Research and Application of Fracturing Testing Technology in a South-West Weizhou Oilfield Shale Oil Exploration Well

Abstract

:1. Introduction

2. Challenges of Large-Scale Fracturing for Offshore Shale Oil

- (1)

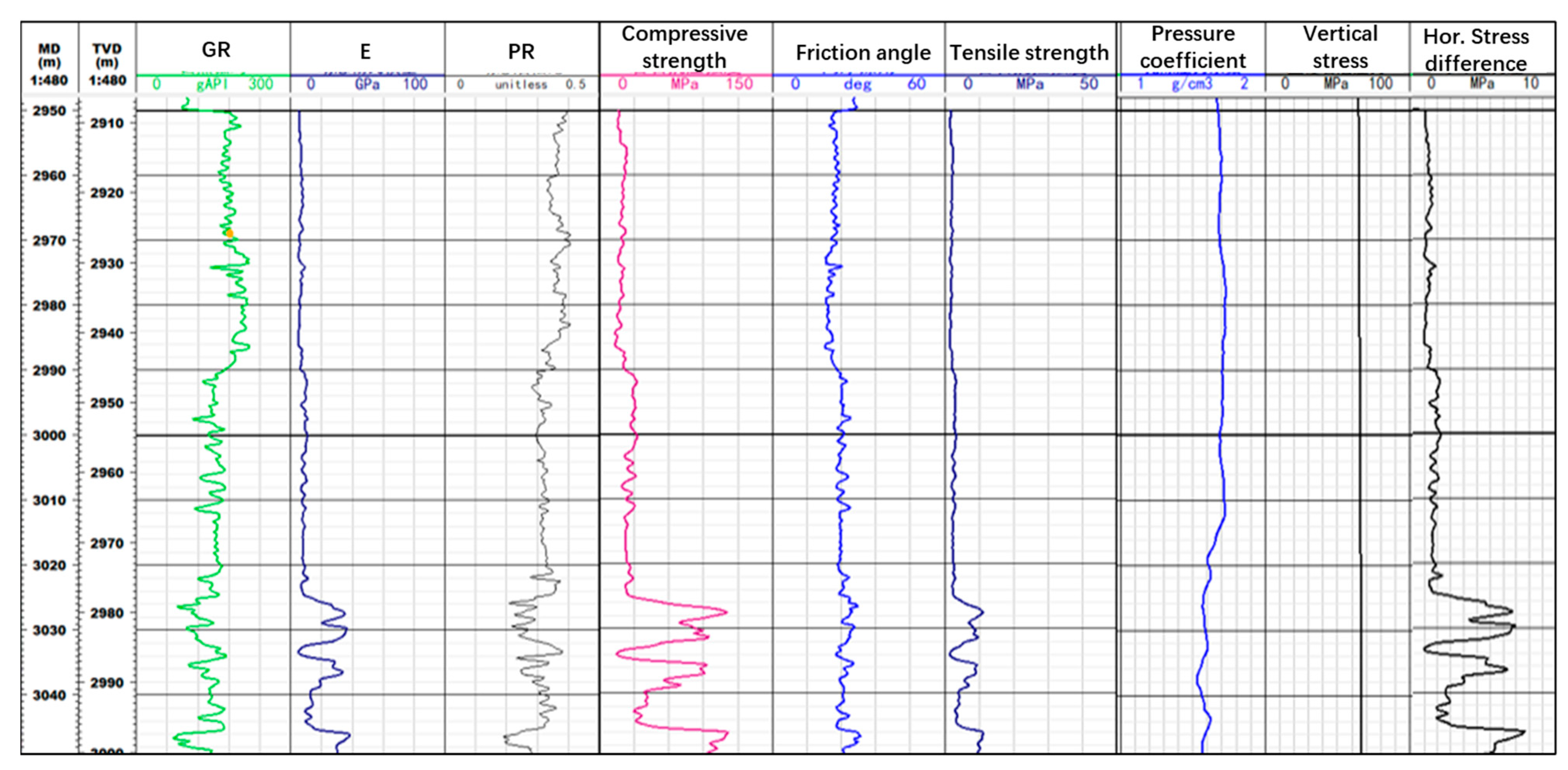

- The shale oil has developed bedded, which makes fracturing and seam control difficult. The shale oil in the western South China Sea is mostly interbedded oil shale, with 1–2 m of argillaceous siltstone sandwiched between large sets of brownish gray mud shale. Vertically, the depth of the shale oil reservoir is more than 3000 m, and the strata are dense, with the formation fracture pressure coefficient exceeding 2.0. Longitudinally, the oil shale is different from conventional sandstone. The stratigraphic surface inclination, tensile strength, stratigraphic stress difference, etc., have an important impact on the ability of shale oil fracturing through the layer; the height of the fracturing fracture seam is limited, so it is difficult to form a complex fracture network, which affects the effect of large-scale fracturing and renovation [34,35].

- (2)

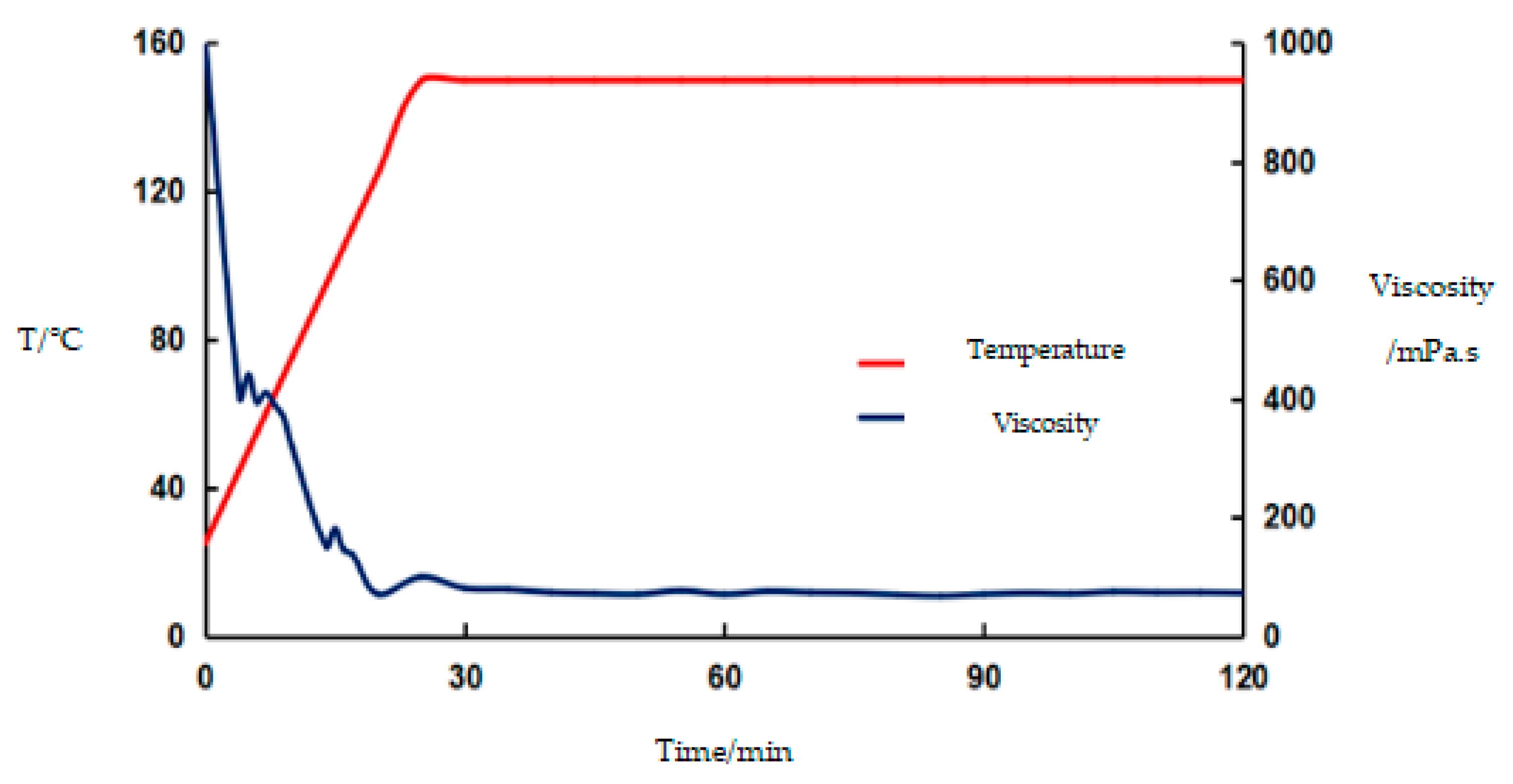

- The seawater-based fracturing fluids require high swelling performance. Traditional freshwater-based fracturing fluids rely on the mud pit volume of the platform, and the long-time preparation and storage of freshwater-based fracturing fluid base fluid can easily lead to degradation of the base fluid, which affects the fracturing effect and makes it difficult to achieve large-scale fracturing. Seawater is inexhaustible, and mixing seawater-based fracturing fluids using a continuous mixing process is an important way to achieve large-scale fracturing on offshore platforms [36,37]. Continuous mixing construction requires that guar gum thickeners can increase viscosity rapidly in seawater, but due to the high salinity of seawater reaching 40,000 mg/L, it is difficult to form the random nematic clusters in seawater with a lack of cross-linking bonding, and the rate of dissolution is also slow, making it difficult to meet the requirements of continuous mixing [38,39,40].

- (3)

- The integrated testing and fracturing strings are difficult to design. Conventional testing strings are generally equipped with APR test tools such as RD circulation valve, RD test valve, RD safety circulation valve, etc. APR test tools are sensitive to the annulus pressure. In the process of a large-rate fracturing operation, the sudden change in wellbore temperature leads to the change in annulus pressure, which affects the normal switching of APR test tools. In addition, sand-containing fluids will cause high-speed erosion of testing tools, and the abnormal action of these tools will directly lead to the failure of the whole testing and fracturing operation [41].

- (4)

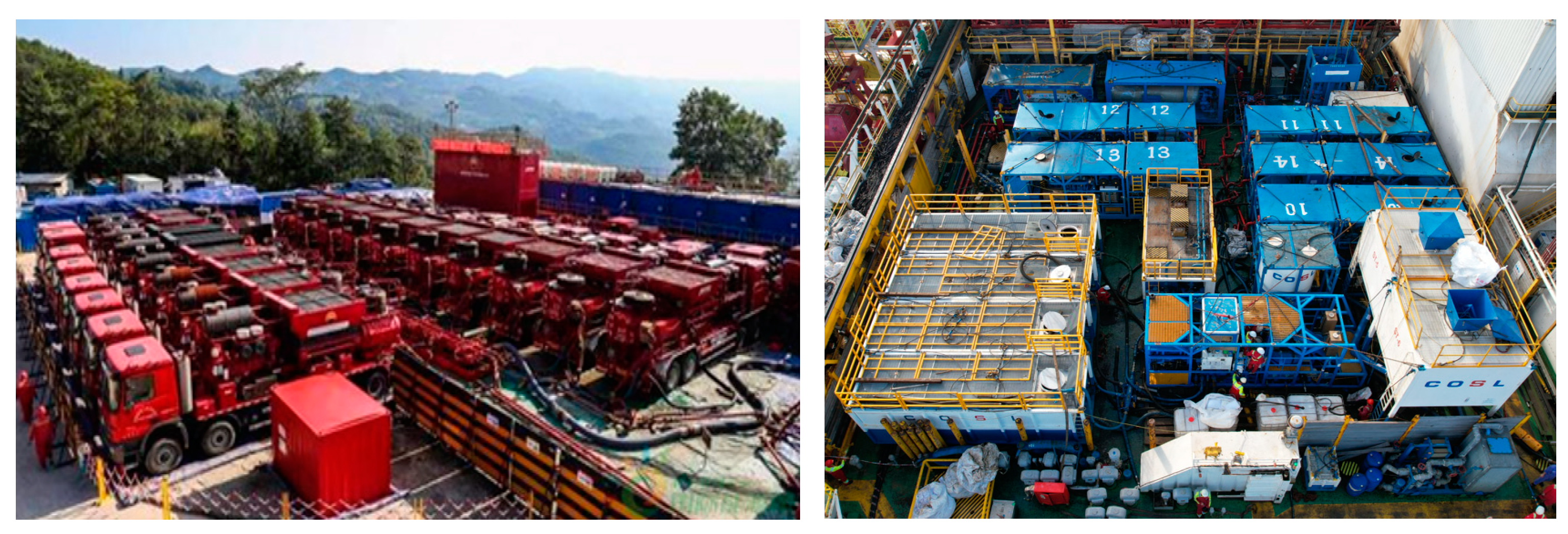

- The small platform size makes it difficult to place large fracturing equipment. Onshore fracturing equipment placement is less affected by the size of the well site, and the number of fracturing equipment can be placed more than 20 suits. However, the deck area of offshore drilling platforms is small, and the load-bearing capacity of the platform is limited, and the fracturing equipment, including sand tanks, fracturing units, continuous mixing units, etc., are relatively large and heavy, and the number and location of placements are limited, so it is difficult to carry out large-scale fracturing operations on the sea [42]. The layout of onshore (Changqing oil field, China) and offshore (Weizhou oil field, China) fracturing equipment is shown in Figure 1.

3. Materials and Methods

3.1. Experimental Samples

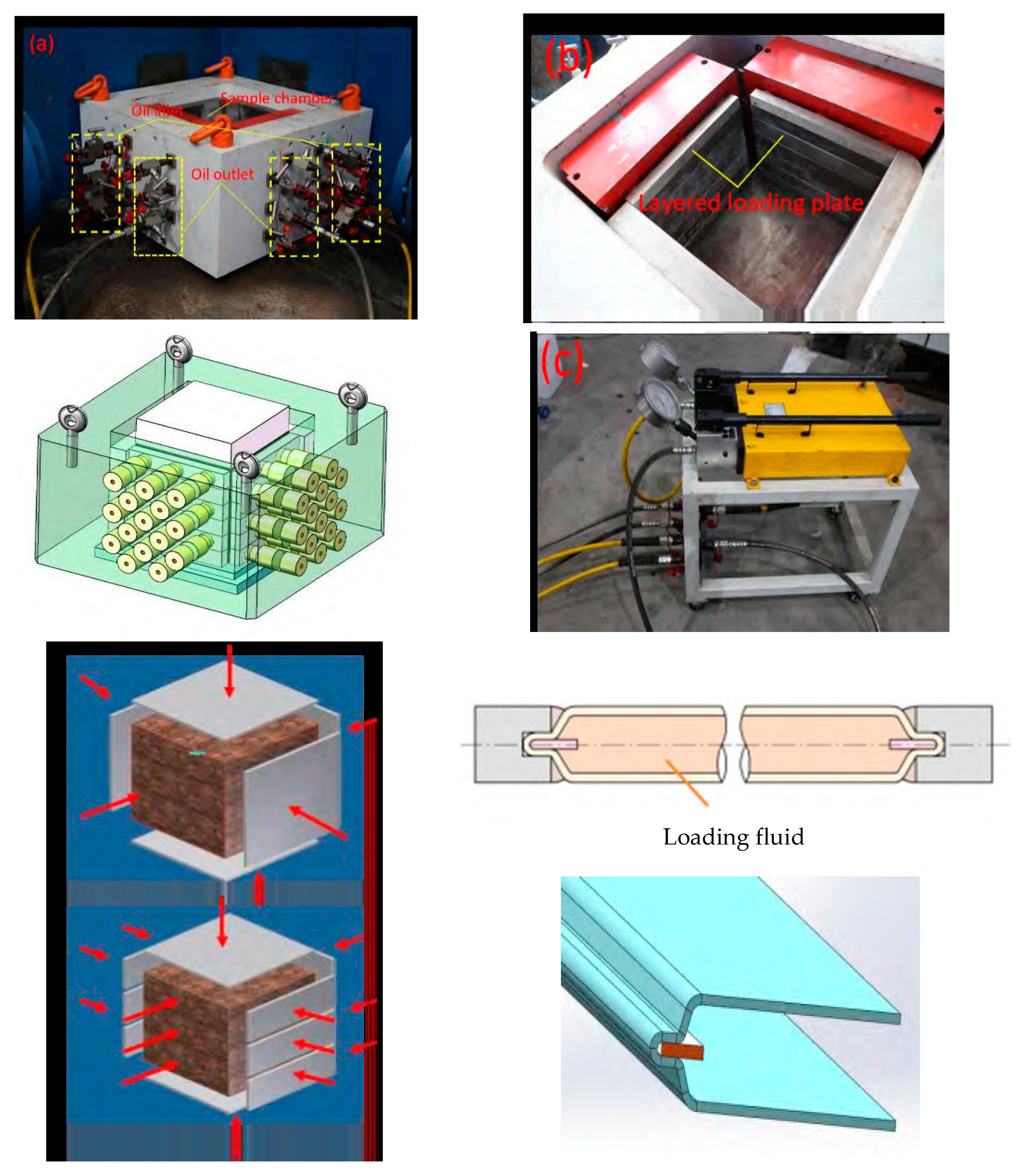

3.2. Experimental Device

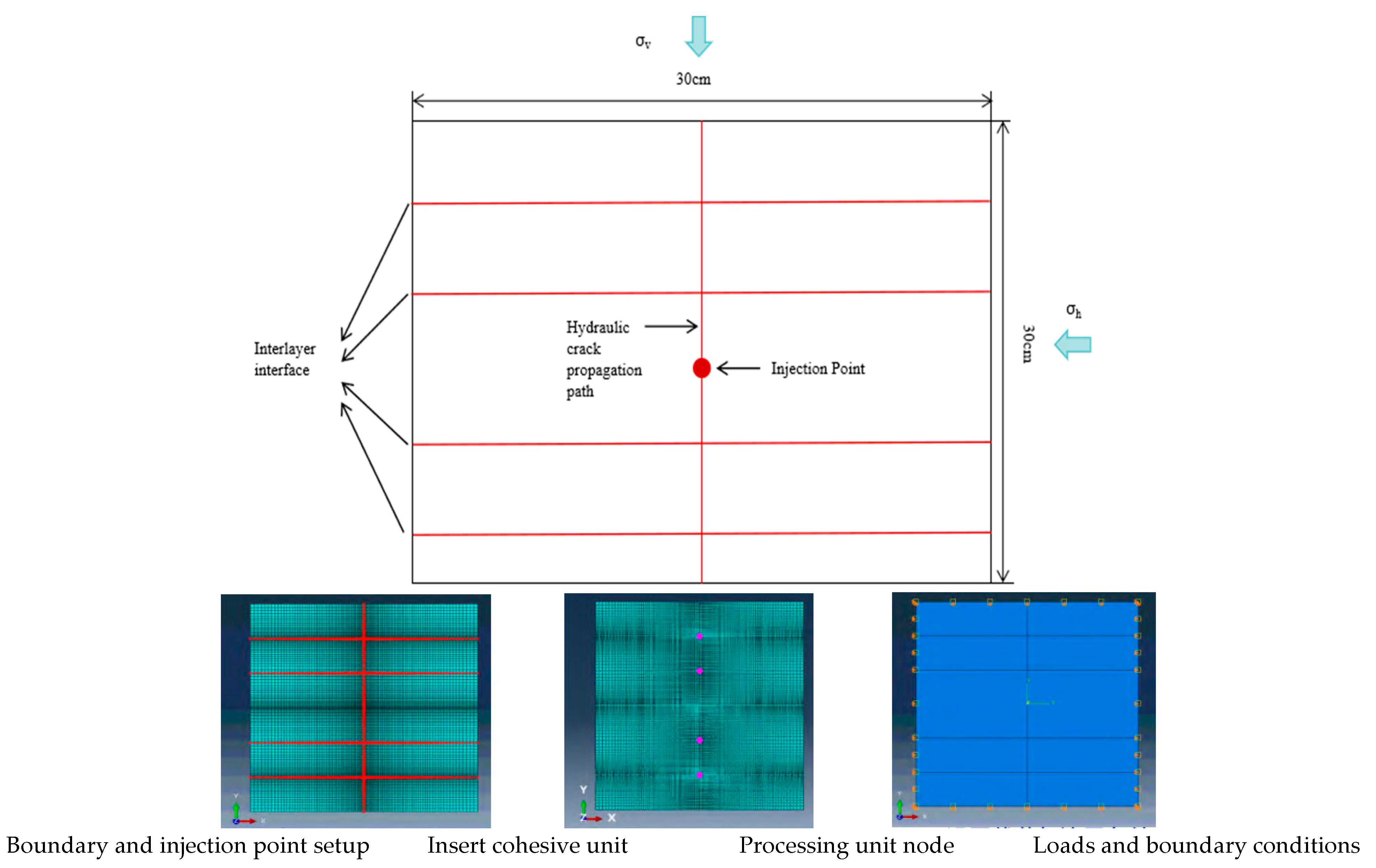

3.3. Numerical Simulation Method

4. Results and Discussion

4.1. Experimental Results and Analysis

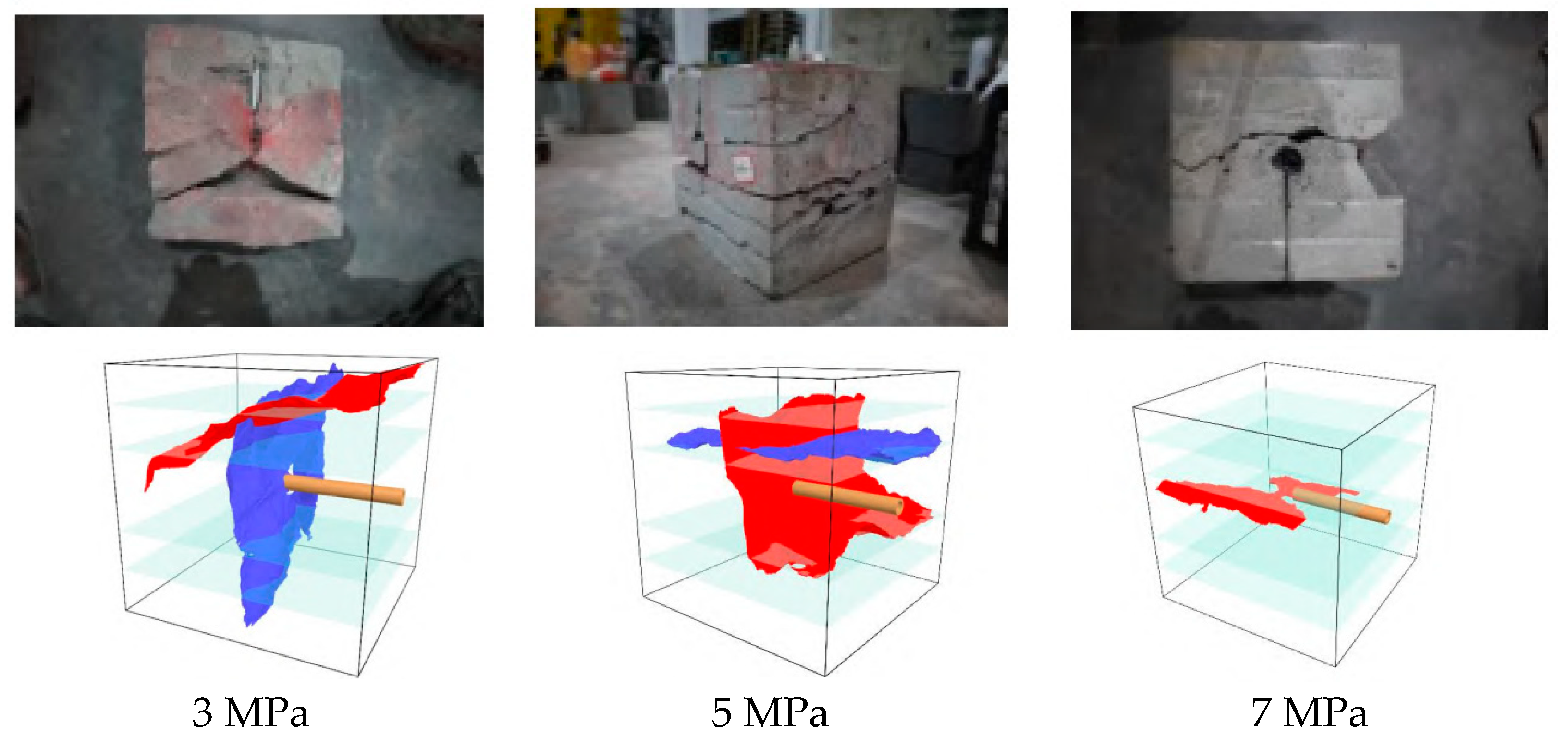

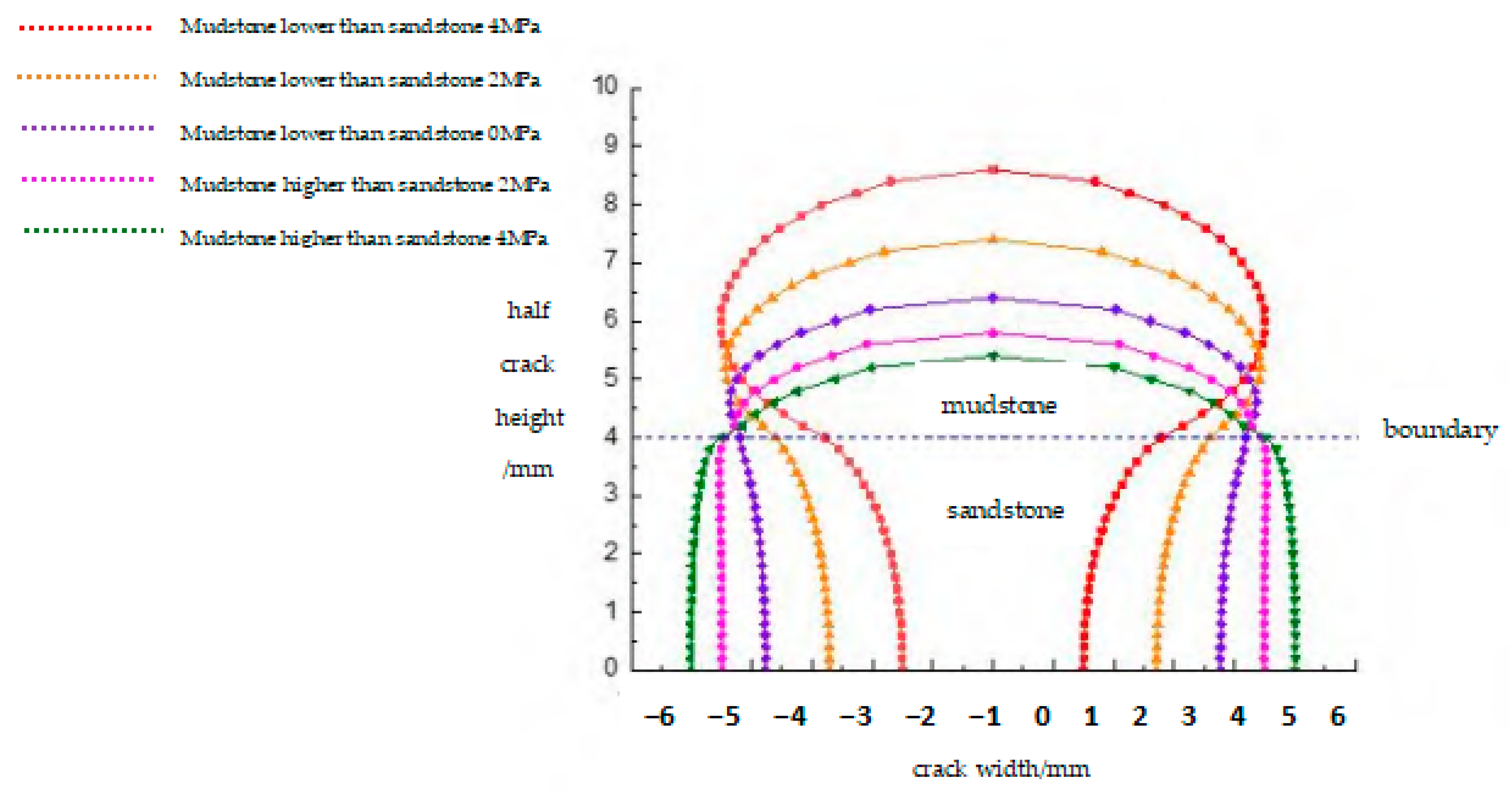

4.1.1. Influence of Different Stress Differences on Cracks

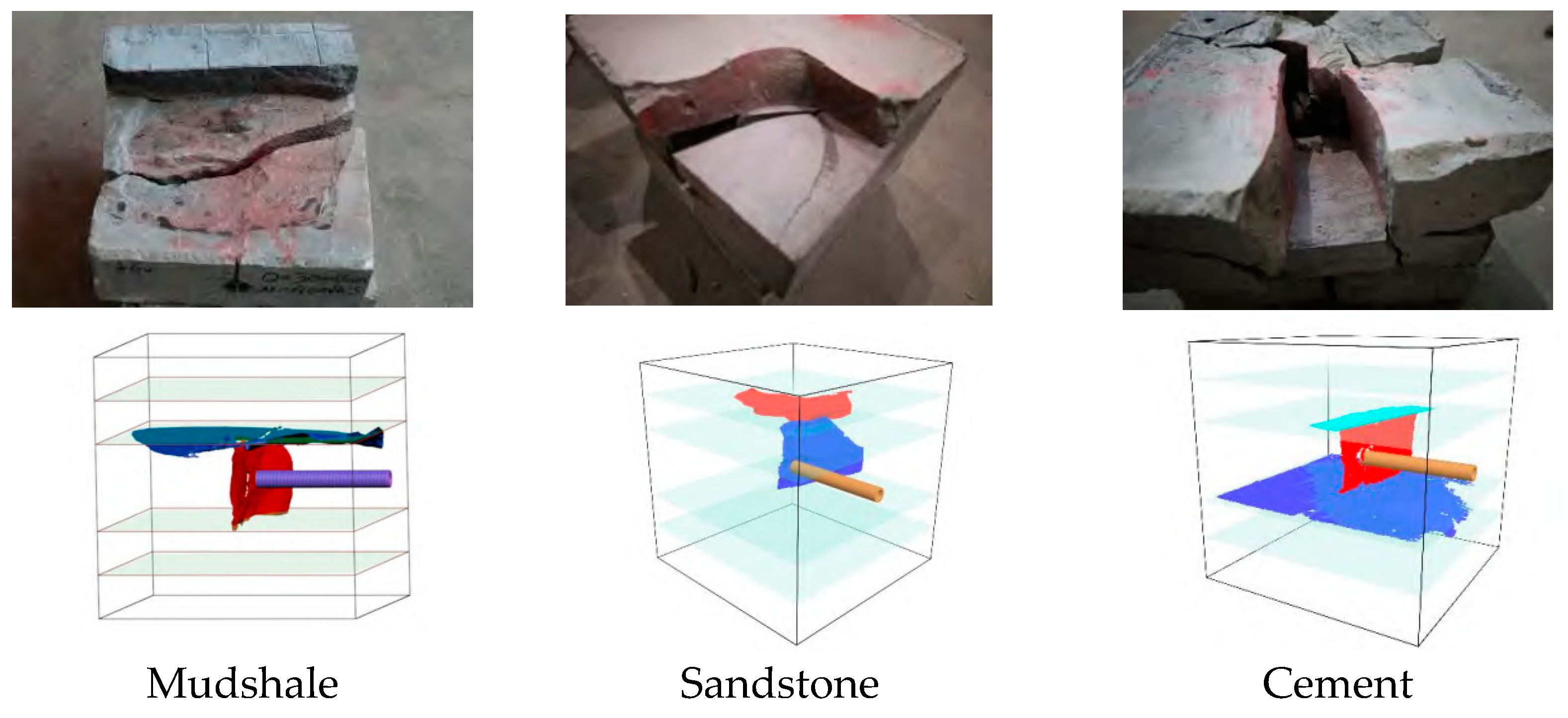

4.1.2. Influence of Different Traversed Layers on Cracks

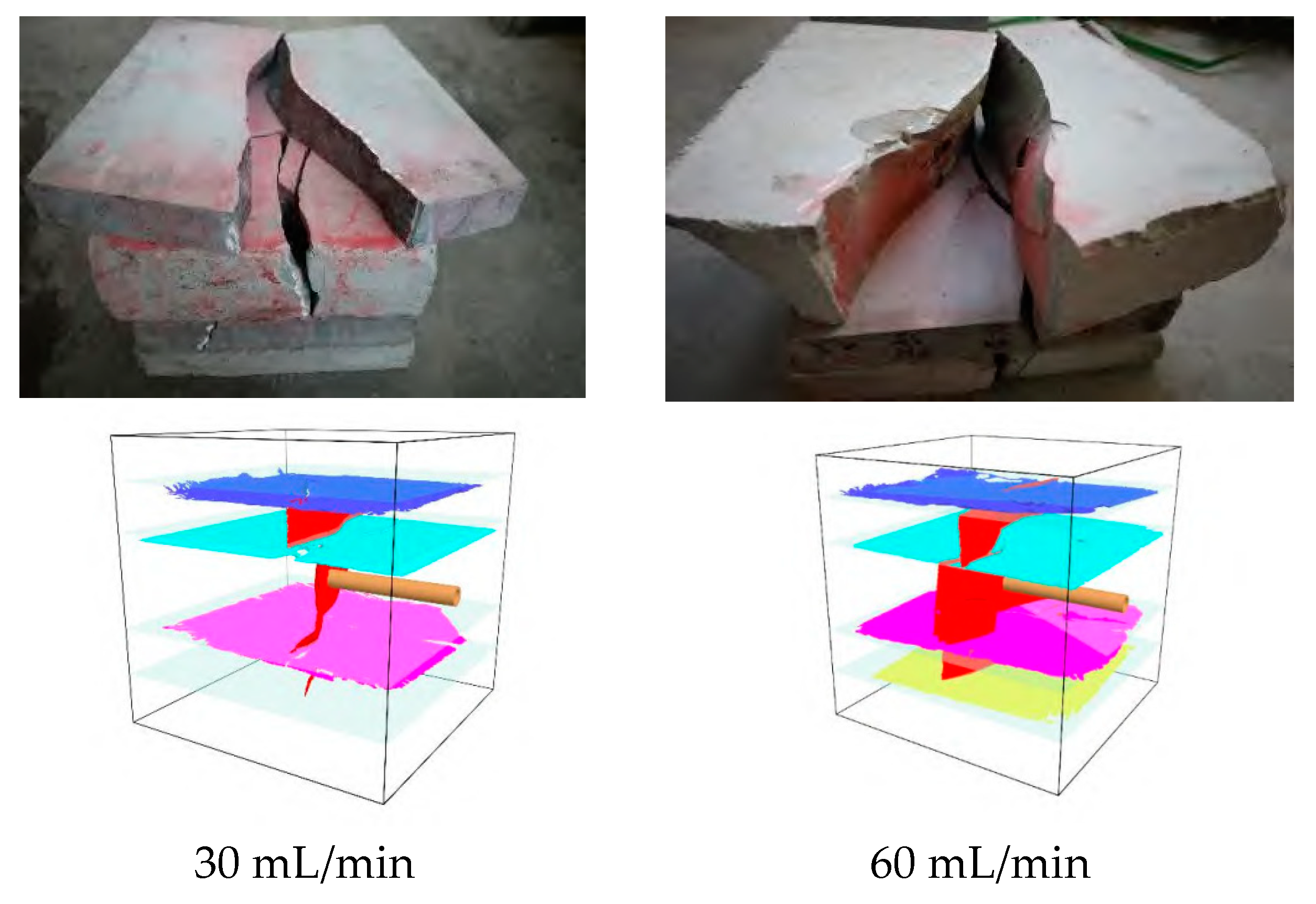

4.1.3. Influence of Fracturing Fluid Parameters on Cracks

4.2. Numerical Simulation Results and Analysis

4.2.1. Influence of Young’s Modulus on Cracks

4.2.2. Influence of Minimum Horizontal Principal Stress on Cracks

4.2.3. Influence of Fracturing Fluid Injection Rate on Cracks

5. Field Application and Effect

5.1. Field Application Technology Countermeasures

5.1.1. Select Fracturing Sweet Spots

5.1.2. Field Mixing Process for Seawater-Based Fracturing Fluids

5.1.3. Platform Space Optimization Process

5.2. Fracturing Operation and Effect

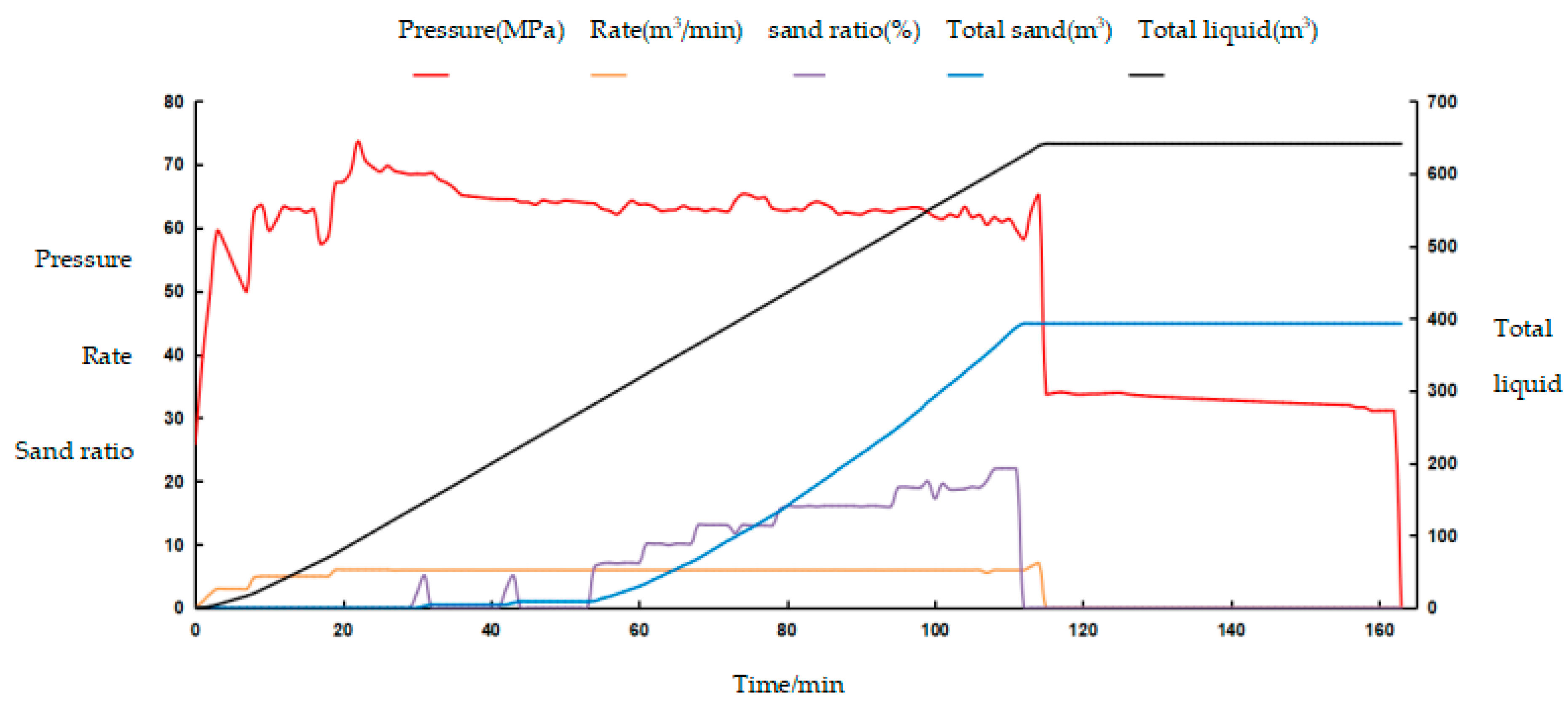

5.2.1. Small-Scale Fracturing Operation

5.2.2. Main Fracturing Operation

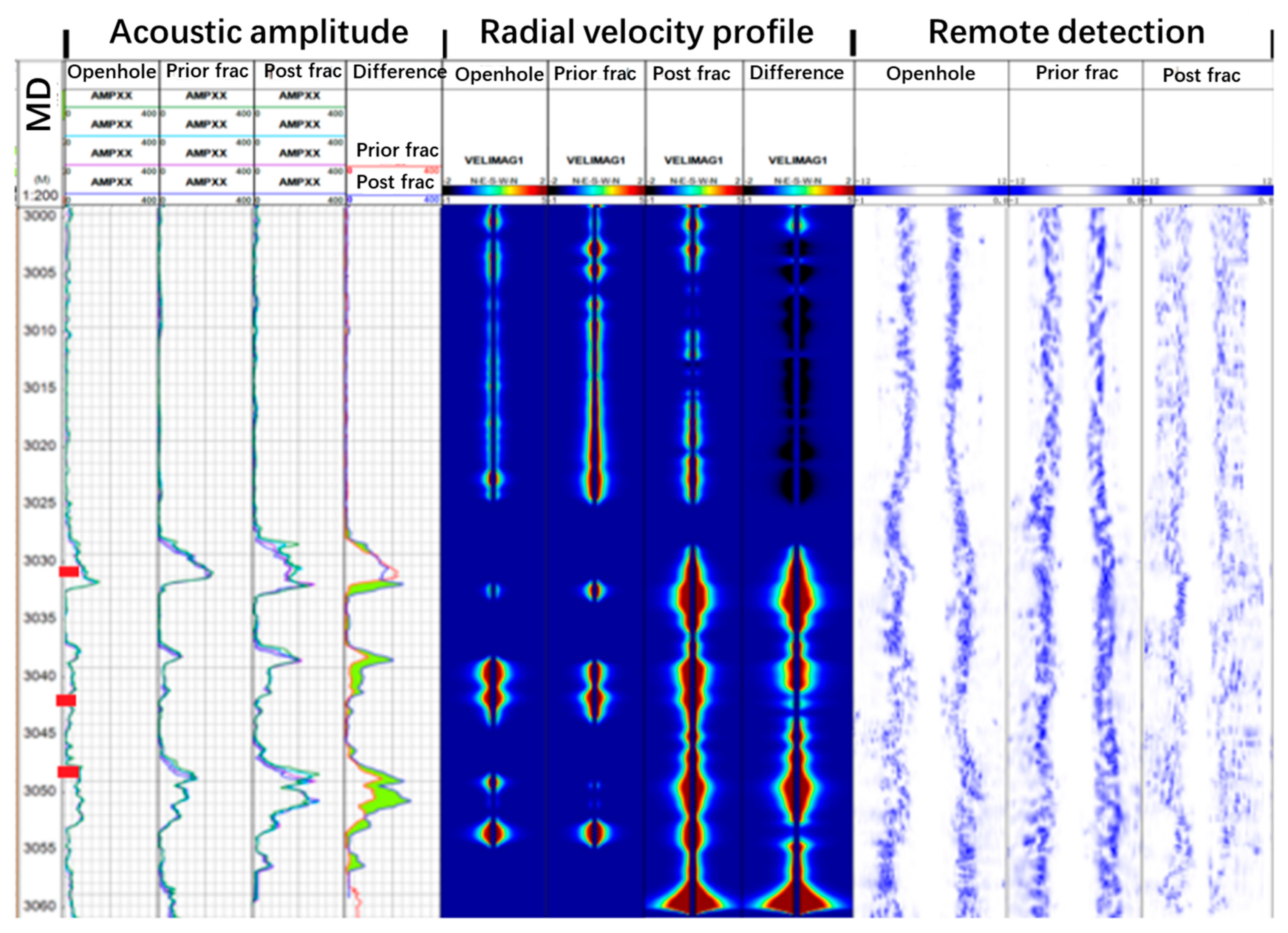

5.2.3. Fracturing Effectiveness

6. Conclusions

- (1)

- Aiming at the technical challenges of offshore shale oil fracturing testing, based on the characteristics of shale oil reservoirs in southwestern Weizhou, a numerical analysis model of sand-mudstone thin interlayer fracturing is established based on the study of low-modulus mudstone rupture and fracture characteristics, and a set of experimental devices for layered stress loading is designed and developed independently. Through numerical simulation and experimental testing, the key influencing factors in penetrating fracturing of shale oil were analyzed, and it was obtained that the injection of high-rate and high-viscosity fracturing fluid has a significant impact on the hydraulic fracture surface penetration. Numerical simulation analysis shows that the smaller the elastic modulus of the mudstone interlayer and the lower the minimum horizontal principal stress compared to the sandstone layer, the more favorable it is for fracture propagation.

- (2)

- In view of the actual well conditions of a shale oil well in the south-west Weizhou oilfield, based on the analyses of formation stress difference calculated by simulation, we have formed the supporting technical measures for large-scale fracturing of the south-west Weizhou oilfield shale oil by focusing on the selection of interlayer shale oil sweet spots, supporting the research and development of seawater-based fracturing fluids and the application of the on-line continuous mixing process, as well as the optimization of the limited space of the platform.

- (3)

- By overcoming the spatial limitation of the platform, during the site fracturing construction, the seawater lifting pump was used to extract seawater for continuous mixing fracturing fluids at the site, and two operation procedures of small-scale fracturing and main fracturing were adopted to carry out the fracturing operation of China’s first offshore shale oil well successfully. The highest injection rate reached 7 m3/min, and the results of post-fracturing acoustic logging showed obvious fracture response characteristics, with the farthest detected fracture response well distance reaching 12 m, which indicated that the post-fracturing modification effect was good and it provided a technical guarantee for the subsequent offshore shale oil fracturing construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The fracture propagation behavior of CO2 fracturing fluid in unconventional low permeability reservoirs: Factor analysis and mechanism revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Evolution and Mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Zhou, Q.; Jin, Z.; Yang, G.; Dong, N.; Shang, Z. Shale oil exploration and production in the U.S.: Status and outlook. Oil Gas Geol. 2019, 40, 469–477. [Google Scholar]

- Yang, L.; Jin, Z. Global shale oil development and prospects. China Pet. Explor. 2019, 24, 553–559. [Google Scholar]

- Chen, Z.; Liu, H.; Li, Y.; Shen, Z.; Xu, G. The Current Status and Development Suggestions for Shale Oil Reservoir Stimulation at Home and Abroad. Pet. Drill. Tech. 2021, 49, 1–7. [Google Scholar]

- Xu, W.; Xiao, M.; Sun, X.; Wang, Y.; Jia, Y. Pilot test of multi-stage fracturing technology for horizontal wells in offshore low permeability reservoirs. China Offshore Oil Gas 2017, 29, 108–114. [Google Scholar]

- Liu, N.; Ning, X.; Chen, Z. Research and practice of large scale fracturing technology in offshore exploration well. Chem. Eng. Oil Gas 2012, 41, 216–218+250–251. [Google Scholar]

- Beugelsdijk, L.; De Pater, C.; Sato, K. Experimental hydraulic fracture propagation in a multi-fractured medium. In SPE Asia Pacific Conference on Integrated Modelling for Asset Management; SPE: Calgary, AB, Canada, 2000; pp. 177–184, SPE-59419-MS. [Google Scholar]

- Rueda Cordero, J.A.; Mejia Sanchez, E.C.; Deane, R.; Pereira, L.C. Hydro-mechanical modeling of hydraulic fracture propagation and its interactions with frictional natural fractures. Comput. Geotech. 2019, 111, 290–300. [Google Scholar] [CrossRef]

- Wei, S.; Kao, J.; Jin, Y. A discontinuous discrete fracture model for coupled flow and geomechanics based on FEM. J. Pet. Sci. Eng. 2021, 204, 108677. [Google Scholar] [CrossRef]

- Wu, Z. Exploration of optimization of volume fracturing process parameters for intensive cutting of Daqing Gulong shale oil. Well Test. 2023, 32, 34–40. [Google Scholar]

- Zhang, M.; Tao, C.; Zuo, T. Key technologies and practices for reservoir stimulation of shale oil Hua H100 platform. Drill. Prod. Technol. 2023, 46, 53–58. [Google Scholar]

- Liu, W.; Xu, X.; Liu, C.; Chen, S.; Bai, J.; Li, Y. The stimulation mechanism and performance analysis of supercritical CO2 and hydraulic sand-carrying composite volume fracturing technology on continental shale reservoirs. Acta Pet. Sin. 2022, 43, 399–409. [Google Scholar]

- Zhang, Y.; Wang, L.; Liu, Y.; Zhang, J.; Zhou, D.; Ge, H. Advances and Challenges of Integration of Fracturing and Enhanced Oil Recovery in Shale Oil Reservoirs. Pet. Drill. Tech. 2024, 52, 84–95. [Google Scholar]

- Yue, K.; Lee, H.P.; Olson, J.E. Apparent fracture toughness for LEFM applications in hydraulic fracture modeling. Eng. Fract. Mech. 2020, 230, 106984. [Google Scholar] [CrossRef]

- Marco, M.; Infante-García, D.; Belda, R. A comparison between some fracture modelling approaches in 2D LEFM using finite elements. Int. J. Fract. 2020, 223, 151–171. [Google Scholar] [CrossRef]

- Dahi Taleghani, A.; Gonzalez-Chavez, M.; Yu, H.; Asala, H. Numerical simulation of hydraulic fracture propagation in naturally fractured formations using the cohesive zone mode. J. Pet. Sci. Eng. 2018, 165, 42–57. [Google Scholar] [CrossRef]

- Gordeliy, E.; Peirce, A. Implicit level set schemes for modeling hydraulic fractures using the XFEM. Comput. Methods Appl. Mech. Eng. 2013, 266, 125–143. [Google Scholar] [CrossRef]

- Olson, J.E. Multi-fracture propagation modeling: Applications to hydraulic fracturing in shales and tight gas sands. In Proceedings of the 42nd U.S. Rock Mechanics Symposium (USRMS), San Francisco, CA, USA, 29 June–2 July 2008; p. ARMA-08-327. [Google Scholar]

- Roodhart, L.P.; Davies, D.R. Relation Between Chemistry and Flow Mechanics of Borate Cross linked Fracturing Fluids. SPE Prod. Facil. 1993, 8, 165–170. [Google Scholar]

- Mack, M.; Elbel, J.L. Hydraulic Fracture Orientation and Pressure Response During Fracturing of Producing Wells. Rock Mech. 1994, 175, 183. [Google Scholar]

- Alohaly, M.; BinGhanim, A.; Rahal, R.; Rahim, S. Seawater Fracturing Fluid Development Challenges: A Comparison Between Seawater-Based and Freshwater-Based Fracturing Fluids Using Two Types of Guar Gum Polymers. In Proceedings of the SPE Kingdom of Saudi Arabia Technical Symposium and Exhibition, Dammam, Saudi Arabia, 25–28 April 2016; p. SPE-182799-MS. [Google Scholar]

- Bao, W.; Wang, X.; Guo, B.; Chen, L.; Liu, H.; Li, M. Research and application of high temperature seawater-based fracturing fluid. Fault-Block Oil Gas Field 2017, 24, 434–436. [Google Scholar]

- Yang, Q. Construction and Mechanism of SiO2 Nanoparticle Enhanced Seawater Based Heat Resistant Clean Fracturing Fluid. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2020. (In Chinese). [Google Scholar]

- Parker, M.; Slabaugh, B.; Walters, H.; Weaver, J.; Hanes, R. New hydraulic fracturing fluid technology reduces impact on the environment through recovery and reuse. In Proceedings of the SPE/EPA/DOE Exploration and Production Environmental Conference, San Antonio, TX, USA, 10–12 March 2003; p. SPE-80590-MS. [Google Scholar]

- Smirnov, N.; Li, K.; Skryleva, E.; Pestov, D.; Shamina, A.; Qi, C.; Kiselev, A. Mathematical Modeling of Hydraulic Fracture Formation and Cleaning Processes. Energies 2022, 15, 1967. [Google Scholar] [CrossRef]

- Kang, W.; Mushi, S.J.; Yang, H.; Wang, P.; Hou, X. Development of smart viscoelastic surfactants and its applications in fracturing fluid: A review. J. Pet. Sci. Eng. 2020, 190, 107107. [Google Scholar] [CrossRef]

- Li, C. Introduction of New Trend of Oil and Gas Well Test Technology and Its New technology. Well Test. 2016, 25, 56–58+77–78. [Google Scholar]

- Shao, L. Integration technology for low permeability reservoir fracturing flowback. Nat. Gas Oil 2013, 31, 59–60, 65. [Google Scholar]

- Guo, S. Perforation-Fracturing-Well Test Integrated Tech on Semi Submersible Drilling Platform. Well Test. 2011, 20, 70–71+74+78. [Google Scholar]

- Li, J. Application of combined technology of composite perforation and APR testing tool. Well Test. 2012, 21, 36–37. [Google Scholar]

- Pandey, V.J.; Burton, R.C.; Nozaki, M. Evolution of Frac-Pack Design and Completion Procedures for High-Permeability Gas Wells in Subsea Service. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 3–5 February 2015; p. SPE-168636-MS. [Google Scholar]

- Lian, Z.; Zhang, Y.; Zhao, X.; Ding, S.; Lin, T. Mechanical and mathematical models of multi-stage horizontal fracturing strings and their application. Nat. Gas Ind. B 2015, 2, 185–191. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, B.; Wang, D.; Jia, Z. Features of fracture height propagation in cross-layer fracturing of shale oil reservoirs. Pet. Explor. Dev. 2021, 48, 402–410. [Google Scholar] [CrossRef]

- Cui, Z.; Hou, B.; Fu, S.; Lv, J. Fractures cross-layer propagation characteristics of integrated fracturing in shale oil tight reservoir. Fault-Block Oil Gas Field 2021, 48, 402–410. [Google Scholar]

- Li, M.; Chen, L.; Bao, W.; Shen, J.; Zhao, J. Application of Instant Dissolved Seawater Based Fracturing Fluids in Bohai Oilfield. Offshore Oil 2022, 42, 45–48. [Google Scholar]

- Xiong, J.; Zhao, Z.; An, Q.; Wang, S. Synthesis and Performance Evaluation of Zwitterion Guar for High Temperature Seawater Base Fracturing Fluid. Oilfield Chem. 2018, 35, 401–405+410. [Google Scholar]

- Ye, D.; Wang, S.; Cai, Y.; Ren, Y.; Luo, C. Application of continuously mixing fracturing fluid and such flow process. Nat. Gas Ind. 2013, 33, 47–51. [Google Scholar]

- Wu, W.; Liu, Y.; Yi, D.; Xiong, Y. Application of technology continuous mixing fracturing fluid on large-scale fracturing. Chem. Eng. Oil Gas 2016, 45, 57–60. [Google Scholar]

- Peng, P.; Xun, Y.; Wang, Y. Current Status and Development of Fracturing Fluid Continuous Mixing Equipment. Petro Chem. Equip. 2016, 19, 15–17. [Google Scholar]

- Zhao, Z.; Zhang, C.; Xu, G.; Li, X.; Li, S. Optimized design and application of fracturing string for offshore low porosity and low permeability reservoirs. China Offshore Oil Gas 2013, 25, 83–86. [Google Scholar]

- Yao, F.; Cao, B.; Wang, S.; Hu, Z.; Xia, Y. Application of Secondary Sand Fracturing Technique in Offshore Low Porosity and Permeability Sandstone Gas Reservoir. Sci. Technol. Eng. 2020, 20, 5615–5621. [Google Scholar]

- NB/T 14003.3-2017; Shale Gas-Fracturing Fluid-Part 3: Performance Index and Evaluation Methods for Fracturing Fluid Blended on-the-Fly. National Energy Administration: Beijing, China, 2017.

| No. | Cement–Sand Ratio | Water–Cement Ratio/% | Water Reducing Agent/% | Weighting Agent/% | Bentonite/% | UCS/MPa | Young’s Modulus/MPa | Tensile Strength/MPa | Fracture Toughness/MPa.m0.5 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3:1 | 22.5 | 0 | 0 | 0 | 99.23 | 22,710 | 2.77 | 0.44 |

| 2 | 3:1 | 25 | 0.1 | 5 | 5 | 81.48 | 18,810 | 1.86 | 0.29 |

| 3 | 3:1 | 30 | 0.2 | 10 | 10 | 50.57 | 12,000 | 1.79 | 0.26 |

| 4 | 3:1 | 35 | 0.3 | 15 | 15 | 62.28 | 14,580 | 1.97 | 0.25 |

| 5 | 2:1 | 22.5 | 0.1 | 10 | 15 | 86.74 | 19,960 | 2.38 | 0.33 |

| 6 | 2:1 | 25 | 0 | 15 | 10 | 64.25 | 15,010 | 2.23 | 0.40 |

| 7 | 2:1 | 30 | 0.3 | 0 | 5 | 56.36 | 13,280 | 1.61 | 0.25 |

| 8 | 2:1 | 35 | 0.2 | 5 | 0 | 52.30 | 12,390 | 1.52 | 0.21 |

| 9 | 1:1 | 22.5 | 0.2 | 15 | 5 | 30.78 | 7650 | 1.21 | 0.27 |

| 10 | 1:1 | 25 | 0.3 | 10 | 0 | 50.05 | 11,890 | 1.68 | 0.26 |

| 11 | 1:1 | 30 | 0.1 | 5 | 15 | 47.22 | 11,270 | 1.40 | 0.28 |

| 12 | 1:1 | 35 | 0.2 | 0 | 10 | 38.55 | 9360 | 1.77 | 0.34 |

| 13 | 1:2 | 22.5 | 0.3 | 5 | 10 | 32.49 | 8030 | 1.54 | 0.30 |

| 14 | 1:2 | 25 | 0.2 | 0 | 15 | 35.38 | 8660 | 1.27 | 0.24 |

| 15 | 1:2 | 30 | 0.1 | 15 | 0 | 41.46 | 10,000 | 1.31 | 0.26 |

| 16 | 1:2 | 35 | 0 | 10 | 5 | 34.51 | 8470 | 1.26 | 0.21 |

| Stress Parameters | |||

|---|---|---|---|

MPa | MPa | ||

| Mudshale | 28 | 20 | 30 |

| Sandstone | 28 | 25 | 35 |

| Concentration % | Base Liquid Viscosity mPa·s (30 °C Water Bath) | Thickening Rate % | Industry Standards [43] | |

|---|---|---|---|---|

| 5 min | 240 min | |||

| 0.2 | 3 | 3.5 | 85.7 | ≥85% |

| 0.3 | 18.1 | 21.0 | 86.2 | |

| 0.4 | 27 | 31.2 | 86.5 | |

| 0.5 | 32.5 | 37.4 | 86.9 | |

| 0.6 | 45.6 | 52.3 | 87.2 | |

| Parameter Category | Parameter Name | Value |

|---|---|---|

| Rock mechanical properties | Young’s modulus (GPa) | 25 |

| Poisson’s ratio | 0.25 | |

| Geostress | Vertical geostress (MPa) | 50 |

| Maximum horizontal geostress (MPa) | 55 | |

| Minimum horizontal geostress (MPa) | 45 | |

| Fracturing parameters | Fracturing fluid viscosity (mPa·s) | 5 |

| Pumping rate (m3/min) | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, W.; Jin, Y.; Lu, Y.; Ren, G.; Wei, S. Research and Application of Fracturing Testing Technology in a South-West Weizhou Oilfield Shale Oil Exploration Well. Energies 2025, 18, 2007. https://doi.org/10.3390/en18082007

Meng W, Jin Y, Lu Y, Ren G, Wei S. Research and Application of Fracturing Testing Technology in a South-West Weizhou Oilfield Shale Oil Exploration Well. Energies. 2025; 18(8):2007. https://doi.org/10.3390/en18082007

Chicago/Turabian StyleMeng, Wenbo, Yan Jin, Yunhu Lu, Guanlong Ren, and Shiming Wei. 2025. "Research and Application of Fracturing Testing Technology in a South-West Weizhou Oilfield Shale Oil Exploration Well" Energies 18, no. 8: 2007. https://doi.org/10.3390/en18082007

APA StyleMeng, W., Jin, Y., Lu, Y., Ren, G., & Wei, S. (2025). Research and Application of Fracturing Testing Technology in a South-West Weizhou Oilfield Shale Oil Exploration Well. Energies, 18(8), 2007. https://doi.org/10.3390/en18082007