Multifunctional, Polyurethane-Based Foam Composites Reinforced by a Fabric Structure: Preparation, Mechanical, Acoustic, and EMI Shielding Properties

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Free-Foaming Polyurethane Gradient Composites

2.3. Characterizations

3. Results and Discussion

3.1. Effects of Water Content on Cell Structure

3.2. Effects of Structure on Compression Resistance of MFRCs

3.3. Effects of Structure on Acoustic Property of MFRCs

3.4. Effects of Structure and Interface on EMI SE of MFRCs

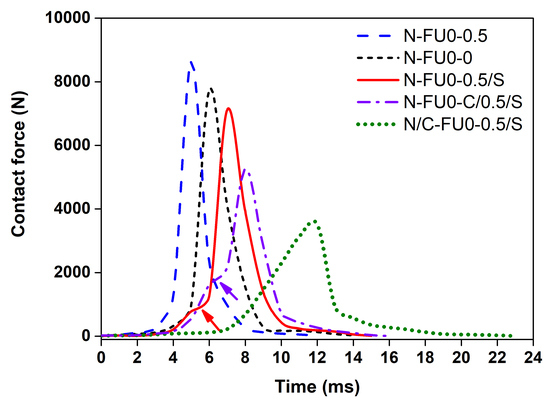

3.5. Effects of Structure on Drop Impact Test of MFRCs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ding, F.; Liu, J.; Zeng, S.; Xia, Y.; Wells, K.M.; Nieh, M.P.; Sun, L. Biomimetic nanocoatings with exceptional mechanical, barrier, and flame-retardant properties from large-scale one-step coassembly. Sci. Adv. 2017, 3, e1701212. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; Lee, H.; Kim, Y.B.; Kim, G.H. Fabrication of a Biomimetic Hierarchical Surface Replicated from a Lotus Leaf and In Vitro Cellular Activities. Plasma Process. Polym. 2015, 12, 141–152. [Google Scholar] [CrossRef]

- Thielen, M.; Schmitt, C.N.Z.; Eckert, S.; Speck, T.; Seidel, R. Structure-function relationship of the foam-like pomelo peel (Citrus maxima)—An inspiration for the development of biomimetic damping materials with high energy dissipation. Bioinspir. Biomim. 2013, 8, 25001. [Google Scholar] [CrossRef] [PubMed]

- Fischer, S.F.; Thielen, M.; Loprang, R.R.; Seidel, R.; Fleck, C.; Speck, T.; Bührig-Polaczek, A. Pummelos as Concept Generators for Biomimetically Inspired Low Weight Structures with Excellent Damping Properties. Adv. Eng. Mater. 2010, 12, B658–B663. [Google Scholar] [CrossRef]

- Bührig-Polaczek, A.; Fleck, C.; Speck, T.; Schüler, P.; Fischer, S.F.; Caliaro, M.; Thielen, M. Biomimetic cellular metals-using hierarchical structuring for energy absorption. Bioinspir. Biomim. 2016, 11, 45002. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Minn, K.S.; Lee, H.R.; Yang, S.H.; Yu, C.B.; Pak, S.Y.; Oh, C.S.; Song, Y.S.; Kang, Y.J.; Youn, J.R. Cell openness manipulation of low density polyurethane foam for efficient sound absorption. J. Sound Vib. 2017, 406, 224–236. [Google Scholar] [CrossRef]

- Scarpa, F.; Smith, F.C. Passive and MR fluid-coated auxetic PU foam—Mechanical, acoustic, and electromagnetic properties. J. Intell. Mat. Syst. Struct. 2004, 15, 973–979. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed]

- Gama, N.; Silva, R.; Carvalho, A.P.O.; Ferreira, A.; Barros-Timmons, A. Sound absorption properties of polyurethane foams derived from crude glycerol and liquefied coffee grounds polyol. Polym. Test. 2017, 62, 13–22. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Şerban, D.; Weissenborn, O.; Geller, S.; Marşavina, L.; Gude, M. Evaluation of the mechanical and morphological properties of long fibre reinforced polyurethane rigid foams. Polym. Test. 2016, 49, 121–127. [Google Scholar] [CrossRef]

- Baferani, A.H.; Katbab, A.A.; Ohadi, A.R. The role of sonication time upon acoustic wave absorption efficiency, microstructure, and viscoelastic behavior of flexible polyurethane/CNT nanocomposite foam. Eur. Polym. J. 2017, 90, 383–391. [Google Scholar] [CrossRef]

- Sung, C.H.; Lee, K.S.; Lee, K.S.; Oh, S.M.; Kim, J.H.; Kim, M.S.; Jeong, R.M. Sound damping of a polyurethane foam nanocomposite. Maromol. Res. 2007, 15, 443–448. [Google Scholar] [CrossRef]

- Pan, Y.; Hsieh, C.; Huang, C.; Huang, C.; Lou, C.; Li, C.; Lin, J. Sound Absorbent, Flame Retardant Warp Knitting Spacer Fabrics: Manufacturing Techniques and Characterization Evaluations. Fiber Polym. 2015, 16, 2682–2688. [Google Scholar] [CrossRef]

- Lin, J.; Lin, C.; Huang, C.; Lin, C.; Hsieh, C.; Liao, Y. Evaluation of the manufacture of sound absorbent sandwich plank made of PET/TPU honeycomb grid/PU foam. J. Compos. Mater. 2010, 45, 1355–1362. [Google Scholar] [CrossRef]

- Asadi Khanouki, M.; Ohadi, A. Improved acoustic damping in polyurethane foams by the inclusion of silicon dioxide nanoparticles. Adv. Polym. Technol. 2018. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, Z.; Wang, Z.; Zhang, F.; You, F.; Yao, C. Preparation and Sound Absorption Properties of a Barium Titanate/Nitrile Butadiene Rubber–Polyurethane Foam Composite with Multilayered Structure. Materials 2018, 11, 474. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.M.; Lee, Y.; Jang, M.G.; Han, C.; Kim, W.N. Electrical conductivity and EMI shielding effectiveness of polyurethane foam-conductive filler composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Kim, H.M.; Kim, K.; Lee, C.Y.; Joo, J.; Cho, S.J.; Yoon, H.S.; Pejaković, D.A.; Yoo, J.W.; Epstein, A.J. Electrical conductivity and electromagnetic interference shielding of multiwalled carbon nanotube composites containing Fe catalyst. Appl. Phys. Lett. 2004, 84, 589–591. [Google Scholar] [CrossRef] [Green Version]

- Jeddi, J.; Katbab, A.A. The electrical conductivity and EMI shielding properties of polyurethane foam/silicone rubber/carbon black/nanographite hybrid composites. Polym. Compos. 2017. [Google Scholar] [CrossRef]

- Raagulan, K.; Braveenth, R.; Jang, H.; Seon Lee, Y.; Yang, C.; Mi Kim, B.; Moon, J.; Chai, K. Electromagnetic Shielding by MXene-Graphene-PVDF Composite with Hydrophobic, Lightweight and Flexible Graphene Coated Fabric. Materials 2018, 11, 1803. [Google Scholar] [CrossRef] [PubMed]

- Ameli, A.; Jung, P.U.; Park, C.B. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

- Pan, Y.; Lou, C.; Hsieh, C.; Huang, C.; Lin, Z.; Li, C.; Lin, J. Nonwoven fabric/spacer fabric/polyurethane foam composites: Physical and mechanical evaluations. Fiber Polym. 2016, 17, 789–794. [Google Scholar] [CrossRef]

- Huang, S.; Lou, C.; Yan, R.; Lin, Q.; Li, T.; Chen, Y.; Lin, J. Investigation on structure and impact-resistance property of polyurethane foam filled, three-dimensional fabric reinforced sandwich flexible composites. Compos. Part B-Eng. 2017, 131, 43–49. [Google Scholar] [CrossRef]

- Chen, S.; Long, H.; Liu, Y.; Hu, F. Mechanical properties of 3D-structure composites based on warp-knitted spacer fabrics. Autex Res. J. 2015, 15, 127–137. [Google Scholar] [CrossRef]

- ASTM D3574-17, Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E1050-12, Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D4935-18, Standard Test Method for Measuring the Electromagnetic Shielding Effectiveness of Planar Materials; ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D1596-14, Standard Test Method for Dynamic Shock Cushioning Characteristics of Packaging Material; ASTM International: West Conshohocken, PA, USA, 2014.

- Shen, J.; Cao, X.; James Lee, L. Synthesis and foaming of water expandable polystyrene–clay nanocomposites. Polymer 2006, 47, 6303–6310. [Google Scholar] [CrossRef]

- Gwon, J.G.; Kim, S.K.; Kim, J.H. Sound absorption behavior of flexible polyurethane foams with distinct cellular structures. Mater. Des. 2016, 89, 448–454. [Google Scholar] [CrossRef]

- Gwon, J.G.; Sung, G.; Kim, J.H. Modulation of cavities and interconnecting pores in manufacturing water blown flexible poly (urethane urea) foams. Int. J. Precis. Eng. Manuf. 2015, 16, 2299–2307. [Google Scholar] [CrossRef]

- Choe, H.; Sung, G.; Kim, J.H. Chemical treatment of wood fibers to enhance the sound absorption coefficient of flexible polyurethane composite foams. Compos. Sci. Technol. 2018, 156, 19–27. [Google Scholar] [CrossRef]

- Doutres, O.; Atalla, N.; Dong, K. Effect of the microstructure closed pore content on the acoustic behavior of polyurethane foams. J. Appl. Phys. 2011, 110, 64901. [Google Scholar] [CrossRef] [Green Version]

- Cao, W.; Chen, F.; Zhu, Y.; Zhang, Y.; Jiang, Y.; Ma, M.; Chen, F. Binary Strengthening and Toughening of MXene/Cellulose Nanofiber Composite Paper with Nacre-Inspired Structure and Superior Electromagnetic Interference Shielding Properties. ACS Nano 2018, 12, 4583–4593. [Google Scholar] [CrossRef] [PubMed]

- Ameli, A.; Nofar, M.; Wang, S.; Park, C.B. Lightweight Polypropylene/Stainless-Steel Fiber Composite Foams with Low Percolation for Efficient Electromagnetic Interference Shielding. ACS Appl. Mater. Int. 2014, 6, 11091–11100. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man, H.S.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Wang, L.B.; See, K.Y.; Ma, J. Effect of carbon nanofiber reinforcement on electromagnetic interference shielding effectiveness of syntactic foam. J. Mater. Sci. 2013, 48, 7757–7763. [Google Scholar] [CrossRef]

- Pothupitiya Gamage, S.; Yang, K.; Braveenth, R.; Raagulan, K.; Kim, H.; Lee, Y.; Yang, C.; Moon, J.; Chai, K. MWCNT Coated Free-Standing Carbon Fiber Fabric for Enhanced Performance in EMI Shielding with a Higher Absolute EMI SE. Materials 2017, 10, 1350. [Google Scholar] [CrossRef]

- Xing, D.; Lu, L.; Teh, K.S.; Wan, Z.; Xie, Y.; Tang, Y. Highly flexible and ultra-thin Ni-plated carbon-fabric/polycarbonate film for enhanced electromagnetic interference shielding. Carbon 2018, 132, 32–41. [Google Scholar] [CrossRef]

- Yan, D.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.; Wang, J.; Li, Z. Structured Reduced Graphene Oxide/Polymer Composites for Ultra-Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Marsavina, L.; Linul, E.; Voiconi, T.; Sadowski, T. A comparison between dynamic and static fracture toughness of polyurethane foams. Polym. Test. 2013, 32, 673–680. [Google Scholar] [CrossRef]

- Linul, E.; Şerban, D.A.; Marsavina, L.; Sadowski, T. Assessment of collapse diagrams of rigid polyurethane foams under dynamic loading conditions. Arch. Civil Mech. Eng. 2017, 17, 457–466. [Google Scholar] [CrossRef]

- Gupta, N.; Woldesenbet, E. Characterization of Flexural Properties of Syntactic Foam Core Sandwich Composites and Effect of Density Variation. J. Compos. Mater. 2005, 39, 2197–2212. [Google Scholar] [CrossRef] [Green Version]

- Zhi, C.; Long, H. Flexural Properties of Syntactic foam Reinforced by Warp Knitted Spacer Fabric. Autex Res. J. 2016, 16, 57–66. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Hu, H.; Long, H.; Zhao, L. Impact compressive behavior of warp-knitted spacer fabrics for protective applications. Text. Res. J. 2011, 82, 773–788. [Google Scholar] [CrossRef]

| Sample Code | Upper Layer | Lower Layer | ||

|---|---|---|---|---|

| First | Second | Third | Fourth | |

| N-FU0-0 | Nylon | FU0 | - | FU0 |

| N-FU0-0.5 | Nylon | FU0 | - | FU0.5 |

| N-FU0-0.5/S | Nylon | FU0 | - | FU0.5/WSF |

| N-FU0-C/0.5/S | Nylon | FU0 | Carbon | FU0.5/WSF |

| N/C-FU0-0.5/S | Nylon/Carbon | FU0 | - | FU0.5/WSF |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Li, T.-T.; Wu, L.; Lou, C.-W.; Lin, J.-H. Multifunctional, Polyurethane-Based Foam Composites Reinforced by a Fabric Structure: Preparation, Mechanical, Acoustic, and EMI Shielding Properties. Materials 2018, 11, 2085. https://doi.org/10.3390/ma11112085

Wang H, Li T-T, Wu L, Lou C-W, Lin J-H. Multifunctional, Polyurethane-Based Foam Composites Reinforced by a Fabric Structure: Preparation, Mechanical, Acoustic, and EMI Shielding Properties. Materials. 2018; 11(11):2085. https://doi.org/10.3390/ma11112085

Chicago/Turabian StyleWang, Hongyang, Ting-Ting Li, Liwei Wu, Ching-Wen Lou, and Jia-Horng Lin. 2018. "Multifunctional, Polyurethane-Based Foam Composites Reinforced by a Fabric Structure: Preparation, Mechanical, Acoustic, and EMI Shielding Properties" Materials 11, no. 11: 2085. https://doi.org/10.3390/ma11112085

APA StyleWang, H., Li, T.-T., Wu, L., Lou, C.-W., & Lin, J.-H. (2018). Multifunctional, Polyurethane-Based Foam Composites Reinforced by a Fabric Structure: Preparation, Mechanical, Acoustic, and EMI Shielding Properties. Materials, 11(11), 2085. https://doi.org/10.3390/ma11112085