Internal Cracks and Non-Metallic Inclusions as Root Causes of Casting Failure in Sugar Mill Roller Shafts

Abstract

1. Introduction

- Fine grooves, containing 5–20 mm of pitch

- Medium grooves, containing 20–50 mm of pitch

- Coarse grooves, containing >50 mm of pitch

1.1. Internal Cracks and Porosity

1.2. Non-Metallic Inclusions

- Endogenous-type inclusions form when high-temperature liquid metal reacts with some deoxidizers, such as aluminum or silicon, during the process of desulfurization. The chemical reaction makes a new product, which cannot be dissolved through slag. However, their fractions can be minimized through the vacuum-arc melting of the secondary filtration of melt-metal.

- Exogenous-type inclusions transfer into the melted metal from external sources, such as flux material, initial raw material, refractory material, sand or slag covering the metal. The final size of the exogenous inclusions is bigger than that of endogenous inclusions.

1.3. Research Objective

2. Research Methodology

2.1. Non-Destructive Testing

2.1.1. Liquid Penetrant Testing (PT)

2.1.2. Ultrasonic Testing (UT)

- No indication should be above the reference DAC curve.

- Two or more indications should not exceed 50% of the DAC curve within 12.7mm of each other, in any direction.

2.2. Destructive Testing

2.2.1. X-Ray Spectroscopy Analysis

2.2.2. Magnetic Particle (MT) Testing

2.2.3. Metallographic Testing and Microstructure Analysis

3. Results and Discussion

3.1. Non-Destructive Testing

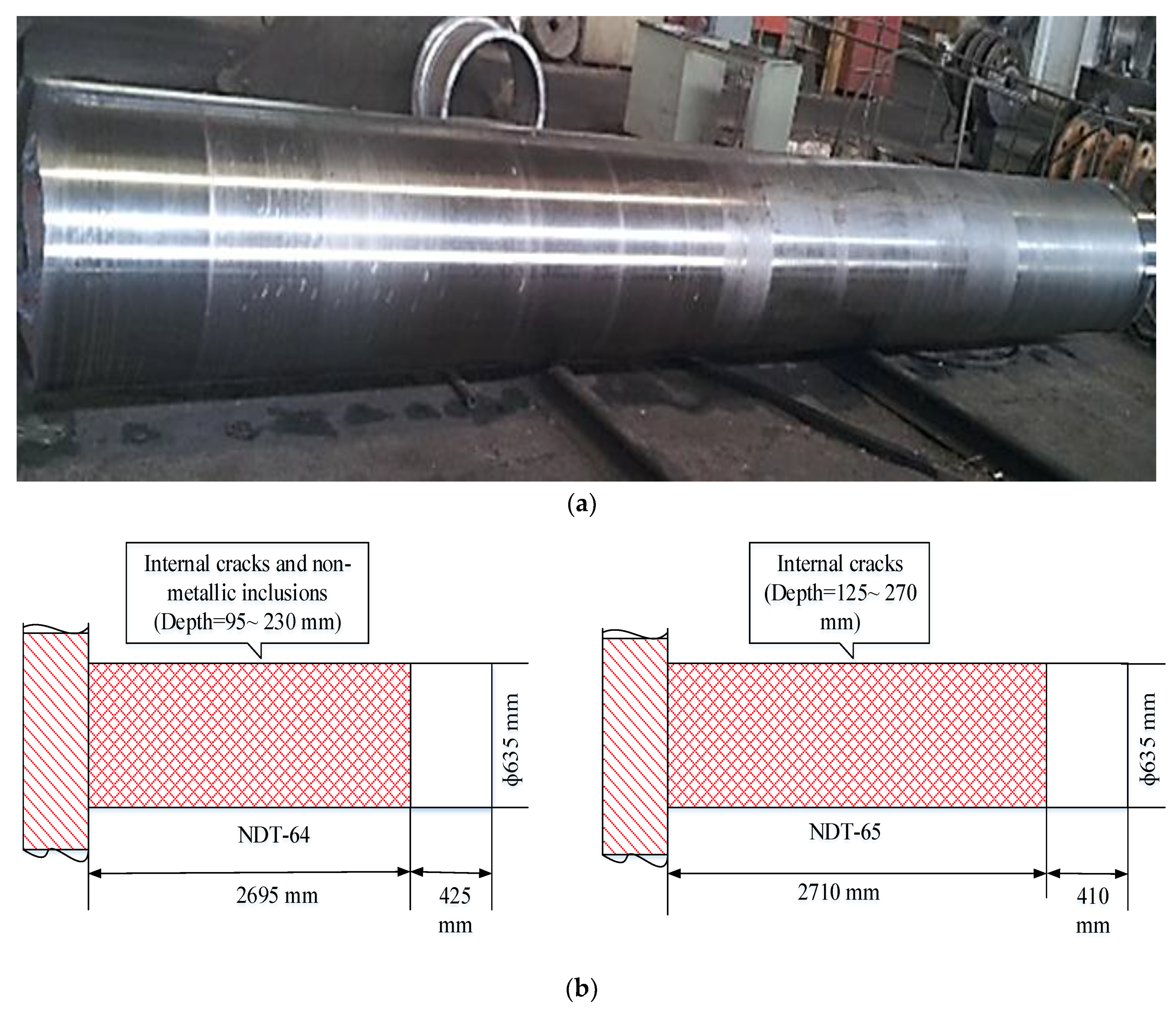

Ultrasonic Testing (UT)

3.2. Destructive Testing

3.2.1. X-ray Spectroscopy Analysis

3.2.2. Magnetic Particle Testing (MT)

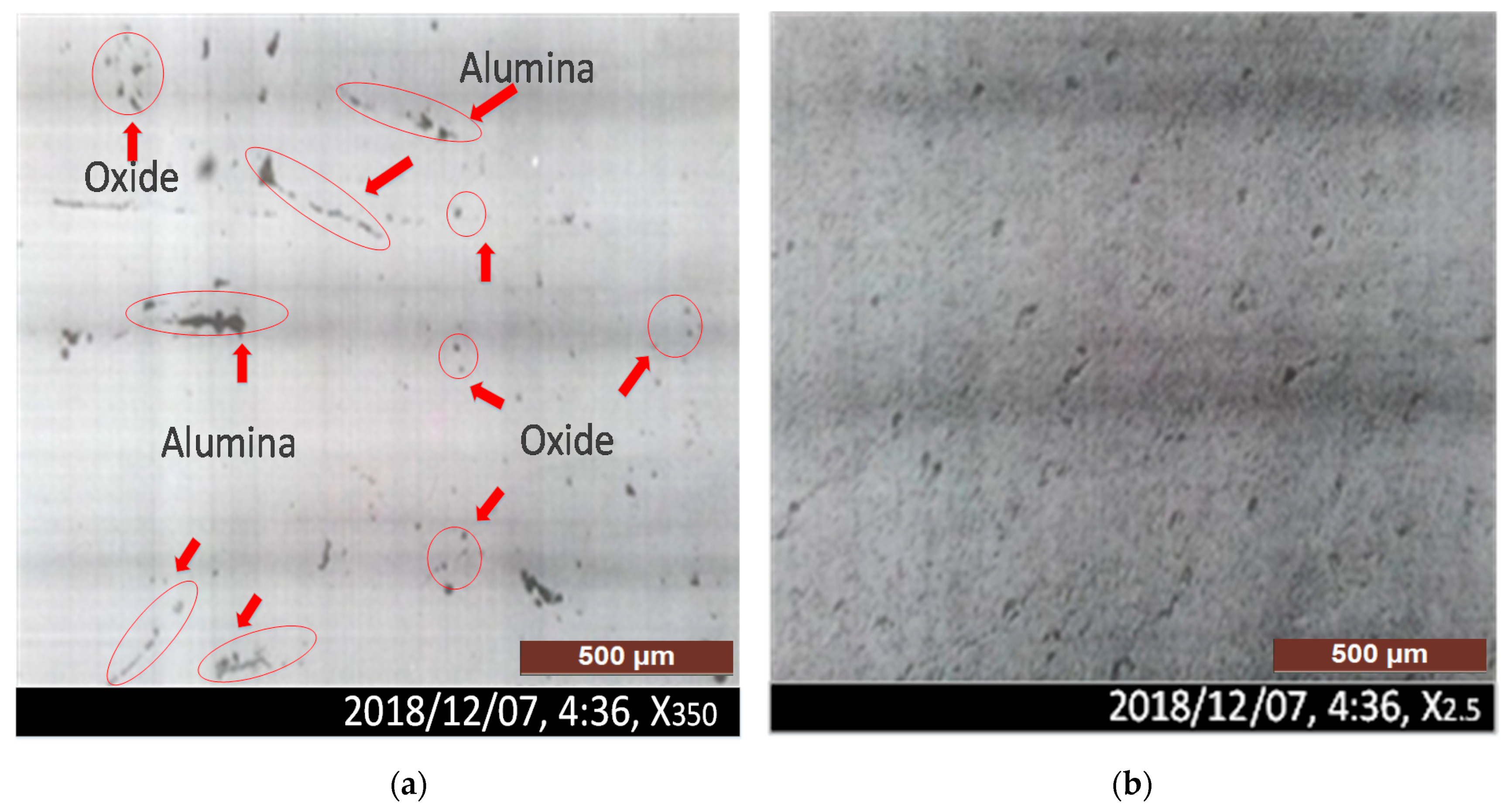

3.2.3. Microscopic Analysis and Testing

3.2.4. Macroscopic Study/Macro-Etching Analysis

4. Root Cause Analysis and Implementation

5. Conclusions

- Raw material should be properly segregated.

- The scrap should be shredded to break raw material into small pieces.

- The temperature of the furnace should be attained as nearly equal to the hot ingot temperature.

- There should be uniform pre-heating of the shaft before forging to avoid thermal stresses.

- The furnace lining should be maintained to avoid heat losses.

- Anti-hydrogen treatment can be avoided by introducing a vacuum degassing facility.

- A pyrometer should be used to measure high temperature.

- Qualification checks should be incorporated at each step.

- Equipment should be maintained properly to reduce cycle time.

- Top management should ensure the satisfaction level of their employees.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rathod, C.T.; Rathod, W.S. Design, and analysis of two roller sugar mill using fea techniques. Int. J. Sci. Eng. Technol. 2012, 1, 148–152. [Google Scholar]

- Marín, J.J. Fracture Mechanics Approach of Repaired Top Roll Shafts in Sugar Cane Mills. J. Mech. Behav. Mater. 2005, 16, 419–429. [Google Scholar] [CrossRef]

- Shinde, V.V.; Swami, M.C.; Parmeshwar, P. Weight Reduction and Analysis of Sugar Mill Roller Using FEA Techniques. Int. J. Latest. Trends Eng. Tech. 2015, 5, 346–354. [Google Scholar]

- Rivas, J.S.; Coronado, J.J.; Gómez, A.L. Tribological aspects for the shafts and bearings of sugar cane mills. Wear 2006, 261, 779–784. [Google Scholar] [CrossRef]

- ELSawy, E.E.; EL-Hebeary, M.R.; El Mahallawi, I.S. Effect of manganese, silicon and chromium additions on microstructure and wear characteristics of grey cast iron for sugar industries applications. Wear 2017, 390, 113–124. [Google Scholar] [CrossRef]

- Kakade, A.B.; Ingole, S.P.; Bhatt, D.V.; Menghani, J.V. Tribological behavior of sugar mill roller shaft in laboratory simulated conditions. Wear 2013, 302, 1568–1572. [Google Scholar] [CrossRef]

- Kakade, A.; Ingole, S.; Bhatt, D.V.; Menghani, J.V. Tribochemistry of Sugar Mill Roller Shaft Materials. Mater. Today Proc. 2017, 4, 434–441. [Google Scholar] [CrossRef]

- Coombs, J. Handbook of Cane Sugar Engineering, 3rd ed.; Elsevier Science Publishers: Amsterdam, The Netherlands, 2014; ISBN 0-444-42438-5. [Google Scholar]

- Sarkar, B.; Cárdenas-Barrón, L.E.; Sarkar, M.; Singgih, M.L. An economic production quantity model with random defective rate, rework process and backorders for a single stage production system. J. Manuf. Syst. 2014, 33, 423–435. [Google Scholar] [CrossRef]

- Jahanshahi, A.A.; Gashti, M.A.; Mirdamadi, S.A.; Nawaser, K.; Khaksar, S.M. Study the effects of customer service and product quality on customer satisfaction and loyalty. Int. J. Hum. Soc. Sci. 2011, 1, 253–260. [Google Scholar]

- Dudek-Burlikowska, M.; Szewieczek, D. The Poka-Yoke method as an improving quality tool of operations in the process. J. Achiev. Mater. Manuf. Eng. 2009, 36, 95–102. [Google Scholar]

- Goetsch, D.L.; Davis, S.B. Quality Management for Organizational Excellence; Pearson: London, UK, 2014. [Google Scholar]

- Agunsoye, J.O.; Isaac, T.S.; Awe, O.I.; Onwuegbuzie, A.T. Effect of silicon additions on the wear properties of grey cast iron. J. Miner. Mater. Character. Eng. 2013, 1, 61. [Google Scholar] [CrossRef]

- Bowler, J.R.; Bowler, N. Evaluation of the magnetic field near a crack with application to magnetic particle inspection. J. Phys. D Appl. Phys. 2002, 35, 2237. [Google Scholar] [CrossRef]

- Rokhlin, S.I.; Kim, J.Y.; Xie, B.; Zoofan, B. Nondestructive sizing and localization of internal microcracks in fatigue samples. NDT E Int. 2007, 40, 462–470. [Google Scholar] [CrossRef]

- Kukla, D.; Bałkowiec, A.; Grzywna, P. Evaluation of microstructural changes of S235 steel after rolling on the basis of microscopic observations and eddy current non-destructive method. Adv. Mater. Sci. 2014, 14, 40–48. [Google Scholar] [CrossRef]

- Zhang, L.; Thomas, B.G. State of the art in the control of inclusions during steel ingot casting. Metall. Mater. Trans. B 2006, 37, 733–761. [Google Scholar] [CrossRef]

- Fuller, R.W.; Ehrgott, J.Q., Jr.; Heard, W.F.; Robert, S.D.; Stinson, R.D.; Solanki, K.; Horstemeyer, M.F. Failure analysis of AISI 304 stainless steel shaft. Eng. Fail. Anal. 2008, 15, 835–846. [Google Scholar] [CrossRef]

- Zhao, L.H.; Xing, Q.K.; Wang, J.Y.; Li, S.L.; Zheng, S.L. Failure and root cause analysis of vehicle drive shaft. Eng. Fail. Anal. 2019, 99, 225–234. [Google Scholar] [CrossRef]

- Ni, T.W.; Ding, Q.; Yang, Z.G.; Zheng, H.L.; Lou, X. Failure analysis on premature fracture of boric acid recycle pump shaft in 1000 MW nuclear power plant. Eng. Fail. Anal. 2018, 92, 317–326. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Klinger, C.; Bettge, D.; Murakami, Y. Defects as a root cause of fatigue failure of metallic components. II: Non-metallic inclusions. Eng. Fail. Anal. 2019. [Google Scholar] [CrossRef]

- Federici, M.; Straffelini, G.; Gialanella, S. Pin-on-disc testing of low-metallic friction material sliding against HVOF coated cast iron: Modelling of the contact temperature evolution. Tribol. Lett. 2017, 65, 121. [Google Scholar] [CrossRef]

- Pavan, A.H.; Vikrant, K.S.; Swamy, M.; Jayaraman, G. Root cause analysis of bowl-mill pinion shaft failures. Case Stud. Eng. Fail. Anal. 2013, 1, 103–109. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, C.; Parameswaran, P.; Punniyamoorthy, R.; Chandramouli, S.; Saroja, S.; Rajan, K.K.; Vijayalakshmi, M. Failure analysis of a 304 steel component aged at 623 K. Eng. Fail. Anal. 2013, 31, 28–39. [Google Scholar] [CrossRef]

- Mapelli, C. Non-metallic inclusions and clean steel. Met. Ital. 2008, 16, 43. [Google Scholar]

- Saberifar, S.; Mashreghi, A.R.; Mosalaeepur, M.; Ghasemi, S.S. The interaction between non-metallic inclusions and surface roughness in fatigue failure and their influence on fatigue strength. Mater. Des. 2012, 35, 720–724. [Google Scholar] [CrossRef]

- Yang, Z.G.; Yao, G.; Li, G.Y.; Li, S.X.; Chu, Z.M.; Hui, W.J.; Dong, H.; Weng, Y.Q. The effect of inclusions on the fatigue behavior of fine-grained high strength 42CrMoVNb steel. Int. J. Fatigue 2004, 26, 959–966. [Google Scholar] [CrossRef]

- Khan, A.M.; Jamil, M.; Mozammel, M.; Yurievich, P.D.; Rashitovich, G.V.; Munish, K.G.; He, N. Multi-objective optimization for grinding of AISI D2 steel with Al2O3 wheel under MQL. Materials 2018, 11, 2269. [Google Scholar] [CrossRef] [PubMed]

- Chan, K.S. A microstructure-based fatigue-crack-initiation model. Metall. Mater. Trans. A 2003, 34, 43–58. [Google Scholar] [CrossRef]

- Chan, K.S. Roles of microstructure in fatigue crack initiation. Int. J. Fatigue 2010, 32, 1428–1447. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Bathias, C.; Kawagoishi, N.; Chen, Q. Effect of inclusion on subsurface crack initiation and gigacycle fatigue strength. Int. J. Fatigue 2002, 24, 1269–1274. [Google Scholar] [CrossRef]

- Hong, Y.; Zhao, A.; Qian, G.; Zhou, C. Fatigue strength and crack initiation mechanism of very-high-cycle fatigue for low alloy steels. Metall. Mater. Trans. A 2012, 43, 2753–2762. [Google Scholar] [CrossRef]

- Santosh, Y.S. Static Structural Analysis of Conventional Sugar Mill Roller Shaft for Ø40”x 80” Milling Plant. Int. J. Late. Trend. Eng. Tech. 2015, 5, 141–150. [Google Scholar]

- Kalinichenko, N.P.; Kalinichenko, A.N.; Lobanova, I.S.; Zaitseva, A.A. Universal reference test blocks for liquid penetrant testing. Eng. Mater 2016, 685, 355–359. [Google Scholar] [CrossRef]

- Glazkov, Y.A. Peculiarities of the certification of reference specimens for liquid-penetrant testing. Russ. J. Nondestr. Test 2004, 40, 629–636. [Google Scholar] [CrossRef]

- Adams, R.D.; Cawley, P.D. A review of defect types and nondestructive testing techniques for composites and bonded joints. NDT Int. 1988, 21, 208–222. [Google Scholar]

- ASTM International. ASTM E45-18a Standard Test Methods for Determining the Inclusion Content of Steel; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. ASTM E381-17 Standard Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Zeng, Y.P.; Xu, C.M.; Dong, J.X.; Zhang, M.C.; Xie, X.S. Micro behavior study of non-metallic inclusion in high strength shaft steel. Eng. Mater. 2005, 297, 1229–1234. [Google Scholar]

- Card, D.N. Myths and strategies of defect causal analysis. In Proceedings of the Pacific Northwest Software Quality Conference, Portland, OR, USA, 17–19 October 2006. [Google Scholar]

- Sobel, K. Root Cause Analysis: Parsing Complex Challenges in Academic Libraries. J. Academ. Librar. 2017, 43, 312–318. [Google Scholar] [CrossRef]

- Jayswal, A.; Li, X.; Zanwar, A.; Lou, H.H.; Huang, Y. A sustainability root cause analysis methodology and its application. Comput. Chem. Eng. 2011, 35, 2786–2798. [Google Scholar] [CrossRef]

- Schoenfisch, J.; Meilicke, C.; von Stülpnagel, J.; Ortmann, J.; Stuckenschmidt, H. Root cause analysis in IT infrastructures using ontologies and abduction in Markov Logic Networks. Inf. Syst. 2018, 74, 103–116. [Google Scholar] [CrossRef]

- Lokrantz, A.; Gustavsson, E.; Jirstrand, M. Root cause analysis of failures and quality deviations in manufacturing using machine learning. Procedia CIRP 2018, 72, 1057–1062. [Google Scholar] [CrossRef]

- Mahshid, R.; Mansourvar, Z.; Hansen, H.N. Tolerance analysis in manufacturing using process capability ratio with measurement uncertainty. Precis. Eng. 2018, 52, 201–210. [Google Scholar] [CrossRef]

- Hmc. Heavy Mechanical Complex. Available online: http://hmc.com.pk/ (accessed on 15 June 2019).

| Chemical Properties | Name of the Components | ||||||

|---|---|---|---|---|---|---|---|

| C% | Mn% | Si% | S% | P% | Mo% | Cr% | |

| 0.38–0.45 | 0.6–0.90 | 0.15–0.40 | Max 0.035 | Max 0.025 | 0.15–0.3 | 0.9–1.20 | |

| Mechanical properties | Tensile strength | 980 N/mm2 | Yield Strength | 850 N/mm2 | Material Elongation | 14% (Min) | |

| Step Height (mm) | Surface Distance of Flat Bottom Hole (FBH) (mm) | FBH Diameter (mm) | Depth of FBH (mm) |

|---|---|---|---|

| 150 | 125 | 6 | 25 |

| 275 | 250 | ||

| 400 | 375 |

| Chemical Composition | Name of the Components | ||||||

|---|---|---|---|---|---|---|---|

| C% | Mn% | Si% | S% | P% | Mo% | Cr% | |

| Sample-1 | 0.38 | 0.82 | 0.349 | 0.028 | 0.02 | 0.144 | 1.0 |

| Sample-2 | 0.371 | 0.81 | 0.357 | 0.030 | 0.018 | 0.152 | 0.98 |

| Sample-3 | 0.384 | 0.80 | 0.341 | 0.033 | 0.025 | 0.145 | 0.97 |

| Sample-4 | 0.367 | 0.84 | 0.336 | 0.035 | 0.021 | 0.156 | 1.02 |

| Mechanical Properties | Tensile strength | 965 N/mm2 | Yield Strength | 815 N/mm2 | Elongation | 12% (Min) | |

| Serial. No | Nature of Defects | Percentage |

|---|---|---|

| 1 | Non-metallic inclusions and subsurface cracks | 50% |

| 2 | Piping | 31.3% |

| 3 | Surface cracks | 18.7% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamil, M.; Khan, A.M.; Hegab, H.; Sarfraz, S.; Sharma, N.; Mia, M.; Gupta, M.K.; Zhao, G.; Moustabchir, H.; Pruncu, C.I. Internal Cracks and Non-Metallic Inclusions as Root Causes of Casting Failure in Sugar Mill Roller Shafts. Materials 2019, 12, 2474. https://doi.org/10.3390/ma12152474

Jamil M, Khan AM, Hegab H, Sarfraz S, Sharma N, Mia M, Gupta MK, Zhao G, Moustabchir H, Pruncu CI. Internal Cracks and Non-Metallic Inclusions as Root Causes of Casting Failure in Sugar Mill Roller Shafts. Materials. 2019; 12(15):2474. https://doi.org/10.3390/ma12152474

Chicago/Turabian StyleJamil, Muhammad, Aqib Mashood Khan, Hussien Hegab, Shoaib Sarfraz, Neeraj Sharma, Mozammel Mia, Munish Kumar Gupta, GuLong Zhao, H. Moustabchir, and Catalin I. Pruncu. 2019. "Internal Cracks and Non-Metallic Inclusions as Root Causes of Casting Failure in Sugar Mill Roller Shafts" Materials 12, no. 15: 2474. https://doi.org/10.3390/ma12152474

APA StyleJamil, M., Khan, A. M., Hegab, H., Sarfraz, S., Sharma, N., Mia, M., Gupta, M. K., Zhao, G., Moustabchir, H., & Pruncu, C. I. (2019). Internal Cracks and Non-Metallic Inclusions as Root Causes of Casting Failure in Sugar Mill Roller Shafts. Materials, 12(15), 2474. https://doi.org/10.3390/ma12152474