Microstructure and Mechanical Properties of Al–(12-20)Si Bi-Material Fabricated by Selective Laser Melting

Abstract

:1. Introduction

2. Experimental Methods

3. Results and Discussion

4. Conclusions

- (1)

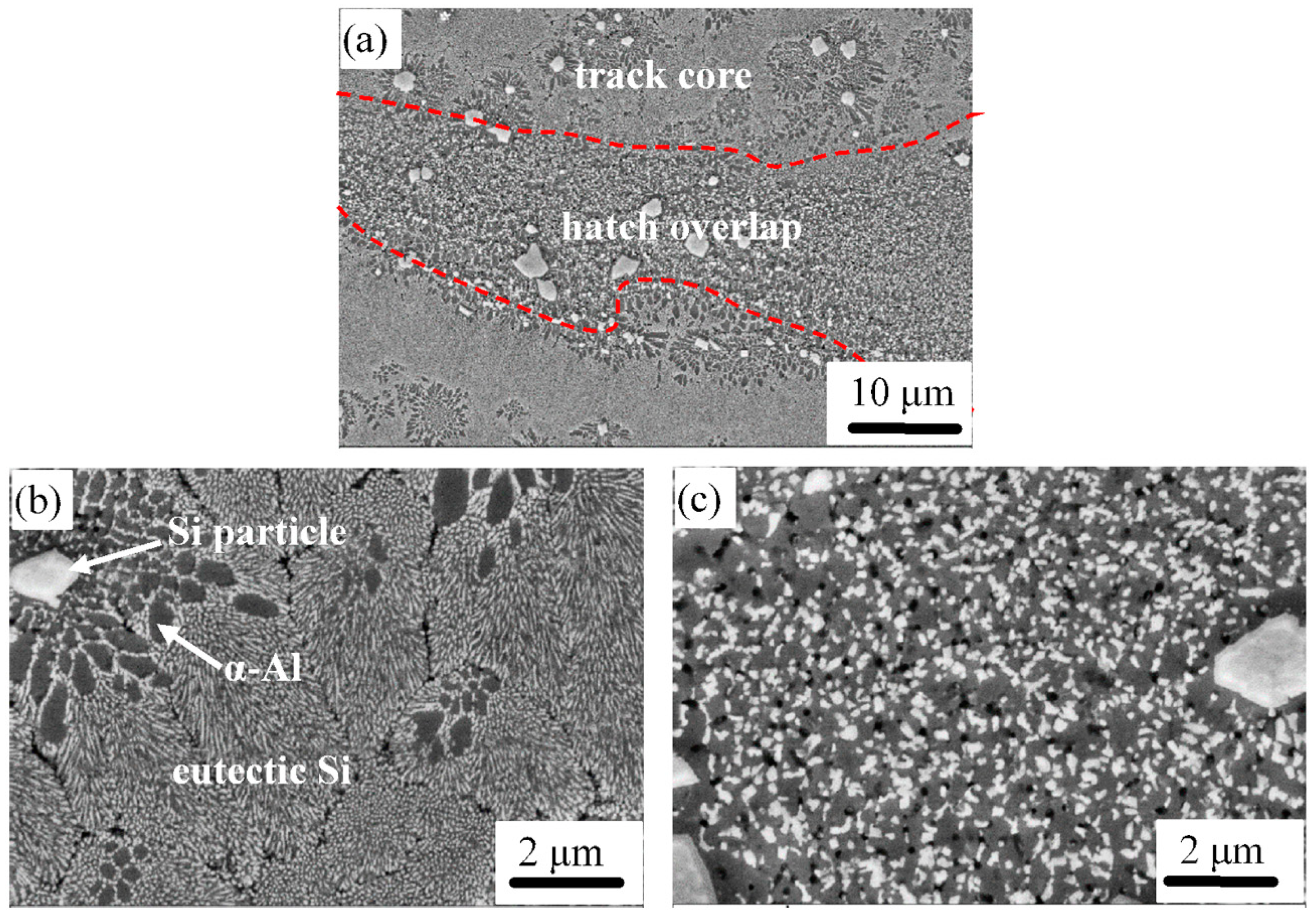

- The interfaces are well bonded and can be evidently observed in the bi-material after SLM, whereas they become blurry and finally disappear with increased heat treatment temperature. The microstructure is well refined along both sides (the Al–12Si side and the Al–20Si side). The hardness difference between both sides gradually decreases when the samples are heat treated at 673 K and the hardness values tend to be consistent.

- (2)

- The tensile strength and elongation of the bi-material after SLM are between that of as-prepared SLM Al–12Si and Al–20Si alloys, and failure occurs along the Al–20Si side with quasi-cleavage fracture. The average yield strength, ultimate tensile strength and elongation of the Al–Si bi-material after SLM are 300 MPa, 450 MPa, and 2.2% respectively.

- (3)

- The yield strength and the ultimate tensile strength decrease to 100 MPa and 130 MPa, respectively, and the elongation increases to 14.1% after heat treatment at 673 K for 6 h. Failure is characterized by a ductile fracture mode as a result of increased Si particle size and a decreased number of Si particles.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gupta, S.; Taupin, V.; Fressengeas, C.; Jrad, M. Geometrically Nonlinear Field Fracture Mechanics and Crack Nucleation, Application to Strain Localization Fields in Al-Cu-Li Aerospace Alloys. Materials 2018, 11, 498. [Google Scholar] [CrossRef] [PubMed]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; Smet, P.D.; Haszler, A.; Vierrgge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Ferreira, V.; Egizabal, P.; Popov, V.; Cortázar, M.G.; Irazustabarrena, A.; López-Sabirón, A.M.; Ferreira, G. Lightweight automotive components based on nano diamond-reinforced aluminium alloy: A technical and environmental evaluation. Diam. Relat. Mater. 2019, 92, 174–186. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of Selective Laser Melting Process Parameters on the Quality of Al Alloy Parts: Powder Characterization, Density, Surface Roughness, and Dimensional Accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Loeber, L.; Schimansky, P.; Pyczak, F.; Eckert, J. In processing of Al-12Si-TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Tensile properties of Al-12Si fabricated via selective laser melting (SLM) at different temperatures. Technologies 2016, 4, 38. [Google Scholar] [CrossRef]

- Koli, D.K.; Agnihotri, G.; Purohit, R. Advanced Aluminium Matrix Composites: The Critical Need of Automotive and Aerospace Engineering Fields. Mater. Today Proc. 2015, 2, 3032–3041. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chatterjee, R.P.; Salman, O.O.; Eckert, J. Additive Manufacturing: Reproducibility of metallic parts. Technologies 2017, 5, 8. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Ma, Y.J.; Jin, Y.S. Effect of Si content on the dry sliding wear properties of spray-deposited Al-Si alloy. Mater. Des. 2004, 25, 163–166. [Google Scholar] [CrossRef]

- Guo, C.Y.; He, X.B.; Ren, S.B.; Qu, X.H. Effect of (0-40) wt % Si addition to Al on the thermal conductivity and thermal expansion of diamond/Al composites by pressure infiltration. J. Alloys Compd. 2016, 664, 777–783. [Google Scholar] [CrossRef]

- Jung, J.G.; Lee, J.M.; Cho, Y.H.; Yoon, W.H. Combined effects of ultrasonic melt treatment, Si addition and solution treatment on the microstructure and tensile properties of multicomponent Al-Si alloys. J. Alloys Compd. 2017, 693, 201–210. [Google Scholar] [CrossRef]

- Li, R.X.; Liu, L.J.; Zhang, L.J.; Sun, J.H.; Shi, Y.J.; Yu, B.Y. Effect of Squeeze casting on Microstructure and Mechanical Properties of Hypereutectic Al-xSi Alloys. J. Mater. Sci. Technol. 2017, 33, 404–410. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shakur Shahabi, H.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Dinnis, C.M.; Taylor, J.A.; Dahle, A.K. As-cast morphology of iron-intermetallics in Al-Si foundry alloys. Scr. Mater. 2005, 53, 955–958. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Yan, X.C.; Li, Q.; Yin, S.; Chen, Z.Y.; Jenkins, R.; Chen, C.Y.; Wang, J.; Ma, W.Y.; Bolot, R.; Lupoi, R.; et al. Mechanical and in vitro study of an isotropic Ti6Al4V lattice structure fabricated using selective laser melting. J. Alloys Compd. 2019, 782, 209–223. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the energy density a reliable parameter for materials synthesis by selective laser melting. Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef]

- Schwab, H.; Prashanth, K.G.; Loeber, L.; Kuehn, U.; Eckert, J. Selective laser melting of Ti-45Nb alloy. Metals 2015, 5, 686–694. [Google Scholar] [CrossRef]

- Jia, Y.D.; Ma, P.; Prashanth, K.G.; Wang, G.; Yi, J.; Scudino, S.; Cao, F.Y.; Sun, J.F.; Eckert, J. Microstructure and thermal expansion behavior of Al-50Si synthesized by selective laser melting. J. Alloys Compd. 2017, 699, 548–553. [Google Scholar] [CrossRef]

- Scudino, S.; Unterfoerfer, C.; Prashanth, K.G.; Attar, H.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Additive manufacturing of Cu-10Sn bronze. Mater. Lett. 2015, 156, 202–204. [Google Scholar] [CrossRef]

- Xi, L.X.; Zhang, H.; Wang, P.; Li, H.C.; Prashanth, K.G.; Lin, K.J.; Kaban, I.; Gu, D.D. Comparative investigation of microstructure, mechanical properties and strengthening mechanisms of Al-12Si/TIB2 fabricated by selective laser melting and hot pressing. Ceram. Int. 2018, 44, 17635–17642. [Google Scholar] [CrossRef]

- Wang, P.; Deng, L.; Prashanth, K.G.; Pauly, S.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of Al-Cu alloys fabricated by selective laser melting of powder mixtures. J. Alloys Compd. 2018, 735, 2263–2266. [Google Scholar] [CrossRef]

- Zhao, X.; Song, B.; Fan, W.R.; Zhang, Y.J.; Shi, Y.S. Selective laser melting of carbon/AlSi10Mg composites: Microstructure, mechanical and electronical properties. J. Alloys Compd. 2016, 665, 271–281. [Google Scholar] [CrossRef]

- Ma, P.; Prashanth, K.G.; Scudino, S.; Jia, Y.D.; Wang, H.W.; Zou, C.M.; Wei, Z.J.; Eckert, J. Influence of Annealing on Mechanical Properties of Al-20Si Processed by Selective Laser Melting. Meterials 2014, 4, 28–36. [Google Scholar] [CrossRef]

- Kang, N.; Coddet, P.; Liao, H.L. Macrosegregation mechanism of primary silicon phase in selective laser melting hypereutectic Al-High Si alloy. J. Alloys Compd. 2016, 662, 259–262. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloys Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Loeber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Ma, P.; Jia, Y.D.; Prashanth, K.G.; Yu, Z.S.; Li, C.G.; Zhao, J.; Yang, S.L.; Huang, L.X. Effect of Si content on the microstructure and properties of Al-Si alloys fabricated using hot extrusion. J. Mater. Res. 2017, 32, 2210–2217. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Damodaram, R.; Scudino, S.; Wang, Z.; Prasad Rao, K.; Eckert, J. Friction welding of Al-12Si parts produced by selective laser melting. Mater. Des. 2014, 57, 632–637. [Google Scholar] [CrossRef]

- Kucukomeroglu, T. Effect of equal-channel angular extrusion on mechanical and wear properties of eutectic Al-12Si alloy. Mater. Des. 2010, 31, 782–789. [Google Scholar] [CrossRef]

- Purcek, G.; Saray, O.; Kul, O. Microstructural Evolution and Mechanical Properties of Severely Deformed Al-12Si Casting Alloy by Equal-Channel Angular Extrusion. Met. Mater. Int. 2010, 16, 145–154. [Google Scholar] [CrossRef]

- Jung, J.G.; Lee, S.H.; Cho, Y.H.; Yoon, W.H.; Ahn, T.Y.; Ahn, Y.S.; Lee, J.M. Effect of transition elements on the microstructure and tensile properties of Al-12Si alloy cast under ultrasonic melt treatment. J. Alloys Compd. 2017, 712, 277–287. [Google Scholar] [CrossRef]

- Wang, Z.; Prashanth, K.G.; Chaubey, A.K.; Löber, L.; Schimansky, F.P.; Pyczak, F.; Zhang, W.W.; Scudino, S.; Eckert, J. Tensile properties of Al-12Si matrix composites reinforced with Ti-Al-based particles. J. Alloys Compd. 2015, 630, 256–259. [Google Scholar] [CrossRef]

- Choi, H.; Konishi, H.; Li, X.C. Al2O3 nanoparticles induced simultaneous refinement and modification of primary and eutectic Si particles in hypereutectic Al-20Si alloy. Mater. Sci. Eng. A 2012, 541, 159–165. [Google Scholar] [CrossRef]

- Kilicaslan, M.F.; Lee, W.R.; Lee, T.H.; Sohn, Y.; Hong, S.J. Effect of Sc addition on the microstructure and mechanical properties of as-atomized and extruded Al-20Si alloys. Mater. Lett. 2012, 71, 164–167. [Google Scholar] [CrossRef]

- Yoon, S.C.; Hong, S.J.; Hong, S.I.; Kim, H.S. Mechanical properties of equal channel angular pressed powder extrudates of a rapidly solidified hypereutectic Al-20 wt % Si alloy. Mater. Sci. Eng. A 2007, 449–451, 966–970. [Google Scholar] [CrossRef]

- Ma, P.; Wei, Z.J.; Jia, Y.D.; Zou, C.M.; Scudino, S.; Prashanth, K.G.; Yu, Z.S.; Yang, S.L.; Li, C.G.; Eckert, J. Effect of high pressure solidification on tensile properties and strengthening mechanisms of Al-20Si. J. Alloys Compd. 2016, 688, 88–93. [Google Scholar] [CrossRef]

- Jung, H.J.; Choi, S.J.; Prashanth, K.G.; Stoica, M.; Scudino, S.; Yi, S.; Kuehn, U.; Kim, D.H.; Kim, K.B.; Eckert, J. Fabricate of Fe-based bulk metallic glass by selective laser melting. Mater. Des. 2015, 86, 703–708. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.S.; Yan, C.Z.; Shi, Y.S. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.Y.; Chen, Z.; Du, J.; He, Y.Y.; Li, J.F.; Zhou, Y.T. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2018, 408, 38–50. [Google Scholar] [CrossRef]

| Composition | Status | UTS (MPa) | YS (MPa) | Elongation (%) |

|---|---|---|---|---|

| Al–20Si | SLM | 500 ± 13 | 340 ± 9 | 1.8 ± 0.1 |

| SLM + 673 K/6 h | 240 ± 7 | 150 ± 3 | 5.0 ± 0.2 | |

| Al–Si bi-material | SLM | 450 ± 11 | 300 ± 9 | 2.2 ± 0.1 |

| SLM + 673 K/6 h | 200 ± 7 | 125 ± 3 | 9.0 ± 0.4 | |

| Al–12Si | SLM | 380 ± 10 | 260 ± 7 | 2.5 ± 0.1 |

| SLM + 673 K/6 h | 130 ± 3 | 100 ± 3 | 14.1 ± 0.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Ma, P.; Jia, Y.; Yu, Z.; Sokkalingam, R.; Shi, X.; Ji, P.; Eckert, J.; Prashanth, K.G. Microstructure and Mechanical Properties of Al–(12-20)Si Bi-Material Fabricated by Selective Laser Melting. Materials 2019, 12, 2126. https://doi.org/10.3390/ma12132126

Zhang S, Ma P, Jia Y, Yu Z, Sokkalingam R, Shi X, Ji P, Eckert J, Prashanth KG. Microstructure and Mechanical Properties of Al–(12-20)Si Bi-Material Fabricated by Selective Laser Melting. Materials. 2019; 12(13):2126. https://doi.org/10.3390/ma12132126

Chicago/Turabian StyleZhang, Shikai, Pan Ma, Yandong Jia, Zhishui Yu, Rathinavelu Sokkalingam, Xuerong Shi, Pengcheng Ji, Juergen Eckert, and Konda Gokuldoss Prashanth. 2019. "Microstructure and Mechanical Properties of Al–(12-20)Si Bi-Material Fabricated by Selective Laser Melting" Materials 12, no. 13: 2126. https://doi.org/10.3390/ma12132126

APA StyleZhang, S., Ma, P., Jia, Y., Yu, Z., Sokkalingam, R., Shi, X., Ji, P., Eckert, J., & Prashanth, K. G. (2019). Microstructure and Mechanical Properties of Al–(12-20)Si Bi-Material Fabricated by Selective Laser Melting. Materials, 12(13), 2126. https://doi.org/10.3390/ma12132126