Economic Analysis of Biofuel Production in Agrophotovoltaic Systems Using Building-Integrated Photovoltaics in South Korea

Abstract

1. Introduction

2. Materials and Methods

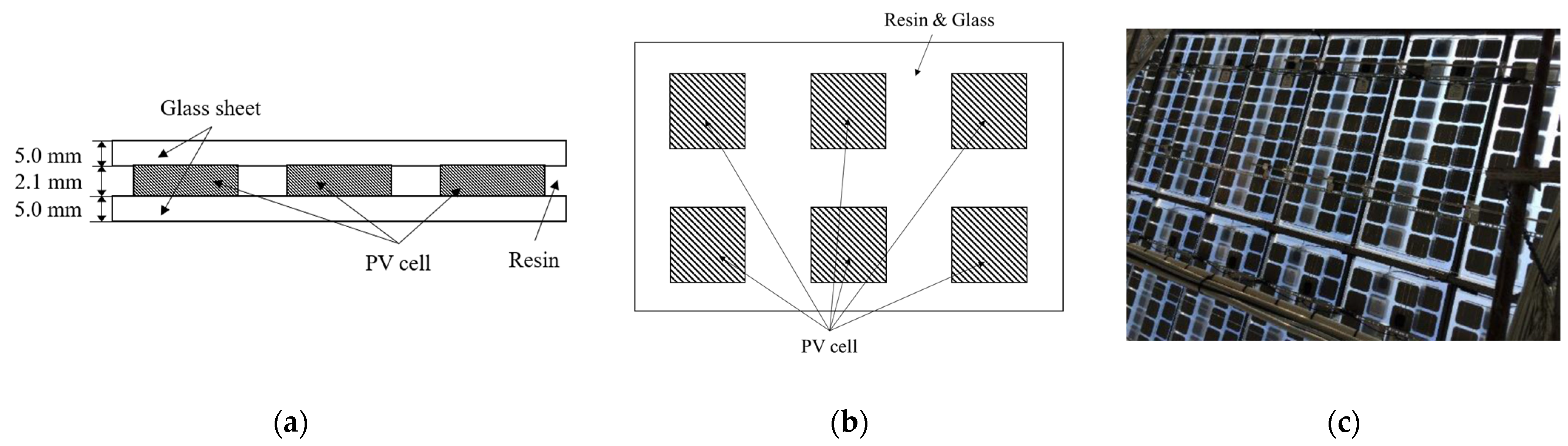

2.1. Use of Building-Integrated Photovoltaics in South Korea

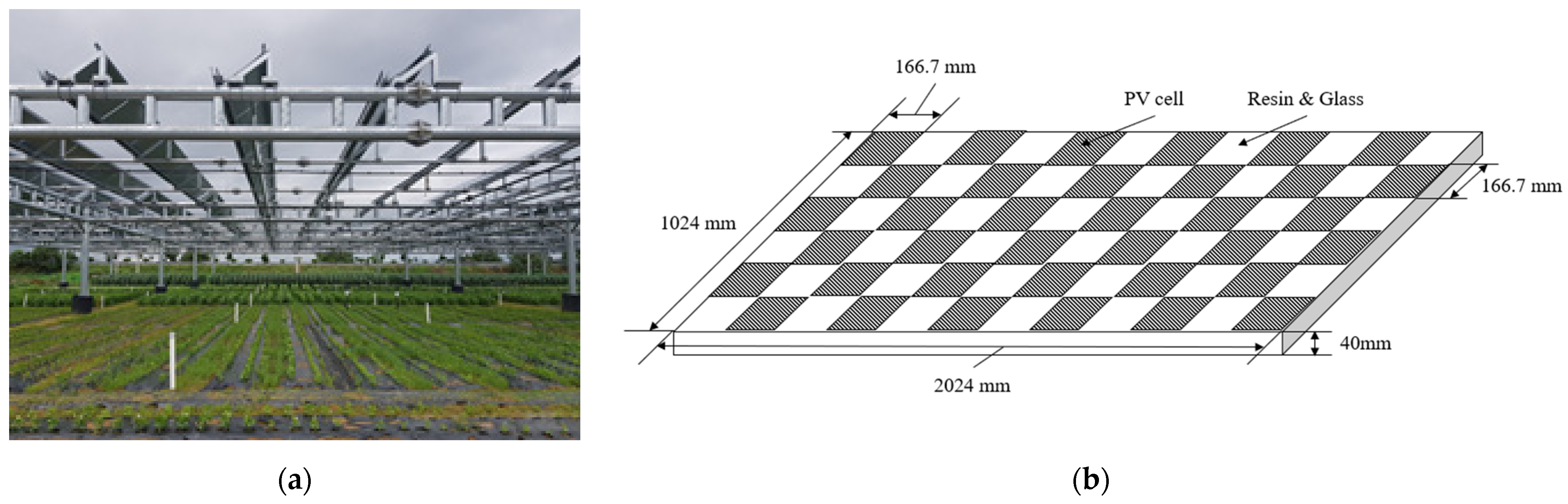

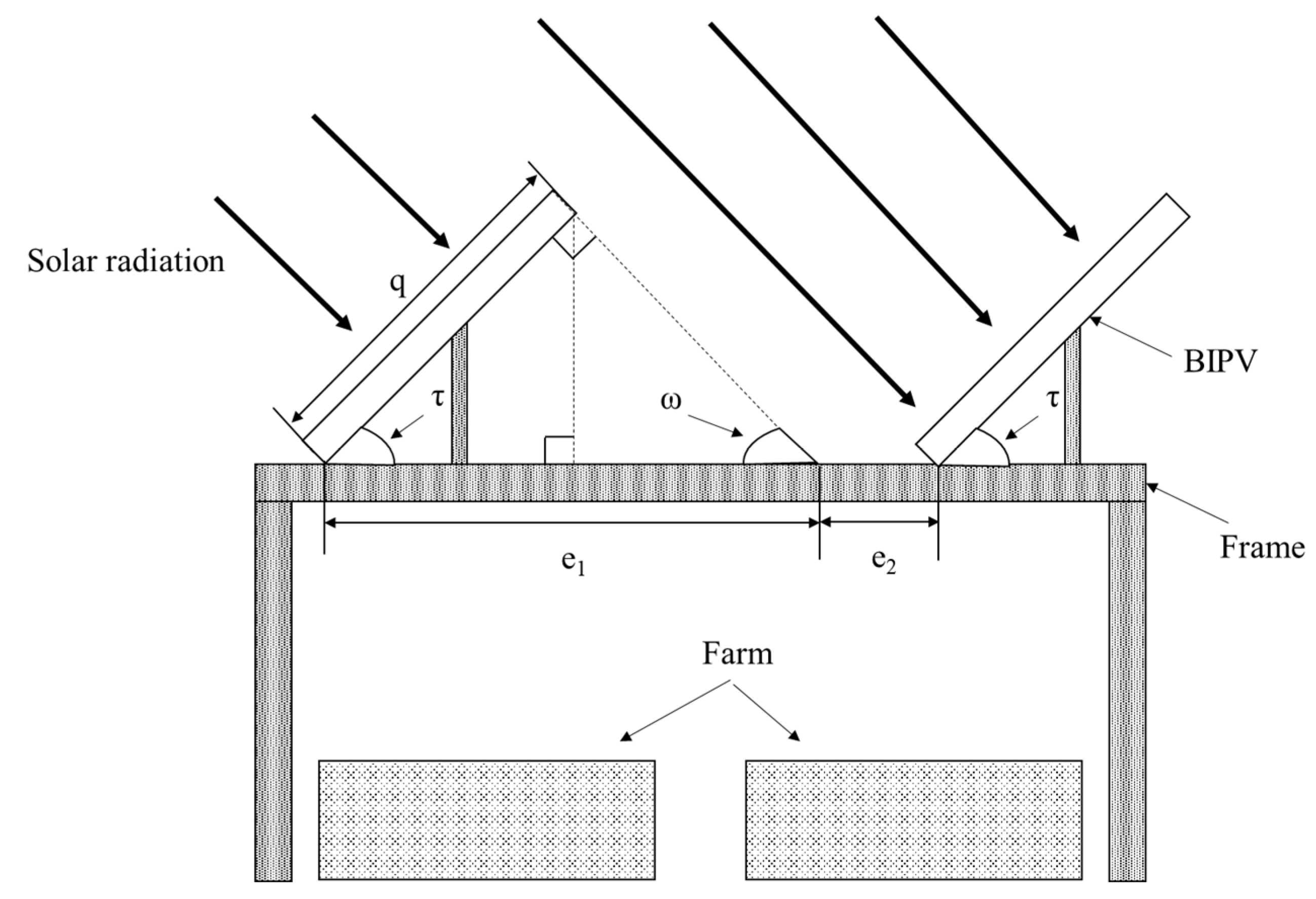

2.2. Agrophotovoltaic Systems with Building-Integrated Photovoltaics (APV–BIPV Systems)

2.3. Biofuel Production in APV–BIPV Systems

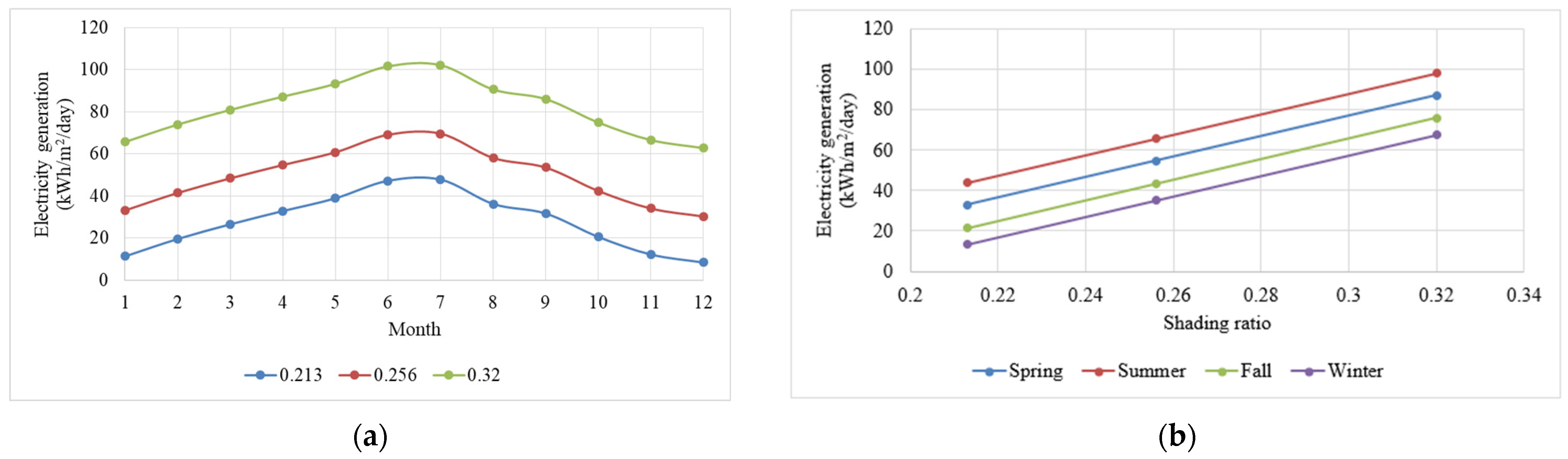

2.4. Electricity Generation in APV–BIPV Systems

2.5. Performance Metric

3. Results

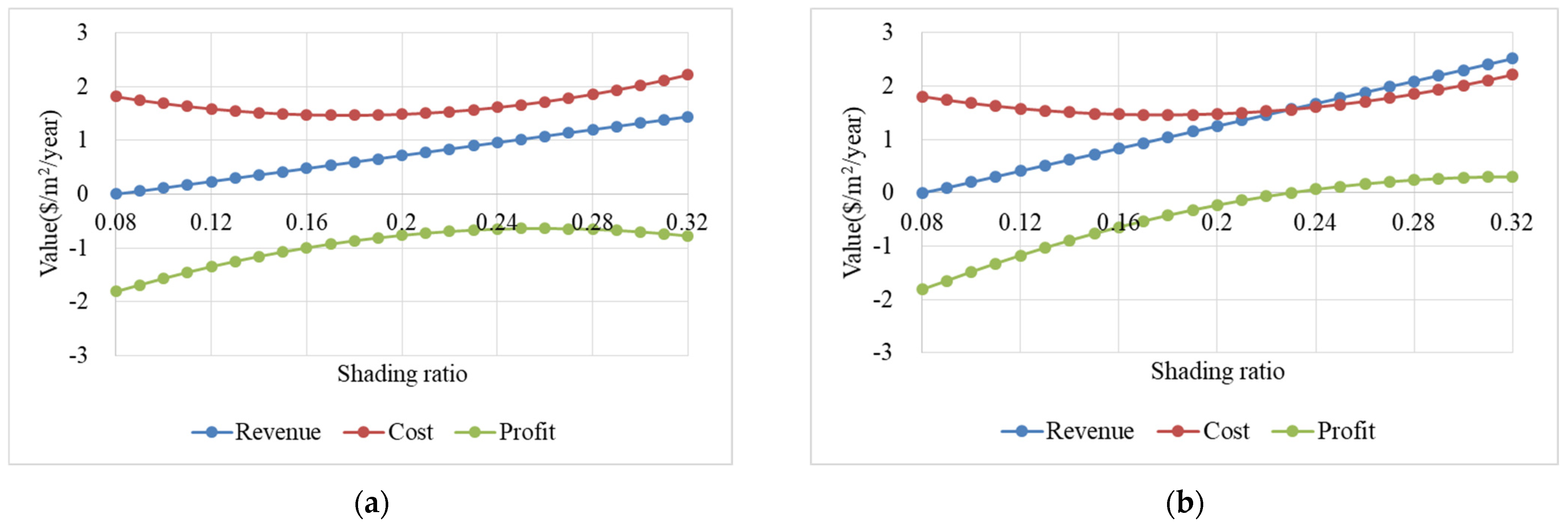

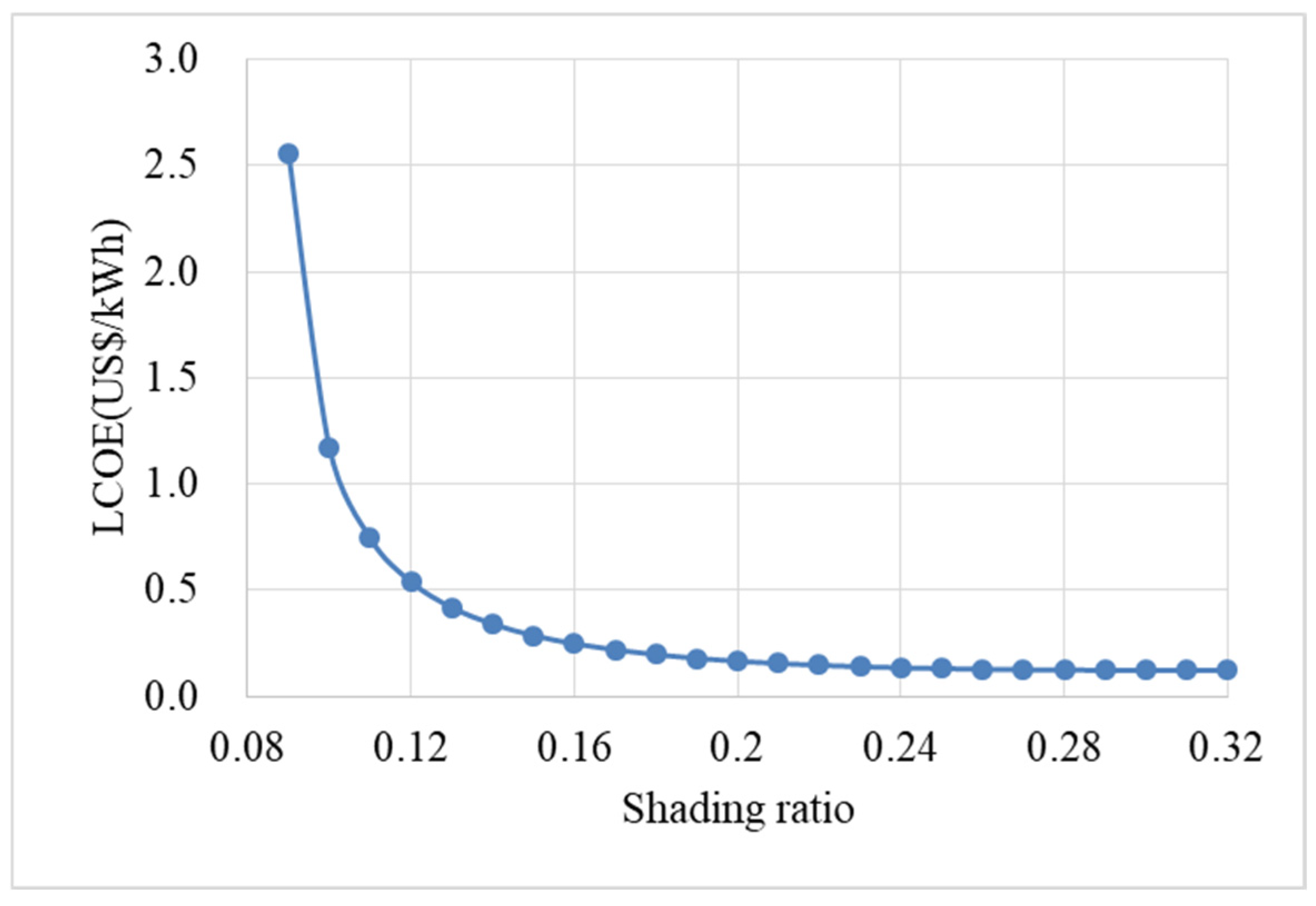

3.1. Feasibility Analysis on APV–BIPV Systems

3.2. Feasibility Analysis on Biofuel Production in APV–BIPV Systems

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Information | Value |

|---|---|

| Cell Configuration | 72 Cells |

| Module Dimensions | |

| Weight | 20.3 kg |

| Operating Temperature | −40~90 °C |

| Maximum Power | 405 W |

| MPP Voltage | 41.0 V |

| MPP Current | 9.89 A |

| Module Efficiency | 19.5% |

References

- Kim, Y.; Kim, S.; Kim, S. An integrated agent-based simulation modeling framework for sustainable production of an Agrophotovoltaic system. J. Clean. Prod. 2023, 420, 138307. [Google Scholar] [CrossRef]

- IEA. Renwables 2023. International Energy Agency. 2023. Available online: https://www.iea.org/reports/renewables-2023/electricity (accessed on 8 April 2025).

- Erofeev, Y. Over 340 GW of Solar Power Plants Are to Be Installed This Year. Medium. 2023. Available online: https://medium.com/@erofeev.yury/over-340-gw-of-solar-power-plants-are-to-be-installed-this-year-3fda86bb2f44 (accessed on 8 April 2025).

- Bernreuter Research. Polysilicon Market Reports. 2024. Available online: https://www.bernreuter.com/polysilicon/price-trend/ (accessed on 8 April 2025).

- Kang, J.H. 2023 Semi-Annual Report. Export-Import Bank of Korea. 2023. Available online: https://www.ctis.re.kr/ko/downloadBbsFile.do?atchmnflNo=9673 (accessed on 8 April 2025).

- Sartori, I.; Napolitano, A.; Voss, K. Net zero energy buildings: A consistent definition framework. Energy Build. 2012, 48, 220–232. [Google Scholar] [CrossRef]

- Kim, S.; Aydin, B.; Kim, S. Simulation modeling of a photovoltaic-green roof system for energy cost reduction of a building: Texas case study. Energies 2021, 14, 5443. [Google Scholar] [CrossRef]

- Costa, A.; Keane, M.M.; Torrens, J.I.; Corry, E. Building operation and energy performance: Monitoring, analysis and optimisation toolkit. Appl. Energy 2013, 101, 310–316. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Economic Feasibility Comparison between Building-Integrated Photovoltaics and Green Systems in Northeast Texas. Energies 2023, 16, 4672. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Kapsis, K.; Wilson, H.R.; Delisle, V.; Yang, R.; Olivieri, L.; Polo, J.; Eisenlohr, J.; Roy, B.; Maturi, L.; et al. Building-Integrated Photovoltaic (BIPV) products and systems: A review of energy-related behavior. Energy Build. 2022, 262, 111998. [Google Scholar] [CrossRef]

- IEC 63092-1; Photovoltaics in Buildings—Part 1: Requirements for Building-Integrated Photovoltaic Modules. International Electrotechnical Commission: Geneva, Switzerland, 2020.

- Bonomo, P.; Eder, G.; Martín Chivelet, N.; Eisenlohr, J.; Frontini, F.; Kapsis, C.; Scognamiglio, A.; Wilson, H.R.; Yang, R. Categorization of BIPV Applications. 2021. Available online: https://iea-pvps.org/key-topics/categorization-of-bipv-applications/ (accessed on 24 May 2024).

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent advancement in BIPV product technologies: A review. Energy Build. 2017, 140, 188–195. [Google Scholar] [CrossRef]

- Eder, G.; Peharz, G.; Trattnig, R.; Bonomo, P.; Saretta, E.; Frontini, F.; López, C.S.P.; Wilson, H.R.; Eisenlohr, J.; Chivelet, N.M.; et al. Coloured Bipv: Market, Research and Development. International Energy Agency. 2019. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/IEA-PVPS_15_R07_Coloured_BIPV_report.pdf (accessed on 8 April 2025).

- Kim, S.; Kim, S.; Yoon, C.Y. An efficient structure of an agrophotovoltaic system in a temperate climate region. Agronomy 2021, 11, 1584. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Agricultural Research and Development Center Design with Building Integrated Photovoltaics in Fiji. Energies 2023, 17, 207. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Design of an Agrivoltaic System with Building Integrated Photovoltaic. Agronomy 2023, 13, 2140. [Google Scholar] [CrossRef]

- Romaní, J.; Ramos, A.; Salom, J. Review of transparent and semi-transparent building-integrated photovoltaics for fenestration application modeling in building simulations. Energies 2022, 15, 3286. [Google Scholar] [CrossRef]

- Colantoni, A.; Monarca, D.; Marucci, A.; Cecchini, M.; Zambon, I.; Di Battista, F.; Maccario, D.; Saporito, M.G.; Beruto, M. Solar radiation distribution inside a greenhouse prototypal with photovoltaic mobile plant and effects on flower growth. Sustainability 2018, 10, 855. [Google Scholar] [CrossRef]

- Kılkış, Ş. Benchmarking the sustainability of urban energy, water and environment systems and envisioning a cross-sectoral scenario for the future. Renew. Sustain. Energy Rev. 2023, 103, 529–545. [Google Scholar]

- Shim, H.; Lee, S. A Study on the Performance Increase in Building Energy Technology according to the Korea’s Zero Energy Building Policy. J. Korea Acad.-Ind. Coop. Soc. 2021, 22, 543–553. [Google Scholar]

- Li, L.; Dai, C. Internal and External Factors Influencing Rural Households’ Investment Intentions in Building Photovoltaic Integration Projects. Energies 2024, 17, 1071. [Google Scholar] [CrossRef]

- NEA. Notice on the Announcement of the Pilot List of Distributed Rooftop Photovoltaic Development in Whole Counties (Cities and Districts); NEA: Beijing, China, 2021. [Google Scholar]

- South Korean Ministry of Trade, Industry and Energy. Renewable Energy Supply Project (Building Support). 2010. Available online: https://www.aurum.re.kr/Policy/PolicyOffice.aspx?pcode=H06 (accessed on 24 May 2024).

- HS Solar Energy. BIPV/BAPV Solar Panel. Available online: https://www.solar-onestop.com/ (accessed on 24 May 2024).

- IAAN. Construction Case of Photovoltaics Sunroom. Available online: http://iaansunroom.com/index.php/sunroom_construction_case/?mod=document&uid=826 (accessed on 24 May 2024).

- Azhar, M.H.A.; Alhammadi, S.; Jang, S.; Kim, J.; Kim, J.; Kim, W.K. Long-Term Field Observation of the Power Generation and System Temperature of a Roof-Integrated Photovoltaic System in South Korea. Sustainability 2023, 15, 9493. [Google Scholar] [CrossRef]

- Kanagawa, M.; Nakata, T. Assessment of access to electricity and the socio-economic impacts in rural areas of developing countries. Energy Policy 2008, 36, 2016–2029. [Google Scholar]

- Lee, J.; Shepley, M.M. Benefits of solar photovoltaic systems for low-income families in social housing of Korea: Renewable energy applications as solutions to energy poverty. J. Build. Eng. 2020, 28, 101016. [Google Scholar]

- On, Y.; Kim, S.; Kim, S. Multi-Objective optimization for design of an Agrophotovoltaic system under Non-Dominated sorting Genetic algorithm II. Comput. Electron. Agric. 2024, 224, 109237. [Google Scholar]

- Bipvkorea. GIPV. Available online: https://bipvkorea.com/home/sub.php?menukey=466 (accessed on 24 May 2024).

- Lu, S.M.; Zainali, S.; Stridh, B.; Avelin, A.; Amaducci, S.; Colauzzi, M.; Campana, P.E. Photosynthetically active radiation decomposition models for agrivoltaic systems applications. Sol. Energy 2022, 244, 536–549. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Rising Corn Prices and Oversupply Push Ethanol Operating Margins to Multiyear Lows. Available online: https://www.eia.gov/todayinenergy/detail.php?id=40813# (accessed on 16 December 2024).

- Korea Meteorological Administration. Automated Synoptic Observing System (ASOS) Data. Available online: https://data.kma.go.kr/data/grnd/selectAsosRltmList.do?pgmNo=36 (accessed on 24 May 2024).

- WEUP Power Co., Ltd. Products. Available online: https://www.weuppower.com/ (accessed on 16 February 2025).

- Walker, A.; Lockhart, E.; Desai, J.; Ardani, K.; Klise, G.; Lavrova, O.; Tansy, T.; Deot, J.; Fox, B.; Pochiraju, A. Model of Operation-and-Maintenance Costs for Photovoltaic Systems; Technical Report No. NREL/TP-5C00-74840; National Renewable Energy Laboratory: Golden, CO, USA, 2020. [Google Scholar]

- Korea Power Exchange. Today Power Information. Available online: https://www.kpx.or.kr/ (accessed on 16 February 2025).

- Korea Agro-Fisheries & Food Trade Corporation. Price Information. Available online: https://www.kamis.or.kr/customer/main/main.do (accessed on 16 February 2025).

- City of Seoul. Energy Information. Available online: https://energyinfo.seoul.go.kr/main/main (accessed on 25 May 2024).

- PVTech. Solar LCOE Continues to Decrease Globally–Wood Mackenzie. Available online: https://www.pv-tech.org/solar-lcoe-continues-to-decrease-globally-wood-mackenzie/ (accessed on 25 May 2024).

| Crop Type | Shading Ratios (%) | |||

|---|---|---|---|---|

| 0 | 21.3 | 25.6 | 32 | |

| Total Grain Yield (Mg ha−1) | ||||

| Sesame | 0.96 | 0.89 (−7%) | 0.83 (−14%) | 0.45 (−53%) |

| Mung Bean | 1.95 | 1.54 (−21%) | 1.1 (−44%) | 1.09 (−44%) |

| Red Bean | 2.35 | 1.75 (−26%) | 1.52 (−35%) | 1.47 (−37%) |

| Corn | 8.09 | 8.56 (+6%) | 6.4 (−21%) | 5.63 (−30%) |

| Soybean | 3.64 | 3.15 (−13%) | 2.88 (−21%) | 2.54 (−30%) |

| Month | Solar Radiation (MJ/m2) | Maximum Surface Temperature (°C) 1 | Minimum Surface Temperature (°C) 2 | Precipitation (mm) | Humidity (%) | Wind Speed (m/s) |

|---|---|---|---|---|---|---|

| January | 1.54 | 5.40 | −1.31 | 32.93 | 74.55 | 3.76 |

| February | 1.84 | 6.75 | −0.65 | 29.31 | 72.64 | 4.06 |

| March | 2.12 | 12.18 | 3.47 | 76.54 | 74.27 | 3.76 |

| April | 2.34 | 17.37 | 8.77 | 96.46 | 73.64 | 3.45 |

| May | 2.52 | 22.61 | 13.89 | 83.69 | 75.82 | 3.05 |

| June | 2.85 | 25.86 | 19.15 | 116.38 | 83.00 | 2.67 |

| July | 2.89 | 28.97 | 23.27 | 213.89 | 87.27 | 2.93 |

| August | 2.48 | 30.45 | 24.26 | 181.65 | 84.18 | 2.90 |

| September | 2.30 | 26.25 | 19.26 | 153.35 | 81.55 | 2.65 |

| October | 1.85 | 20.95 | 13.16 | 82.07 | 75.36 | 3.21 |

| November | 1.56 | 14.34 | 7.00 | 55.82 | 74.80 | 3.51 |

| December | 1.44 | 7.54 | 0.65 | 45.42 | 75.10 | 3.89 |

| Average | 2.14 | 18.22 | 10.91 | 97.29 | 77.68 | 3.32 |

| Data Type | Shading Ratio | ||

|---|---|---|---|

| 21.3% | 25.6% | 32% | |

| BIPV Module Cost (US$/m2) 1 | 9.31 | 9.94 | 13.41 |

| Structural Cost (US$/m2) | 7.24 | 7.72 | 10.43 |

| Electrical Distribution System Cost (US$/m2) | 3.45 | 3.68 | 4.97 |

| Additional Costs (US$/m2) 2 | 0.25 | 0.27 | 0.36 |

| Total Construction Cost (US$/m2) | 20.26 | 21.61 | 29.17 |

| Annual Operating and Maintenance Costs (US$/m2/year) 3 | 0.59 | 0.71 | 0.89 |

| Discount Rate | SMP Case | REC and SMP Case | ||||

|---|---|---|---|---|---|---|

| 0.01 | 0.05 | 0.10 | 0.01 | 0.05 | 0.10 | |

| Shading ratio of the highest electricity generation profit | 0.26 | 0.24 | 0.23 | 0.32 | 0.28 | 0.26 |

| Electricity generation profit (US$/m2/year) | −0.638 | −1.181 | −1.992 | 0.302 | −0.362 | −1.248 |

| Type of Crop | Cost of Materials (USD) | Cost of Labor (USD) | Overhead Costs (USD) | |||

|---|---|---|---|---|---|---|

| Seeds | Fertilizers | Pesticides | Miscellaneous | |||

| Corn (USD/m2/year) | 0.67 | 0.04 | 0.02 | 0.02 | 0.03 | 1.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Kim, S. Economic Analysis of Biofuel Production in Agrophotovoltaic Systems Using Building-Integrated Photovoltaics in South Korea. Energies 2025, 18, 1949. https://doi.org/10.3390/en18081949

Kim Y, Kim S. Economic Analysis of Biofuel Production in Agrophotovoltaic Systems Using Building-Integrated Photovoltaics in South Korea. Energies. 2025; 18(8):1949. https://doi.org/10.3390/en18081949

Chicago/Turabian StyleKim, Youngjin, and Sojung Kim. 2025. "Economic Analysis of Biofuel Production in Agrophotovoltaic Systems Using Building-Integrated Photovoltaics in South Korea" Energies 18, no. 8: 1949. https://doi.org/10.3390/en18081949

APA StyleKim, Y., & Kim, S. (2025). Economic Analysis of Biofuel Production in Agrophotovoltaic Systems Using Building-Integrated Photovoltaics in South Korea. Energies, 18(8), 1949. https://doi.org/10.3390/en18081949