Abstract

The present paper is a review of the use of different types of blends of Jet A aviation fuel with biodiesel and alcohols, respectively, as sustainable aviation fuels (SAF). The scientific literature published from 2017 to 2024 was addressed and highlighted that the use of Jet A fuel blended with alcohols and biodiesel has gained attention as a potential pathway to reducing aviation emissions and enhancing sustainability. Alcohol-blended Jet A fuels, such as ethanol and methanol mixtures, offer advantages including lower carbon monoxide (CO) and unburned hydrocarbon (HC) emissions due to their improved combustion efficiency. Similarly, biodiesel blends contribute to reduced particulate matter (PM) and CO emissions, while their oxygen content promotes cleaner combustion. Both types of blends have the potential to decrease the aviation sector’s carbon footprint and enhance fuel diversification. However, several gaps and limitations remain, including lower energy density leading to increased fuel consumption, material compatibility issues, increased nitrogen oxide (NOx) emissions, and concerns over fuel stability. Further research is needed to optimize blend ratios, improve combustion control strategies, and ensure the safe and efficient integration of these alternative fuels in aviation.

1. Introduction

The aviation industry’s commitment to reducing its environmental impact and enhancing fuel efficiency has led to extensive research into alternative fuel blends. Among these, combinations of Jet A fuel with alcohols and biodiesel have garnered significant attention. This comprehensive review synthesizes findings from scientific studies published since 2018, focusing on the effects of these blends on turbojet engine performance, the specific types of blends utilized, and the resultant gaseous emissions.

Alcohols, particularly ethanol and methanol, but also longer-chain ones (up to C8), have been explored as additives to Jet A fuel due to their potential to enhance combustion efficiency and reduce particulate emissions.

Recent studies [1] have evaluated the performance of turbojet engines using Jet A-alcohol blends. For instance, research has demonstrated that engines can operate stably with ethanol concentrations of up to 35%. However, higher ethanol content may lead to decreased engine speed and exhaust gas temperature, indicating potential declines in performance metrics. Specifically, a 35% ethanol blend resulted in a reduction in engine speed by approximately 7500 rpm at a constant fuel flow, suggesting that while ethanol can serve as an additive, it may necessitate increased fuel consumption to maintain desired performance levels.

Studies such as [2], which have tested blends containing 10%, 20%, and 30% methanol by volume in micro turbojet engines, have indicated stable engine performance with 10% and 20% methanol blends. However, at a 30% methanol concentration, engine stability was shown decrease significantly, especially at idle and maximum speeds, leading to notable rpm fluctuations. This suggests that while lower methanol concentrations, such as 10–20%, are viable for use in terms of engine performance, higher percentages, such as 30%, may compromise engine stability, especially at “sensible” regimes (e.g., idle and max.).

The environmental impact of alcohol blends has been a focal point of recent research. Studies have observed that incorporating ethanol into Jet A-1 reduces carbon monoxide (CO) and hydrocarbon (HC) emissions by 5% and 37%, respectively [1]. This reduction is attributed to the oxygen-rich nature of ethanol, which facilitates more complete combustion. Conversely, there was an 11% increase in carbon dioxide (CO2) and a 27% rise in nitrogen oxide (NOx) emissions, likely due to the higher combustion temperatures associated with ethanol blends.

Similarly, in paper [3], methanol blends were reported to decrease CO and sulfur dioxide (SO2) emissions. As the methanol concentration increased, CO emissions decreased, which is consistent with the enhanced combustion efficiency provided by methanol’s oxygen content. However, specific percentages regarding the reduction in emissions were not detailed.

Biodiesel, derived from renewable biological sources, presents a promising alternative to traditional jet fuels. Studies have examined the effects of blending biodiesel with Jet A fuel on engine performance and emissions.

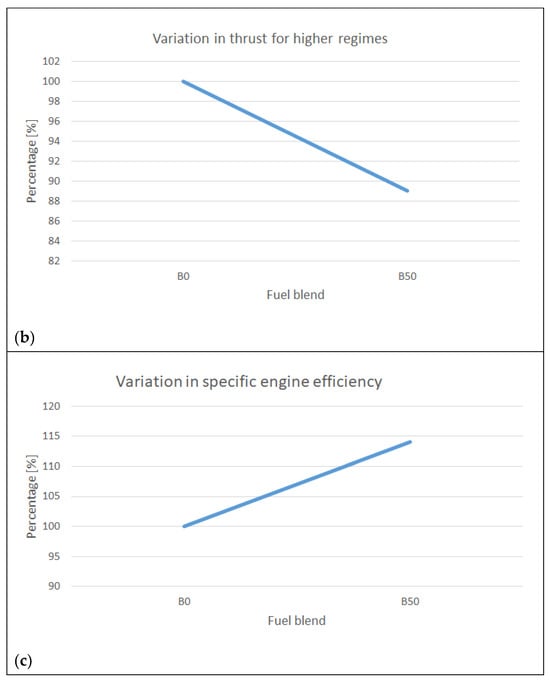

Research into the use of biodiesel blends with Jet A-1 in gas turbine engines has shown that up to a 50% biodiesel blend can be utilized without significant adverse effects on engine performance. Notably, a B50 blend resulted in a 2% increase in static thrust at lower and medium engine speeds, while a decrease of 11% was observed at higher speeds. Additionally, the thrust-specific fuel consumption (TSFC) for biodiesel blends was lower than that of pure Jet A-1, and engine efficiency increased by 14% with the B50 blend [4]. Figure 1 shows the variation in thrust vs. fuel blends at different regimes and the variation in engine efficiency vs. fuel blends.

Figure 1.

Variation in different parameters vs. fuel blends: (a) variation in thrust at lower regimes; (b) variation in thrust at higher regimes; (c) variation of engine efficiency.

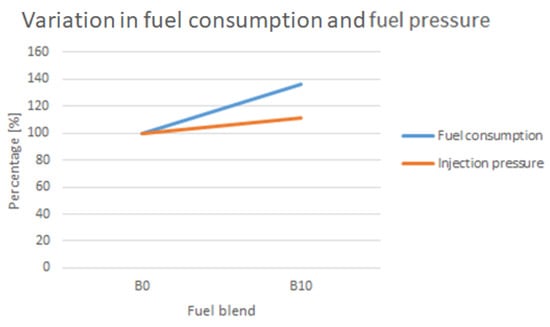

Further studies have assessed the performance of turbojet engines using blends of Jet A-1 and palm oil biodiesel. Blends with up to 10% biodiesel were tested across various load regimes, showing no significant variations in thrust force and exhaust gas temperature across all operating regimes. However, a maximum increase of 36% in fuel consumption and an 11% rise in injection pressure were observed at idle operation between B0 (pure Jet A-1) and B10 blends [5]. Figure 2 shows the variation in the above-described aspects.

Figure 2.

Variation in fuel consumption and pressure vs. fuel blends.

The environmental benefits of biodiesel blends are evident in emission reductions. Studies have reported that increasing biodiesel content leads to higher oxygen concentrations in exhaust emissions, with a 6% increase observed for the B50 blend. This oxygen enrichment contributed to a 5% reduction in CO emissions and a 37% decrease in HC emissions. However, there was an 11% increase in CO2 and a 27% rise in NOx emissions, possibly due to the elevated combustion temperatures associated with biodiesel use. Additionally, sulfur dioxide (SO2) emissions decreased by 75% with biodiesel blends, which has been attributed to the negligible sulfur content in biodiesel compared to conventional Jet A-1 fuel [4].

Other studies have observed a reduction in CO and HC emissions with the use of biodiesel blends, with the most significant variation recorded at the cruise regime (80% RPM). While exact percentage reductions were not specified, a clear trend of decreased emissions with increasing biodiesel content was noted in [6].

Several overarching limitations have been highlighted by worldwide research teams in the use of Jet A blends with alcohols and biodiesel: Material Compatibility—Alcohols, particularly ethanol, can act as solvents, potentially degrading fuel system components not designed for such fuels. This necessitates material compatibility assessments and possible modifications to existing fuel systems [7]; Energy Density—Both ethanol and biodiesel have lower energy densities compared to Jet A fuel. This results in increased fuel consumption to achieve the same thrust, impacting the aircraft’s range and operational efficiency [4]; Hygroscopic Nature—Ethanol’s tendency to absorb water can lead to phase separation and microbial growth in fuel systems, posing risks of corrosion and fuel degradation [8]; Emission Trade-offs—While reductions in CO and HC emissions are beneficial, the associated increase in NOx emissions presents a challenge. Mitigating NOx formation requires advanced combustion technologies or after-treatment systems, which may add complexity and weight to the aircraft [9].

Aromatic Content: The lack of aromatics in biodiesel affects fuel properties such as density and seal swell characteristics, which are crucial for engine performance and fuel system integrity. This limitation restricts the proportion of biodiesel that can be blended without compromising safety and performance [8].

This review aims to address the use of alcohols and biodiesel blended with “classical” Jet A aviation fuel and highlight its main aspects. Therefore, the discussion takes into account the use of such blends and their impact on the environment, engine performance, and material compatibility. Moreover, other aspects have been addressed, such as current knowledge gaps and limitations as well as future research directions on the use of such blends in the aviation industry.

2. Fuel Blends and Their Impact on Engine Performance

The integration of alternative fuels in the aviation industry, particularly blends of Jet A with alcohols and biodiesel, has been extensively studied to assess their impact on turbojet engine performance. This review synthesizes findings from scientific studies published since 2018, focusing on engine performance metrics when utilizing these fuel blends.

2.1. Jet A and Alcohol Blends

Alcohols, notably ethanol and methanol, have been investigated as additives to Jet A fuel to enhance combustion properties and reduce emissions.

2.1.1. Ethanol Blends

A study by Cican et al. [9] examined the effects of methanol-kerosene blends on a micro turbojet engine’s performance. Blends containing 10%, 20%, and 30% methanol by volume were tested. The study found that, up to a 20% methanol blend, the engine operated stably across various regimes, including idle and maximum speeds. However, at a 30% methanol concentration, engine stability decreased significantly, leading to notable rpm fluctuations, especially at idle and maximum speeds. This suggests that while lower methanol concentrations are viable, higher percentages may compromise engine stability.

2.1.2. Methanol Blends

Andoga et al. [7] explored the use of ethanol as a sustainable fuel in small turbojet engines. Their study evaluated various ethanol-Jet A-1 mixtures to determine their effects on engine parameters. The results indicated that ethanol concentrations up to 30% maintained stable engine operation. However, higher ethanol content led to a decrease in engine speed and exhaust gas temperature, suggesting potential declines in performance. Specifically, a 35% ethanol blend resulted in a reduction in engine speed by approximately 7500 rpm at a constant fuel flow, implying that while ethanol can serve as an additive, it may necessitate increased fuel consumption to maintain desired performance levels.

2.1.3. Butanol Blends

Butanol has gained attention as a potential alternative to ethanol and methanol due to its higher energy density and better compatibility with aviation engines. Unlike ethanol and methanol, butanol has a higher boiling point, making it less prone to evaporation and easier to handle in fuel systems. Cican et al. tested n-butanol blended with Jet A fuel in turbojet engines. Their results showed that the addition of n-butanol improved combustion efficiency and reduced emissions, especially of SO2 and CO. The blends also demonstrated a reduction in particulate matter (PM) emissions compared to pure Jet A fuel. These improvements were attributed to butanol’s higher energy content, which resulted in better thermal efficiency in the engine [3]. Similarly, Cheng et al. found that butanol-based blends with Jet A fuel showed an improvement in combustion stability and reduced the formation of harmful emissions. However, the study also noted that as the concentration of butanol increased beyond 15%, the power output of the engine decreased slightly, suggesting that while butanol has potential as a fuel additive, the blend composition must be carefully controlled to avoid performance degradation at higher concentrations [10].

2.1.4. Pentanol Blends

Pentanol, a five-carbon alcohol, has also emerged as a potential candidate for blending with aviation fuels. Vishwanath et al. investigated the effect of n-pentanol on soot formation and emissions in Jet A fuel. The study found that pentanol addition significantly reduced soot production, particularly at higher concentrations. The presence of pentanol also led to reductions in CO and NOx emissions, which is promising for achieving cleaner combustion in aviation engines. This study concluded that pentanol could provide a more sustainable and efficient alternative to ethanol and methanol due to its improved combustion characteristics and soot reduction potential [11]. A comparative analysis of pentanol and other alcohol-based fuel blends in aviation kerosene was performed by Suchocki et al. Their results indicated that pentanol blends resulted in lower NOx and CO emissions and higher thermal efficiency than methanol and ethanol blends. The study also noted that pentanol’s longer carbon chain provides better fuel stability and energy density, making it a more suitable alternative for aviation applications [12].

2.1.5. Hexanol Blends

Hexanol is a six-carbon alcohol with a relatively high boiling point and a relatively low vapor pressure, making it less volatile than ethanol and suitable for blending with aviation fuels. Research by Mirea et al. showed that blends of hexanol with Jet A fuel enhanced the fuel’s thermal stability and combustion efficiency in turbojet engines. At lower concentrations (up to 10%), hexanol blends exhibited improved combustion characteristics, including reduced carbon monoxide (CO) emissions and enhanced combustion efficiency [13]. However, when hexanol concentrations exceeded 15%, engine performance was slightly reduced, and the emission reduction effect diminished. This suggests that while hexanol can help improve the fuel’s properties, its high carbon chain may lead to lower performance at higher concentrations due to energy density mismatches. Suchoki evaluated the performance of hexanol-blended aviation fuels in small turbojet engines. The researchers observed that hexanol improved fuel efficiency and reduced particulate matter (PM) emissions compared to pure Jet A fuel. However, excessive concentrations of hexanol (above 20%) led to a reduction in engine power, indicating that there is an optimal concentration range for achieving both efficiency and emission reductions [14].

2.1.6. Heptanol Blends

Heptanol, a seven-carbon alcohol, is an alcohol that has received attention due to its promising combustion and emission characteristics. A study by Yılmaz et al. on heptanol-blended Jet A fuel found that heptanol improved the combustion stability of aviation engines while maintaining relatively high energy density compared to shorter-chain alcohols. Blending heptanol up to 10% with Jet A fuel did not negatively affect engine power or efficiency, but the engine performed optimally when the concentration was kept below 15%. Beyond this concentration, the increased alcohol content resulted in a slight decrease in thrust and an increase in carbon dioxide (CO2) emissions [15]. In a subsequent study by Battal et al., the performance of heptanol-blended fuel was tested in a diesel engine. The researchers observed that, similar to hexanol, heptanol improved combustion efficiency, leading to lower NOx and CO emissions. Heptanol also reduced the formation of soot particles, which is crucial for ensuring cleaner exhaust gases. However, as the alcohol content in the fuel increased, the exhaust temperature rose, potentially causing thermal stresses on the engine components. These findings underscore the importance of optimizing heptanol concentrations for balancing combustion efficiency, emissions, and thermal management in turbo engines [16].

2.1.7. Octanol Blends

Octanol has been increasingly studied for its potential in aviation fuel blends due to its superior energy density and thermal stability. Research by Prakash et al. found that octanol blends with aviation kerosene (Jet-A) provided an increase in energy density compared to shorter-chain alcohols, making it more comparable to traditional aviation fuels. Their experiments showed that octanol blends of up to 15% did not compromise engine performance and reduced NOx emissions significantly compared to pure Jet A fuel. Additionally, octanol blends exhibited a higher flash point, making them safer for handling and transportation [17]. However, when the concentration of octanol exceeded 20%, the researchers observed a slight drop in engine power and a marginal increase in carbon monoxide (CO) emissions. This suggests that while octanol has a higher energy content than hexanol or heptanol, its performance benefits diminish when used in high concentrations, likely due to the mismatch in energy density with Jet A fuel.

Chang et al. further confirmed the positive impact of octanol on reducing harmful emissions. Their experiments showed that octanol blends reduced particulate emissions and soot formation in comparison with traditional fuels, which is particularly important for meeting stringent emission standards. Moreover, octanol demonstrated superior cold-start performance due to its higher energy density and lower evaporation rate, making it a suitable candidate for use in colder climates [18].

2.2. Jet A and Biodiesel Blends

Biodiesel, derived from renewable biological sources, has been studied as a blending agent with Jet A fuel to improve sustainability and reduce emissions.

2.2.1. Thrust and Fuel Consumption

Ali et al. [4] conducted experiments on a turbojet engine using blends of Jet A-1 and biodiesel produced from cotton and corn oils. Their study tested blends with 10% (B10), 20% (B20), and 50% (B50) biodiesel by volume. The results indicated that up to a 50% biodiesel blend could be utilized without significant adverse effects on engine performance. Notably, the B50 blend resulted in a 2% increase in static thrust at lower and medium engine speeds, while a decrease of 11% was observed at higher speeds. Additionally, the thrust-specific fuel consumption (TSFC) for biodiesel blends was lower than that of pure Jet A-1, and engine efficiency increased by 14% with the B50 blend. In a more recent study, Altarazi et al. [19] examined the performance of a small-scale turbojet engine fueled with blends of Jet A-1 and fatty acid methyl ester (FAME) biodiesel. The blends tested included 10% (B10), 20% (B20), and 30% (B30) biodiesel by volume. The findings revealed that while there was a slight reduction in thrust with increasing biodiesel content, the engine operated stably across all tested blends. The B10 blend exhibited the best specific fuel consumption (SFC) value at 42.43 g/kN·s, indicating that lower biodiesel concentrations may offer a balance between performance and fuel efficiency.

2.2.2. Combustion Efficiency and Thermal Performance

The impact of biodiesel blends on combustion efficiency has also been a subject of investigation. Gawron et al. [20] studied the effects of blending Jet A-1 with hydroprocessed esters and fatty acids (HEFA) on a miniature turbojet engine. Their research demonstrated that HEFA blends led to a decrease in thrust and fuel consumption, attributed to the higher heat of combustion and lower density of the HEFA fuel. This suggests that while HEFA blends may reduce fuel consumption, they could also result in a slight performance penalty in terms of thrust. Similarly, Feser et al. [21] investigated the effects of Jet A-1 blends with butanol on gas turbine engine performance. The study found that increasing the butanol content in the blend resulted in a decrease in operational thrust range. However, there was a concurrent reduction in nitrogen oxide (NOx) and carbon monoxide (CO) emissions, indicating an improvement in combustion efficiency. This highlights a trade-off between engine performance and emission benefits when using alcohol-based additives.

Biodiesel blends improve fuel efficiency, combustion completeness, and emissions, but their impact on thrust varies based on concentration. Lower blends (B10–B20) provide an optimal balance between fuel savings and stable thrust, whereas higher blends (B50) may enhance efficiency but with potential thrust losses at high speeds. Additionally, oxygen content and cetane number play crucial roles in optimizing combustion quality and emissions. Therefore, developing optimized fuel formulations will be essential for achieving both performance and environmental benefits in aviation propulsion.

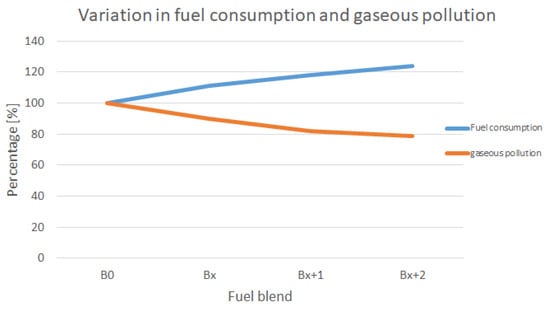

Figure 3 shows the variation in fuel consumption and gaseous pollution as aviation fuel blends incorporate greater concentrations of biofuels. It can be seen that the optimal values are for lower concentrations of biofuels in classical aviation fuel. As the concentration of biofuels increases, the effects become less significant and ultimately lead to a decrease in engine performance.

Figure 3.

Variation in fuel consumption and gaseous emissions vs. fuel blends.

3. Comparative Analysis

Alcohol blends, such as ethanol and methanol, have been shown to maintain stable engine performance at lower concentrations (up to 20–30%). However, higher concentrations may lead to decreased engine speed and stability issues. By contrast, biodiesel blends up to 50% have demonstrated the potential to enhance static thrust and reduce TSFC, indicating improved fuel efficiency. Nonetheless, higher biodiesel blends may increase fuel consumption at idle operations.

3.1. Engine Stability and Performance

The lower energy density of alcohols compared to Jet A fuel necessitates higher fuel flow rates to achieve equivalent thrust, potentially impacting fuel efficiency. Biodiesel’s higher viscosity can affect fuel atomization, potentially leading to incomplete combustion and efficiency losses. Additionally, the hygroscopic nature of alcohols, particularly ethanol, can lead to water contamination, posing risks to engine components. Material compatibility is also a concern, as alcohols can degrade seals and hoses, leading to maintenance challenges.

Studies have shown that biodiesel blends of up to 50% can be utilized without significant adverse effects on engine performance. However, higher concentrations may lead to decreased thrust at elevated engine speeds. Lower biodiesel concentrations, such as B10, have demonstrated optimal specific fuel consumption, suggesting a favorable balance between performance and efficiency.

3.2. Fuel Properties and Engine Compatibility

Alcohols generally improve combustion efficiency due to their high oxygen content. However, their lower energy density compared to conventional jet fuels can reduce power output and overall engine performance when used in higher concentrations. Yılmaz et al. observed that while ethanol blends of up to 10% did not degrade engine performance, higher concentrations (15–30%) resulted in a noticeable decrease in power output and efficiency [15].

Similarly, Cican et al. found that butanol blends improved combustion efficiency compared to pure Jet A fuel, but performance started to decline when concentrations exceeded 15%. This was due to the energy density mismatch between butanol and Jet-A, leading to a reduction in engine power output [3].

The higher viscosity and density of biodiesel compared to Jet A-1 can affect fuel atomization and combustion characteristics. These properties may lead to slight reductions in thrust and changes in fuel consumption. Additionally, the oxygen content in biodiesel contributes to more complete combustion, potentially reducing certain emissions but also influencing thermal efficiency. Table 1 exemplifies the different physico-chemical characteristics of different alcohol/Jet A blends and Table 2 shows the different physico-chemical characteristics of different biodiesel/Jet A blends

Table 1.

Experimental density (g/cm3) and kinematic viscosity, ν (mm2/s), of the alcohol/Jet A blends.

Table 2.

Experimental results for physic-chemical properties for fuel blends.

4. Gaseous Emissions and Environmental Impact

4.1. Jet A and Alcohol Blends

Alcohols such as methanol, ethanol, and n-butanol have mostly been explored as additives to Jet A fuel to enhance combustion efficiency and reduce harmful emissions.

4.1.1. Methanol Blends

Blends containing 10%, 20%, and 30% methanol by volume were tested under various operating conditions. The results indicated that increasing methanol content led to a reduction in carbon monoxide (CO) and unburned hydrocarbon (HC) emissions, attributed to methanol’s higher oxygen content facilitating more complete combustion. However, nitrogen oxide (NOx) emissions increased with higher methanol concentrations, likely due to elevated combustion temperatures. This trade-off suggests that while methanol can improve combustion efficiency, careful optimization is necessary to manage NOx emissions [9].

4.1.2. Ethanol Blends

Research into ethanol-kerosene blends has demonstrated similar emission patterns. Studies have shown that incorporating ethanol reduces CO and HC emissions due to enhanced combustion. However, an increase in NOx emissions was observed, necessitating advanced combustion control strategies to mitigate this effect.

4.1.3. N-Butanol Blends

The use of n-butanol as a sustainable aviation fuel has been investigated for its potential to reduce emissions. Experimental studies have shown that n-butanol/Jet-A blends can significantly enhance combustion efficiency and reduce emissions compared to conventional Jet A fuel. Notably, reductions in particulate matter (PM), CO, and HC emissions were observed, while NOx emissions exhibited a slight increase, underscoring the need for balanced blend ratios and engine tuning [3].

Overall, the primary advantages of using alcohol-blended Jet A fuels, such as ethanol and methanol mixtures, include the following:

Emission Reduction—Alcohol-blended fuels generally result in lower carbon monoxide (CO), unburned hydrocarbon (HC), and particulate matter (PM) emissions due to their higher oxygen content, which promotes more complete combustion. The presence of alcohols can also reduce sulfur oxide (SOx) and nitrogen oxide (NOx) emissions, contributing to improved air quality and reduced environmental impact.

Combustion Efficiency—Since alcohols such as ethanol and methanol have a higher latent heat of vaporization, which can enhance fuel-air mixing and lead to more efficient combustion.

These fuels typically have higher flame speeds and combustion temperatures, which can improve engine thermal efficiency and power output. The oxygen content in alcohols promotes improved oxidation of the fuel, reducing soot formation and increasing energy extraction from the fuel.

4.2. Jet A and Biodiesel Blends

Biodiesel, derived from renewable sources, has been blended with Jet A fuel to assess its impact on emissions and environmental sustainability.

4.2.1. Emission Profiles

Ali et al. [4] investigated the performance and environmental impact of a turbojet engine fueled by blends of Jet A-1 and biodiesel. Their findings indicated that biodiesel blends resulted in a decrease in CO and HC emissions by 5% and 37%, respectively, compared to pure Jet A-1 fuel. This reduction is attributed to the oxygenated nature of biodiesel, promoting more complete combustion. However, an increase in NOx emissions by 27% was observed, likely due to higher flame temperatures associated with biodiesel combustion. Additionally, sulfur dioxide (SO2) emissions decreased by 75%, reflecting the low sulfur content in biodiesel.

CO is primarily formed due to incomplete combustion when there is insufficient oxygen to fully oxidize carbon-based fuels into carbon dioxide (CO2). The additional oxygen content in biodiesel enhances the oxidation process, reducing CO formation by promoting a more complete fuel burn. Improved combustion efficiency with biodiesel blends results in lower CO emissions, as more fuel is converted into usable energy rather than incomplete byproducts.

4.2.2. Particulate Matter Emissions

A NASA study [22] confirmed that using biofuels in jet engines can reduce particle emissions by as much as 50% to 70%.

Biodiesel contains oxygen molecules (typically 10–12% oxygen %wt.), which promote more complete combustion, leading to reduced soot and PM formation. The oxygen-rich nature of biodiesel helps in breaking down hydrocarbon chains more effectively, reducing the production of solid carbon particulates. Lower sulfur content in biodiesel blends also contributes to lower sulfate-based PM emissions.

The oxygen presence in biodiesel molecules plays a crucial role in enhancing the combustion reaction, ensuring a more efficient oxidation of fuel components. This leads to the following outcomes: a reduction in carbonaceous soot precursors, lowering PM emissions; increased CO to CO2 conversion, minimizing CO emissions; and improved combustion temperature and efficiency; further decreasing emissions of harmful pollutants.

This significant reduction in particulate matter is beneficial for both environmental and public health, as it leads to cleaner combustion and a lower environmental impact at airports and in the upper atmosphere.

4.3. Environmental Impact

The adoption of alcohol and biodiesel blends in aviation fuels presents both benefits and challenges in terms of environmental impact.

4.3.1. Greenhouse Gas Emissions

The use of biofuels can lead to a net reduction in greenhouse gas emissions, as the CO2 released during combustion is offset by the CO2 absorbed during the feedstock’s growth phase. However, the overall environmental benefit depends on the entire lifecycle of the biofuel, including feedstock cultivation, processing, and transportation. Sustainable sourcing and production practices are crucial to maximizing the environmental advantages of biofuels.

4.3.2. Resource Utilization and Sustainability

The large-scale production of biofuels raises concerns about land and water use, food security, and biodiversity. For instance, cultivating crops for biofuels may compete with food production or lead to deforestation. Therefore, selecting appropriate feedstocks, such as non-food crops or waste materials, and implementing sustainable agricultural practices are essential to minimize negative environmental impacts.

5. Limitations and Challenges

Several overarching limitations exist in the use of Jet A blends with alcohols and biodiesel:

- Material Compatibility—Alcohols, particularly ethanol, can act as solvents, potentially degrading fuel system components that are not designed for such fuels. This necessitates material compatibility assessments and possible modifications to existing fuel systems.

- Energy Density—Both ethanol and biodiesel have lower energy densities compared to Jet A fuel. This results in increased fuel consumption to achieve the same thrust, impacting the aircraft’s range and operational efficiency. Studies have shown that blending ethanol with Jet A fuel can affect engine performance. For instance, Andoga et al. [7] explored the use of ethanol in small turbojet engines and found that ethanol concentrations above 40% negatively impacted engine speed and thrust. The lower energy density of ethanol compared to Jet A results in reduced thrust and increased fuel consumption. Additionally, ethanol’s hygroscopic nature can lead to water contamination, posing risks to engine components. Moreover, ethanol’s solvent properties may degrade seals and hoses, leading to maintenance challenges.

- Hygroscopic Nature—Ethanol’s tendency to absorb water can lead to phase separation and microbial growth in fuel systems, posing risks of corrosion and fuel degradation.

- Emission Trade-offs—While reductions in CO and HC emissions are beneficial, the associated increase in NOx emissions presents a challenge. Mitigating NOx formation requires advanced combustion technologies or after-treatment systems, which may add complexity and weight to the aircraft. While ethanol blends can reduce certain emissions, they may increase others. Andoga et al. [7] reported that ethanol-blended fuels led to a decrease in carbon monoxide (CO) and unburned hydrocarbon (HC) emissions due to more complete combustion. However, there was an increase in nitrogen oxide (NOx) emissions, likely due to higher combustion temperatures. This trade-off highlights the need for advanced combustion control strategies to mitigate NOx emissions when using ethanol blends.

- Aromatic Content: The lack of aromatics in biodiesel affects fuel properties such as density and seal swell characteristics, which are crucial for engine performance and fuel system integrity. This limitation restricts the proportion of biodiesel that can be blended without compromising safety and performance. Ali et al. [4] reported that biodiesel blends resulted in reduced CO and HC emissions, likely due to the oxygen content in biodiesel promoting more complete combustion. However, there was an increase in NOx emissions, which could be attributed to higher flame temperatures. Furthermore, the absence of aromatics in biodiesel may affect the fuel’s lubricity and energy density, posing challenges for high-altitude operations where aromatics are required.

6. Future Perspectives

The aviation industry is actively exploring sustainable alternatives to conventional Jet A fuel to reduce its environmental footprint. One promising approach involves blending Jet A with biofuels, such as alcohols and biodiesel. These blends have the potential to lower greenhouse gas emissions and promote the use of renewable energy sources. This discussion delves into the future perspectives of utilizing Jet A-alcohol and Jet A-biodiesel blends in aviation turbo engines, considering technological advancements, economic factors, and environmental implications.

6.1. Technological Advancements

Recent technological developments have significantly enhanced the feasibility of producing and utilizing Jet A-biofuel blends.

6.1.1. Alcohol-To-Jet (ATJ) Technology

ATJ technology converts alcohols, such as ethanol and butanol, into jet fuel through catalytic processes. This pathway has gained traction due to its versatility in utilizing various feedstocks, including biomass and industrial waste gases. Companies like LanzaTech have pioneered the conversion of industrial emissions into ethanol, which is subsequently processed into sustainable aviation fuel (SAF). This approach not only reduces emissions but also promotes circular economy principles by repurposing waste streams. The scalability of ATJ technology is being enhanced through continuous research and development aimed at improving conversion efficiencies and reducing production costs.

6.1.2. Biodiesel Integration

Biodiesel, typically derived from vegetable oils or animal fats, can be processed into hydroprocessed esters and fatty acids (HEFA) for blending with Jet A fuel. The HEFA pathway is well-established and has been certified for aviation use. Advancements in feedstock diversification, including the use of non-food crops and waste oils, are expanding the availability of sustainable biodiesel. Additionally, improvements in processing technologies are enhancing the quality and compatibility of biodiesel with existing jet engines, ensuring that performance standards are met without necessitating significant engine modifications.

The choice of feedstock is pivotal in determining both the cost-effectiveness and sustainability of biodiesel. Common feedstocks include vegetable oils, animal fats, and waste cooking oils. Utilizing waste cooking oil not only reduces raw material expenses but also addresses waste management challenges. A study comparing biodiesel derived from used cooking oil and sunflower oil revealed that both types exhibited similar engine performance and emission profiles, underscoring the viability of waste-derived biodiesel [23].

6.2. Economic Considerations

The economic viability of Jet A-biofuel blends is influenced by production costs, market demand, and policy frameworks.

6.2.1. Production Costs and Market Dynamics

Currently, SAFs are more expensive to produce than conventional jet fuel, primarily due to feedstock costs and processing complexities. However, as technologies mature and scale, production costs are expected to decrease. Investments in large-scale facilities, such as the proposed $1.7 billion refinery in Brisbane by Wagner Corporation, aim to increase SAF supply and reduce costs through economies of scale. This facility plans to convert construction and agricultural waste into SAF, potentially reducing CO2 emissions by up to 84%. Such initiatives are crucial for meeting the growing demand for sustainable fuels in aviation. The economic viability of biodiesel production is intricately linked to feedstock costs, processing technologies, and market dynamics [24].

6.2.2. Policy and Regulatory Support

Government policies play a pivotal role in promoting the adoption of Jet A-biofuel blends. Regulatory measures, such as blending mandates and tax incentives, can stimulate market demand and encourage investment in SAF production. For instance, the European Union and the United Kingdom have implemented regulations requiring a certain percentage of SAF usage, with targets set to increase over the coming decades. These policies aim to reduce emissions from aviation and drive the transition towards more sustainable fuel options. Collaborative efforts between governments, airlines, and fuel producers are essential to establish a stable market and supply chain for SAFs.

6.3. Environmental Implications

The adoption of Jet A-biofuel blends offers several environmental benefits, alongside certain challenges.

6.3.1. Emission Reductions

Blending biofuels with Jet A can significantly reduce greenhouse gas emissions. Studies have shown that SAFs can lower lifecycle carbon emissions by up to 80% compared to conventional jet fuel. This reduction is achieved through the utilization of renewable feedstocks and the sequestration of CO2 during biomass growth. Additionally, biofuels typically contain fewer impurities, leading to reductions in particulate matter and sulfur oxide emissions, which have positive implications for air quality and public health.

6.3.2. Sustainability of Feedstocks

The sustainability of biofuel production is contingent on responsible feedstock sourcing. Utilizing waste materials and non-food crops can mitigate concerns related to land use and food security. However, large-scale biofuel production must be managed to prevent adverse environmental impacts, such as deforestation and biodiversity loss. Lifecycle assessments are essential to ensure that the environmental benefits of biofuels are not offset by negative consequences in other areas. Ongoing research into alternative feedstocks, such as algae and municipal waste, holds promise for more sustainable biofuel production pathways.

6.4. Future Outlook

The integration of Jet A with alcohols and biodiesel presents a viable pathway towards more sustainable aviation. Continued technological innovation, supported by robust policy frameworks and strategic investments, is essential to overcome current economic and logistical challenges. Collaborative efforts among stakeholders—including governments, industry players, and research institutions—will be crucial in scaling up production, reducing costs, and ensuring the environmental integrity of biofuels. Advancements in biodiesel production technologies have focused on enhancing efficiency and environmental performance. Traditional transesterification processes are being supplemented with innovative approaches. For instance, research into the synergistic combustion of alcohols and biodiesel has demonstrated improvements in combustion efficiency and emission reductions in diesel engines. Furthermore, studies assessing the compatibility of renewable motor fuels based on plant oils with conventional fuels have highlighted the importance of understanding fuel properties to ensure seamless integration and optimal engine performance [25].

As the aviation sector strives to achieve net-zero emissions by 2050, the adoption of Jet A-biofuel blends is poised to play a significant role in this transition.

7. Conclusions

- ➢

- Blending Jet A fuel with alcohols or biodiesel presents potential environmental benefits; however, significant gaps and limitations remain. Challenges such as material compatibility, energy density, hygroscopicity, emission trade-offs, and aromatic content require further investigation. Addressing these issues will necessitate the development of advanced materials, optimization of blend ratios, and the implementation of innovative combustion control strategies to ensure the viable integration of these alternative fuels into aviation.

- ➢

- The use of biodiesel as a blending agent with Jet A fuel offers both opportunities and challenges for turbojet engine performance. Lower concentrations of biodiesel can enhance specific fuel consumption and combustion efficiency, while higher concentrations may lead to thrust reduction and fuel property alterations. Continued research is crucial to refine blend ratios and develop engine technologies that can accommodate these fuels without compromising performance or safety.

- ➢

- Similarly, the integration of alcohols into Jet A fuel introduces both advantages and drawbacks. While lower concentrations may improve specific performance metrics, higher concentrations can negatively impact engine stability, fuel consumption, and material compatibility. Research efforts must focus on optimizing blending proportions and adapting engine technologies to maintain reliable and efficient operation.

- ➢

- From an environmental perspective, blending Jet A fuel with alcohols or biodiesel has shown promising results in reducing CO, HC, and particulate matter emissions, contributing to aviation sustainability. However, the increase in NOx emissions presents a significant challenge that requires further investigation into combustion optimization and emission control technologies. A comprehensive assessment of biofuels’ environmental impact should also account for their entire lifecycle, ensuring that production and usage align with broader sustainability goals.

- ➢

- Future advancements in biofuel integration will rely on interdisciplinary collaboration among researchers, industry leaders, and policymakers. Addressing technical and environmental challenges through continued innovation will be essential for achieving sustainable aviation fuel solutions without compromising engine performance and safety.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

The paper received technical support from the Romanian Research and Development Institute for Gas Turbines-COMOTI.

Conflicts of Interest

The author declares no conflicts of interests.

References

- Mendez, C.J.; Parthasarathy, R.N.; Gollahalli, S.R. Performance and Emission Characteristics of Alcohol/Jet A Blends in a Small-Scale Gas Turbine Engine. Appl. Energy 2014, 118, 135–140. [Google Scholar] [CrossRef]

- Cican, G.; Mirea, R.; Rimbu, G. Experimental Evaluation of Methanol/Jet-A Blends as Sustainable Aviation Fuels for Turbo-Engines: Performance and Environmental Impact Analysis. Fire 2024, 7, 155. [Google Scholar] [CrossRef]

- Cican, G.; Mirea, R. An Experimental Insight on the Use of N-Butanol as Sustainable Aviation Fuel. Fire 2024, 7, 313. [Google Scholar] [CrossRef]

- Ali, A.H.H.; Ibrahim, M.N. Performance and Environmental Impact of a Turbojet Engine Fueled by Blends of Biodiesels. Int. J. Environ. Sci. Technol. 2017, 14, 1253–1266. [Google Scholar] [CrossRef]

- Talero, G.; Bayona-Roa, C.; Muñoz, G.; Galindo, M.; Silva, V.; Pava, J.; Lopez, M. Experimental Methodology and Facility for the J69-Engine Performance and Emissions Evaluation Using Jet A1 and Biodiesel Blends. Energies 2019, 12, 4530. [Google Scholar] [CrossRef]

- Şen, S. The effect of using triple bio-fuel blend with Jet-A on engine performance and emissions in mini-scale turbojet engine. Energy Sources Part A Recover. Util. Environ. Eff. 2024, 45, 4616–4632. [Google Scholar] [CrossRef]

- Andoga, R.; Főző, L.; Schrötter, M.; Szabo, S. The Use of Ethanol as an Alternative Fuel for Small Turbojet Engines. Sustainability 2021, 13, 2541. [Google Scholar] [CrossRef]

- Cheng, T.C.; Jo-Han, N. Limitations to sustainable renewable jet fuels production attributed to cost than energy-water-food resource availability. Nat. Commun. 2023, 14, 8156. [Google Scholar] [CrossRef]

- Cican, G.; Mirea, R. Performance and environmental impact of ethanol-kerosene blends as sustainable aviation fuels in micro turbo-engines. Int. J. Engine Res. 2024, 25, 2204–2214. [Google Scholar] [CrossRef]

- Kumar, M.; Cheng, T.C.; Karmakar, S.W. Combustion characteristics of butanol-Jet A-1 fuel blends in a swirl-stabilized combustor under the influence of preheated swirling air. Int. J. Energy Res. 2021. [Google Scholar] [CrossRef]

- Vishwanath, R.; Carniglia, P.A.; Weber, J.K.; Gulder, O.L. Effects of n-pentanol blending on soot formation in swirl-stabilized turbulent spray flames of Jet A-1 in a laboratory gas turbine combustor. Fuel 2024, 357, 129971. [Google Scholar] [CrossRef]

- Suchocki, T.; Kazimierski, P.; Lampart, P.; Janusewicz, K. A comparative study of pentanol (C5 alcohol) and kerosene blends in terms of gas turbine engine performance and exhaust gas emission. Fuel 2023, 334, 1–13. [Google Scholar] [CrossRef]

- Mirea, R.; Cican, G. Theoretical Assessment of Different Aviation Fuel Blends based on their Physical-Chemical Properties. Eng. Technol. Appl. Sci. Res. 2024, 14, 14134–14140. [Google Scholar] [CrossRef]

- Suchocki, T. Performance and Emission Characteristics of a Small Gas Turbine Engine Using Hexanol as a Biomass-Derived Fuel. Materials 2024, 17, 6011. [Google Scholar] [CrossRef]

- Yılmaz, N.; Vigil, F.M.; Atmanli, A.; Donaldson, B. Influence of Fuel Oxygenation on Regulated Pollutants and Unregulated Aromatic Compounds with Biodiesel and n-Pentanol Blends. Int. J. Energy Res. 2023. [Google Scholar] [CrossRef]

- Battal, D.; Cakmak, A.; Yesilyurt, M.K.; Erol, D. Investigation on 1-heptanol as an oxygenated additive with diesel fuel for compression-ignition engine applications: An approach in terms of energy, exergy, exergoeconomic, enviroeconomic, and sustainability analyses. Fuel 2020, 275, 117973. [Google Scholar] [CrossRef]

- Betgeri, V.; Prakash, B.; Pischinger, S. Investigation of the drop-in capabilities of a renewable 1-Octanol based E-fuel for heavy-duty engine applications. Energy 2023, 282, 128811. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L.; Luan, P.; Wu, Y.; Cheng, Z.; Zhang, Z.; King, X.; Liu, H.; Chen, G. Effect of diesel blended with di-n-butyl ether/1-octanol on combustion and emission in a heavy-duty diesel engine. Environ. Pollut. 2022, 311, 119977. [Google Scholar] [CrossRef]

- Altarazi, Y.S.M.; Talib, A.R.A.; Gires, E.; Yu, J.; Lucas, J.; Yusaf, T. Performance and Exhaust Emissions Rate of Small-Scale Turbojet Engine Running on Dual Biodiesel Blends Using GasTurb. Energy 2021, 232, 120971. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T. Impact of a Jet A-1/HEFA blend on the performance and emission characteristics of a miniature turbojet engine. Int. J. Environ. Sci. Technol. 2018, 15, 1501–1508. [Google Scholar] [CrossRef]

- Feser, J.; Gupta, A. Performance and Emissions of Drop-In Aviation Biofuels in a Lab-Scale Turbine Combustor. J. Energy Resources Technol. 2021, 143, 042103. [Google Scholar] [CrossRef]

- Available online: https://www.nasa.gov/news-release/nasa-study-confirms-biofuels-reduce-jet-engine-pollution/ (accessed on 24 February 2025).

- Gholami, A.; Pourfayaz, F.; Saifoddin, A. Techno-economic assessment and sensitivity analysis of biodiesel production intensified through hydrodynamic cavitation. Energy Sci. Eng. 2021, 9, 1997–2018. [Google Scholar] [CrossRef]

- Available online: https://www.reuters.com/business/energy/chinas-biodiesel-producers-seek-new-outlets-hefty-eu-tariffs-bite-2024-08-16/?utm_source=chatgpt.com (accessed on 6 March 2025).

- Mizik, T.; Gyarmati, G. Economic and Sustainability of Biodiesel Production—A Systematic Literature Review. Clean Technol. 2021, 3, 19–36. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).