 3.

- Control Theory Arc Model.

5.2. Thermal–Electric Decomposition of Insulation Materials

5.3. Explosion and Impact Process of Cable Joints

6. Fire and Explosion Prevention Measures

7. Conclusions

- (1)

- The explosion of cable joints often starts with partial discharge, which is a key factor in the degradation of insulation. The heat and charged particles generated by partial discharge accelerate insulation aging, expand the discharge area, and eventually lead to insulation failure. Defects in cable joints, such as air gaps, burrs, and scratches, can trigger partial discharge. Currently, various detection methods, including high-frequency current, ultra-high-frequency, and acoustic emission methods, are widely used to detect joint defects. However, these methods face challenges, such as being easily disturbed by external factors and lacking sufficient accuracy in identifying defect types. In the future, further improvements in the accuracy and practicality of detection technologies are needed to enable effective early identification of defects.

- (2)

- Partial discharge, when developed to a certain extent, can lead to arc breakdown, releasing a large amount of energy and causing the insulation material to decompose and produce characteristic gases. The arc breakdown path includes both radial and axial discharge, yet the research on arc models is still incomplete and requires more experimental data for calibration. Studies on the decomposition of insulation materials have primarily focused on XLPE, with relatively fewer studies on silicone rubber, and most of these analyses have been based on single factors. Future research should consider the electro-thermal coupling effect to more accurately simulate real operating conditions. Additionally, to more precisely obtain the composition and proportion of decomposition products from insulation materials, experiments using actual cable joints should be conducted.

- (3)

- The explosion of high-voltage cable intermediate joints generates intense shockwaves and flying debris, posing a threat to the safety of on-site personnel and potentially causing fires. Existing fire and explosion protection measures, such as fire- and explosion-proof partitions, joint protection boxes, and fire- and explosion-proof blankets, mainly focus on reducing the impact of explosions, with limited explosion-proof capabilities. Future research and development should focus on fundamentally preventing explosions, such as inhibiting arc development or coordinating with relay protection to ensure reliable operation of relay protection before joint explosion. At the same time, when developing cable joint explosion-proof products with complete fire and explosion protection functions, it is essential to ensure their ability to withstand high-temperature and high-pressure impacts and destruction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| XLPE | Cross-linked polyethylene |

| SiR | Silicone rubber |

| HFCT | High-frequency current transformer |

| UHF | Ultra-high frequency |

| AE | Acoustic emission |

| GC-MS | Gas chromatography–mass spectrometry |

References

- Wei, F. Design of Transmission Line Based on High Voltage Cable. Electron. Technol. 2022, 51, 266–267. [Google Scholar]

- Guo, W.; Zhou, S.; Wang, L.; Pei, H.; Zhang, C. Design and Application of Online Monitoring System for Electrical Cable States. High Volt. Eng. 2019, 45, 3459–3466. [Google Scholar]

- Li, S.; Wang, S.; Yang, L.; Zhao, J.; Jing, Z. Important Properties and Fundamental Issues of the Crosslinked Polyethylene Insulating Materials Used in High-voltage Cable. Proc. CSEE 2022, 42, 4247–4255. [Google Scholar]

- Hui, B.; Fu, M.; Liu, T.; Hou, S.; Liu, C.; Guo, J. Statistical Analysis on Failures of 110 kV and Above Power Cable System. South. Power Syst. Technol. 2017, 11, 44–50+67. [Google Scholar]

- Hong, J.; He, W.; He, H.; Yang, T.; Li, H. Research on Electric Field Simulation of Insulation Defects of Cable Intermediate Joints and Detection of Partial Discharge in Discharge Chamber. Power Syst. Clean Energy 2019, 35, 56–61. [Google Scholar]

- Huang, S. A Study on the Explosion Mechanism of a 220 kV Cable Joint in a Power Tunnel and Its Countermeasures. Technol. Dev. Enterp. 2019, 35, 56–61. [Google Scholar]

- Huang, F.; Guo, J.; Tang, J. Analysis of Causes and Preventive Measures for the Fault of an Intermediate Joint of a 110 kV XLPE Cable. Hongshui River 2018, 37, 63–65. [Google Scholar]

- Kan, Y.; Gao, S.; Ren, X.; Feng, Z. Anatomical Analysis on a 220 kV Cable Intermediate Joint Fault. Hubei Electr. Power 2023, 47, 40–45. [Google Scholar]

- Zheng, B.; Gu, W. Cause Analysis and Measures of a 220 kV XLPE Cable Intermediate Joint Breakdown Fault. Electr. Eng. 2021, 543, 99–100+154. [Google Scholar]

- Guo, W.; Pu, Z.; Ren, Z.; Zhou, S.; Quan, L.; Men, Y.; Pan, Z. Analysis of Abnormal Detection Data of Fire Accident in Power Cable Tunnel and Field Test Study on Characteristic Parameters of Tunnel Fire. Front. Energy Res. 2022, 10, 860707. [Google Scholar]

- Jin, C. Cause of Traversing under Railway 220 kV Cable Explosion. Wire Cable 2020, 63, 37–39+44. [Google Scholar]

- Zeng, H. The Electric Field Distortion in 110 kV Power Cable Intermediate Joints Leading to Line Faults. Telecom World 2017, 24, 111–112. [Google Scholar]

- Bian, B.; Su, W.; Zhu, Z.; Ju, L.; Zhong, Q.; Zhong, Q.; Liu, J. Study on Explosion proof Technology and Temperature Rise Characteristics of 110 kV XLPE Cable Joint. J. Electr. Power 2018, 33, 278–286. [Google Scholar]

- Zhang, C.; Rui, H.; Liu, H.; Liu, Y. Inducted Voltage Simulation of Metal Sheath and Analysis on Maximum Allowable Laying Length for High Voltage Single⁃core Cable. High Volt. Appar. 2020, 56, 143–148. [Google Scholar]

- Xu, X.; Wang, B. Design of Laying Long-distance 500 kV Cable in Power Tunnel. East China Electr. Power 2010, 38, 529–532. [Google Scholar]

- Guan, B.; Wu, A.; Gu, Y.; Chen, H.; Yan, Y.; Dai, R.; Wu, W.; Xu, J.; Miao, J.; Wang, Z.; et al. Key Technology and Product Development of New Type Prefabricated 35 kV and Below Wrapping Middle Joint Based on Fault Analysis of Current Cable Middle Joint. Power Energy 2020, 41, 470–475. [Google Scholar]

- Electric Field Distribution and Structure Optimizing of Integral Prefabricated Joint and Taped Joint. J. Harbin Univ. Sci. Technol. 2018, 23, 77–81.

- Miao, F.; Yan, M.; Fu, P.; Han, W.; Hou, X. Charactoristics and Application of Medium Voltage XLPE Cable Heat Shrinkable Accessories. Electr. Eng. 2014, 15, 93–97. [Google Scholar]

- Xu, T.; Jia, C.; Xu, S. Research Method of Stress Cone Size for High Voltage Electrical Accessories—Taking 500 kV Cable as an Example. Telecom Power Technol. 2018, 35, 41–43. [Google Scholar]

- Shang, K.; Cao, J.; Zhao, Z.; Han, Z.; Ma, L.; Li, W. Simulation Analysis and Design Optimization of 320 kV HVDC Cable Joint. Proc. CSEE 2016, 36, 2018–2024. [Google Scholar]

- Zhang, W. The development of polyurethane elastic potting sealant. Adv. Mater. Ind. 2012, 41–45. [Google Scholar]

- Qiu, W.; Cui, J.; Huang, S.; Liu, Z.; Yang, X.; Zhong, Q.; Liang, Z. Optimum design of the front part structure of explosion-proof device for high-voltage cable joints based on multi-physics coupling. Electrotech. Appl. 2019, 38, 86–92. [Google Scholar]

- Li, S.; Xie, S.; Peng, Y.; Tang, W.; Zhou, H.; Fan, F. Cause Analysis on Copper Shield Burst of 110 kV Cable Joint. Hunan Electr. Power 2023, 43, 121–126. [Google Scholar]

- Chen, X.; Pan, C.; Wu, J.; Wu, K.; Zhang, J. Influencing Factors on Characteristics of Partial Discharge in Void of Insulating Materials. Guangdong Electr. Power 2016, 29, 86–92. [Google Scholar]

- Wang, Z.; Zhou, K.; Zhu, G.; Li, Z.; Fu, Y.; Wang, Z. Effect and Mechanism of Silicone Grease Swelling on Partial Discharge at Air-gap Defects of XLPE-SiR Interface. High Volt. Eng. 2021, 47, 4245–4254. [Google Scholar]

- Du, B.X.; Gu, L. Effects of Interfacial Pressure on Tracking Failure between XLPE and Silicon Rubber. IEEE Trans. Dielect. Electr. Insul. 2010, 17, 1922–1930. [Google Scholar] [CrossRef]

- Gu, L.; Zhao, A.; Hao, H.; Liu, X. Simulation Study on Effect of Defects on Temperature Distribution of Cable Intermediate Joint. Insul. Mater. 2019, 52, 69–74. [Google Scholar]

- Li, H.; Shen, B.; Zhou, Y.; Shen, Y.; Zou, X.; Ren, Q.; Li, X.; Huang, W. Electric Field Simulation Analysis of Typical Breakdown Mechanism of HV Cable Accessories. Power Energy 2019, 40, 649–653+659. [Google Scholar]

- Xiang, E.; Zhou, W.; Wang, K.; Wang, P.; Ma, Y.; Yang, N.; Zhou, Q.; Lei, Y. Discharge in High Voltage Cable Joint with Defect on Outer Semi⁃conductive Layer. High Volt. Appar. 2020, 56, 135–140. [Google Scholar]

- Liu, G.; Ruan, B.; Chen, Z.; Xiong, J. Analysis on the Electric Field of 10 kV XLPE Cable Joint Connecting Pipe with Air Gap Defects. Insul. Mater. 2011, 44, 62–66+73. [Google Scholar]

- Zhao, X.; Yang, J.; Li, S.; Shi, B.; Long, J.; Yang, H. Simulation and Partial Discharge Experimental Study on Cable Intermediate Joints with Defects. J. Henan Inst. Technol. 2024, 32, 1–7. [Google Scholar]

- Wei, Z.; Xu, R.; Zhang, H.; Liu, S.; Lin, G. Effects of Different Defects on the Electrical-Thermal Field Distribution Characteristics of 220 kV Cable Joints. Proc. CSU-EPSA 2025, 1–7. [Google Scholar] [CrossRef]

- Liang, Z.; Peng, J.; Liu, Z.; Zhong, M.; Sun, H.; Yang, X. Finite element calculation of temperature and stress variation of composite interface under high voltage cable joint crimping defects. Electrotech. Appl. 2020, 39, 60–66. [Google Scholar]

- Wang, H.; Wang, X.; Yu, D.; Shu, Z.; Cui, J.; Qiu, W. Study on Closing Overvoltage Simulation of 110 kV Cable Intermediate Joint. High Volt. Appar. 2021, 57, 127–134. [Google Scholar]

- Liu, Y.; Li, J.; Feng, X.; Li, Q.; Hui, B.; Zhang, Y. Analysis on Switching Overvoltage and Suppression Method of Cable Joint in 220 kV Cable Line. Insul. Surge Arresters 2020, 146–152. [Google Scholar] [CrossRef]

- Cao, J.; Jiang, Y.; Wang, S.; Zhou, X.; Li, T.; Zhou, L.; Yang, Y. Analysis and Prospect of Defect Detection Key Technology for XLPE Power Cable Joints. High Volt. Appar. 2018, 54, 87–97. [Google Scholar]

- Álvarez Gómez, F.; Albarracín-Sánchez, R.; Garnacho Vecino, F.; Granizo Arrabé, R. Diagnosis of Insulation Condition of MV Switchgears by Application of Different Partial Discharge Measuring Methods and Sensors. Sensors 2018, 18, 720. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, G.; Dong, J.; Wang, J. Study on Miniaturized UHF Antennas for Partial Discharge Detection in High-Voltage Electrical Equipment. Sensors 2015, 15, 29434–29451. [Google Scholar] [CrossRef]

- Wu, C.; Chen, Y.; Huang, T.; Xiao, J.; Wang, C.; Zhen, W.; Chen, Y.; Cheng, Y.; Zhao, P.; Hao, Y. Overview of Condition Sensing and Detection Technology for Power Cables. High Volt. Appar. 2024, 60, 86–103. [Google Scholar]

- He, C.; Yuan, C.; Zeng, W.; Zhang, A. Detection Method for Partial Discharge of XLPE High-Voltage Power Cable. Power Syst. Clean Energy 2016, 32, 27–33. [Google Scholar]

- Xue, R.; Zhang, L.; Huang, Z.; Zhang, W.; Li, H. Comparative Study on Partial Discharge Characteristics of XLPE Cable under Damped Oscillating Wave Voltage and AC Voltage. Insul. Mater. 2015, 48, 43–48. [Google Scholar]

- Fotis, G.; Vita, V.; Mladenov, V. Monitoring and Digitalization Technologies for HV Power Cable Systems. In Proceedings of the 2024 16th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 19 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar]

- Jiang, Y.; Min, H.; Xia, R.; Li, W. Capacitive Coupling Detection and Characteristic Analysis of Partial Discharge in High-voltage XLPE Power Cable Joints. High Volt. Eng. 2010, 36, 2005–2011. [Google Scholar]

- Zhou, L.; Cao, J.; Wang, S.; Liu, L.; Yang, Y.; Jiang, H. Comprehensive State Evaluation of High Voltage Cable Based on Multi-state Variables Characteristics and Variation Law. High Volt. Eng. 2019, 45, 3954–3963. [Google Scholar]

- Tang, B.; Qiu, H.; Wu, H. Design and implementation of partial discharge acousto-optic joint detection system for high voltage cable connector. Electrotech. Appl. 2021, 40, 10–20. [Google Scholar]

- Huang, C.; Liu, G.; Cui, J.; Qiu, W.; Wang, X.; Liu, S.; Zhao, Y.; Li, C.; Xu, X. Two Cases of Explosion in High-Voltage Cable Joints: Fault Evolution Deduction and Combustion Physical Modeling Analysis. Eng. Fail. Anal. 2025, 169, 109100. [Google Scholar]

- Ma, Z.; Mei, D.; Yang, G.; Xu, F.; Niu, W.; Dai, S. Effect of Voltage Frequency on the Propagation Characteristic of Electrical Tree in Silicone Rubber. Insul. Mater. 2013, 46, 57–61. [Google Scholar]

- Liu, Q.; Cao, W.; Shen, W.; Chen, C.; Yang, H.; Zhang, M. Influence of Material Aging on Flashover Characteristic of Cable Joint Composite Interface. Guangdong Electr. Power 2020, 33, 118–126. [Google Scholar]

- Huang, C.; Zhao, Y.; Hu, R.; Liu, G.; Tang, W. Moisture-induced Discharge Evolution Analysis of XLPE-SiR Insulation Interface in 10 kV Cable Joints. Guangdong Electr. Power 2024, 37, 120–128. [Google Scholar]

- Chen, T.; Ke, H. Modeling and Simulation of High Voltage Circuit Breaker Based on PSCAD. In Proceedings of the 2018 3rd International Conference on Communications, Information Management and Network Security (CIMNS 2018), Wuhan, China, 27–28 September 2018; Atlantis Press: Shenzhen, China, 2018. [Google Scholar]

- Liu, X.; Mo, F. An Incipient Fault Location Method Based on Impedance Calculation. Chin. J. Electron Devices 2022, 45, 1202–1206. [Google Scholar]

- Wang, R. Development of Arc Phenomenon Models. High Volt. Appar. 1991, 27, 39–46. [Google Scholar]

- Liu, S.; Hu, Y.; Zheng, J.; Su, X.; Xu, Y. Dynamics Simulation of 10 kV Cable Tunnel Fire for Single-phase Arc Grounding Fault. High Volt. Eng. 2021, 47, 4341–4348. [Google Scholar]

- Guo, W.; Wang, Y.; Huang, C.; Qin, H.; Zhang, J.; Shi, C.; Xu, Y. Research on Traveling Wave Ranging of Transient Are Breakdown Faults in Medium Voltage Cables. Power Syst. Clean Energy 2024, 40, 31–38. [Google Scholar]

- Wang, B.; Cui, X. Nonlinear Modeling and Analytical Analysis of Are High Resistance Grounding Fault in Distribution Network With Neutral Grounding via Arc Suppression Coil. Proc. CSEE 2021, 41, 3864–3873. [Google Scholar]

- Fan, J.; Ma, Y. Study on Are Modeling of Live Breaking of 220 kV Non-loaded Cable. Electr. Eng. 2018, 38–40. [Google Scholar]

- Qiu, W.; Cui, J.; Huang, S.; Liang, Z.; Yang, X. Finite element simulation of discharge arc characteristics of high voltage cable joints based on magneto-hydrodynamics. Electrotech. Appl. 2019, 38, 62–68. [Google Scholar]

- Wang, F.; Zhou, P.; Han, Y. Study on Influence of Insulation Breakdown Arc on Thermal-stress Characteristics of Cable Joints Based on Coupled Field Calculation. Distrib. Util. 2019, 36, 83–90. [Google Scholar]

- Huang, Y.; Zheng, Z.; Lin, Z.; Zhang, Y.; Yuan, H.; Kong, J.; Zhou, K. Molecular dynamics simulation for gassing of XLPE degradation. Eng. Plast. Appl. 2024, 52, 155–163. [Google Scholar]

- Yuan, H.; Zhou, K.; Kong, J.; Li, Y.; Li, Z.; Liu, C. Evolved Gas Characteristics of High-Voltage XLPE Cables Under Different Fault Conditions. High Volt. Eng. 2025, 51, 946–955. [Google Scholar]

- Wan, L.; Zhang, G.; Zhao, Y.; Zhao, M.; Liao, Z. Analysis of Internal Pyrolysis Characteristics of Crosslinked Polyethylene Cable. In Proceedings of the 2020 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 22 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 498–503. [Google Scholar]

- Wang, L.; Ma, X.; Zhang, J.; Chen, T.; Yang, S.; Yang, H. Reactive force field simulation of electrothermal cracking of silicone rubber under steep temperature rise. Insul. Mater. 2023, 56, 59–65. [Google Scholar]

- Cao, H.; Wang, D.; Guo, M.; Sun, X.; Sun, T.; Du, L.; Wang, F.; Du, Z. The thermal degradation of waste silicone rubber composite insulators. J. Beijing Univ. Chem. Technol. (Nat. Sci. Ed.) 2018, 45, 38–42. [Google Scholar]

- Tao, J.; Li, C.; Cao, X.; Li, S.; Wang, J.; Hu, G. Modeling of the Arc Characteristics inside a Thermal Laminar Plasma Torch with Different Gas Components. Processes 2024, 12, 1207. [Google Scholar] [CrossRef]

- Xiong, J.; Li, L.; Dai, H.; Wu, H.; Peng, M. Analysis of Shock Wave Overpressure Effect of High Current Impulse Arcs Based on the Explosive Wave and Energy Balance Theory. Proc. CSEE 2018, 38, 6746–6753. [Google Scholar]

- Von, N.J. The Point Source Solution; National Defense Research Committee Division B Report No. AM-9: Washington, DC, USA, 1941. [Google Scholar]

- Sedovl, I. Propagation of strong blast waves. Prikl. Mat. Mekh. 1946, 10, 241–250. [Google Scholar]

- Taylor, G. The formation of a blast wave by a very intense explosion. Proc. R. Soc. Lond. 1950, 201, 175–186. [Google Scholar]

- Liu, Q.; Shao, H.; Zhang, Y. Study on shock waves induced by electric spark discharge. China Sci. 2016, 11, 2649–2653. [Google Scholar]

- Yang, X.; Sun, H.; Liu, Z.; Zhong, M.; Qiu, W.; Cui, J. Test and Calculation of Short-circuit Are Explosion Wave Energy of 220 kV High Voltage Cable Joint. High Volt. Appar. 2021, 57, 44–49. [Google Scholar]

- Xu, Z.; Yang, X.; Feng, Y.; Xu, J.; Zhang, H.; Liu, F.; Dong, H. Shock Wave Characteristics and Overpressure Peak Simulation of Short-Circuit Arc Explosion in High-voltage Cable Joints. In Proceedings of the 2023 Panda Forum on Power and Energy (PandaFPE), Chengdu, China, 27–30 April 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1355–1359. [Google Scholar]

- Liu, F.; Lu, J.; Zhang, H.; Feng, Y.; Xue, Z.; Zhu, K.; Zhao, F. Study on Effectiveness of Fire-proof and Explosion-proof Measures for High-voltage Cable Joints. High Volt. Appar. 2023, 59, 258–268. [Google Scholar]

- Qiu, W.; Liu, Z.; Zhong, M.; Sun, H.; Yang, X. Design of Energy Discharge Hole and Wall Thickness for Metal Type Protection Device of 220 kV High Voltage Cable Joint. High Volt. Appar. 2022, 58, 190–198. [Google Scholar]

- Li, G.; Zhang, K.; Wu, Z.; Yang, J.; Cao, J. Exploration of Cable Fire Protection in Power Cable Tunnels and Channels. Sci. Technol. Innov. 2024, 83–86. [Google Scholar]

- Ding, L.; Deng, X.; Ying, H.; Wang, L. Structure Design and Performance Verification of High Voltage Cable Joint Protection Box. Electr. Eng. 2020, 91–93+97. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, L.; Ma, C. Application of Fiberglass Reinforced Plastic Shell in the Leakage Treatment of Cable Tunnel. Electr. Saf. Technol. 2022, 24, 35–36+40. [Google Scholar]

- Xia, C.; Liu, H.; Wu, G.; Xia, Z. Research on heat dispersion and ampacity of three-core cable joints with explosion-proof box. Electr. Meas. Instrum. 2022, 59, 47–52. [Google Scholar]

- Xu, Y.; Wang, P.; Liu, Y.; Guo, S.; Wang, Z.; Liu, G. Experiment Analysis on Influence of Glass Fiber Reinforced Plastic Protection Shell on Thermal Field of Cable Joint. Guangdong Electr. Power 2016, 29, 78–83. [Google Scholar]

- Xiao, J.; Zhang, J.; Bao, S.; Shan, L.; Su, J.; Xu, Y.; Murong, Q.; He, W. Heat Dissipation Measures of High Voltage Cable Joint with Protective Box. Guangdong Electr. Power 2021, 34, 120–126. [Google Scholar]

- Cao, K. Design and Research of Flexible Cable Joint Explosion-Proof Bags. Mech. Electr. Inf. 2023, 39–41+45. [Google Scholar] [CrossRef]

- Yang, X.; Zhong, M.; Sun, H.; Dong, P.; Qiu, W.; Cui, J. Explosion-proof Design and Test of 220 kV Cable Joint Protection Device with Spring Contraction Energy Release Mode. High Volt. Appar. 2023, 59, 86–94. [Google Scholar]

| References | Research Summary | Research Deficiency |

|---|---|---|

| [13] | The heat generated by arc breakdown causes the gas near the cable core to expand, leading to an explosion | Lacks analysis of the gas source and provides an insufficient description of the explosion process |

| [22] | The short-circuit arc releases enormous energy, causing the decomposition of solid materials and gas expansion, ultimately triggering an explosion | Lacks an explanation of the dynamic explosion process |

| [23] | The explosion process involves the development of radial channels, the melting of the joint body, and the rupture of the copper shell, eventually leading to violent combustion of the gases in the air | Fails to analyze multiple possible explosion paths and the causes of arc formation |

| References | Defect Type | Simulation Results |

|---|---|---|

| [29] | Through defects in the outer semi-conductive layer | The maximum field strength inside the air gap exceeds the breakdown field strength of air |

| [30] | Air gaps and improper winding of insulating tape between the crimping tube and the high-voltage shielding tube | The maximum field strength is more than twice the normal value, which can easily lead to the breakdown of the air gap |

| [31] | Edges and burrs on the surface of the crimping tube | They cause local field strength distortion, increasing the risk of partial discharge |

| [32] | Conductive impurities, water droplets, and air gaps | All three defects lead to distortion of local field strength and temperature, with the air gap defect having the most significant impact |

| [33] | Compression defects | They cause secondary distortion of interface stress, accelerating the aging of insulation materials |

| References | Partial Discharge Detection Technology | Advantages | Disadvantages |

|---|---|---|---|

| [37] | High-Frequency Current Method |

|

|

| [38] | Ultra-High-Frequency Method |

|

|

| [39] | Acoustic Emission Method |

|

|

| References | Research Object | Experimental/Simulation Method | Gas Products |

|---|---|---|---|

| [59] | XLPE | Molecular dynamics simulation and experimental verification | Hydrocarbon gases and carbon oxides |

| [60] | XLPE | Experimental research |

|

| [61] | XLPE | Experimental research | C2H4, C2H6, C3H6, C3H8 |

| [62] | SiR | ReaxFF model simulation | CH4, H2, C2H4, C2H2, H2O |

| [63] | SiR | Experimental research |

|

| References | Fire and Explosion Prevention Measures | Advantages | Disadvantages |

|---|---|---|---|

| [74] | Fire- and Explosion-Proof Partitions |

|

|

| [75] | Flame-Retardant Plastic Protection Boxes |

|

|

| [75,76] | Fiberglass Protection Boxes |

|

|

| [75] | Aluminum–Magnesium Alloy Protection Boxes |

|

|

| [75] | Flexible Fireproof Blankets |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, W.; Li, C.; Chen, N.; Huang, Y.; Jiang, Z.; Cui, J.; Wang, P.; Liu, G. Review of Explosion Mechanism and Explosion-Proof Measures for High-Voltage Cable Intermediate Joints. Energies 2025, 18, 1552. https://doi.org/10.3390/en18061552

Qiu W, Li C, Chen N, Huang Y, Jiang Z, Cui J, Wang P, Liu G. Review of Explosion Mechanism and Explosion-Proof Measures for High-Voltage Cable Intermediate Joints. Energies. 2025; 18(6):1552. https://doi.org/10.3390/en18061552

Chicago/Turabian StyleQiu, Wei, Chen Li, Nianqiao Chen, Yuhua Huang, Zhibin Jiang, Jiangjing Cui, Peifeng Wang, and Gang Liu. 2025. "Review of Explosion Mechanism and Explosion-Proof Measures for High-Voltage Cable Intermediate Joints" Energies 18, no. 6: 1552. https://doi.org/10.3390/en18061552

APA StyleQiu, W., Li, C., Chen, N., Huang, Y., Jiang, Z., Cui, J., Wang, P., & Liu, G. (2025). Review of Explosion Mechanism and Explosion-Proof Measures for High-Voltage Cable Intermediate Joints. Energies, 18(6), 1552. https://doi.org/10.3390/en18061552