Giant Enhancement of Magnetostrictive Response in Directionally-Solidified Fe83Ga17Erx Compounds

Abstract

:1. Introduction

2. Materials and Methods

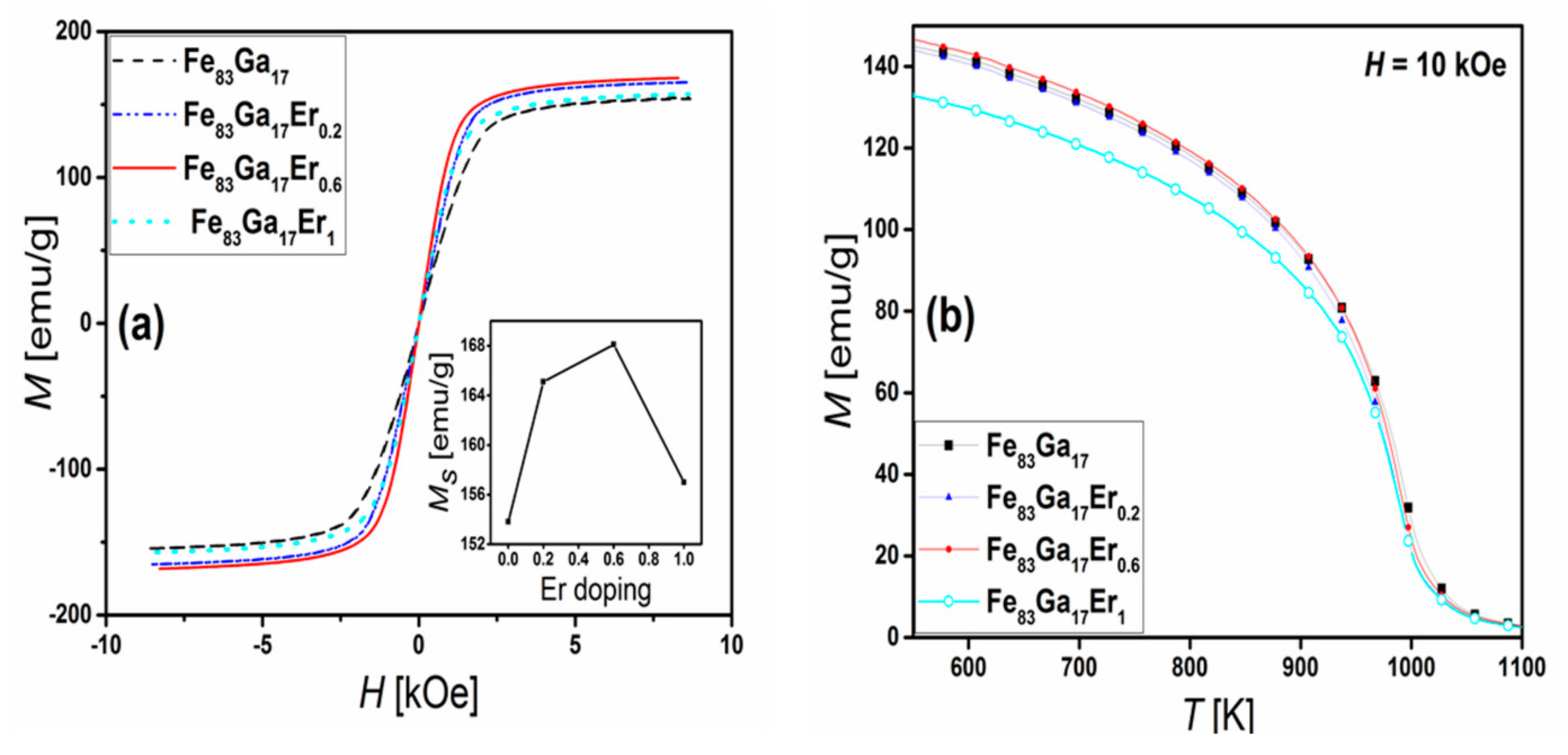

3. Experimental Results & Discussion

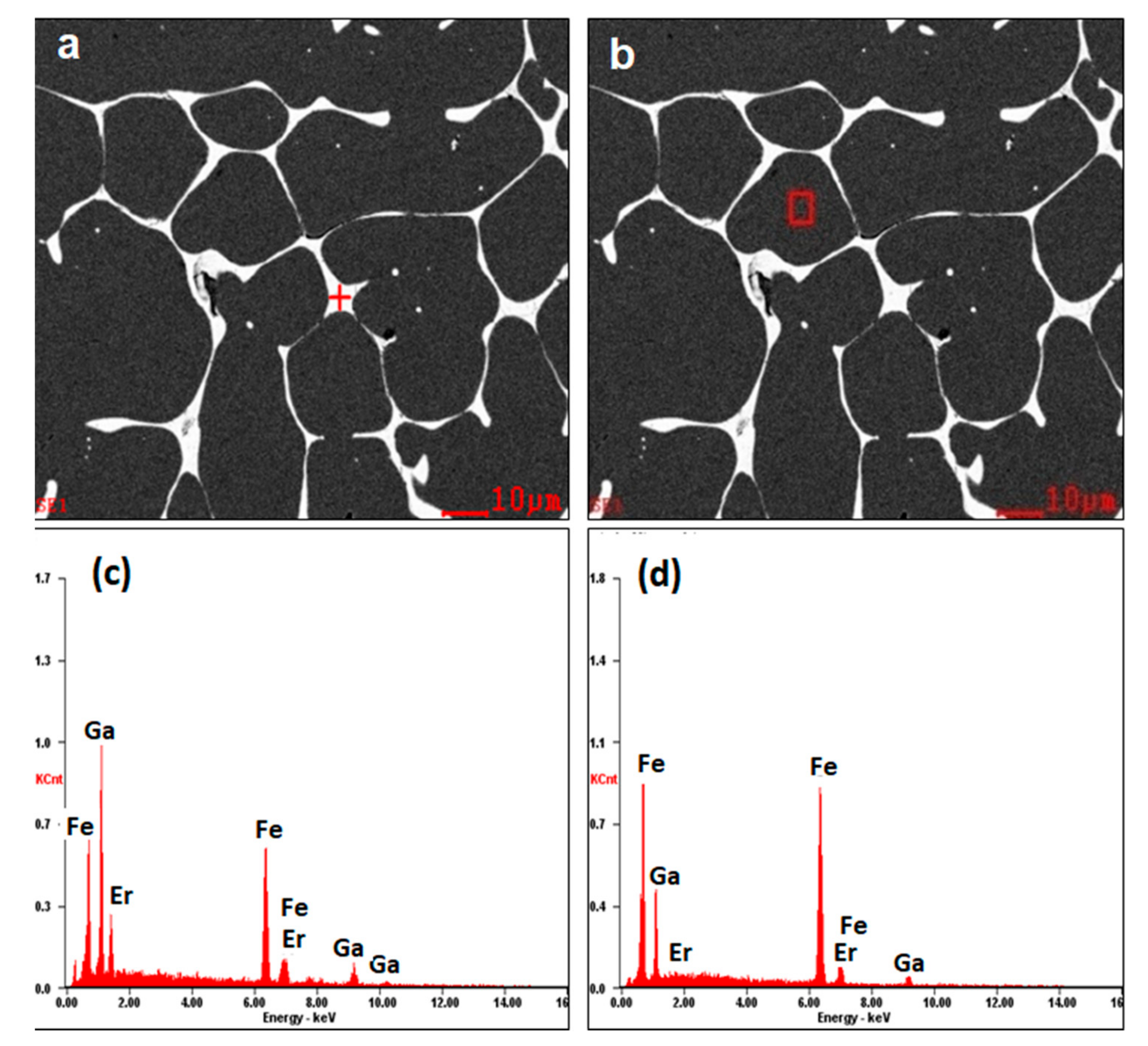

3.1. Structural Attributes: Crystallographic and Microstructural Properties

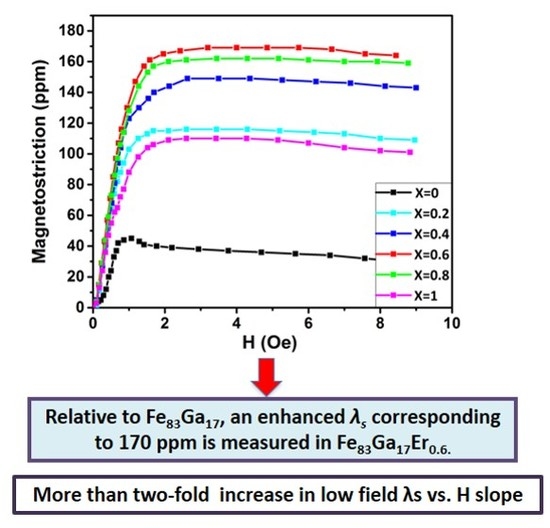

3.2. Enhanced Functional Response: Magnetostriction Measurements at Room Temperature

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Parsons, M.J.; Datta, S.; Mudivarthi, C.; Na, S.M.; Flatau, A. Torque sensing using rolled galfenol patches. In Proceedings of the SPIE Smart Sensor Phenomena, Technology, Networks, and Systems, San Diego, CA, USA, 7 April 2008; Volume 6933, p. 693314. [Google Scholar]

- Weng, L.; Wang, B.; Dapino, M.J.; Sun, Y.; Wang, L.; Cui, B. Relationships between magnetization and dynamic stress for Galfenol rod alloy and its application in force sensor. J. Appl. Phys. 2013, 113, 17A917. [Google Scholar] [CrossRef]

- Berbyuk, V. Vibration energy harvesting using Galfenol-based transducer. In Proceedings of the SPIE: Active and Passive Smart Structures and Integrated Systems, San Diego, CA, USA, 10 April 2013; Volume 8688, p. 86881F. [Google Scholar]

- Clark, E.; Teter, J.P.; McMasters, O.D. Magnetostriction “jumps” in twinned Tb0.3Dy0.7Fe1.9. J. Appl. Phys. 1988, 63, 3910. [Google Scholar] [CrossRef]

- Humphries, M. Rare Earth Elements: The Global Supply Chain; Diane Publishing Company: Collingdale, PA, USA, 2010. [Google Scholar]

- Olabi, A.G.; Grunwald, A. Design and application of magnetostrictive materials. Mater. Des. 2008, 29, 469–483. [Google Scholar] [CrossRef] [Green Version]

- Kellogg, R.A. Development and Modelling of Iron-Gallium Alloys. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2003. [Google Scholar]

- Atulasimha, J.; Flatau, A.B. A review of magnetostrictive iron-gallium alloys. Smart Mater. Struct. 2011, 20, 043001. [Google Scholar] [CrossRef]

- Xing, Q.; Du, Y.; McQueeney, R.J.; Lograsso, T.A. Structural investigations of Fe-Ga alloys: Phase relations and magnetostrictive behavior. Acta Mater. 2008, 56, 4536–4546. [Google Scholar] [CrossRef]

- Lograsso, T.A.; Summers, E.M. Detection and quantification of D03 chemical order in Fe-Ga alloys using high resolution X-ray diffraction. Mater. Sci. Eng. A 2006, 416, 240–245. [Google Scholar] [CrossRef]

- Srisukhumbowornchai, N.; Guruswamy, S. Influence of ordering on the magnetostriction of Fe–27.5 at.% Ga alloys. J. Appl. Phys. 2002, 92, 5371. [Google Scholar] [CrossRef]

- Taheri, P.; Barua, R.; Hsu, J.; Zamanpour, M.; Chen, Y.; Harris, V.G. Structure, magnetism, and magnetostrictive properties of mechanically alloyed Fe81Ga19. J. Alloys Compd. 2016, 661, 306–311. [Google Scholar] [CrossRef]

- Atulasimha, J.; Flatau, A.B.; Cullen, J.R. Analysis of the effect of gallium content on the magnetomechanical behavior of single-crystal FeGa alloys using an energy-based model. Smart Mater. Struct. 2008, 17, 025027. [Google Scholar] [CrossRef]

- Hattrick-Simpers, J.R.; Hunter, D.; Craciunescu, C.M.; Jang, K.S.; Murakami, M.; Cullen, J.; Wuttig, M.; Takeuchi, I.; Lofland, S.E.; Bendersky, L.; et al. Combinatorial Investigation of Magnetostriction in FeGa and FeGa-Al. Appl. Phys. Lett. 2008, 93, 8–13. [Google Scholar] [CrossRef]

- Mungsantisuk, P.; Corson, R.P.; Guruswamy, S. Influence of Be and Al on the magnetostrictive behavior of FeGa alloys. J. Appl. Phys. 2005, 98, 1–7. [Google Scholar] [CrossRef]

- Dai, L.; Cullen, J.; Wuttig, M.; Lograsso, T.; Quandt, E. Magnetism, elasticity, and magnetostriction of FeCoGa alloys. J. Appl. Phys. 2003, 93, 8627–8629. [Google Scholar] [CrossRef]

- Restorff, J.B.; Clark, A.E.; Lograsso, T.A.; Ross, A.R. Magnetostriction of ternary Fe-Ga-X alloys (X = Ni, Mo, Sn, Al). J. Appl. Phys. 2002, 91, 8225. [Google Scholar] [CrossRef]

- Clark, A.E.; Restorff, J.B.; Wunfogle, M.; Hathaway, K.B.; Lograsso, T.A. Magnetostriction of ternary Fe-Ga-X (X = C, V, Cr, Mn, Co, Rh) alloys. J. Appl. Phys. 2016, 507, 99–102. [Google Scholar] [CrossRef]

- Huang, M.; Lograsso, T.A.; Clark, A.E.; Restorff, J.B.; Wun-Fogle, M. Effect of interstitial additions on magnetostriction in Fe-Ga alloys. J. Appl. Phys. 2008, 103, 1–4. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, J.; Hao, H.; Zhang, G.; Wu, S.; Chen, Y.; Obi, O.; Fitchorov, T.; Harris, V.G. Giant enhancement in the magnetostrictive effect of FeGa alloys doped with low levels of terbium. Appl. Phys. Lett. 2013, 102, 222409. [Google Scholar] [CrossRef]

- Jin, T.; Wu, W.; Jiang, C. Improved magnetostriction of Dy-doped Fe83Ga17 melt-spun ribbons. Scr. Mater. 2014, 74, 100–103. [Google Scholar] [CrossRef]

- Yao, Z.; Tian, X.; Jiang, L.; Hao, H.; Zhang, G.; Wu, S. Influences of rare earth element Ce-doping and melt-spinning on microstructure and magnetostriction of Fe83Ga17 alloy. J. Alloys Compd. 2015, 637, 431–435. [Google Scholar] [CrossRef]

- Jiheng, L.I.; Ximing, X.; Chao, Y.; Xuexu, G.A.O.; Xiaoqian, B.A.O. Effect of yttrium on the mechanical and magnetostrictive properties of Fe83Ga17 alloy. J. Rare Earths 2015, 33, 1087–1092. [Google Scholar]

- He, Y.; Jiang, C.; Wu, W.; Wang, B.; Duan, H.; Wang, H.; Zhang, T.; Wang, J.; Liu, J.; Zhang, Z.; et al. Giant heterogeneous magnetostriction in FeGa alloys: Effect of trace element doping. Acta. Mater. 2016, 109, 177–186. [Google Scholar] [CrossRef]

- Meng, C.; Jiang, C. Magnetostriction of a Fe83Ga17 single crystal slightly doped with Tb. Scr. Mater. 2016, 114, 9–12. [Google Scholar] [CrossRef]

- Golovin, I.S.; Balagurov, A.M.; Palacheva, V.V.; Emdadi, A.; Bobrikov, I.A.; Churyumov, A.Y.; Cheverikin, V.V.; Pozdniakov, A.V.; Mikhaylovskaya, A.V.; Golovin, S.A. Influence of Tb on structure and properties of Fe-19% Ga and Fe-27% Ga alloys. J. Alloys Compd. 2017, 707, 51–56. [Google Scholar] [CrossRef]

- Wei, W.; Jiang, C. Improved magnetostriction of Fe83Ga17 ribbons doped with Sm. Rare Met. 2017, 36, 18–22. [Google Scholar]

- He, Y.; Ke, X.; Jiang, C.; Miao, N.; Wang, H.; Coey, J.M.D.; Wang, Y.; Xu, H. Interaction of Trace Rare-Earth Dopants and Nanoheterogeneities Induces Giant Magnetostriction in Fe-Ga Alloys. Adv. Funct. Mater. 2018, 28, 1800858. [Google Scholar] [CrossRef]

- Novak, G.A.; Colville, A.A. A practical interactive least-squares cell-parameter program using an electronic spreadsheet and a personal computer. Am. Miner. 1989, 74, 488–490. [Google Scholar]

- Koblischka-Veneva, A.; Koblischka, M.R.; Simon, P. Electron backscatter diffraction study of polycrystalline YBa2Cu3O7−δ. Phys. C: Supercond. 2002, 382, 311–322. [Google Scholar] [CrossRef]

- Koblischka-Veneva, A.; Muchlich, F.; Koblischka, M.R.; Babu, N.H.; Cardwell, D.A. Crystallographic Orientation of Y2Ba4CuMO. J. Am. Ceram. Soc. 2007, 90, 2582–2588. [Google Scholar] [CrossRef]

- Chen, Y.; Gillette, S.M.; Fitchorov, T.; Jiang, L.; Hao, H.; Li, J.; Gao, X.; Geiler, A.; Vittoria, C.; Harris, V.G. Quasi-one-dimensional miniature multiferroic magnetic field sensor with high sensitivity at zero bias field. J. Appl. Phys. 2011, 99, 042505. [Google Scholar] [CrossRef]

- Geiler, A.L.; Gillette, S.M.; Chen, Y.; Wang, J.; Chen, Z.; Yoon, S.D.; He, P.; Gao, J.; Vittoria, C.; Harris, V.G. Multiferroic heterostructure fringe field tuning of meander line microstrip ferrite phase shifter. Appl. Phys. Lett. 2010, 96, 053508. [Google Scholar] [CrossRef]

- Fitchorov, T.; Chen, Y.; Hu, B.; Gillette, S.M.; Geiler, A.; Vittoria, C.; Harris, V.G. Tunable fringe magnetic fields induced by converse magnetoelectric coupling in a FeGa/PMN-PT multiferroic heterostructure. J. Appl. Phys. 2011, 110, 123916. [Google Scholar] [CrossRef] [Green Version]

- Stephan, M.; Jahns, R.; Greve, H.; Quandt, E.; Knöchel, R.; Wagner, B. MEMS magnetic field sensor based on magnetoelectric composites. J. Micromech. Microeng. 2012, 22, 6. [Google Scholar]

- Dong, S.; Zhai, J.; Li, J.; Viehland, D.; Summers, E. Strong magnetoelectric charge coupling in stress-biased multilayer-piezoelectric/magnetostrictive composites. J. Appl. Phys. 2007, 101, 124102. [Google Scholar] [CrossRef]

- Clark, A.E.; Hathaway, K.B.; Wun-Fogle, M.; Restorff, J.B.; Lograsso, T.A.; Keppens, V.M.; Petculescu, G.; Taylor, R.A. Extraordinary magnetoelasticity and lattice softening in bcc Fe-Ga alloys. J. Appl. Phys. 2003, 93, 8621. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Liu, J.; Jiang, C.; Xu, H. Giant magnetostriction in Tb-doped Fe83Ga17 melt-spun ribbons. Appl. Phys. Lett. 2013, 103, 262403. [Google Scholar] [CrossRef]

| Alloy | Fabrication Technique | λ110 (ppm) | Condition | References |

|---|---|---|---|---|

| Fe83Ga17 | Directional solidification | 45 | Bulk; Pre-stressed | Current work |

| Fe83Ga17 | Directional solidification | 68 | Bulk; Pre-stressed | L. Jiang et al. [20] |

| Fe81Ga19Tb0.3 | Directional solidification | 85 | Bulk; Pre-stressed | T.I. Fitchorov et al. [34] |

| Fe83Ga17Y0.64 | Directional solidification | 133 | Bulk; Compressed under 15 MPa | L. Jiheng et al. [23] |

| Fe83Ga17Tb0.2 | Directional solidification | 160 | Bulk; Pre-stressed | L. Jiang et al. [20] |

| Fe83Ga17Er0.6 | Directional solidification | 170 | Bulk; Pre-stressed | Current work |

| Fe83Ga17Ce0.8 | Directional solidification | 200 | Bulk; Pre-stressed; Sample not at saturation | Z. Yao et al. [22] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barua, R.; Taheri, P.; Chen, Y.; Koblischka-Veneva, A.; Koblischka, M.R.; Jiang, L.; Harris, V.G. Giant Enhancement of Magnetostrictive Response in Directionally-Solidified Fe83Ga17Erx Compounds. Materials 2018, 11, 1039. https://doi.org/10.3390/ma11061039

Barua R, Taheri P, Chen Y, Koblischka-Veneva A, Koblischka MR, Jiang L, Harris VG. Giant Enhancement of Magnetostrictive Response in Directionally-Solidified Fe83Ga17Erx Compounds. Materials. 2018; 11(6):1039. https://doi.org/10.3390/ma11061039

Chicago/Turabian StyleBarua, Radhika, Parisa Taheri, Yajie Chen, Anjela Koblischka-Veneva, Michael R. Koblischka, Liping Jiang, and Vincent G. Harris. 2018. "Giant Enhancement of Magnetostrictive Response in Directionally-Solidified Fe83Ga17Erx Compounds" Materials 11, no. 6: 1039. https://doi.org/10.3390/ma11061039

APA StyleBarua, R., Taheri, P., Chen, Y., Koblischka-Veneva, A., Koblischka, M. R., Jiang, L., & Harris, V. G. (2018). Giant Enhancement of Magnetostrictive Response in Directionally-Solidified Fe83Ga17Erx Compounds. Materials, 11(6), 1039. https://doi.org/10.3390/ma11061039