Characterization of South African Woody and Non-Woody Invasive Alien Plant Species for Sustainable Bio-Oil Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Structural Analysis

2.2.2. Elemental Analysis

2.2.3. Proximate Analysis

2.2.4. Van Krevelen Diagram

2.2.5. Higher Heating Value (HHV)

2.2.6. Thermogravimetric Analysis

2.2.7. Data Analysis

3. Results and Discussion

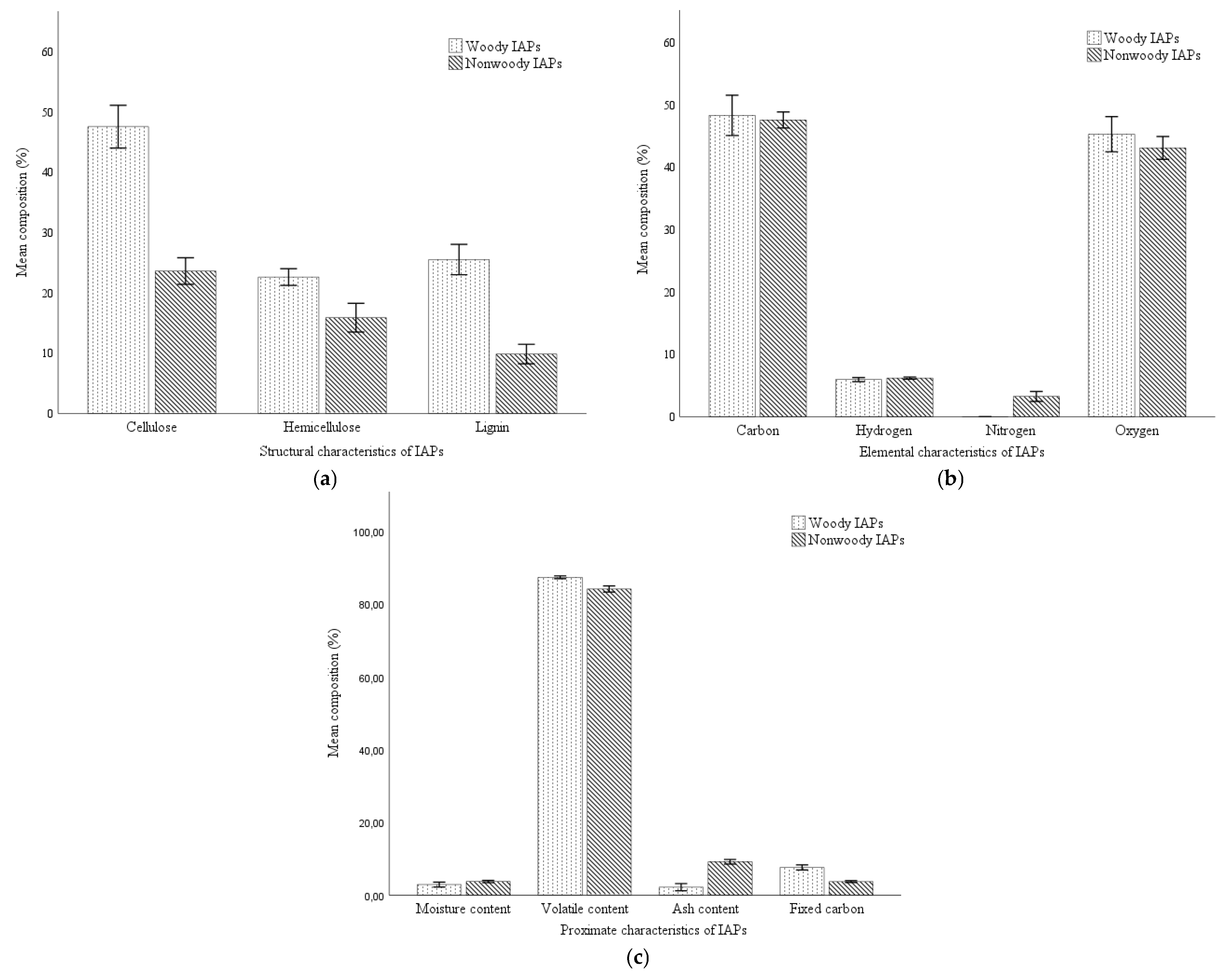

3.1. Structural Analysis

3.2. Elemental Analysis

3.3. Proximate Analysis

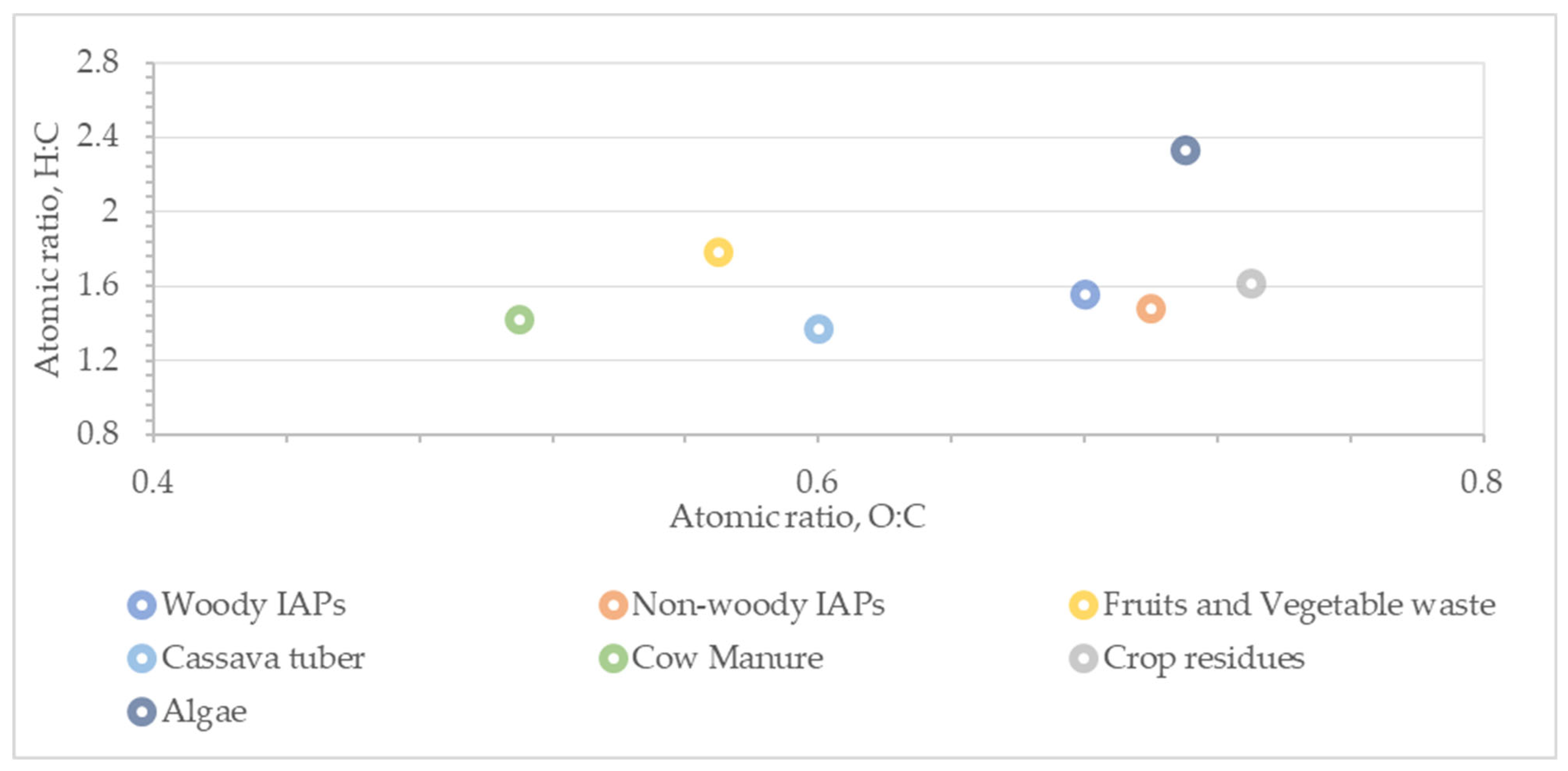

3.4. Van Krevelen Diagram

| Biomass | H:C | O:C | N:C | References |

|---|---|---|---|---|

| Woody IAPs | 1.47 | 0.70 | ND | Present study |

| Nonwoody IAPs | 1.55 | 0.68 | 0.058 | Present study |

| Scenedesmus obliquus microalgae | 2.33 | 0.71 | 0.135 | [15] |

| Sugar bagasse | 1.62 | 0.73 | 0.0027 | [52] |

| Fruit and vegetable waste | 1.78 | 0.57 | 0.047 | [58] |

| Cassava tuber | 1.33 | 0.58 | 0.028 | [58] |

3.5. Higher Heating Values

| Species | HHV from Structural Composition (MJ/kg) | HHV from Elemental Composition (MJ/kg) | HHV from Proximate Composition (MJ/kg) |

|---|---|---|---|

| Woody IAPs | |||

| A. mearnsii | 18.28 0.73 | 17.87 0.96 | 18.94 0.52 |

| E. grandis | 18.13 0.56 | 20.39 0.10 | 18.54 0.72 |

| P. patula | 18.83 0.87 | 20.20 0.13 | 18.81 0.35 |

| Nonwoody IAPs | |||

| L. camara | 17.32 0.39 | 19.45 0.18 | 16.40 0.12 |

| C. odorata | 17.24 0.48 | 18.88 0.29 | 16.71 0.29 |

| S. mauritianum | 17.04 0.44 | 19.03 1.45 | 16.19 0.31 |

| South African Coal | |||

| Coal | Higher heating value (MJ/kg) [63] | ||

| Peat | 17.4 to 22.4 | ||

| Lignite | 26.5 to 31.7 | ||

| Bituminous | 19.9 to 36.4 | ||

| Anthracite | 30.6–36.2 | ||

3.6. Thermogravimetric Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahman, M.M.; Khan, I.; Field, D.L.; Techato, K.; Alameh, K. Powering agriculture: Present status, future potential, and challenges of renewable energy applications. Renew. Energy 2022, 188, 731–749. [Google Scholar] [CrossRef]

- Cloete, K.; Pienaar, L.; Van der Merwe, M. Is persistent “loadshedding” pulling the plug on agriculture in the Western Cape, South Africa? Agrekon 2023, 62, 228–240. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Progress of the applications of bio-oil. Renew. Sustain. Energ. Rev. 2020, 134, 110124–110151. [Google Scholar] [CrossRef]

- Shrivastava, P.; Kumar, A.; Tekasakul, P.; Lam, S.S.; Palamanit, A. Comparative investigation of yield and quality of bio-oil and biochar from pyrolysis of woody and non-woody biomasses. Energies 2021, 14, 1092–1115. [Google Scholar] [CrossRef]

- Akrofi, M. An analysis of energy diversification and transition trends in Africa. Int. J. Energy Water Res. 2021, 5, 1–12. [Google Scholar] [CrossRef]

- Rial, R.C. Biofuels versus climate change: Exploring potentials and challenges in the energy transition. Renew. Sustain. Energy Rev. 2024, 196, 114369–114379. [Google Scholar] [CrossRef]

- Pyšek, P.; Hulme, P.E.; Simberloff, D.; Bacher, S.; Blackburn, T.M.; Carlton, J.T.; Dawson, W.; Essl, F.; Foxcroft, L.C.; Genovesi, P. Scientists’ warning on invasive alien species. Biol. Rev. 2020, 95, 1511–1534. [Google Scholar] [CrossRef]

- Maluleke, M.; Fraser, G.C.; Hill, M.P. Economic evaluation of chemical and biological control of four aquatic weeds in South Africa. Biocontrol Sci. Technol. 2021, 31, 896–911. [Google Scholar] [CrossRef]

- Ceriani, A.; Dalle Fratte, M.; Agosto, G.; Montagnoli, A.; Cerabolini, B.E.L. Using plant functional traits to define the biomass energy potential of invasive alien plant species. Plants 2023, 12, 3198–3210. [Google Scholar] [CrossRef]

- Mugido, W.; Blignaut, J.; Joubert, M.; De Wet, J.; Knipe, A.; Joubert, S.; Cobbing, B.; Jansen, J.; Le Maitre, D.; Van der Vyfer, M. Determining the feasibility of harvesting invasive alien plant species for energy. S. Afr. J. Sci. 2014, 110, 01–06. [Google Scholar] [CrossRef]

- Vera, I.; Goosen, N.; Batidzirai, B.; Hoefnagels, R.; van der Hilst, F. Bioenergy potential from invasive alien plants: Environmental and socio-economic impacts in Eastern Cape, South Africa. Biomass Bioenergy 2022, 158, 106340–106353. [Google Scholar] [CrossRef]

- Melane, M.; Ham, C.; Meincken, M. Characteristics of selected non-woody invasive alien plants in South Africa and an evaluation of their potential for electricity generation. J. Energy S. Afr. 2017, 28, 92–98. [Google Scholar] [CrossRef]

- Inayat, A.; Ahmed, A.; Tariq, R.; Waris, A.; Jamil, F.; Ahmed, S.F.; Ghenai, C.; Park, Y.-K. Techno-economical evaluation of bio-oil production via biomass fast pyrolysis process: A review. Front. Energy Res. 2022, 9, 770355–770364. [Google Scholar] [CrossRef]

- Sekar, M.; Mathimani, T.; Alagumalai, A.; Chi, N.T.L.; Duc, P.A.; Bhatia, S.K.; Brindhadevi, K.; Pugazhendhi, A. A review on the pyrolysis of algal biomass for biochar and bio-oil–Bottlenecks and scope. Fuel 2021, 283, 119190–119197. [Google Scholar] [CrossRef]

- Mustapha, S.I.; Mohammed, U.A.; Rawat, I.; Bux, F.; Isa, Y.M. Production of high-quality pyrolytic bio-oils from nutrient-stressed Scenedesmus obliquus microalgae. Fuel 2023, 332, 126299–126310. [Google Scholar] [CrossRef]

- Pagano, M.; Hernando, H.; Cueto, J.; Cruz, P.L.; Dufour, J.; Moreno, I.; Serrano, D.P. Insights on the acetic acid pretreatment of wheat straw: Changes induced in the biomass properties and benefits for the bio-oil production by pyrolysis. Chem. Eng. J. 2023, 454, 140206–140220. [Google Scholar] [CrossRef]

- Cichy, W.; Witczak, M.; Walkowiak, M. Fuel properties of woody biomass from pruning operations in fruit orchards. BioResources 2017, 12, 6458–6470. [Google Scholar] [CrossRef]

- Eke, J.; Onwudili, J.A.; Bridgwater, A.V. Influence of moisture contents on the fast pyrolysis of trommel fines in a bubbling fluidized bed reactor. Waste Biomass Valorization 2020, 11, 3711–3722. [Google Scholar] [CrossRef]

- Singh, Y.D.; Mahanta, P.; Bora, U. Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renew. Energy 2017, 103, 490–500. [Google Scholar] [CrossRef]

- Khudyakova, K.K.; Kosolapova, V. Determining the structural carbohydrates and lignin levels in forage using the van soest and kizel methods. Russ. Agric. Sci. 2022, 48, 400–404. [Google Scholar] [CrossRef]

- Sahoo, A.; Kumar, S.; Kumar, J.; Bhaskar, T. A detailed assessment of pyrolysis kinetics of invasive lignocellulosic biomasses (Prosopis juliflora and Lantana camara) by thermogravimetric analysis. Bioresour. Technol. 2021, 319, 124060–124074. [Google Scholar] [CrossRef] [PubMed]

- Tajfar, I.; Pazoki, M.; Pazoki, A.; Nejatian, N.; Amiri, M. Analysis of heating value of hydro-char produced by hydrothermal carbonization of cigarette butts. Pollution 2023, 9, 1273–1280. [Google Scholar]

- Mishra, R.K.; Mohanty, K. Characterization of non-edible lignocellulosic biomass in terms of their candidacy towards alternative renewable fuels. Biomass Convers. Biorefinery 2018, 8, 799–812. [Google Scholar] [CrossRef]

- Da Silva Ignacio, L.H.; de Almeida Santos, P.E.; Duarte, C.A.R. An experimental assessment of Eucalyptus urosemente energy potential for biomass production in Brazil. Renew. Sustain. Energy Rev. 2019, 103, 361–369. [Google Scholar] [CrossRef]

- Fajobi, M.; Lasode, O.; Adeleke, A.; Ikubanni, P.; Balogun, A. Investigation of physicochemical characteristics of selected lignocellulose biomass. Sci. Rep. 2022, 12, 2918–2922. [Google Scholar] [CrossRef]

- Vargas-Moreno, J.; Callejón-Ferre, A.; Pérez-Alonso, J.; Velázquez-Martí, B. A review of the mathematical models for predicting the heating value of biomass materials. Renew. Sustain. Energy Rev. 2012, 16, 3065–3083. [Google Scholar] [CrossRef]

- Álvarez, A.; Pizarro, C.; García, R.; Bueno, J.L. Spanish biofuels heating value estimation based on structural analysis. Ind. Crop Prod. 2015, 77, 983–991. [Google Scholar] [CrossRef]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Acar, Ş.; Ayanoğlu, A. Determination of higher heating values (HHVs) of biomass fuels. Educ. Sci. Technol. A 2012, 28, 749–758. [Google Scholar]

- Jenkins, B.M.; Ebeling, J.M. Correlation of physical and chemical properties of terrestrial biomass with conversion. Biomass Bioenergy 1985, 125, 317–403. [Google Scholar]

- Annamalai, K.; Sweeten, J.; Ramalingam, S. Technical Notes: Estimation of gross heating values of biomass fuels. Trans. ASAE 1987, 30, 1205–1208. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Jiménez, L.; González, F. Study of the physical and chemical properties of lignocellulosic residues with a view to the production of fuels. Fuel 1991, 70, 947–950. [Google Scholar] [CrossRef]

- Egbosiuba, T.C. Biochar and bio-oil fuel properties from nickel nanoparticles assisted pyrolysis of cassava peel. Heliyon 2022, 8, 227–240. [Google Scholar] [CrossRef]

- Teh, J.S.; Teoh, Y.H.; How, H.G.; Sher, F. Thermal analysis technologies for biomass feedstocks: A state-of-the-art review. Processes 2021, 9, 1610–1646. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, C.; Wang, G.; Li, Y.; Zhang, X.; Cui, Y.; Hu, Z.; Shen, S.; Xu, X.; Cao, Y. Variation pattern in the macromolecular (cellulose, hemicelluloses, lignin) composition of cell walls in Pinus tabulaeformis tree trunks at different ages as revealed using multiple techniques. Int. J. Biol. Macromol. 2024, 268, 131619–131630. [Google Scholar] [CrossRef]

- Schädel, C.; Blöchl, A.; Richter, A.; Hoch, G. Quantification and monosaccharide composition of hemicelluloses from different plant functional types. Plant Physiol. Biochem. 2010, 48, 1–8. [Google Scholar] [CrossRef]

- Tan, H.; Lee, C.; Ong, P.; Wong, K.; Bong, C.; Li, C.; Gao, Y. A review on the comparison between slow pyrolysis and fast pyrolysis on the quality of lignocellulosic and lignin-based biochar. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 12075–12084. [Google Scholar] [CrossRef]

- Das, S.K.; Ghosh, G.K.; Avasthe, R. Application of biochar in agriculture and environment, and its safety issues. Biomass Convers. Biorefinery 2020, 1051, 1359–1369. [Google Scholar] [CrossRef]

- Ayaa, F.; Lubwama, M.; Kirabira, J.B.; Jiang, X. Potential of invasive shrubs for energy applications in Uganda. Energy Ecol. Environ. 2022, 7, 563–576. [Google Scholar] [CrossRef]

- Yang, K.; Wu, K.; Zhang, H. Machine learning prediction of the yield and oxygen content of bio-oil via biomass characteristics and pyrolysis conditions. Energy 2022, 254, 124320–124329. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; Martins-Vieira, J.C.; Missau, J.; Anshu, K.; Siakpebru, O.K.; Thengane, S.K.; Morais, A.R.C.; Tanabe, E.H.; Bertuol, D.A. Review on biomass pyrolysis with a focus on bio-oil upgrading techniques. Analytica 2023, 4, 182–205. [Google Scholar] [CrossRef]

- Abd-Elnabi, A.D.; El-sawy, E.A.F.; El-Adawy, E.M. Insecticidal effects of the fast pyrolysis bio-oil against Spodoptera littoralis and Aphis gossypii insect pests. J. Asia-Pac. Entomol. 2024, 27, 1226–8615. [Google Scholar] [CrossRef]

- Darvell, L.I.; Brindley, C.; Baxter, X.C.; Jones, J.M.; Williams, A. Nitrogen in biomass char and its fate during combustion: A model compound approach. Energy Fuels 2012, 26, 6482–6491. [Google Scholar] [CrossRef]

- Fakayode, O.A.; Wahia, H.; Zhang, L.; Zhou, C.; Ma, H. State-of-the-art co-pyrolysis of lignocellulosic and macroalgae biomass feedstocks for improved bio-oil production—A review. Fuel 2023, 332, 126071–126085. [Google Scholar] [CrossRef]

- Asadullah, M.; Rahman, M.A.; Ali, M.M.; Rahman, M.; Motin, M.; Sultan, M.; Alam, M. Production of bio-oil from fixed bed pyrolysis of bagasse. Fuel 2007, 86, 2514–2520. [Google Scholar] [CrossRef]

- Reza, M.S.; Ahmed, A.; Caesarendra, W.; Abu Bakar, M.S.; Shams, S.; Saidur, R.; Aslfattahi, N.; Azad, A.K. Acacia holosericea: An invasive species for bio-char, bio-oil, and biogas production. Bioengineering 2019, 6, 33–49. [Google Scholar] [CrossRef]

- Bhavsar, P.; Jagadale, M.; Khandetod, Y.; Mohod, A. Proximate analysis of selected non woody biomass. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 2846–2849. [Google Scholar] [CrossRef]

- Bakker, R.R.; Elbersen, H.W. Managing ash content and quality in herbaceous biomass: An analysis from plant to product. In Proceedings of the 14th European Biomass Conference, Wageningen, The Netherlands, 17 October 2005; Volume 6700, pp. 210–213. [Google Scholar]

- Puri, L.; Hu, Y.; Naterer, G. Critical review of the role of ash content and composition in biomass pyrolysis. Front. Fuels 2024, 2, 1378361–1378380. [Google Scholar] [CrossRef]

- Gollakota, A.R.; Shu, C.-M.; Sarangi, P.K.; Shadangi, K.P.; Rakshit, S.; Kennedy, J.F.; Gupta, V.K.; Sharma, M. Catalytic hydrodeoxygenation of bio-oil and model compounds-Choice of catalysts, and mechanisms. Renew. Sustain. Energy Rev. 2023, 187, 113700–113727. [Google Scholar] [CrossRef]

- Onokwai, A.O.; Okokpujie, I.P.; Ajisegiri, E.S.; Nnodim, C.T.; Kayode, J.F.; Tartibu, L.K. Application of response surface methodology for the modelling and optimisation of bio-oil yield via intermediate pyrolysis process of sugarcane bagasse. Adv. Mater. Process Technol. 2024, 10, 3028–3046. [Google Scholar] [CrossRef]

- Park, Y.-K.; Ha, J.-M.; Oh, S.; Lee, J. Bio-oil upgrading through hydrogen transfer reactions in supercritical solvents. Chem. Eng. J. 2021, 404, 126527–126539. [Google Scholar] [CrossRef]

- Silvestre, W.P.; Pauletti, G.F.; Baldasso, C. Fodder radish (Raphanus sativus L.) seed cake as a feedstock for pyrolysis. Ind. Crop Prod. 2020, 154, 112689–112695. [Google Scholar] [CrossRef]

- Xu, K.; Li, J.; Zeng, K.; Zhong, D.; Peng, J.; Qiu, Y.; Flamant, G.; Yang, H.; Chen, H. The characteristics and evolution of nitrogen in bio-oil from microalgae pyrolysis in molten salt. Fuel 2023, 331, 125903–125915. [Google Scholar] [CrossRef]

- Zhong, D.; Zeng, K.; Li, J.; Qiu, Y.; Flamant, G.; Nzihou, A.; Vladimirovich, V.S.; Yang, H.; Chen, H. Characteristics and evolution of heavy components in bio-oil from the pyrolysis of cellulose, hemicellulose and lignin. Renew. Sustain. Energy Rev. 2022, 157, 111989–120006. [Google Scholar] [CrossRef]

- Yu, Y.; Chua, Y.W.; Wu, H. Characterization of pyrolytic sugars in bio-oil produced from biomass fast pyrolysis. Energy Fuel 2016, 30, 4145–4149. [Google Scholar] [CrossRef]

- Sawyerr, N.; Trois, C.; Workneh, T.; Okudoh, V.I. An overview of biogas production: Fundamentals, applications and future research. Int. J. Energy Econ. Policy 2019, 20, 4145–4149. [Google Scholar]

- Krička, T.; Matin, A.; Bilandžija, N.; Jurišić, V.; Antonović, A.; Voćal, N.; Grubor, M. Biomass valorisation of Arundo donax L., Miscanthus× giganteus and Sida hermaphrodita for biofuel production. Int. Agrophys. 2017, 31, 575–581. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Lu, J.; Yang, M.; Wu, Y. Improved bio-oil quality from pyrolysis of pine biomass in pressurized hydrogen. Appl. Sci. 2021, 12, 46–58. [Google Scholar] [CrossRef]

- Kutlu, O.; Kocar, G. Upgrading lignocellulosic waste to fuel by torrefaction: Characterisation and process optimization by response surface methodology. Int. J. Energy Res. 2018, 42, 4746–4760. [Google Scholar] [CrossRef]

- Makgato, S.S.; Chirwa, E.M.N. Waterberg coal characteristics and SO2 minimum emissions standards in South African power plants. J. Environ. Manag. 2017, 201, 294–302. [Google Scholar] [CrossRef] [PubMed]

- Gouws, S.M.; Carrier, M.; Bunt, J.R.; Neomagus, H.W. Co-pyrolysis of coal and raw/torrefied biomass: A review on chemistry, kinetics and implementation. Renew. Sustain. Energy Rev. 2021, 135, 110189–110213. [Google Scholar] [CrossRef]

- Argyropoulos, D.S.; Menachem, S.B. 64. Lignin, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 1997; pp. 127–158. [Google Scholar]

- Shafiq, M.; Capareda, S.C. Effect of different temperatures on the properties of pyrolysis products of Parthenium hysterophorus. J. Saudi Chem. Soc. 2021, 25, 101197–101210. [Google Scholar]

| HHV Formula | Author | R2 | Biomass | Accuracy |

|---|---|---|---|---|

| HHV from structural composition | ||||

| [27] | - | 1.13% | ||

| [28] | 0.95 | Wood/nonwood | 0.056% | |

| [29] | 0.93 | Wood/nonwood | - | |

| HHV from elemental composition | ||||

| [30] | 0.792 | Biomass | 1.78 | |

| [31] | 0.720 | Biomass | −0.59% | |

| [32] | 0.834 | Biomass | 0.07% | |

| HHV from proximate composition | ||||

| [32] | 0.617 | Biomass | 0.26 | |

| [30] | - | Biomass | - | |

| [33] | 1.16 | Biomass | 0.533 | |

| Sample Name | Woody IAPs | Nonwoody IAPs | ||||

|---|---|---|---|---|---|---|

| A. Mearnsii | E. Grandis | P. Patula | L. Camara | C. Odorata | S. Mauritianum | |

| Structural analysis | ||||||

| (%) | ||||||

| Cellulose | 43.73 ± 1.10 | 53.54 ± 0.11 | 45.27 ± 0.26 | 26.65 ± 0.08 | 24.07 ± 0.07 | 20.08 ± 0.17 |

| Hemicellulose | 23.67 ± 0.70 | 20.26 ± 0.26 | 23.88 ± 0.12 | 19.28 ± 0.02 | 16.18 ± 0.03 | 12.16 ± 0.15 |

| Lignin | 22.83 ± 0.15 | 23.86 ± 0.18 | 29.82 ± 0.12 | 12.23 ± 0.03 | 9.92 ± 0.07 | 7.39 ± 0.26 |

| Elemental analysis | ||||||

| (%) | ||||||

| Carbon | 44.58 ± 3.01 | 50.83 ± 3.06 | 50.52 ± 1.29 | 48.09 ± 1.08 | 46.11 ± 0.50 | 48.51 ± 2.20 |

| Hydrogen | 5.63 ± 0.25 | 6.08 ± 0.56 | 6.11 ± 0.37 | 6.08 ± 0.25 | 6.18 ± 0.21 | 6.29 ± 0.25 |

| Nitrogen | ND | ND | ND | 2.32 ± 0.10 | 2.86 ± 0.18 | 4.54 ± 0.50 |

| Oxygen | 48.79 ± 3.53 | 43.09 ± 3.57 | 43.98 ± 0.63 | 43.50 ± 1.26 | 45.13 ± 0.50 | 40.65 ± 2.30 |

| Sulfur | ND | ND | ND | ND | ND | ND |

| Proximate analysis | ||||||

| (%) | ||||||

| Moisture content | 3.90 ± 0.09 | 1.89 ± 0.13 | 2.89 ± 0.12 | 4.24 ± 0.03 | 3.34 ± 0.59 | 3.61 ± 0.15 |

| Volatile content | 87.15 ± 0.21 | 87.90 ± 0.06 | 86.82 ± 0.15 | 84.03 ± 0.09 | 85.34 ± 0.45 | 82.89 ± 0.29 |

| Ash content | 0.94 ± 0.07 | 3.79 ± 0.001 | 1.80 ± 0001 | 8.14 ± 0.03 | 9.63 ± 0.34 | 9.63 ± 0.46 |

| Fixed carbon | 7.92 ± 0.08 | 6.42 ± 0.03 | 8.45 ± 0.09 | 3.36 ± 0.06 | 3.91 ± 0.38 | 3.87 ± 0.38 |

| Dehydration | Active Pyrolysis | Passive Pyrolysis | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Woody IAPs | |||||||||

| Sample | |||||||||

| E. grandis | 2.5 | 33 | 147 | 77.6 | 147 | 468 | 279 | 468 | 600 |

| A. mearnsii | 1.6 | 33 | 205 | 98.1 | 205 | 470 | 305 | 470 | 600 |

| P. patula | 3.4 | 34 | 155 | 75.5 | 155 | 446 | 286 | 446 | 600 |

| Nonwoody IAPs | |||||||||

| Sample | |||||||||

| L. camara | 5.1 | 35 | 176 | 58.5 | 176 | 476 | 315 | 476 | 600 |

| C. odorata | 6.2 | 33 | 177 | 59.5 | 177 | 474 | 308 | 474 | 600 |

| S. mauritianum | 5.3 | 33 | 180 | 59 | 180 | 480 | 326 | 480 | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mtshali, B.; Kassim, A.; Sibanda, S.; Workneh, T. Characterization of South African Woody and Non-Woody Invasive Alien Plant Species for Sustainable Bio-Oil Production. Energies 2025, 18, 1919. https://doi.org/10.3390/en18081919

Mtshali B, Kassim A, Sibanda S, Workneh T. Characterization of South African Woody and Non-Woody Invasive Alien Plant Species for Sustainable Bio-Oil Production. Energies. 2025; 18(8):1919. https://doi.org/10.3390/en18081919

Chicago/Turabian StyleMtshali, Bongiwe, Alaika Kassim, Sipho Sibanda, and Tilahun Workneh. 2025. "Characterization of South African Woody and Non-Woody Invasive Alien Plant Species for Sustainable Bio-Oil Production" Energies 18, no. 8: 1919. https://doi.org/10.3390/en18081919

APA StyleMtshali, B., Kassim, A., Sibanda, S., & Workneh, T. (2025). Characterization of South African Woody and Non-Woody Invasive Alien Plant Species for Sustainable Bio-Oil Production. Energies, 18(8), 1919. https://doi.org/10.3390/en18081919