Finite Element Analysis of Interfacial Debonding in Copper/Diamond Composites for Thermal Management Applications

Abstract

:1. Introduction

2. Scope and Methodology

3. Experimental Work

4. Finite Element Analysis

4.1. Thermo-Mechanical Model

4.1.1. Coupling Phenomenon

4.1.2. Thermal Analysis

4.1.3. Mechanical Analysis

4.1.4. Yield Strength

4.2. Microstructure Based Modelling

4.3. Interactions and Boundary Conditions

- • Case 1

- - Thermal BCs: Prescribed temperatures on the edges OP: 100 °C; QR: 20 °C- Mechanical BCs: Displacements at vertices O: Ux = Uy = 0; P: Ux = 0; R: Uy = 0- Interactions: Perfect contact, absolute conductance

- • Case 2

- - Thermal BCs: Prescribed temperatures on the edges OP: 100 °C; QR: 20 °C- Mechanical BCs: Displacements at vertices O: Ux = Uy = 0; P: Ux = 0; R: Uy = 0- Interactions: COHESIVE contact between D and Cu

- • Case 3

- - Thermal BCs: Prescribed temperatures on the edges OP: 100 °C; QR: 20 °C- Mechanical BCs: Displacements at vertices O: Ux = Uy = 0; P: Ux = 0; R: Uy = 0- Interactions: TIE constraint at Cr/D interface, COHESIVE contact between Cr and Cu

- • Case 4

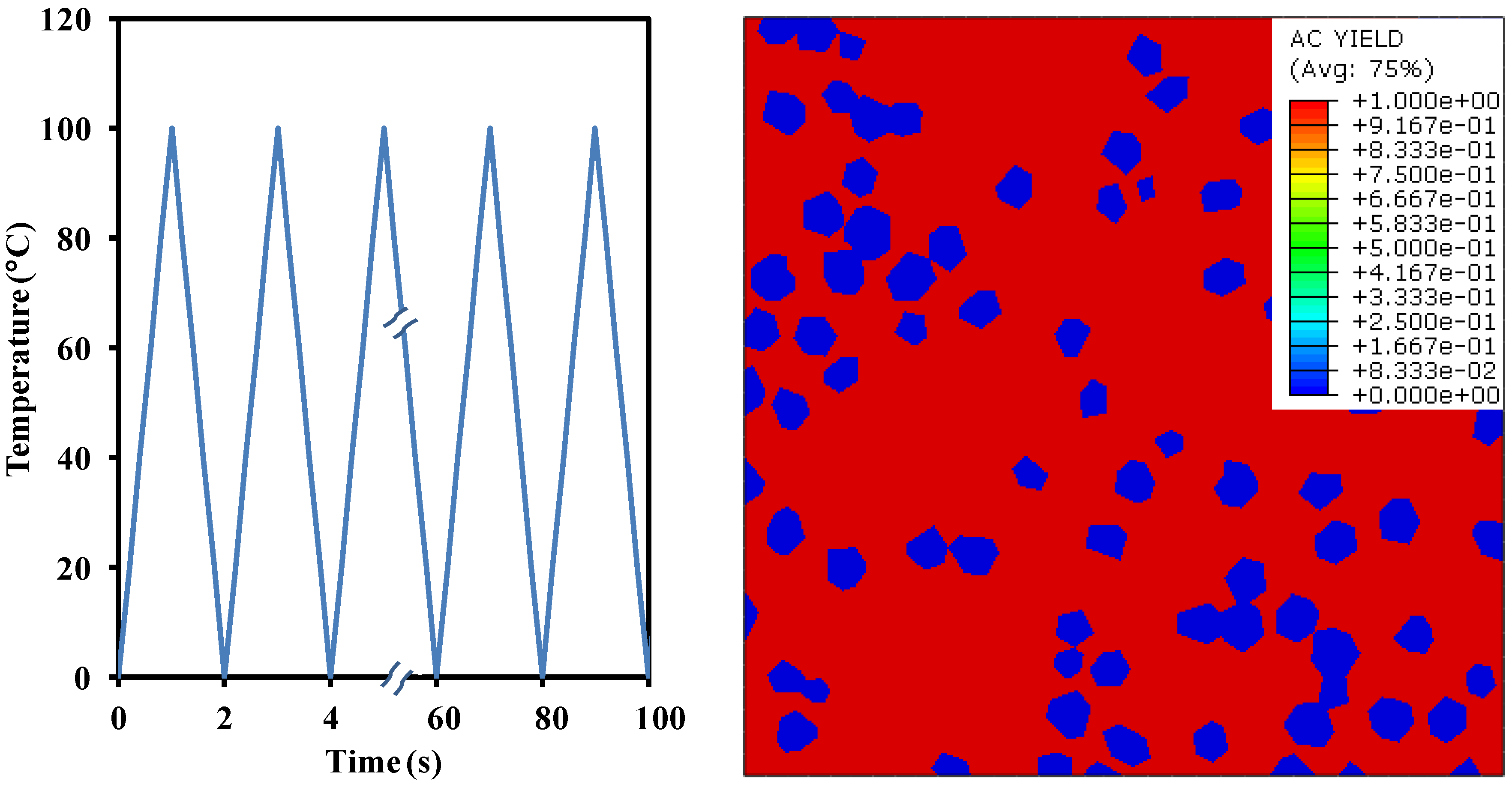

- - Thermal BCs: Cyclic BC on all nodes, Max. T: 160 °C; Temperature rate: 100 °C/s- Mechanical BCs: Displacements at vertices O: Ux = Uy = 0; P: Ux = 0; R: Uy = 0- Interactions: Perfect contact, absolute conductance

4.4. Cohesion/Separation Criterion

5. Results and Discussion

5.1. Steady-State Analysis without Interacting Surfaces—Case 1

5.1.1. Temperature Contours

5.1.2. Actively Yielding Regions

5.1.3. Plastic Strain Distribution

5.1.4. Mises Equivalent Stress Distribution

5.2. Steady-State Analysis with Interacting Surfaces—Case 2 vs. Case 3

5.2.1. Temperature Contours

5.2.2. Plastic Strain Distribution

5.2.3. Mises Equivalent Stress Distribution

5.2.4. Interfacial Cohesion/Separation

5.3. Transient Analysis without Interacting Surfaces—Case 4

5.3.1. Steady-State vs. Transient Analysis

5.3.2. Yielding and Cyclic Response

5.3.3. Mises Equivalent Stress Distribution

5.4. Comparison with Published Works

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, Y.; Zhang, H.L.; Wu, J.H.; Wang, X.T. Enhanced thermal conductivity in copper matrix composites reinforced with titanium-coated diamond particles. Scr. Mater. 2011, 65, 1097–1100. [Google Scholar] [CrossRef]

- Ren, S.; Shen, X.; Guo, C.; Liu, N.; Zang, J.; He, X.; Qu, X. Effect of coating on the microstructure and thermal conductivities of diamond–Cu composites prepared by powder metallurgy. Compos. Sci. Technol. 2011, 71, 1550–1555. [Google Scholar] [CrossRef]

- Chu, K.; Liu, Z.; Jia, C.; Chen, H.; Liang, X.; Gao, W.; Tian, W.; Guo, H. Thermal conductivity of SPS consolidated Cu/diamond composites with Cr-coated diamond particles. J. Alloys Compd. 2010, 490, 453–458. [Google Scholar] [CrossRef]

- Xia, Y.; Song, Y.; Lin, C.; Cui, S.; Fang, Z. Effect of carbide formers on microstructure and thermal conductivity of diamond-Cu composites for heat sink materials. Trans. Nonferrous Met. Soc. China 2009, 19, 1161–1166. [Google Scholar] [CrossRef]

- Bai, H.; Ma, N.; Lang, J.; Zhu, C.; Ma, Y. Thermal conductivity of Cu/diamond composites prepared by a new pretreatment of diamond powder. Compos. Part B 2013, 52, 182–186. [Google Scholar] [CrossRef]

- Shen, X.Y.; He, X.B.; Ren, S.B.; Zhang, H.M.; Qu, X.H. Effect of molybdenum as interfacial element on the thermal conductivity of diamond/Cu composites. J. Alloys Compd. 2012, 529, 134–139. [Google Scholar] [CrossRef]

- Raza, K.; Khalid, F.A. Optimization of sintering parameters for diamond–copper composites in conventional sintering and their thermal conductivity. J. Alloys Compd. 2014, 615, 111–118. [Google Scholar] [CrossRef]

- Mizuuchi, K.; Inoue, K.; Agari, Y.; Yamada, S.; Tanaka, M.; Sugioka, M.; Takeuchi, T.; Tani, J.; Kawahara, M.; Lee, J.H.; et al. Thermal properties of diamond-particle-dispersed Cu-matrix-composites fabricated by spark plasma sintering (SPS). Mater. Sci. Forum 2010, 638–642, 2115–2120. [Google Scholar] [CrossRef]

- Kang, Q.; He, X.; Ren, S.; Zhang, L.; Wu, M.; Guo, C.; Cui, W.; Qu, X. Preparation of copper-diamond composites with chromium carbide coatings on diamond particles for heat sink applications. Appl. Therm. Eng. 2013, 60, 423–429. [Google Scholar] [CrossRef]

- Abyzov, A.M.; Kidalov, S.V.; Shakhov, F.M. High thermal conductivity composite of diamond particles with tungsten coating in a copper matrix for heat sink application. Appl. Therm. Eng. 2012, 48, 72–80. [Google Scholar] [CrossRef]

- Kidalov, S.V.; Shakhov, F.M. Thermal Conductivity of Diamond Composites. Materials 2009, 2, 2467–2495. [Google Scholar] [CrossRef]

- Hamid, Z.A.; Moustafa, S.F.; Morsy, F.A.; Khalifa, N.A.A.; Mouez, F.A. Fabrication and characterization copper/diamond composites for heat sink application using powder metallurgy. Nat. Sci. 2011, 3, 936–947. [Google Scholar] [CrossRef]

- Bakker, K. Using the finite element method to compute the influence of complex porosity and inclusion structures on the thermal and electrical conductivity. Int. J. Heat Mass Transf. 1997, 40, 3503–3511. [Google Scholar] [CrossRef]

- Decarlis, A.; Jaeger, M. Effective thermal conductivity of heterogeneous two-phase material using the self-consistent finite element method. Scr. Mater. 2001, 44, 1955–1958. [Google Scholar] [CrossRef]

- Yamada, R.; Igawa, N.; Taguchi, T.; Jitsukawa, S. Highly thermal conductive, sintered SiC fiber-reinforced 3D-SiC/SiC composites: Experiments and finite-element analysis of the thermal diffusivity/conductivity. J. Nucl. Mater. 2002, 307–311, 1215–1220. [Google Scholar] [CrossRef]

- Yang, W.; Peng, K.; Zhou, L.; Zhu, J.; Li, D. Finite element simulation and experimental investigation on thermal conductivity of diamond/aluminium composites with imperfect interface. Comput. Mater. Sci. 2014, 83, 375–380. [Google Scholar] [CrossRef]

- Rape, A.; Gott, K.; Kulkarni, A.; Singh, J. Simulation of matrix conductivity in copper-diamond composites sintered by field assisted sintering technology. Comput. Mater. Sci. 2015, 110, 29–33. [Google Scholar] [CrossRef]

- Zain-ul-abdein, M.; Raza, K.; Khalid, F.A.; Mabrouki, T. Numerical investigation of the effect of interfacial thermal resistance upon the thermal conductivity of copper/diamond composites. Mater. Des. 2015, 86, 248–258. [Google Scholar] [CrossRef]

- Simon, N.J.; Drexler, E.S.; Reed, R.P. Properties of Copper and Copper Alloys at Cryogenic Temperatures; USA Government Printing Office: Washington, DC, USA, 1992.

- Reeber, R.R.; Wang, K. Thermal expansion, molar volume and specific heat of diamond from 0 to 3000 K. J. Electron. Mater. 1996, 25, 63–67. [Google Scholar] [CrossRef]

- Ho, C.Y.; Powell, R.W.; Liley, P.E. Thermal conductivity of the elements. J. Phys. Chem. Ref. Data 1972, 1, 279. [Google Scholar] [CrossRef]

- White, G.K.; Collocott, S.J. Heat capacity of reference materials: Cu and W. J. Phys. Chem. Ref. Data 1984, 13, 1251. [Google Scholar] [CrossRef]

- Pankratz, L.B. Thermodynamic Properties of Halides, Bulletin 674; USA Bureau of Mines: Washington, DC, USA, 1982.

- Spear, K.E.; Dismukes, J.P. Synthetic Diamond—Emerging CVD Science and Technology; Wiley: New York, NY, USA, 1994; p. 315. ISBN 978-0-471-53589-8. [Google Scholar]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Mańkowski, P.; Dominiak, A.; Domański, R.; Kruszewski, M.J.; Ciupiński, L. Thermal conductivity enhancement of copper–diamond composites by sintering with chromium additive. J. Therm. Anal. Calorim. 2014, 116, 881–885. [Google Scholar] [CrossRef]

- Ikeda, Y.; Nashida, N.; Horio, M.; Takubo, H.; Takahashi, Y. Ultra compact, low thermal impedance and high reliability module structure with SiC Schottky Barrier Diodes. In Proceedings of the 26th Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Fort Worth, TX, USA, 6–11 March 2011; pp. 1298–1300. [Google Scholar]

- Halasz, G.A.S. Performance trends in high-end processors. Proc. IEEE 1995, 83, 20–36. [Google Scholar] [CrossRef]

- Turon, A.; Dávila, C.G.; Camanho, P.P.; Costa, J. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 2007, 74, 1665–1682. [Google Scholar] [CrossRef]

- Figiel, L.; Kamiński, M. Mechanical and thermal fatigue delamination of curved layered composites. Comput. Struct. 2003, 81, 1865–1873. [Google Scholar] [CrossRef]

| Description | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Composite | Cu/D 1 | Cu/D | Cu/CrD 1 | Cu/D |

| Analysis type | SS 1 | SS | SS | TS 1 |

| Model orientation | PL 1 | PL | PL | PD 1 |

| Interfacial resistance | NO | YES | YES | NO |

| Interfacial debonding | NO | YES | YES | NO |

| Material Property (Units) | Copper | Diamond | ||

|---|---|---|---|---|

| Value | Ref | Value | Ref | |

| Density (kg·m−3) | [19] | [20] | ||

| Thermal conductivity (W·m−1·K−1) | [19] | [21] | ||

| Specific heat (J·kg−1·K−1) | [22] | [23] | ||

| CTE (K−1) | [19] | [20] | ||

| Young’s Modulus (GPa) | [19] | [24] | ||

| Poisson’s ratio | [19] | [24] | ||

| Yield strength (MPa) | Equation (6) | [25] | [24] | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zain-ul-abdein, M.; Ijaz, H.; Saleem, W.; Raza, K.; Mahfouz, A.S.B.; Mabrouki, T. Finite Element Analysis of Interfacial Debonding in Copper/Diamond Composites for Thermal Management Applications. Materials 2017, 10, 739. https://doi.org/10.3390/ma10070739

Zain-ul-abdein M, Ijaz H, Saleem W, Raza K, Mahfouz ASB, Mabrouki T. Finite Element Analysis of Interfacial Debonding in Copper/Diamond Composites for Thermal Management Applications. Materials. 2017; 10(7):739. https://doi.org/10.3390/ma10070739

Chicago/Turabian StyleZain-ul-abdein, Muhammad, Hassan Ijaz, Waqas Saleem, Kabeer Raza, Abdullah Salmeen Bin Mahfouz, and Tarek Mabrouki. 2017. "Finite Element Analysis of Interfacial Debonding in Copper/Diamond Composites for Thermal Management Applications" Materials 10, no. 7: 739. https://doi.org/10.3390/ma10070739

APA StyleZain-ul-abdein, M., Ijaz, H., Saleem, W., Raza, K., Mahfouz, A. S. B., & Mabrouki, T. (2017). Finite Element Analysis of Interfacial Debonding in Copper/Diamond Composites for Thermal Management Applications. Materials, 10(7), 739. https://doi.org/10.3390/ma10070739