Evaluation of Mechanical, Physical, and Morphological Properties of Epoxy Composites Reinforced with Different Date Palm Fillers

Abstract

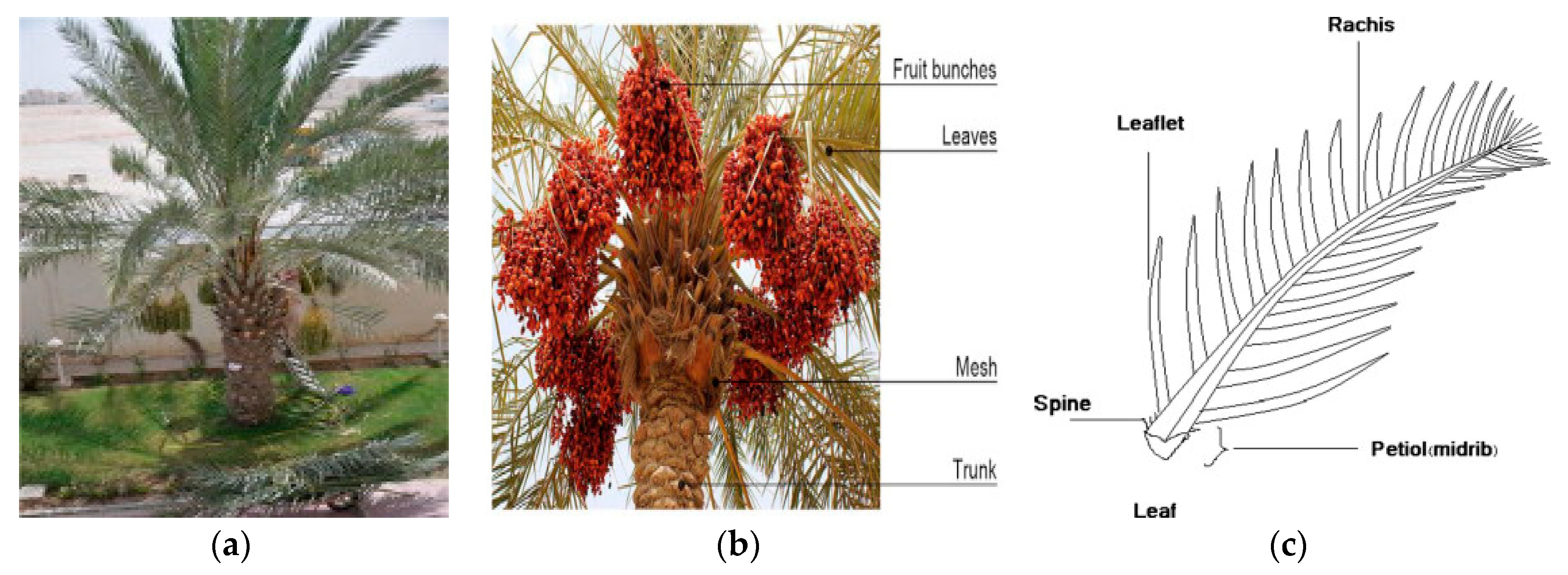

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Fabrication of Composites

3. Characterizations

3.1. Flexural Test

3.2. Tensile Test

3.3. Impact Test

3.4. Water Absorption Test

3.5. Thickness Swelling Test

3.6. Scanning Electron Microscopy (SEM)

4. Results and Discussion

4.1. Flexural Properties

4.2. Tensile Properties

4.3. Impact Strength

4.4. Water Absorption

4.5. Thickness Swelling

4.6. Density

4.7. Morphological Analysis

5. Promising Applications of AA Filler/Epoxy Composites

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saba, N.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.; Sain, M. Mechanical, morphological and structural properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 97, 190–200. [Google Scholar] [CrossRef] [PubMed]

- Saba, N.; Jawaid, M. Epoxy resin based hybrid polymer composites. In Hybrid Polymer Composite Materials: Properties and Characterisation; Elsevier: Cambridge, UK, 2017; pp. 57–82. [Google Scholar]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Lu, B.; Zheng, G.; Dai, K.; Liu, C.; Chen, J.; Shen, C. Enhanced mechanical properties of polyethylene composites with low content of electrospun nylon-66 nanofibers. Mater. Lett. 2015, 140, 131–134. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.; Abdan, K.; Ibrahim, N. Effect of oil palm nano filler on mechanical and morphological properties of kenaf reinforced epoxy composites. Constr. Build. Mater. 2016, 123, 15–26. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.; Abdan, K.; Ibrahim, N. Physical, structural and thermomechanical properties of oil palm nano filler/kenaf/epoxy hybrid nanocomposites. Mater. Chem. Phys. 2016, 184, 64–71. [Google Scholar] [CrossRef]

- Meredith, J.; Coles, S.R.; Powe, R.; Collings, E.; Cozien-Cazuc, S.; Weager, B.; Müssig, J.; Kirwan, K. On the static and dynamic properties of flax and Cordenka epoxy composites. Compos. Sci. Technol. 2013, 80, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Paridah, M.; Al-othman, O. A review on flammability of epoxy polymer, cellulosic and non-cellulosic fiber reinforced epoxy composites. Polym. Adv. Technol. 2016, 27, 577–590. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.; Pua, G.; Jawaid, M.; Islam, M.S. A review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Ghori, W.; Saba, N.; Jawaid, M.; Asim, M. A review on date palm (phoenix dactylifera) fibers and its polymer composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012009. [Google Scholar]

- Gheith, M.H.; Aziz, M.A.; Ghori, W.; Saba, N.; Asim, M.; Jawaid, M.; Alothman, O.Y. Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 853–860. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Nógellová, Z.; Janigová, I.; Krupa, I. Improved mechanical properties of recycled linear low-density polyethylene composites filled with date palm wood powder. Mater. Des. 2014, 58, 209–216. [Google Scholar] [CrossRef]

- Benaimeche, O.; Carpinteri, A.; Mellas, M.; Ronchei, C.; Scorza, D.; Vantadori, S. The influence of date palm mesh fibre reinforcement on flexural and fracture behaviour of a cement-based mortar. Compos. Part B Eng. 2018, 152, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Mirmehdi, S.M.; Zeinaly, F.; Dabbagh, F. Date palm wood flour as filler of linear low-density polyethylene. Compos. Part B Eng. 2014, 56, 137–141. [Google Scholar] [CrossRef]

- Almi, K.; Lakel, S.; Benchabane, A.; Kriker, A. Characterization of date palm wood used as composites reinforcement. Acta Phys. Pol. A 2015, 127, 1072–1074. [Google Scholar] [CrossRef]

- Almi, K.; Benchabane, A.; Lakel, S.; Kriker, A. Potential utilization of date palm wood as composite reinforcement. J. Reinf. Plast. Compos. 2015, 34, 1231–1240. [Google Scholar] [CrossRef]

- Mahdavi, S.; Kermanian, H.; Varshoei, A. Comparison of mechanical properties of date palm fiber-polyethylene composite. BioResources 2010, 5, 2391–2403. [Google Scholar]

- AlMaadeed, M.A.; Nogellova, Z.; Mičušík, M.; Novak, I.; Krupa, I. Mechanical, sorption and adhesive properties of composites based on low density polyethylene filled with date palm wood powder. Mater. Des. 2014, 53, 29–37. [Google Scholar] [CrossRef]

- Abu-Sharkh, B.; Hamid, H. Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: Mechanical and thermal analysis. Polym. Degrad. Stab. 2004, 85, 967–973. [Google Scholar] [CrossRef]

- Al-Kaabi, K.; Al-Khanbashi, A.; Hammami, A. Date palm fibers as polymeric matrix reinforcement: DPF/polyester composite properties. Polym. Compos. 2005, 26, 604–613. [Google Scholar] [CrossRef]

- Dehghani, A.; Ardekani, S.M.; Al-Maadeed, M.A.; Hassan, A.; Wahit, M.U. Mechanical and thermal properties of date palm leaf fiber reinforced recycled poly (ethylene terephthalate) composites. Mater. Des. (1980–2015) 2013, 52, 841–848. [Google Scholar] [CrossRef]

- Alodan, H.A.; Alsuhybani, M.S.; Alshammari, B.A.; Alkhuraiji, T.S. Effect of Fiber Loading on Physical, Mechanical, and Thermal Properties of Low Density Polyethylene/Palm Tree Waste Fiber Composites. Sci. Adv. Mater. 2018, 10, 1341–1350. [Google Scholar] [CrossRef]

- Adel, A.; El-Shafei, A.; Ibrahim, A.; Al-Shemy, M. Extraction of oxidized nanocellulose from date palm (Phoenix Dactylifera L.) sheath fibers: Influence of CI and CII polymorphs on the properties of chitosan/bionanocomposite films. Ind. Crops Prod. 2018, 124, 155–165. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Bourmaud, A.; Dhakal, H.; Habrant, A.; Padovani, J.; Siniscalco, D.; Ramage, M.H.; Beaugrand, J.; Shah, D.U. Exploring the potential of waste leaf sheath date palm fibres for composite reinforcement through a structural and mechanical analysis. Compos. Part A Appl. Sci. Manuf. 2017, 103, 292–303. [Google Scholar] [CrossRef] [Green Version]

- Oushabi, A.; Sair, S.; Abboud, Y.; Tanane, O.; El Bouari, A. An experimental investigation on morphological, mechanical and thermal properties of date palm particles reinforced polyurethane composites as new ecological insulating materials in building. Case Stud. Constr. Mater. 2017, 7, 128–137. [Google Scholar] [CrossRef]

- Chikhi, M. Young’s modulus and thermophysical performances of bio-sourced materials based on date palm fibers. Energy Build. 2016, 129, 589–597. [Google Scholar] [CrossRef]

- Abdelaziz, S.; Guessasma, S.; Bouaziz, A.; Hamzaoui, R.; Beaugrand, J.; Souid, A.A. Date palm spikelet in mortar: Testing and modelling to reveal the mechanical performance. Constr. Build. Mater. 2016, 124, 228–236. [Google Scholar] [CrossRef]

- Dhakal, H.; Bourmaud, A.; Berzin, F.; Almansour, F.; Zhang, Z.; Shah, D.U.; Beaugrand, J. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind. Crops Prod. 2018, 126, 394–402. [Google Scholar] [CrossRef] [Green Version]

- Benzidane, R.; Sereir, Z.; Bennegadi, M.; Doumalin, P.; Poilâne, C. Morphology, static and fatigue behavior of a natural UD composite: The date palm petiole ‘wood’. Compos. Struct. 2018, 203, 110–123. [Google Scholar] [CrossRef]

- Lassoued, M.; Mnasri, T.; Hidouri, A.; Younes, R.B. Thermomechanical behavior of Tunisian palm fibers before and after alkalization. Constr. Build. Mater. 2018, 170, 121–128. [Google Scholar] [CrossRef]

- Swain, P.T.R.; Das, S.N.; Jena, S.P. Manufacturing and Study of Thermo-Mechanical Behaviour of Surface Modified Date Palm Leaf/Glass Fiber Reinforced Hybrid Composite. Mater. Today Proc. 2018, 5, 18332–18341. [Google Scholar] [CrossRef]

- Alshabanat, M. Morphological, thermal, and biodegradation properties of LLDPE/treated date palm waste composite buried in a soil environment. J. Saudi Chem. Soc. 2019, 23, 355–364. [Google Scholar] [CrossRef]

- Ibrahim, H.; Farag, M.; Megahed, H.; Mehanny, S. Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr. Polym. 2014, 101, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Poulose, A.M.; Elnour, A.Y.; Anis, A.; Shaikh, H.; Al-Zahrani, S.; George, J.; Al-Wabel, M.I.; Usman, A.R.; Ok, Y.S.; Tsang, D.C.; et al. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total Environ. 2018, 619, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Ghofrani, M.; Ashori, A.; Mehrabi, R. Mechanical and acoustical properties of particleboards made with date palm branches and vermiculite. Polym. Test. 2017, 60, 153–159. [Google Scholar] [CrossRef]

- Zadeh, K.M.; Ponnamma, D.; Al-Maadeed, M.A.A. Date palm fibre filled recycled ternary polymer blend composites with enhanced flame retardancy. Polym. Test. 2017, 61, 341–348. [Google Scholar] [CrossRef]

- Masri, T.; Ounis, H.; Sedira, L.; Kaci, A.; Benchabane, A. Characterization of new composite material based on date palm leaflets and expanded polystyrene wastes. Constr. Build. Mater. 2018, 164, 410–418. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B. Influence of date palm fibre and graphite filler on mechanical and wear characteristics of epoxy composites. Mater. Des. 2014, 59, 264–273. [Google Scholar] [CrossRef]

- Alsaeed, T.; Yousif, B.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- ASTM Inernational. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM D790-07; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Shahroze, R.M. Effect of Freezing Temperature and Stacking Sequence on the Mechanical Properties of Hybrid Fibre Metal Laminates Made with Carbon, Flax, and Sugar Palm Fibres. BioResources 2019, 14, 3042–3056. [Google Scholar]

- Shrivastava, R.; Telang, A.; Rana, R.S.; Purohit, R. Mechanical Properties of Coir/G Lass Fiber Epoxy Resin Hybrid Composite. Mater. Today Proc. 2017, 4, 3477–3483. [Google Scholar] [CrossRef]

- Sohn, J.S.; Ryu, Y.; Yun, C.S.; Zhu, K.; Cha, S.W. Extrusion Compounding Process for the Development of Eco-Friendly SCG/PP Composite Pellets. Sustainability 2019, 11, 1720. [Google Scholar] [CrossRef]

- Panda, B.P.; Mohanty, S.; Nayak, S.K. Mechanical behavior and fracture toughness evaluation of multiphase polymer nanocomposites using impact and-integral via locus method. Chin. J. Eng. 2013, 2013, 245718. [Google Scholar] [CrossRef]

- Adam, N.A.; Asik, J. Mechanical performance of oil palm empty fruit bunches fibre reinforced polyester resin. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 469. [Google Scholar]

- Razak, N.W.A.; Anizah, K. Effect of OPEFB size on the mechanical properties and water absorption behaviour of OPEFB/PPnanoclay/PP hybrid composites. Procedia Eng. 2012, 41, 1593–1599. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Freitag, C.; Morrell, J.J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Adekomaya, O.; Adama, K. Investigating water absorption and thickness swelling tendencies of polymeric composite materials for external wall application in refrigerated vehicles. Niger. J. Technol. 2018, 37, 167–172. [Google Scholar] [CrossRef]

- Manickam, C.; Kumar, J.; Athijayamani, A.; Easter Samuel, J. Effect of various water immersions on mechanical properties of roselle fiber–vinyl ester composites. Polym. Compos. 2015, 36, 1638–1646. [Google Scholar] [CrossRef]

- Omoniyi, T.E. Potential of Oil Palm (Elaeisguineensis) Empty Fruit Bunch Fibres Cement Composites for Building Applications. AgriEngineering 2019, 1, 153–163. [Google Scholar] [CrossRef]

- Sana, R.; Foued, K.; Yosser, B.M.; Mounir, J.; Slah, M.; Bernard, D. Flexural properties of typha natural fiber-reinforced polyester composites. Fibers Polym. 2015, 16, 2451–2457. [Google Scholar] [CrossRef]

- Safri, S.N.; Sultan, M.T.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Chen, R.S.; Ab Ghani, M.H.; Salleh, M.N.; Ahmad, S.; Tarawneh, M.A.A. Mechanical, water absorption, and morphology of recycled polymer blend rice husk flour biocomposites. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Binoj, J.; Raj, R.E.; Sreenivasan, V.; Thusnavis, G.R. Morphological, physical, mechanical, chemical and thermal characterization of sustainable indian areca fruit husk fibers (Areca Catechu L.) as potential alternate for hazardous synthetic fibers. J. Bionic Eng. 2016, 13, 156–165. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.; Jawaid, M.; Zahari, N.I. Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Senthilkumar, K.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Rajini, N.; Alothman, O.Y.; Siengchin, S. Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr. Build. Mater. 2019, 195, 423–431. [Google Scholar] [CrossRef]

- Negawo, T.A.; Polat, Y.; Buyuknalcaci, F.N.; Kilic, A.; Saba, N.; Jawaid, M. Mechanical, morphological, structural and dynamic mechanical properties of alkali treated Ensete stem fibers reinforced unsaturated polyester composites. Compos. Struct. 2019, 207, 589–597. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.A.; Liu, W.B. The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: Mechanical, thermal and water absorption properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Arpitha, G.; Yogesha, B. An overview on mechanical property evaluation of natural fiber reinforced polymers. Mater. Today Proc. 2017, 4, 2755–2760. [Google Scholar] [CrossRef]

- Al-Khanbashi, A.; Al-Kaabi, K.; Hammami, A. Date palm fibers as polymeric matrix reinforcement: Fiber characterization. Polym. Compos. 2005, 26, 486–497. [Google Scholar] [CrossRef]

- Poletto, M.; Zeni, M.; Zattera, A.J. Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. J. Thermoplast. Compos. Mater. 2012, 25, 821–833. [Google Scholar] [CrossRef]

- Mallick, P.K. Failure of polymer matrix composites (PMCs) in automotive and transportation applications. In Failure Mechanisms in Polymer Matrix Composites; Woodhead Publishing: Cambridge, UK, 2012; pp. 368–392. [Google Scholar]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Leman, Z.; Sapuan, S.; Saifol, A.; Maleque, M.; Ahmad, M. Moisture absorption behavior of sugar palm fiber reinforced epoxy composites. Mater. Des. 2008, 29, 1666–1670. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.; Zainudin, E.; Maleque, M. Effect of water absorption on mechanical properties of sugar palm fibre reinforced sugar palm starch (SPF/SPS) biocomposites. J. Biobased Mater. Bioenergy 2013, 7, 90–94. [Google Scholar] [CrossRef]

- Shakeri, A.; Ghasemian, A. Water absorption and thickness swelling behavior of polypropylene reinforced with hybrid recycled newspaper and glass fiber. Appl. Compos. Mater. 2010, 17, 183–193. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Chen, T.; Liu, W.; Qiu, R. Mechanical properties and water absorption of hemp fibers–reinforced unsaturated polyester composites: Effect of fiber surface treatment with a heterofunctional monomer. BioResources 2013, 8, 2780–2791. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.M.; Abdan, K.; Ibrahim, N.A. Fabrication of epoxy nanocomposites from oil palm nano filler: Mechanical and morphological properties. BioResources 2016, 11, 7721–7736. [Google Scholar] [CrossRef]

- Ali, M.E.; Alabdulkarem, A. On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

| Date Palm Fibers | Polymer Matrix | References |

|---|---|---|

| Date palm sheath fibers | Commercial chitosan | [25] |

| Alkali treated DPF | Polyurethane | [26] |

| Alkali treated date palm leaf fibers | Recycled poly (ethylene-terephthalate) | [23] |

| Leaf sheath DPF | - | [27] |

| Date palm particles | Rigid Polyurethane | [28] |

| DPF (petiole, bunches and rachis) | Gypsum | [29] |

| Date palm spikelet | Mortar | [30] |

| Date palm sheath fibers | Polycaprolactone | [31] |

| Date palm petiole wood | Parenchyma (matrix). | [32] |

| Alkali treated date palm petiole fibers | - | [33] |

| Hybridized date palm leaf/Glass fibers | Epoxy | [34] |

| Date palm wastes | Linear-low density polyethylene matrix | [35] |

| Hybridized date palm and flax fibers | Thermoplastic starch | [36] |

| Pyrolysis date palm waste biochar | PP homo-polymer | [37] |

| Date palm mesh fibres | Cement-based mortar | [15] |

| Date palm stem fibres | Epoxy | [13] |

| Date palm branches and expanded vermiculite | Particleboard | [38] |

| DPF | Recycled polypropylene and LDPE/High density polyethylene ternary blends | [39] |

| Date palm leaflets | Expanded polystyrene | [40] |

| DPF/Graphite filler | Epoxy | [41] |

| Date palm wood flour (rachis, leaflet and leaf) | Polyethylene | [16] |

| Date palm wood powder | LDPE | [20] |

| Date palm wood powder | Recycled linear LDPE | [14] |

| DPF | Cellulose | Hemicellulose | Lignin |

|---|---|---|---|

| A (Palm tree leaf stalk) | 35.00% | 15.40% | 20.10% |

| AA (Palm tree fruit bunch stalk) | 44.00% | 26.00% | 11.00% |

| G (Leaf sheath fiber) | 43.50% | 24.00% | 18.00% |

| L(Palm tree trunk fiber) | 40.00% | 9.75% | 29.50% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshammari, B.A.; Saba, N.; Alotaibi, M.D.; Alotibi, M.F.; Jawaid, M.; Alothman, O.Y. Evaluation of Mechanical, Physical, and Morphological Properties of Epoxy Composites Reinforced with Different Date Palm Fillers. Materials 2019, 12, 2145. https://doi.org/10.3390/ma12132145

Alshammari BA, Saba N, Alotaibi MD, Alotibi MF, Jawaid M, Alothman OY. Evaluation of Mechanical, Physical, and Morphological Properties of Epoxy Composites Reinforced with Different Date Palm Fillers. Materials. 2019; 12(13):2145. https://doi.org/10.3390/ma12132145

Chicago/Turabian StyleAlshammari, Basheer A., Naheed Saba, Majed D. Alotaibi, Mohammed F. Alotibi, Mohammad Jawaid, and Othman Y. Alothman. 2019. "Evaluation of Mechanical, Physical, and Morphological Properties of Epoxy Composites Reinforced with Different Date Palm Fillers" Materials 12, no. 13: 2145. https://doi.org/10.3390/ma12132145

APA StyleAlshammari, B. A., Saba, N., Alotaibi, M. D., Alotibi, M. F., Jawaid, M., & Alothman, O. Y. (2019). Evaluation of Mechanical, Physical, and Morphological Properties of Epoxy Composites Reinforced with Different Date Palm Fillers. Materials, 12(13), 2145. https://doi.org/10.3390/ma12132145