Optimization of Injection Strategy for CH4/Diesel Dual-Fuel Engine Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. Response Surface Methodology

3. Results and Discussion

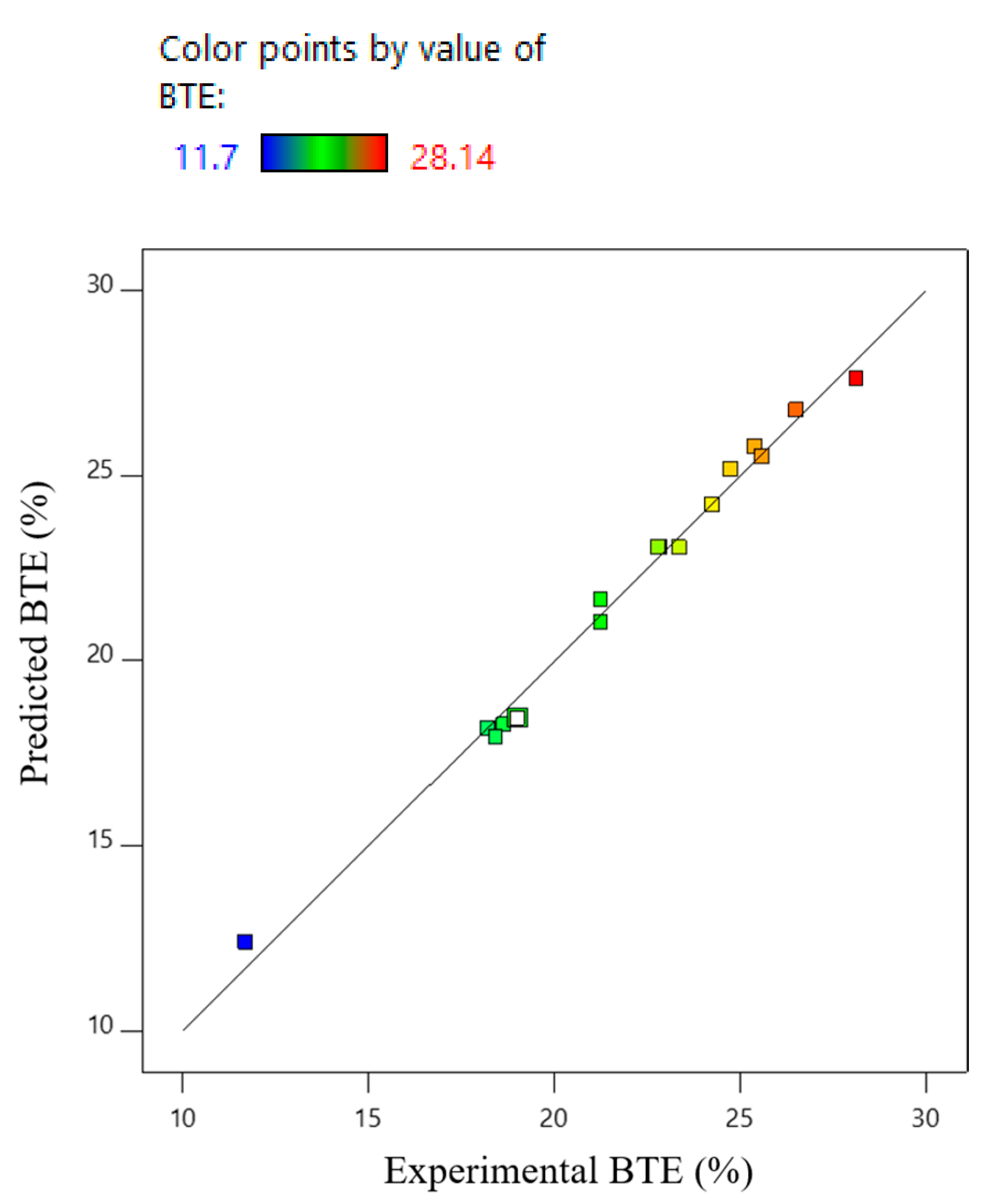

3.1. Brake Thermal Efficiency (BTE) Model

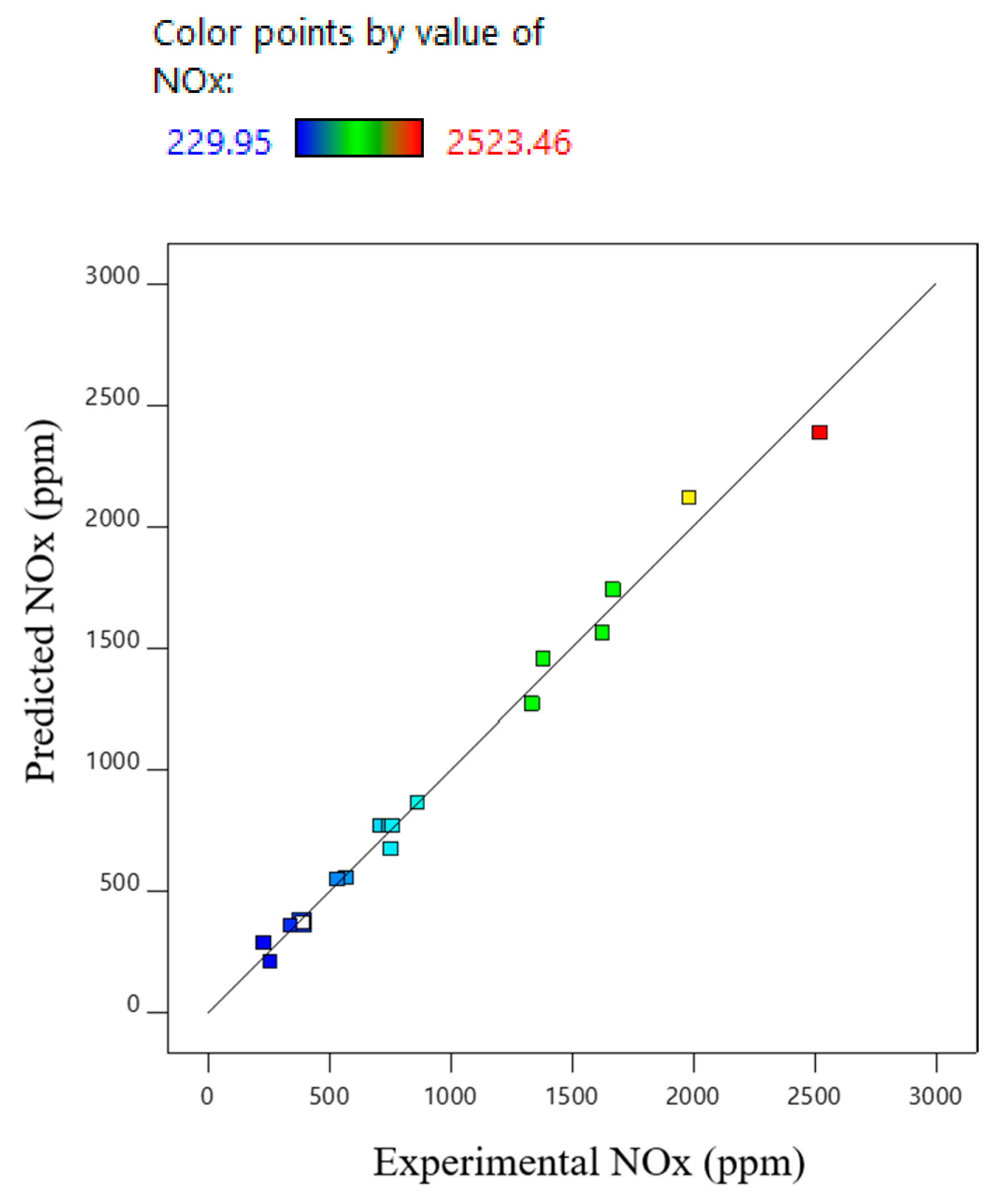

3.2. Nitrogen Oxide Emission (NOx) Model

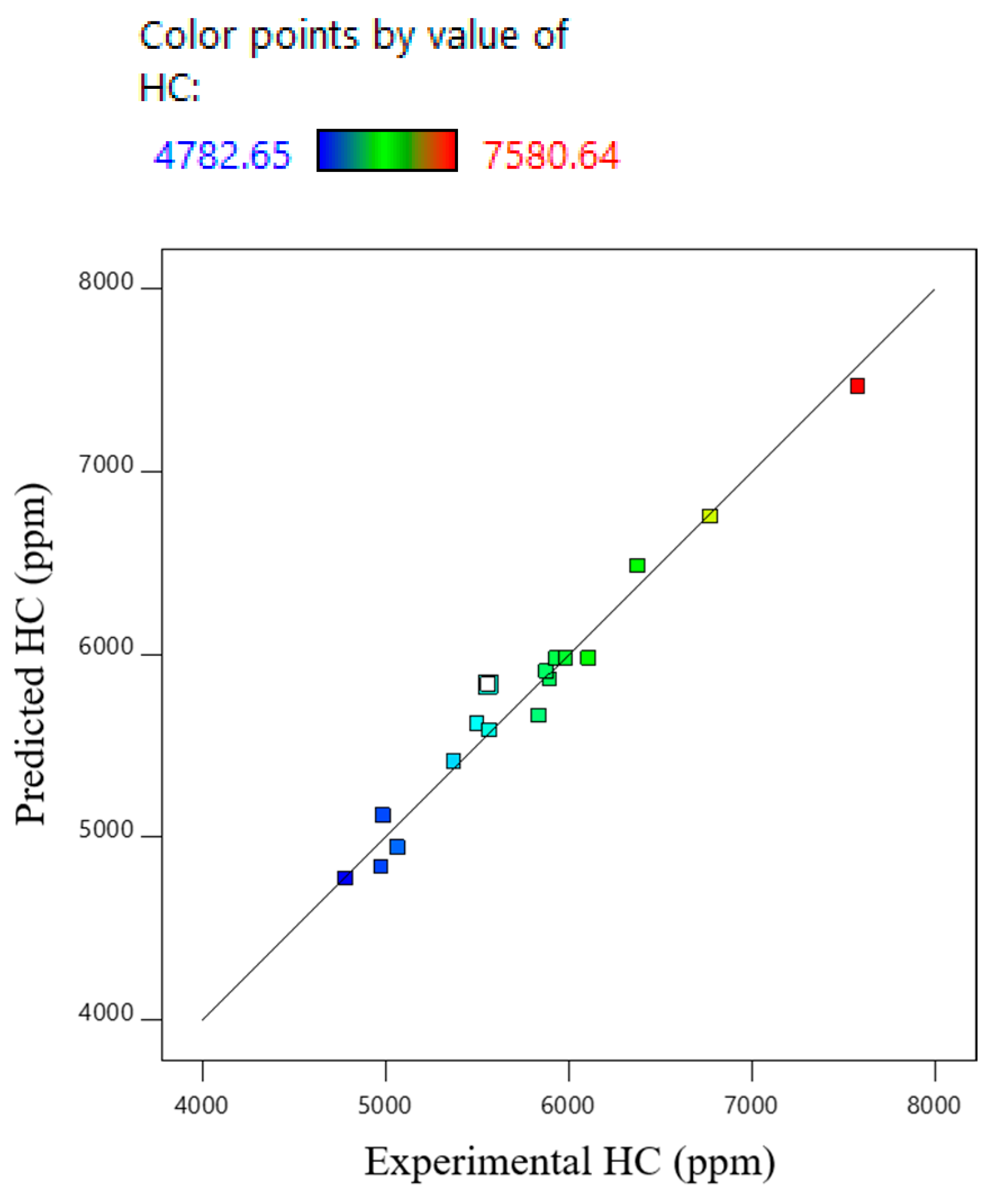

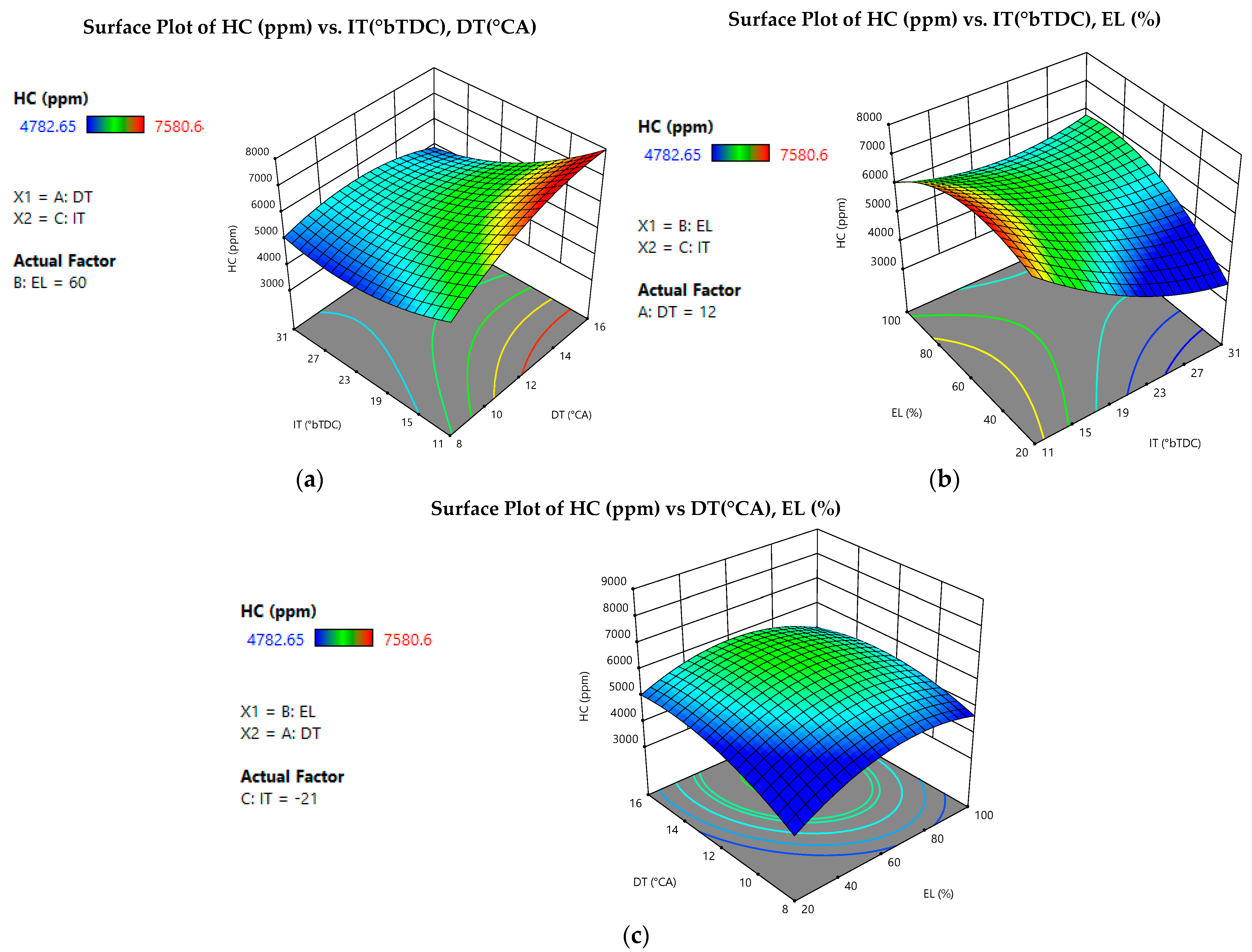

3.3. Unburned Emission (HC) Model

4. Response Optimization and Validation Test

5. Conclusions

- The developed statistical model resulted in a p-value less than 0.05 for the experimental results. This revealed that the developed models were statistically significant.

- The predicted results were compared with the experimental data. It revealed a significant correlation between the experimental findings and the model results. Coefficient of variance (R2) values are close to 1, suggesting that the independent variables are highly correlated.

- Higher desirability of 0.84 is obtained for the optimized operating parameters.

- The best combination of engine operating parameters was obtained as an 87% load, 11° bTDC pre-injection timing, and a dwell time of 8° CA, corresponding to 28.14% for BTE, 5313.93 ppm for NOx and 709.85 ppm for HC. The validation experiments were carried out for the RSM-predicted outcomes. The average error for BTE, HC, and NOx was found to be 2.83%, 3.7%, and 2.85%, respectively, which signified that the present optimization model delivered appropriate results with acceptable error levels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geng, P.; Cao, E.; Tan, Q.; Wei, L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew. Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar] [CrossRef]

- Breuer, J.L.; Samsun, R.C.; Peters, R.; Stolten, D. The impact of diesel vehicles on NOx and PM10 emissions from road transport in urban morphological zones: A case study in North Rhine-Westphalia, Germany. Sci. Total Environ. 2020, 727, 138583. [Google Scholar] [CrossRef]

- Verma, S.K.; Gaur, S.; Akram, T.; Gautam, S.; Kumar, A. Emissions from homogeneous charge compression ignition (HCCI) engine using different fuels: A review. Environ. Sci. Pollut. Res. 2022, 29, 50960–50969. [Google Scholar] [CrossRef] [PubMed]

- Krishnasamy, A.; Gupta, S.K.; Reitz, R.D. Prospective fuels for diesel low temperature combustion engine applications: A critical review. Int. J. Engine Res. 2021, 22, 2071–2106. [Google Scholar] [CrossRef]

- Elkelawy, M.; El Shenawy, E.; Mohamed, S.A.; Elarabi, M.M.; Bastawissi, H.A.-E. Impacts of using EGR and different DI-fuels on RCCI engine emissions, performance, and combustion characteristics. Energy Convers. Manag. X 2022, 15, 100236. [Google Scholar]

- Wardana, M.K.A.; Lim, O. Review of improving the NOx conversion efficiency in various diesel engines fitted with SCR system technology. Catalysts 2022, 13, 67. [Google Scholar] [CrossRef]

- Salvi, B.; Subramanian, K. Sustainable development of road transportation sector using hydrogen energy system. Renew. Sustain. Energy Rev. 2015, 51, 1132–1155. [Google Scholar] [CrossRef]

- Li, W.; Liu, Z.; Wang, Z. Experimental and theoretical analysis of the combustion process at low loads of a diesel natural gas dual-fuel engine. Energy 2016, 94, 728–741. [Google Scholar] [CrossRef]

- Lounici, M.S.; Loubar, K.; Tarabet, L.; Balistrou, M.; Niculescu, D.-C.; Tazerout, M. Towards improvement of natural gas-diesel dual fuel mode: An experimental investigation on performance and exhaust emissions. Energy 2014, 64, 200–211. [Google Scholar] [CrossRef]

- Ouchikh, S.; Lounici, M.; Loubar, K.; Tarabet, L.; Tazerout, M. Effect of diesel injection strategy on performance and emissions of CH4/diesel dual-fuel engine. Fuel 2022, 308, 121911. [Google Scholar] [CrossRef]

- Yang, B.; Wang, L.; Ning, L.; Zeng, K. Effects of pilot injection timing on the combustion noise and particle emissions of a diesel/natural gas dual-fuel engine at low load. Appl. Therm. Eng. 2016, 102, 822–828. [Google Scholar] [CrossRef]

- Yang, B.; Xi, C.; Wei, X.; Zeng, K.; Lai, M.-C. Parametric investigation of natural gas port injection and diesel pilot injection on the combustion and emissions of a turbocharged common rail dual-fuel engine at low load. Appl. Energy 2015, 143, 130–137. [Google Scholar] [CrossRef]

- Aydın, M.; Uslu, S.; Çelik, M.B. Performance and emission prediction of a compression ignition engine fueled with biodiesel-diesel blends: A combined application of ANN and RSM based optimization. Fuel 2020, 269, 117472. [Google Scholar] [CrossRef]

- Tosun, E.; Aydin, K.; Bilgili, M. Comparison of linear regression and artificial neural network model of a diesel engine fueled with biodiesel-alcohol mixtures. Alex. Eng. J. 2016, 55, 3081–3089. [Google Scholar] [CrossRef]

- Ganapathy, T.; Gakkhar, R.; Murugesan, K. Optimization of performance parameters of diesel engine with Jatropha biodiesel using response surface methodology. Int. J. Sustain. Energy 2011, 30, S76–S90. [Google Scholar] [CrossRef]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Azmi, W.; Kadirgama, K.; Yusri, I.; Leman, A.; Yusaf, T. Response surface methodology (RSM) based multi-objective optimization of fusel oil-gasoline blends at different water content in SI engine. Energy Convers. Manag. 2017, 150, 222–241. [Google Scholar] [CrossRef]

- Ganapathy, T.; Murugesan, K.a.; Gakkhar, R. Performance optimization of Jatropha biodiesel engine model using Taguchi approach. J. Appl. Energy 2009, 86, 2476–2486. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Kumar, S.; Dinesha, P. Optimization of engine parameters in a bio diesel engine run with honge methyl ester using response surface methodology. Measurement 2018, 125, 224–231. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Tiwari, S.; Singla, A. Optimization of diesel engine performance and emission parameters employing cassia tora methyl esters-response surface methodology approach. Energy 2019, 168, 909–918. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Singh, G.K.; Singla, A.; Singh, N.K. Optimization of performance and emission parameters of direct injection diesel engine fuelled with pongamia methyl esters-response surface methodology approach. Ind. Crops Prod. 2018, 126, 218–226. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Determination of a diesel engine operating parameters powered with canola, safflower and waste vegetable oil based biodiesel combination using response surface methodology (RSM). Fuel 2020, 270, 117496. [Google Scholar] [CrossRef]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. J. R. Stat. Soc. B 1992, 13, 270–310. [Google Scholar]

- Bharadwaz, Y.D.; Rao, B.G.; Rao, V.D.; Anusha, C. Improvement of biodiesel methanol blends performance in a variable compression ratio engine using response surface methodology. Alex. Eng. J. 2016, 55, 1201–1209. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S.; Rana, D.; Nagendran, A. Combined effect of injection timing and exhaust gas recirculation (EGR) on performance and emissions of a DI diesel engine fuelled with next-generation advanced biofuel–diesel blends using response surface methodology. Energy Convers. Manag. 2016, 123, 470–486. [Google Scholar] [CrossRef]

- Kashyap, D.; Das, S.; Kalita, P. Exploring the efficiency and pollutant emission of a dual fuel CI engine using biodiesel and producer gas: An optimization approach using response surface methodology. Sci. Total Environ. 2021, 773, 145633. [Google Scholar] [CrossRef]

| Engine Type | 4 Strokes, CI, Diesel Direct Injection (DI) |

|---|---|

| Bore × stroke | 85.01 mm × 90 mm |

| Connecting rod | 165.3 mm |

| Volumetric capacity | 511 cm3 |

| Compression ratio | 17:1 |

| Power output | 6 kW at 4500 rpm |

| Number of injections | 5 |

| Number of valves | 2 admission, 2 exhaust |

| IVO | 0° CA before TDC |

| IVC | 14° CA after BDC |

| EVO | 24° CA before BDC |

| EVC | 3° CA after TDC |

| Input Parameters | Symbol | Coded Level | ||||

|---|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | ||

| Dwell time (DT) (°CA) | A | 8 | 10 | 12 | 14 | 16 |

| Engine load (EL) (%) | B | 20 | 40 | 60 | 80 | 100 |

| Pre-injection timing (IT) (°bTDC) | C | 31 | 26 | 21 | 16 | 11 |

| Factor 1 | Factor 2 | Factor 3 | Response 1 | Response 2 | Response 3 | ||

|---|---|---|---|---|---|---|---|

| Std | Run | DT | EL | IT | BTE | HC | NOx |

| °CA | % | °bTDC | % | ppm | ppm | ||

| 6 | 1 | 14 | 40 | 16 | 18.43 | 6775.08 | 229.95 |

| 5 | 2 | 10 | 40 | 16 | 19.02 | 5563.49 | 390.56 |

| 3 | 3 | 10 | 80 | 26 | 25.42 | 5503.38 | 2523.46 |

| 9 | 4 | 8 | 60 | 21 | 24.26 | 5068.12 | 1382.42 |

| 15 | 5 | 12 | 60 | 21 | 23.37 | 5935.43 | 711.04 |

| 16 | 6 | 12 | 60 | 21 | 22.83 | 6111.02 | 748.13 |

| 7 | 7 | 10 | 80 | 16 | 26.52 | 5899.03 | 864.28 |

| 12 | 8 | 12 | 100 | 21 | 28.14 | 5374.28 | 1670.62 |

| 14 | 9 | 12 | 60 | 11 | 21.26 | 7580.64 | 256.27 |

| 2 | 10 | 14 | 40 | 26 | 18.66 | 4988.03 | 755.6 |

| 10 | 11 | 16 | 60 | 21 | 22.85 | 5881.04 | 532.75 |

| 17 | 12 | 12 | 60 | 21 | 22.81 | 5984.98 | 759.9 |

| 1 | 13 | 10 | 40 | 26 | 18.21 | 4782.65 | 1336.86 |

| 11 | 14 | 12 | 20 | 21 | 11.7 | 4976.82 | 340.48 |

| 13 | 15 | 12 | 60 | 31 | 21.26 | 5571 | 1985 |

| 4 | 16 | 14 | 80 | 26 | 24.75 | 5838.51 | 1625.2 |

| 8 | 17 | 14 | 80 | 16 | 25.61 | 6379.47 | 570.15 |

| Model Terms | BTE Model | HC Model | NOx Model | |||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Model | 83.32 | <0.0001 | 27.58 | 0.0001 | 74.70 | <0.0001 |

| A (DT) | 3.84 | 0.0908 | 30.06 | 0.0009 | 79.80 | <0.0001 |

| B (EL) | 690.56 | <0.0001 | 10.74 | 0.0135 | 184.87 | <0.0001 |

| C (IT) | 1.20 | 0.3090 | 114.29 | <0.0001 | 353.15 | <0.0001 |

| AB | 0.7732 | 0.4084 | 1.46 | 0.2661 | 2.45 | 0.1612 |

| AC | 0.6109 | 0.4601 | 5.35 | 0.0539 | 12.70 | 0.0092 |

| BC | 0.7101 | 0.4273 | 10.75 | 0.0135 | 18.66 | 0.0035 |

| A2 | 1.20 | 0.3095 | 11.92 | 0.0107 | 6.30 | 0.0404 |

| B2 | 33.78 | 0.0007 | 28.33 | 0.0011 | 9.18 | 0.0191 |

| C2 | 10.66 | 0.0138 | 11.79 | 0.0109 | 18.27 | 0.0037 |

| Lack of fit | 4.25 | 0.2014 | 4.89 | 0.1785 | 21.86 | 0.0443 |

| BTE Model | HC Model | NOx Model | |

|---|---|---|---|

| R2 | 0.9908 | 0.9726 | 0.9897 |

| R2 (adj.) | 0.9789 | 0.9373 | 0.9764 |

| Predicted R2 | 0.9269 | 0.8007 | 0.9171 |

| Input Control Variable | Output Response | |||||

|---|---|---|---|---|---|---|

| EL (%) | DT | IT | BTE (%) | HC (ppm) | NOx (ppm) | |

| 87% | 8° CA | 11° bTDC | Predicted | 28.14 | 5313.93 | 709.85 |

| Experimental | 27.34 | 5468.69 | 737.13 | |||

| % Error | 2.83 < 5% | 3.70 < 5% | 2.85 < 5% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouchikh, S.; Lounici, M.S.; Loubar, K.; Tazerout, M. Optimization of Injection Strategy for CH4/Diesel Dual-Fuel Engine Using Response Surface Methodology. Energies 2025, 18, 2115. https://doi.org/10.3390/en18082115

Ouchikh S, Lounici MS, Loubar K, Tazerout M. Optimization of Injection Strategy for CH4/Diesel Dual-Fuel Engine Using Response Surface Methodology. Energies. 2025; 18(8):2115. https://doi.org/10.3390/en18082115

Chicago/Turabian StyleOuchikh, Sarah, Mohand Said Lounici, Khaled Loubar, and Mohand Tazerout. 2025. "Optimization of Injection Strategy for CH4/Diesel Dual-Fuel Engine Using Response Surface Methodology" Energies 18, no. 8: 2115. https://doi.org/10.3390/en18082115

APA StyleOuchikh, S., Lounici, M. S., Loubar, K., & Tazerout, M. (2025). Optimization of Injection Strategy for CH4/Diesel Dual-Fuel Engine Using Response Surface Methodology. Energies, 18(8), 2115. https://doi.org/10.3390/en18082115