1. Introduction

Over the last few decades, the aeronautical industry has been highlighted for its capacity to develop and manufacture structural elements built with advanced materials, having achieved a leading position in this area of activity with respect to other sectors.

In this sense, the aeronautical industry has demonstrated its capacity for the development and manufacture of complex elements built with advanced materials. Thus, the main manufacturers (Airbus and Boeing) have increased the use of new materials, mainly plastic matrix composites, in combination with those traditionally used, such as Duralumin alloys of 2XXX or the Al-Zn of 7XXX series, with the aim of reducing aircraft weight, maintaining the structural integrity of the assembly. These materials have undoubted advantages linked to the demand of greater safety, and lower energy consumption and maintenance costs that characterize the air-transport today. Additionally, they provide an excellent relationship between mechanical strength and weight, rigidity and an increase in the life-cycle thanks their good behavior against fatigue and corrosion [

1,

2].

Most of the structural elements used in aircraft construction need to undergo different machining operations, mainly drilling or milling of contours, prior to assembly work through rivets in the Final Assembly Lines (FAL) [

3,

4]. During the assembly tasks in aeronautical structures, these materials are joined in the form of stacks, which must be processed with drilling cycles under strict dimensional and geometric requirements, making it difficult to keep these tolerances under control when the nature of the materials is different [

5,

6,

7,

8].

Indeed, the combination of materials of a different nature has a negative impact during machining operations. On the one hand, both the heterogeneity of the material and the abrasive behavior of the carbon fiber negatively affect the tool life. Therefore, machining conditions and tool geometry must be adapted to these materials in order to reduce tool wear and thermal and mechanical defects produced during the cutting process, such as delamination or thermal damage to the composite matrix [

9,

10,

11]. Moreover, Sorrentino et al. [

12] demonstrated that Abrasive Waterjet Machining (AWJM) extends the high cycle fatigue strength of bolt holes and the fatigue life of bolted composite joints. On the other hand, aluminum alloys tend to modify the geometry of the tool [

13], especially by the development of adhesive phenomena such as Build Up Layer (BUL) or Build Up Edge (BUE) [

5,

14]. The union of these phenomena causes accelerated wear of the tool through the loss of geometry and the increase in temperature reached during the cutting process, which causes a reduction in tool life due to the synergy of the wear mechanisms produced.

This is compounded by problems at the stack interface, such as burring and cleaning due to accumulated chip residues. As a result, the drilling process is complex to carry out in a single step [

15]. Instead, different successive drilling steps must be carried out until the final diameter is obtained, including cleaning the rework at the interface, which does not allow One Way Assembly (OWA) to be achieved as a key technology for process automation.

Alternatively, some authors have conducted studies of machining stacks with unconventional technologies such as laser or AWJM [

10,

16,

17,

18,

19]. In particular, AWJM has been widely studied as one of these machining alternatives to replace contour milling processes, although experimental studies are also beginning to appear, analyzing the influence of drilling on different aeronautical materials,

Table 1. This is mainly due to different factors that positively affect the surface integrity of the final parts. Among them, and in comparison with conventional machining processes, the absence of tool wear, the reduction of residual stresses induced on the surface of the material and the reduction of surface thermal damage as a result of low cutting temperatures should be highlighted [

10,

20,

21].

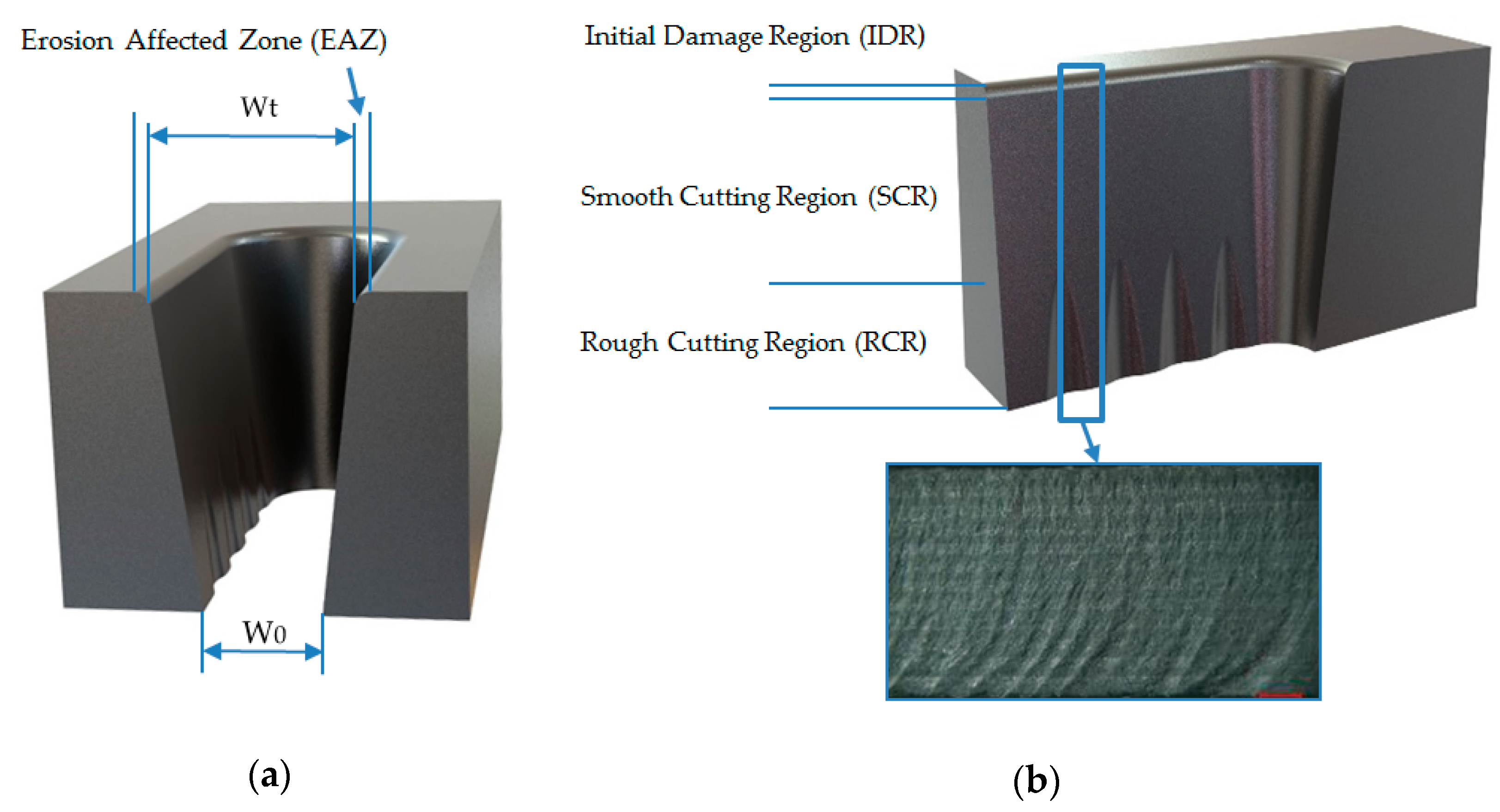

However, the AWJM process shows its own limitations that lead to the appearance of specific defects during the cutting process (

Figure 1). The most common defects in the process are the kerf taper, the Erosion Affected Zone (EAZ) and the formation of three possible different roughness zones along the machined surface [

22]:

- -

Initial Damage Region (IDR). The area where the water jet hits on the material producing EAZ. The roughness in this region is high due to the abrasive particles impacting the material.

- -

Smooth Cutting Region (SCR). The region of variable thickness depending on the cutting parameters. It is the region with the best surface quality because it does not suffer the impact of particles and the jet still has enough kinetic energy to cut.

- -

Rough Cutting Region (RCR). The final region where the jet ends of cut material. The jet has lost enough cutting capacity and produces macrogeometrical defects as striation marks.

Specifically, the removal of material through AWJM is produced by erosion caused by particles that impact the material at high velocity and affect each material differently. In the case of carbon fiber reinforced with plastic matrix, the formation of the erosion process produces the breakage of the fibers and the degradation of the matrix. This prevents the layers of the material from remaining bonded causing the formation of initial cracks that result in delaminations when abrasive particles penetrate between the layers of the composite [

30].

However, some characteristic defects in the final part may occur as a result of the effect of the combination of different parameters. In this article a study based on the influence of the main cutting parameters on AWJM is carried out in order to reduce the appearance of the defects mentioned in stacks formed by the aluminum alloy UNS A97050 and Carbon Fiber Reinforced Plastic (CFRP). To this end, two experiments were carried out based on the operations most required in the machining of aeronautical structures: Straight cuts to analyze the cutting profile and drills to study the viability of the process. Finally, the state of the cuts was evaluated through the use of microscopic inspection techniques and macro and microgeometric deviations.

2. Materials and Methods

For the experimental development a CFRP AIMS 05-01-002 composite plate,

Table 2, and a UNS A97075 aluminum alloy plate with a tensile strength of 496 MPa and a shear strength of 290 MPa have been used. Both 5 mm thickness plates have been mechanically joined by eight bolts to obtain two stack configurations: CFRP/UNS A97075 and UNS A97075/CFRP.

As technological parameters, combinations were made for each configuration of the three most significant parameters: Water pressure (WP), abrasive mass flow rate (AMFR) and traverse feed rating (TFR), due to the influence analyzed in [

31]. The separation distance was kept constant at 3 mm throughout the experimental phase and the abrasive selected was garnet with an average particle size of 80 µm in order to optimize aluminum penetration [

32]. Under these considerations, the experimental design based on levels shown in

Table 3 was established.

To carry out the tests, two experimental blocks for each stack were made. On the one hand, straight cuts were made in order to study the influence on the kerf taper and the different roughness zones. On the other hand, 8 mm holes were drilled to study macrogeometry due to the fact that 7.92 mm is a common drill diameter used in the aeronautical industry. For this purpose, the experimental design and pre-simulation were carried out using the CAD/CAM software Lantek® edition 34.02.02.02.02.02.02, making a total of 48 tests mechanized with a TCI water jet cutting machine model BPC 3020.

For the evaluation of straight cuts, on the one hand, optical evaluation of the machined material has been used by means of Stereoscopic Optical Microscopy (SOM) and Scanning Electronic Microscopy (SEM) techniques, and on the other hand, electron dispersive spectroscopy (EDS) was used to analyze the compositional state of the samples. A Nikon SMZ 800 stereo optical microscope was used for the SOM inspection and the Hitachi SU 1510 microscope was used for the SEM inspection. These techniques were used to study the incrustation of abrasive particles in the IDR zone and in the delaminations produced. In addition, it was used to generate a deeper measurement of the kerf taper. The literature tends to evaluate the taper as the difference between the cutting width of the water inlet and the cutting width of the water outlet depending on the thickness of the plate [

19,

20,

33] as shown in

Figure 2b. However, this process concurs in a high variability depending on two width measures (W

top and W

bottom). Since the IDR may interfere with that extent, this paper proposes a new methodology based on image processing methods, for which ImageJ and Microsoft Excel

® software were used. It consists of capturing the image of the cut and its subsequent digitalization in 10 points with a non-linear distribution, as shown in

Figure 2c. Then, a coefficient between W

top and W

bottom is usually obtained, however as it can be observed in

Figure 2c, the representation of the cut would be unreal. Regarding

Figure 2c, once you remove the IDR the shape of the cut is almost a vertical line. That is why, in this paper, measures to calculate the average width of the cut have been used.

This new methodology does not provide a coefficient as taper measure, but an average distance. A distance that represents, in a more realistic way, the profile of the cut. However, in order to obtain an accurate result, data from the IDR has to be rejected, as is already regarded by some authors [

34]. That way, the cut depth was divided into 10 measures with cosinoidal distribution, ensuring more measures density near the top and the bottom. Then, the measures that maintained a height variation regarding the next measure have been disposed, that is the case of the upper measure and the second one in

Figure 2c. Taking all other measures, an average is calculated and that is the kerf taper vale proposed.

For the evaluation of the holes, a station of measurement Mahr MMQ44 Form Tester (Mahr, Göttingen, Germany) was used to measure the roundness at the entrance and exit of the drill in each material, the cylindricity of the entire profile of the drill, and the straightness in four separate generatrices to 90° as seen in

Figure 3a. To analyze the macrogeometric deviations, replicas of the holes due to the impossibility of direct measuring on the material were fabricated. These replicas were made with a polymer type F80 Ra (R.G.X, Plastiform, Madrid, Spain) with the ability to guarantee stability during the measurement process for diameters greater than 4 mm. It is a two component polymer that solidifies after mixture. Plastiform provides a tool that ensures correct mixture while the polymers are injected into the hole that was replicated. It is a manual process that leads to hole replicas after 10 minutes of polymer solidification.

For the measurement of roughness, the Mahr Perthometer Concept PGK 120 (Mahr, Göttingen, Germany) was employed, as shown in

Figure 3. This measurement was focused on the parameter Average Roughness (Ra), since it is one of the most used roughness parameters in the literature.

Ra analysis performed to the specimens in each test was carried out in three different zones coinciding with IDR, SCR and RCR (

Figure 4). That way, six measures were obtained for each test performed, making a total of 144 roughness measurements.

Finally, to distinguish the most significant parameters for evaluation results, analysis of variance (ANOVA) for a 95% confidence interval was employed. After that, contour charts for each variable studied in the experimental were obtained.