Experimental and Numerical Study of Viscoelastic Properties of Polymeric Interlayers Used for Laminated Glass: Determination of Material Parameters

Abstract

1. Introduction

2. Material Model

2.1. Overview

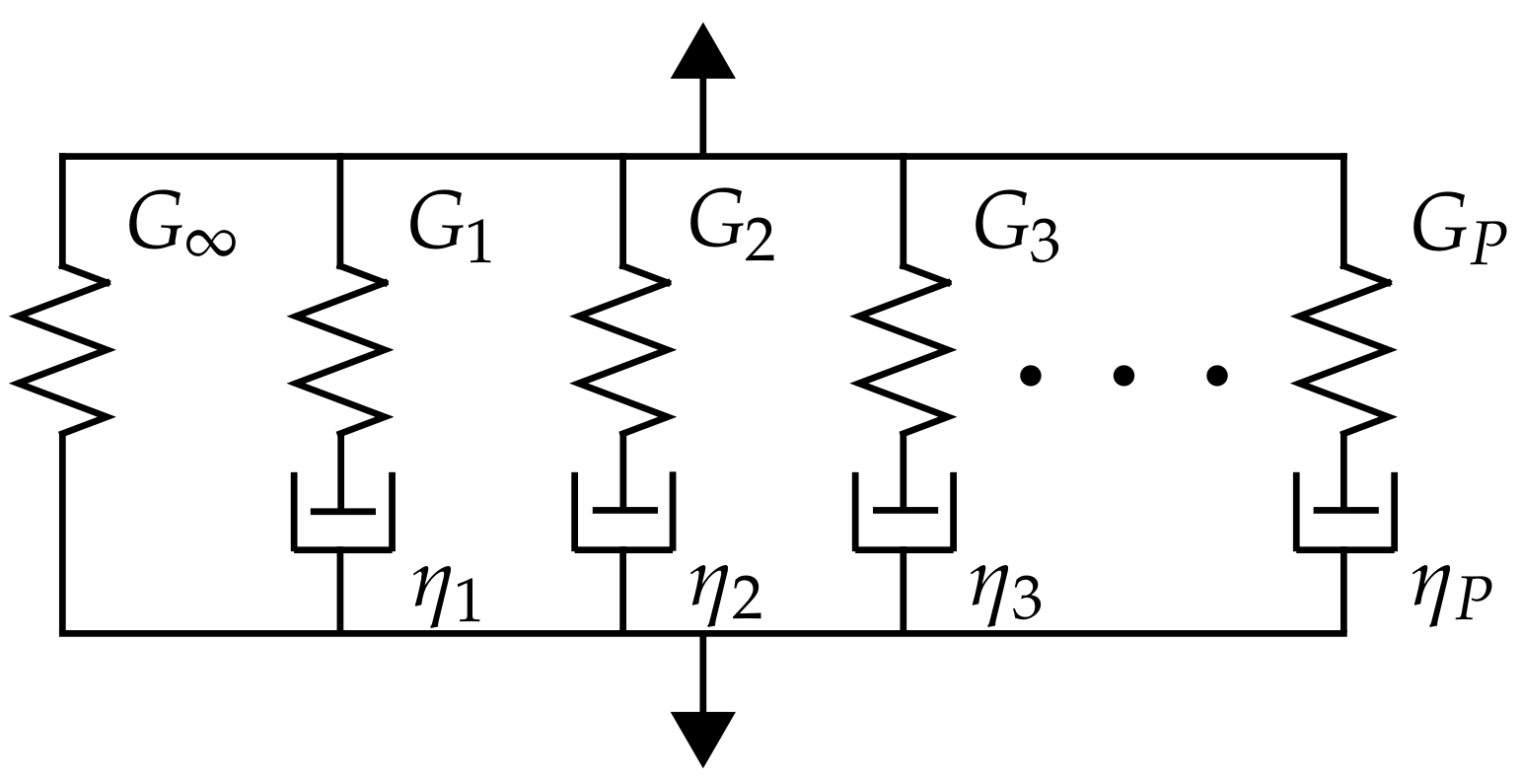

2.2. Generalized Maxwell Model

2.3. Temperature Shifting

2.4. Parameter Identification

3. Experimental Methods

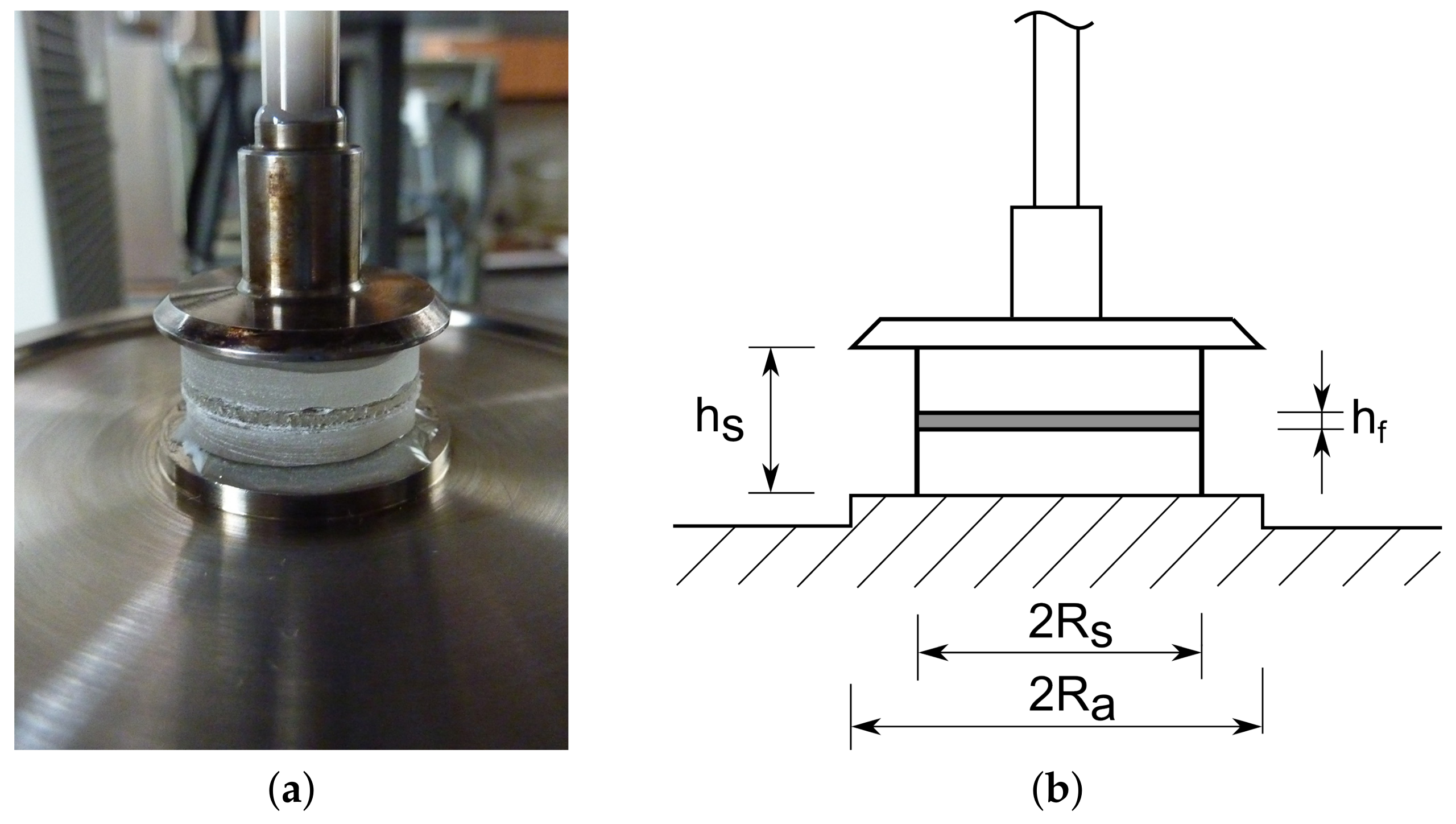

3.1. Dynamic Single-Lap Shear Test

3.1.1. Test Setup

3.1.2. Method of Results Evaluation

3.2. Dynamic Torsion Tests

3.2.1. Test Set-Up

3.2.2. Method of Results Evaluation

4. Results

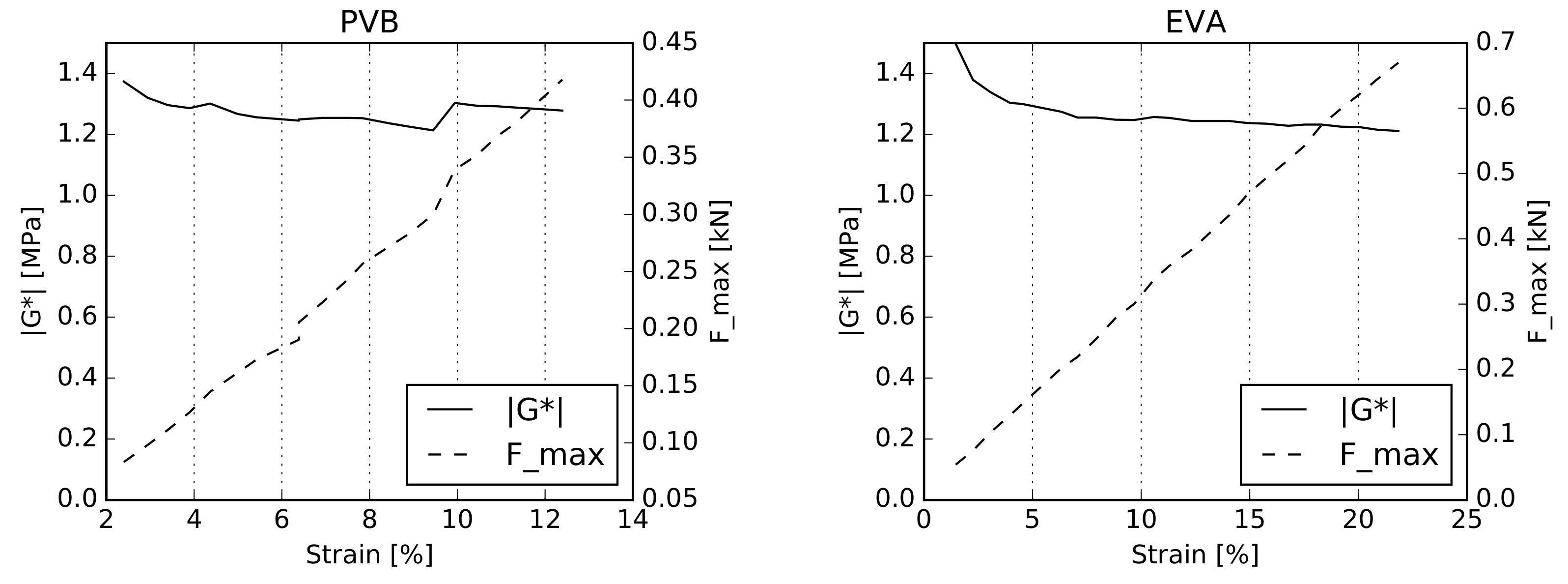

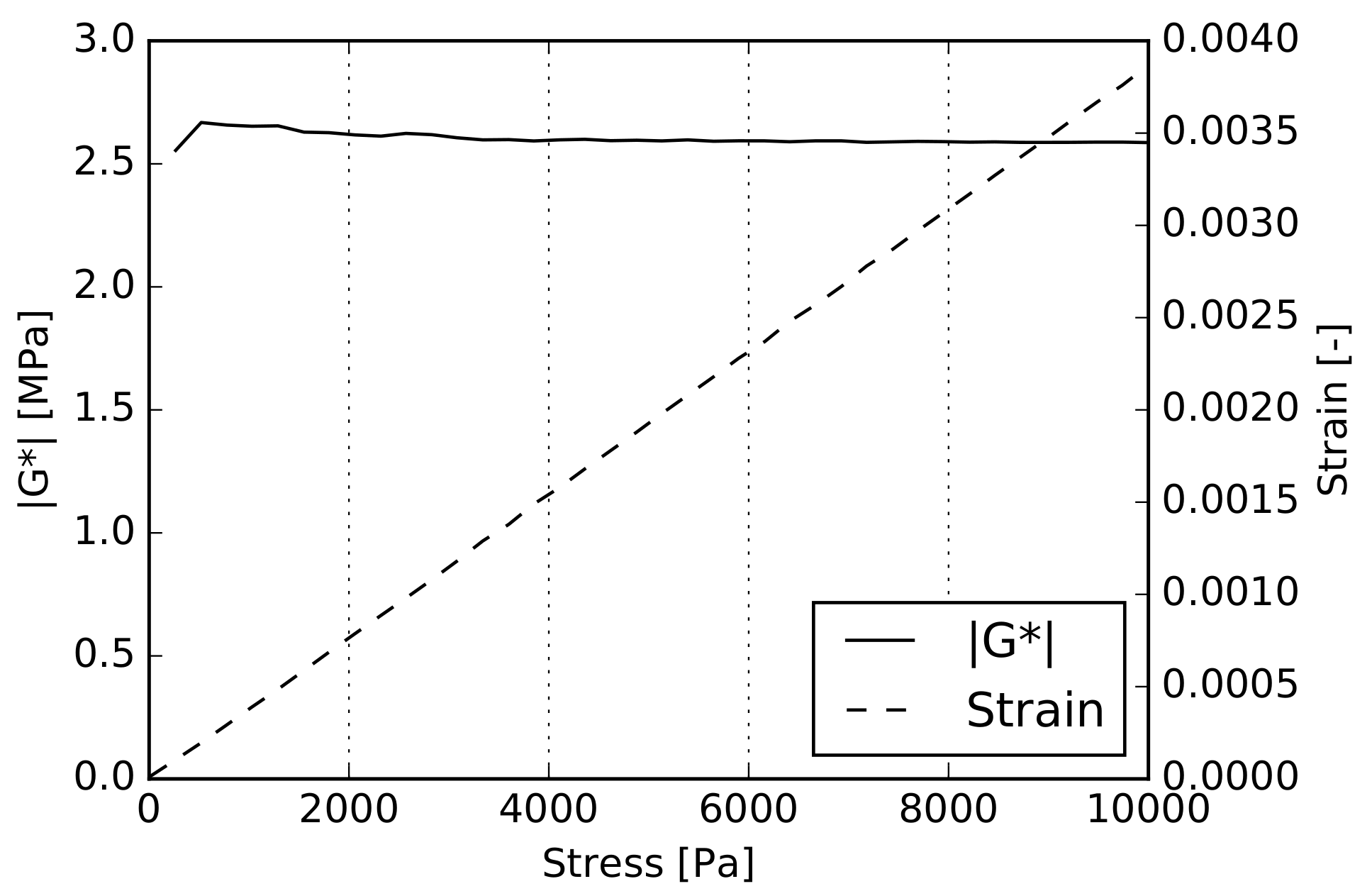

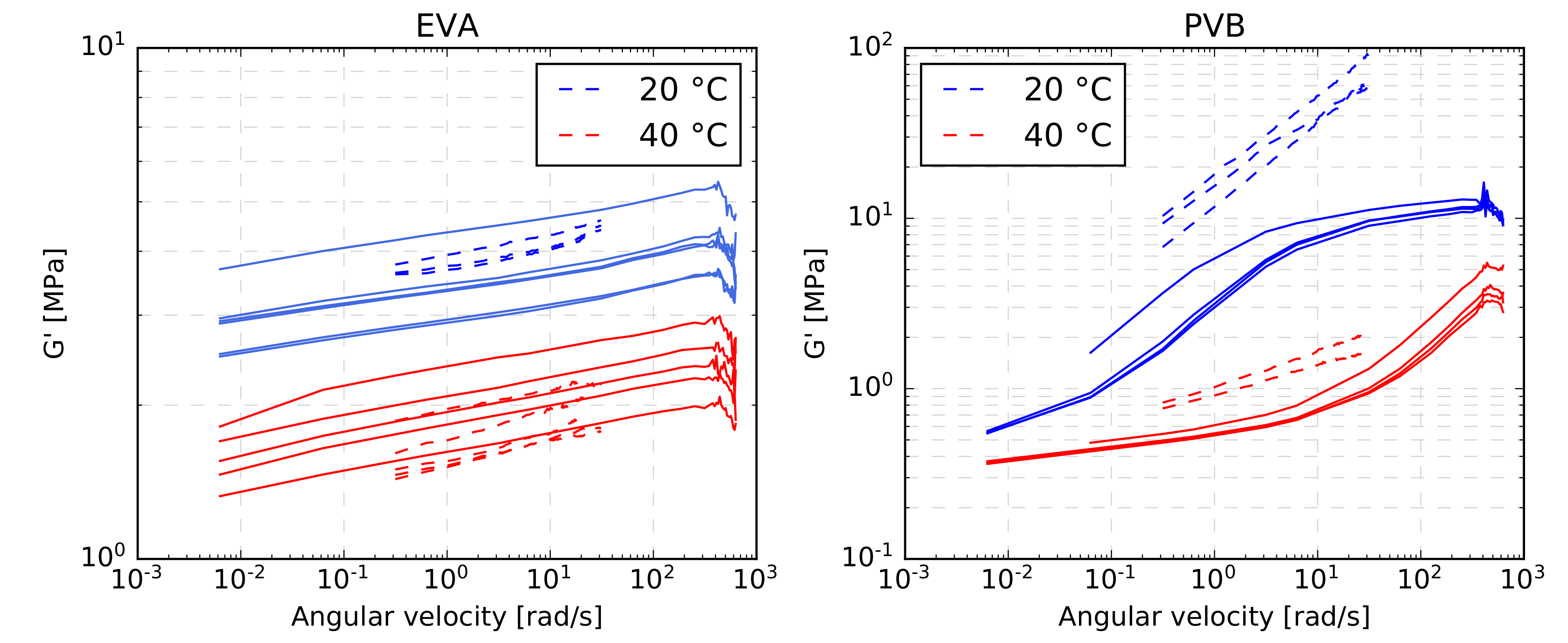

4.1. Linearity Validation

4.2. Comparison of Obtained Results

4.3. Identification of the Maxwell Model

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ward, I.M.; Hadley, D.W. AN Introduction to the Mechanical Properties of Solid Polymers; John Wiley & Sons, Inc.: Chichester, NY, USA, 1993. [Google Scholar]

- Hooper, P.; Blackman, B.; Dear, J. The mechanical behaviour of poly (vinyl butyral) at different strain magnitudes and strain rates. J. Mater. Sci. 2012, 47, 3564–3576. [Google Scholar] [CrossRef]

- Kraus, M.A.; Schuster, M.; Kuntsche, J.; Siebert, G.; Schneider, J. Parameter identification methods for visco-and hyperelastic material models. Glass Struct. Eng. 2017, 2, 147–167. [Google Scholar] [CrossRef]

- Mohagheghian, I.; Wang, Y.; Jiang, L.; Zhang, X.; Guo, X.; Yan, Y.; Kinloch, A.; Dear, J. Quasi-static bending and low velocity impact performance of monolithic and laminated glass windows employing chemically strengthened glass. Eur. J. Mech. A Solids 2017, 63, 165–186. [Google Scholar] [CrossRef]

- Bennison, S.J.; Qin, M.H.; Davies, P.S. High-performance laminated glass for structurally efficient glazing. In Innovative Light-Weight Structures and Sustainable Facades; Hong Kong, 2008; Available online: http://www2.dupont.com/SafetyGlass/ja_JP/assets/pdfs/Bennison_Lightweight_Structures.pdf (accessed on 10 July 2019).

- Zemanová, A.; Janda, T.; Zeman, J.; Schmidt, J.; Šejnoha, M. Effect of Interlayer Mechanical Properties on Quasi-static and Free Vibration Response of Laminated Glass. Chall. Glass Conf. Proc. 2018, 6, 485–494. [Google Scholar]

- Castori, G.; Speranzini, E. Structural analysis of failure behavior of laminated glass. Compos. Part B Eng. 2017, 125, 89–99. [Google Scholar] [CrossRef]

- Biolzi, L.; Cagnacci, E.; Orlando, M.; Piscitelli, L.; Rosati, G. Long term response of glass–PVB double-lap joints. Compos. Part B Eng. 2014, 63, 41–49. [Google Scholar] [CrossRef]

- Shitanoki, Y.; Bennison, S.J.; Koike, Y. A practical, nondestructive method to determine the shear relaxation modulus behavior of polymeric interlayers for laminated glass. Polym. Test. 2014, 37, 59–67. [Google Scholar] [CrossRef]

- Duser, A.V.; Jagota, A.; Bennison, S.J. Analysis of glass/polyvinyl butyral laminates subjected to uniform pressure. J. Eng. Mech. 1999, 125, 435–442. [Google Scholar] [CrossRef]

- Hooper, P.; Sukhram, R.; Blackman, B.; Dear, J. On the blast resistance of laminated glass. Int. J. Solids Struct. 2012, 49, 899–918. [Google Scholar] [CrossRef]

- Schiessel, H.; Metzler, R.; Blumen, A.; Nonnenmacher, T. Generalized viscoelastic models: Their fractional equations with solutions. J. Phys. A Math. Gen. 1995, 28, 6567. [Google Scholar] [CrossRef]

- Renaud, F.; Dion, J.L.; Chevallier, G.; Tawfiq, I.; Lemaire, R. A new identification method of viscoelastic behavior: Application to the generalized Maxwell model. Mech. Syst. Signal Process. 2011, 25, 991–1010. [Google Scholar] [CrossRef]

- Paggi, M.; Sapora, A. An accurate thermoviscoelastic rheological model for ethylene vinyl acetate based on fractional calculus. Int. J. Photoenergy 2015, 2015, 252740. [Google Scholar] [CrossRef]

- Eitner, U. Thermomechanics of Photovoltaic Modules. Ph.D. Thesis, Martin-Luther-Universität Halle-Wittenberg, Halle, Germany, 2011. [Google Scholar]

- Zienkiewicz, O.; Watson, M.; King, I. A numerical method of visco-elastic stress analysis. Int. J. Mech. Sci. 1968, 10, 807–827. [Google Scholar] [CrossRef]

- Zemanová, A.; Zeman, J.; Janda, T.; Šejnoha, M. Layer-wise numerical model for laminated glass plates with viscoelastic interlayer. Struct. Eng. Mech. 2018, 65, 369–380. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Jirásek, M. Numerical Analysis of Creep Problems. In Creep and Hygrothermal Effects in Concrete Structures; Springer: Dordrecht, The Netherlands, 2018; pp. 141–175. [Google Scholar] [CrossRef]

- Xiao, R.; Sun, H.; Chen, W. An equivalence between generalized Maxwell model and fractional Zener model. Mech. Mater. 2016, 100, 148–153. [Google Scholar] [CrossRef]

- Sasso, M.; Palmieri, G.; Amodio, D. Application of fractional derivative models in linear viscoelastic problems. Mech. Time Depend. Mater. 2011, 15, 367–387. [Google Scholar] [CrossRef]

- Lesieutre, G.A.; Lee, U. A finite element for beams having segmented active constrained layers with frequency-dependent viscoelastics. Smart Mater. Struct. 1996, 5, 615. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- Kraus, M.; Niederwald, M. Generalized collocation method using Stiffness matrices in the context of the Theory of Linear viscoelasticity (GUSTL). Tech. Mech. 2017, 37, 82–106. [Google Scholar]

- Louter, C.; Belis, J.; Veer, F.; Lebet, J.P. Durability of SG-laminated reinforced glass beams: Effects of temperature, thermal cycling, humidity and load-duration. Constr. Build. Mater. 2012, 27, 280–292. [Google Scholar] [CrossRef]

- Schwarzl, F. Polymermechanik—Struktur und Mechanisches Verhalten von Polymeren; Springer: Berlin/Heidelberg, Germany, 1990. [Google Scholar]

- Brinson, H.F.; Brinson, L.C. Polymer Engineering Science and Viscoelasticity; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Williams, M.; Landel, R.; Ferry, J. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- CEN/TC 129. Draft PrEN 16613: Glass in Building—Laminated Glass And Laminated Safety Glass—Determination of Interlayer Mechanical Properties; Technical Report; European Committee for Standardization (CEN): Brussels, Belgium, 2013. [Google Scholar]

- Kraus, M.; Niederwald, M.; Siebert, G.; Keuser, M. Rheological modelling of linear viscoelastic materials for strengthening in bridge engineering. In Proceedings of the 11th German Japanese Bridge Symposium, Osaka, Japan, 30–31 August 2016. [Google Scholar]

- Kuntsche, J.; Schuster, M.; Schneider, J.; Langer, S. Viscoelastic properties of laminated glass interlayers: Theory and experiments. Proceedings of Glass Performance Days, Tampere, Finland, 24–26 June 2015; pp. 143–147. [Google Scholar]

- Juang, Y.; Lee, L.J.; Koelling, K.W. Rheological Analysis of Polyvinyl Butyral Near the Glass Transition Temperature. Polym. Eng. Sci. 2001, 41, 275–292. [Google Scholar] [CrossRef]

- Yang, T.C.K.; Chang, W.H.; Viswanath, D.S. Thermal degradation of poly (vinyl butyral) in alumina, mullite and silica composites. J. Therm. Anal. 1996, 47, 697–713. [Google Scholar] [CrossRef]

- Barrientos, E.; Pelayo, F.; Noriega, Á.; Lamela, M.J.; Fernández-Canteli, A.; Tanaka, E. Optimal discrete-time Prony series fitting method for viscoelastic materials. Mech. Time Depend. Mater. 2018, 23, 193–206. [Google Scholar] [CrossRef]

- Nelder, J.A.; Mead, R. A Simplex Method for Function Minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Pelayo, F.; Lamela-Rey, M.J.; Muniz-Calvente, M.; López-Aenlle, M.; Álvarez-Vázquez, A.; Fernández-Canteli, A. Study of the time-temperature-dependent behaviour of PVB: Application to laminated glass elements. Thin Walled Struct. 2017, 119, 324–331. [Google Scholar] [CrossRef]

- Andreozzi, L.; Bati, S.B.; Fagone, M.; Ranocchiai, G.; Zulli, F. Dynamic torsion tests to characterize the thermo-viscoelastic properties of polymeric interlayers for laminated glass. Constr. Build. Mater. 2014, 65, 1–13. [Google Scholar] [CrossRef]

- Pelayo, F.; López-Aenlle, M.; Hermans, L.; Fraile, A. Modal Scaling of a Laminated Glass Plate. In Proceedings of the 5th International Operational Modal Analysis Conference, Guimaraes, Portugal, 13–15 May 2013; pp. 1–10. [Google Scholar]

- Feldman, M.; Kaspar, R.; Abeln, B.; Gessler, A.; Langosch, K.; Beyer, J.; Scheider, J.; Schula, S.; Siebert, G.; Haese, A.; et al. Guidance for European Structural Design of Glass Components; Report EUR 26439 EN; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Ranocchiai, G.; Zulli, F.; Andreozzi, L.; Fagone, M. Test Methods for the Determination of Interlayer Properties in Laminated Glass. J. Mater. Civ. Eng. 2016, 29, 04016268. [Google Scholar]

- Zhang, E.; Chazot, J.D.; Antoni, J.; Hamdi, M. Bayesian characterization of Young’s modulus of viscoelastic materials in laminated structures. J. Sound Vib. 2013, 332, 3654–3666. [Google Scholar] [CrossRef]

- Lakes, R. Viscoelastic Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Schmidt, J.; Janda, T.; Šejnoha, M. Experimental determination of visco-elasic properties of laminated glass interlayer. In Engineering Mechanics 2017—Book of Full Texts; Brno University of Technology, Institute of Solid Mechanics, Mechatronics and Biomechanics: Brno, Czech Republic, 2017; pp. 850–853. [Google Scholar]

- Hana, T.; Eliasova, M.; Machalicka, K.; Vokac, M. Determination of PVB interlayer´s shear modulus and its effect on normal stress distribution in laminated glass panels. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012076. [Google Scholar] [CrossRef]

| Polymer | PVB | EVA | |||||

| Long-term shear modulus | 232.26 | 682.18 | kPa | ||||

| Reference temperature | 20 | 20 | |||||

| Parameters | 8.635 | 339.102 | – | ||||

| 42.422 | 1185.816 | ||||||

| PVB | EVA | PVB | EVA | ||||

| θp | Gp | Gp | θp | Gp | Gp | ||

| [s] | [kPa] | [kPa] | [s] | [kPa] | [kPa] | ||

| 1 | – | 6933.9 | 12 | 587.2 | 445.1 | ||

| 2 | – | 3898.6 | 13 | 258.0 | 300.1 | ||

| 3 | – | 2289.2 | 14 | 63.8 | 401.6 | ||

| 4 | – | 1672.7 | 15 | 168.4 | 348.1 | ||

| 5 | 1,782,124.2 | 761.6 | 16 | – | 111.6 | ||

| 6 | 519,208.7 | 2401.0 | 17 | – | 127.2 | ||

| 7 | 546,176.8 | 65.2 | 18 | – | 137.8 | ||

| 8 | 216,893.2 | 248.0 | 19 | – | 50.5 | ||

| 9 | 13,618.3 | 575.6 | 20 | – | 322.9 | ||

| 10 | 4988.3 | 56.3 | 21 | – | 100.0 | ||

| 11 | 1663.8 | 188.6 | 22 | – | 199.9 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hána, T.; Janda, T.; Schmidt, J.; Zemanová, A.; Šejnoha, M.; Eliášová, M.; Vokáč, M. Experimental and Numerical Study of Viscoelastic Properties of Polymeric Interlayers Used for Laminated Glass: Determination of Material Parameters. Materials 2019, 12, 2241. https://doi.org/10.3390/ma12142241

Hána T, Janda T, Schmidt J, Zemanová A, Šejnoha M, Eliášová M, Vokáč M. Experimental and Numerical Study of Viscoelastic Properties of Polymeric Interlayers Used for Laminated Glass: Determination of Material Parameters. Materials. 2019; 12(14):2241. https://doi.org/10.3390/ma12142241

Chicago/Turabian StyleHána, Tomáš, Tomáš Janda, Jaroslav Schmidt, Alena Zemanová, Michal Šejnoha, Martina Eliášová, and Miroslav Vokáč. 2019. "Experimental and Numerical Study of Viscoelastic Properties of Polymeric Interlayers Used for Laminated Glass: Determination of Material Parameters" Materials 12, no. 14: 2241. https://doi.org/10.3390/ma12142241

APA StyleHána, T., Janda, T., Schmidt, J., Zemanová, A., Šejnoha, M., Eliášová, M., & Vokáč, M. (2019). Experimental and Numerical Study of Viscoelastic Properties of Polymeric Interlayers Used for Laminated Glass: Determination of Material Parameters. Materials, 12(14), 2241. https://doi.org/10.3390/ma12142241