The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Specimens

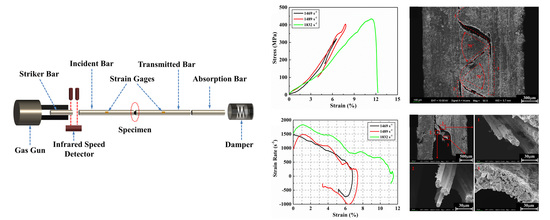

2.2. Theory and Experimental Scheme

3. Results and Discussion

3.1. The Strain Rate Dependence of an Out-of-Plane Compression Response

3.2. Damage Kinetics

3.3. Failure Mode and Damage Mechanism

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Yoshida, T.; Uenoya, T.; Miyamoto, H. Impact damage characterization in cross-plied carbon fiber/thermoplastic composites using thermoelastic stress analysis. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 1 May 2012. [Google Scholar]

- Bishop, S.M. The mechanical performance and impact behavior of carbon-fibre reinforced PEEK. Compos. Struct. 1985, 3, 295–318. [Google Scholar] [CrossRef]

- Dorey, G.; Bishop, S.M.; Curtis, P.T. On the impact performance of carbon fibre laminates with epoxy and PEEK matrices. Compos. Sci. Technol. 1985, 23, 221–237. [Google Scholar] [CrossRef]

- Ishikawa, T.; Sugimoto, S.; Matsushima, M.; Hayashi, Y. Some experimental findings in compression-after-impact (CAI) tests of CF/PEEK (APC-2) and conventional CF/epoxy flat plates. Compos. Sci. Technol. 1995, 55, 349–363. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, L.; Hong, H.; Zhang, J. A strain-rate-dependent damage model for evaluating the low velocity impact induced damage of composite laminates. Compos. Struct. 2018, 201, 995–1003. [Google Scholar] [CrossRef]

- Thierry, V.; Brown, L.; Chronopoulos, D. Multi-scale wave propagation modelling for two-dimensional periodic textile composites. Compos. Part B Eng. 2018, 150, 144–156. [Google Scholar] [CrossRef]

- Johnson, A.F.; Pickett, A.K.; Rozycki, P. Computational methods for predicting impact damage in composite structures. Compos. Sci. Technol. 2001, 61, 2183–2192. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Silani, M.; Weinberg, K. Fracture studies of Ultra-High Performance Concrete using dynamic Brazilian tests. Theor. Appl. Fract. Mech. 2018, 93, 302–310. [Google Scholar] [CrossRef]

- Weinberg, K.; Khosravani, M.R. On the tensile resistance of UHPC at impact. Eur. Phys. J. Spec. Top. 2018, 227, 167–177. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Ninan, L.; Tsai, J.; Sun, C. Use of split Hopkinson pressure bar for testing off-axis composites. Int. J. Impact Eng. 2001, 25, 291–313. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Zhi, Z.; Guo, Y.; Ouyang, N. The compressive and tensile behavior of a 0/90 C fiber woven composite at high strain rates. Carbon 2013, 61, 97–104. [Google Scholar] [CrossRef]

- Tsai, J.; Sun, C.T. Constitutive model for high strain rate response of polymeric composites. Compos. Sci. Technol. 2002, 62, 1289–1297. [Google Scholar] [CrossRef]

- Kumar, P.; Garg, A.; Agarwal, B.D. Dynamic compressive behavior of unidirectional GFRP for various fibre orientations. Mater. Lett. 1986, 4, 111–116. [Google Scholar] [CrossRef]

- Hosur, M.V.; Alexander, J.; Vaidya, U.K.; Jeelani, S.; Mayer, A. Studies on the off-axis high strain rate compression loading of satin weave carbon/epoxy composites. Compos. Struct. 2004, 63, 75–85. [Google Scholar] [CrossRef]

- Li, D.S.; Chen, H.R.; Ge, D.Y.; Jiang, N.; Jiang, L. Split Hopkinson pressure bar testing of 3D multi-axial warp knitted carbon/epoxy composites. Compos. Part B Eng. 2015, 79, 692–705. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, Y.; Li, H.; Li, S.; Guo, L. Quasi-static and dynamic compressive fracture behavior of carbon/carbon composites. Carbon 2008, 46, 699–703. [Google Scholar]

- Tarfaoui, M.; Choukri, S.; Neme, A. Effect of fibre orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef] [Green Version]

- Arbaoui, J.; Tarfaoui, M.; Alaoui, A.E.M. Mechanical behavior and damage kinetics of woven E-glass/vinylester laminate composites under high strain rate dynamic compressive loading: Experimental and numerical investigation. Int. J. Impact Eng. 2016, 87, 44–54. [Google Scholar] [CrossRef]

- Kapoor, R.; Pangeni, L.; Bandaru, A.K.; Ahmad, S.; Bhatnagar, N. High strain rate compression response of woven Kevlar reinforced polypropylene composites. Compos. Part B 2016, 89, 374–382. [Google Scholar] [CrossRef]

- Weeks, C.A.; Sun, C.T. Modeling non-linear rate-dependent behavior in fiber-reinforced composites. Compos. Sci. Technol. 1998, 58, 603–611. [Google Scholar] [CrossRef]

- Kawai, M.; Masuko, Y.; Kawase, Y.; Negishi, R. Micromechanical analysis of the off-axis rate-dependent inelastic behavior of unidirectional AS4/PEEK at high temperature. Int. J. Mech. Sci. 2001, 43, 2069–2090. [Google Scholar] [CrossRef]

- Totry, E.; González, C.; Llorca, J. Prediction of the failure locus of C/PEEK composites under transverse compression and longitudinal shear through computational micromechanics. Compos. Sci. Technol. 2008, 68, 3128–3136. [Google Scholar] [CrossRef] [Green Version]

- Hsu, S.Y.; Vogler, T.J.; Kyriakides, S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part II: Modeling. Int. J. Plast. 1999, 15, 807–836. [Google Scholar]

- Vogler, T.J.; Kyriakides, S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part I: Experiments. Int. J. Plast. 1999, 15, 783–806. [Google Scholar]

- Dong, L.; Harding, J. A single-lap shear specimen for determining the effect of strain rate on the interlaminar shear strength of carbon fibre-reinforced laminates. Composites 1994, 25, 129–138. [Google Scholar] [CrossRef]

- Khosravani, M.R. Composite Materials Manufacturing Processes. Appl. Mech. Mater. 2012, 110, 1361–1367. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. Sec. B 1949, 62, 676. [Google Scholar] [CrossRef]

- Davies, R. A critical study of the Hopkinson pressure bar. Phil. Trans. R. Soc. Lond. A 1948, 240, 375–457. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, B.; Forrestal, M. A split Hopkinson bar technique for low-impedance materials. Exp. Mech. 1999, 39, 81–85. [Google Scholar] [CrossRef]

- Yang, L.M.; Shim, V.P.W. An analysis of stress uniformity in split Hopkinson bar test specimens. Int. J. Impact Eng. 2005, 31, 129–150. [Google Scholar] [CrossRef]

- Wang, T.-T.; Shang, B. Three-wave mutual-checking method for data processing of SHPB experiments of concrete. J. Mech. 2014, 30, N5–N10. [Google Scholar] [CrossRef]

- Francis, D.K.; Whittington, W.R.; Lawrimore, W.B.; Allison, P.G.; Turnage, S.A.; Bhattacharyya, J.J. Split Hopkinson Pressure Bar Graphical Analysis Tool. Exp. Mech. 2017, 57, 179–183. [Google Scholar] [CrossRef]

| Specimens | Thickness (mm) | Surface (mm2) | Stacking Sequence | Strain Rates (/s) |

|---|---|---|---|---|

| A1 | 2.02 | 4.96 × 4.98 | (0°/90°)4s | 6848 |

| A2 | 2.00 | 5.06 × 5.02 | (0°/90°)4s | 3866 |

| A3 | 1.98 | 4.98 × 5.04 | (0°/90°)4s | 1469 |

| A4 | 1.98 | 5.04 × 5.02 | (0°/90°)4s | 1832 |

| A5 | 2.02 | 5.88 × 5.90 | (0°/90°)4s | 1489 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, H.; Yin, W.; Cai, C.; Wang, B.; Liu, A.; Yang, Z.; Li, Y.; He, X. The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials 2018, 11, 2312. https://doi.org/10.3390/ma11112312

Zou H, Yin W, Cai C, Wang B, Liu A, Yang Z, Li Y, He X. The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials. 2018; 11(11):2312. https://doi.org/10.3390/ma11112312

Chicago/Turabian StyleZou, Huiran, Weilong Yin, Chaocan Cai, Bing Wang, Ankang Liu, Zhen Yang, Yibin Li, and Xiaodong He. 2018. "The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates" Materials 11, no. 11: 2312. https://doi.org/10.3390/ma11112312

APA StyleZou, H., Yin, W., Cai, C., Wang, B., Liu, A., Yang, Z., Li, Y., & He, X. (2018). The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials, 11(11), 2312. https://doi.org/10.3390/ma11112312