Thermal Performance of Deep Borehole Heat Exchangers (DBHEs) Installed in a Groundwater-Filled Hot Dry Rock (HDR) Well in Qinghai, China

Abstract

1. Introduction

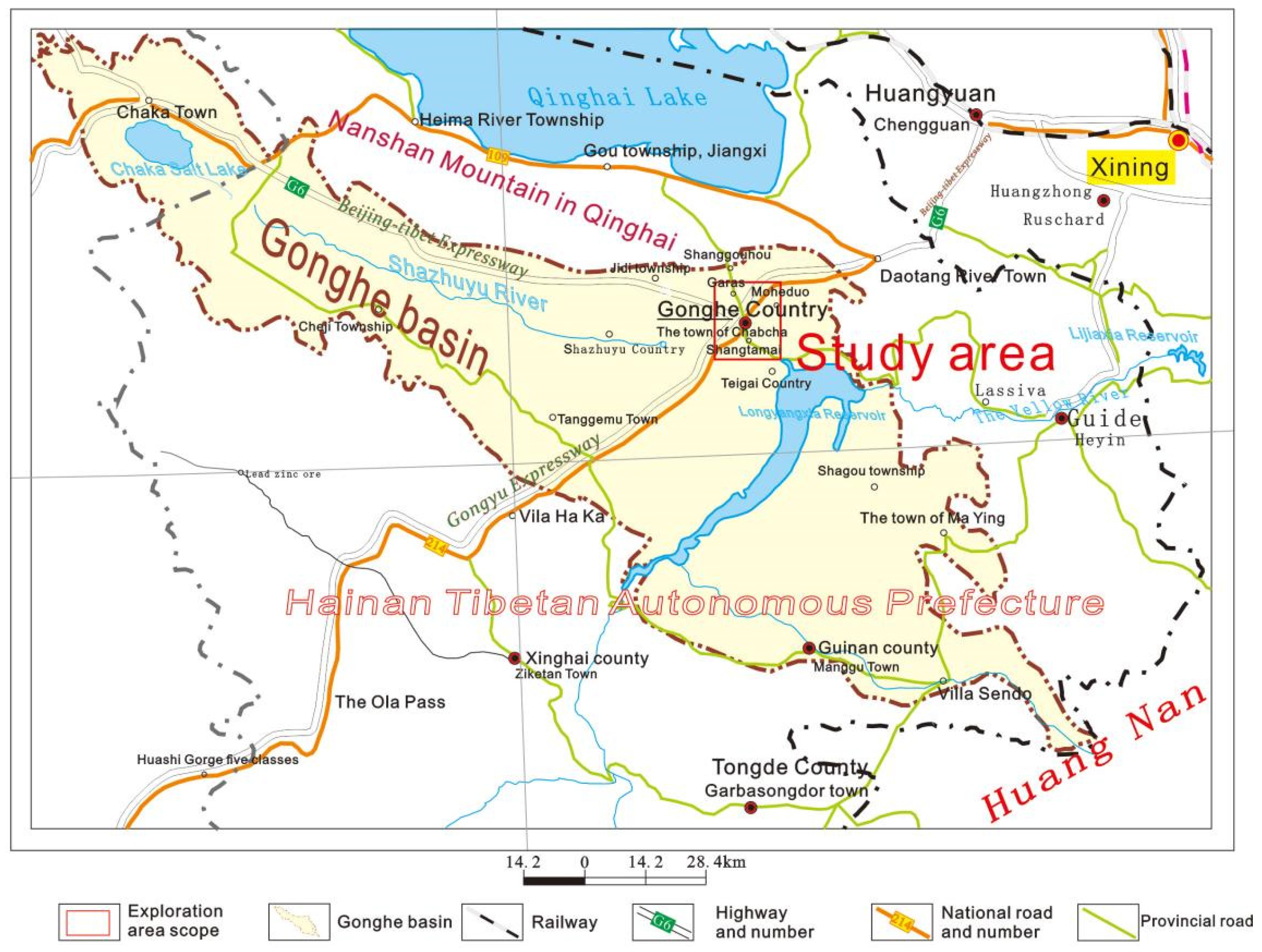

2. Geological Setting and Study Methodology

2.1. Geological Setting

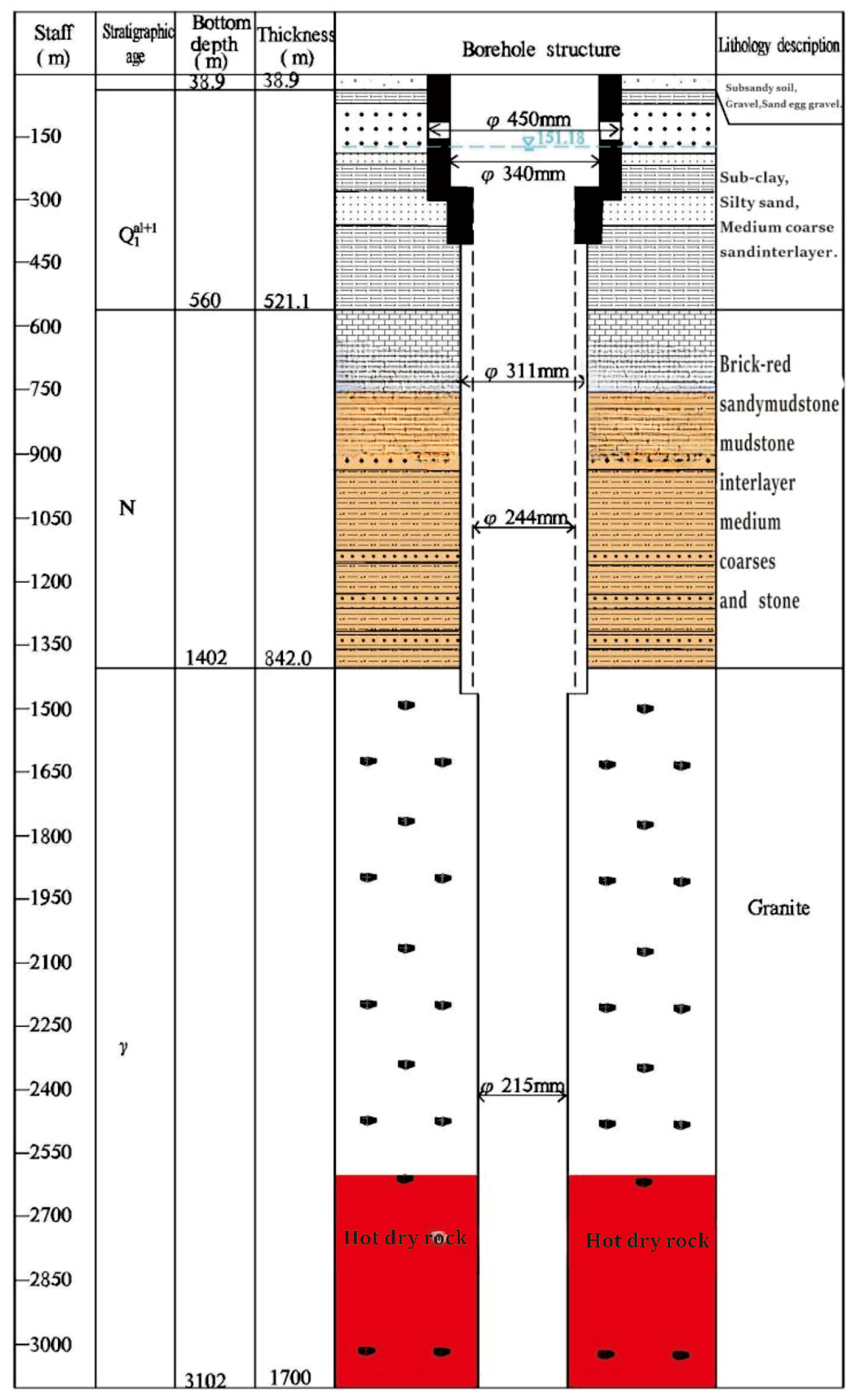

2.1.1. Stratigraphic Lithology

2.1.2. Geothermal Conditions

2.2. Study Methodology

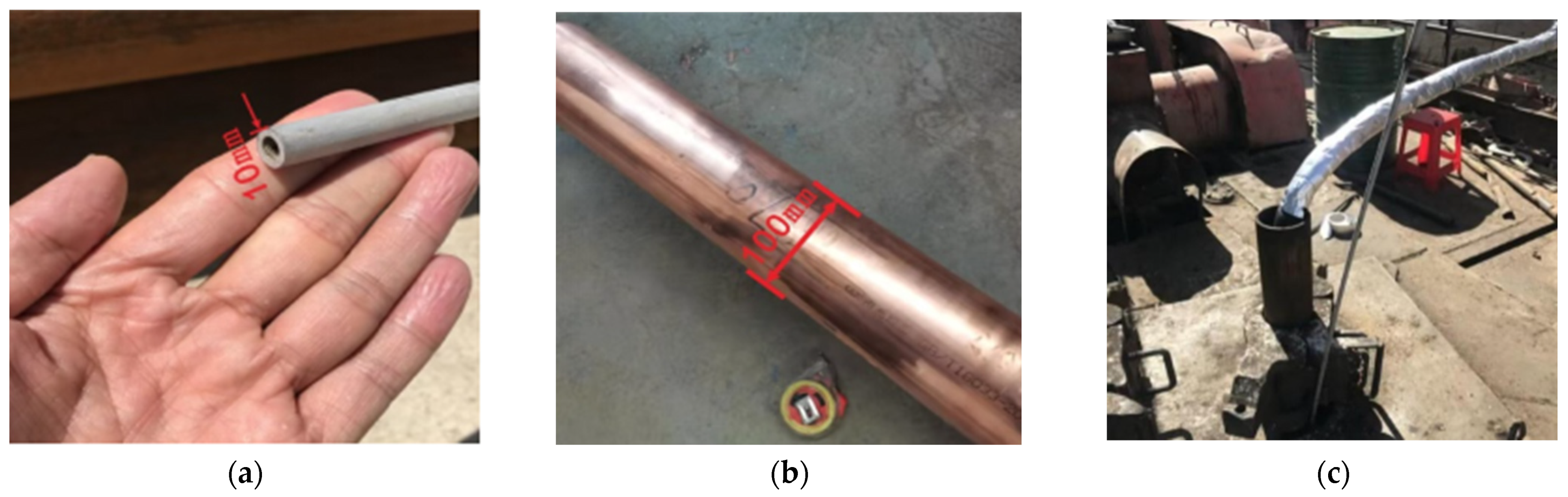

2.2.1. In Situ Test Setup

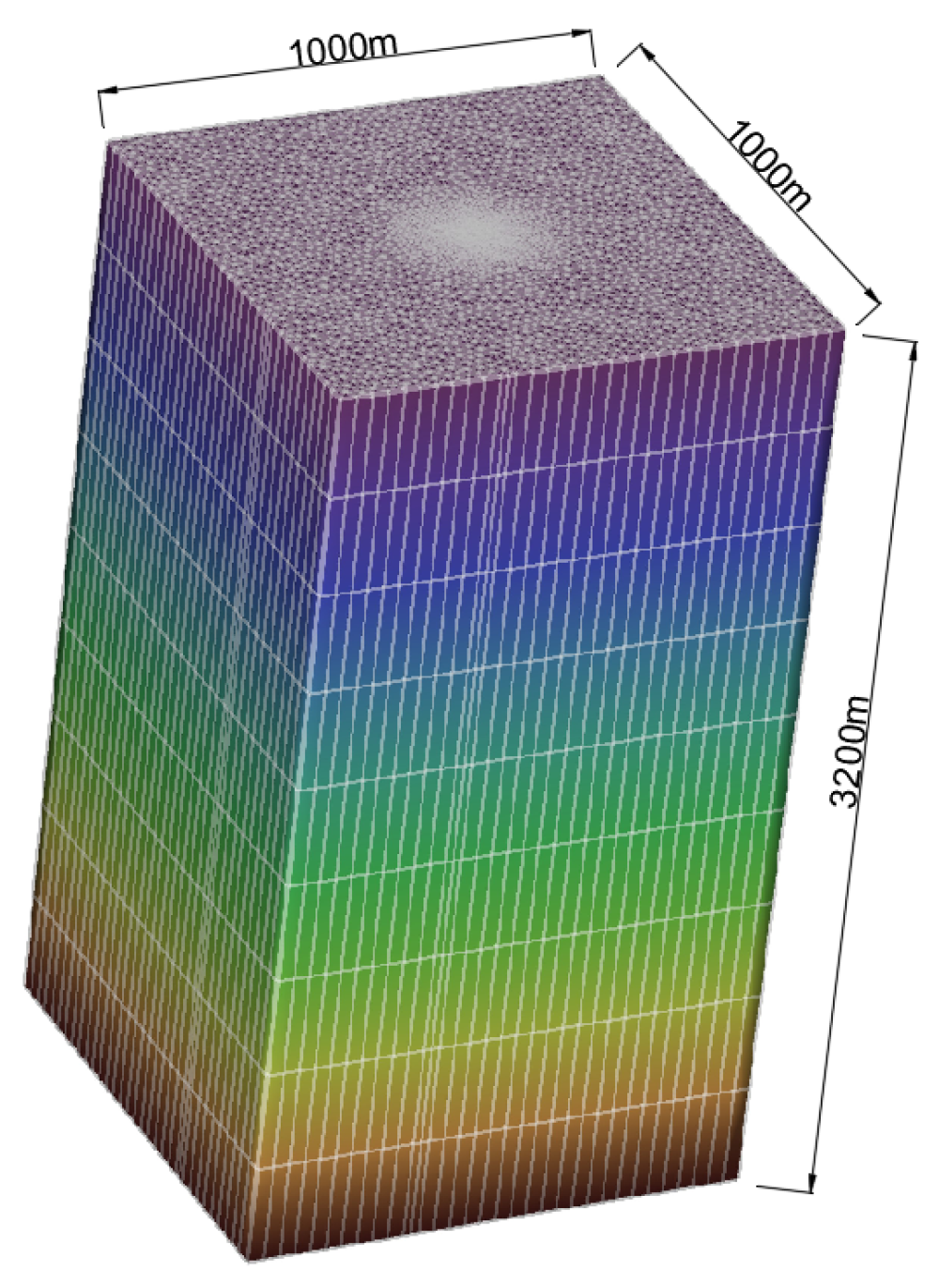

2.2.2. Development of a Numerical Model

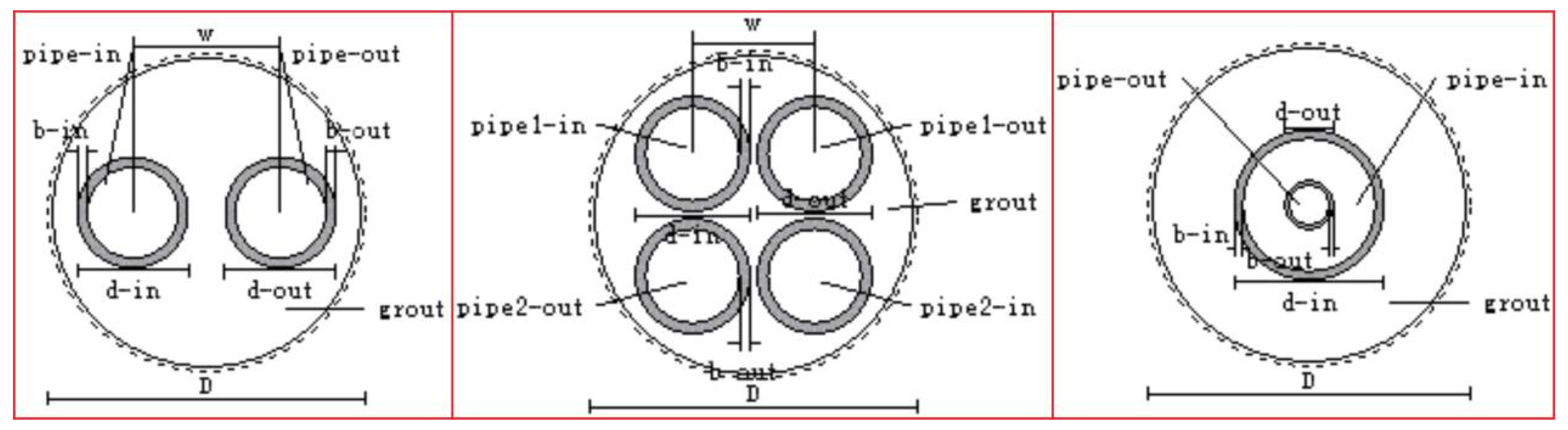

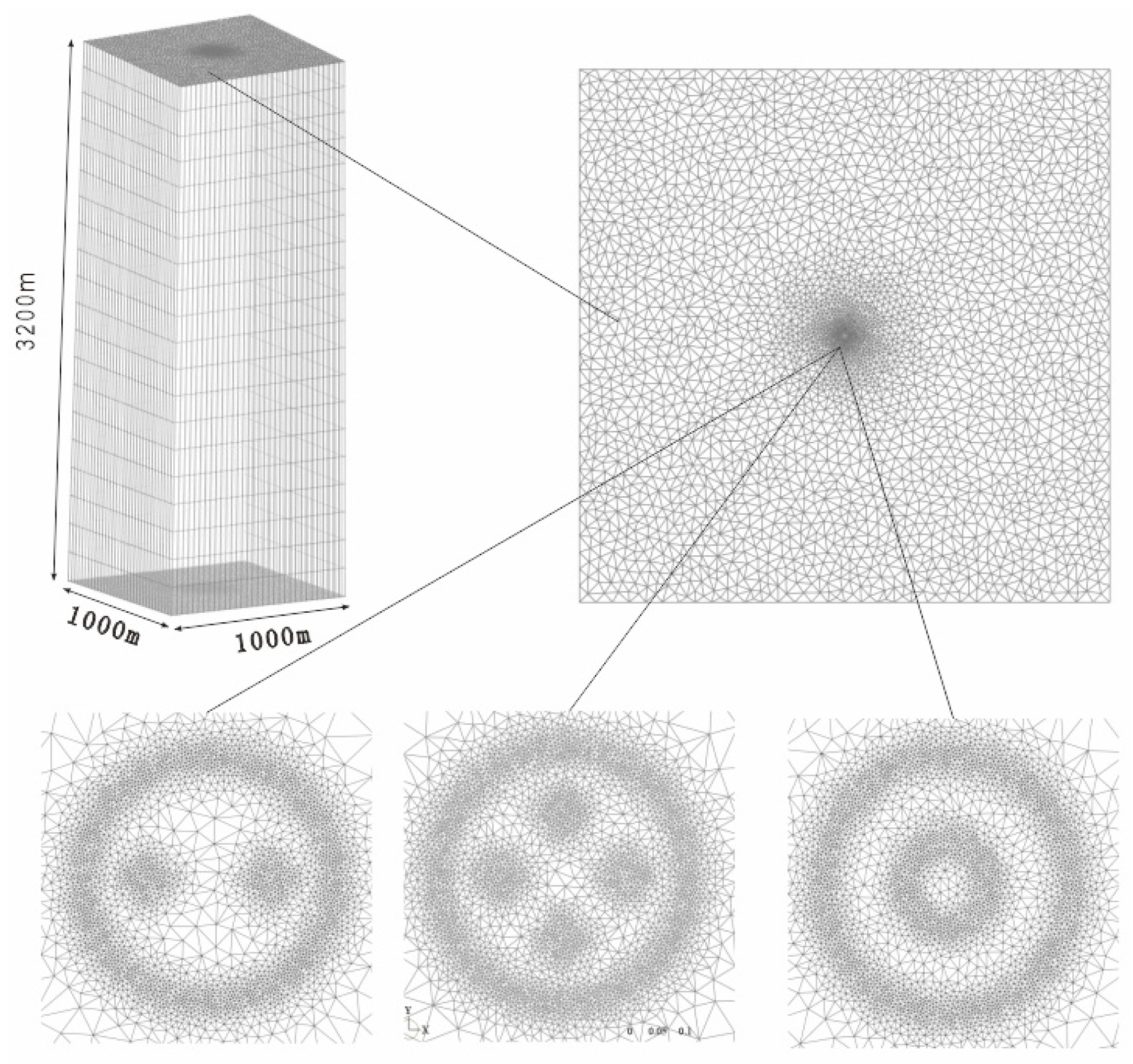

2.2.3. Effects of Pipe Configuration and Low Rate on Heat Transfer Performance

2.2.4. Thermal Performance with Three Pipe Configurations

3. Results and Discussion

3.1. Experimental Results

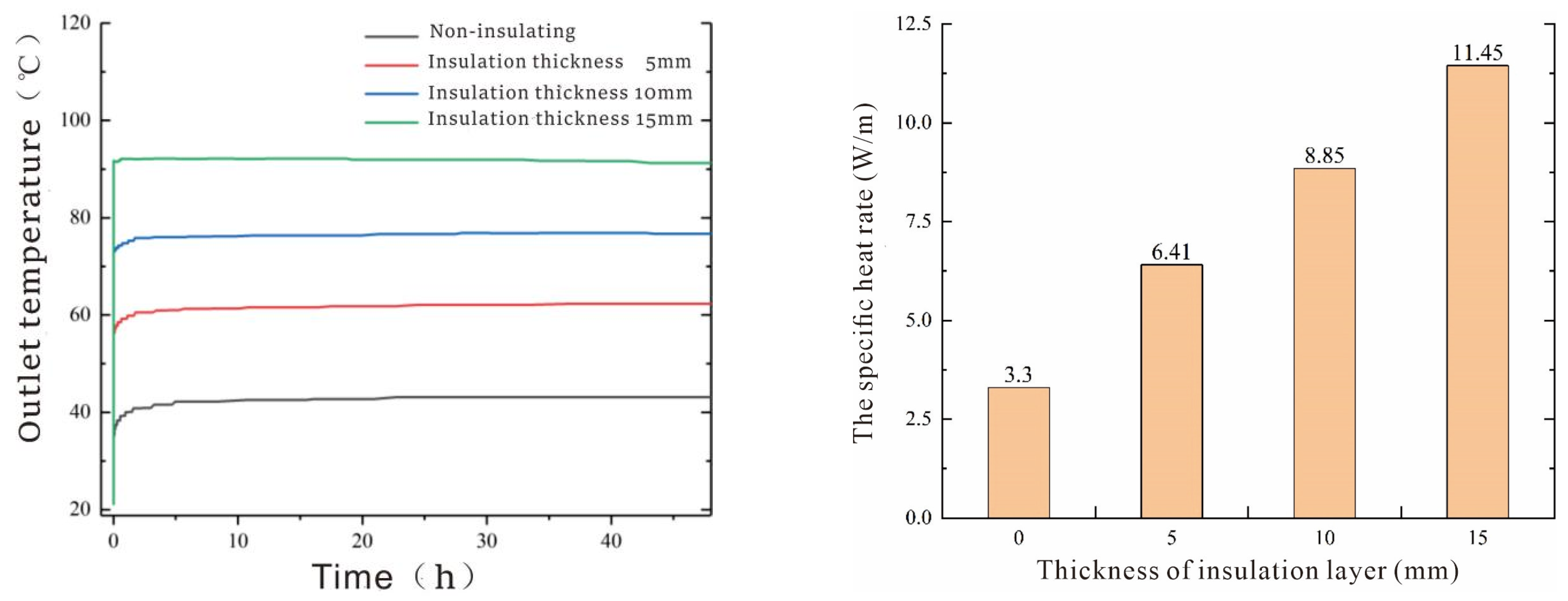

3.2. Effects of Pipe Insulation on Thermal Performance

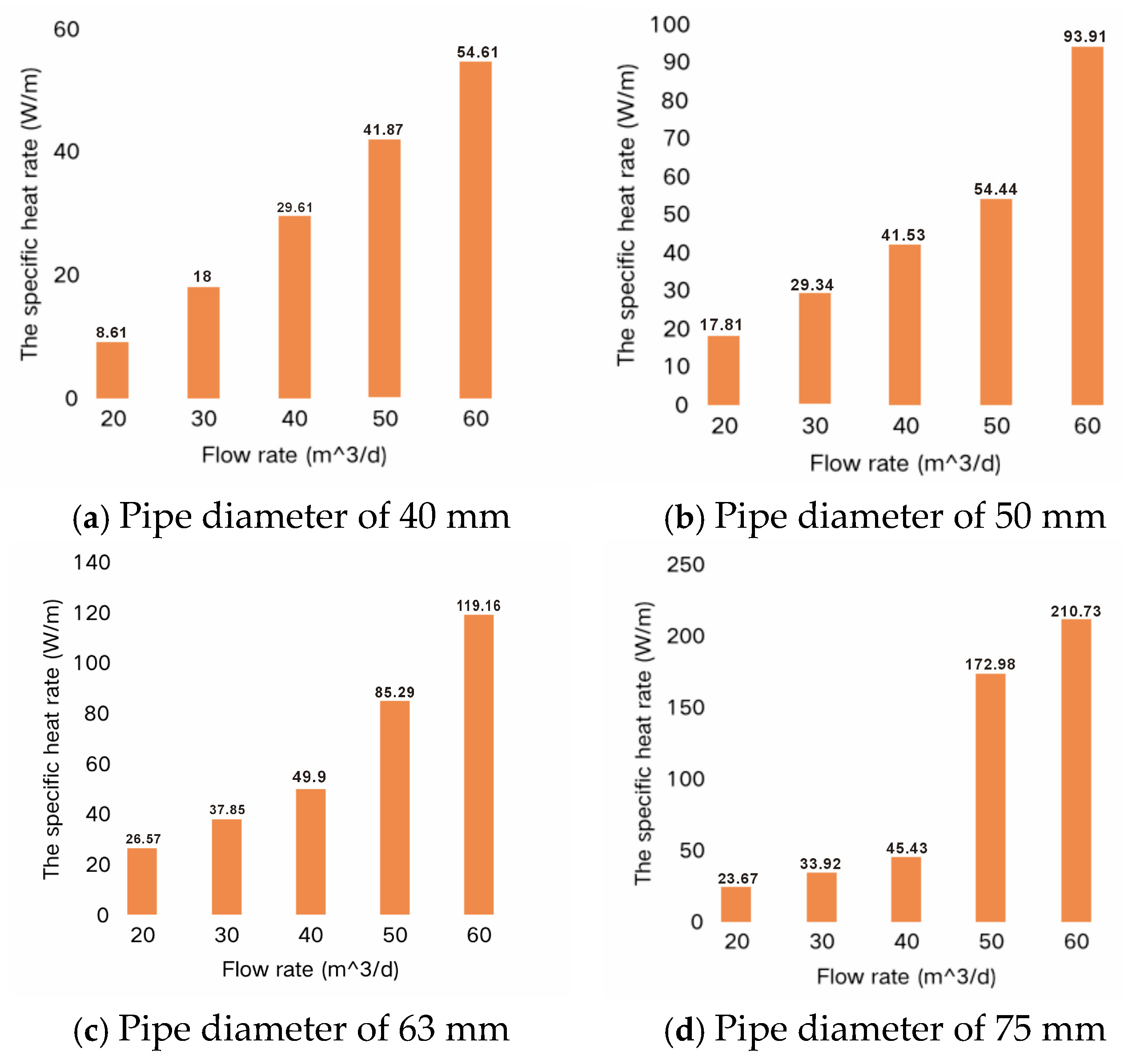

3.3. The Influence of Pipe Diameter and Fluid Flow Rate on Heat Performance

3.4. Thermal Performance Comparison of GHEs with Three Pipe Configurations

4. Conclusions

- A geothermal energy exploitation system was successfully developed in an open well with a temperature of 180 °C and a hydraulic pressure of 30 MPa. The system operated under fluid injection pressures ranging from 1.0 to 3.9 MPa for 24 h. The highest water outlet temperature reached 26.7 °C, and the average flow rate was 120 L/h. At the same hole depth, both the fluid flow rate and the outlet temperature increased with rising injection pressure. Specifically, when the injection pressure increased by 1.0 MPa, the fluid flow rate increased by 10.23 L/h, and the water temperature rose by 2.3 °C, indicating that increasing the injection pressure increases the fluid flow rate and enhances the thermal performance.

- The effect of pipe insulation on the heat transfer efficiency of the GHE system in the HDR well was simulated. The results show that with a continuous operation for 48 h, the heat transfer pipe’s outlet temperatures for the insulation thicknesses of 0 mm, 5 mm, 10 mm, and 15 mm were 43.15 °C, 62.34 °C, 76.71 °C, and 91.26 °C, respectively. The specific heat rates were calculated to be 3.3 W/m, 6.41 W/m, 8.85 W/m, and 11.45 W/m, indicating that increasing the insulation thickness increased the specific heat rate by 94.24%, 126.32% 168.18%, and 246.97%, respectively. This demonstrates the significant impact of pipe insulation on the thermal extraction performance of the system. Further simulation indicated that enlarging the pipe diameter and fluid flow rate can achieve a higher thermal performance of the ground heat exchanger.

- Three types of ground heat exchangers (GHE), including single U-shaped, double U-shaped, and coaxial pipes, were numerically investigated. The maximum possible pipe diameters for these configurations were 75 mm for single U-shaped pipes, 63 mm for double U-shaped pipes, and 178 mm for coaxial pipes. The results indicated that the heat exchange efficiency of the single U-shaped and double U-shaped configurations was slightly lower than that of the coaxial pipe. For the single U-shaped type with a 75 mm buried pipe diameter and a flow rate of 300 m3/d, the best heat transfer effect was 273.73 W/m. The double U-shaped type, constrained by the borehole size, could only accommodate a maximum buried pipe diameter of 63 mm, with the best heat transfer effect of 341.33 W/m at the same flow rate of 300 m3/d. For the coaxial type, with an outer diameter of 178 mm and an inner diameter of 110 mm, the best heat transfer effect was 315.93 W/m at a flow rate of 600 m3/d.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tang, X.; Cheng, L.; Xu, W. Numerical study on factors that influence the heat transfer performance of mid-deep coaxial casing heat exchanger in the Xi.an area. Chin. J. Geol. (Sci. Geol. Sin.) 2021, 56, 985–999. [Google Scholar] [CrossRef]

- Liu, M.; Rehman, S.; Tang, X.; Gu, K.; Fan, Q.; Chen, D.; Ma, W. Methodologies for Improving HDR Efficiency. Front. Genet. 2019, 9, 691. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.; Kong, Y.; Chen, C.; Pang, Z.; Wang, J. Optimization of the utilization of deep borehole heat exchangers. Geotherm. Energy 2020, 8, 6. [Google Scholar] [CrossRef]

- Liu, J.; Wang, F.; Cai, W.; Wang, Z.; Li, C. Numerical investigation on the effects of geological parameters and layered subsurface on the thermal performance of medium-deep borehole heat exchanger. Renew Energy 2020, 149, 384–399. [Google Scholar] [CrossRef]

- Deng, J.; Wei, Q.; Liang, M.; He, S.; Zhang, H. Field test on energy performance of medium-depth geothermal heat pump systems (MD-GHPs). Energy Build. 2019, 184, 289–299. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Zhang, X.; Niu, D.; Wang, F.; Chai, J.; Lu, Y.; Sun, Y.; Lin, Z. Effects of climate change on long-term building heating performance of medium-deep borehole heat exchanger coupled heat pump. Energy Build. 2023, 293, 113208. [Google Scholar] [CrossRef]

- Song, X.; Wang, G.; Shi, Y.; Li, R.; Xu, Z.; Zheng, R.; Wang, Y.; Li, J. Numerical analysis of heat extraction performance of a deep coaxial borehole heat exchanger geothermal system. Energy 2018, 164, 1298–1310. [Google Scholar] [CrossRef]

- Holmberg, H.; Acuña, J.; Næss, E.; Sønju, O.K. Thermal evaluation of coaxial deep borehole heat exchangers. Renew Energy 2016, 97, 65–76. [Google Scholar] [CrossRef]

- Kolo, I.; Brown, C.S.; Nibbs, W.; Cai, W.; Falcone, G.; Nagel, T.; Chen, C. A comprehensive review of deep borehole heat exchangers (DBHEs): Subsurface modelling studies and applications. Geotherm. Energy 2024, 12, 19. [Google Scholar] [CrossRef]

- Le Lous, M.; Larroque, F.; Dupuy, A.; Moignard, A. Thermal performance of a deep borehole heat exchanger: Insights from a synthetic coupled heat and flow model. Geothermics 2015, 57, 157–172. [Google Scholar] [CrossRef]

- Niu, Q.; Ma, K.; Wang, W.; Pan, J.; Wang, Q.; Du, Z.; Wang, Z.; Yuan, W.; Zheng, Y.; Shangguan, S.; et al. Multifactor analysis of heat extraction performance of coaxial heat exchanger applied to hot dry rock resources exploration: A case study in matouying uplift, Tangshan, China. Energy 2023, 282, 128277. [Google Scholar] [CrossRef]

- Wang, C.; Fang, H.; Wang, X.; Lu, J.; Sun, Y. Study on the influence of borehole heat capacity on deep coaxial borehole heat exchanger. Sustainability 2022, 14, 2043. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Z.; Pang, Z. A Fast Simulation Approach to the Thermal Recovery Characteristics of Deep Borehole Heat Exchanger after Heat Extraction. Sustainability 2020, 12, 2021. [Google Scholar] [CrossRef]

- Li, Y.; Xu, S.; Zhang, W.; Sun, Y.; Han, Y.; Zhang, H.; Huang, J. Thermal short-circuiting and heat transfer performance of coaxial borehole heat exchanger. Coal Geol. Explor. 2020, 48, 183–188. [Google Scholar] [CrossRef]

- Bao, X. Study on Heat Transfer Characteristics of the Middle-Deep Coaxial Casing Ground Heat Exchanger; Hebei University of Engineering: Handan, China, 2020. [Google Scholar] [CrossRef]

- Fang, L.; Diao, N.; Shao, Z.; Wang, Z.; Fang, Z. Study on Thermal Resistance of Coaxial Tube Boreholes in Ground-Coupled Heat Pump Systems. Procedia Eng. 2017, 205, 3735–3742. [Google Scholar] [CrossRef]

- Fang, L.; Diao, N.; Shao, Z.; Zhu, K.; Fang, Z. A computationally efficient numerical model for heat transfer simulation of deep borehole heat exchangers. Energy Build. 2018, 167, 79–88. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, W.; Qian, C.; Chen, X.; Jin, G. Investigation on the feasibility and performance of ground source heat pump (GSHP) in three cities in cold climate zone, China. Renew Energy 2015, 84, 89–96. [Google Scholar] [CrossRef]

- Wu, T.; Liu, Y.; Dong, Z.; Fang, Y.; Liu, Y. Research and application of ground source heat pump refrigeration. Chin. J. Refrig. Technol. 2014, 4, 71–75. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M. Progress in ground-source heat pumps using natural refrigerants. Int. J. Refrig. 2018, 92, 70–85. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Sadaghiani, M.S.; Ghazvini, M.; Shahriar, S.; Alhuyi Nazari, M. Ground source heat pump carbon emissions and ground-source heat pump systems for heating and cooling of buildings: A review. Environ. Prog. Sustain. Energy 2018, 37, 1241–1265. [Google Scholar] [CrossRef]

- Brown, C.S.; Kolo, I.; Falcone, G.; Banks, D. Investigating scalability of deep borehole heat exchangers: Numerical modelling of arrays with varied modes of operation. Renew Energy 2023, 202, 442–452. [Google Scholar] [CrossRef]

- Chen, C.; Shao, H.; Naumov, D.; Kong, Y.; Tu, K.; Kolditz, O. Numerical investigation on the performance, sustainability, and efficiency of the deep borehole heat exchanger system for building heating. Geotherm. Energy 2019, 7, 18. [Google Scholar] [CrossRef]

- Cheng, N.; Zhou, C.; Luo, Y.; Shen, J.; Tian, Z.; Sun, D.; Fan, J.; Zhang, L.; Deng, J.; Rosen, M.A. Thermal behavior and performance of shallow-deep-mixed borehole heat exchanger array for sustainable building cooling and heating. Energy Build. 2023, 291, 113108. [Google Scholar] [CrossRef]

- Manzoor, A.; Saghir, M. Heat transfer enhancement in multiple pipes configuration using different fluid mixtures: A numerical approach. Int. J. Thermofluids 2021, 10, 100088. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Li, L.; Lu, X.; Zhang, W.; Tang, C.; Kong, X. An integrated system combining MDBHE (multi-casing DBHE) and heat pump achieves heating and cooling for medium-deep geothermal energy utilization. Energy 2024, 295, 131061. [Google Scholar] [CrossRef]

- Luo, Y.; Xu, G.; Zhang, S.; Cheng, N.; Tian, Z.; Yu, J. Heat extraction and recover of deep borehole heat exchanger: Negotiating with intermittent operation mode under complex geological conditions. Energy 2022, 241, 122510. [Google Scholar] [CrossRef]

| Property and Configuration | Argument | Unit |

|---|---|---|

| Hole diameter (D) | 215 | mm |

| Inlet and outlet pipe | Vertical heat exchanger | (-) |

| Buried pipe’s diameter (d) | 10 | mm |

| Buried pipe’s depth (H) | 3102 | m |

| Heat exchanger (w) | 100 | mm |

| Heat exchanger tube thickness (b) | 3 | mm |

| Heat exchanger’s thermal conductivity | 350 | W/(m·K) |

| No. | Pipe Diameter (mm) | Insulation Thickness (mm) | |

|---|---|---|---|

| External Diameter | Internal Diameter | ||

| 1 | 10 | 6 | 0 |

| 2 | 20 | 6 | 5 |

| 3 | 30 | 6 | 10 |

| 4 | 40 | 6 | 15 |

| Pipe Type | Model Size | Aperture (mm) | Heat Exchanger Pipe Diameter (Outside Diameter), mm | Tube Spacing, w | Pipe’s Thermal Conductivity, W/(m·K) | Platform File |

|---|---|---|---|---|---|---|

| Single U-shaped | 1000 m × 1000 m × 3200 m | 215 | 32/40/50/63/75 | 80 mm | Uninsulated: 42 Thermal insulation: 0.042 | Single-U FEM platform.fem |

| Double U-shaped | 32/40/50/63/75 | 80 mm | Double-U FEM platform.fem | |||

| Coaxial | Inner pipe: 32/40/50/63 Outer pipe: 40/50/63/75 | - | Coaxial FEM platform.fem |

| Flow Rate (m3/d) Type of the Buried Pipe | 40 | 50 | 60 | 180 | 240 | 300 | 600 |

|---|---|---|---|---|---|---|---|

| Single U-shaped pipe (75 mm) heat transfer (W/m) | 27.4 | 38.5 | 61.3 | 171.9 | 210.7 | 274.0 | - |

| Double U-shaped pipe (63 mm) heat transfer (W/m) | 33.6 | 48.1 | 76.6 | 214.8 | 263.4 | 341.3 | - |

| Coaxial pipe (inner diameter of 110 mm, outer diameter of 178 mm) heat transfer (W/m) | - | - | - | - | 273.5 | 225.6 | 315.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Lu, F.; Huang, Y.; Tan, L.; Luo, J.; Duan, L. Thermal Performance of Deep Borehole Heat Exchangers (DBHEs) Installed in a Groundwater-Filled Hot Dry Rock (HDR) Well in Qinghai, China. Energies 2025, 18, 2229. https://doi.org/10.3390/en18092229

Zhang Q, Lu F, Huang Y, Tan L, Luo J, Duan L. Thermal Performance of Deep Borehole Heat Exchangers (DBHEs) Installed in a Groundwater-Filled Hot Dry Rock (HDR) Well in Qinghai, China. Energies. 2025; 18(9):2229. https://doi.org/10.3390/en18092229

Chicago/Turabian StyleZhang, Qixing, Feiyang Lu, Yong Huang, Liwei Tan, Jin Luo, and Longcheng Duan. 2025. "Thermal Performance of Deep Borehole Heat Exchangers (DBHEs) Installed in a Groundwater-Filled Hot Dry Rock (HDR) Well in Qinghai, China" Energies 18, no. 9: 2229. https://doi.org/10.3390/en18092229

APA StyleZhang, Q., Lu, F., Huang, Y., Tan, L., Luo, J., & Duan, L. (2025). Thermal Performance of Deep Borehole Heat Exchangers (DBHEs) Installed in a Groundwater-Filled Hot Dry Rock (HDR) Well in Qinghai, China. Energies, 18(9), 2229. https://doi.org/10.3390/en18092229