Investigation on the Material Removal and Surface Generation of a Single Crystal SiC Wafer by Ultrasonic Chemical Mechanical Polishing Combined with Ultrasonic Lapping

Abstract

1. Introduction

2. Experimental Section

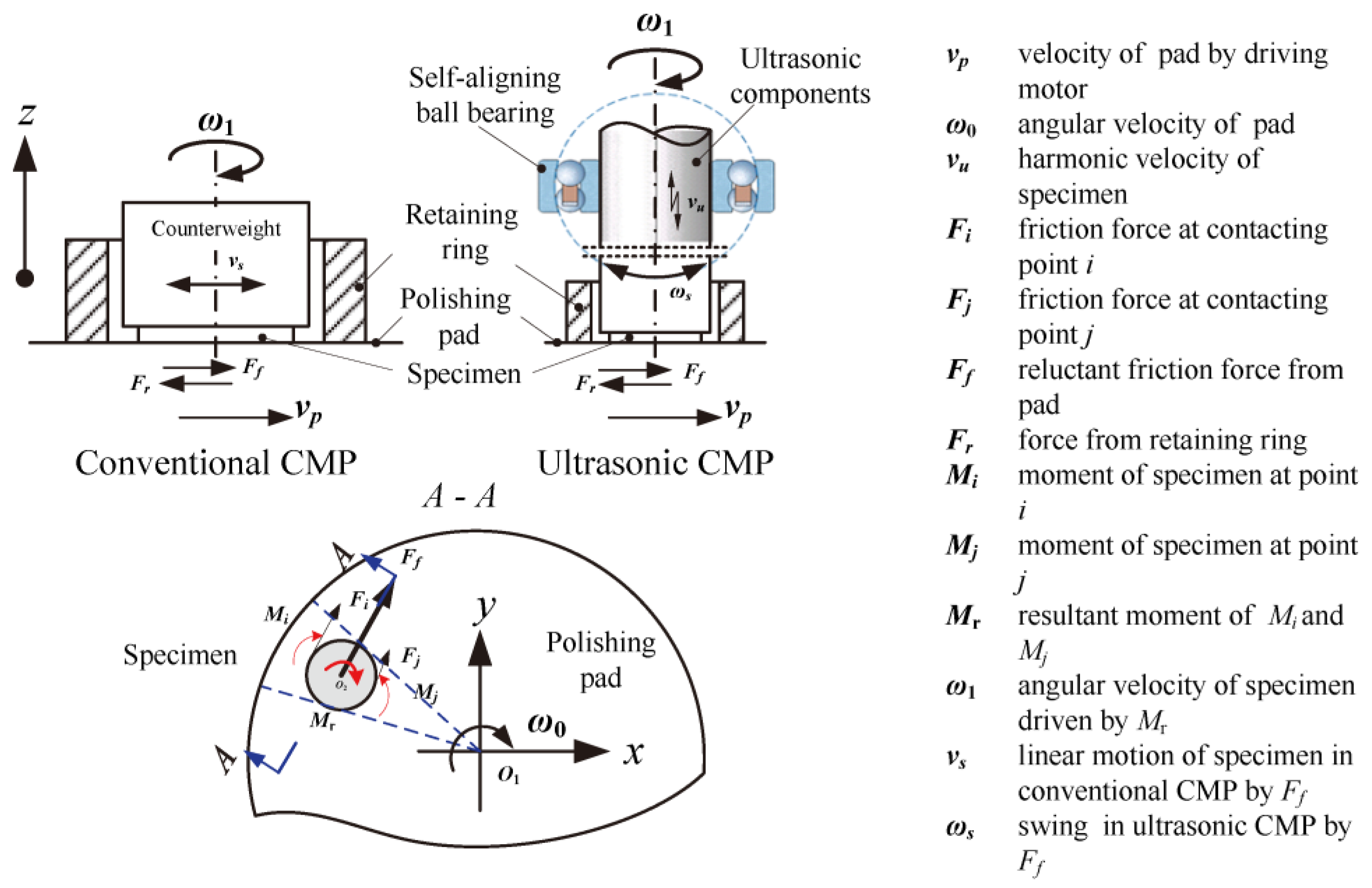

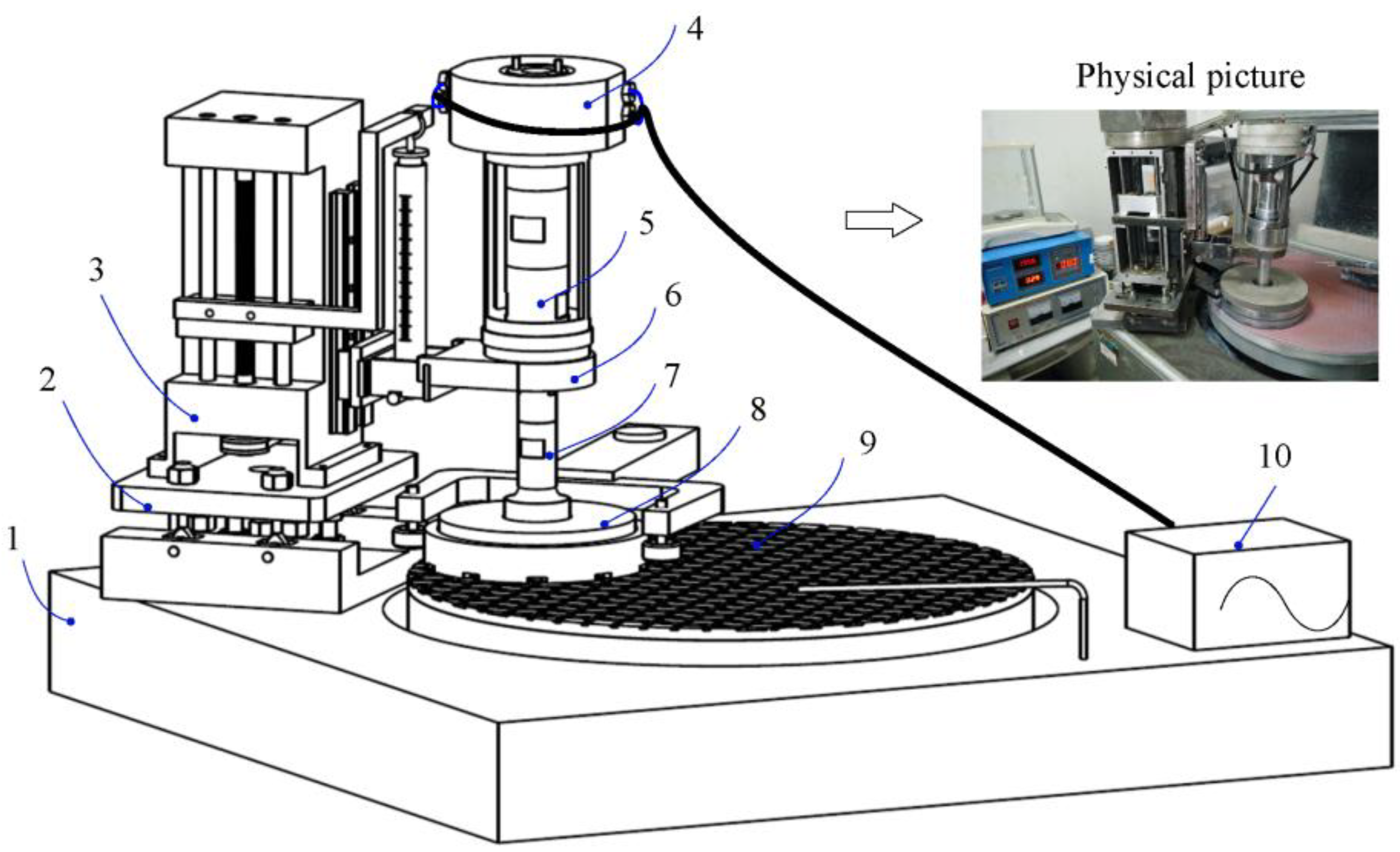

2.1. Experimental Setup

2.2. Design of Experiments and Performance Characterization

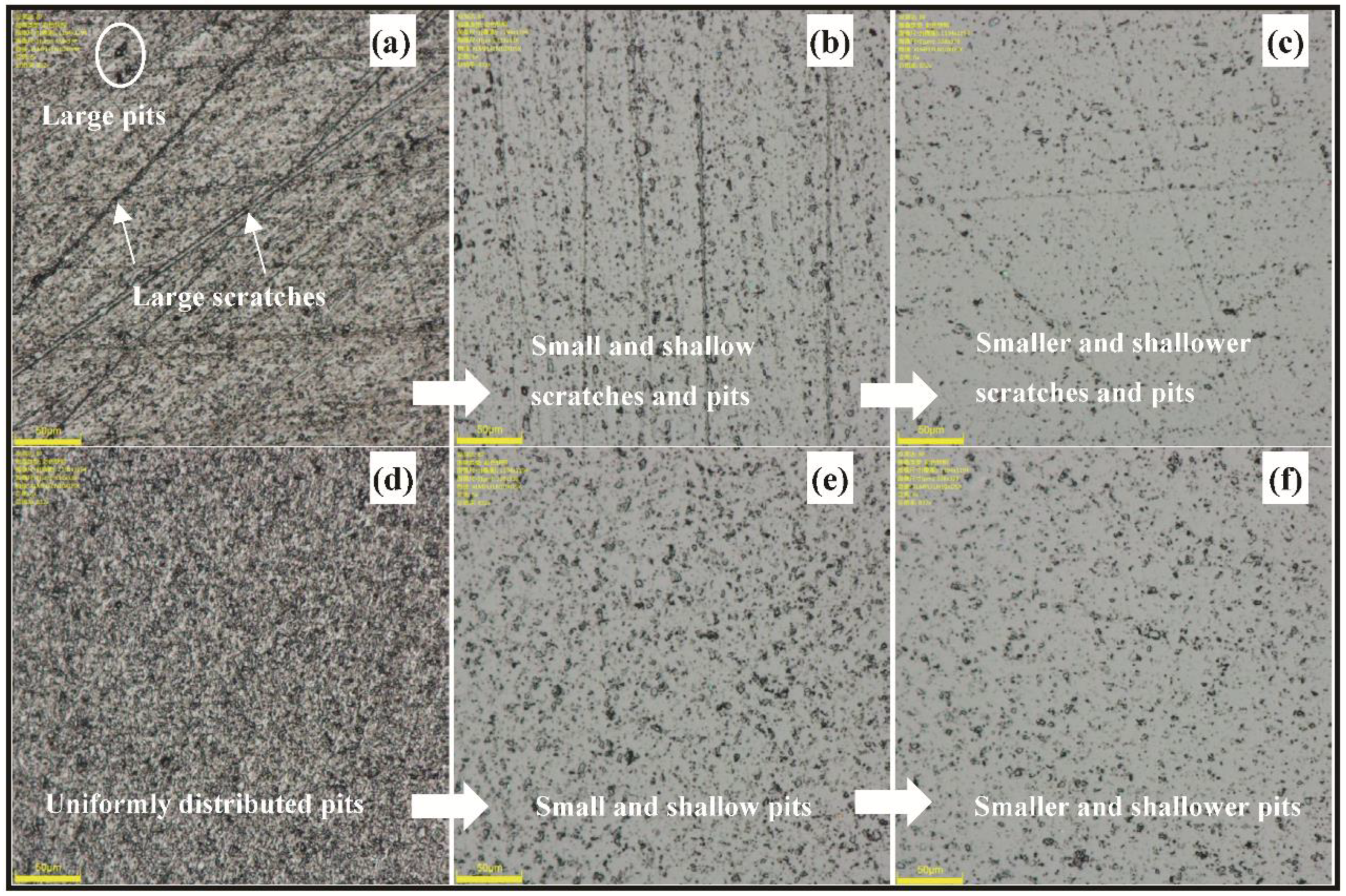

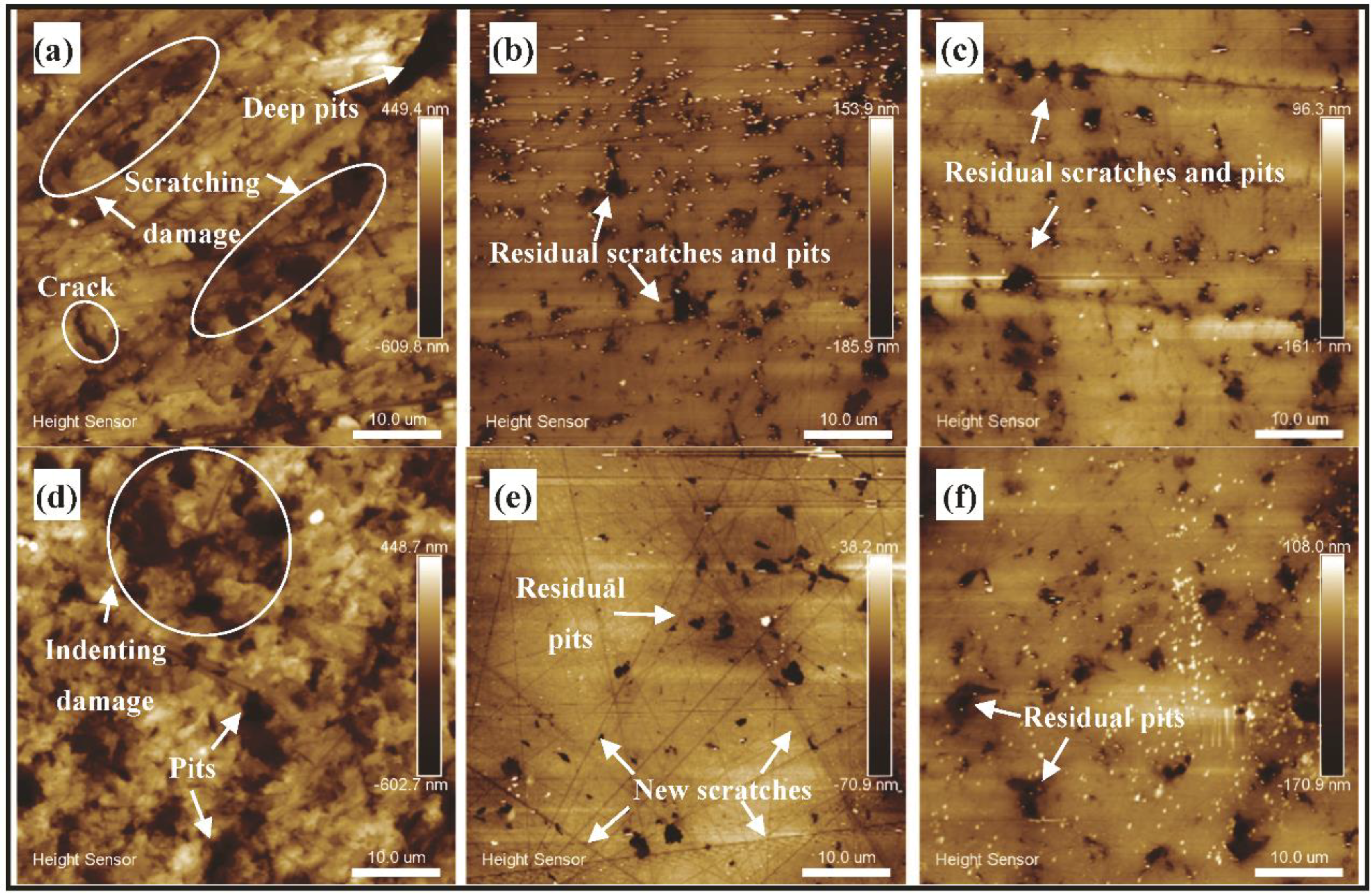

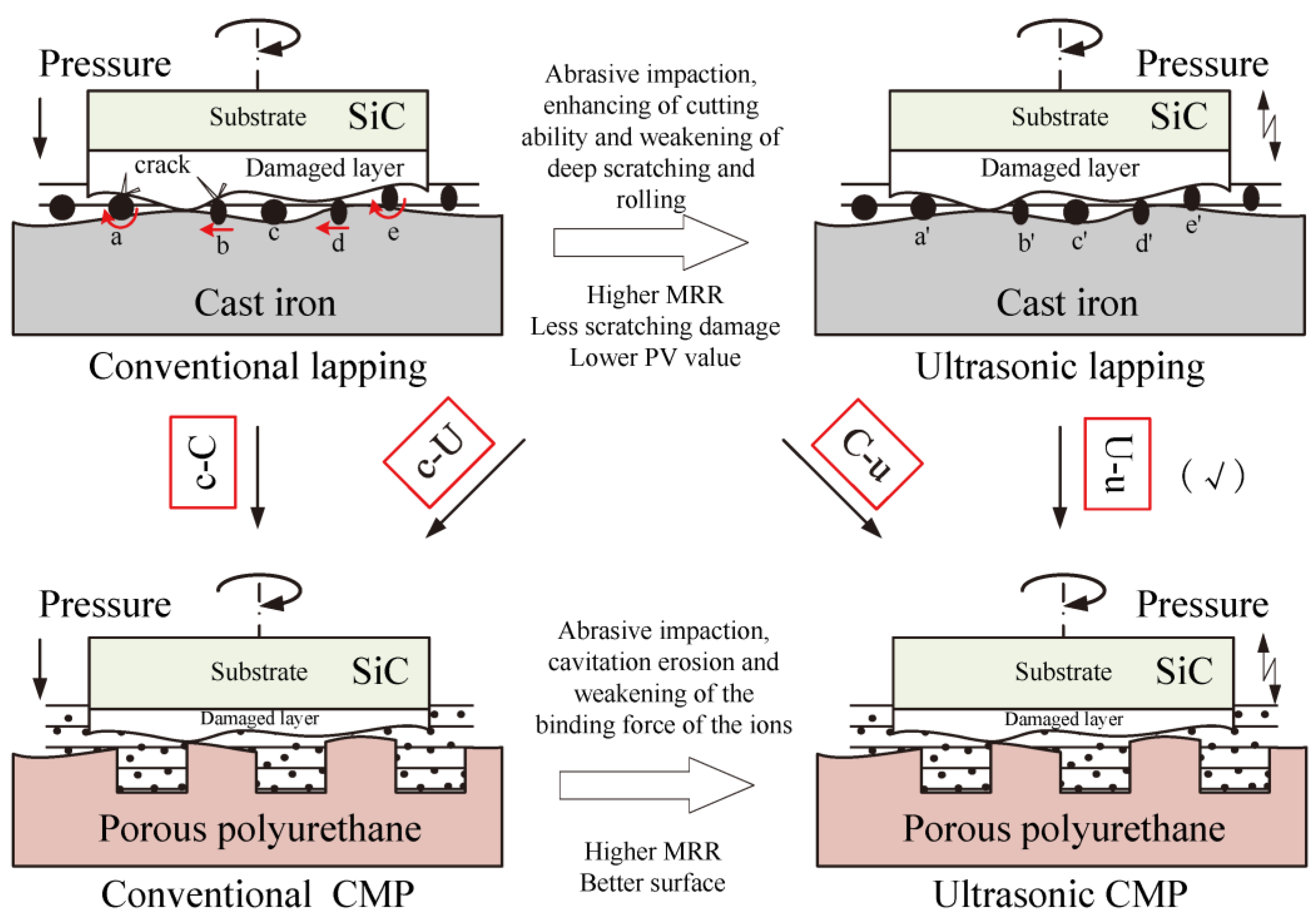

3. Results and Discussion

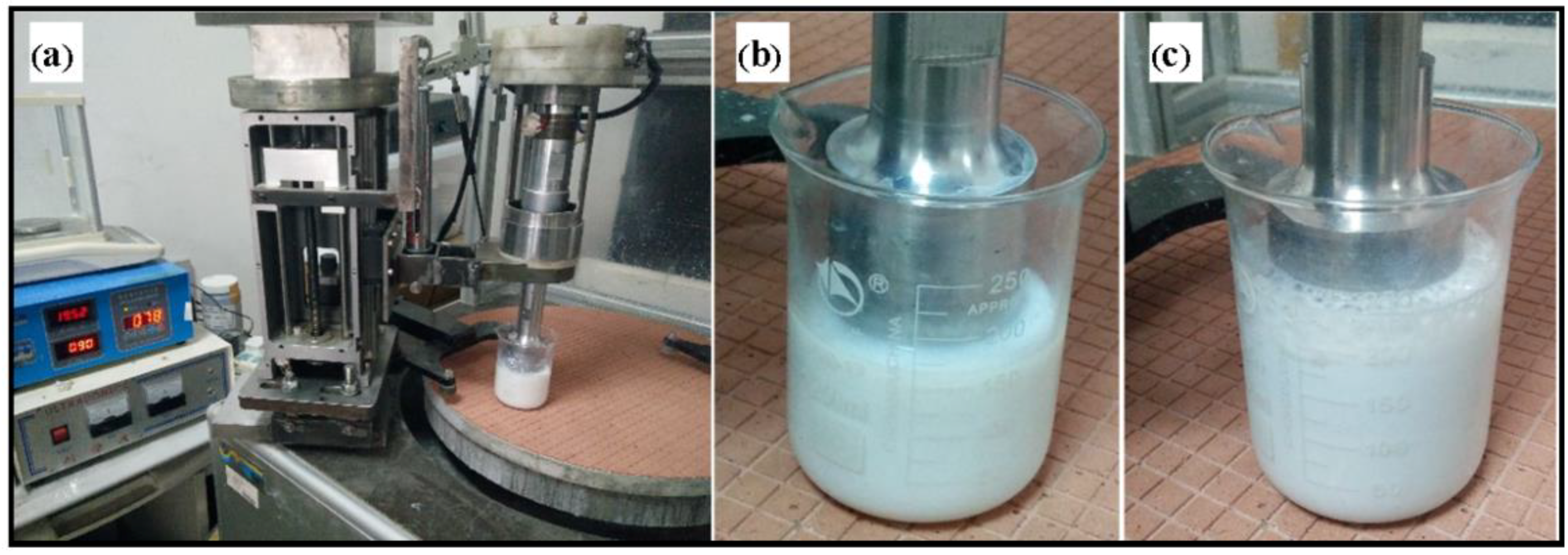

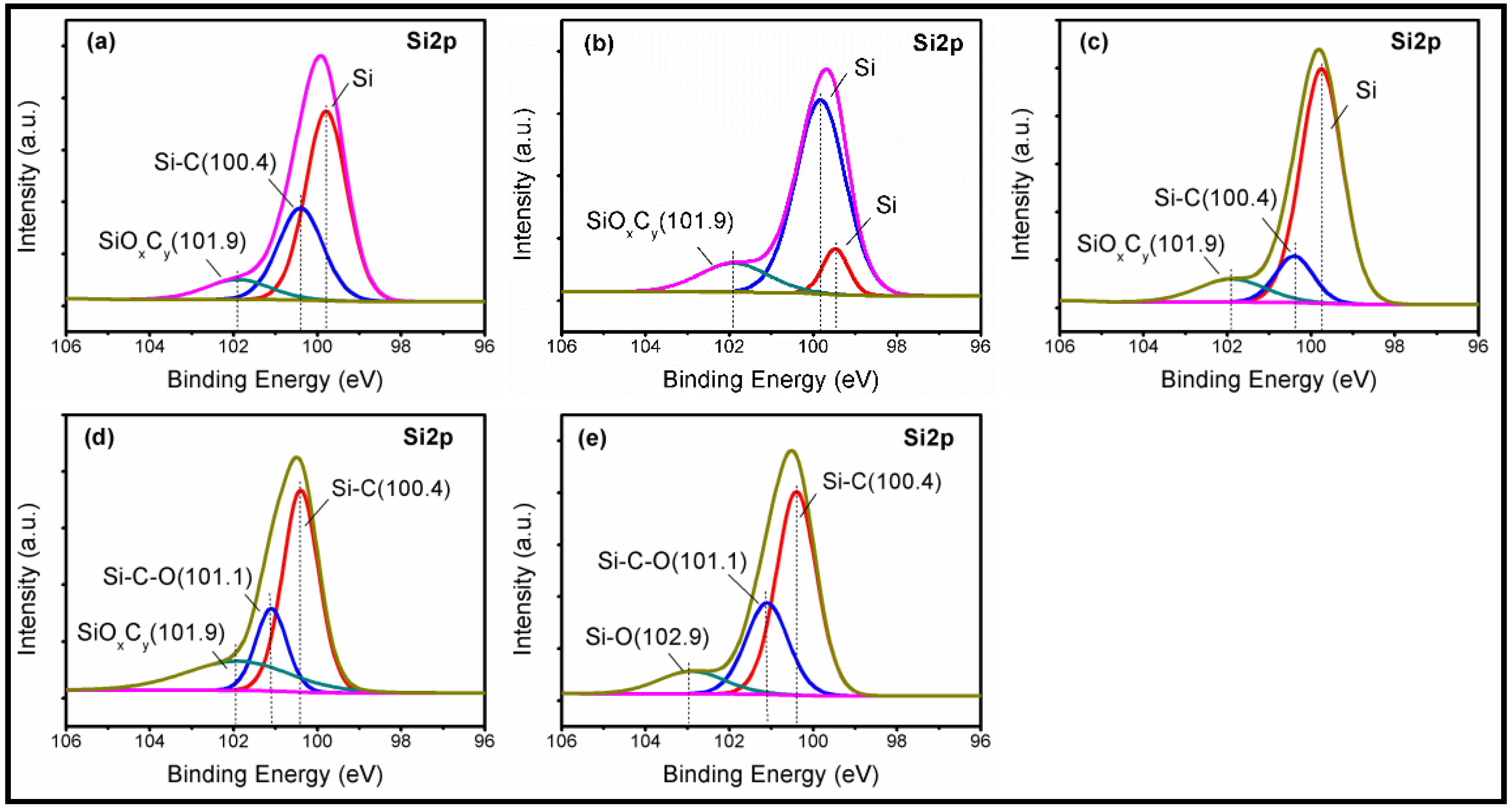

3.1. Effect of Ultrasonic on the Chemical Corrosion of Single Crystal SiC

3.2. Effect of Ultrasonic on the CMP Performance of Single Crystal SiC

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Deng, H.; Endo, K.; Yamamura, K. Competition between surface modification and abrasive polishing: A method of controlling the surface atomic structure of 4H-SiC (0001). Sci. Rep. 2015, 5, 8947. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, D.; Edgar, J. Wet etching of GaN, AlN, and SiC: A review. Mater. Sci. Eng. R 2005, 48, 1–46. [Google Scholar] [CrossRef]

- Tsai, M.Y.; Yan, L.W. Characteristics of chemical mechanical polishing using graphite impregnated pad. Int. J. Mach. Tool Manuf. 2010, 50, 1031–1037. [Google Scholar] [CrossRef]

- Zhou, L.; Audurier, V.; Pirouz, P.; Powell, J.A. Chemomechanical polishing of silicon carbide. J. Electrochem. Soc. 1997, 144, L161–L163. [Google Scholar] [CrossRef]

- Heydemann, V.D.; Everson, W.J.; Gamble, R.D.; Snyder, D.W.; Skowronski, M. Chemi-mechanical polishing of on-axis semi-insulating SiC substrates. Mater. Sci. Forum. 2004, 457–460, 805–808. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, D.I.; An, J.H.; Lee, H.J.; Kim, K.H.; Jeong, H. Hybrid polishing mechanism of single crystal SiC using mixed abrasive slurry (MAS). CIRP Ann. 2010, 59, 333–336. [Google Scholar] [CrossRef]

- Nitta, H.; Isobe, A.; Hong, P.J.; Hirao, T. Research on Reaction Method of High Removal Rate Chemical Mechanical Polishing Slurry for 4H-SiC Substrate. Jpn. J. Appl. Phys. 2011, 50. [Google Scholar] [CrossRef]

- Zhou, Y.; Pan, G.S.; Shi, X.L.; Gong, H.; Luo, G.H.; Gu, Z.H. Chemical mechanical planarization (CMP) of on-axis Si-face SiC wafer using catalyst nanoparticles in slurry. Surf. Coat. Technol. 2014, 251, 48–55. [Google Scholar] [CrossRef]

- Pan, G.S.; Zhou, Y.; Luo, G.H.; Shi, X.L.; Zou, C.L.; Gong, H. Chemical mechanical polishing (CMP) of on-axis Si-face 6H-SiC wafer for obtaining atomically flat defect-free surface. J. Mater. Sci. Mater. Electron. 2013, 24, 5040–5047. [Google Scholar] [CrossRef]

- Kubota, A.; Yoshimura, M.; Fukuyama, S.; Iwamoto, C.; Touge, M. Planarization of C-face 4H-SiC substrate using Fe particles and hydrogen peroxide solution. Precis. Eng. 2012, 36, 137–140. [Google Scholar] [CrossRef]

- Yagi, K.; Murata, J.; Kubota, A.; Sano, Y.; Hara, H.; Okamoto, T.; Arima, K.; Mimura, H.; Yamauchi, K. Catalyst-referred etching of 4H-SiC substrate utilizing hydroxyl radicals generated from hydrogen peroxide molecules. Surf. Interface Anal. 2008, 40, 998–1001. [Google Scholar] [CrossRef]

- Deng, H.; Hosoya, K.; Imanishi, Y.; Endo, K.; Yamamura, K. Electro-chemical mechanical polishing of single-crystal SiC using CeO2 slurry. Electrochem. Commun. 2015, 52, 5–8. [Google Scholar] [CrossRef]

- Yamamura, K.; Takiguchi, T.; Ueda, M.; Deng, H.; Hattori, A.N.; Zettsu, N. Plasma assisted polishing of single crystal SiC for obtaining atomically flat strain-free surface. CIRP Ann. 2011, 60, 571–574. [Google Scholar] [CrossRef]

- Yuan, Z.W.; He, Y.; Sun, X.W.; Wen, Q. UV-TiO2 photocatalysis-assisted chemical mechanical polishing 4H-SiC wafer. Mater. Manuf. Process. 2018, 33, 1214–1222. [Google Scholar] [CrossRef]

- Tsai, M.Y.; Yang, W.Z. Combined ultrasonic vibration and chemical mechanical polishing of copper substrates. Int. J. Mach. Tool Manuf. 2012, 53, 69–76. [Google Scholar] [CrossRef]

- Xu, W.H.; Lu, X.C.; Pan, G.S.; Lei, Y.Z.; Luo, J.B. Effects of the ultrasonic flexural vibration on the interaction between the abrasive particles; pad and sapphire substrate during chemical mechanical polishing (CMP). Appl. Surf. Sci. 2011, 257, 2905–2911. [Google Scholar] [CrossRef]

- Xu, W.H.; Lu, X.C.; Pan, G.S.; Lei, Y.Z.; Luo, J.B. Ultrasonic flexural vibration assisted chemical mechanical polishing for sapphire substrate. Appl. Surf. Sci. 2010, 256, 3936–3940. [Google Scholar] [CrossRef]

- Liang, L.; Qing, H.; Mian, Z.; Zheng, L. Contribution of ultrasonic traveling wave to chemical-mechanical polishing. Ultrasonics 2015, 56, 530–538. [Google Scholar] [CrossRef]

- Ke, Z.; Qing, H.; Liang, L.; Yi, R. Study on chemical mechanical polishing of silicon wafer with megasonic vibration assisted. Ultrasonics 2017, 80, 9–14. [Google Scholar] [CrossRef]

- Liu, D.F.; Yan, R.M.; Chen, T. Material removal model of ultrasonic elliptical vibration-assisted chemical mechanical polishing for hard and brittle materials. Int. J. Adv. Manuf. Technol. 2017, 92, 81–99. [Google Scholar] [CrossRef]

- Zhao, Q.L.; Sun, Z.Y.; Guo, B. Material removal mechanism in ultrasonic vibration assisted polishing of micro cylindrical surface on SiC. Int. J. Mach. Tool Manuf. 2016, 103, 28–39. [Google Scholar] [CrossRef]

- Qu, W.; Wang, K.; Miller, M.H.; Huang, Y.; Chandra, A. Using vibration-assisted grinding to reduce subsurface damage. Precis. Eng. 2000, 24, 329–337. [Google Scholar] [CrossRef]

- Cao, J.G.; Wu, Y.B.; Li, J.Y.; Zhang, Q.J. A grinding force model for ultrasonic assisted internal grinding (UAIG) of SiC ceramics. Int. J. Adv. Manuf. Technol. 2015, 81, 875–885. [Google Scholar] [CrossRef]

- Chen, G.M.; Ni, Z.F.; Xu, L.J.; Li, Q.Z.; Zhao, Y.W. Performance of colloidal silica and ceria based slurries on CMP of Si-face 6H-SiC substrates. Appl. Surf. Sci. 2015, 359, 664–668. [Google Scholar] [CrossRef]

- Rosso, M.; Arafat, A.; Schroen, K.; Giesbers, M.; Roper, C.S.; Maboudian, R.; Zuilhof, H. Covalent attachment of organic monolayers to silicon carbide surfaces. Langmuir 2008, 24, 4007–4012. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Pan, G.S.; Shi, X.L.; Xu, L.; Zou, C.L.; Gong, H.; Luo, G.H. XPS, UV-vis spectroscopy and AFM studies on removal mechanisms of Si-face SiC wafer chemical mechanical polishing (CMP). Appl. Surf. Sci. 2014, 316, 643–648. [Google Scholar] [CrossRef]

- Seo, J.; Gowda, A.; Babu, S.V. Almost Complete Removal of Ceria Particles Down to 10 nm Size from Silicon Dioxide Surfaces. ECS J. Solid State Sci. Technol. 2018, 7, P243–P252. [Google Scholar] [CrossRef]

- Suslick, K.S.; Didenko, Y.; Fang, M.M.; Hyeon, T.; Kolbeck, K.J.; McNamara, W.B.; Mdleleni, M.M.; Wong, M. Acoustic cavitation and its chemical consequences. Philos. Trans. R. Soc. Lond. A 1999, 357, 335–353. [Google Scholar] [CrossRef]

- Cao, J.G.; Wu, Y.B.; Lu, D.; Fujimoto, M.; Nomura, M. Material removal behavior in ultrasonic-assisted scratching of SiC ceramics with a single diamond tool. Int. J. Mach. Tool. Manuf. 2014, 79, 49–61. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.H.; Meng, B.B.; Liu, L.F.; Rao, X.S. Material removal mechanism and grinding force modelling of ultrasonic vibration assisted grinding for SiC ceramics. Ceram. Int. 2017, 43, 2981–2993. [Google Scholar] [CrossRef]

| Corroding | CMP |

|---|---|

| Conventional corroding After conventional lapping (C-c’) | Conventional CMP After conventional lapping (C-c) |

| Ultrasonic corroding After conventional lapping (C-u’) | Ultrasonic CMP After conventional lapping (C-u) |

| Conventional corroding After ultrasonic lapping (U-c’) | Conventional CMP After ultrasonic lapping (U-c) |

| Ultrasonic corroding After ultrasonic lapping (U-u’) | Ultrasonic CMP After ultrasonic lapping (U-u) |

| Category | Parameters |

|---|---|

| Specimen | 6H-SiC wafer: 2 inch × (440 ± 25) μm (from the Tankeblue semiconductor, Beijing, China) |

| Mechanical action | Abrasive: diamond (4 μm/4 wt%), Al2O3 (W1.5/6 wt%) Slurry supplying rate: 10 mL/min Lapping disc: cast iron (φ500 mm) Revolution speed of disc: 40 rpm Pressure: 20 KPa |

| Ultrasonic vibration | Maximum power (Pmax): 2 KW Setting power: 70% × Pmax (f = 19.54 KHz, A = 2 μm) |

| Time | 5 min diamond + 5 min Al2O3 |

| Category | Parameters |

|---|---|

| Ultrasonic vibration | Maximum power (Pmax): 2 KW Setting power: 70% × Pmax (f = 19.54 KHz, A = 2 μm) |

| Mechanical action | Platen rotation speed: 40 rpm (0.6–1 m/s) Download pressure: 60 KPa Pad: Porous Polyurethane (shenyang kejing, China) |

| Slurry | Type: colloidal silica Supplying rate: 25 mL/min Abrasive size/mass fraction: Average 100 nm/20 wt% Oxidant and catalyst: 6 wt% H2O2 and 0.6 wt% alkali KOH |

| Time | 1 h |

| Experiments | Before (g) | After (g) | Weight Change (g) |

|---|---|---|---|

| Conventional lapping | 2.8612 | 2.7635 | 0.0977 |

| Ultrasonic lapping | 2.7750 | 2.6645 | 0.1105 |

| C-c | 2.7640 | 2.7617 | 0.0023 |

| C-u | 2.7539 | 2.7492 | 0.0047 |

| U-c | 2.6821 | 2.6783 | 0.0038 |

| U-u | 2.7645 | 2.7575 | 0.0070 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Shi, D.; Hu, Y.; Zhao, H.; Sun, X. Investigation on the Material Removal and Surface Generation of a Single Crystal SiC Wafer by Ultrasonic Chemical Mechanical Polishing Combined with Ultrasonic Lapping. Materials 2018, 11, 2022. https://doi.org/10.3390/ma11102022

Hu Y, Shi D, Hu Y, Zhao H, Sun X. Investigation on the Material Removal and Surface Generation of a Single Crystal SiC Wafer by Ultrasonic Chemical Mechanical Polishing Combined with Ultrasonic Lapping. Materials. 2018; 11(10):2022. https://doi.org/10.3390/ma11102022

Chicago/Turabian StyleHu, Yong, Dong Shi, Ye Hu, Hongwei Zhao, and Xingdong Sun. 2018. "Investigation on the Material Removal and Surface Generation of a Single Crystal SiC Wafer by Ultrasonic Chemical Mechanical Polishing Combined with Ultrasonic Lapping" Materials 11, no. 10: 2022. https://doi.org/10.3390/ma11102022

APA StyleHu, Y., Shi, D., Hu, Y., Zhao, H., & Sun, X. (2018). Investigation on the Material Removal and Surface Generation of a Single Crystal SiC Wafer by Ultrasonic Chemical Mechanical Polishing Combined with Ultrasonic Lapping. Materials, 11(10), 2022. https://doi.org/10.3390/ma11102022