Analysis of Energy Sustainability and Problems of Technological Process of Primary Aluminum Production

Abstract

1. Introduction

2. Research Methodology

- Systematic analysis of the scientific and technical literature. The purpose of this stage is to determine the current state of research in the field of the primary production process of aluminum and MHD instability. Methods used include the following: analysis of publications in scientific journals (Scopus, Web of Science, Google Scholar, etc.) and study of patents and technical reports containing engineering solutions for process stabilization. Source selection criteria include the following: relevance (publications not older than 10 years, except for fundamental research) and applicability to industrial conditions.

- Classification of process challenges and factors of MHD instability. The aim is to systematize and structure the main causes of MHD instability in electrolyzers. Methods include the following: analysis of the collected literature; identification of the main factors affecting the stability of the electrolytic process; and classification of problem areas, including electrolyzer parameters (bath shape, magnetic fields, and electrode processes).

- Review of methods of identification and modeling of MHD-unsteadiness. The aim of this stage is to determine the existing approaches to the identification and analysis of MHD oscillations. Methods include the following: comparative analysis of mathematical models (hydrodynamic, electromagnetic, and complex); study of numerical modeling methods; and review of experimental diagnostic methods (current, voltage, and vibration sensors).

- Analysis of technical solutions to reduce MHD-unsteadiness. The purpose of this stage is to identify and systematize methods of MHD effects minimization in industrial production. Methods include the following: analysis of engineering solutions in patents and scientific articles; classification of ways to control MHD instability (constructive changes in electrolyzers, change in power supply modes, and active control of magnetic fields).

- Formation of conclusions and recommendations. The purpose is as follows: systematization of the analysis results and suggesting directions for further research. Methods are as follows: formation of the final table for visualization of the challenge and development of recommendations for optimization of the technological process.

3. Primary Aluminum Production Process

3.1. A Description of the Steps of the Technological Process of Aluminum Production

- The extraction of bauxite: bauxite is the main raw material containing aluminum oxides. Extraction is carried out by open-pit mining, which allows large volumes of ore to be extracted.

- Enrichment: after mining, the ore is crushed, pulverized, and categorized to separate valuable components from waste rock.

- Bayer process: In this stage, bauxite is dissolved in a hot alkaline solution (NaOH) under pressure. Aluminum passes into solution in the form of sodium aluminate, and insoluble impurities are removed. From the cooled solution with the addition of CO2, aluminum hydroxide (Al(OH)3) precipitates, which, after filtration, washing, and calcination, turns into pure alumina.

- Electrolysis: Alumina is dissolved in molten cryolite (Na3AlF6) with the additions of AlF3 and CaF2 to lower the melting point. At a temperature of about 950–980 °C, the alumina decomposes in the electrolysis bath: aluminum ions are deposited on the cathode as a metal, and oxygen is released at the anode, reacting with the carbon of the anode to form CO2. The process is accompanied by anode combustion.

- The extraction and casting of aluminum: liquid aluminum is regularly extracted from the bath with ladles and transported to the foundry, where it is cast into molds—ingots, bars, plates, and other products.

3.2. Classification of Aluminum Electrolyzers

3.3. Structural Scheme of Primary Aluminum Production in TCF Electrolyzers

4. Analysis of Basic Aluminum Production Technology

4.1. Main Production Indicators of the Aluminum Electrolyzer

- 1.

- Current density (current per unit area of anode)

- Influence on the indicator: The current density depends on the electrolysis characteristics, e.g., the geometric size of the cells, as well as the composition and temperature of the electrolyte. The process equipment and anode design also influence this indicator.

- Effect on the process: Higher current densities may result in faster aluminum reduction, but there is an increased likelihood of the anode and cathode overheating, which can cause premature wear. Reduced current densities result in a reduced plant throughput.

- 2.

- Electrolysis voltage

- Effect on the indicator: The voltage depends on the electrolyte composition, temperature, and condition of the anodes. Changes in the chemical composition or temperature of the electrolyte as well as the wear of the anodes and cathodes can cause voltage fluctuations.

- Impact on the process: A high voltage can lead to higher energy consumption, which increases the cost of production. Reducing the voltage improves energy efficiency but can slow down the electrolysis process, especially if the voltage is too low.

- 3.

- Electrolyte temperature

- Influence on the figure: The temperature is directly related to the power supplied to the electrolyzer and the design of the equipment, including cooling and thermal insulation systems. The temperature is also affected by the characteristics of the anodes and cathodes.

- Effect on the process: Increasing the electrolyte temperature accelerates the electrolysis process and improves the conductivity of the solution, which reduces the energy consumption. However, too high a temperature may cause the accelerated destruction of anodes and cathodes and may result in unnecessary emissions of harmful substances.

- 4.

- Cathode and anode quality

- Influence on the indicator: the condition of cathodes and anodes depends on their material, production technology, and operating conditions (temperature, current density, and aggressiveness of the electrolyte).

- Impact on the process: High-quality cathodes and anodes contribute to a more efficient electrolysis process, reducing energy costs and extending the equipment life. The wear of anodes and cathodes leads to higher energy costs and lower aluminum yields.

- 5.

- Concentration of aluminum oxide in the electrolyte (Al2O3)

- Influence on the index: This index depends on how efficiently the process of aluminum reduction from the oxide is carried out. The concentration of Al2O3 in the electrolyte solution can vary depending on the temperature, composition, and state of the electrolyte.

- Process impact: An insufficient aluminum oxide concentration slows down the aluminum production process and increases the energy consumption, often causing undesirable anodic effects (AEs). Too high a concentration can also lead to poor conductivity and undesirable chemical reactions.

- 6.

- Energy efficiency (kg of aluminum per kWh)

- Effect on the index: this index depends on all the above factors, such as current density, voltage, electrolyte temperature, and the quality and design of the equipment.

- Process impact: Energy efficiency has a direct impact on the cost of the aluminum production. An increased efficiency reduces operating costs and contributes to a greener production.

- 7.

- Plant capacity (aluminum output per unit time)

- Influence on the index: This index depends on the size of the electrolyzer, the current density, the composition of the electrolyte, and the condition of the anodes and cathodes. The stability of all operating parameters, such as temperature and voltage, is also important.

- Impact on the process: Increasing the productivity requires increasing the capacity of the electrolyzer and improving the conditions for the stable operation of the equipment. However, if the production loads are too high, the equipment may overheat, which reduces its durability.

- 8.

- Composition of gases emitted during electrolysis

- Impact on the indicator: The composition of the gases depends on the type of electrolyte used and the process temperature. The control of carbon dioxide emissions, which are released during the reaction with carbon anodes, is important.

- Process impact: Gas emissions can have an impact on the environmental performance of the production process. Controlling the composition of gases can minimize harmful emissions and improve the environmental safety of the process.

- 9.

- Aluminum yield (main product)

- Influence on the figure: The aluminum yield depends on the efficiency of all electrolysis steps, the quality of the anodes and cathodes, and the composition of the electrolyte. Unstable parameters, such as a high temperature or voltage, can reduce the yield.

- Process impact: maximizing the aluminum yield increases the economic efficiency of production and reduces the cost of the final product.

4.2. Anodic Effect

4.3. MHD Instability

- Busbar geometry and design: an unfortunate busbar configuration resulting in an asymmetric or overly strong horizontal component of the magnetic field increases the likelihood of MHD instability.

- Magnitude of the current flowing: The higher the current, the stronger the created magnetic field is and the higher the risk of inducing oscillations. In large baths with currents of 300–500 kA and more, the task of preventing MHD instabilities comes to the forefront.

- Aluminum layer thickness and electrolyte level: A too thin aluminum layer makes the metal–electrolyte medium more mobile, which makes it easier to form waveforms. If the aluminum thickness is very thick the mixing losses increase and the optimal geometry of the current distribution may change.

- Electrolyte density and temperature: Changes in the electrolyte density (e.g., with variations in the Al2O3 content or other additives) affect the wave processes. Higher temperatures can contribute to changes in the melt viscosity and make the motion more intense.

- Location of neighboring baths and mutual influence: in large shops, the electrical circuits of the baths are often interconnected, and the magnetic fields from neighboring electrolyzers overlap, amplifying or, less often, compensating the waves.

- Metal level fluctuations: during strong fluctuations, aluminum can locally rise to the anodes, increasing the risk of short circuits and an uncontrolled current flow through the metal.

- Increased energy consumption: changing the current distribution in the bath leads to increased losses and voltage fluctuations, which ultimately have a negative impact on energy efficiency.

- Reduced metal quality: wavy movements can promote an increased mixing of the slag, electrolyte, and metal, increasing the risk of aluminum contamination or impurities.

- Accelerated wear of equipment: high dynamic loads on anode surfaces and bath walls can shorten the service life of process components.

- As a result of MHD instability growth, the aluminum surface undulations become comparable to the interpole gap. When a critical value is reached, the continued growth of the MHD instability can provoke a sharp deterioration of the electrolyzer performance. The identification of MHD instability is one of the most difficult challenges; the solution of which directly affects the quality of the products.

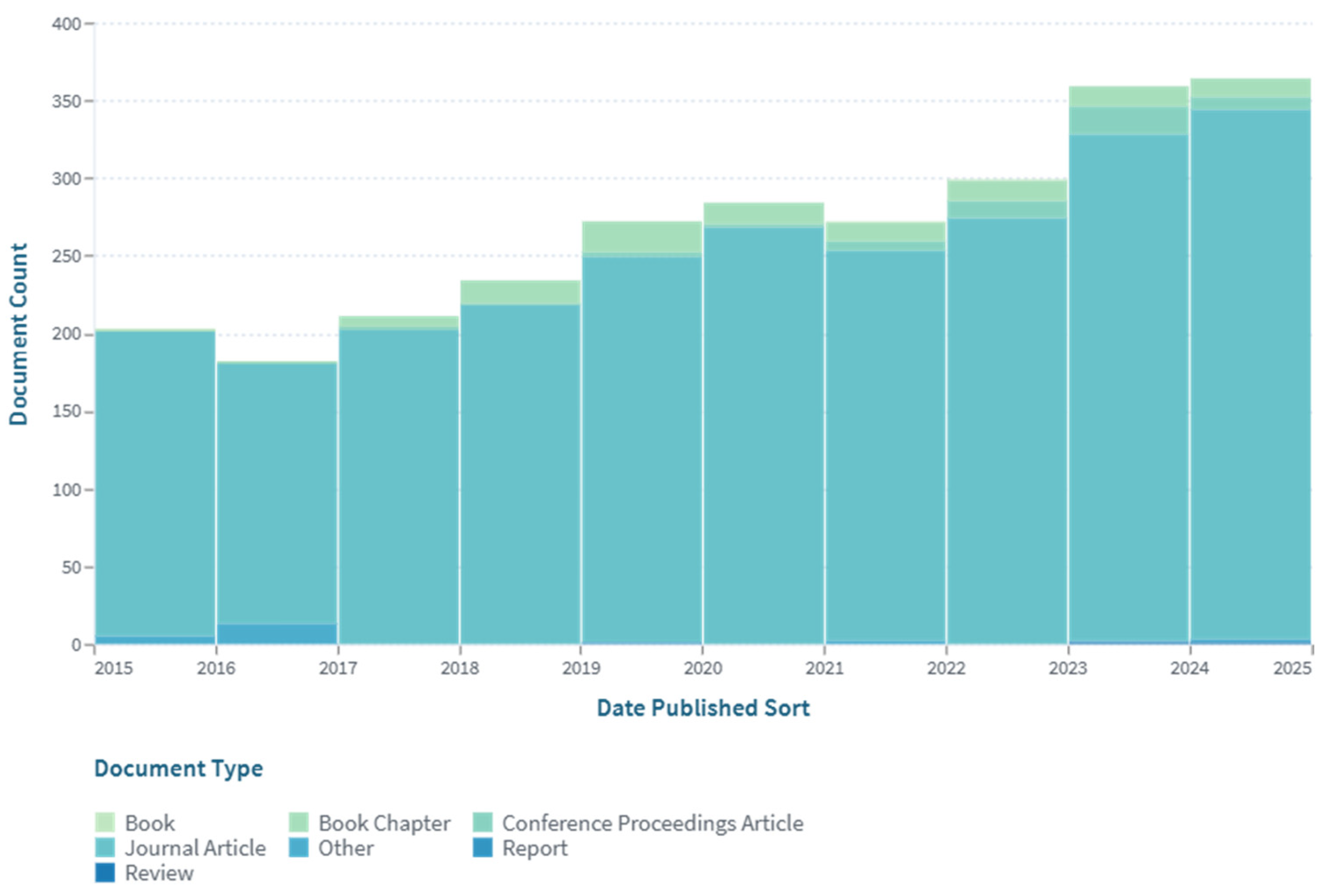

5. Scientific Papers and the State of Scientific Research

- Analyzing the problem of the research topic;

- Analyzing existing research on the research topic;

- The identification of unresolved scientific challenges related to the object of research;

- Analyzing promising theoretical research that can be applied to solve the identified open science challenges.

5.1. Analyzing the Problem of the Research Topic

5.2. Analysis of Existing Studies

5.3. Existing Unresolved Scientific Issues

5.4. A Theoretical Study of Challenge Solving

6. Discussion

7. Conclusions

- 1.

- Improving energy efficiency:

- Manufacturers are striving to reduce energy costs by improving equipment and utilizing energy-saving technologies.

- New designs for electrolyzers with improved thermal insulation and optimized process modes are being introduced.

- 2.

- Greening of production:

- Environmental regulations are becoming more stringent, so companies are looking for ways to minimize greenhouse gas emissions, toxic fluoride compounds, and other harmful substances.

- Priority is given to switching to cleaner energy sources (hydroelectric, solar, and wind power) in order to reduce aluminum’s carbon footprint.

- 3.

- Digital integration and automation:

- The process is automated thanks to monitoring and control systems based on Big Data, machine learning, and the Internet of Things (IoT).

- Predictive algorithms are used to monitor electrolyzers, predict failures, and optimize the process in real time.

- 4.

- Development of MHD stable technologies:

- More and more attention is being paid to the challenge of MHDS, as any perturbations have a negative impact on the energy efficiency and aluminum quality.

- Comprehensive systems for the identification and control of MHD-unsteadiness, including numerical modeling and machine learning algorithms, are developed.

- 5.

- Consolidation of production facilities:

- To reduce unit costs and improve competitiveness, aluminum companies often go down the path of consolidating and scaling up production.

- Large enterprises implement innovative solutions faster than small ones because they have the resources for research and modernization.

- 6.

- Application diversification and demand:

- Aluminum is in demand in the automotive, aerospace, electronics, and construction industries, which is driving the development of better and cleaner alloys.

- The growing demand for lightweight and strong materials (e.g., for electric vehicles) is pushing for further improvements in technologies that reduce costs and improve metal properties.

- 7.

- Strengthening scientific and technical collaboration:

- Companies, research institutes, and universities are increasingly joining consortia to develop new electrolysis methods and analyze data.

- Best practices are being shared internationally, and large companies are investing in startups engaged in the digital transformation of the aluminum industry.

- Simulation has become a major tool for designing and optimizing the performance of aluminum electrolyzers and remains a priority area of research.

- To ensure a good service life of the electrolysis bath, it is necessary to select a rational composition of lining material or to take measures to improve the efficiency of the existing ones.

- Primary aluminum production today is characterized by a high energy demand and greenhouse gas emissions, where electrolysis is one of the most energy-intensive processes.

- More energy-efficient technologies and practices have been developed over the years, and historically inefficient or environmentally unfavorable equipment is being modernized as the effects of emissions are better understood.

- There is an assumption that the most optimal electrolyzer will be one with a large number of anodes in the form of pins with the same potentials and with a minimum distance between them.

- The benefit of future developments is that they will consider and connect hydrodynamic, electromagnetic, thermal, and electrochemical processes, along with changes in the bath shape caused by heat and mass transfer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MHDS | magnetohydrodynamic stability |

| MHD | magnetohydrodynamic |

| SCF | side current feed |

| TCF | top current feed |

| AA | annealed anodes |

| SAA | self-annealing anodes |

| AAFS | automatic alumina feeding system |

| APCS | automated process control system |

| AE | anode effect |

| FEM | finite element method |

| IoT | Internet of Things |

References

- Chen, S.; Ebe, F.; Morris, J.; Lorenz, H.; Kondzialka, C.; Heilscher, G. Implementation and Test of an IEC 61850-Based Automation Framework for the Automated Data Model Integration of DES (ADMID) into DSO SCADA. Energies 2022, 15, 1552. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Pershin, I.M.; Nosova, V.A.; Tsapleva, V.V. Methodology for Designing Distributed Self-tuning Control Systems. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21 September 2023; pp. 110–114. [Google Scholar] [CrossRef]

- Nainar, K.; Ciontea, C.I.; Shahid, K.; Iov, F.; Olsen, R.L.; Schäler, C.; Schwefel, H.-P.C. Experimental Validation and Deployment of Observability Applications for Monitoring of Low-Voltage Distribution Grids. Sensors 2021, 21, 5770. [Google Scholar] [CrossRef]

- Lundby, E.T.B.; Rasheed, A.; Gravdahl, J.T.; Halvorsen, I.J. A novel hybrid analysis and modeling approach applied to aluminum electrolysis process. J. Process Control 2021, 105, 62–77. [Google Scholar] [CrossRef]

- Gorlanov, E.S.; Leontev, L.I. Directions in the technological development of aluminium pots. J. Min. Inst. 2024, 266, 246–259. [Google Scholar]

- Musii, R.; Lis, M.; Pukach, P.; Chaban, A.; Szafraniec, A.; Vovk, M.; Melnyk, N. Analysis of Varying Temperature Regimes in a Conductive Strip during Induction Heating under a Quasi-Steady Electromagnetic Field. Energies 2024, 17, 366. [Google Scholar] [CrossRef]

- Szulborski, M.; Łapczyński, S.; Kolimas, Ł. Thermal Analysis of Heat Distribution in Busbars during Rated Current Flow in Low-Voltage Industrial Switchgear. Energies 2021, 14, 2427. [Google Scholar] [CrossRef]

- Allard, F.; Désilets, M.; Blais, A. A Modeling Approach for Time-Dependent Geometry Applied to Transient Heat Transfer of Aluminum Electrolysis Cells. Metall. Mater. Trans. B 2019, 50, 958–980. [Google Scholar] [CrossRef]

- Piskazhova, T.V.; Shaydulin, Y.R.; Dontsova, T.V.; Avdeev, Y.O. Control of heat balance of aluminum cell. Tsvetnye Met. 2019, 50–55. [Google Scholar] [CrossRef]

- Gołębiowski, J.; Zaręba, M. The Distribution of the Thermal Field in an Elliptical Electric Conductor Coated with Insulation. Energies 2021, 14, 6880. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Grudyaeva, E.K.; Chernyshev, A.B. Calculation of the Temperature Maximum Value Access Time at the Observation Point. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg, Moscow, Russia, 26–29 January 2021; pp. 1014–1018. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Chernyshev, A.B. Calculation of the First Switch-on Time of Distributed Object’s Control Action. In Proceedings of the 2020 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg, Moscow, Russia, 27–30 January 2020; pp. 750–754. [Google Scholar] [CrossRef]

- Makeev, A.V.; Belolipetski, V.M.; Piskazhova, T.V.; Portyankin, A.A. A Model of Heat Exchange in the Startup Period of an Electrolyzer Aimed at the Optimization of Voltage Reduction. Metallurgist 2019, 62, 1054–1061. [Google Scholar] [CrossRef]

- Dzurňák, R.; Varga, A.; Jablonský, G.; Variny, M.; Pástor, M.; Lukáč, L. Analyzing the Formation of Gaseous Emissions during Aluminum Melting Process with Utilization of Oxygen-Enhanced Combustion. Metals 2021, 11, 242. [Google Scholar] [CrossRef]

- Eremeeva, A.M.; Kondrasheva, N.K.; Korshunov, G.I. Method to reduce harmful emissions when diesel locomotives operate in coal mines. Top. Issues Ration. Use Nat. Resour. 2019, 1, 10–15. [Google Scholar] [CrossRef]

- Golovina, E.I.; Grebneva, A.V. Features of groundwater resources management in the transboundary territories (on the example of the kaliningrad region). Geol. Miner. Resour. Sib. 2022, 4, 85–94. [Google Scholar] [CrossRef]

- Golovina, E.; Karennik, K. Modern Trends in the Field of Solving Transboundary Problems in Groundwater Extraction. Resources 2021, 10, 107. [Google Scholar] [CrossRef]

- Meshkov, A.A.; Korshunov, G.I.; Kondrasheva, N.K.; Eremeeva, A.M.; Seregin, A.S. Method of Reducing Air Pollution of the Coal Mines Working Areas with Diesel Locomotives Harmful Emissions. Occup. Saf. Ind. 2020, 1, 68–72. [Google Scholar] [CrossRef]

- Sidorenko, S.; Trushnikov, V.; Sidorenko, A. Methane Emission Estimation Tools as a Basis for Sustainable Underground Mining of Gas-Bearing Coal Seams. Sustainability 2024, 16, 3457. [Google Scholar] [CrossRef]

- Kozyrev, B.A.; Sizyakov, V.M.; Arsentyev, V.A. Principles of rational processing of red mud with the use of carboxylic acids. Non-Ferr. Met. 2022, 53, 30–34. [Google Scholar] [CrossRef]

- Kozyrev, B.A.; Sizyakov, V.M. Heap leaching of red mud by the formate method. Obogashchenie Rud 2021, 4, 40–45. [Google Scholar] [CrossRef]

- Bakesheva, A.T.; Fetisov, V.G.; Pshenin, V.V. A refined algorithm for leak location in gas pipelines with determination of quantitative parameters. Int. J. Eng. Res. Technol. 2019, 12, 2867–2869. [Google Scholar]

- Demenkov, P.A.; Trushko, O.V.; Potseshkovskaya, I.V. Numerical experiments on the modeling of compensatory injection for the protection of buildings during tunneling. ARPN J. Eng. Appl. Sci. 2018, 13, 9161–9169. [Google Scholar]

- Fetisov, V.G.; Nikolaev, A.K.; Lykov, Y.V. Aggregative simulation method for implementing mathematical models for gas transmission systems. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 022033. [Google Scholar] [CrossRef]

- Massel, L.; Komendantova, N.; Massel, A.; Tsvetkova, A.; Zaikov, K.; Marinina, O. Resilience of socio-ecological and energy systems: Intelligent information technologies for risk assessment of natural and technogenic threats. J. Infrastruct. Policy Dev. 2024, 8, 4700. [Google Scholar] [CrossRef]

- Sidorenko, A.A.; Ivanov, V.V.; Sidorenko, S.A. Computer modeling of rock massif stress condition for mining planning on overworked seam. J. Phys. Conf. Ser. 2020, 1661, 012082. [Google Scholar] [CrossRef]

- Barykin, S.E.; Sergeev, S.M.; Provotorov, V.V.; Lavskaya, K.K.; Shidlovskaya, K.A.; Dedyukhina, N.; Mikhov, O.; Buniak, V.; Dzhamaludinova, M.Y. Sustainability Analysis of Energy Resources Transport Based on A Digital N-D Logistics Network. Eng. Sci. 2024, 29, 1093. [Google Scholar] [CrossRef]

- Iakhiaev, D.; Grigorishchin, A.; Zaikov, K.; Bezdudnaya, A.; Ukhanova, A.; Tsvetkova, A.; Fadeev, A. Methodological approach to assessing the digital infrastructure of the northern regions of the Russian Federation. J. Infrastruct. Policy Dev. 2024, 8, 8747. [Google Scholar] [CrossRef]

- Katysheva, E.G. Application of BigData technology to improve the efficiency of Arctic shelf fields development. IOP Conf. Ser. Earth Environ. Sci. 2021, 937, 042080. [Google Scholar] [CrossRef]

- Katysheva, E. Risk management and costs optimization in drilling of oil wells based on the application of smart field tools. Environ. Econ. 2021, 21, 855–862. [Google Scholar] [CrossRef]

- Khaykin, M.M.; Priyma, K.A. Digital transformation management issues: An oil-and-gas industry example. Navigating Digital Transformation: Original Research Across Smart Cities. Sustain. Dev. Beyond 2024, 99–112. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-85201999356&origin=resultslist (accessed on 18 March 2025).

- Marinin, M.A.; Marinina, O.A.; Rakhmanov, R.A. Methodological approach to assessing influence of blasted rock fragmentation on mining costs. Gorn. Zhurnal 2023, 9, 28–34. [Google Scholar] [CrossRef]

- Potseshkovskaya, I.V.; Soroka, A.N. Revitalization of urban industrial areas based on sustainable development principles. E3S Web Conf. 2021, 266, 08012. [Google Scholar] [CrossRef]

- Semenova, T.; Al-Dirawi, A.; Al-Saadi, T. Environmental Challenges for Fragile Economies: Adaptation Opportunities on the Examples of the Arctic and Iraq. Agronomy 2022, 12, 2021. [Google Scholar] [CrossRef]

- Semenova, T.; Martínez Santoyo, J.Y. Economic Strategy for Developing the Oil Industry in Mexico by Incorporating Environmental Factors. Sustainability 2023, 16, 36. [Google Scholar] [CrossRef]

- Nechitailo, A.R.; Marinina, O.A. Analysis of technological directions of electrification of hydrocarbon production facilities in poorly developed territories. North Mark. Form. Econ. Order 2022, 25, 45–57. [Google Scholar] [CrossRef]

- Fedorova, E.; Pupysheva, E.; Morgunov, V. Modelling of Red-Mud Particle-Solid Distribution in the Feeder Cup of a Thickener Using the Combined CFD-DPM Approach. Symmetry 2022, 14, 2314. [Google Scholar] [CrossRef]

- Fedorova, E.R.; Pupysheva, E.A.; Morgunov, V.V. Settling parameters determined during thickening and washing of red muds. Tsvetnye Met. 2023, 4, 77–85. [Google Scholar] [CrossRef]

- Andreeva, R.; Tsanev, A.; Stoychev, D. Improving the Corrosion Resistance of Anodized Al 1050 Alloy by Sealing in Cerium-Containing and Mixed Sodium Phosphate Mono Basic and Calcium Nitrate Solutions. Metals 2024, 14, 768. [Google Scholar] [CrossRef]

- Girginov, C.; Portolesi, S.; Kozhukharov, S.; Tsanev, A.; Lilov, E.; Petkov, P. Selection of appropriate electrochemical deposition regime for cerium conversion coating on anodized AA2024-T3 aircraft alloy. J. Appl. Electrochem. 2024, 54, 1171–1202. [Google Scholar] [CrossRef]

- Soffritti, C.; Fortini, A.; Nastruzzi, A.; Sola, R.; Merlin, M.; Garagnani, G.L. Dry Sliding Behavior of an Aluminum Alloy after Innovative Hard Anodizing Treatments. Materials 2021, 14, 3281. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Q.; Liu, W.; Yang, Y.; Wang, Z. Impact of Local Cathode Electrical Cut-Off on Bath–Metal Two-Phase Flow in an Aluminum Reduction Cell. Metals 2020, 10, 110. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Z. Analysis of Electromagnetic Properties of New Graphene Partial Discharge Sensor Electrode Plate Material. Sensors 2022, 22, 2550. [Google Scholar] [CrossRef] [PubMed]

- Probst, F.L.; Beltle, M.; Tenbohlen, S. Measurement of Transient Overvoltages by Capacitive Electric Field Sensors. Sensors 2024, 24, 1357. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Sun, K. Influence of Current Density on the Microstructure of Carbon-Based Cathode Materials during Aluminum Electrolysis. Appl. Sci. 2020, 10, 2228. [Google Scholar] [CrossRef]

- Yurkov, A.L.; Malakho, A.P.; Avdeev, V.V. Carbon Lining Cathode Materials for the Production of Aluminum by Electrolysis. Improvement of the Properties. Refract. Ind. Ceram. 2020, 61, 5–10. [Google Scholar] [CrossRef]

- Pianykh, A.A.; Arkhipov, G.V.; Tretyakov, Y.A. Mathematical Model of Magnetic Hydrodynamics and Heat Transfer in an Aluminum Reduction Cell. Russ. J. Non-Ferr. Met. 2020, 61, 65–73. [Google Scholar] [CrossRef]

- Rastyannikova, E.V. Global Non-Ferrous Metallurgy Resources Market. East. Anal. 2020, 3, 109–130. [Google Scholar] [CrossRef]

- Ma, Y.; Pettersen, J.B. Life cycle assessment of pig iron production from bauxite residue: A European case study. J. Ind. Ecol. 2023, 27, 1639–1652. [Google Scholar] [CrossRef]

- Lian, X.; Gao, H.; Shen, L.; Yu, Y.; Wang, Y.; Peng, Z. Life Cycle Assessment of Primary Aluminum Production. Processes 2025, 13, 419. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, S.; Wang, X.; Bilal, M.; Zhang, Z.; Yang, S.; Jing, C.; Xu, G.; Ni, C. Recovery of Carbon and Cryolite from Spent Carbon Anode Slag Using a Grinding Flotation Process Based on Mineralogical Characteristics. Separations 2023, 10, 193. [Google Scholar] [CrossRef]

- Zhdaneev, O.V. Technological sovereignty of the Russian Federation fuel and energy complex. J. Min. Inst. 2022. Online first. [Google Scholar] [CrossRef]

- Trushko, V.L.; Trushko, O.V. Integrated development of iron ore deposits based on competitive underground geotechnologies. J. Min. Inst. 2021, 250, 569–577. [Google Scholar] [CrossRef]

- Friedrich, B.; Jovićević, J.N.; Feldhaus, D.; Cvetković, V.S. Advances in Understanding Metal Electrolysis Process. Metals 2023, 13, 307. [Google Scholar] [CrossRef]

- Tyutrin, A.A.; Nemchinova, N.V.; Volodkina, A.A. Effects of electrolysis parameters on the technical and economic performance indicators of OA-300M baths. Proc. Irkutsk State Tech. Univ. 2020, 24, 906–918. [Google Scholar] [CrossRef]

- Lobato, B.; Cuesta, N.; Cameán, I.; Martínez-Tarazona, M.R.; García, R.; Arenillas, A.; García, A.B. Sustainable Carbon Materials from Sucrose as Anodes for Sodium-Ion Batteries. Molecules 2025, 30, 1003. [Google Scholar] [CrossRef]

- Gao, B.; Niu, H.; Guan, Y.; Wang, Z.; Liu, J.; Taylor, M.P.; Chen, J.J.J. Visualization of Anode Effect in Aluminum Electrolysis. J. Electrochem. Soc. 2022, 169, 013505. [Google Scholar] [CrossRef]

- Cui, J.; Li, Z.; Li, X.; Liu, B.; Li, Q.; Yan, Q.; Huang, R.; Lu, H.; Cao, B. A Novel Method of Local Anode Effect Prediction for Large Aluminum Reduction Cell. Appl. Sci. 2022, 12, 12403. [Google Scholar] [CrossRef]

- Shakhrai, S.G.; Dekterev, A.A.; Skuratov, A.P.; Minakov, A.V.; Bazhin, V.Y. Increase in Electrolyzer Energy Efficiency with a Self-Baking Anode. Metallurgist 2019, 62, 950–955. [Google Scholar] [CrossRef]

- Banerjee, D.; Krishna Prasad, S.; Pant, V.; McLaughlin, J.A.; Antolin, P.; Magyar, N.; Ofman, L.; Tian, H.; Van Doorsselaere, T.; De Moortel, I.; et al. Magnetohydrodynamic Waves in Open Coronal Structures. Space Sci. Rev. 2021, 217, 76. [Google Scholar] [CrossRef]

- Wakif, A.; Sehaqui, R. Generalized differential quadrature scrutinization of an advanced MHD stability problem concerned water-based nanofluids with metal/metal oxide nanomaterials: A proper application of the revised two-phase nanofluid model with convective heating and through-flow boundary conditions. Numer. Methods Partial. Differ. Equ. 2022, 38, 608–635. [Google Scholar] [CrossRef]

- Rodríguez, E. Magnetohydrodynamic stability and the effects of shaping: A near-axis view for tokamaks and quasisymmetric stellarators. J. Plasma Phys. 2023, 89, 905890211. [Google Scholar] [CrossRef]

- Kavitha, G.N.; Shankar, B.M.; Shivakumara, I.S. On the magnetohydrodynamic stability of channel flow of Navier–Stokes–Voigt fluid. Phys. Fluids 2024, 36, 043105. [Google Scholar] [CrossRef]

- Salinas, G.; Lozon, C.; Kuhn, A. Unconventional applications of the magnetohydrodynamic effect in electrochemical systems. Curr. Opin. Electrochem. 2023, 38, 101220. [Google Scholar] [CrossRef]

- Pianykh, A.A.; Bogovalov, S.V.; Tronin, I.V.; Tkacheva, O.Y.; Radzyuk, A.Y. 3-D Numerical Modeling of MHD Flows in an Aluminum Reduction Cell. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 062071. [Google Scholar] [CrossRef]

- Savenkova, N.P.; Yu Mokin, A.; Udovichenko, N.S. The MHD stability investigation of an aluminum electrolyzer under various process conditions. J. Phys. Conf. Ser. 2020, 1560, 012068. [Google Scholar] [CrossRef]

- Yang, Y.; Tao, W.; Liu, W.; Hu, X.; Wang, Z.; Shi, Z.; Shu, X. The Adsorption Behavior of Moisture on Smelter Grade Alumina during Transportation and Storage—For Primary Aluminum Production. Metals 2020, 10, 325. [Google Scholar] [CrossRef]

- Curtolo, D.C.; Xiong, N.; Friedrich, S.; Friedrich, B. High- and Ultra-High-Purity Aluminum, a Review on Technical Production Methodologies. Metals 2021, 11, 1407. [Google Scholar] [CrossRef]

- Vahedi Nemani, A.; Ghaffari, M.; Sabet Bokati, K.; Valizade, N.; Afshari, E.; Nasiri, A. Advancements in Additive Manufacturing for Copper-Based Alloys and Composites: A Comprehensive Review. J. Manuf. Mater. Process. 2024, 8, 54. [Google Scholar] [CrossRef]

- Khrustaleva, I.N.; Lyubomudrov, S.A.; Larionova, T.A.; Brovkina, Y.Y. Increasing the efficiency of technological preparation for the production of the manufacture components equipment for the mineral resource complex. J. Min. Inst. 2021, 249, 417–426. [Google Scholar] [CrossRef]

- Zhukovskiy, Y.L.; Batueva, D.E.; Buldysko, A.D.; Gil, B.; Starshaia, V.V. Fossil Energy in the Framework of Sustainable Development: Analysis of Prospects and Development of Forecast Scenarios. Energies 2021, 14, 5268. [Google Scholar] [CrossRef]

- Nosova, V.A.; Pershin, I.M. Determining the Optimal Number of Wells during Field Development. In Proceedings of the 2021 IV International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2021; pp. 42–44. [Google Scholar] [CrossRef]

- Zhu, X.; Jiang, L.; Xiao, Y. Study on the Optimization of the Material Distribution Path in an Electronic Assembly Manufacturing Company Workshop Based on a Genetic Algorithm Considering Carbon Emissions. Processes 2023, 11, 1500. [Google Scholar] [CrossRef]

- Qin, J.; Jiang, X.; Qin, J.; Zhao, H.; Dai, M.; Liu, H.; Chen, X. Effects of Lead Pollution on Photosynthetic Characteristics and Chlorophyll Fluorescence Parameters of Different Populations of Miscanthus floridulus. Processes 2023, 11, 1562. [Google Scholar] [CrossRef]

- Tang, D.; Solangi, Y.A. Fostering a Sustainable Energy Future to Combat Climate Change: EESG Impacts of Green Economy Transitions. Processes 2023, 11, 1548. [Google Scholar] [CrossRef]

- Litvinenko, V.S.; Petrov, E.I.; Vasilevskaya, D.V.; Yakovenko, A.A.; Naumov, I.A.; Ratnikov, M.A. Assessment of the role of the state in the management of mineral resources. J. Min. Inst. 2022. Online first. [Google Scholar] [CrossRef]

- Kryukovskij, V.A.; Sirazutdinov, G.A. Electrolysis Unit for Aluminum Production. Federal Service for Intellectual Property. Patent No. RU2722605C1, 2 June 2020. Available online: https://patents.google.com/patent/RU2722605C1/ru (accessed on 18 March 2025).

- Hou, W.; Li, H.; Li, M.; Cheng, B.; Feng, Y. Effects of electrolysis process parameters on alumina dissolution and their optimization. Trans. Nonferrous Met. Soc. China 2020, 30, 3390–3403. [Google Scholar] [CrossRef]

- Sarnovsky, M.; Bednar, P.; Smatana, M. Cross-Sectorial Semantic Model for Support of Data Analytics in Process Industries. Processes 2019, 7, 281. [Google Scholar] [CrossRef]

- Liu, X. Electrode Configurations for Electrolytic Cells and Related Methods. U.S. Patent No. US11585003B2, 21 February 2023. Available online: https://patents.google.com/patent/US11585003B2 (accessed on 18 March 2025).

- Mann, V.K.; Pingin, V.V.; Platonov, V.V.; Zavadyak, A.V. Modular Busbar for Series of Aluminum Electrolysis Cells. Federal Service for Intellectual Property. Patent No. RU2678624C1, 30 January 2019. Available online: https://patents.google.com/patent/RU2678624C1/ru (accessed on 18 March 2025).

- D’Astolfo, L.; Mickelson, L.; Ruan, Y. Controlling Electrode Current Density of an Electrolytic Cell. U.S. Patent No. US20240003031A1, 1 January 2024. Available online: https://patents.google.com/patent/US20240003031A1 (accessed on 18 March 2025).

- Arkhipov, P.; Tkacheva, O. The Electrical Conductivity of Molten Oxide-Fluoride Cryolite Mixtures. Materials 2021, 14, 7419. [Google Scholar] [CrossRef]

- Ono, S. Nanostructure Analysis of Anodic Films Formed on Aluminum-Focusing on the Effects of Electric Field Strength and Electrolyte Anions. Molecules 2021, 26, 7270. [Google Scholar] [CrossRef]

- Razaz, G.; Arshadirastabi, S.; Blomquist, N.; Örtegren, J.; Carlberg, T.; Hummelgård, M.; Olin, H. Aluminum Alloy Anode with Various Iron Content Influencing the Performance of Aluminum-Ion Batteries. Materials 2023, 16, 933. [Google Scholar] [CrossRef]

- Guimaraes, B.P.B.; Ribeiro Junior, R.F.; Andrade, M.V.; Dos Santos Areias, I.A.; Foster, J.G.L.; Bonaldi, E.L.; Assuncao, F.D.O.; De Oliveira, L.E.D.L.; Steiner, F.M.; El-Heri, Y. The Development of a Reduced-Scale Laboratory for the Study of Solutions for Microgrids. Energies 2024, 17, 609. [Google Scholar] [CrossRef]

- Boikov, A.; Payor, V.; Savelev, R.; Kolesnikov, A. Synthetic Data Generation for Steel Defect Detection and Classification Using Deep Learning. Symmetry 2021, 13, 1176. [Google Scholar] [CrossRef]

- Li, C.; Xie, Y.; Chen, X. Semi-Supervised Ensemble Classification Method Based on Near Neighbor and Its Application. Processes 2020, 8, 415. [Google Scholar] [CrossRef]

- Zhao, C.; Sun, H. Dynamic Distributed Monitoring Strategy for Large-Scale Nonstationary Processes Subject to Frequently Varying Conditions Under Closed-Loop Control. IEEE Trans. Ind. Electron. 2019, 66, 4749–4758. [Google Scholar] [CrossRef]

- Zhu, Y.-J.; Guo, W.; Liu, H.-C. Knowledge Representation and Reasoning with an Extended Dynamic Uncertain Causality Graph under the Pythagorean Uncertain Linguistic Environment. Appl. Sci. 2022, 12, 4670. [Google Scholar] [CrossRef]

- Pedneault, J.; Majeau-Bettez, G.; Krey, V.; Margni, M. What future for primary aluminium production in a decarbonizing economy? Glob. Environ. Change 2021, 69, 102316. [Google Scholar] [CrossRef]

- Stopic, S.; Friedrich, B. Advances in Understanding of the Application of Unit Operations in Metallurgy of Rare Earth Elements. Metals 2021, 11, 978. [Google Scholar] [CrossRef]

- Smol’nikov, A.D.; Sharikov, Y.V. Simulation of the Aluminum Electrolysis Process in a High-Current Electrolytic Cell in Modern Software. Metallurgist 2020, 63, 1313–1320. [Google Scholar] [CrossRef]

- Tulyakov, T.; Afanaseva, O. Development of a Methodology for Introducing Robotic Devices for Technical Inspection of Power Lines Based on Data Mining. In Proceedings of the II International Scientific Forum on Sustainable Development and Innovation (WFSDI 2023), Porto, Portugal, 27–28 April 2023; pp. 2018–2026. [Google Scholar]

- Li, M.; Ma, S.; Li, H.; Hou, W.; Cheng, B.; Hu, T.; Wang, Y. Mode Coupling Analysis of Interfacial Stability and Critical Anode–Cathode Distance in a 500-kA Aluminum Electrolysis Cell. JOM 2021, 73, 2741–2751. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Yu, J.; Wang, Z.; Shi, Z. Study on the Inter-Electrode Process of Aluminum Electrolysis (II)—Digital Analysis of the Anode Gas Distribution Patterns on the Anode Surface Using A See-Through Cell. Appl. Sci. 2021, 11, 7702. [Google Scholar] [CrossRef]

- González-Herbón, R.; González-Mateos, G.; Rodríguez-Ossorio, J.R.; Domínguez, M.; Alonso, S.; Fuertes, J.J. An Approach to Develop Digital Twins in Industry. Sensors 2024, 24, 998. [Google Scholar] [CrossRef]

- Da Silva, A.L.N.; Dos Santos, C.A.L.; De Araújo, R.D.M.R.; Feldhaus, D.; Friedrich, B.; Landgraf, F.J.G.; Guardani, R. Model and Mechanism of Anode Effect of an Electrochemical Cell for Nd or (Nd, Pr) Reduction. Metals 2022, 12, 498. [Google Scholar] [CrossRef]

- Ademujimi, T.; Prabhu, V. Digital Twin for Training Bayesian Networks for Fault Diagnostics of Manufacturing Systems. Sensors 2022, 22, 1430. [Google Scholar] [CrossRef]

- Boikov, A.; Payor, V. The Present Issues of Control Automation for Levitation Metal Melting. Symmetry 2022, 14, 1968. [Google Scholar] [CrossRef]

- Zhu, J.; Li, J. Diagnosis Method for the Heat Balance State of an Aluminum Reduction Cell Based on Bayesian Network. Metals 2020, 10, 604. [Google Scholar] [CrossRef]

- Kulakowska, A.; Pajdak, A.; Krzywanski, J.; Grabowska, K.; Zylka, A.; Sosnowski, M.; Wesolowska, M.; Sztekler, K.; Nowak, W. Effect of Metal and Carbon Nanotube Additives on the Thermal Diffusivity of a Silica Gel-Based Adsorption Bed. Energies 2020, 13, 1391. [Google Scholar] [CrossRef]

- Kryukovskij, V.A.; Sirazutdinov, G.A. Electrolytic Cell For Aluminum Production. Federal Service for Intellectual Property. Patent No. RU2696124C1, 31 July 2019. Available online: https://patents.google.com/patent/RU2696124C1 (accessed on 18 March 2025).

- Zeng, Z.; Gui, W.; Chen, X.; Xie, Y.; Wu, R. A mechanism knowledge-driven method for identifying the pseudo dissolution hysteresis coefficient in the industrial aluminium electrolysis process. Control Eng. Pract. 2020, 102, 104533. [Google Scholar] [CrossRef]

- Lin, M.; Ma, L. Research on Setting Voltage of Electrolyzer Based on LGBM-LSTM Algorithm. In Proceedings of the 2021 IEEE 4th International Conference on Computer and Communication Engineering Technology (CCET), Beijing, China, 13–15 August 2021; pp. 414–419. [Google Scholar] [CrossRef]

- Lu, D.; Peng, Y.; Sun, J. Dual-Stage Optimization Scheduling Model for a Grid-Connected Renewable Energy System with Hybrid Energy Storage. Energies 2024, 17, 737. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, J.; Cheng, R.; Chen, R.; Luo, Z.; Li, H. A ALO-LSSVM Model for the Cell Voltage Optimization in Aluminum Electrolysis Process. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 1431–1436. [Google Scholar] [CrossRef]

- Zhang, M.; Liao, S.; Xu, J.; Li, L.; Chen, Y.; Zhu, X. System static voltage stability analysis considering load characteristics of electrolytic aluminum. Energy Rep. 2022, 8, 1112–1121. [Google Scholar] [CrossRef]

- Kuz’min, V.I.; Lysak, V.I. High-Efficiency Composite Anodic Conductor in an Aluminum Electrolyzer. Russ. Eng. Res. 2019, 39, 110–112. [Google Scholar] [CrossRef]

- Fang, B.; Wang, J.; Li, C.; Chai, D.; Qiu, S.; Zhou, Y.; Jiao, Q.; Wang, Y. Production Management of Aluminum Electrolysis at Super Low Voltage. In Light Metals; Perander, L., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 419–422. [Google Scholar] [CrossRef]

- Grabowski, N.; Kremser, R.; Düssel, R.; Mulder, A.; Tutsch, D. Information Extraction from Industrial Sensor Data Using Time Series Meta-Features. Appl. Sci. 2023, 13, 7065. [Google Scholar] [CrossRef]

- D’Astolfo, L.; Prince, D.; Chaudhary, R.; Findley, N. Measuring Temperature of an Electrolytic Bath (World Intellectual Property). Organization Patent No. WO2023193099A1, 12 October 2023. Available online: https://patents.google.com/patent/WO2023193099A1 (accessed on 18 March 2025).

- Opalev, A.S.; Alekseeva, S.A. Methodological substantiation of the choice for optimal modes of equipment operation during the stage-wise concentrate removal in iron ores beneficiation. J. Min. Inst. 2022, 256, 593–602. [Google Scholar] [CrossRef]

- Kampker, A.; Heimes, H.H.; Dorn, B.; Clever, H.; Ludwigs, R.; Li, R.; Drescher, M. Concept for Digital Product Twins in Battery Cell Production. World Electr. Veh. J. 2023, 14, 108. [Google Scholar] [CrossRef]

- Nad, A.; Jooshaki, M.; Tuominen, E.; Michaux, S.; Kirpala, A.; Newcomb, J. Digitalization Solutions in the Mineral Processing Industry: The Case of GTK Mintec, Finland. Minerals 2022, 12, 210. [Google Scholar] [CrossRef]

- Ullrich, M.; Thalappully, R.; Heieck, F.; Lüdemann-Ravit, B. Virtual Commissioning of Linked Cells Using Digital Models in an Industrial Metaverse. Automation 2024, 5, 1. [Google Scholar] [CrossRef]

- Yang, C.; Zhou, L.; Huang, K.; Ji, H.; Long, C.; Chen, X.; Xie, Y. Multimode process monitoring based on robust dictionary learning with application to aluminium electrolysis process. Neurocomputing 2019, 332, 305–319. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Li, X.; Wang, J.; Zhao, Y. Graphene-Based Wearable Temperature Sensors: A Review. Nanomaterials 2023, 13, 2339. [Google Scholar] [CrossRef] [PubMed]

- Espinosa-Gavira, M.J.; Agüera-Pérez, A.; Sierra-Fernández, J.M.; González de-la-Rosa, J.J.; Palomares-Salas, J.C.; Florencias-Oliveros, O. Design and Test of a High-Performance Wireless Sensor Network for Irradiance Monitoring. Sensors 2022, 22, 2928. [Google Scholar] [CrossRef]

- Daul, L.; Jin, T.; Busch, I.; Koenders, L. Influence of Geometric Properties of Capacitive Sensors on Slope Error and Nonlinearity of Displacement Measurements. Sensors 2021, 21, 4270. [Google Scholar] [CrossRef]

- Huang, K.; Wen, H.; Ji, H.; Cen, L.; Chen, X.; Yang, C. Nonlinear process monitoring using kernel dictionary learning with application to aluminum electrolysis process. Control Eng. Pract. 2019, 89, 94–102. [Google Scholar] [CrossRef]

- Folgado, F.J.; González, I.; Calderón, A.J. PEM Electrolyser Digital Twin Embedded within MATLAB-Based Graphical User Interface. In Proceedings of the 1st International Electronic Conference on Processes: Processes System Innovation, Online, 17–31 May 2022; p. 21. [Google Scholar] [CrossRef]

- Nguyen, Q.-D.; Huang, Y.; Keith, F.; Leroy, C.; Thi, M.-T.; Dhouib, S. Manufacturing 4.0: Checking the Feasibility of a Work Cell Using Asset Administration Shell and Physics-Based Three-Dimensional Digital Twins. Machines 2024, 12, 95. [Google Scholar] [CrossRef]

- Mourtzis, D.; Tsoubou, S.; Angelopoulos, J. Robotic Cell Reliability Optimization Based on Digital Twin and Predictive Maintenance. Electronics 2023, 12, 1999. [Google Scholar] [CrossRef]

- Chen, Y.; Silvestri, L.; Lei, X.; Ladouceur, F. Optically powered gas monitoring system using single-mode fibre for underground coal mines. Int. J. Coal Sci. Technol. 2022, 9, 26. [Google Scholar] [CrossRef]

- Li, X.; Liu, B.; Qian, W.; Rao, G.; Chen, L.; Cui, J. Design of Soft-Sensing Model for Alumina Concentration Based on Improved Deep Belief Network. Processes 2022, 10, 2537. [Google Scholar] [CrossRef]

- Yang, D.; Cui, Y.; Xia, Q.; Jiang, F.; Ren, Y.; Sun, B.; Feng, Q.; Wang, Z.; Yang, C. A Digital Twin-Driven Life Prediction Method of Lithium-Ion Batteries Based on Adaptive Model Evolution. Materials 2022, 15, 3331. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Wu, H.; Gao, S.; Sun, M.; Song, H.; Wang, Q. Temperature-Independent Sensor of the Magnetic Field Based on FBG and Terfenol-D. Nanomaterials 2023, 13, 2109. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.; Jia, S.; Bian, J.; Zhang, S.; Liu, J.; Zhou, X. Recent Progress on Electromagnetic Field Measurement Based on Optical Sensors. Sensors 2019, 19, 2860. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, K.; Shi, H.; Zhao, J.; Li, J. A two-stage classifier switchable aluminum electrolysis fault diagnosis method. Trans. Inst. Meas. Control 2022, 44, 1708–1720. [Google Scholar] [CrossRef]

- Zhukovskiy, Y.; Tsvetkov, P.; Koshenkova, A.; Skvortsov, I.; Andreeva, I.; Vorobeva, V. A Methodology for Forecasting the KPIs of a Region’s Development: Case of the Russian Arctic. Sustainability 2024, 16, 6597. [Google Scholar] [CrossRef]

- Shklyarskiy, Y.; Andreeva, I.; Sutikno, T.; Jopri, M.H. Energy management in hybrid complexes based on wind generation and hydrogen storage. Bull. Electr. Eng. Inform. 2024, 13, 1483–1494. [Google Scholar] [CrossRef]

- Shklyarskiy, Y.; Skvortsov, I.; Sutikno, T.; Manap, M. The optimization technique for a hybrid renewable energy system based on solar-hydrogen generation. Int. J. Power Electron. Drive Syst. (IJPEDS) 2024, 15, 1. [Google Scholar] [CrossRef]

- Suzdaltsev, A.V.; Nikolaev, A.Y.; Zaikov, Y.P. Towards the Stability of Low-Temperature Aluminum Electrolysis. J. Electrochem. Soc. 2021, 168, 046521. [Google Scholar] [CrossRef]

- Polyakov, A.A.; Gorlanov, E.S.; Mushihin, E.A. Analytical Modeling of Current and Potential Distribution over Carbon and Low-Consumable Anodes during Aluminum Reduction Process. J. Electrochem. Soc. 2022, 169, 053502. [Google Scholar] [CrossRef]

- Polyakov, P.V.; Sharypov, N.A.; Osipova, V.A.; Pianykh, A.A. Mathematical modeling of current distribution in the presence of abnormalities on the reduction cell anode bottom. Tsvetnye Met. 2019, 1, 25–30. [Google Scholar] [CrossRef]

- Bi, X.; Wang, L.; Marignetti, F.; Zhou, M. Research on Electromagnetic Field, Eddy Current Loss and Heat Transfer in the End Region of Synchronous Condenser with Different End Structures and Material Properties. Energies 2021, 14, 4636. [Google Scholar] [CrossRef]

- Hou, W.; Sun, K.; Sun, S.; Li, M. Numerical Investigation of Electro-Thermal Field Distribution Law of Busbar under Different Operating Conditions. Metals 2023, 13, 1361. [Google Scholar] [CrossRef]

- Zhu, J.; Li, J.; Zhang, H. CFD Investigation of Bath Flow and Its Related Alumina Transmission in Aluminum Reduction Cells: Slotted Anodes and Busbar Designs. Metals 2020, 10, 805. [Google Scholar] [CrossRef]

- Murzin, M.A.; Tepina, M.S. Impact of Metallurgical Production on the Environment. Metallurgist 2022, 66, 167–171. [Google Scholar] [CrossRef]

- Man, G.T.; Albu, P.C.; Nechifor, A.C.; Grosu, A.R.; Popescu, D.I.; Grosu, V.-A.; Marinescu, V.E.; Nechifor, G. Simultaneously Recovery of Thorium and Tungsten through Hybrid Electrolysis–Nanofiltration Processes. Toxics 2024, 12, 103. [Google Scholar] [CrossRef]

- Birat, J.-P. Society, Materials, and the Environment: The Case of Steel. Metals 2020, 10, 331. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Hou, W.; Li, M.; Cheng, B.; Feng, Y.; Xu, T. The Study of Carbon Recovery from Electrolysis Aluminum Carbon Dust by Froth Flotation. Metals 2021, 11, 145. [Google Scholar] [CrossRef]

- Proshkin, A.V.; Sbitnev, A.G.; Zherdev, A.S.; Pingin, V.V.; Orlov, A.S. Method Forlining Cathode Device Ofelectrolyzerforproduction of Aluminum. Federal Service for Intellectual Property. Patent No. RU2754560C1, 3 September 2021. Available online: https://patents.google.com/patent/RU2754560C1 (accessed on 18 March 2025).

- Ivanova, A.M.; Arkhipov, P.A.; Rudenko, A.V.; Tkacheva, O.Y.; Zaikov, Y.P. Formation of Side Ledge and Bottom Ledge in an Aluminum Electrolyzer. Russ. J. Non-Ferr. Met. 2019, 60, 624–631. [Google Scholar] [CrossRef]

- Luneng, R.; Bertel, S.N.; Mikkelsen, J.; Ratvik, A.P.; Grande, T. Chemical Durability of Thermal Insulating Materials in Hall-Héroult Electrolysis Cells. Ceramics 2019, 2, 441–459. [Google Scholar] [CrossRef]

- Milyuts, V.G.; Tsukanov, V.V.; Pryakhin, E.I.; Nikitina, L.B. Development of Manufacturing Technology for High-Strength Hull Steel Reducing Production Cycle and Providing High-Quality Sheets. J. Min. Inst. 2019, 239, 536–543. [Google Scholar] [CrossRef]

- Nemchinova, N.V.; Tyutrin, A.A.; Somov, V.V. Determination of Optimal Fluorine Leaching Parameters from the Coal Part of the Waste Lining of Dismantled Electrolytic Cells for Aluminum Production. J. Min. Inst. 2019, 239, 544–549. [Google Scholar] [CrossRef]

- Pervukhin, D.; Kotov, D.; Trushnikov, V. Development of a Conceptual Model for the Information and Control System of an Autonomous Underwater Vehicle for Solving Problems in the Mineral and Raw Materials Complex. Energies 2024, 17, 5916. [Google Scholar] [CrossRef]

- Mal’Tsev, P.A.; Shatilova, N.A.; Abramkin, S.E. Synthesis of a Control System for the Oil Cooling Process in the Oil Supply System of a Gas Turbine Engine. In Proceedings of the 2022 XXV International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 25–27 May 2022; pp. 68–71. [Google Scholar] [CrossRef]

- Kukharova, T.; Maltsev, P.; Novozhilov, I. Development of a Control System for Pressure Distribution During Gas Production in a Structurally Complex Field. Appl. Syst. Innov. 2025, 8, 51. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Deng, Z.; Zhang, H.; Zeng, J. Distributed Robust Dictionary Pair Learning and Its Application to Aluminum Electrolysis Industrial Process. Processes 2022, 10, 1850. [Google Scholar] [CrossRef]

- Huang, K.; Wu, Y.; Yang, C.; Peng, G.; Shen, W. Structure Dictionary Learning-Based Multimode Process Monitoring and its Application to Aluminum Electrolysis Process. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1989–2003. [Google Scholar] [CrossRef]

- Afanaseva, O.; Tulyakov, T.; Romashin, D.; Panova, A. Development of a Robotic Complex for the Manufacture of Parts Used in Civil Engineering. In Challenges and Advancements in Civil Engineering; Rao, K.J., Aditya, B.R., Eds.; Grinrey Publishing: Parner, India, 2023; pp. 51–58. [Google Scholar] [CrossRef]

- Romashin, D.V. Application of Artificial Intelligence to Improve the Efficiency of Monitoring and Diagnosing the Condition of Complex Technical Objects. In Proceedings of the 2024 Conference of Young Researchers in Electrical and Electronic Engineering (ElCon), St. Petersburg, Russia, 29–31 January 2024; pp. 485–488. [Google Scholar] [CrossRef]

- Talanov, N.A.; Khloponina, V.S.; Fedorov, M.C. Systematic and Analytical Research of Methods for Analysing and Identifying the Technical Condition of Complex Technical Systems. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2023; pp. 92–95. [Google Scholar] [CrossRef]

- Li, J.; Gao, T.; Ji, X. Multi-model and multi-level aluminum electrolytic fault diagnosis method. Trans. Inst. Meas. Control 2019, 41, 4409–4423. [Google Scholar] [CrossRef]

- Zeng, Z.; Gui, W.; Chen, X.; Xie, Y.; Zhang, H.; Sun, Y. A Cell Condition-Sensitive Frequency Segmentation Method Based on the Sub-Band Instantaneous Energy Spectrum of Aluminum Electrolysis Cell Voltage. Engineering 2021, 7, 1282–1292. [Google Scholar] [CrossRef]

- Asadulagi, M.-A.M.; Fedorov, M.S.; Trushnikov, V.E. Control Methods of Mineral Water Wells. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2023; pp. 152–155. [Google Scholar] [CrossRef]

- Asadulagi, M.-A.M.; Pershin, I.M.; Tsapleva, V.V. Research on Hydrolithospheric Processes Using the Results of Groundwater Inflow Testing. Water 2024, 16, 487. [Google Scholar] [CrossRef]

- Kukharova, T.V.; Utkin, V.A.; Pershin, I.M. Modeling of a Decision Support System for a Psychiatrist Based on the Dynamics of Electrical Conductivity Parameters. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg, Russia, 26–29 January 2021; pp. 975–978. [Google Scholar] [CrossRef]

- Pervukhin, D.A.; Davardoost, H.; Gasimov, E.; Hawezy, A.L.J. Optimizing Multimodal Logistics in Petroleum Supply Chains Using Linear Goal Programming: A Case Study on South Pars Gas Field Development. Int. J. Eng. 2025, 38, 1909–1921. [Google Scholar] [CrossRef]

- Souza, A.M.F.D.; Soares, F.M.; Castro, M.A.G.D.; Nagem, N.F.; Bitencourt, A.H.D.J.; Affonso, C.D.M.; Oliveira, R.C.L.D. Soft Sensors in the Primary Aluminum Production Process Based on Neural Networks Using Clustering Methods. Sensors 2019, 19, 5255. [Google Scholar] [CrossRef]

- Legemza, J.; Fröhlichová, M.; Findorák, R.; Džupková, M. Modelling of Mass and Thermal Balance and Simulation of Iron Sintering Process with Biomass. Metals 2019, 9, 1010. [Google Scholar] [CrossRef]

- Rodríguez-Alemán, S.; Hernández-Cooper, E.M.; Pérez-Álvarez, R.; Otero, J.A. Effects of Total Thermal Balance on the Thermal Energy Absorbed or Released by a High-Temperature Phase Change Material. Molecules 2021, 26, 365. [Google Scholar] [CrossRef] [PubMed]

- Ding, W.; Yao, L.; Li, Y.; Long, W.; Yi, J.; He, T. Dynamic evolutionary model based on a multi-sampling inherited HAPFNN for an aluminium electrolysis manufacturing system. Appl. Soft Comput. 2021, 99, 106925. [Google Scholar] [CrossRef]

- Zhou, W.; Shi, J.; Yin, G.; He, W.; Yi, J. Optimal Control for Aluminum Electrolysis Process Using Adaptive Dynamic Programming. IEEE Access 2020, 8, 220374–220383. [Google Scholar] [CrossRef]

- Capalbo, C.E.; De Gregoriis, D.; Tamarozzi, T.; Devriendt, H.; Naets, F.; Carbone, G.; Mundo, D. Parameter, input and state estimation for linear structural dynamics using parametric model order reduction and augmented Kalman filtering. Mech. Syst. Signal Process. 2023, 185, 109799. [Google Scholar] [CrossRef]

- Guérard, S.; Côté, P. A Transient Model of the Anodic Current Distribution in an Aluminum Electrolysis Cell. In Light Metals; Chesonis, C., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 595–603. [Google Scholar] [CrossRef]

- Gombár, M.; Vagaská, A.; Harničárová, M.; Valíček, J.; Kušnerová, M.; Czán, A.; Kmec, J. Experimental Analysis of the Influence of Factors Acting on the Layer Thickness Formed by Anodic Oxidation of Aluminium. Coatings 2019, 9, 57. [Google Scholar] [CrossRef]

- Lv, H.; Xie, M.; Wu, Z.; Li, L.; Yang, R.; Han, J.; Liu, F.; Zhao, H. Effective Extraction of the Al Element from Secondary Aluminum Dross Using a Combined Dry Pressing and Alkaline Roasting Process. Materials 2022, 15, 5686. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, X.; Zeng, A. Decoupling analysis between economic growth and aluminum cycle: From the perspective of aluminum use and carbon emissions. J. Environ. Manag. 2023, 344, 118461. [Google Scholar] [CrossRef]

- Sun, K.; Li, J.; Zhang, H.; Li, T.; Li, J. First-Principles Study on the Mechanism of Greenhouse Gas Generation in Aluminum Electrolysis. Metals 2021, 11, 1118. [Google Scholar] [CrossRef]

- Stanic, N.; Bø, E.T.; Sandnes, E. CO and CO2 Anode Gas Concentration at Lower Current Densities in Cryolite Melt. Metals 2020, 10, 1694. [Google Scholar] [CrossRef]

- He, Y.; Zhou, K.; Zhang, Y.; Xiong, H.; Zhang, L. Recent progress of inert anodes for carbon-free aluminium electrolysis: A review and outlook. J. Mater. Chem. A 2021, 9, 25272–25285. [Google Scholar] [CrossRef]

- Guan, P.; Liu, A.; Shi, Z.; Hu, X.; Wang, Z. Corrosion Behavior of Fe-Ni-Al Alloy Inert Anode in Cryolite Melts. Metals 2019, 9, 399. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca, V.; Matei, E.; Polosan, S. Synthesis of Cobalt–Nickel Aluminate Spinels Using the Laser-Induced Thermionic Vacuum Arc Method and Thermal Annealing Processes. Nanomaterials 2022, 12, 3895. [Google Scholar] [CrossRef]

- Selpiana, S.; Haryati, S.; Bustan, M.D. Graphite/β-PbO2 Composite Inert Anode Synthesis Using Electrochemical Methods. ChemEngineering 2023, 7, 20. [Google Scholar] [CrossRef]

- Gardner, C.L.; Sarma, P.J.; Kjeang, E. Accumulation of Inert Impurities in a Polymer Electrolyte Fuel Cell System with Anode Recirculation and Periodic Purge: A Simple Analytical Model. Energies 2022, 15, 1968. [Google Scholar] [CrossRef]

- Wang, Y.; Song, J.; Cheng, N.; Guo, Z.; Li, J.; Yang, S.; Zhao, M.; Wang, C. Application of Graphite Electrode Plasma Heating Technology in Continuous Casting. Materials 2022, 15, 2590. [Google Scholar] [CrossRef]

- Li, L.; Li, Q.; Yong, W.; Zhang, S.; Yang, M.; Jiang, P. Intelligent Online Inspection of the Paste Quality of Prebaked Carbon Anodes Using an Anomaly Detection Algorithm. Systems 2023, 11, 484. [Google Scholar] [CrossRef]

- Kansoun, Z.; Chaouki, H.; Picard, D.; Lauzon-Gauthier, J.; Alamdari, H.; Fafard, M. Strain Rate and Stress Amplitude Effects on the Mechanical Behavior of Carbon Paste Used in the Hall–Héroult Process and Subjected to Cyclic Loadings. Materials 2022, 15, 1263. [Google Scholar] [CrossRef]

- Tsvetkov, P.; Samuseva, P.; Nikolaychuk, L. The research of the impact of energy efficiency on mitigating greenhouse gas emissions at the national level. Energy Convers. Manag. 2024, 314, 118671. [Google Scholar] [CrossRef]

- Aarhaug, T.A.; Ratvik, A.P. Aluminium Primary Production Off-Gas Composition and Emissions: An Overview. JOM 2019, 71, 2966–2977. [Google Scholar] [CrossRef]

- Ming, Y.; Zhou, N. Thermodynamic Performance Analysis of a Waste Heat Power Generation System (WHPGS) Applied to the Sidewalls of Aluminum Reduction Cells. Entropy 2020, 22, 1279. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Li, S.; Chen, D.; Liu, X.; Ma, C.; Li, X. Evaluation of cathode quality and damage of aluminium electrolytic cell based on non-destructive technology. Trans. Nonferrous Met. Soc. China 2021, 31, 3929–3942. [Google Scholar] [CrossRef]

- Yuan, J.; Li, H.; Ding, S. Leaching Kinetics of Aluminum from Alkali-Fused Spent Cathode Carbon Using Hydrochloric Acid and Sodium Fluoride. Processes 2022, 10, 849. [Google Scholar] [CrossRef]

- Storozhev Yu, I.; Zlobin, V.S. Perspective Solutions of Environmental Problems of Aluminum Plants. Ecol. Ind. Russ. 2018, 22, 10–13. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Ferretti, I. Energy Efficiency Investments in Industry with Uncertain Demand Rate: Effects on the Specific Energy Consumption. Energies 2019, 13, 161. [Google Scholar] [CrossRef]

- Ling, J.; Yang, H.; Tan, Y.; Cheng, J.; Tian, G.; Wang, X. Review and prospects of numerical simulation in electrochemical metallurgy. J. Ind. Eng. Chem. 2024, 129, 24–37. [Google Scholar] [CrossRef]

- Saitov, A.V.; Bazhin, V.Y. Features of Using Modified Carbon-Graphite Lining Materials in Aluminum Electrolyzers. Refract. Ind. Ceram. 2018, 59, 278–286. [Google Scholar] [CrossRef]

- Litvinenko, V.S. Digital Economy as a Factor in the Technological Development of the Mineral Sector. Nat. Resour. Res. 2020, 29, 1521–1541. [Google Scholar] [CrossRef]

- Pelevin, A.E. Iron ore beneficiation technologies in Russia and ways to improve their efficiency. J. Min. Inst. 2022, 256, 579–592. [Google Scholar] [CrossRef]

- Romashev, A.O.; Nikolaeva, N.V.; Gatiatullin, B.L. Adaptive approach formation using machine vision technology to determine the parameters of enrichment products deposition. J. Min. Inst. 2022, 256, 677–685. [Google Scholar] [CrossRef]

- Stepanov, S.N.; Larionova, T.A.; Stepanov, S.S. Study of Aluminum Influence on the Adhesion of Stainless Steel in Flame Spraying. J. Min. Inst. 2020, 245, 591–598. [Google Scholar] [CrossRef]

| № | Problem Type | Problem Literary |

|---|---|---|

| 1 | Temperature problems | [7,8,9,10,11,12,13,14,15] |

| 2 | Chemical problems | [16,17,18,19,20,21,22] |

| 3 | Physical problems | [23,24,25,26,27] |

| 4 | Economic problems | [28,29,30,31,32,33,34,35,36] |

| 5 | Electrical problems | [11,37,38,39,40,41,42,43,44,45,46,47,48] |

| Challenge | Objectives | Methods | Planned or Achieved Results |

|---|---|---|---|

| Lack of possibility to accurately measure dynamic parameters in the bath during electrolysis |

|

|

|

| Increase in the level of environmental pollution |

|

|

|

| Wear and destruction of metal structures of the cathode device |

|

|

|

| Electricity losses due to interaction of electric and magnetic fields |

|

|

|

| Disturbance of MHDS of the electrolyzer |

|

|

|

| Lining wear under electrolysis conditions |

|

|

|

| Damage to anodes during slight circulation of electrolyte near the back of the unit |

|

|

|

| Insufficient study of the nature of the mutual influence of electromagnetic and thermal fields during electrolysis |

|

|

|

| Uneven heating of metal in the working area due to an uneven electromagnetic field |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilyushin, Y.V.; Boronko, E.A. Analysis of Energy Sustainability and Problems of Technological Process of Primary Aluminum Production. Energies 2025, 18, 2194. https://doi.org/10.3390/en18092194

Ilyushin YV, Boronko EA. Analysis of Energy Sustainability and Problems of Technological Process of Primary Aluminum Production. Energies. 2025; 18(9):2194. https://doi.org/10.3390/en18092194

Chicago/Turabian StyleIlyushin, Yury Valeryevich, and Egor Andreevich Boronko. 2025. "Analysis of Energy Sustainability and Problems of Technological Process of Primary Aluminum Production" Energies 18, no. 9: 2194. https://doi.org/10.3390/en18092194

APA StyleIlyushin, Y. V., & Boronko, E. A. (2025). Analysis of Energy Sustainability and Problems of Technological Process of Primary Aluminum Production. Energies, 18(9), 2194. https://doi.org/10.3390/en18092194