Effects of PTFE Micro-Particles on the Fiber-Matrix Interface of Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results

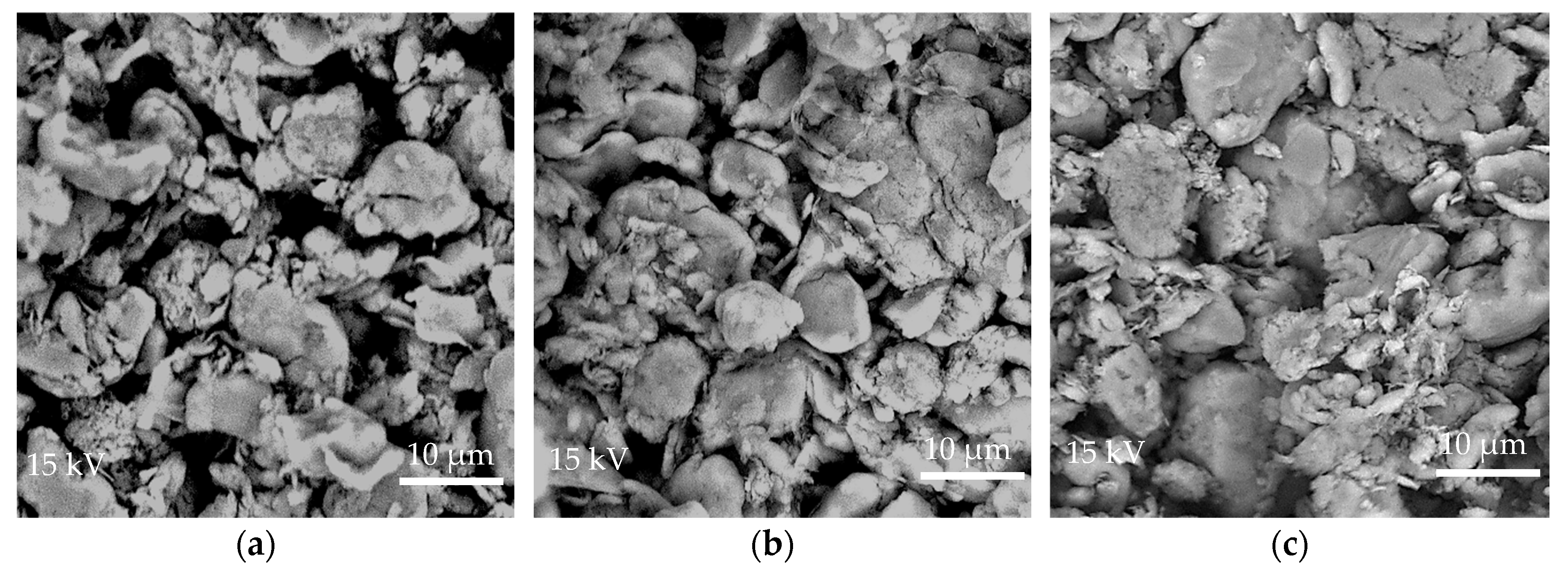

3.1. Effects of Chemical Etching on PTFE Micro-Particles

3.2. Tribological Behavior of POM/GF/PTFE Composites

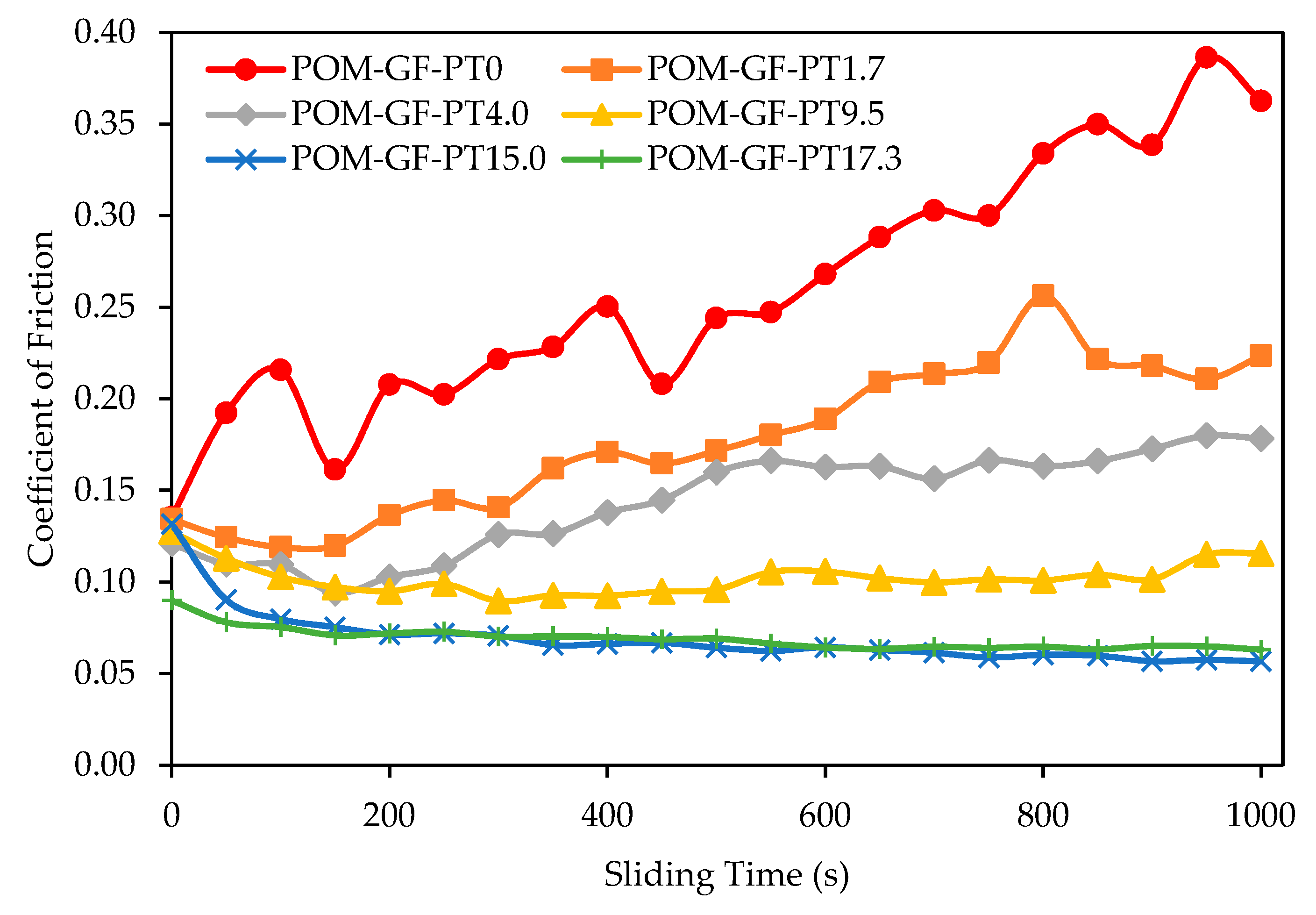

3.2.1. Friction

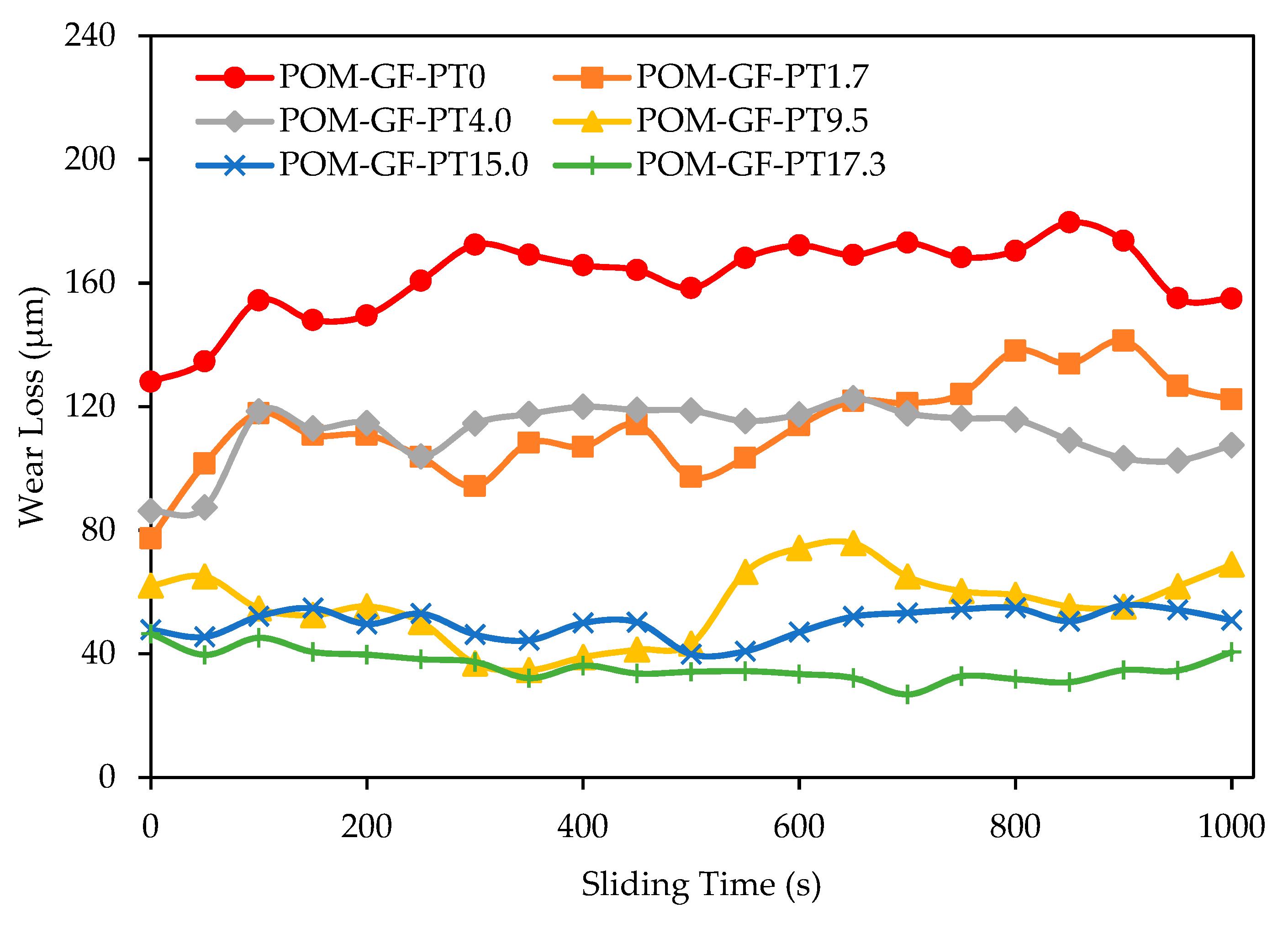

3.2.2. Wear Loss

3.3. Morphology of Worn Surfaces

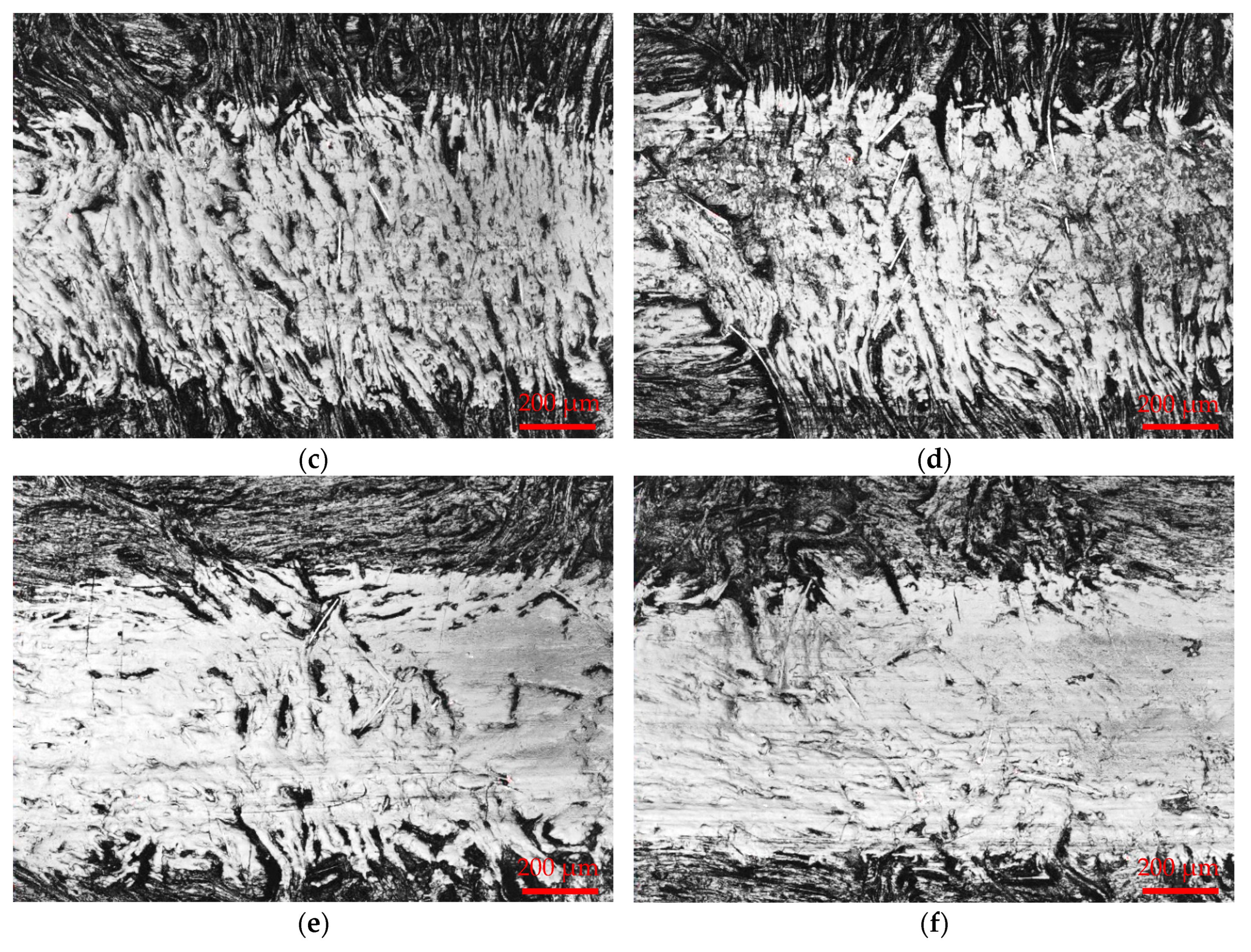

3.3.1. Optical Microscopy of POM/GF/PTFE Worn Surfaces

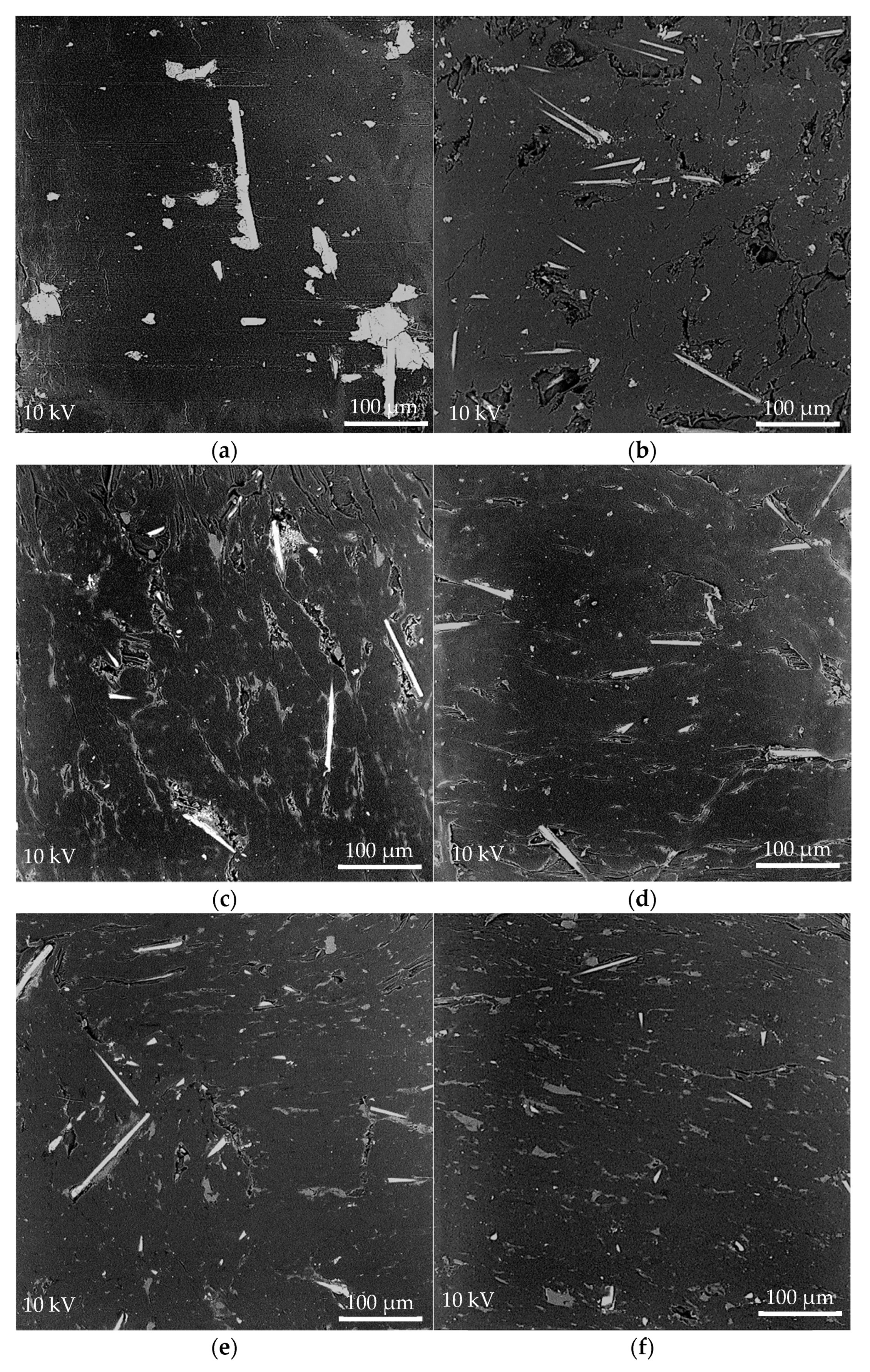

3.3.2. SEM Microscopy of POM/GF/PTFE Worn Surfaces

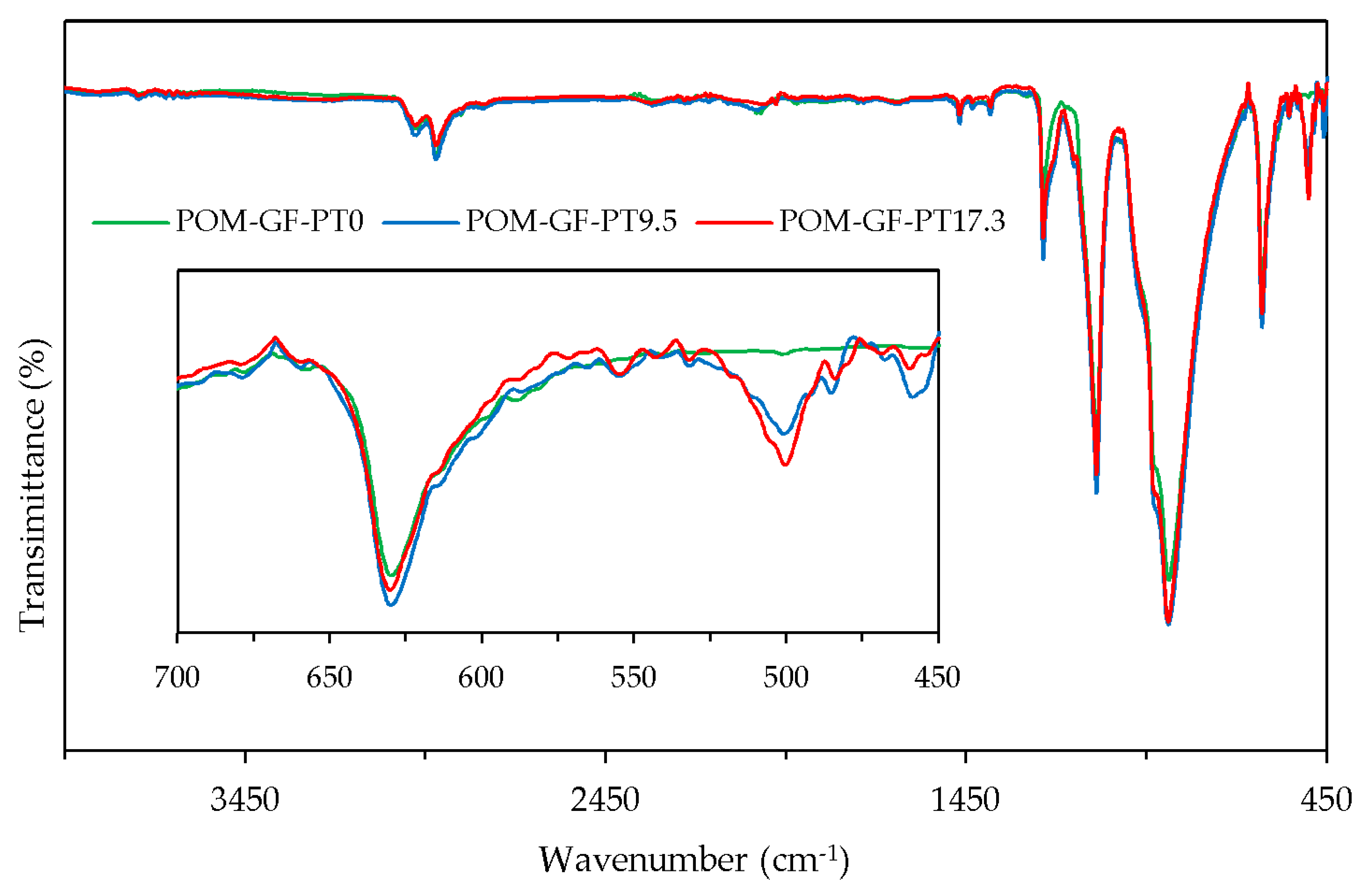

3.4. FTIR Spectroscopy

3.4.1. Characterization of Surface Etched PTFE

3.4.2. Characterization of POM/GF/PTFE Composites

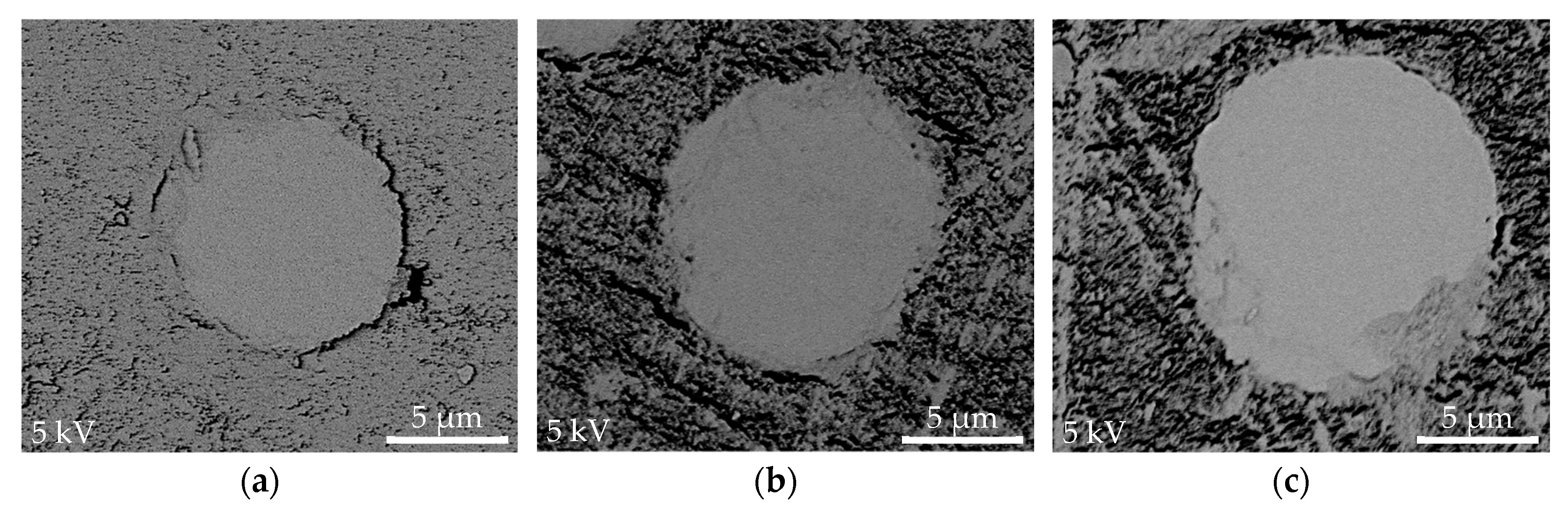

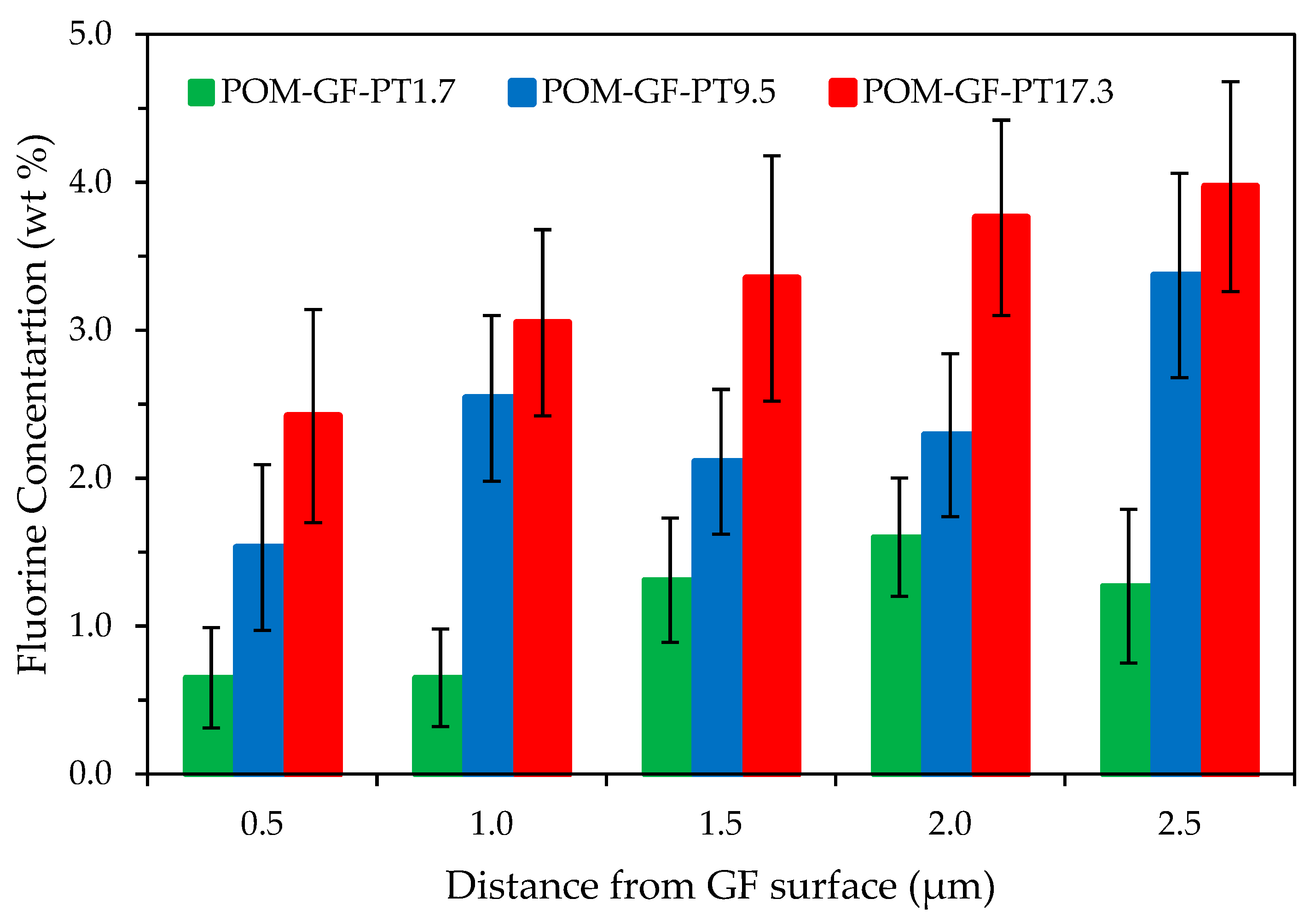

3.5. Mapping of Fiber-Matrix Interface Region

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fried, J.L. Polymer Science and Technology, 3rd ed.; Prentice Hall: Westford, MA, USA, 2014; pp. 281–282. ISBN 978-0-13-703955-5. [Google Scholar]

- Brostow, W.; Hagg Lobland, H.E.; Hnatchuk, N.; Perez, J.M. Improvement of Scratch and Wear Resistance of Polymers by Fillers Including Nanofillers. Nanomaterials 2017, 7, 66. [Google Scholar] [CrossRef] [PubMed]

- Papanicolaou, G.C.; Paipetis, A.S.; Theocaris, P.S. The concept of boundary interphase in composite mechanics. Colloid Polym. Sci. 1978, 256, 625–630. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2015, 73, 1–43. [Google Scholar] [CrossRef] [Green Version]

- Brostow, W.; Deborde, J.L.; Jaklewicz, M.; Olszynski, P. Tribology with emphasis on polymers: Friction, scratch resistance and wear. J. Mater. Educ. 2003, 24, 119–132. [Google Scholar]

- Brostow, W.; Kovačević, V.; Vrsaljko, D.; Whitworth, J. Tribology of polymers and polymer-based composites. J. Mater. Educ. 2010, 32, 273–290. [Google Scholar]

- Nirmal, U.; Hashim, J.; Lau, S.T.W. Testing methods in tribology of polymeric composites. Int. J. Mech. Mater. Eng. 2011, 3, 367–373. [Google Scholar]

- De Baets, P.; Glavatskih, S.; Ost, W.; Sukumaran, J. Polymer tribology: Challenges and Opportunities. In Proceedings of the 1st International Conference on Polymer Tribology, Bled, Slovenia, 11–12 September 2014. [Google Scholar]

- Myshkin, N.K.; Pesetskii, S.S.; Grigoriev, A.Y. Polymer tribology: Current state and applications. Tribol. Ind. 2015, 37, 284–290. [Google Scholar]

- Mergler, Y.J.; Schaake, R.P.; Huis in’t Veld, A.J. Material transfer of POM in sliding contact. Wear 2004, 256, 294–301. [Google Scholar] [CrossRef]

- Samyn, P.; De Baets, P.; Schoukens, G.; Quintelier, J. Wear transitions and stability of polyoxymethylene homopolymer in highly loaded applications compared to small-scale testing. Tribol. Int. 2007, 40, 819–833. [Google Scholar] [CrossRef]

- Poulios, K.; Drago, N.; Klit, P.; De Chiffre, L. A reciprocating pin-on-plate test-rig for studying friction materials for holding brakes. Wear 2014, 311, 40–46. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.L.; Zhang, C.T.; Wang, X.L. The Wear Behavior of Textured Steel Sliding against Polymers. Materials 2017, 10, 330. [Google Scholar] [CrossRef] [PubMed]

- Benabdallah, H.; Olender, D. Finite element simulation of the wear of polyoxymethylene in pin-on-disc configuration. Wear 2006, 261, 1213–1224. [Google Scholar] [CrossRef]

- Kalacska, G. An engineering approach to dry friction behavior of numerous engineering plastics with respect to the mechanical properties. Express Polym. Lett. 2013, 7, 199–210. [Google Scholar] [CrossRef]

- De Santis, F.; Gnerre, C.; Nobile, M.R.; Lambretti, G. The rheological and crystallization behavior of polyoxymethylene. Polym. Test. 2017, 57, 203–208. [Google Scholar] [CrossRef]

- Sun, L.H.; Yang, Z.G.; Li, X.H. Study on the friction and wear behavior of POM/Al2O3 nanocomposites. Wear 2008, 264, 693–700. [Google Scholar] [CrossRef]

- Wacharawichanant, S.; Thongyai, S.; Phutthaphan, A.; Eiamsam-ang, C. Effect of particles sizes of zinc oxide on mechanical, thermal and morphological properties of polyoxymethylene/zinc oxide nanocomposites. Polym. Test. 2008, 27, 971–976. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Wettability and surface analysis of glass fibres. Indian J. Fibr. Text. 2000, 25, 8–13. [Google Scholar]

- Sauer, B.B.; Carney, T.E. Dynamic Contact Angle Measurements on Glass Fibers: Influence of Fiber Diameter on Hysteresis and Contact Line Pinning. Langmuir 1990, 6, 1002–1007. [Google Scholar] [CrossRef]

- Etcheverry, M.; Barbosa, S.E. Glass Fiber Reinforced Polypropylene Mechanical Properties Enhancement by Adhesion Improvement. Materials 2012, 5, 1084–1113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsu, C.I.; Hwang, J.R.; Ting, P.H. Influence of Process Conditions on Tensile Properties Polyoxymethylene Composite. J. Reinf. Plast. Comp. 2010, 29, 2402–2412. [Google Scholar] [CrossRef]

- Unal, H.; Mimaroglu, A.; Demir, Z. Tribological performance of POM, PTFE and PSU composites used in electrical engineering applications. Int. J. Polym. Mater. 2010, 59, 808–817. [Google Scholar] [CrossRef]

- Hunke, H.; Soin, N.; Shah, T.; Kramer, E.; Pascual, A.; Karuna, M.; Siores, E. Low-Pressure H2, NH3 microwave plasma treatment of polytetrafluoroethylene (PTFE) powders: Chemical, thermal and wettability analysis. Materials 2015, 8, 2258–2275. [Google Scholar] [CrossRef]

- Vesel, A.; Kovac, J.; Zaplotnik, R.; Modic, M.; Mozetic, M. Modifications of polytetrafluoroethylene surfaces using H2S plasma treatment. Appl. Surf. Sci. 2015, 357, 1325–1332. [Google Scholar] [CrossRef]

- Drzal, L.T.; Rich, M.J.; Lloyd, P.F. Adhesion of graphite fibers to epoxy matrices: 1. The role of fiber surface treatment. J. Adhes. 1983, 16, 1–30. [Google Scholar] [CrossRef]

- Cech, V.; Palesch, E.; Lukes, J. The glass fiber-polymer matrix interface/interphase characterized by nanoscale imaging techniques. Compos. Sci. Technol. 2013, 83, 22–26. [Google Scholar] [CrossRef]

- Drelich, J.; Miller, J.D. A critical review of wetting and adhesion phenomena in the preparation of polymer-mineral composites. Miner. Metall. Proc. 1995, 12, 197–204. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.L.; Mader, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Cercle, C.; Favis, B.D. Generalizing interfacial modification in polymer blends. Polymer 2012, 53, 4338–4343. [Google Scholar] [CrossRef]

- Tze, W.T.Y.; Gardner, D.J.; Tripp, C.P.; O’Neill, S.C. Cellulose fiber/polymer adhesion: effects of fiber/matrix interfacial chemistry on the micromechanics of the interphase. J. Adhes. Sci. Technol. 2006, 20, 1649–1668. [Google Scholar] [CrossRef]

- Lim, K.M.; Ching, Y.C.; Gan, S.N. Effect of palm oil bio-based plasticizer on the morphological, thermal and mechanical properties of poly(vinyl chloride). Polymers 2015, 7, 2031–2043. [Google Scholar] [CrossRef]

- Azman, H.; Mat, U.W.; Ching, Y.C. Mechanical and morphological properties of PP/NR/LLDPE ternary blend—Effect of HVA-2. Polym. Test. 2003, 22, 281–290. [Google Scholar]

- Azman, H.; Mat, U.W.; Ching, Y.C. Mechanical and morphological properties of PP/LLPDE/NR blends effects of polyoctenamer. Polym. Plast. Technol. Eng. 2005, 44, 1245–1256. [Google Scholar]

- Asadi, A.; Miller, M.; Moon, R.J.; Kalaitzidou, K. Improving the interfacial and mechanical properties of short glass fiber/epoxy composites by coating the glass fibers with cellulose nanocrystals. Express Polym. Lett. 2016, 10, 587–597. [Google Scholar] [CrossRef]

- Nurfatimah, A.B.; Ching, Y.C.; Luqman, C.A.; Chantara, T.R.; Nor, A.I. Thermal and dynamic mechanical properties of grafted kenaf filled poly(vinyl chloride)/ethylene vinyl acetate composites. Mater. Des. 2015, 65, 204–211. [Google Scholar]

- Karger-Kocsis, J.; Hoecker, F. Effects of crystallinity and supermolecular formations on the interfacial shear strength and adhesion in GF/PP composites. Polym. Bull. 1993, 31, 707–714. [Google Scholar]

- Ching, Y.C.; Goh, K.Y.; Luqman, C.A.; Kalyani, N. Effect of nanosilica and titania on thermal stability of polypropylene/oil palm empty fruit fibre composite. J. Biobased Mater. Bioenergy 2013, 7, 169–174. [Google Scholar]

- Ravati, S.; Favis, B.D. Interfacial coarsening of ternary polymer blends with partial and complete wetting structures. Polymer 2013, 54, 6739–6751. [Google Scholar] [CrossRef]

- Arao, Y.; Yumitori, S.; Suzuki, H.; Tanaka, T.; Tanaka, K.; Katayama, T. Mechanical properties of injection-molded carbon fiber/polypropylene composites hybridized with nanofillers. Compos. Part A Appl. Sci. Manuf. 2013, 55, 19–26. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Pegoretti, A. Expanded graphite nanoplatelets as coupling agents in glass fiber reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2014, 55, 19–26. [Google Scholar] [CrossRef]

- Zhang, J.N.; Deng, S.Q.; Wang, Y.L.; Ye, L.; Zhou, L.M.; Zhang, Z. Effect of nanoparticles on the interfacial properties of carbon fibre-epoxy composites. Compos. Part A Appl. Sci. Manuf. 2013, 55, 35–44. [Google Scholar] [CrossRef]

- Upadhyaya, P.; Kumar, S. Micromechanics of stress transfer through the interphase in fiber-reinforced composites. Mech. Mater. 2015, 89, 190–201. [Google Scholar] [CrossRef]

- Schoneich, M.; Zamanzade, M.; Stommel, M. Fiber-matrix interphase in applied short glass fiber composites determined by a nano-scratch method. Compos. Sci. Technol. 2015, 119, 100–107. [Google Scholar] [CrossRef]

- Olmos, D.; Arroyo, J.M.; Gonzalez-Benito, J. Interphase morphology in glass fiber/PMMA modified epoxy matrix composites. Effect of molecular weight of PMMA. Polym. Test. 2012, 31, 785–791. [Google Scholar] [CrossRef]

- Graupner, N.; Roβler, J.; Ziegmann, G.; Mussig, J. Fibre/matrix adhesion of cellulose fibres in PLA, PP and MAPP: A critical review of pull-out test, microbond test and single fibre fragmentation rest results. Compos. Part A Appl. Sci. Manuf. 2014, 63, 133–148. [Google Scholar] [CrossRef]

- Huang, T.; Lu, R.G.; Wang, H.Y.; Ma, Y.N.; Tian, J.S.; Li, T.S. Investigation on the Tribological Properties of POM Modified by Nano-PTFE. J. Macromol. Sci. B 2011, 50, 1235–1248. [Google Scholar] [CrossRef]

- Benabdallah, H. Friction and wear of blended polyoxymethylene sliding against coated steel plates. Wear 2003, 254, 1239–1246. [Google Scholar] [CrossRef]

- Zhang, L.G.; Qi, H.M.; Li, G.T.; Zhang, G.; Wang, T.M.; Wang, Q.H. Impact of reinforcing fillers’ properties of transfer film structure and tribological performance of POM-based materials. Tribol. Int. 2017, 109, 58–68. [Google Scholar] [CrossRef]

- Kunnan Singh, J.S.; Ching, Y.C.; Abdullah, L.C.; Ching, K.Y.; Razali, S.; Gan, S.N. Optimization of Mechanical Properties for Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites Using Response Surface Methodology. Polymers 2018, 10, 338. [Google Scholar] [CrossRef]

- Yee, Y.Y.; Ching, Y.C.; Rozali, S.; Hashim, N.A.; Singh, R. Preparation and characterization of poly(lactic acid)-based composite reinforced with oil palm empty fruit bunch fiber and nanosilica. BioResources 2016, 11, 2269–2286. [Google Scholar] [CrossRef]

- Liang, C.Y.; Krimm, S. Infrared Spectra of High Polymers. III. Polytetrafluoroethylene and Polychlorotrifluoroethylene. J. Chem. Phys. 1955, 25, 563–571. [Google Scholar] [CrossRef]

- Huang, C.Y.; Tseng, C.I. The Effect of Interface Modification between POM and PTFE on the Properties of POM/PTFE Composites. J. Appl. Polym. Sci. 2000, 78, 800–807. [Google Scholar] [CrossRef]

- LeRoy, L.; Briani, G.; Briois, C.; Cottin, H.; Fray, N.; Thirkell, L.; Poulet, G.; Hilchenbach, M. On the prospective detection of polyoxymethylene in comet 67P/Churyumov–Gerasimenko with the COSIMA instrument on board Rosetta. Planet. Space Sci. 2012, 65, 83–92. [Google Scholar] [CrossRef]

- Mihály, J.; Sterkel, S.; Ortner, H.M.; Kocsis, L.; Hajba, L.; Furdyga, E.; Minka, J. FTIR and FT-Raman Spectroscopic Study on Polymer Based High Pressure Digestion Vessels. Croat. Chem. Acta 2006, 79, 497–501. [Google Scholar]

- Domagala, W.U. The Use of the Spectrometric Technique FTIR-ATR to Examine the Polymers Surface. In Advanced Aspects of Spectroscopy, 1st ed.; Farrukh, M.A., Ed.; InTech: Rijeka, Croatia, 2012; pp. 85–104. ISBN 978-953-51-0715-6. [Google Scholar]

- Udenni Gunathilake, T.M.S.; Ching, Y.C.; Yong, K.C.; Cheng, H.C.; Luqman, C.A. Biomedical and microbiological applications of bio-based porous materials: A review. Polymers 2017, 9, 160. [Google Scholar] [CrossRef]

- Hunke, H.; Soin, N.; Shah, T.; Kramer, E.; Witan, K.; Siores, E. Influence of plasma pre-treatment of polytetrafluoroethylene (PTFE) micropowders on the mechanical and tribological performance of Polyethersulfone (PESU)-PTFE composites. Wear 2015, 328–329, 480–487. [Google Scholar] [CrossRef]

| Sample Name | PTFE Etch Time (min) | PTFE Weight (%) |

|---|---|---|

| POM-GF-PT0 | - | 0 |

| POM-GF-PT1.7 | 10 | 1.7 |

| POM-GF-PT4.0 | 10 | 4.0 |

| POM-GF-PT9.5 | 10 | 9.5 |

| POM-GF-PT15.0 | 10 | 15.0 |

| POM-GF-PT017.3 | 10 | 17.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, J.S.K.; Ching, Y.C.; Liu, D.S.; Ching, K.Y.; Razali, S.; Gan, S.N. Effects of PTFE Micro-Particles on the Fiber-Matrix Interface of Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites. Materials 2018, 11, 2164. https://doi.org/10.3390/ma11112164

Singh JSK, Ching YC, Liu DS, Ching KY, Razali S, Gan SN. Effects of PTFE Micro-Particles on the Fiber-Matrix Interface of Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites. Materials. 2018; 11(11):2164. https://doi.org/10.3390/ma11112164

Chicago/Turabian StyleSingh, Jasbir Singh Kunnan, Yern Chee Ching, De Shin Liu, Kuan Yong Ching, Shaifulazuar Razali, and Seng Neon Gan. 2018. "Effects of PTFE Micro-Particles on the Fiber-Matrix Interface of Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites" Materials 11, no. 11: 2164. https://doi.org/10.3390/ma11112164

APA StyleSingh, J. S. K., Ching, Y. C., Liu, D. S., Ching, K. Y., Razali, S., & Gan, S. N. (2018). Effects of PTFE Micro-Particles on the Fiber-Matrix Interface of Polyoxymethylene/Glass Fiber/Polytetrafluoroethylene Composites. Materials, 11(11), 2164. https://doi.org/10.3390/ma11112164