Multi-Objective Optimization Research Based on NSGA-II and Experimental Study of Triplex-Tube Phase Change Thermal Energy Storage System

Abstract

1. Introduction

2. Methodology

2.1. NSGA-II

2.2. Mathematical Model

2.2.1. Model Assumptions

- 1.

- The HTF flow is treated as one-dimensional along the flow direction with axisymmetric heat transfer, allowing the heat transfer model to be approximated as two-dimensional.

- 2.

- The phase change thermal storage process refers exclusively to latent heat storage, excluding sensible heat effects.

- 3.

- The external insulation layer effectively isolates heat transfer, rendering heat loss between the unit and environment negligible. The outer tube surface is treated as adiabatic.

- 4.

- Except for density, material properties are temperature independent, with natural convection driven solely by density variations, satisfying the Boussinesq approximation.

- 5.

- The HTF is incompressible, with constant thermophysical properties and fixed inlet/outlet temperatures.

- 6.

- The thermal resistance of the heat exchange surfaces in the thermal energy storage unit is negligible.

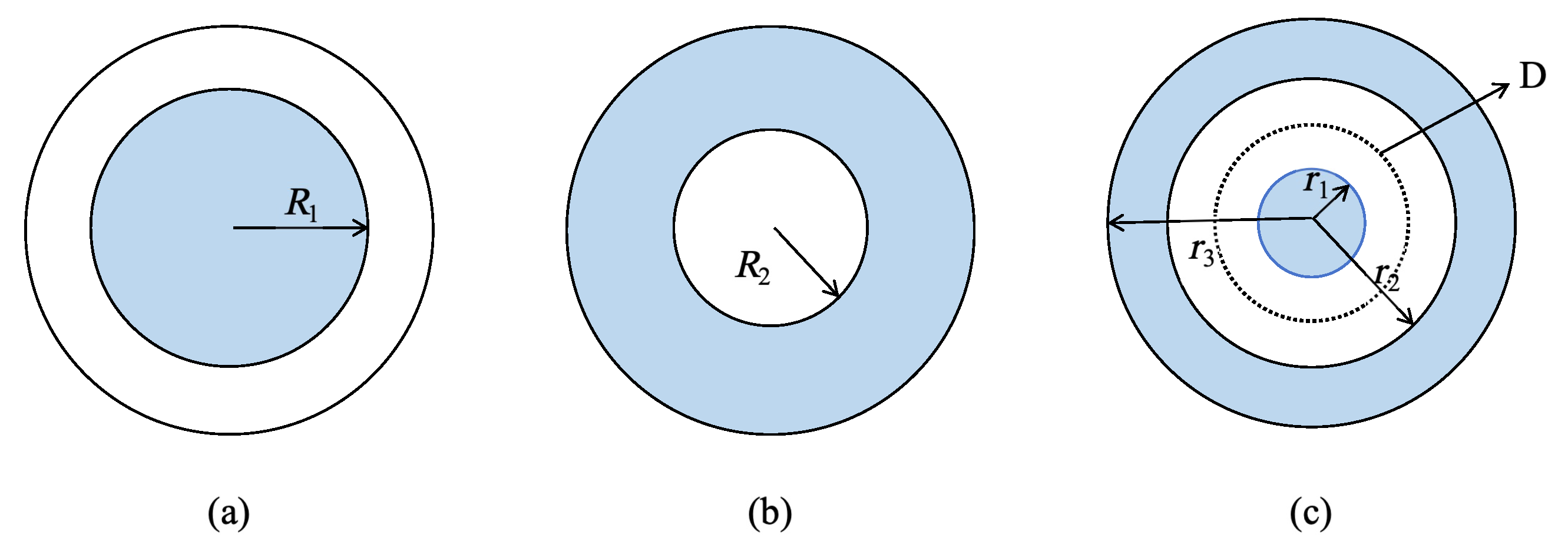

2.2.2. Optimization Variables

2.2.3. Objective Function

2.2.4. Constraints

- 1.

- The variables must satisfy .

- 2.

- The latent heat storage completion time (t) of the triplex-tube phase change thermal storage unit must be less than the user-specified time ().

- 3.

- The unit length (L) cannot exceed the user-defined maximum length (l) due to spatial and practical application limitations.

2.3. Numerical Methods

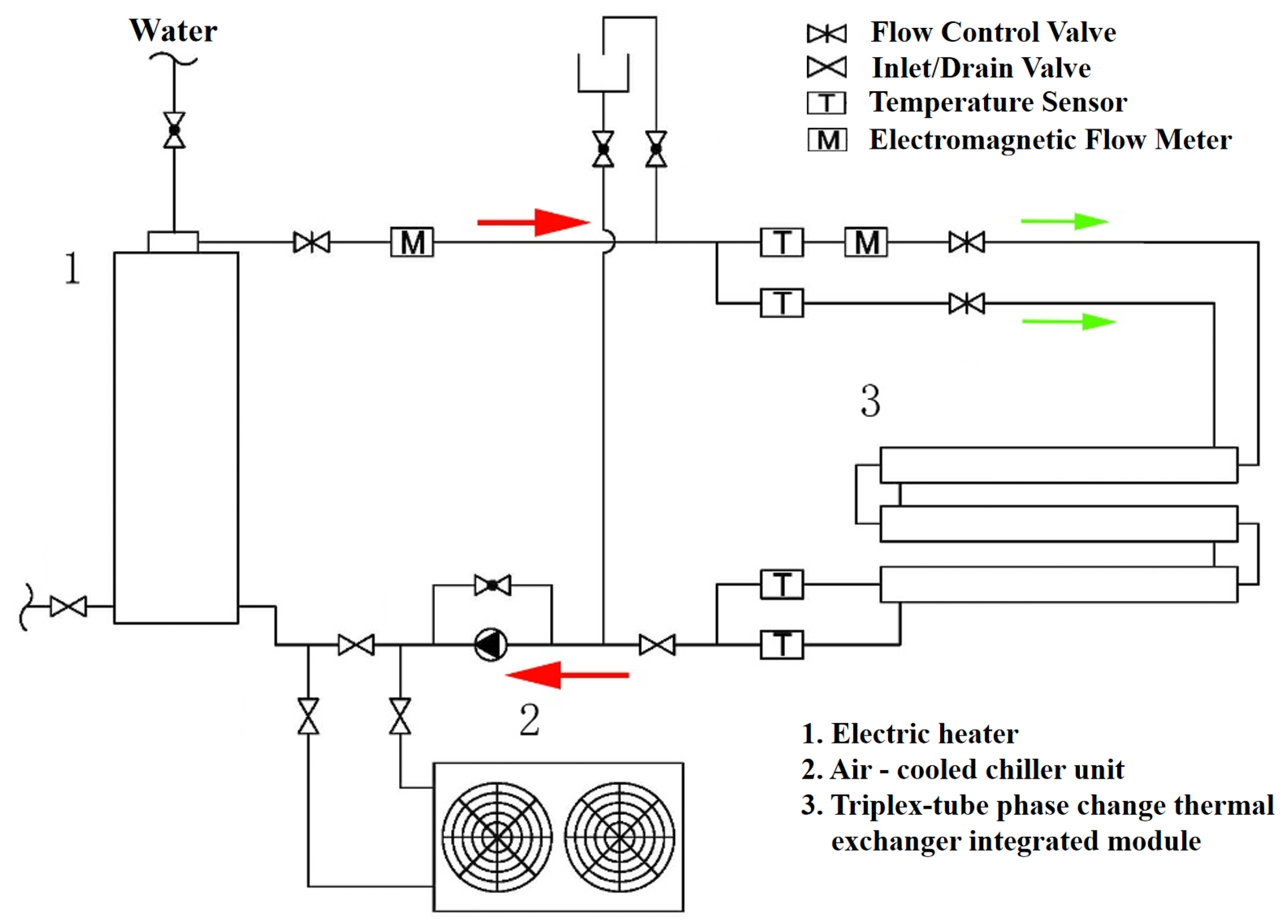

2.4. Experimental Design

3. Results

3.1. Validation of Numerical Model

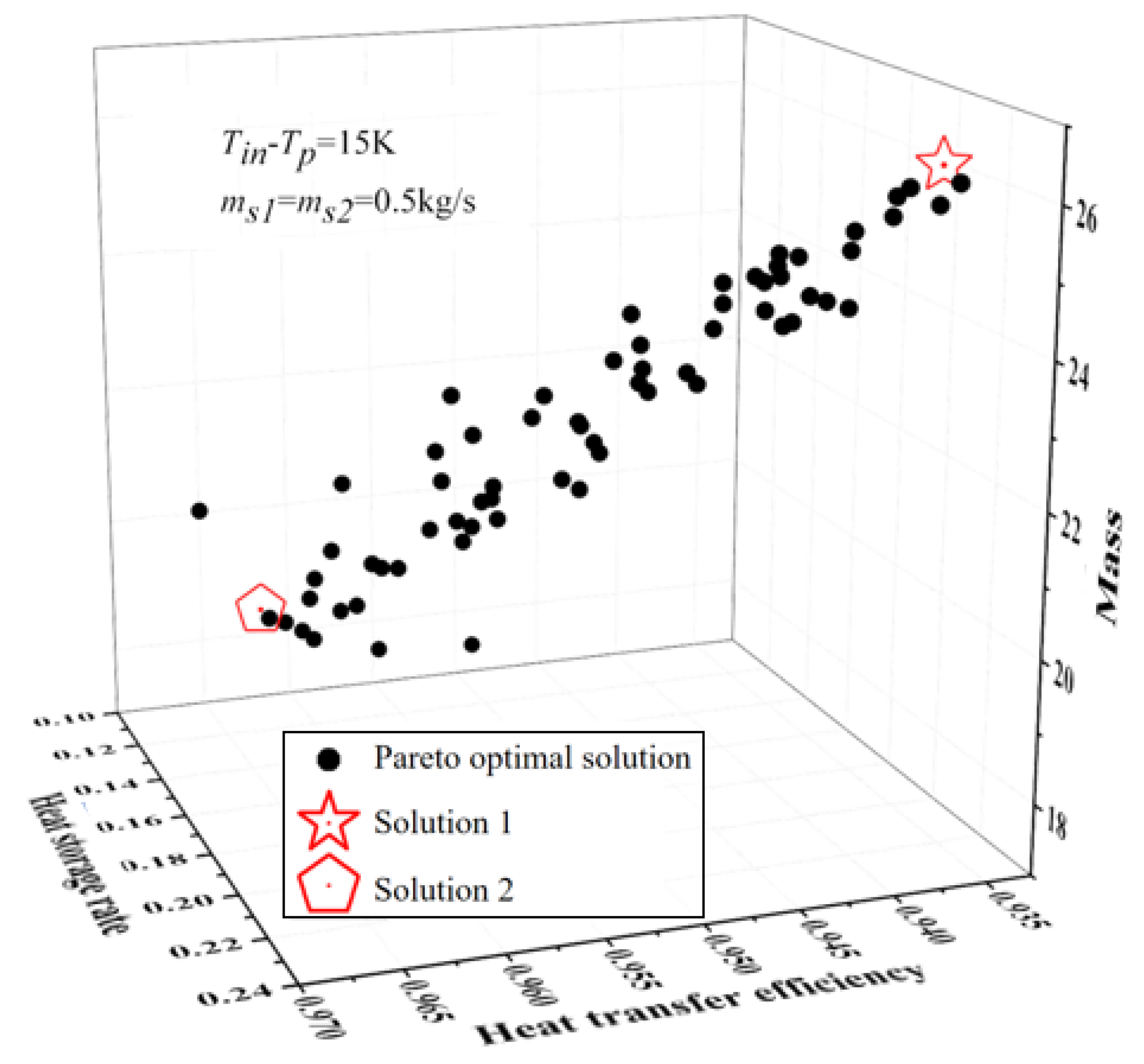

3.2. Optimization Outcomes

3.3. Influence of Geometric Parameters

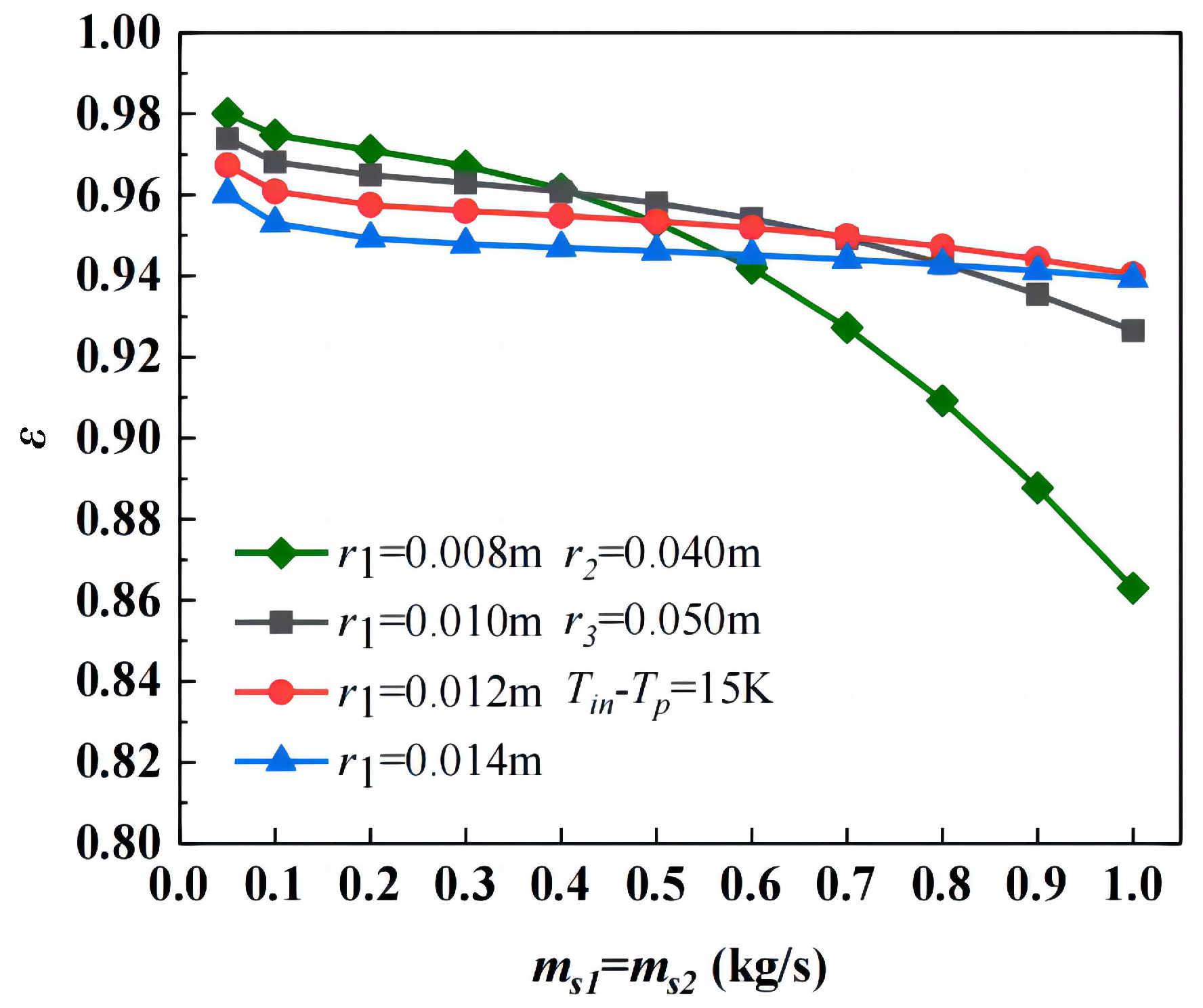

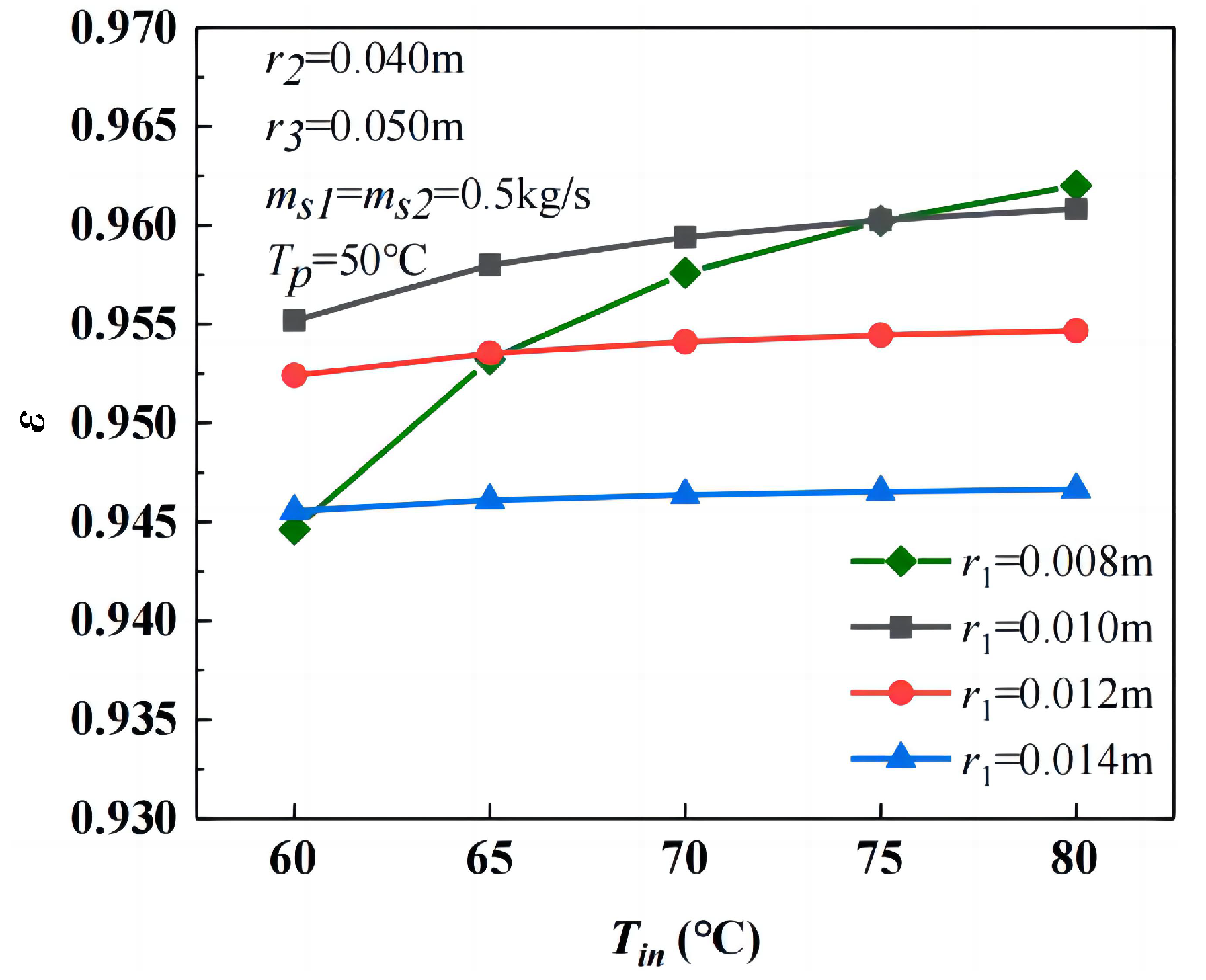

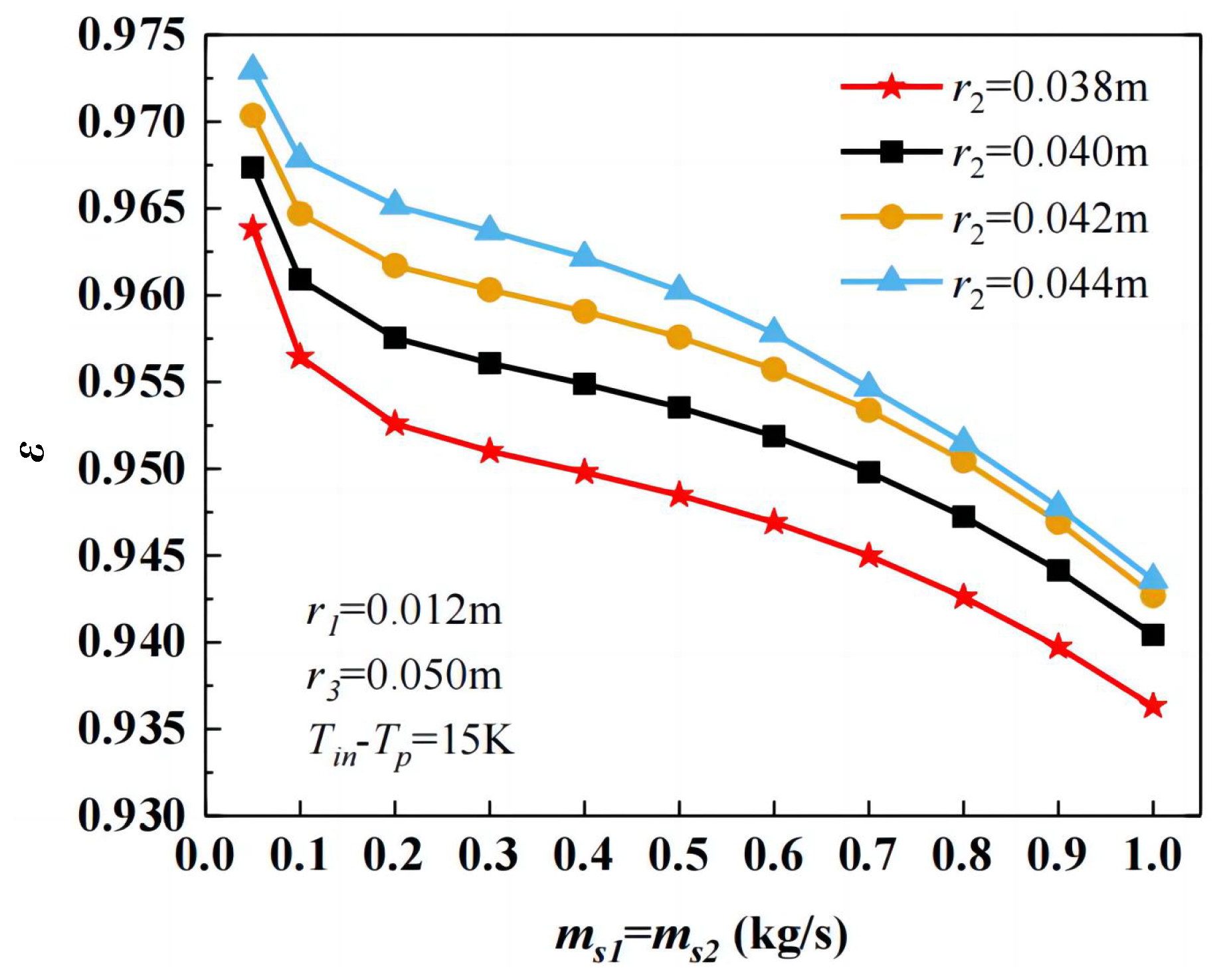

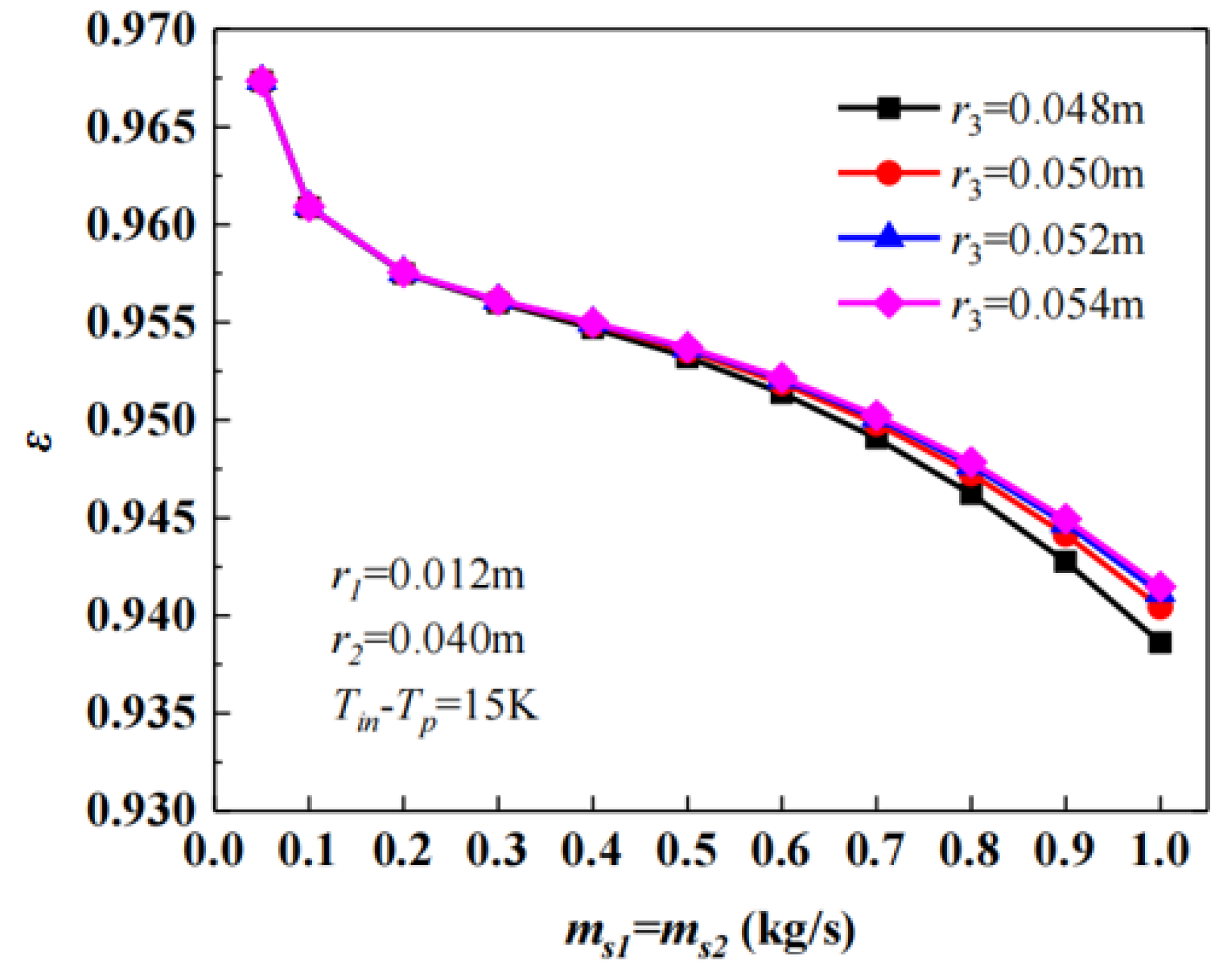

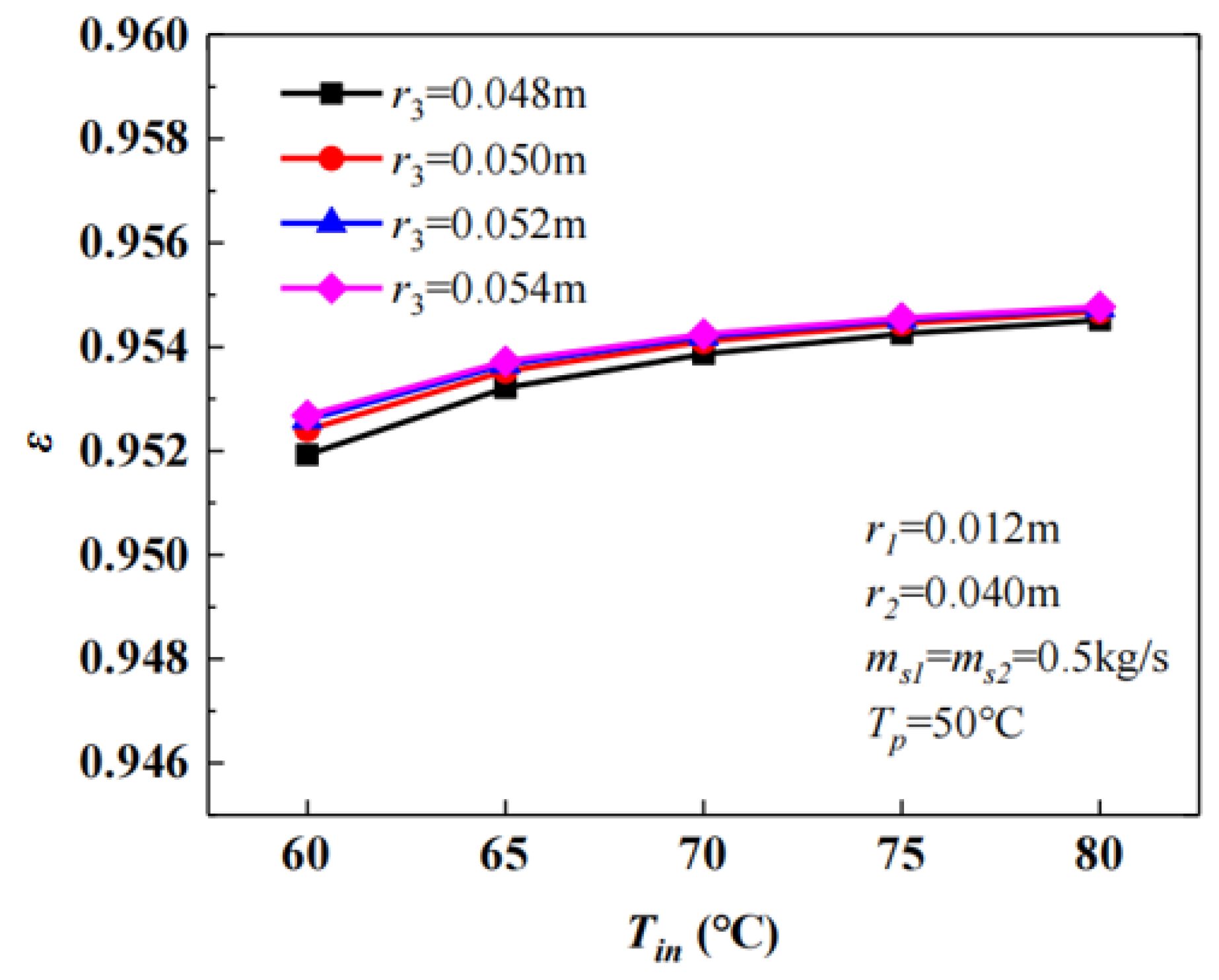

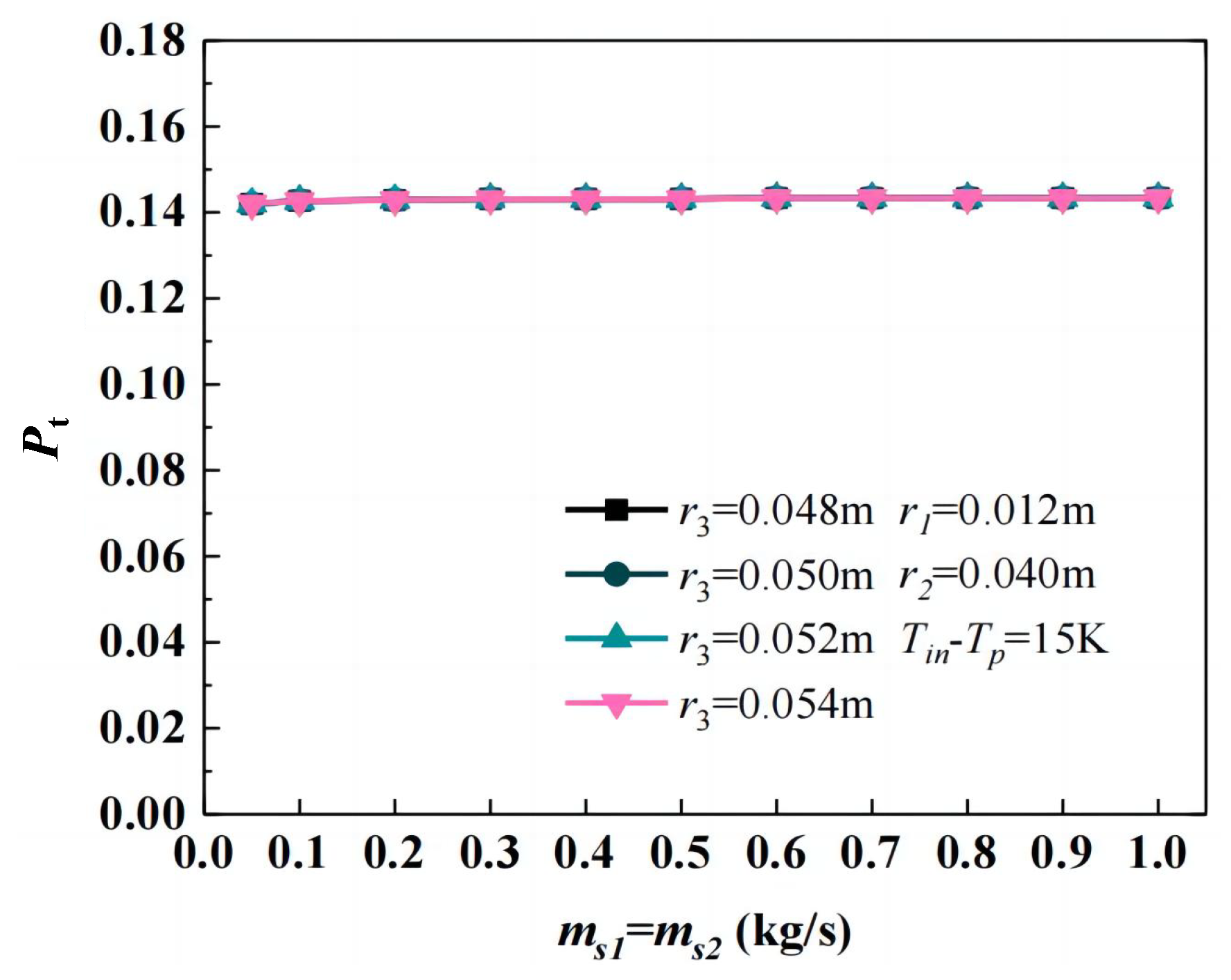

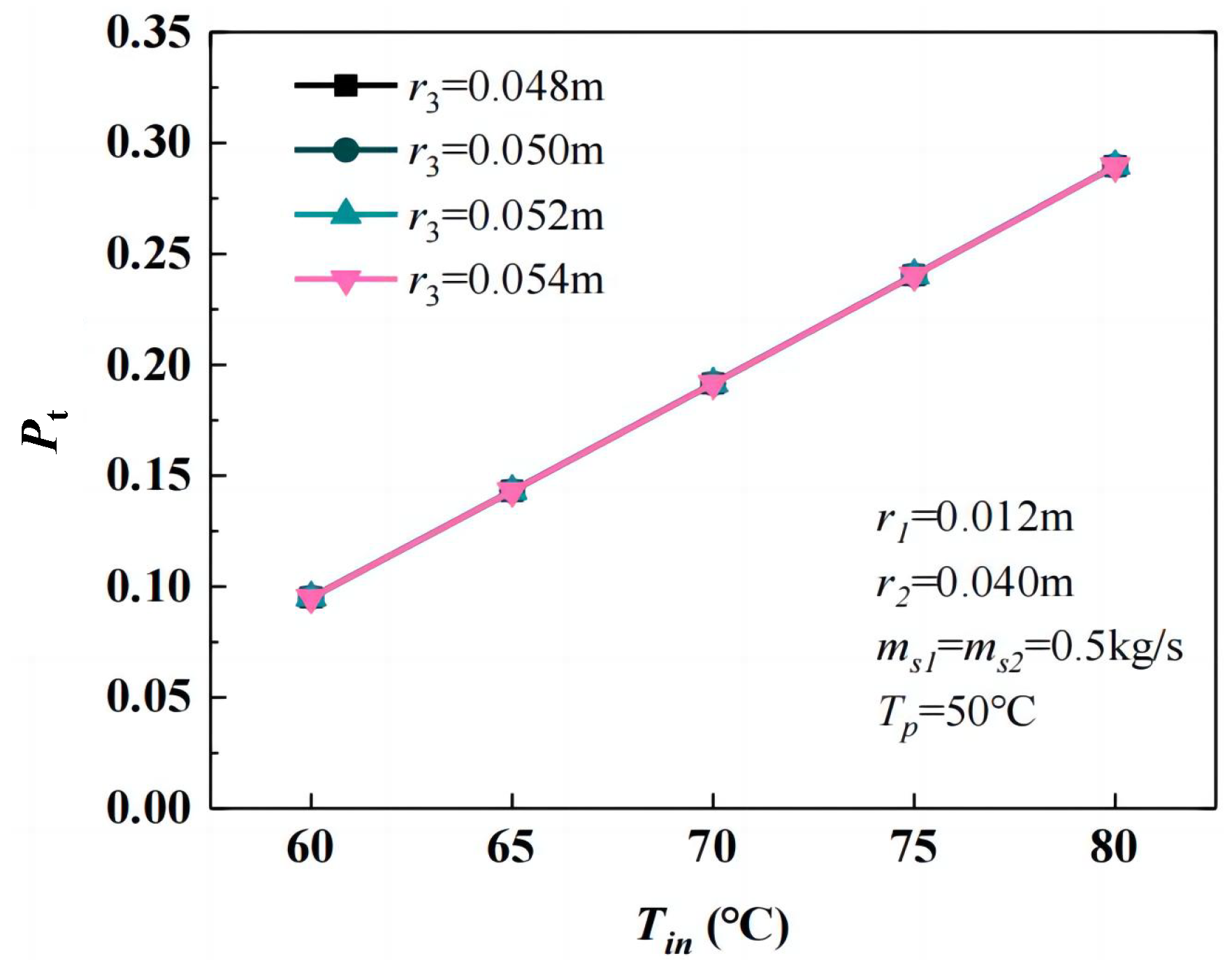

3.3.1. Heat Transfer Efficiency

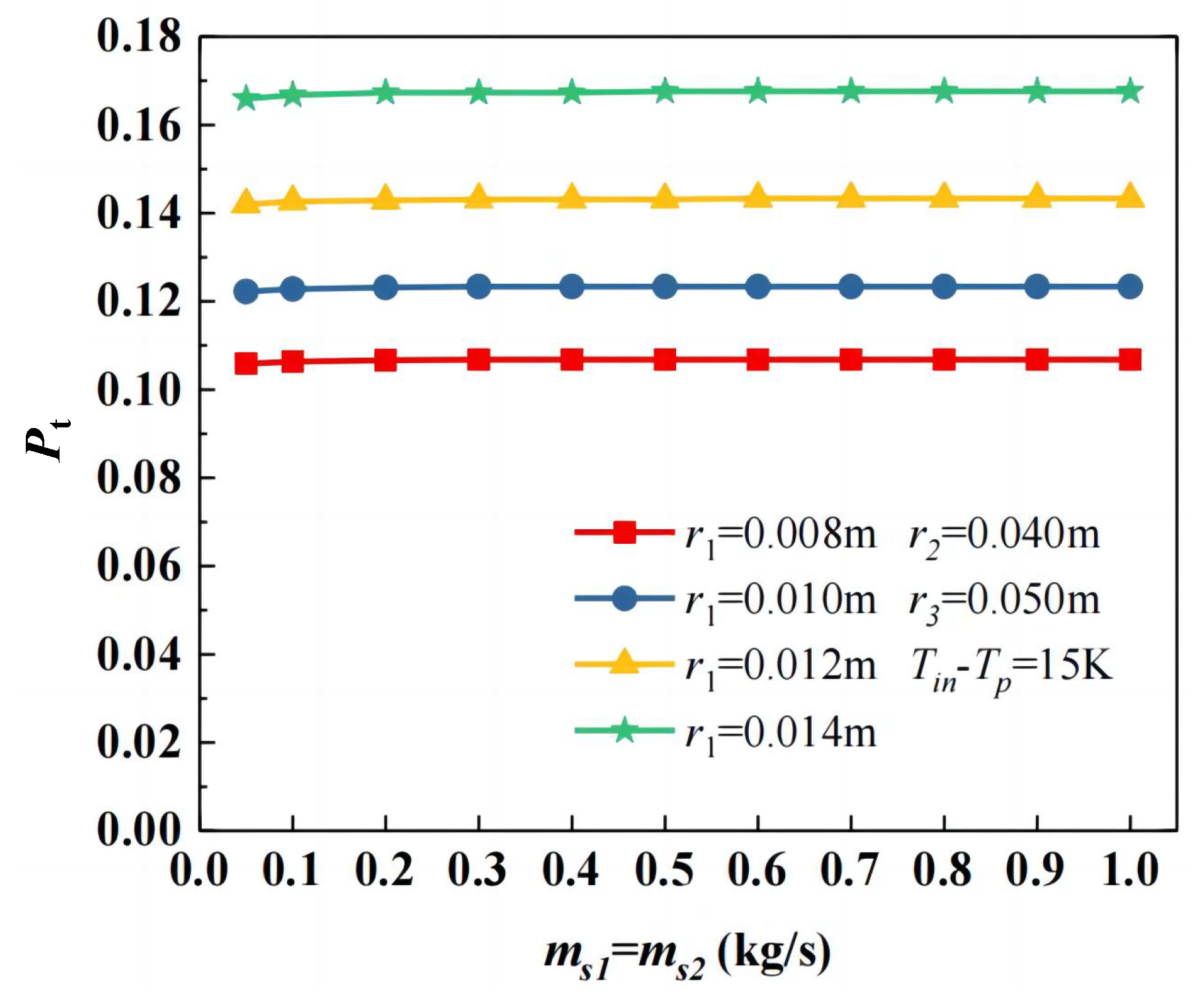

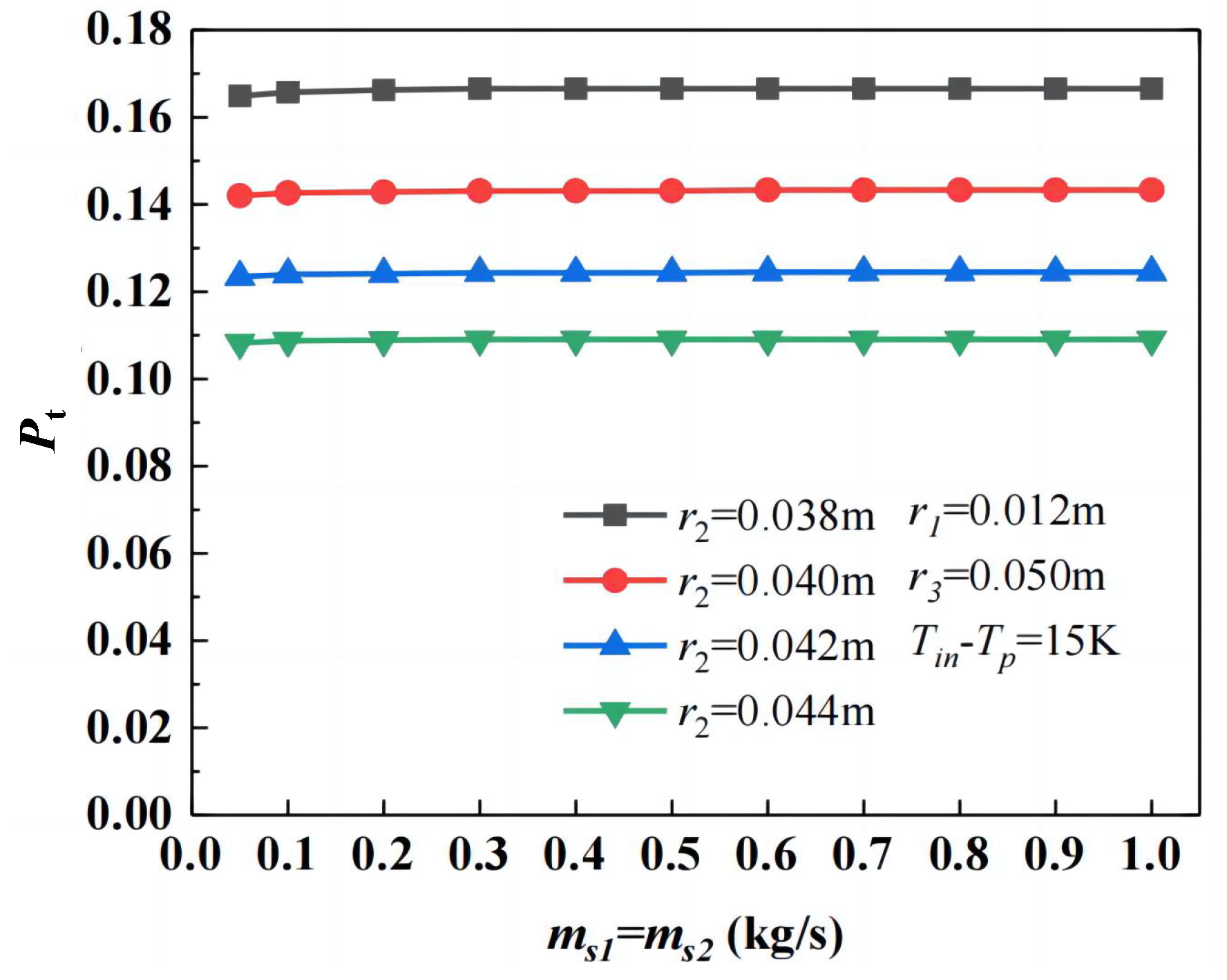

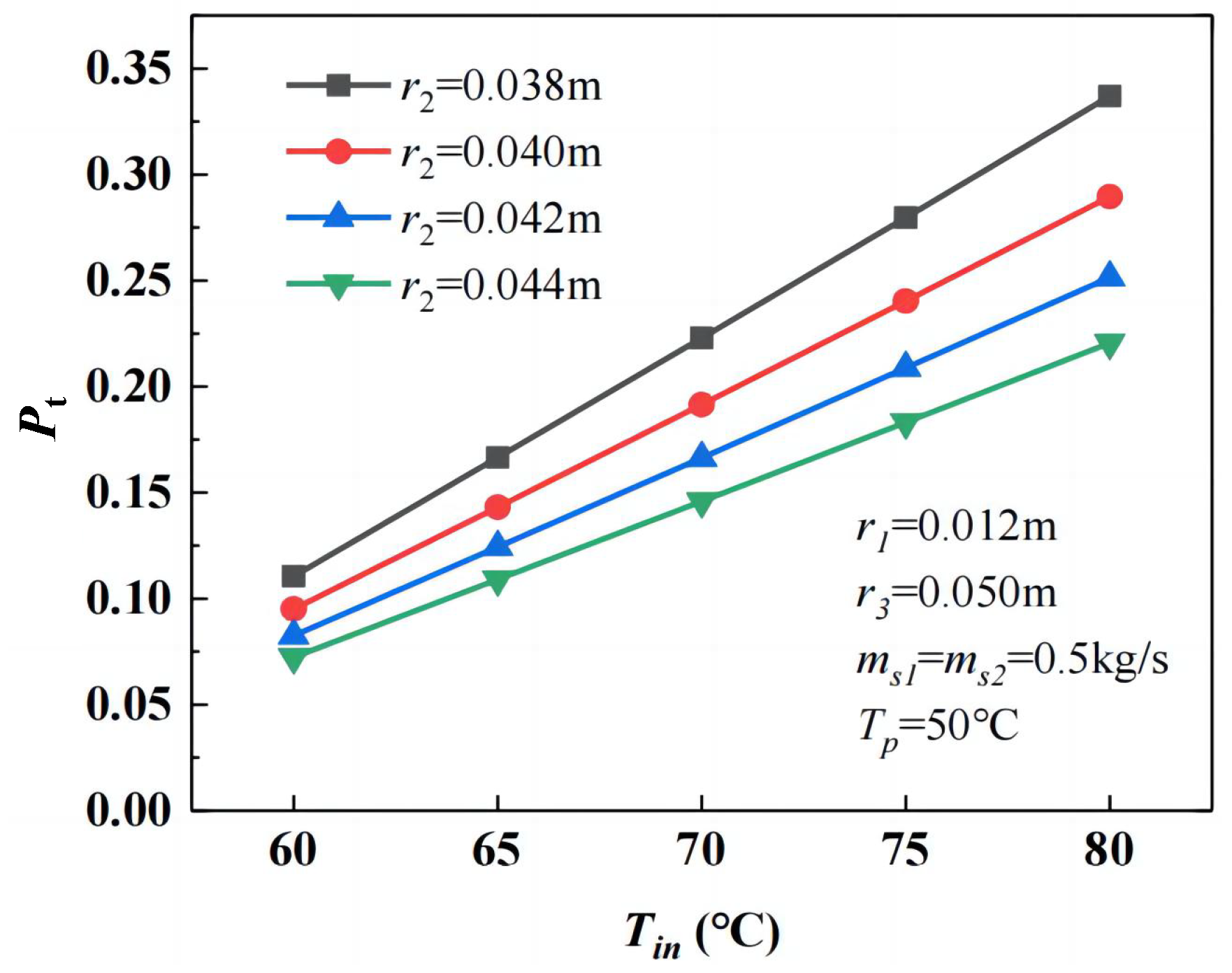

3.3.2. Heat Storage Rate

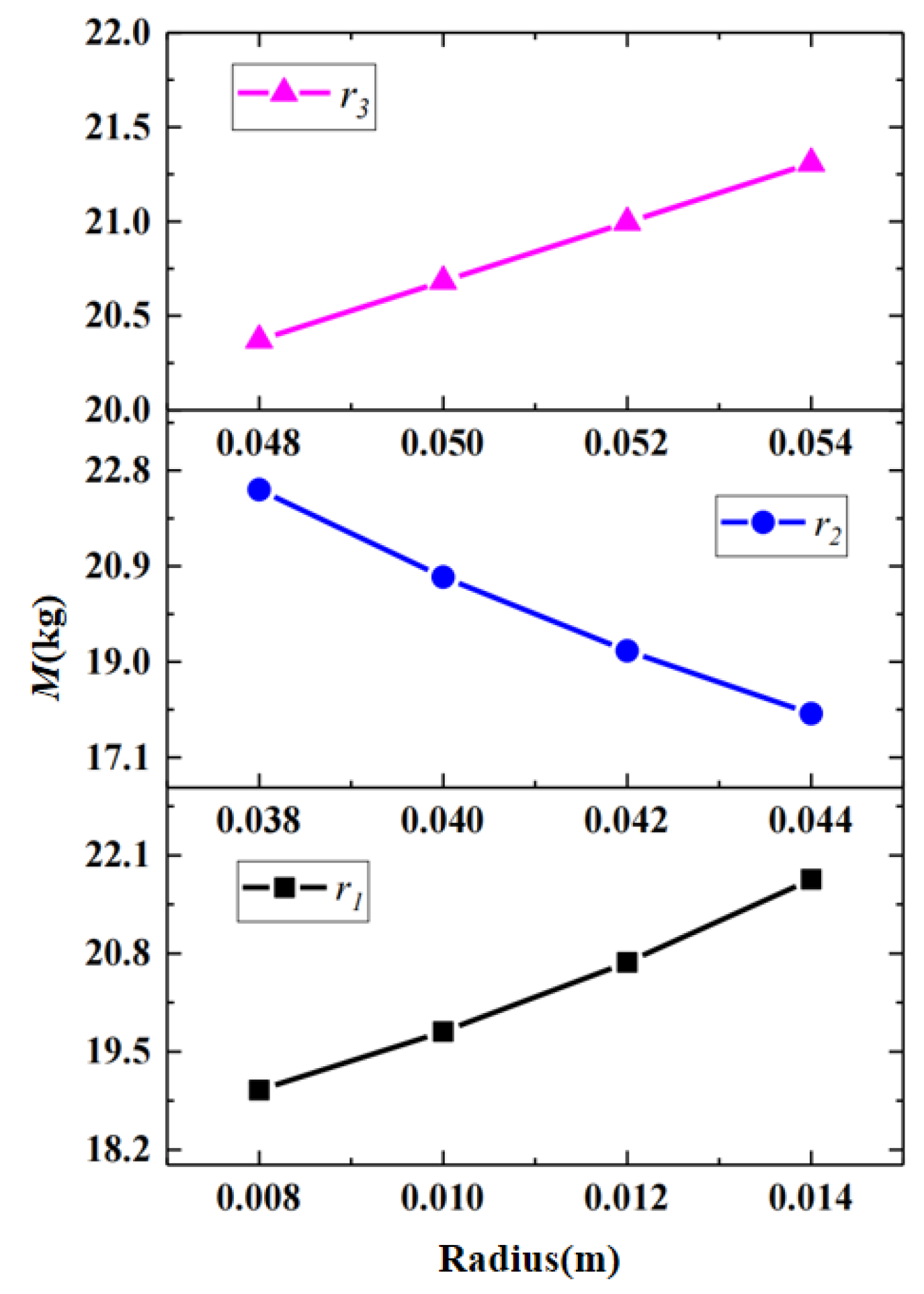

3.3.3. Unit Mass M

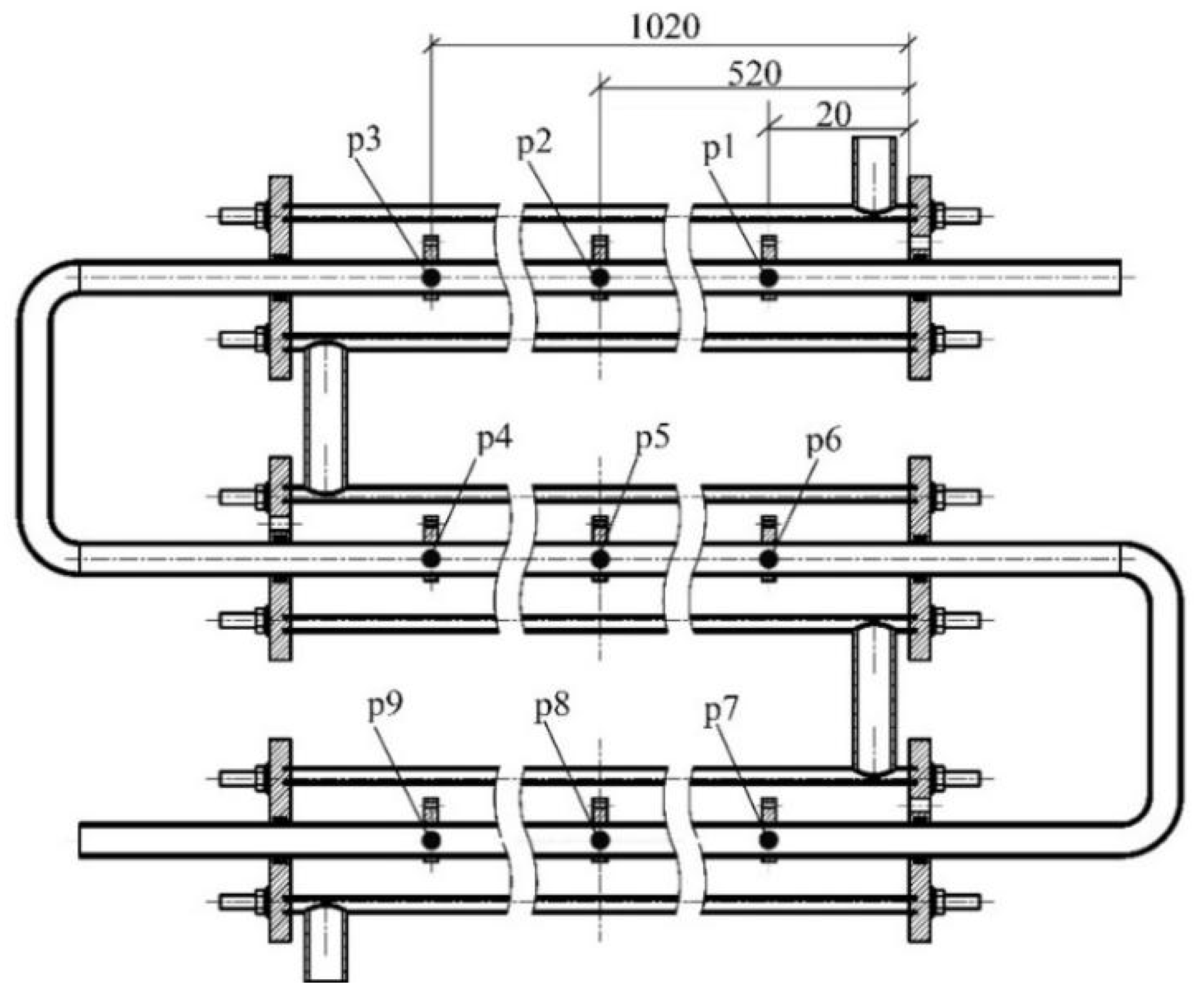

3.4. Performance Characteristics of Integrated Module

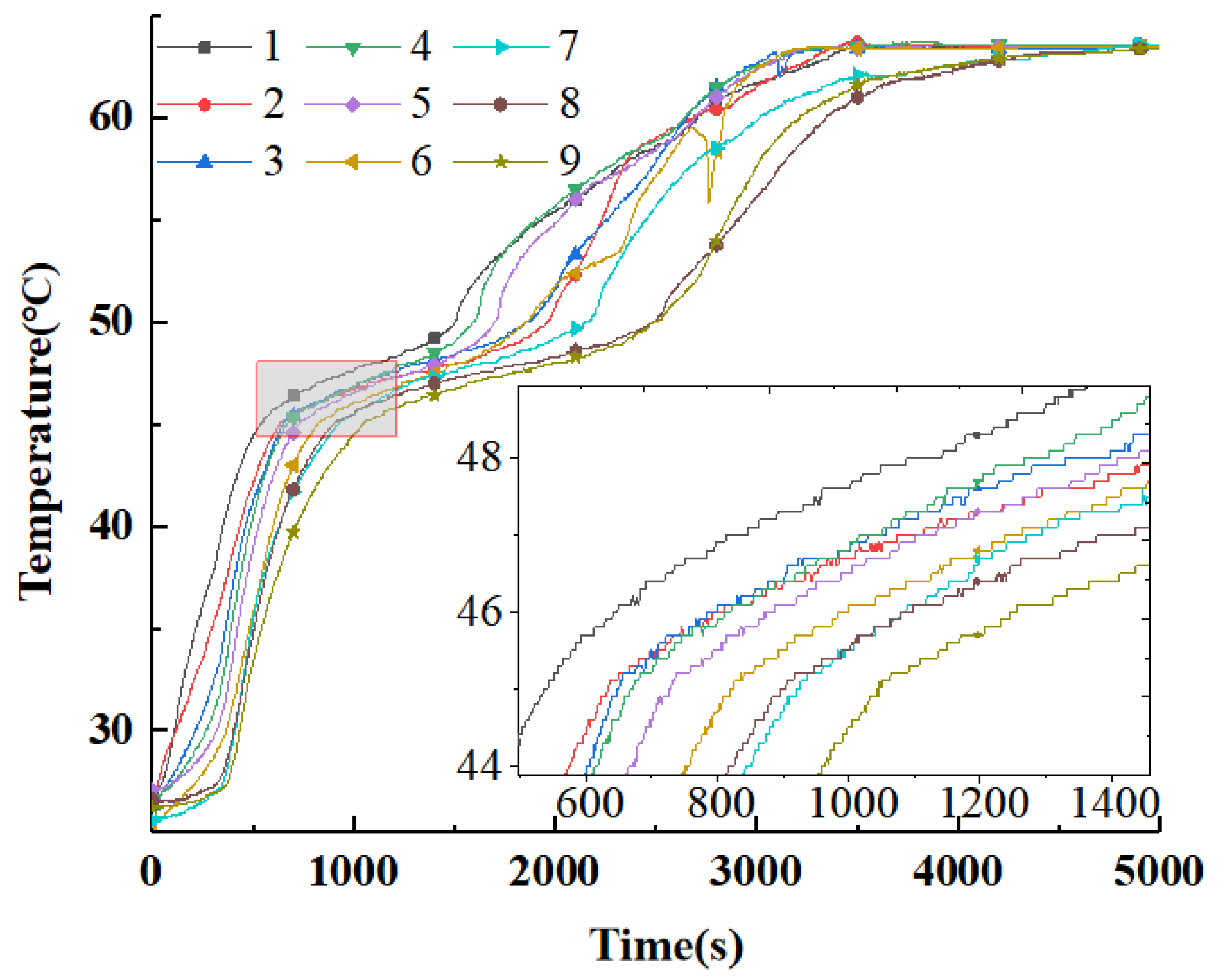

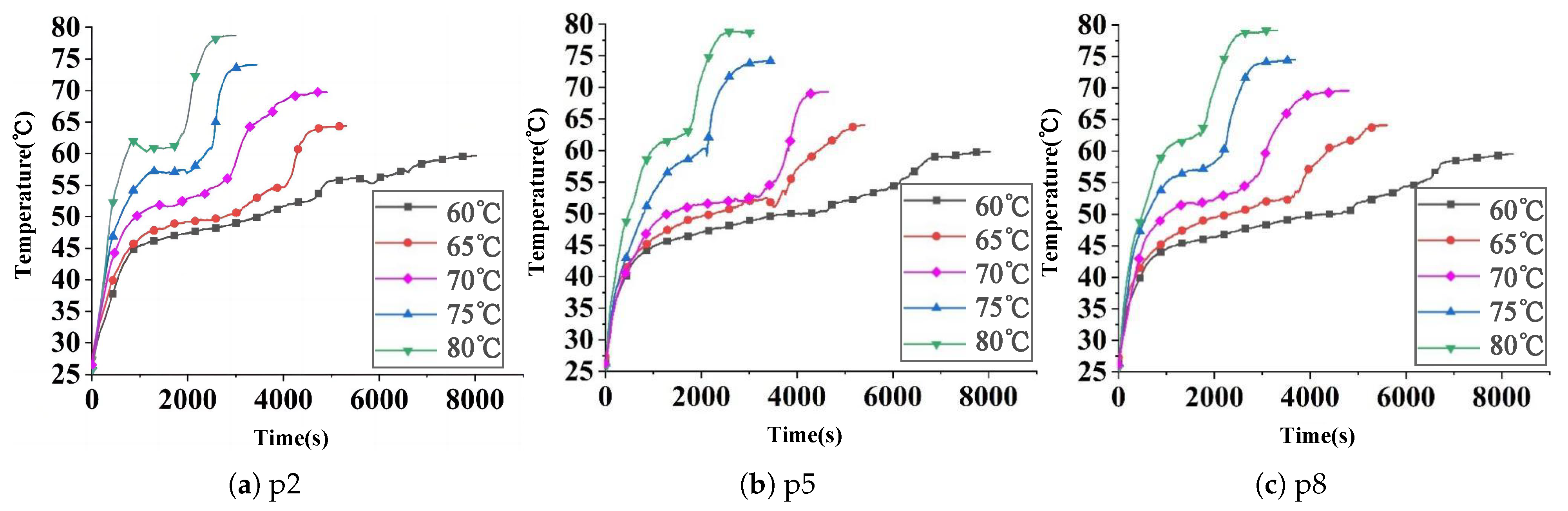

3.4.1. Heat Storage Dynamics

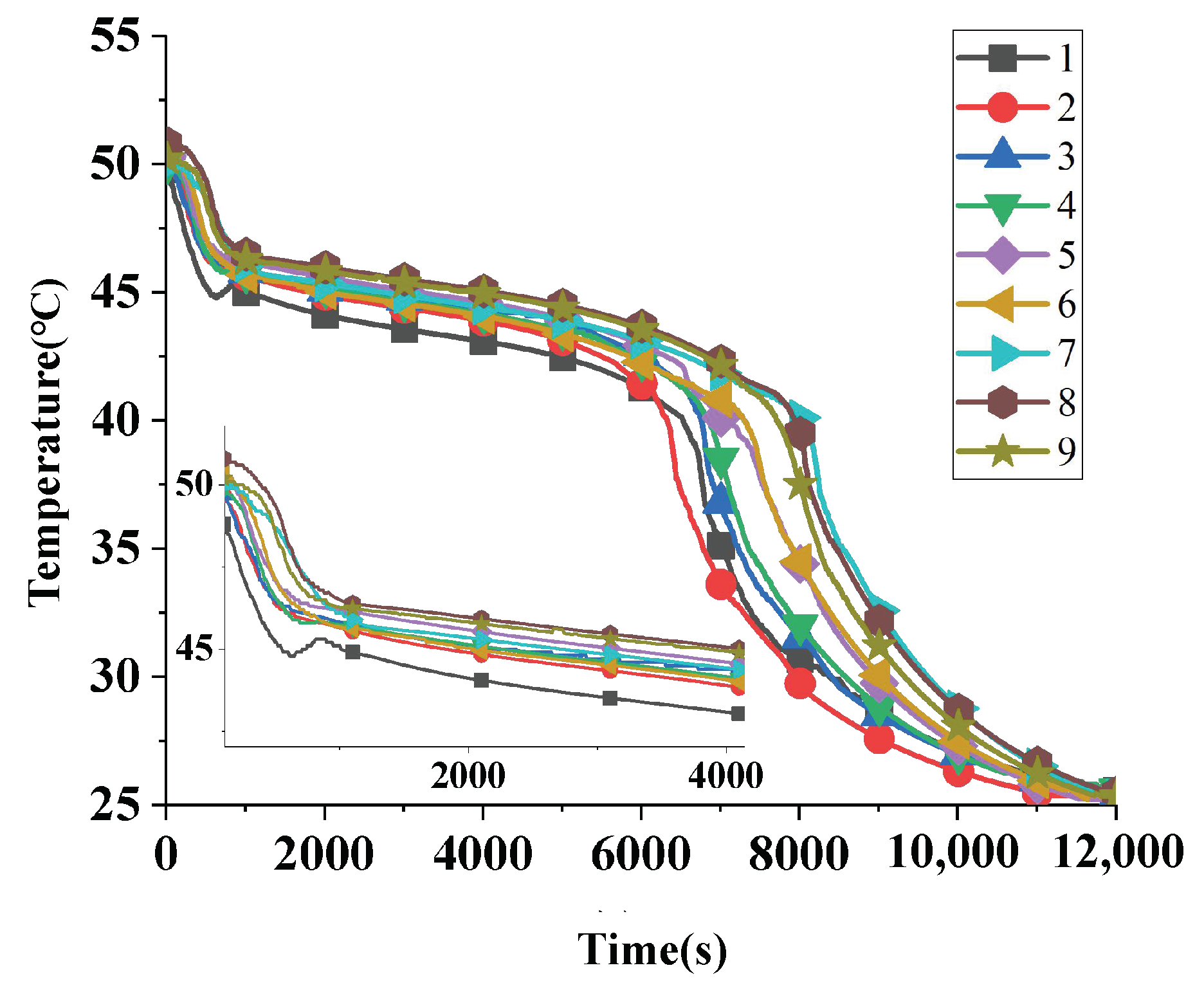

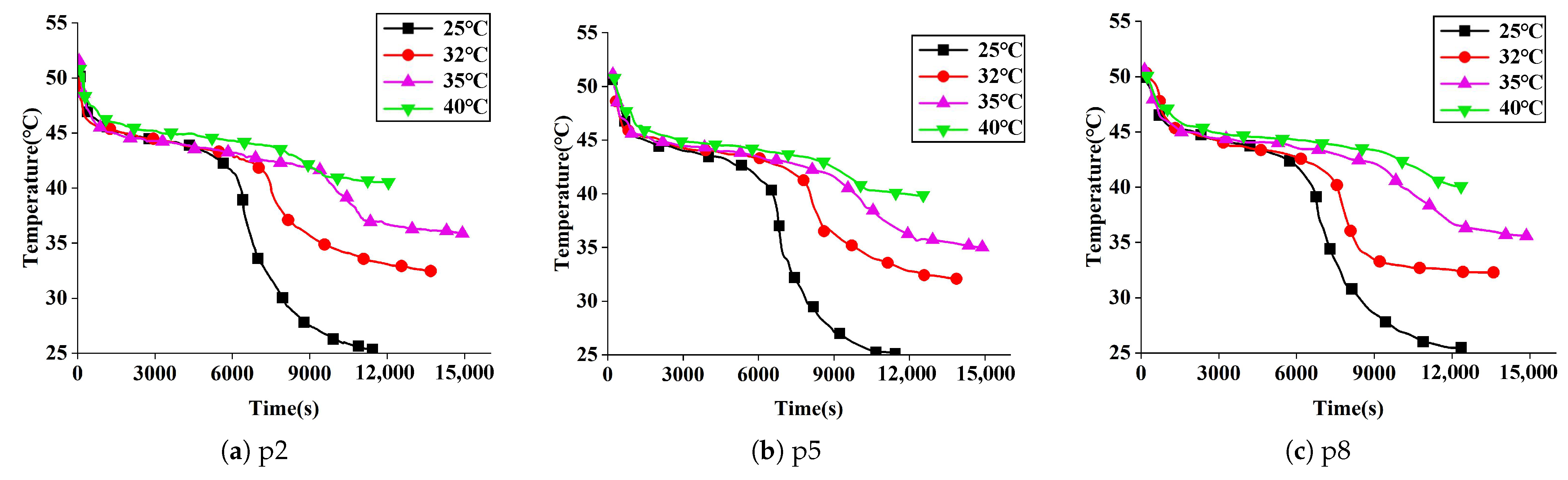

3.4.2. Heat Release Dynamics

3.4.3. Heating Capacity Response Characteristics

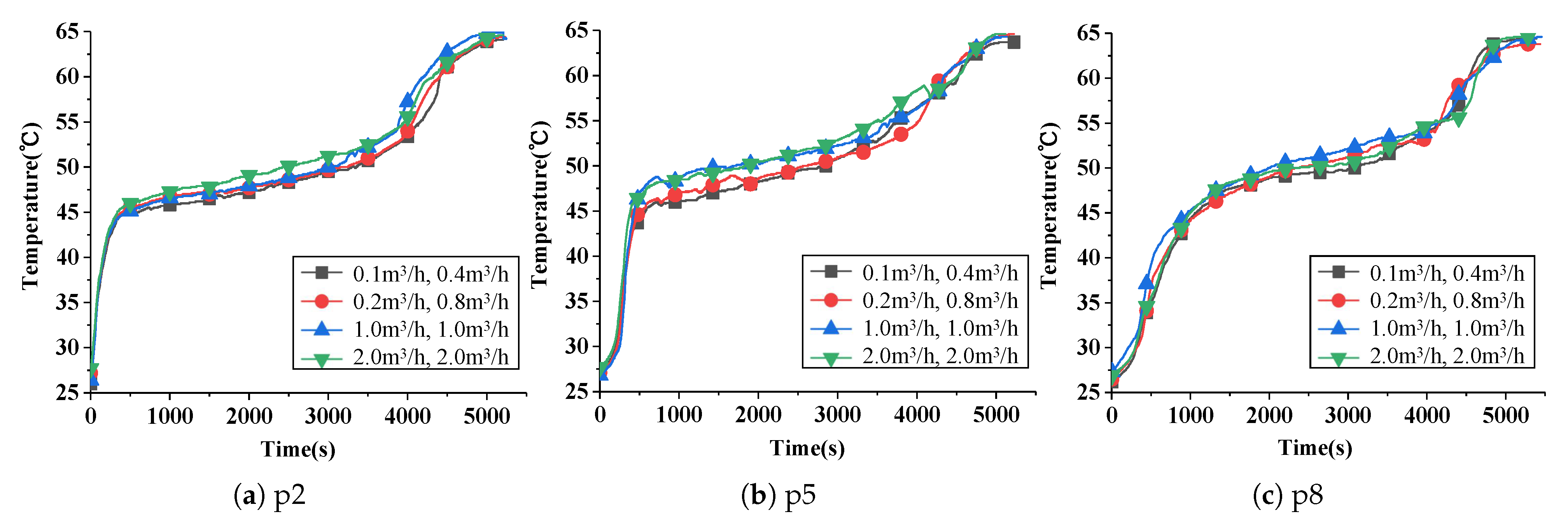

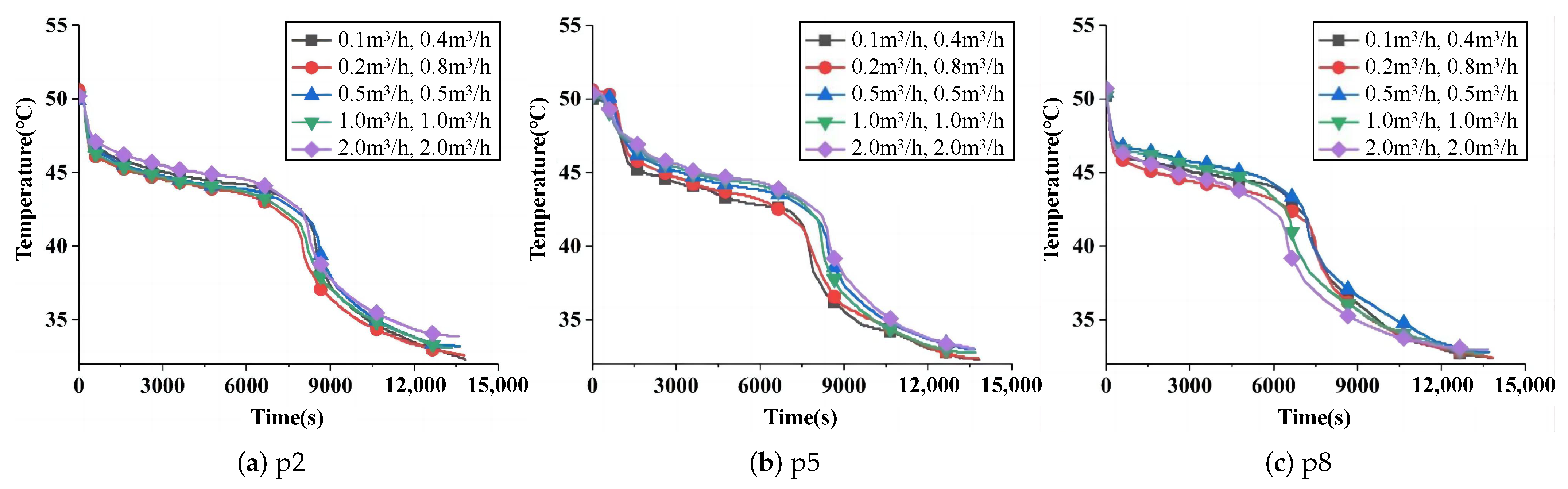

3.4.4. Influence of Flow Parameters on Heat Storage Process

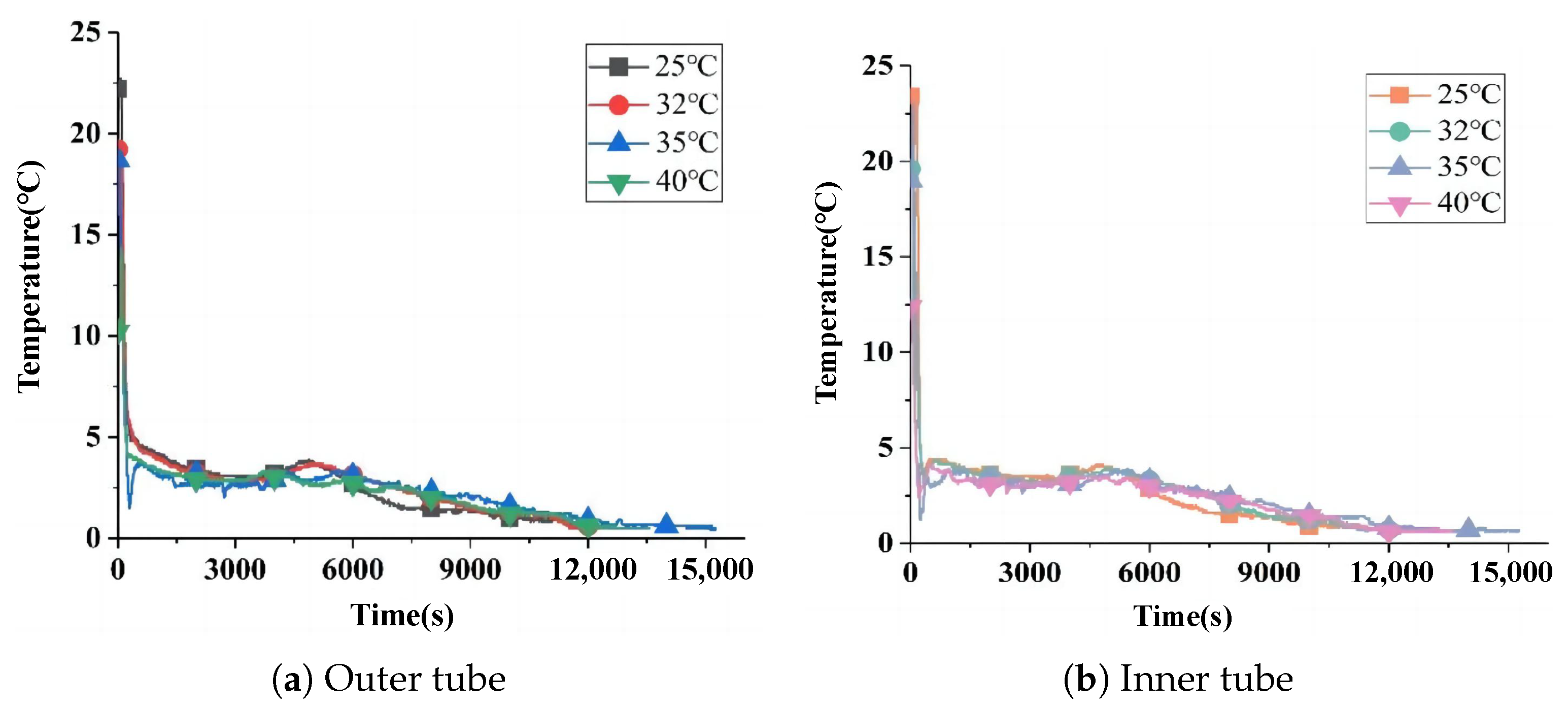

3.4.5. Influence of Flow Parameters on Heat Release Process

4. Discussion

4.1. Practical Implications

4.2. Influence of Structural Parameters

4.3. Dynamic Heat Storage/Release Behavior

4.4. Limitations

5. Conclusions

- 1.

- For a phase change temperature of 50 °C, the optimal configuration ( m, m, and m) outperforms the original design, with a 0.35% improvement in heat transfer efficiency, a 35.87% increase in heat storage rate, and a 1.58% mass reduction, demonstrating superior overall performance. Integrating multiple units into a module enhanced heat transfer efficiency by 2.12% and heat storage rate by 73.23%, demonstrating superior performance and practicality.

- 2.

- Heat transfer efficiency decreases with a larger inner tube radius but further declines if the inner tube is undersized under high mass flow rates or low inlet temperatures. Increasing the casing and outer tube radius improves efficiency, though the latter exhibits negligible effects at low flow rates. The heat storage rate increases with the inner tube radius, decreases with the casing tube radius, and remains unaffected by the outer tube radius. The system mass rises with a larger inner and outer tube radius but decreases with the expansion of the casing tube radius.

- 3.

- Lowering heat release temperature increased the HTF temperature difference but reduced heat supply duration. Reducing the inner tube flow rate from 0.2 m3/h to 0.1 m3/h and the outer tube flow rate from 0.8 m3/h to 0.4 m3/h extended the heat supply time by 7.4%. Increasing the outer tube flow proportion improved heat exchange efficiency, achieving better thermal supply performance.

- 4.

- Higher HTF temperatures significantly reduced heat storage time, with a 30% reduction when increasing from 60 °C to 65 °C and an 11% reduction from 75 °C to 80 °C. However, increasing HTF volume flow had a limited impact on heat storage performance, highlighting the dominant role of temperature control.

- 5.

- Increasing heat release temperature extended PCM heat release time but reduced heat release at excessively high temperatures. Heat release time showed limited sensitivity to volume flow rate variations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PCM | phase change material |

| HTF | heat transfer fluid |

| inner tube radius (m) | |

| casing tube radius (m) | |

| outer tube radius (m) | |

| L | tube length (m) |

| S | latent heat storage (kJ) |

| Q | heat input (kJ) |

| W | pump power consumption (kJ) |

| heat storage rate (kW) | |

| M | mass (kg) |

| Reynolds number | |

| inlet mass flow rate (kg/s) | |

| specific heat capacity (kJ/(kg·K)) | |

| t | heat storage completion time(s) |

| inlet and outlet temperature difference (°C) | |

| pressure losses (Pa) | |

| hydraulic diameter (m) | |

| PCM layer thickness (m) | |

| H | latent heat of phase change (kJ/kg) |

| heat transfer fluid inlet temperature (°C) | |

| phase change temperature (°C) | |

| inner tube radius for HTF flow (m) | |

| outer tube radius for HTF flow (m) | |

| l | user-defined maximum length (m) |

| heat transfer efficiency | |

| wall thickness (m) | |

| density of HTF (kg/m3) | |

| density of the tubing material (kg/m3) | |

| thermal conductivity(W/(m·K)) | |

| friction factor | |

| user-specified time (s) |

References

- Ullah, A.; Nobanee, H.; Ullah, S.; Iftikhar, H. Renewable energy transition and regional integration: Energizing the pathway to sustainable development. Energy Policy 2024, 193, 114270. [Google Scholar] [CrossRef]

- Gaboitaolelwe, J.; Zungeru, A.M.; Yahya, A.; Lebekwe, C.K.; Vinod, D.N.; Salau, A.O. Machine Learning Based Solar Photovoltaic Power Forecasting: A Review and Comparison. IEEE Access 2023, 11, 40820–40845. [Google Scholar] [CrossRef]

- Guo, Y.; Liang, C.; Liu, H.; Gong, L.; Bao, M.; Shen, S. A Review on Phase-Change Materials (PCMs) in Solar-Powered Refrigeration Systems. Energies 2025, 18, 1547. [Google Scholar] [CrossRef]

- Li, Z.; Lu, Y.; Huang, R.; Chang, J.; Yu, X.; Jiang, R.; Yu, X.; Roskilly, A.P. Applications and technological challenges for heat recovery, storage and utilisation with latent thermal energy storage. Appl. Energy 2021, 283, 116277. [Google Scholar] [CrossRef]

- Mika, Ł.; Radomska, E.; Sztekler, K.; Gołdasz, A.; Zima, W. Review of Selected PCMs and Their Applications in the Industry and Energy Sector. Energies 2025, 18, 1233. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Nsofor, E.C. Solidification enhancement of PCM in a triplex-tube thermal energy storage system with nanoparticles and fins. Appl. Energy 2018, 211, 975–986. [Google Scholar] [CrossRef]

- Dong, X.; Zhu, C. Research on the Heat Transfer Performance of Phase Change Heat Storage Heat Exchangers Based on Heat Transfer Optimization. Energies 2024, 17, 4150. [Google Scholar] [CrossRef]

- Yang, X.; Guo, J.; Yang, B.; Cheng, H.; Wei, P.; He, Y.L. Design of non-uniformly distributed annular fins for a shell-and-tube thermal energy storage unit. Appl. Energy 2020, 279, 115772. [Google Scholar] [CrossRef]

- Leong, K.Y.; Hasbi, S.; Gurunathan, B.A. State of art review on the solidification and melting characteristics of phase change material in triplex-tube thermal energy storage. J. Energy Storage 2024, 41, 102932. [Google Scholar] [CrossRef]

- Hao, J.; Wu, X.; Ju, C.; Wang, X.; Hong, F.; Du, X. Bionic-response surface combination optimization method for latent heat storage performance improvement. Appl. Therm. Eng. 2024, 248, 123320. [Google Scholar] [CrossRef]

- Khedher, N.B.; Hosseinzadeh, K.; Abed, A.M.; Khosravi, K.; Mahdi, J.M.; Sultan, H.S.; Mohammed, H.I.; Talebizadehsardari, P. Accelerated charging of PCM in coil heat exchangers via central return tube and inlet positioning: A 3D analysis. Int. Commun. Heat Mass Transf. 2024, 152, 107275. [Google Scholar] [CrossRef]

- Huang, X.; Yao, S.; Yang, X.; Zhou, R. Melting performance assessments on a triplex-tube thermal energy storage system: Optimization based on response surface method with natural convection. Renew. Energy 2022, 188, 890–910. [Google Scholar] [CrossRef]

- Rodríguez, M.B.R.; Rodríguez, J.L.M.; Fontes, C.H.D.O. Thermo ecological optimization of shell and tube heat exchangers using NSGA II. Appl. Therm. Eng. Des. Process. Equip. Econ. 2019, 156, 91–98. [Google Scholar] [CrossRef]

- Srivastava, U.; Sahoo, R.R. Energy and exergy investigation of a eutectic phase change material for a triplex tube thermal energy storage with various configurations. Mater. Today Commun. 2024, 38, 108398. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Lohrasbi, S.; Ganji, D.D.; Nsofor, E.C. Simultaneous energy storage and recovery in the triplex-tube heat exchanger with PCM, copper fins and Al2O3 nanoparticles. Energy Convers. Manag. 2019, 180, 949–961. [Google Scholar] [CrossRef]

- Yao, S.; Zuo, M.; Huang, X. Evaluation and Optimization of the Thermal Storage Performance of a Triplex-Tube Thermal Energy Storage System with V-Shaped Fins. J. Therm. Sci. 2023, 32, 2048–2064. [Google Scholar] [CrossRef]

- Choure, B.K.; Alam, T.; Kumar, R. Optimization of heat transfer in PCM based triple tube heat exchanger using multitudinous fins and eccentric tube. J. Energy Storage 2024, 102, 113981. [Google Scholar] [CrossRef]

- Zaytoun, M.M.; El-Bashouty, M.M.; Sorour, M.M.; Alnakeeb, M.A. Heat transfer characteristics of PCM inside a modified design of shell and tube latent heat thermal energy storage unit. Case Stud. Therm. Eng. 2023, 49, 103372. [Google Scholar] [CrossRef]

- Hussain, B.; Irfan, M.; Khan, M.M.; Ullah, S.; ul Hasnain, F. Geometric optimization of fin structures for accelerated melting of phase change material in a triplex tube heat exchanger. J. Energy Storage 2024, 79, 110162. [Google Scholar] [CrossRef]

- Yan, C.; Kumar Singh, P.; Hamlaoui, O.; hajji, M.k.; Elmasry, Y.; Redhee, A.h.; Abdullaeva, B.S.; Garalleh, H.A.L. Heat release efficiency Betterment inside a novel-designed latent heat exchanger featuring arc-shaped fins and a rotational mechanism via numerical model and artificial neural network. Case Stud. Therm. Eng. 2024, 61, 105093. [Google Scholar] [CrossRef]

- Ren, F.; Li, Q.; Wang, P. Investigation and optimization on a Y-shaped fins for phase change heat storage by rotational mechanism. J. Energy Storage 2024, 94, 112436. [Google Scholar] [CrossRef]

- Boujelbene, M.; Mahdi, J.M.; Abed, A.M.; Ghanim, M.S.; Hammoodi, K.A.; Mohammed, H.I.; Togun, H.; Talebizadehsardari, P. The potential of arch-shaped fins for energy-charge enhancement in triplex-tube heat storage: Comparative analysis and optimization. J. Energy Storage 2024, 79, 110188. [Google Scholar] [CrossRef]

- Wang, L.; Lei, Y.; Du, B.; Li, Y.; Sun, J. Performance enhancement of a horizontal latent thermal energy storage unit with elliptical fins. Appl. Therm. Eng. 2023, 225, 120191. [Google Scholar] [CrossRef]

- Boujelbene, M.; Mohammed, H.I.; Sultan, H.S.; Eisapour, M.; Chen, Z.; Mahdi, J.M.; Cairns, A.; Talebizadehsardari, P. A comparative study of twisted and straight fins in enhancing the melting and solidifying rates of PCM in horizontal double-tube heat exchangers. Int. Commun. Heat Mass Transf. 2024, 151, 107224. [Google Scholar] [CrossRef]

- Ren, F.; Du, J.; Cai, Y.; Guo, J.; Liu, Y.; Zhang, D.; Li, M. Study on thermal performance of a new optimized snowflake longitudinal fin in vertical latent heat storage. J. Energy Storage 2022, 50, 104165. [Google Scholar] [CrossRef]

- Yang, K.; Zhu, N.; Chang, C.; Yu, H.; Yang, S. Numerical analysis of phase-change material melting in triplex tube heat exchanger. Renew. Energy 2020, 145, 867–877. [Google Scholar] [CrossRef]

- Yang, K.; Zhu, N.; Li, Y.; Du, N. Effect of parameters on the melting performance of triplex tube heat exchanger incorporating phase change material. Renew. Energy 2021, 174, 359–371. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, N.; Yuan, Y.; Luo, X. Thermal performance of triplex-tube latent heat storage exchanger: Simultaneous heat storage and hot water supply via condensation heat recovery. Renew. Energy 2020, 157, 616–625. [Google Scholar] [CrossRef]

- Sadiq, I.E.; Aljabair, S.; Karamallah, A.A. Accelerated solidification of PCM via Al2O3/CuO hybrid nanoparticles in triplex tube heat storage. J. Therm. Eng. 2021, 10, 880–903. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, J.; Wang, J. Numerical simulation of heat transfer processes in shell and tube phase change heat exchangers for recovering industrial waste heat. Mater. Res. Express 2024, 11, 125508. [Google Scholar] [CrossRef]

- Khedher, N.B.; Mehryan, S.A.M.; Hajjar, A.; Alghawli, A.S.; Ghalambaz, M.; Ayoubloo, K.A.; Dhahbi, S. Optimizing heat flow: Nano-encapsulated phase change materials in vibration-enhanced gravity-driven thermal convection. Int. Commun. Heat Mass Transf. 2024, 151, 107212. [Google Scholar] [CrossRef]

- Peer, M.S.; Cascetta, M.; Migliari, L.; Petrollese, M. Nanofluids in Thermal Energy Storage Systems: A Comprehensive Review. Energies 2025, 18, 707. [Google Scholar] [CrossRef]

- Cieśliński, J.T.; Fabrykiewicz, M. Thermal energy storage with PCMs in shell-and-tube units: A review. Energies 2023, 16, 936. [Google Scholar] [CrossRef]

- Raud, R.; Cholette, M.E.; Riahi, S.; Bruno, F.; Saman, W.; Will, G.; Steinberg, T.A. Design optimization method for tube and fin latent heat thermal energy storage systems. Energy 2017, 134, 585–594. [Google Scholar] [CrossRef]

- Bauer, T. Approximate analytical solutions for the solidification of PCMs in fin geometries using effective thermophysical properties. Int. J. Heat Mass Transf. 2011, 54, 4923–4930. [Google Scholar] [CrossRef]

- Aliyu, A.M.; Lao, L.; Almabrok, A.A.; Yeung, H. Interfacial shear in adiabatic downward gas/liquid co-current annular flow in pipes. Exp. Therm. Fluid Sci. 2016, 72, 75–87. [Google Scholar] [CrossRef]

- Spurk, J.; Aksel, N. Fluid Mechanics; Springer Science & Business Media: Cham, Switzerland, 2007. [Google Scholar]

- Hager, W.H. Blasius: A life in research and education. Exp. Fluids 2003, 34, 566–571. [Google Scholar] [CrossRef]

- Wien, W. Lehrbuch der Hydrodynamik; S. Hirzel: Stuttgart, Germany, 1900. [Google Scholar]

- Lamb, H. Lehrbuch der Hydrodynamik; BG Teubner: Berlin, Germany, 1907. [Google Scholar]

- Konakov, P. Eine neue Formel für den Reibungskoeffizienten glatter Rohre (Orig. russ.). Berichte der Akad. der Wiss. der Udssr 1946, 7, 503–506. [Google Scholar]

- Wang, W.W.; Wang, L.B.; He, Y.L. Parameter effect of a phase change thermal energy storage unit with one shell and one finned tube on its energy efficiency ratio and heat storage rate. Appl. Therm. Eng. Des. Process. Equipment, Econ. 2016, 93, 50–60. [Google Scholar] [CrossRef]

| Symbol | Value | Unit | Symbol | Value | Unit |

|---|---|---|---|---|---|

| 4.182 | kJ/(kg·K) | 2.5 | mm | ||

| 998.2 | kg/m3 | 8 | mm | ||

| 8954 | kg/m3 | 15 | mm | ||

| 0.2 | W/(m·K) | 37 | mm | ||

| H | 168 | kJ/kg | 45 | mm | |

| l | 1.4 | m | 46 | mm | |

| 6000 | s | 55 | mm |

| Name | Manufacturer | Location | Model | Range | Accuracy |

|---|---|---|---|---|---|

| Electric water heater | A.O.Smith | Milwaukee, WI, USA | DSE-50-90 | 32∼88 °C | 1 °C |

| Air-cooled chiller unit | KYKY | Beijing, China | KYKY-LS 65A | 10∼25 °C | ±0.2 °C |

| Variable-frequency circulating pump | GRUNDFOS | Bjerringbro, Denmark | CM5-3 | Max Flow: | |

| Electromagnetic flowmeter | Meacon | Hangzhou, China | LDG-SUP | 0∼15 | |

| Thermocouple | MINGCON | Xiamen, China | Type K | −200∼900 °C | ±0.1 °C |

| Data collector | YOKOGAWA | Tokyo, Japan | MX-100 |

| Heat Storage Cases | Heat Release Cases | ||||||

|---|---|---|---|---|---|---|---|

| Case | Heat Storage Temperature (°C) | Inlet Flow Rate (m3/h) | Case | Heat Release Temperature (°C) | Inlet Flow Rate (m3/h) | ||

| Inner Tube | Outer Tube | Inner Tube | Outer Tube | ||||

| 1-1 | 80 | 1 | 1 | 2-1 | 25 | 0.1 | 0.4 |

| 1-2 | 75 | 1 | 1 | 2-2 | 32 | 0.1 | 0.4 |

| 1-3 | 70 | 1 | 1 | 2-3 | 35 | 0.1 | 0.4 |

| 1-4 | 65 | 1 | 1 | 2-4 | 40 | 0.1 | 0.4 |

| 1-5 | 60 | 1 | 1 | 2-5 | 32 | 0.2 | 0.8 |

| 1-6 | 65 | 2 | 2 | 2-6 | 32 | 0.5 | 0.5 |

| 1-7 | 65 | 0.2 | 0.8 | 2-7 | 32 | 1 | 1 |

| 1-8 | 65 | 0.1 | 0.4 | 2-8 | 32 | 2 | 2 |

| 2-9 | 32 | 0.1 | 0 | ||||

| 2-10 | 32 | 0 | 0.4 | ||||

| Inlet Temperature (°C) | 80 | 75 | 70 | 65 | 60 |

|---|---|---|---|---|---|

| Experimental value (min) | 38.3 | 46.7 | 58.3 | 78.3 | 114.2 |

| Analog value (min) | 37.1 | 44.8 | 56.2 | 75.2 | 113.3 |

| Error rate | 2.5 | 4.1% | 3.6% | 4.0% | 0.8% |

| M | ||||||

|---|---|---|---|---|---|---|

| Solution 1 | 0.01454 | 0.03723 | 0.05632 | 0.9361 | 0.2209 | 26.322 |

| Solution 2 | 0.01126 | 0.04195 | 0.04916 | 0.9629 | 0.1184 | 18.836 |

| Original solution | 0.01000 | 0.04000 | 0.05000 | 0.9429 | 0.1234 | 21.760 |

| Objective Function | M | ||

|---|---|---|---|

| Unit | 0.9429 | 0.1234 | 21.2306 |

| Integrated modules | 0.9633 | 0.4609 | 63.6919 |

| Relative rate of change | 2.12% | 73.23% | 66.67% |

| Case | Volume Flow Rate (m3/h) | Heating Time (s) | |

|---|---|---|---|

| Inner Tube | Outer Tube | ||

| 2-2 | 0.1 | 0.4 | 8380 |

| 2-5 | 0.2 | 0.8 | 8100 |

| 2-6 | 0.5 | 0.5 | 7900 |

| 2-7 | 1.0 | 1.0 | 7720 |

| 2-8 | 2.0 | 2.0 | 7800 |

| Case | Volume Flow Rate (m3/h) | Re | ||

|---|---|---|---|---|

| Inner Tube | Outer Tube | Inner Tube | Outer Tube | |

| 1-4 | 1.0 | 1.0 | 21891 | 3313 |

| 1-6 | 2.0 | 2.0 | 43783 | 6627 |

| 1-7 | 0.2 | 0.8 | 4378 | 2651 |

| 1-8 | 0.1 | 0.4 | 2189 | 1325 |

| Case | Volume Flow Rate (m3/h) | Re | ||

|---|---|---|---|---|

| Inner Tube | Outer Tube | Inner Tube | Outer Tube | |

| 2-2 | 0.1 | 0.4 | 2189 | 1325 |

| 2-5 | 0.2 | 0.8 | 4378 | 2651 |

| 2-6 | 0.5 | 0.5 | 10,946 | 1657 |

| 2-7 | 1.0 | 1.0 | 21,891 | 3313 |

| 2-8 | 2.0 | 2.0 | 43,783 | 6627 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yu, H.; Hou, Y.; Zhu, N. Multi-Objective Optimization Research Based on NSGA-II and Experimental Study of Triplex-Tube Phase Change Thermal Energy Storage System. Energies 2025, 18, 2129. https://doi.org/10.3390/en18082129

Zhang Y, Yu H, Hou Y, Zhu N. Multi-Objective Optimization Research Based on NSGA-II and Experimental Study of Triplex-Tube Phase Change Thermal Energy Storage System. Energies. 2025; 18(8):2129. https://doi.org/10.3390/en18082129

Chicago/Turabian StyleZhang, Yi, Haoran Yu, Yingzhen Hou, and Neng Zhu. 2025. "Multi-Objective Optimization Research Based on NSGA-II and Experimental Study of Triplex-Tube Phase Change Thermal Energy Storage System" Energies 18, no. 8: 2129. https://doi.org/10.3390/en18082129

APA StyleZhang, Y., Yu, H., Hou, Y., & Zhu, N. (2025). Multi-Objective Optimization Research Based on NSGA-II and Experimental Study of Triplex-Tube Phase Change Thermal Energy Storage System. Energies, 18(8), 2129. https://doi.org/10.3390/en18082129