Impact of Air Tightness on the Evaluation of Building Energy Performance in Lithuania

Abstract

:1. Introduction

- Buildings with more than two residential apartments:

- low air tightness > 5 h−1;

- medium—from 2 to 5 h−1;

- high < 2 h−1.

- Buildings with one or two residential apartments:

- low air tightness > 10 h−1;

- medium—from 4 to 10 h−1;

- high < 4 h−1.

- n50 = 3 h−1—rooms without ventilation devices;

- n50 = 1.5 h−1—rooms with ventilation devices.

2. The Air Tightness Requirements of Buildings in the EPBD

3. Methods

3.1. Studied Houses

| House | Heated Floor Area, A, m2 | Height of the Building h, m | Volume V, m3 | Number of Exposed Facades | Number of Levels | Type of Ventilation System |

|---|---|---|---|---|---|---|

| 1 | 210.2 | 6.2 | 651.6 | 4 | 2 | Recuperation |

| 2 | 190.2 | 6.6 | 627.7 | 4 | 2 | Recuperation |

| 3 | 170.1 | 6.0 | 510.4 | 4 | 2 | Recuperation |

| 4 | 188.8 | 6.5 | 615.4 | 4 | 2 | Recuperation |

| 5 | 200.8 | 6.0 | 602.3 | 4 | 2 | Recuperation |

| 6 | 190.0 | 7.0 | 665.0 | 4 | 2 | Recuperation |

| 7 | 208.8 | 6.5 | 678.6 | 4 | 2 | Recuperation |

| 8 | 201.3 | 6.5 | 654.2 | 4 | 2 | Recuperation |

| 9 | 168.1 | 7.0 | 588.4 | 4 | 2 | Recuperation |

| 10 | 210.6 | 9.1 | 638.9 | 3 | 3 | Mechanical |

| 11 | 134.2 | 7.5 | 503.2 | 3 | 2 | Mechanical |

| 12 | 233.5 | 7.1 | 828.9 | 4 | 2 | Mechanical |

| 13 | 340.2 | 8.9 | 757.1 | 4 | 4 | Mechanical |

| 14 | 168.0 | 5.9 | 991.5 | 3 | 1 | Mechanical |

| 15 | 209.4 | 7.1 | 743.4 | 4 | 2 | Mechanical |

| 16 | 163.7 | 6.2 | 511.6 | 4 | 2 | Mechanical |

| 17 | 210.5 | 7.0 | 736.8 | 4 | 2 | Recuperation |

| 18 | 210.6 | 9.1 | 638.9 | 3 | 3 | Recuperation |

| 19 | 182.2 | 7.3 | 665.0 | 4 | 2 | Mechanical |

| 20 | 140.2 | 6.2 | 438.3 | 4 | 2 | Natural |

| 21 | 107.3 | 4.0 | 432.4 | 4 | 1 | Mechanical |

| 22 | 115.7 | 6.8 | 393.5 | 4 | 2 | Mechanical |

| 23 | 167.1 | 7.5 | 626.6 | 4 | 2 | Natural |

| 24 | 173.7 | 7.6 | 658.3 | 4 | 2 | Natural |

| 25 | 203.7 | 9.2 | 627.5 | 4 | 3 | Mechanical |

| 26 | 107.5 | 5.8 | 623.5 | 4 | 1 | Mechanical |

| 27 | 289.4 | 8.7 | 838.2 | 4 | 3 | Mechanical |

3.2. Building Energy Performance Assessment Methods

- QR.env reference heat loses through building envelope for 1 m2 of heated floor area, kWh/m2·year (approved value [19]);

- QR.vent reference energy consumption for ventilation, kWh/m2·year (approved value [19]);

- Qd1 calculated heat loses due to entrance door opening, kWh/m2·year;

- QR.inf reference heat loses due to over norm infiltration through windows and external doors, kWh/m2·year (approved value [19]);

- ηR.h.s. reference efficiency coefficient of building heating system, by parts of units (approved value [19]);

- Qe heat gains in building due to solar radiation, kWh/m2·year;

- Qi heat gains due to internal heat sources, kWh/m2·year;

- QE annual electricity consumption, kWh/m2·year;

- Qh.w. annual energy consumption due to domestic hot water, kWh/m2·year.

- QN.env normative heat loses through building envelope for 1 m2 of heated floor area, kWh/m2·year (approved value [19]);

- QN.vent normative energy consumption for ventilation, kWh/m2·year (approved value [19]);

- QN.inf normative heat loses due to over norm infiltration through windows and external doors, kWh/m2·year (approved value [19]);

- ηN.h.s. normative efficiency coefficient of building heating system, by parts of units (approved value [19]).

- Qenv calculated heat loses through building envelope for 1 m2 of heated floor area, kWh/m2·year;

- Qvent calculated energy consumption for ventilation, kWh/m2·year;

- Qinf calculated heat loses due to over norm infiltration through windows and external doors, kWh/m2·year;

- ηh.s. efficiency coefficient of building heating system, by parts of units.

- -

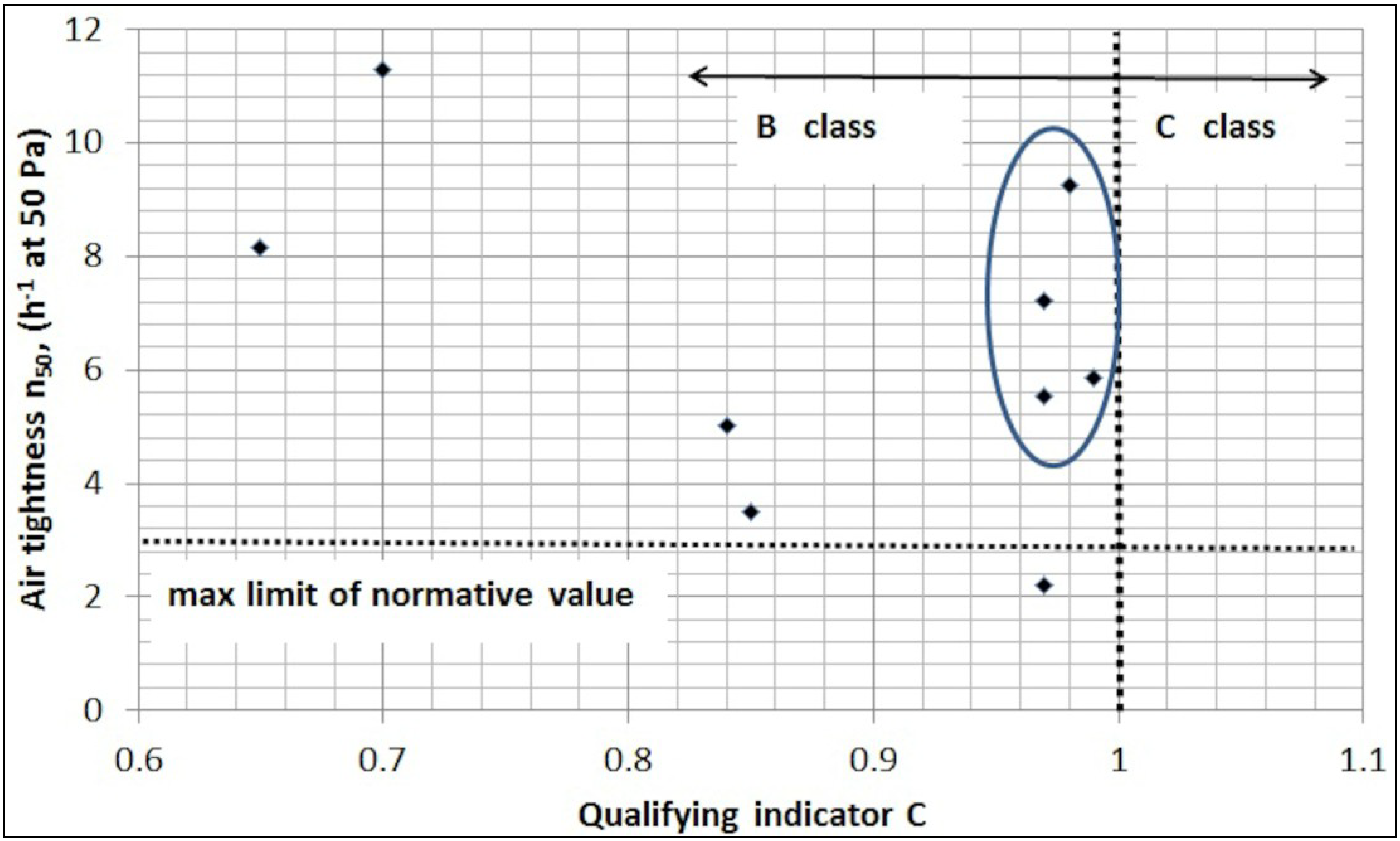

- A class, if C < 0.5;

- -

- B class, if 0.5 ≤ C < 1;

- -

- C class, if 1 ≤ C < 1.5.

3.3. Measurement Methods

4. Results

4.1. Evaluation of Building Energy Efficiency

| House | Qsum, kWh/m2·Year | Qinf, kWh/m2·Year | Qvent, kWh/m2·Year | Value of Qualifying Indicator C | Energy Performance Class | n50, h−1 | q50 m3/(h × m2) |

|---|---|---|---|---|---|---|---|

| 1 | 87.45 | 10.68 | 10.04 | 0.38 | A | 0.41 | 0.40 |

| 2 | 126.35 | 24.06 | 10.21 | 0.38 | A | 0.69 | 0.74 |

| 3 | 90.56 | 20.89 | 10.10 | 0.37 | A | 0.74 | 0.68 |

| 4 | 130.50 | 11.25 | 9.91 | 0.38 | A | 0.55 | 0.52 |

| 5 | 89.60 | 26.34 | 10.04 | 0.40 | A | 0.64 | 0.50 |

| 6 | 100.15 | 15.74 | 9.99 | 0.38 | A | 0.58 | 0.71 |

| 7 | 119.16 | 18.61 | 10.01 | 0.38 | A | 0.61 | 0.62 |

| 8 | 95.36 | 24.00 | 10.20 | 0.38 | A | 0.52 | 0.68 |

| 9 | 87.36 | 26.00 | 10.19 | 0.37 | A | 0.65 | 0.81 |

| 10 | 204.24 | 42.16 | 24.60 | 0.84 | B | 5.01 | 7.71 |

| 11 | 129.72 | 16.48 | 21.78 | 0.98 | B | 9.25 | 9.34 |

| 12 | 152.00 | 10.68 | 34.54 | 0.85 | B | 3.50 | 5.54 |

| 13 | 151.13 | 13.79 | 29.47 | 0.97 | B | 7.21 | 8.19 |

| 14 | 192.00 | 33.04 | 32.21 | 0.97 | B | 5.54 | 6.37 |

| 15 | 201.81 | 32.16 | 36.30 | 0.99 | B | 5.86 | 7.22 |

| 16 | 216.06 | 24.06 | 39.85 | 0.97 | B | 2.19 | 3.01 |

| 17 | 222.08 | 63.90 | 16.37 | 0.70 | B | 11.30 | 14.61 |

| 18 | 152.07 | 10.68 | 12.31 | 0.65 | B | 8.15 | 12.55 |

| 19 | 236.02 | 34.06 | 37.26 | 1.14 | C | 5.50 | 7.21 |

| 20 | 307.30 | 36.78 | 24.04 | 1.06 | C | 3.41 | 2.94 |

| 21 | 207.88 | 19.74 | 33.79 | 1.23 | C | 10.85 | 8.11 |

| 22 | 246.87 | 25.40 | 35.58 | 1.06 | C | 8.60 | 7.46 |

| 23 | 292.66 | 40.84 | 24.04 | 1.41 | C | 7.50 | 7.69 |

| 24 | 273.76 | 41.27 | 24.04 | 1.02 | C | 5.83 | 8.55 |

| 25 | 246.42 | 32.60 | 33.26 | 1.03 | C | 4.55 | 6.57 |

| 26 | 231.83 | 47.69 | 43.86 | 1.31 | C | 5.00 | 4.55 |

| 27 | 255.41 | 24.06 | 43.15 | 1.29 | C | 2.99 | 3.60 |

- Awd.sum, Ad.sum total areas of windows, doors, roof windows, skylights or other transparent partitions, and entrance doors, in m2;

- KR air leakage value of windows, doors, roof windows, skylights or other transparent partitions, and entrance doors, (m3/(m2·h)). This value is determined by a 50 Pa pressure difference;

- vo amount of external air for ventilation of 1 m2 of building, (m3/(m2·h));

- v1 amount of external air infiltration through the entrance door due to opening, (m3/(m2·h));

- Ap building heated floor area, m2;

- θIh average internal temperature during the heating season, °C.

4.2. Air Tightness

| Energy Efficiency Class of the Building | Mean Value of Air Tightness n50 (h−1 at 50 pa) | Standard Deviation | 90% Confidence Interval |

|---|---|---|---|

| A | 0.6 | 0.10 | 0.55–0.67 |

| B | 6.1 | 3.13 | 4.17–8.05 |

| C | 6.0 | 2.54 | 4.45–7.60 |

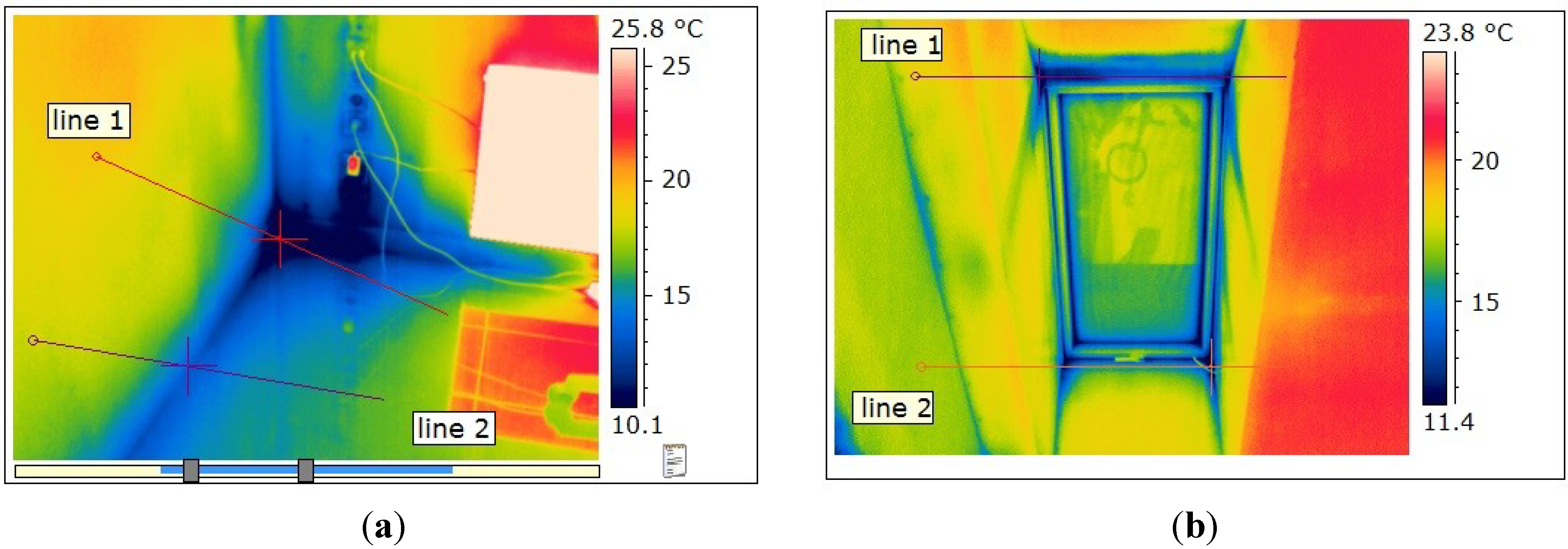

4.3. Thermographic Survey

- junction of the ceiling and floor with the external wall;

- junction of the separating walls with the external wall and roof;

- penetrations of electrical and plumbing installations through the air barrier systems;

- leakage around and through the windows and doors.

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Directive 2002/91/EC of the European Parliament and of the Council of 16 December 2002 on the Energy Performance of Buildings; European Parliament: Brussels, Belgium, 2002.

- Directive 2010/31/EC of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast); European Parliament: Brussels, Belgium, 2010.

- Energy Efficiency of Buildings—Calculation of the Energy Needs, Delivered Energy and Primary Energy for Heating, Cooling, Ventilation, Domestic Hot Water and Lighting; DIN V 18599; German Institute for Standardization: Berlin, Germany, 2007.

- Gonzalez, A.B.R.; Diaz, J.J.V.; Caamano, A.J.; Wilby, M.R. Towards a universal energy efficiency index for buildings. Energy Build. 2011, 43, 980–987. [Google Scholar] [CrossRef]

- Feist, W.; Schnieders, J.; Dorer, V.; Haas, A. Re-inventing air heating: Convenient and comfortable within the frame of the Passive House concept. Energy Build. 2005, 37, 1186–1203. [Google Scholar] [CrossRef]

- Smeds, J.; Wall, M. Enhanced energy conservation in houses through high performance design. Energy Build. 2007, 39, 273–278. [Google Scholar] [CrossRef]

- Jaraminienė, E. Air Infiltration in Buildings with Uncertainty Analysis. Ph.D. Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2008. [Google Scholar]

- Venckus, N.; Bliūdžius, R.; Endriukaitytė, A.; Parasonis, J. Research of low energy house design and construction opportunities in Lithuania. Technol. Econ. Dev. Econ. 2010, 16, 541–554. [Google Scholar] [CrossRef]

- Kalamees, T. Air tightness and air leakages of new lightweight single-family detached houses in Estonia. Build. Environ. 2007, 42, 2369–2377. [Google Scholar] [CrossRef]

- Airaksinen, M.; Vuolle, M. Heating energy and peak-power demand in a standard and low energy building. Energies 2013, 6, 235–250. [Google Scholar] [CrossRef]

- Pan, W. Relationships between air-tightness and its influencing factors of post-2006 new-build dwellings in the UK. Build. Environ. 2010, 45, 2387–2399. [Google Scholar] [CrossRef]

- Kalamees, T.; Kurnitski, J.; Jokisalo, J.; Eskola, L.; Jokiranta, K.; Vinba, J. Measured and simulated air pressure conditions in Finnish residential buildings. Build. Serv. Eng. Res. Technol. 2010, 31, 177–190. [Google Scholar] [CrossRef]

- Sfakianaki, A.; Pavlou, K.; Santamouris, M.; Livada, I.; Assimakopoulos, M.-N.; Mantas, P.; Christakopoulos, A. Air tightness measurements of residential houses in Athens, Greece. Build. Environ. 2008, 43, 398–405. [Google Scholar] [CrossRef]

- Becker, R. Air leakage of curtain walls—diagnostics and remediation. J. Build. Phys. 2010, 34, 57–75. [Google Scholar] [CrossRef]

- Kovanen, K.A.; Laamanen, J.; Kauppinen, T.; Duanmu, L. Air tightness of new residential buildings in Finland. In Proceedings of the 6th International Symposium on HeatingVentilating and Air Conditioning, Nanjing, China, 6–9 November 2009; pp. 207–213.

- Matrosov, Y.A.; Chao, M.; Majersik, C. Increasing Thermal Performance and Energy Efficiency of Buildings in Russia: Problems and Solutions. Available online: http://web.ornl.gov/sci/buildings/2012/2007%20B10%20papers/165_Matrosov.pdf (accessed on 23 July 2014).

- Power of the Building Heating System. Energy Consumption for the Heating; STR 2.09.04: 2008; Ministry of Environment of Republic of Lithuania: Vilnius, Lithuania, 2008. (In Lithuanian)

- Thermal Technology of Building Elements; STR 2.05.01:2005; Ministry of Environment of Republic of Lithuania: Vilnius, Lithuania, 2005. (In Lithuanian)

- Energy Performance of Buildings. Certification of Energy Performance; STR 2.01.09:2005; Ministry of Environment of Republic of Lithuania: Vilnius, Lithuania, 2005. (In Lithuanian)

- Kauppinen, T.; Siikanen, S. Improvement of energy efficiency: The use of thermography and airtighness test in verification of thermal performance of school buildings. In Proceedings of the Thermosense: Thermal Infrared Applications XXXIII, Orlando, FL, USA, 25 April 2011.

- Tronchin, L.; Fabbri, K. Around Robin Test for buildings energy performance in Italy. Energy Build. 2010, 42, 1862–1877. [Google Scholar] [CrossRef]

- Andaloro, A.P.F.; Salomone, R.; Ioppolo, G.; Aldaloro, L. Energy certification of buildings: Acomparative analysis of progress towards implementation in European countries. Energy Policy 2010, 38, 5840–5866. [Google Scholar] [CrossRef]

- Implementing the Energy Performance of Buildings Directive (EPBD)—Featuring Country Reports 2010; European Union: Brussels, Belgium, 2011; p. 342.

- Building Climatology, Technical Regulation; RSN 156-94; Ministry of Environment of Republic of Lithuania: Vilnius, Lithuania, 1995. (In Lithuanian)

- Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method; LST EN 13829; European Union: Brussels, Belgium, 2002.

- Microclimate of Residential and Public Buildings; HN 42:2004; Ministry of Environment of Republic of Lithuania: Vilnius, Lithuania, 2004. (In Lithuanian)

- Ramanauskas, J.; Bliūdžius, R.; Stankevičius, V. Thermal Parameters of the Windows; Monograph: Kaunas, Lithuania, 2005. (In Lithuanian) [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Šadauskienė, J.; Paukštys, V.; Šeduikytė, L.; Banionis, K. Impact of Air Tightness on the Evaluation of Building Energy Performance in Lithuania. Energies 2014, 7, 4972-4987. https://doi.org/10.3390/en7084972

Šadauskienė J, Paukštys V, Šeduikytė L, Banionis K. Impact of Air Tightness on the Evaluation of Building Energy Performance in Lithuania. Energies. 2014; 7(8):4972-4987. https://doi.org/10.3390/en7084972

Chicago/Turabian StyleŠadauskienė, Jolanta, Valdas Paukštys, Lina Šeduikytė, and Karolis Banionis. 2014. "Impact of Air Tightness on the Evaluation of Building Energy Performance in Lithuania" Energies 7, no. 8: 4972-4987. https://doi.org/10.3390/en7084972

APA StyleŠadauskienė, J., Paukštys, V., Šeduikytė, L., & Banionis, K. (2014). Impact of Air Tightness on the Evaluation of Building Energy Performance in Lithuania. Energies, 7(8), 4972-4987. https://doi.org/10.3390/en7084972