An Overview of the Recent Developments in Metal Matrix Nanocomposites Reinforced by Graphene

Abstract

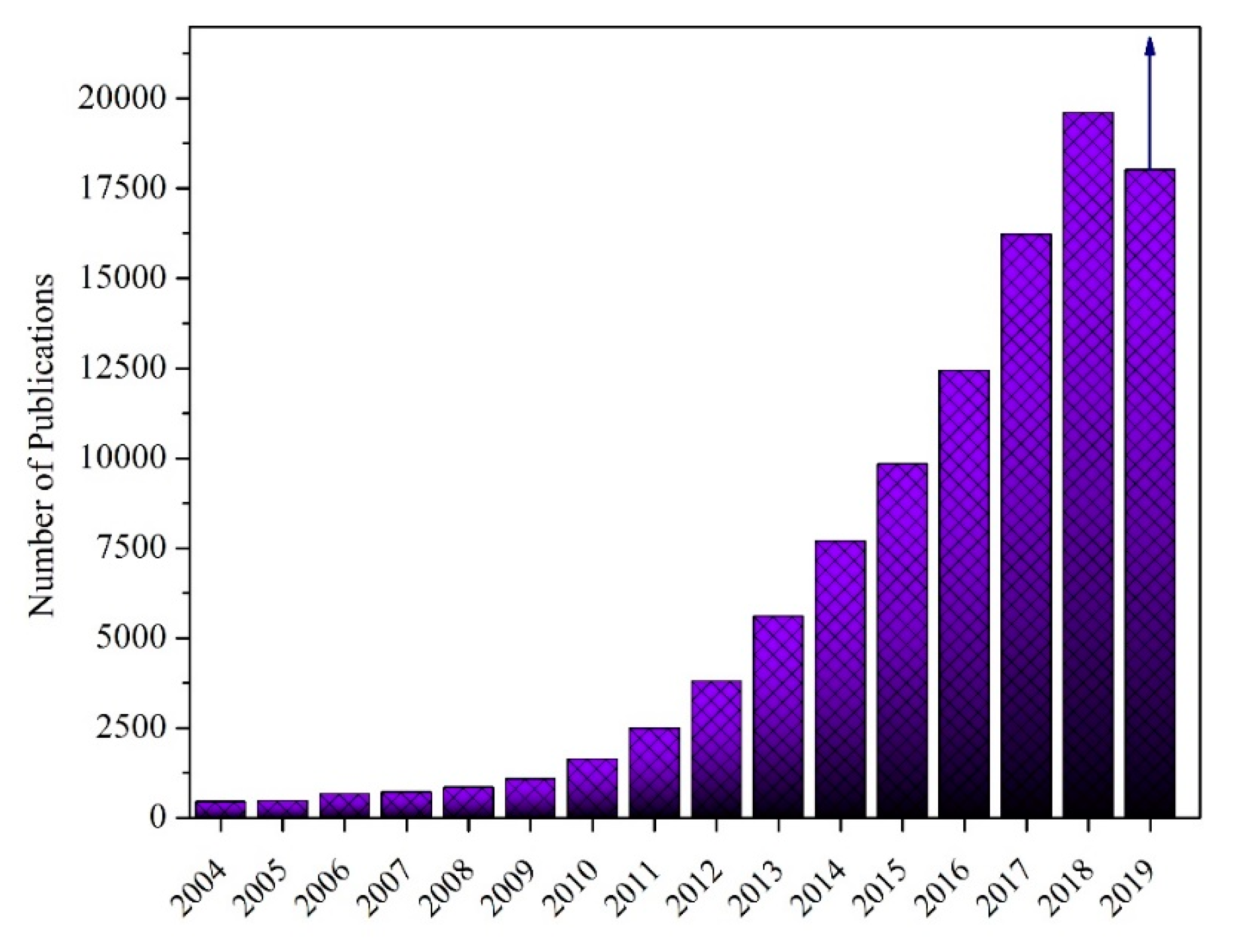

:1. Introduction

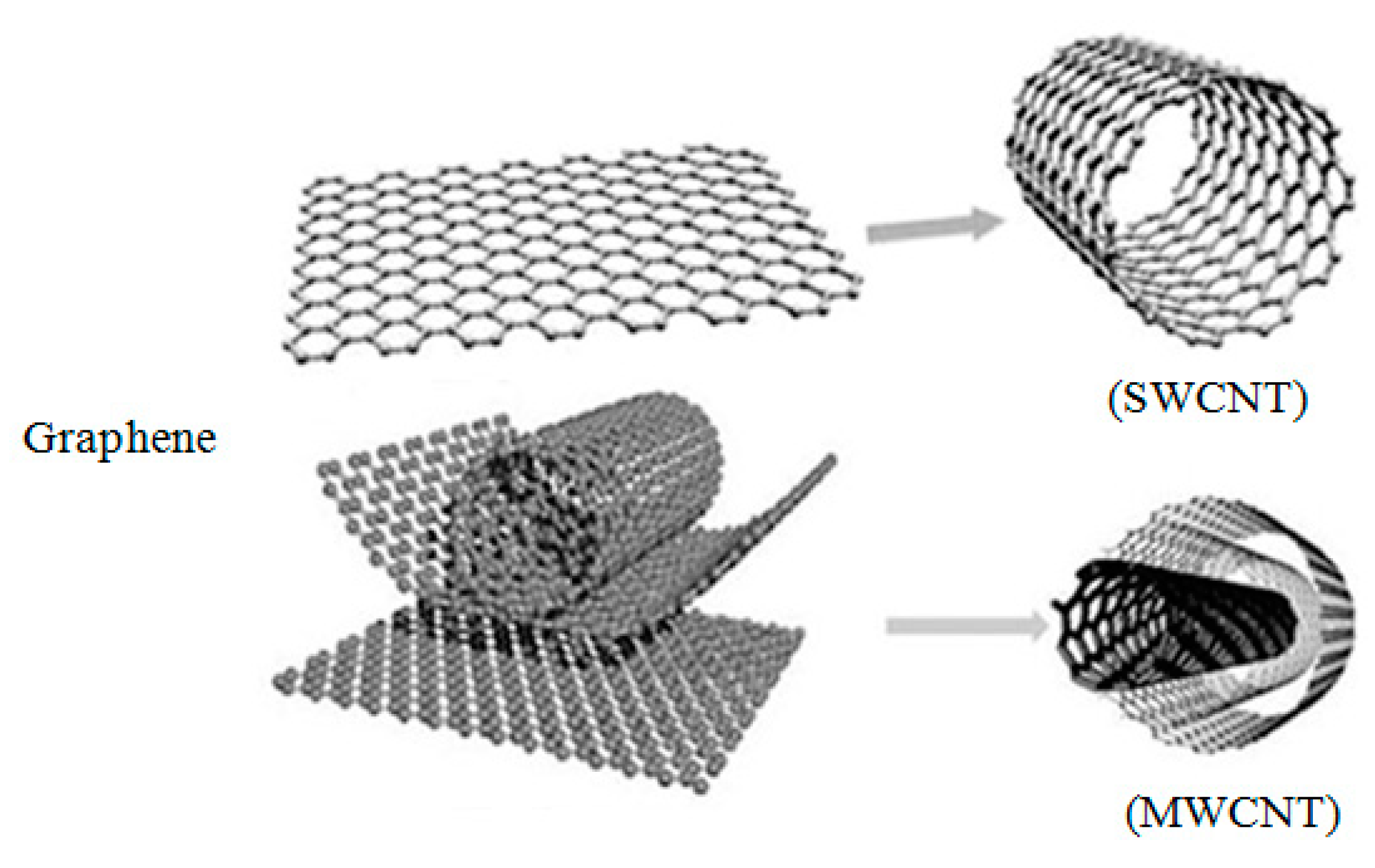

2. Carbonaceous Nanomaterials

3. Mechanical Properties of Carbonaceous Nanomaterials

4. Thermal Properties of Carbonaceous Nanomaterials

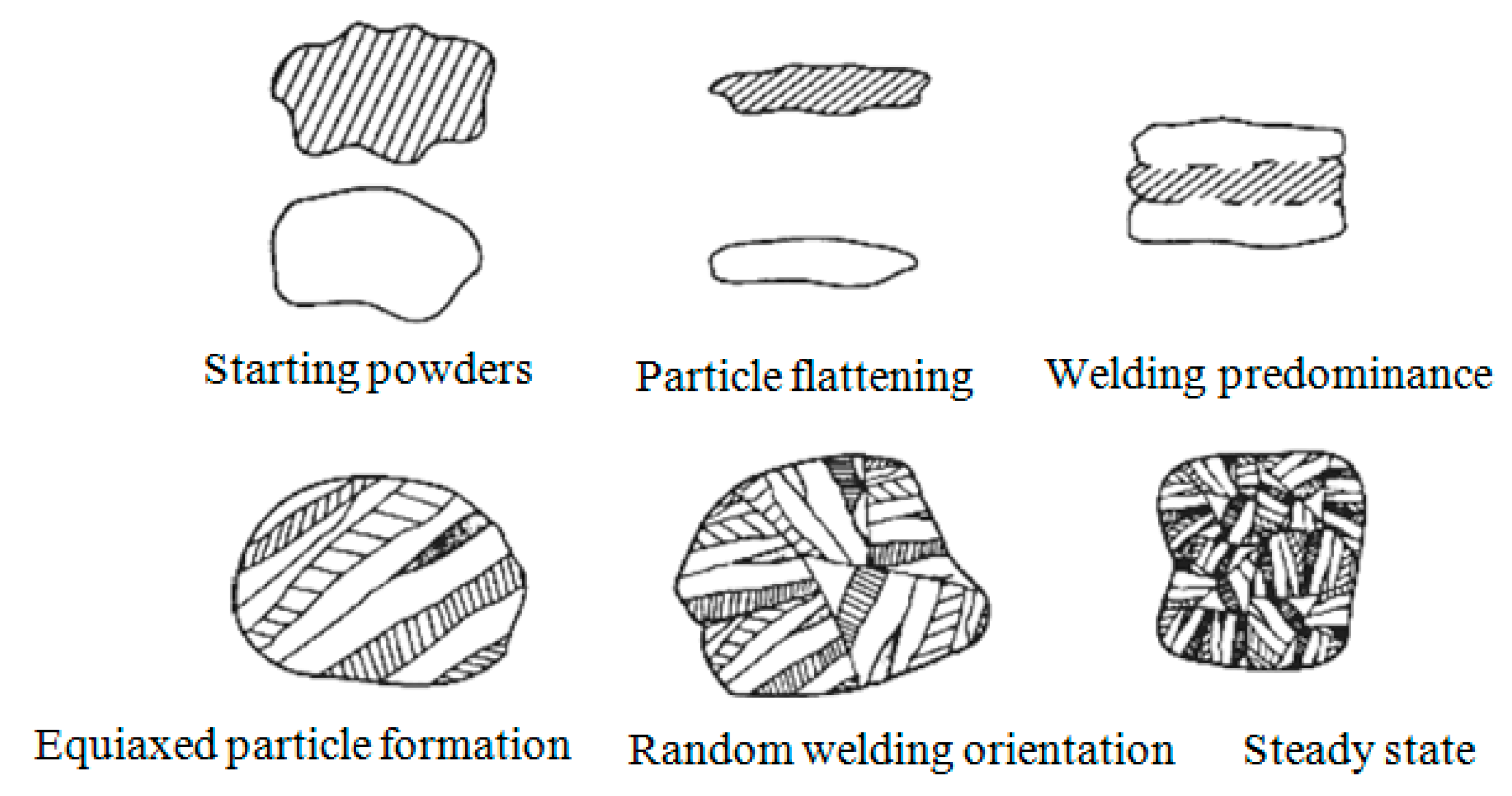

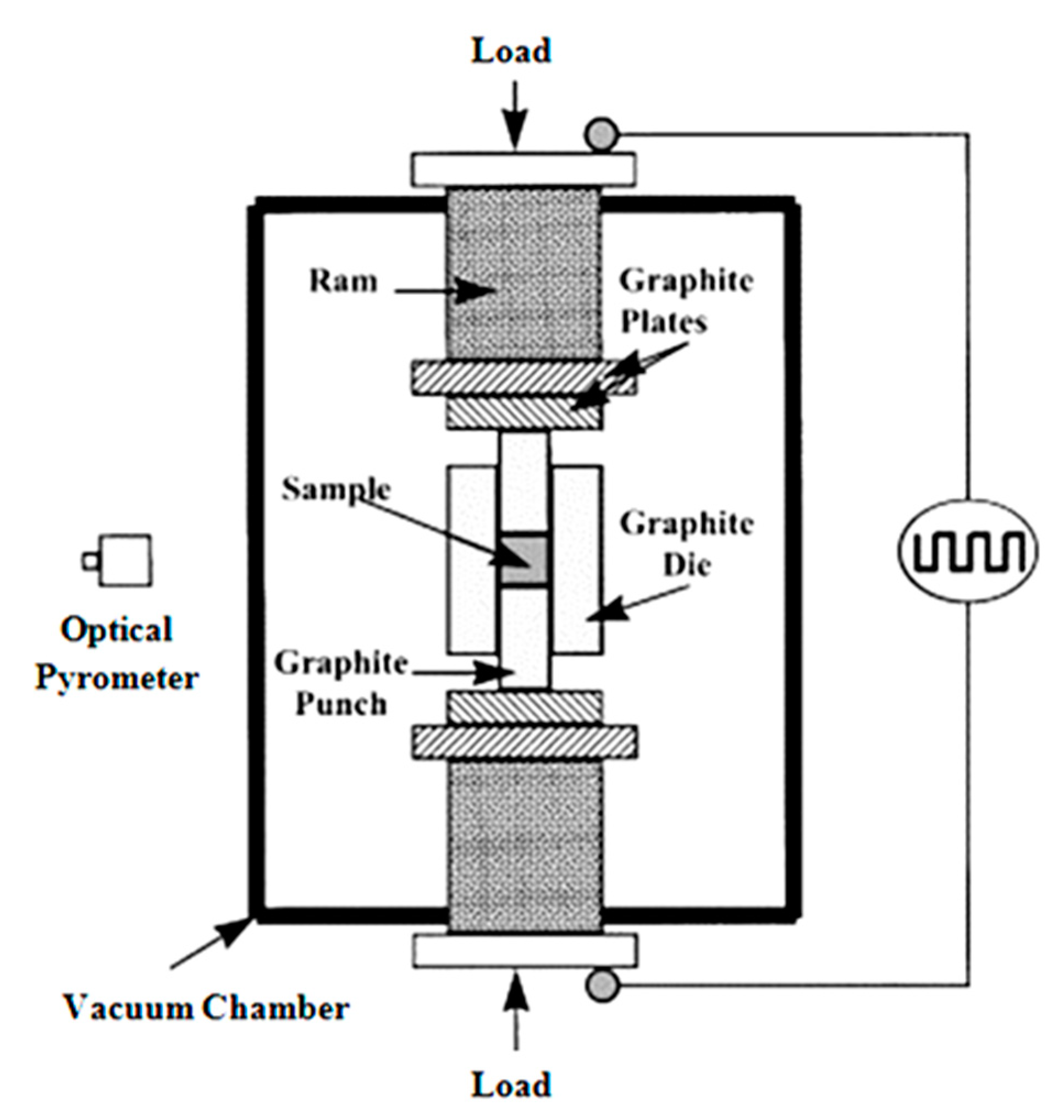

5. Fabrication of MMNCs Reinforced by Graphene

6. Strengthening Mechanisms

7. Metal Matrix Nanocomposites Reinforced by Graphene

7.1. Aluminum Matrix Nanocomposites Reinforced by Graphene

7.2. Magnesium Matrix Nanocomposites Reinforced by Graphene

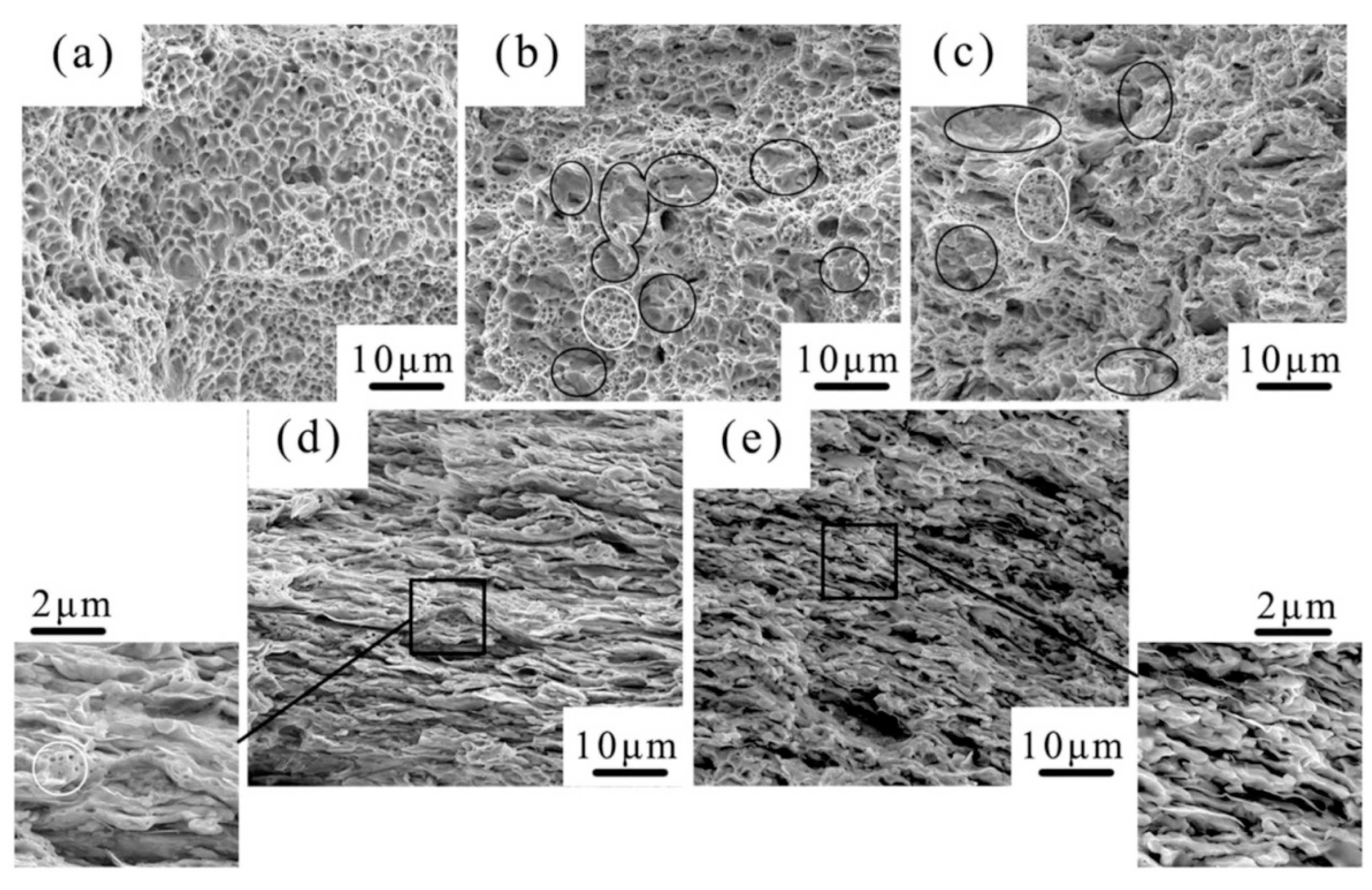

7.3. Copper Matrix Nanocomposites Reinforced by Graphene

7.4. Other Metal Matrix Nanocomposites Reinforced by Graphene

8. Potential Applications of Graphene-reinforced MMNCs

9. Conclusions

- Owing to the unique characteristics, such as a high aspect ratio, an exceptional high elastic modulus and strength, and superior electrical and thermal conductivity, graphene could attract more attention to be utilized in the production of MMCs as a reinforcement to improve their mechanical, thermo-physical and wear properties.

- It is found that the production of these nanocomposites is faced with several challenges, such as the distribution of graphene, undesirable reaction, poor interfacial bonding and preferred orientation of graphene during the fabrication step.

- It is very interesting to point out that, according to the literature, some of the issues can be related to the nature of starting materials, whereas the rest can be attributed to the production process. Those related to the production process can often be addressed by altering the fabrication technique or by employing post-processing methods. More problematic, are the issues attributed to the matrix’s composition and reinforcement composition, its stability and the distribution of particulates, especially if they are in the nano-scale range.

- The majority of the literature has been concentrated on the production, and some studies have targeted the mechanical performance, thermophysical and self-lubricating characteristics.

- AM techniques, that are layer-wise manufacturing processes, are rapidly growing in the fabrication of MMNCs.

- In general, it is revealed that the mechanical performance of MMCs was significantly improved through the addition of graphene.

- The in-depth microstructural analysis demonstrated that the most effective strengthening mechanisms in the MMCs reinforced by graphene phenomena are a mismatch in the thermal expansion of the matrix and graphene and an Orowan looping mechanism.

- Despite the mechanical properties and microstructural analysis of MMCs reinforced by graphene that has been investigated intensively, their tribology is rarely considered and studied.

- The available investigations have shown that graphene can significantly decrease the wear rates and friction coefficients of MMCs with respect to the monolithic material.

- The improvement in the tribological features of MMCs, as well as the mechanical and thermophysical properties, strongly depend on the final graphene content.

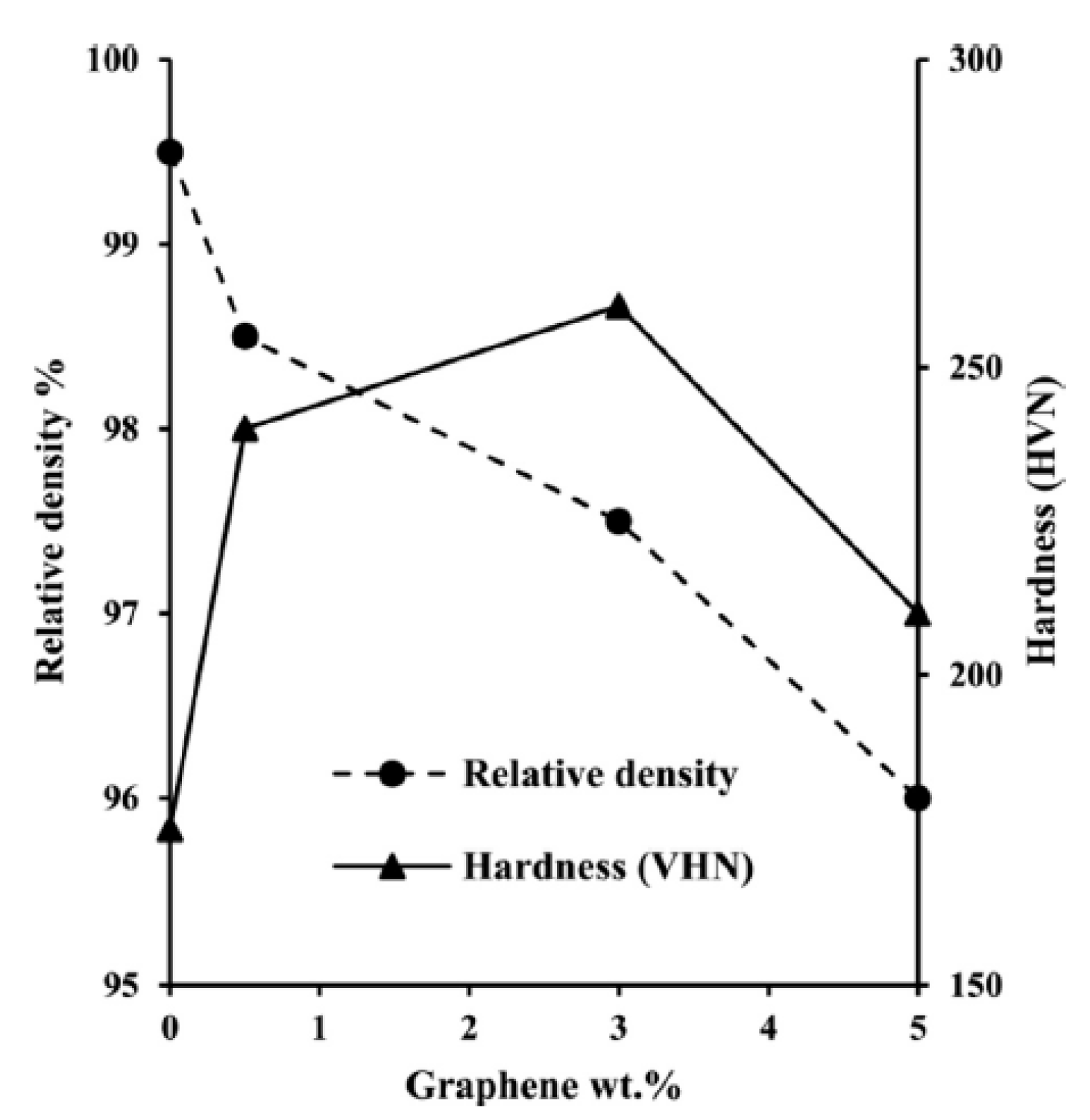

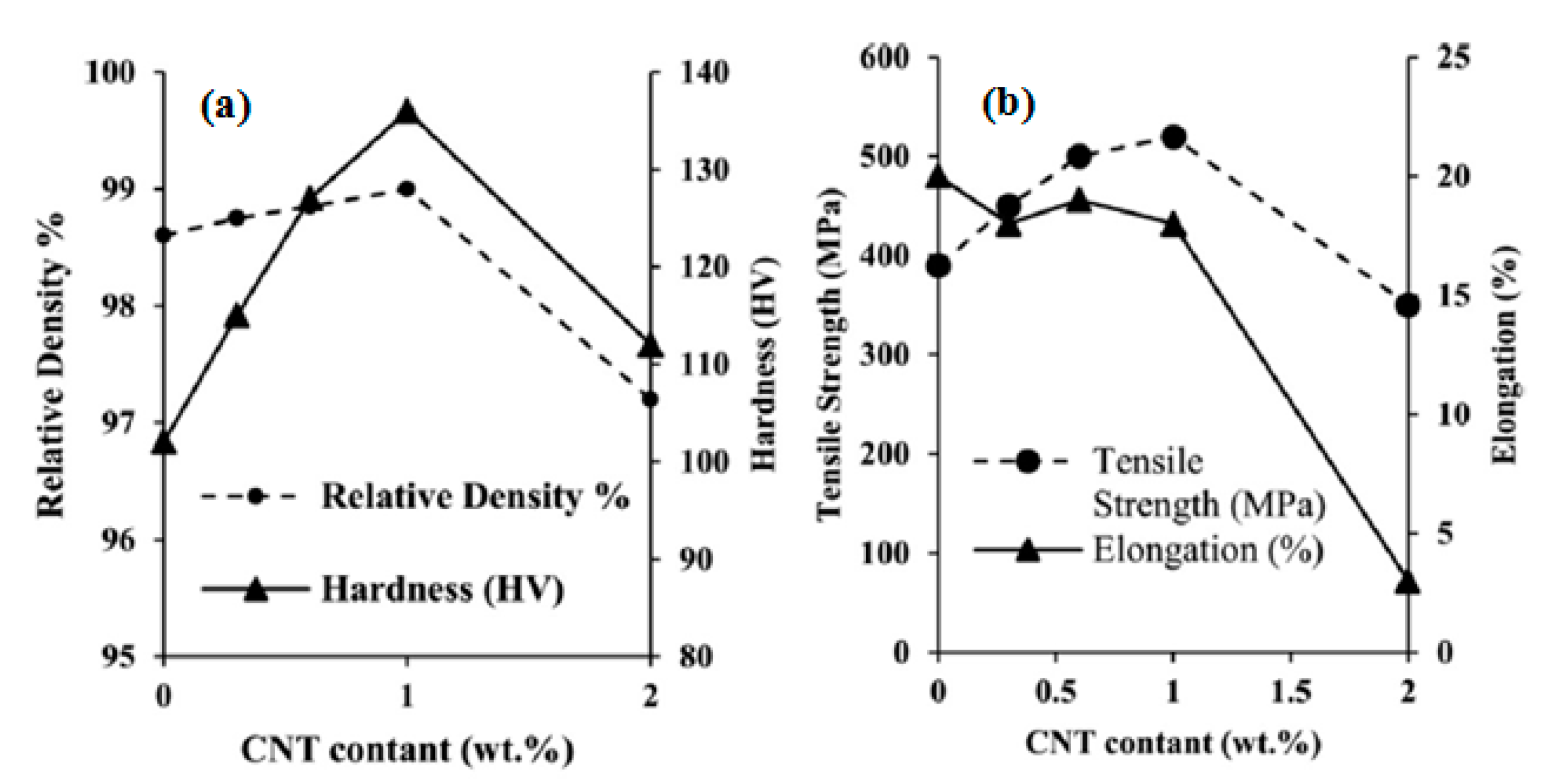

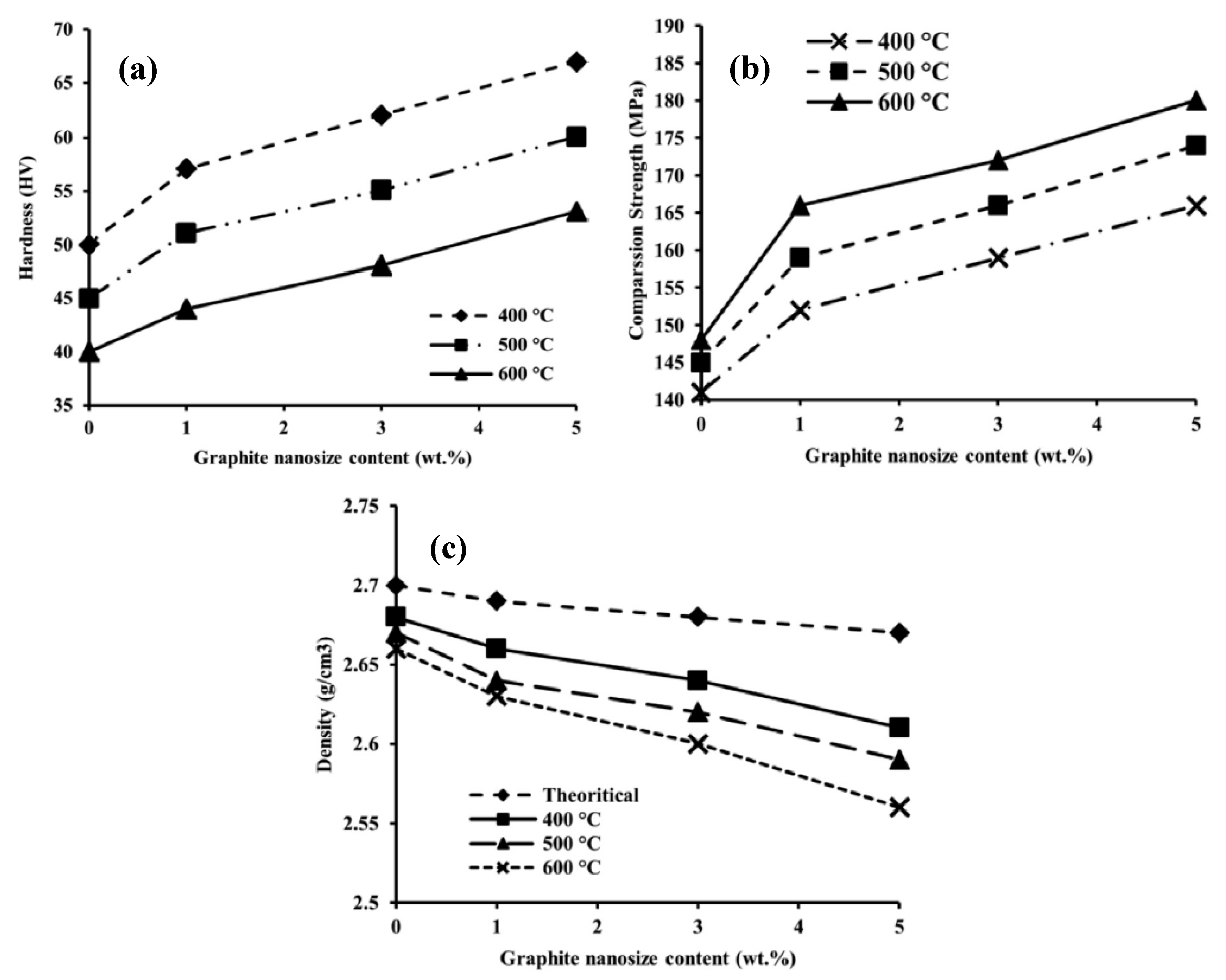

- At higher graphene contents, graphene tends to form big agglomerates that leave some defects, like porosity, in the MMCs after fabrication, and accordingly deteriorate the final properties of MMCs.

- There is a critical limit for the final graphene content, until which the properties of MMCs can be improved, whereas at higher graphene contents, all the properties, such as thermal conductivity, electrical conductivity, mechanical properties and tribological behavior, are deteriorated. In addition to the graphene content, its other characteristics, such as the size of reinforcement, and spatial distribution, have shown to effect mechanical and tribological properties.

- It should be noted that these topics still bring a marked challenge to the materials scientists, and it would be worth mentioning that the production of metal matrix nanocomposites with a uniform distribution of graphene, strong interfacial bonding, without unfavorable reactions and with better isotropic properties is still a challenging topic.

- Each metallic material has some poor characteristics that limit its industrial applications. Theoretically and also on the lab-scale, it was found that through the addition of graphene, it would be possible to address those weakness and accordingly broad their application.

- Despite all the efforts that have been undertaken in the development of new MMNCs reinforced by graphene, the industrialization of these materials are faced with several challenges, and need more attempts.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, B.; Ruan, T.; Chen, Y.; Jin, F.; Peng, L.; Zhou, Y.; Wang, D.; Dou, S. Graphene-based composites for electrochemical energy storage. Energy Storage Mater. 2019. [Google Scholar] [CrossRef]

- Wang, J.; Guo, L.; Lin, W.; Chen, J.; Liu, C.; Chen, S.; Zhang, S.; Zhen, T. Effect of the graphene content on the microstructures and properties of graphene/aluminum composites. New Carbon Mater. 2019, 34, 275–285. [Google Scholar] [CrossRef]

- Saboori, A.; Moheimani, S.K.; Pavese, M.; Badini, C.; Fino, P. New Nanocomposite Materials with Improved Mechanical Strength and Tailored Coefficient of Thermal Expansion for Electro-Packaging Applications. Metals 2017, 7, 536. [Google Scholar] [CrossRef]

- Urbańczyk, E.; Maciej, A.; Stolarczyk, A.; Basiaga, M.; Simka, W. The electrocatalytic oxidation of urea on nickel-graphene and nickel-graphene oxide composite electrodes. Electrochim. Acta 2019, 305, 256–263. [Google Scholar] [CrossRef]

- Agrawal, A.; Mirzaeifar, R. Graphene-Nickel interaction in layered metal-matrix composites. Surf. Sci. 2019, 688, 1–6. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Liao, Z.; Abdelhafeez, A.; Li, H.; Yang, Y.; Diaz, O.G.; Axinte, D. State-of-the-art of surface integrity in machining of metal matrix composites. Int. J. Mach. Tools Manuf. 2019, 143, 63–91. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Tjong, S.C.; Wang, Z.G. Cyclic and static creep behavior of Al–Cu alloy composite reinforced with in-situ Al2O3 and TiB2 particulates. Mater. Sci. Eng. A 1999, 264, 177–187. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Abrasion resistance of stainless-steel composites reinforced with hard TiB2 particles. Compos. Sci. Technol. 2000, 60, 1141–1146. [Google Scholar] [CrossRef]

- Bai, G.; Zhang, Y.; Dai, J.; Wang, L.; Wang, X.; Wang, J.; Kim, M.J.; Chen, X.; Zhang, H. Tunable coefficient of thermal expansion of Cu-B/diamond composites prepared by gas pressure infiltration. J. Alloys Compd. 2019, 794, 473–481. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Schultz, B.F.; Ferguson, J.B.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional Metal Matrix Composites: Self-lubricating, Self-healing, and Nanocomposites-An Outlook. JOM 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Saboori, A.; Chen, X.; Badini, C.; Fino, P.; Pavese, M. Reactive spontaneous infiltration of Al-activated TiO2 by molten aluminum. Trans. Nonferrous Met. Soc. China 2019, 29, 657–666. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos. Part B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Liu, L.; Li, W.; Tang, Y.; Shen, B.; Hu, W. Friction and wear properties of short carbon fiber reinforced aluminum matrix composites. Wear 2009, 266, 733–738. [Google Scholar] [CrossRef]

- Moustafa, S.F.; El-Badry, S.A.; Sanad, A.M.; Kieback, B. Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders. Wear 2002, 253, 699–710. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites e from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Liu, X.-B.; Liu, H.-Q.; Liu, Y.-F.; He, X.-M.; Sun, C.-F.; Wang, M.-D.; Yang, H.-B.; Qi, L.-H. Effects of temperature and normal load on tribological behavior of nickel-based high temperature self-lubricating wear-resistant composite coating. Compos. Part B Eng. 2013, 53, 347–354. [Google Scholar] [CrossRef]

- Wei, J.N.; Wang, D.Y.; Xie, W.J.; Luo, J.L.; Han, F.S. Effects of macroscopic graphite particulates on the damping behavior of Zn–Al eutectoid alloy. Phys. Lett. A 2007, 366, 134–136. [Google Scholar] [CrossRef]

- Wu, Y.W.; Wu, K.; Deng, K.K.; Nie, K.B.; Wang, X.J.; Hu, X.S.; Zheng, M.Y. Damping capacities and tensile properties of magnesium matrix composites reinforced by graphite particles. Mater. Sci. Eng. A 2010, 527, 6816–6821. [Google Scholar] [CrossRef]

- Ma, X.C.; He, G.Q.; He, D.H.; Chen, C.S.; Hu, Z.F. Sliding wear behavior of copper–graphite composite material for use in maglev transportation system. Wear 2008, 265, 1087–1092. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Tabandeh-Khorshid, M.; Omrani, E.; Lovell, M.R.; Menezes, P.L. Tribology of Metal Matrix Composites. In Tribology for Scientists and Engineers: From Basics to Advanced Concepts; Menezes, P.L., Nosonovsky, M., Ingole, S.P., Kailas, S.V., Lovell, M.R., Eds.; Springer New York: New York, NY, USA, 2013; pp. 233–268. ISBN 978-1-4614-1945-7. [Google Scholar]

- Kestursatya, M.; Kim, J.K.; Rohatgi, P.K. Wear performance of copper–graphite composite and a leaded copper alloy. Mater. Sci. Eng. A 2003, 339, 150–158. [Google Scholar] [CrossRef]

- Zhou, M.; Qu, X.; Ren, L.; Fan, L.; Zhang, Y.; Guo, Y.; Quan, G.; Tang, Q.; Liu, B.; Sun, H. The Effects of Carbon Nanotubes on the Mechanical and Wear Properties of AZ31 Alloy. Materials 2017, 10, 1385. [Google Scholar] [CrossRef] [PubMed]

- Akhlaghi, F.; Pelaseyyed, S.A. Characterization of aluminum/graphite particulate composites synthesized using a novel method termed “in-situ powder metallurgy”. Mater. Sci. Eng. A 2004, 385, 258–266. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Sheykh-Jaberi, F.; Kim, C.-S.; Rohatgi, P.K.; Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 2012, 558, 193–204. [Google Scholar] [CrossRef]

- Rawal, S.P. Metal-matrix composites for space applications. JOM 2001, 53, 14–17. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Chen, H.P.; Wang, T.R.; Xu, J.P.; Xu, X.Y.; Dangol, S.D.; He, G.F. Fetal origin of single nucleated erythroblasts and free DNA in the peripheral blood of pregnant women. Int. J. Gynecol. Obstet. 2004, 85, 1–5. [Google Scholar] [CrossRef]

- Gupta, M.; Ling, S.N. Magnesium, Magnesium Alloys, and Magnesium Composites; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Tjong, S.C. Novel Nanoparticle-Reinforced Metal Matrix Composites with Enhanced Mechanical Properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Lin, D.; Motlag, M.; Saei, M.; Jin, S.; Rahimi, R.M.; Bahr, D.; Cheng, G.J. Shock engineering the additive manufactured graphene-metal nanocomposite with high density nanotwins and dislocations for ultra-stable mechanical properties. Acta Mater. 2018, 150, 360–372. [Google Scholar] [CrossRef]

- Hu, Z.; Tong, G.; Lin, D.; Chen, C.; Guo, H.; Xu, J.; Zhou, L. Graphene-reinforced metal matrix nanocomposites–a review. Mater. Sci. Technol. 2016, 32, 930–953. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Liao, T.; Zhang, C.; Wu, X.; Liu, Y.; Qurashi, M.S.; Zheng, F.; Song, Q.; Han, P. Graphene/Cu composites: Electronic and mechanical properties by first-principles calculation. Mater. Chem. Phys. 2019, 231, 188–195. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. J. Int. Mater. Rev. 2013, 41–64. [Google Scholar] [CrossRef]

- Sadowski, P.; Kowalczyk-Gajewska, K.; Stupkiewicz, S. Classical estimates of the effective thermoelastic properties of copper–graphene composites. Compos. Part B Eng. 2015, 80, 278–290. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Grybczuk, M.; Wasiluk, M.; Kurzydlowski, K.J. Heat transfer through metal-graphene interfaces. AIP Adv. 2015, 5, 77142. [Google Scholar] [CrossRef]

- Shao-jiu, Y.A.; Cheng, Y.A.; Qi-hu, H.O.; Jun-zhou, C.H.; Da-bo, L.I.; Sheng-long, D.A. Research of Graphene-reinforced Aluminum Matrix Nanocomposites. J. Mater. Eng. 2011, 1, 1–6. [Google Scholar]

- Bartolucci, S.F.; Paras, J.; Rafiee, M.A.; Rafiee, J.; Lee, S.; Kapoor, D.; Koratkar, N. Graphene–aluminum nanocomposites. Mater. Sci. Eng. A 2011, 528, 7933–7937. [Google Scholar] [CrossRef]

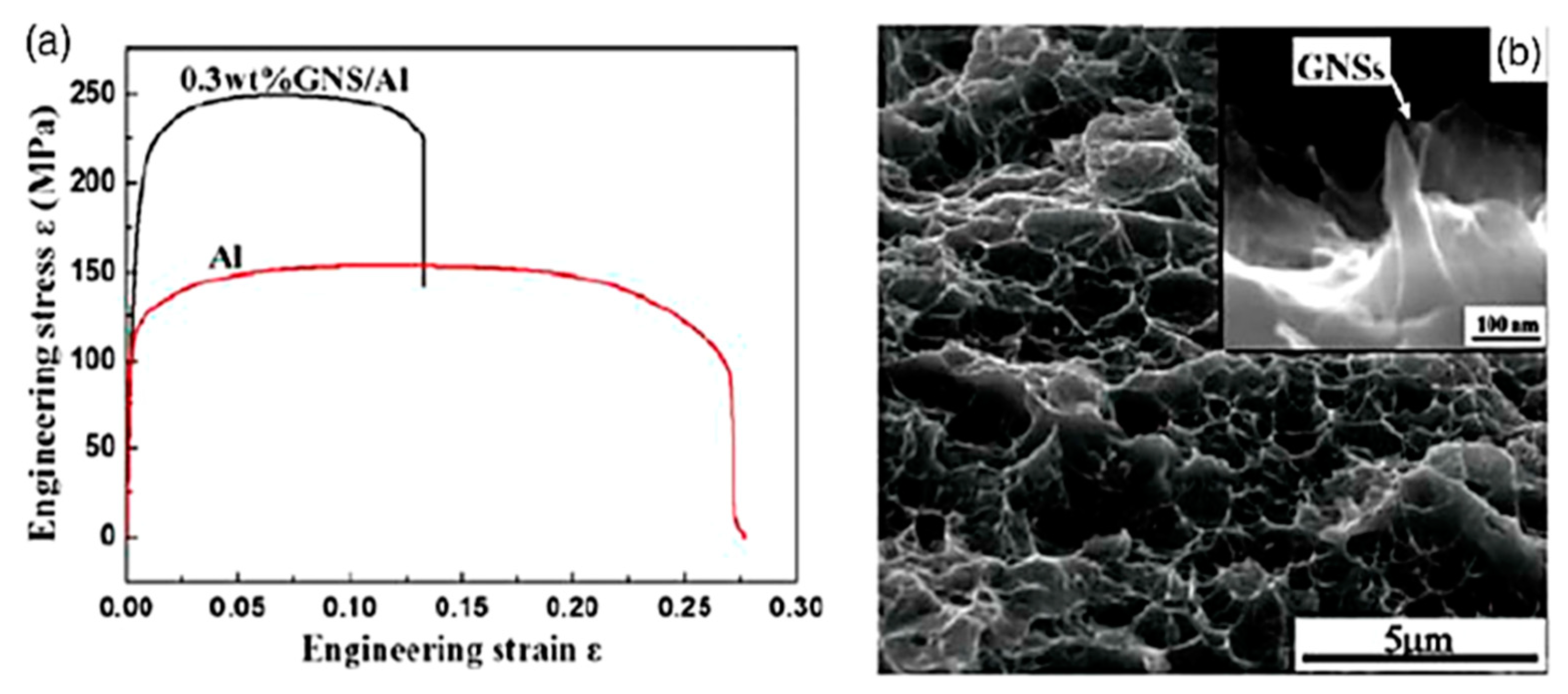

- Wang, J.; Li, Z.; Fan, G.; Pan, H.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Sci. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Fan, G.; Tan, Z.; Guo, Q.; Xiong, D.; Su, Y.; Li, Z.; Zhang, D. Uniform dispersion of graphene oxide in aluminum powder by direct electrostatic adsorption for fabrication of graphene/aluminum composites. Nanotechnology 2014, 25, 325601. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Muradymov, R.V.; Korsun, I.V.; Yakovlev, G.A.; Smirnov, S.V. Novel aluminum-graphene and aluminum-graphite metallic composite materials: Synthesis and properties. J. Alloys Compd. 2016, 663, 449–459. [Google Scholar] [CrossRef]

- Jagannadham, K. Electrical conductivity of copper–graphene composite films synthesized by electrochemical deposition with exfoliated graphene platelets. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct 2012, 30, 1–9. [Google Scholar] [CrossRef]

- Shin, S.E.; Choi, H.J.; Shin, J.H.; Bae, D.H. Strengthening behavior of few-layered graphene/aluminum composites. Carbon N. Y. 2015, 82, 143–151. [Google Scholar] [CrossRef]

- Bastwros, M.; Kim, G.; Zhu, C.; Zhang, K.; Wang, S.; Tang, X.; Wang, X. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. Part B 2014, 60, 111–118. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, Y.C.; Wang, X.D.; Yan, S.J.; Yang, C.; He, W.W.; Chen, J.Z.; Wang, S.Q.; Zhang, X.Y.; Dai, S.L. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater. Sci. Eng. A 2015, 626, 400–405. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Bolaños-Morales, D.; Bonilla-Martínez, J.; Estrada-Guel, I.; Martínez-Sánchez, R. Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying. J. Alloys Compd. 2014, 615, S578–S582. [Google Scholar] [CrossRef]

- Gao, X.; Yue, H.; Guo, E.; Zhang, H.; Lin, X.; Yao, L.; Wang, B. Preparation and tensile properties of homogeneously dispersed graphene reinforced aluminum matrix composites. Mater. Des. 2016, 94, 54–60. [Google Scholar] [CrossRef]

- Musfirah, A.H.; Jaharah, A.G. Magnesium and aluminum alloys in automotive industry. J. Appl. Sci. Res. 2012, 8, 4865–4875. [Google Scholar]

- Zhang, Z.W.; Liu, Z.Y.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. High efficiency dispersal and strengthening of graphene reinforced aluminum alloy composites fabricated by powder metallurgy combined with friction stir processing. Carbon N. Y. 2018, 135, 215–223. [Google Scholar] [CrossRef]

- Tian, W.; Li, S.; Wang, B.; Chen, X.; Liu, J.; Yu, M. Graphene-reinforced aluminum matrix composites prepared by spark plasma sintering. Int. J. Miner. Met. Mater. 2016, 23, 723–729. [Google Scholar] [CrossRef]

- Kim, W.J.; Lee, T.J.; Han, S.H. Multi-layer graphene/copper composites: Preparation using high-ratio differential speed rolling, microstructure and mechanical properties. Carbon N. Y. 2014, 69, 55–65. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C. Enhanced strength in bulk graphene-copper composites. Phys. Status Solidi 2014, 211, 184–190. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.; Wang, Y.; Du, S.; Liu, Z.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon N. Y. 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, J. Fabrication and tensile properties of graphene/copper composites prepared by electroless plating for structrual applications. Phys. Status Solidi 2014, 211, 2878–2885. [Google Scholar] [CrossRef]

- Zhao, X.; Tang, J.; Yu, F.; Ye, N. Preparation of graphene nanoplatelets reinforcing copper matrix composites by electrochemical deposition. J. Alloys Compd. 2018, 766, 266–273. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Liu, E.; He, C.; Han, Y.; Li, Q.; Nash, P.; Zhao, N. Fabrication of three-dimensional graphene/Cu composite by in-situ CVD and its strengthening mechanism. J. Alloys Compd. 2016, 688, 69–76. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering—An Introduction; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Rashad, M.; Pan, F.; Asif, M.; Tang, A. Powder metallurgy of Mg–1%Al–1%Sn alloy reinforced with low content of graphene nanoplatelets (GNPs). J. Ind. Eng. Chem. 2014, 20, 4250–4255. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Hu, H.; Asif, M.; Hussain, S.; She, J. Enhanced tensile properties of magnesium composites reinforced with graphene nanoplatelets. Mater. Sci. Eng. A 2015, 630, 36–44. [Google Scholar] [CrossRef]

- Das, A.; Harimkar, S.P. Effect of Graphene Nanoplate and Silicon Carbide Nanoparticle Reinforcement on Mechanical and Tribological Properties of Spark Plasma Sintered Magnesium Matrix Composites. J. Mater. Sci. Technol. 2014, 30, 1059–1070. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Konishi, H.; Fehrenbacher, A.; Ma, C.; Xu, J.-Q.; Choi, H.; Xu, H.-F.; Pfefferkorn, F.E.; Li, X.-C. Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scr. Mater. 2012, 67, 29–32. [Google Scholar] [CrossRef]

- Meng, L.; Hu, X.; Wang, X.; Zhang, C.; Shi, H.; Xiang, Y.; Liu, N.; Wu, K. Graphene nanoplatelets reinforced Mg matrix composite with enhanced mechanical properties by structure construction. Mater. Sci. Eng. A 2018, 733, 414–418. [Google Scholar] [CrossRef]

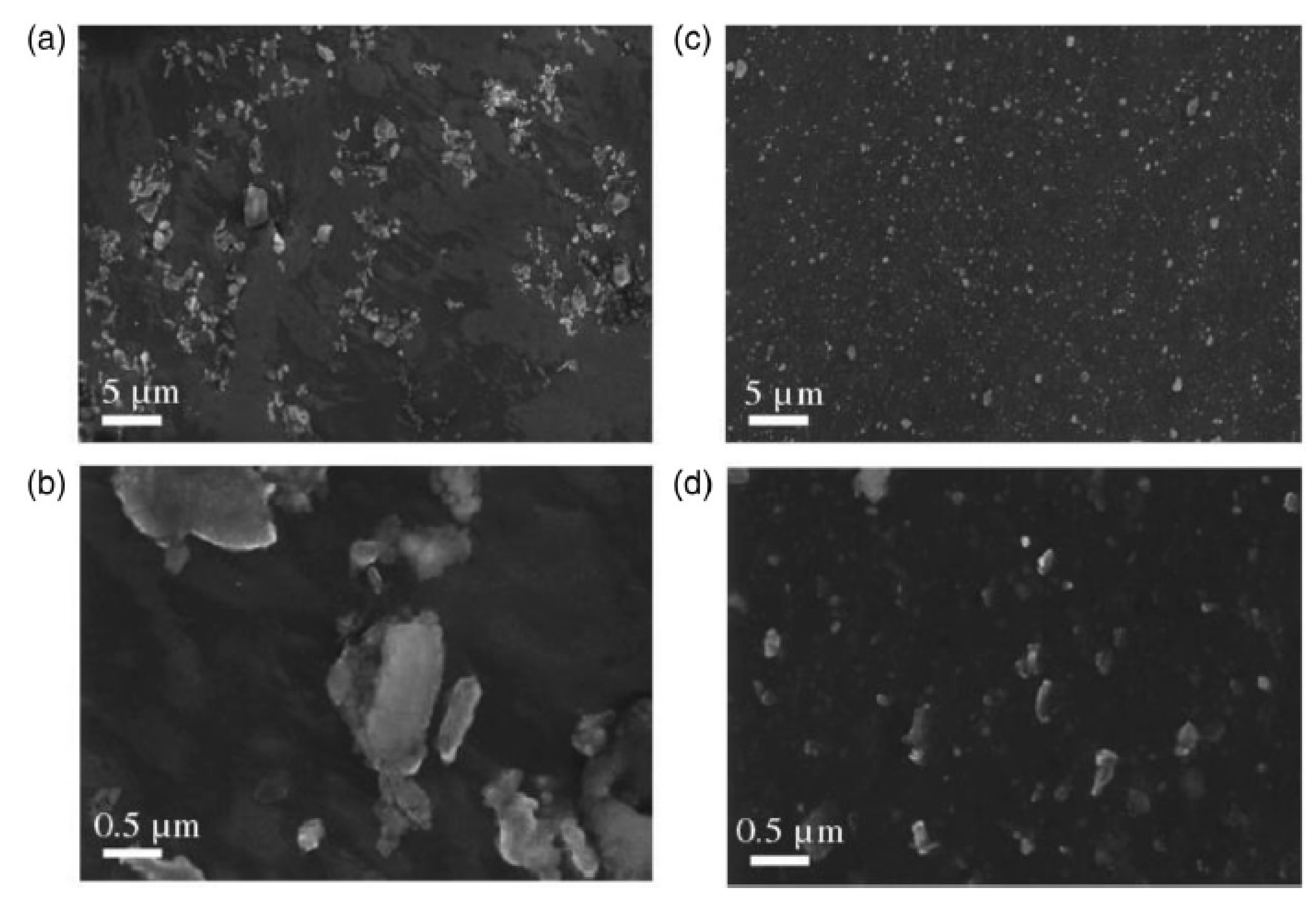

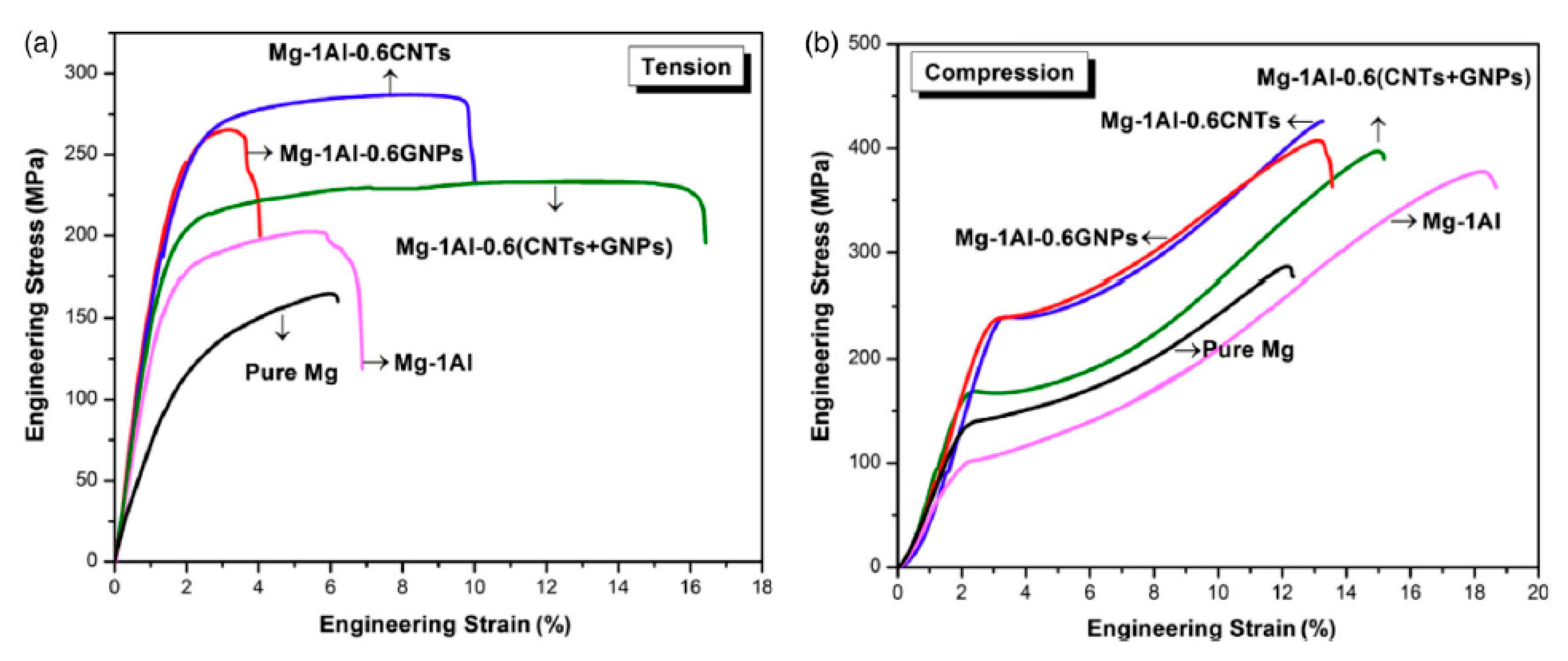

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Aamir, M. Synergetic effect of graphene nanoplatelets (GNPs) and multi-walled carbon nanotube (MW-CNTs) on mechanical properties of pure magnesium. J. Alloys Compd. 2014, 603, 111–118. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; Hussain, S.; Gou, J.; Mao, J. Improved strength and ductility of magnesium with addition of aluminum and graphene nanoplatelets (Al + GNPs) using semi powder metallurgy method. J. Ind. Eng. Chem. 2015, 23, 243–250. [Google Scholar] [CrossRef]

- Du, X.; Du, W.; Wang, Z.; Liu, K.; Li, S. Ultra-high strengthening efficiency of graphene nanoplatelets reinforced magnesium matrix composites. Mater. Sci. Eng. A 2018, 711, 633–642. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M. Exploring mechanical behavior of Mg–6Zn alloy reinforced with graphene nanoplatelets. Mater. Sci. Eng. A 2016, 649, 263–269. [Google Scholar] [CrossRef]

- Lee, J.H.; Marroquin, J.; Rhee, K.Y.; Park, S.J.; Hui, D. Cryomilling application of graphene to improve material properties of graphene/chitosan nanocomposites. Compos. Part B Eng. 2013, 45, 682–687. [Google Scholar] [CrossRef]

- Qiu, F.; Hao, Y.; Li, X.; Wang, B.; Wang, M. Functionalized graphene sheets filled isotactic polypropylene nanocomposites. Compos. Part B Eng. 2015, 71, 175–183. [Google Scholar] [CrossRef]

- Moriche, R.; Prolongo, S.G.; Sánchez, M.; Jiménez-Suárez, A.; Sayagués, M.J.; Ureña, A. Morphological changes on graphene nanoplatelets induced during dispersion into an epoxy resin by different methods. Compos. Part B Eng. 2015, 72, 199–205. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [Green Version]

- Tahriri, M.; Del Monico, M.; Moghanian, A.; Tavakoli Yaraki, M.; Tores, R.; Yadegari, A.; Tayebi, L. Graphene and its derivatives: Opportunities and challenges in dentistry. Mater. Sci. Eng. C 2019, 102, 171–185. [Google Scholar] [CrossRef]

- Mermin, N.D. Crystalline Order in Two Dimensions. Phys. Rev. J. Arch. 1968, 176. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Berger, C.; Song, Z.; Li, T.; Li, X.; Ogbazghi, A.Y.; Feng, R. Ultrathin Epitaxial Graphite: 2D Electron Gas Properties and a Route toward Graphene-based Nanoelectronics. Phys. Chem. B 2004, 108, 19912–19916. [Google Scholar] [CrossRef] [Green Version]

- Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C.; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N.; et al. Electronic Confinement and Coherence in Patterned Epitaxial Graphene. Science 2006, 312, 1191–1196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reina, A.; Jia, X.; Ho, J.; Nezich, D.; Son, H.; Bulovic, V.; Dresselhaus, M.S.; Kong, J. Layer Area, Few-Layer Graphene Films on Arbitrary Substrates by Chemical Vapor Deposition. Nano Lett. 2009, 9, 3087. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Cai, W.; Colombo, L.; Ruoff, R.S. Evolution of Graphene Growth on Ni and Cu by Carbon Isotope Labeling. Nano Lett. 2009, 9, 4268–4272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, L.; Rim, K.T.; Zhou, H.; He, R.; Heinz, T.F.; Pinczuk, A.; Flynn, G.W.; Pasupathy, A.N. Influence of copper crystal surface on the CVD growth of large area monolayer graphene. Solid State Commun. 2011, 151, 509–513. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Fino, P.; Pavese, M. An Overview of Metal Matrix Nanocomposites Reinforced with Graphene Nanoplatelets; Mechanical, Electrical and Thermophysical Properties. Metals 2018, 8, 423. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Cu–GNPs Nanocomposite with Improved Thermal and Mechanical Properties. Acta Met. Sin. 2018, 31, 148–152. [Google Scholar] [CrossRef]

- Rollings, E.; Gweon, G.-H.; Zhou, S.Y.; Mun, B.S.; McChesney, J.L.; Hussain, B.S.; Fedorov, A.V.; First, P.N.; de Heer, W.A.; Lanzara, A. Synthesis and characterization of atomically thin graphite films on a silicon carbide substrate. J. Phys. Chem. Solids 2006, 67, 2172–2177. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; You, H.; Liu, F.; Li, M.; Wan, L.; Li, S.; Li, Q.; Xu, Y.; Tian, R.; Yu, Z.; et al. Large-scale synthesis of few-layered graphene using CVD. Chem. Vap. Depos. 2009, 15, 5356. [Google Scholar] [CrossRef]

- Choi, W.; Lahiri, I.; Seelaboyina, R.; Kang, Y.S. Synthesis of Graphene and Its Applications: A Review. Crit. Rev. Solid State Mater. Sci. 2010, 35, 52–71. [Google Scholar] [CrossRef]

- Soldano, C.; Mahmood, A.; Dujardin, E. Production, properties and potential of graphene. Carbon N. Y. 2010, 48, 2127–2150. [Google Scholar] [CrossRef] [Green Version]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Nuriel, S.; Liu, L.; Barber, A.H.; Wagner, H.D. Direct measurement of multiwall nanotube surface tension. Chem. Phys. Lett. 2005, 404, 263–266. [Google Scholar] [CrossRef]

- Vidu, R.; Rahman, M.; Mahmoudi, M.; Enachescu, M.; Poteca, T.D.; Opris, I. Nanostructures: A platform for brain repair and augmentation. Front. Syst. Neurosci. 2014, 8, 91. [Google Scholar] [CrossRef] [PubMed]

- Cumings, J.; Zettl, A. Low-Friction Nanoscale Linear Bearing Realized from Multiwall Carbon Nanotubes. Science 2000, 289, 602–604. [Google Scholar] [CrossRef]

- Nakajima, M.; Yang, Z.; Saito, Y. In-situ TEM investigation of stepping motion of telescoping carbon nanotube. In Proceedings of the 2010 IEEE/SICE International Symposium on System Integration, Sendai, Japan, 21–22 December 2010; IEEE: Piscataway, NJ, USA; pp. 366–371. [Google Scholar]

- Lide, D.R. Handbook of Chemistry and Physics, 84th ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Nishida, Y. Introduction to Metal Matrix Composites: Fabrication and Recycling; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Cardarelli, F. Materials Handbook: A Coincise Desktop Reference; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Srinivasan, M.; Rafaniello, W. Non-Oxide Materials: Applications and Engineering. In Carbide, Nitride and Boride Materials Synthesis and Processing; Weimer, A.W., Ed.; Springer Netherlands: Dordrecht, The Netherlands, 1997; pp. 3–42. ISBN 978-94-009-0071-4. [Google Scholar]

- Safdari, M. A Computational and Experimental Study on the Electrical and Thermal Properties of Hybrid Nanocomposites Based on Carbon Nanotubes and Graphite Nanoplatelets; Virginia Polytechnic Institute and State University: Blacksburg, Virginia, 2012. [Google Scholar]

- Odegard, G.M.; Gates, T.S.; Nicholson, L.M.; Wise, K.E. Equivalent-continuum modeling of nano-structured materials. Compos. Sci. Technol. 2002, 62, 1869–1880. [Google Scholar] [CrossRef] [Green Version]

- Sakhaee-Pour, A. Elastic properties of single-layered graphene sheet. Solid State Commun. 2009, 149, 91–95. [Google Scholar] [CrossRef]

- Lu, Q.; Bhattacharya, B. The role of atomistic simulations in probing the small-scale aspects of fracture-A case study on a single-walled carbon nanotube. Eng. Fract. Mech. 2005, 72, 2037–2071. [Google Scholar] [CrossRef]

- Tsai, J.-L.; Tu, J.-F. Characterizing mechanical properties of graphite using molecular dynamics simulation. Mater. Des. 2010, 31, 194–199. [Google Scholar] [CrossRef]

- Zheng, Q.; Geng, Y.; Wang, S.; Li, Z.; Kim, J.-K. Effects of functional groups on the mechanical and wrinkling properties of graphene sheets. Carbon N. Y. 2010, 48, 4315–4322. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.; Li, Q.; Carpick, R.; Kysar, J.W.; Hone, J. Elastic and frictional properties of graphene. Phys. Status Solidi 2009, 246, 2562–2567. [Google Scholar] [CrossRef]

- Lin, X.; Shen, X.; Zheng, Q.; Yousefi, N.; Ye, L.; Mai, Y.-W.; Kim, J.-K. Fabrication of Highly-Aligned, Conductive, and Strong Graphene Papers Using Ultralarge Graphene Oxide Sheets. ACS Nano 2012, 6, 10708–10719. [Google Scholar] [CrossRef] [PubMed]

- Xiang, J.; Drzal, L.T. Thermal conductivity of exfoliated graphite nanoplatelet paper. Carbon N. Y. 2011, 49, 773–778. [Google Scholar] [CrossRef]

- Treacy, M.M.J.; Ebbesen, T.W.; Gibson, J.M. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Krishnan, A.; Dujardin, E.; Ebbesen, T.W.; Yianilos, P.N.; Treacy, M.M.J. Young’s modulus of single-walled nanotubes. Phys. Rev. B 1998, 58, 14013–14019. [Google Scholar] [CrossRef]

- Wong, E.W.; Sheehan, P.E.; Lieber, C.M. Nanobeam Mechanics: Elasticity, Strength, and Toughness of Nanorods and Nanotubes. Science 1997, 277, 1971–1975. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Kulik, A.J.; Bonard, J.M.; Briggs, A.D.; Stockli, T.; Metenier, K.; Bonnamy, S.; Beguin, F.; Burnham, N.A.; Forro, L. Elastic modulus of ordered and disordered multiwalled carbon nanotubes. Adv. Mater. 1999, 11, 61–65. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.-F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile Loading of Ropes of Single Wall Carbon Nanotubes and their Mechanical Properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef] [Green Version]

- Demczyk, B.G.; Wang, Y.M.; Cumings, J.; Hetman, M.; Han, W.; Zettl, A.; Ritchie, R.O. Direct mechanical measurement of the tensile strength and elastic modulus of multiwalled carbon nanotubes. Mater. Sci. Eng. A 2002, 334, 173–178. [Google Scholar] [CrossRef]

- Ozkan, T.; Naraghi, M.; Chasiotis, I. Mechanical properties of vapor grown carbon nanofibers. Carbon N. Y. 2010, 48, 239–244. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

- Seol, J.H.; Jo, I.; Moore, A.L.; Lindsay, L.; Aitken, Z.H.; Pettes, M.T.; Li, X.; Yao, Z.; Huang, R.; Broido, D.; et al. Two-Dimensional Phonon Transport in Supported Graphene. Science 2010, 328, 213–216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef] [Green Version]

- Berber, S.; Kwon, Y.-K.; Tománek, D. Unusually High Thermal Conductivity of Carbon Nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef] [Green Version]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal Conductance of an Individual Single-Wall Carbon Nanotube above Room Temperature. Nano Lett. 2006, 6, 96–100. [Google Scholar] [CrossRef]

- Hone, J.; Whitney, M.; Piskoti, C.; Zettl, A. Thermal conductivity of single-walled carbon nanotubes. Phys. Rev. B 1999, 59, R2514–R2516. [Google Scholar] [CrossRef]

- Fujii, M.; Zhang, X.; Xie, H.; Ago, H.; Takahashi, K.; Ikuta, T.; Abe, H.; Shimizu, T. Measuring the Thermal Conductivity of a Single Carbon Nanotube. Phys. Rev. Lett. 2005, 95, 65502. [Google Scholar] [CrossRef]

- Kim, P.; Shi, L.; Majumdar, A.; McEuen, P.L. Thermal Transport Measurements of Individual Multiwalled Nanotubes. Phys. Rev. Lett. 2001, 87, 215502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Pavese, M.; Manfredi, D.; Biamino, S.; Fino, P. Hot deformation behavior of Zr-1%Nb alloy: Flow curve analysis and microstructure observations. Mater. Sci. Eng. A 2017, 696, 366–373. [Google Scholar] [CrossRef]

- Saboori, A.; Tusacciu, S.; Busatto, M.; Lai, M.; Biamino, S.; Fino, P.; Lombardi, M. Production of Single Tracks of Ti-6Al-4V by Directed Energy Deposition to Determine the Layer Thickness for Multilayer Deposition. J. Vis. Exp. 2018, 2018, e56966. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, Y.; Miki, S.; Soga, T.; Itoh, I.; Todoroki, H.; Hosono, T.; Sakaki, K.; Hayashi, T.; Kim, Y.A.; Endo, M.; et al. Multi-walled carbon nanotube-reinforced magnesium alloy composites. Scr. Mater. 2008, 58, 267–270. [Google Scholar] [CrossRef] [Green Version]

- Farayibi, P.K.; Abioye, T.E.; Kennedy, A.; Clare, A.T. Development of metal matrix composites by direct energy deposition of ‘satellited’ powders. J. Manuf. Process. 2019, 45, 429–437. [Google Scholar] [CrossRef]

- Wen, S.; Chen, K.; Li, W.; Zhou, Y.; Wei, Q.; Shi, Y. Selective laser melting of reduced graphene oxide/S136 metal matrix composites with tailored microstructures and mechanical properties. Mater. Des. 2019, 175, 107811. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Saboori, A.; Biamino, S.; Lombardi, M.; Tusacciu, S.; Busatto, M.; Lai, M.; Fino, P. How the nozzle position affects the geometry of the melt pool in directed energy deposition process. Powder Metall. 2019, 62, 213–217. [Google Scholar] [CrossRef]

- Darsono, N.; Yoon, D.-H.; Kim, J. Milling and dispersion of multi-walled carbon nanotubes in texanol. Appl. Surf. Sci. 2008, 254, 3412–3419. [Google Scholar] [CrossRef]

- Morsi, K.; Esawi, A. Effect of mechanical alloying time and carbon nanotube (CNT) content on the evolution of aluminum (Al)--CNT composite powders. J. Mater. Sci. 2007, 42, 4954–4959. [Google Scholar] [CrossRef]

- Poirier, D.; Gauvin, R.; Drew, R.A.L. Structural characterization of a mechanically milled carbon nanotube/aluminum mixture. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1482–1489. [Google Scholar] [CrossRef]

- Shukla, A.K.; Nayan, N.; Murty, S.V.S.N.; Sharma, S.C.; Chandran, P.; Bakshi, S.R.; George, K.M. Processing of copper–carbon nanotube composites by vacuum hot pressing technique. Mater. Sci. Eng. A 2013, 560, 365–371. [Google Scholar] [CrossRef]

- Adamiak, M. Mechanical alloying for fabrication of aluminum matrix composite powders with Ti-Al intermetallics reinforcement. J. Achiev. Mater. Manuf. Eng. 2008, 31, 191–196. [Google Scholar]

- Palza, H.; Garzon, C.; Arias, O. Modifying the electrical behaviour of polypropylene/carbon nanotube composites by adding a second nanoparticle and by annealing processes. Express Polym. Lett. 2012, 6, 639–646. [Google Scholar] [CrossRef] [Green Version]

- Tjong, S.C. Carbon Nanotube Reinforced Composites: Metal and Ceramic Matrices; Wiley-VCH: Veinheim, Germany, 2009. [Google Scholar]

- Behera, M.P.; Dougherty, T.; Singamneni, S. Conventional and Additive Manufacturing with Metal Matrix Composites: A Perspective. Procedia Manuf. 2019, 30, 159–166. [Google Scholar] [CrossRef]

- Zhang, B.; Bi, G.; Chew, Y.; Wang, P.; Ma, G.; Liu, Y.; Moon, S.K. Comparison of carbon-based reinforcement on laser aided additive manufacturing Inconel 625 composites. Appl. Surf. Sci. 2019, 490, 522–534. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Fracture toughness of additively manufactured carbon fiber reinforced composites. Addit. Manuf. 2019, 26, 41–52. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Zhu, J.; Wong, H.M.; Yeung, K.W.K.; Tjong, S.C. Spark Plasma Sintered Hydroxyapatite/Graphite Nanosheet and Hydroxyapatite/Multiwalled Carbon Nanotube Composites: Mechanical and in Vitro Cellular Properties. Adv. Eng. Mater. 2011, 13, 336–341. [Google Scholar] [CrossRef]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al Aqeeli, N.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark Plasma Sintering of Metals and Metal Matrix Nanocomposites: A Review. J. Nanomater. 2012, 2012, 18:18. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X.; Zhao, N.; He, C. Influence of spark plasma sintering temperature on the microstructure and strengthening mechanisms of discontinuous three-dimensional graphene-like network reinforced Cu matrix composites. Mater. Sci. Eng. A 2019, 756, 82–91. [Google Scholar] [CrossRef]

- Shao, G.; Liu, P.; Zhang, K.; Li, W.; Chen, X.; Ma, F. Mechanical properties of graphene nanoplates reinforced copper matrix composites prepared by electrostatic self-assembly and spark plasma sintering. Mater. Sci. Eng. A 2019, 739, 329–334. [Google Scholar] [CrossRef]

- Dong, L.L.; Xiao, B.; Liu, Y.; Li, Y.L.; Fu, Y.Q.; Zhao, Y.Q.; Zhang, Y.S. Sintering effect on microstructural evolution and mechanical properties of spark plasma sintered Ti matrix composites reinforced by reduced graphene oxides. Ceram. Int. 2018, 44, 17835–17844. [Google Scholar] [CrossRef]

- Gao, L.; Hong, J.S.; Miyamoto, H.; Torre, S.D.D. Bending strength and microstructure of Al2O3 ceramics densified by spark plasma sintering. J. Eur. Ceram. Soc. 2000, 20, 2149–2152. [Google Scholar] [CrossRef]

- Haghighi, R.D.; Jahromi, S.A.J.; Moresedgh, A.; Khorshid, M.T. A Comparison Between ECAP and Conventional Extrusion for Consolidation of Aluminum Metal Matrix Composite. J. Mater. Eng. Perform. 2012, 21, 1885–1892. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Geng, L. Improving graphene distribution and mechanical properties of GNP/Al composites by cold drawing. Mater. Des. 2018, 144, 159–168. [Google Scholar] [CrossRef]

- Mishra, R.S.; Stolyarov, V.V.; Echer, C.; Valiev, R.Z.; Mukherjee, A.K. Mechanical behavior and superplasticity of a severe plastic deformation processed nanocrystalline Ti–6Al–4V alloy. Mater. Sci. Eng. A 2001, 298, 44–50. [Google Scholar] [CrossRef]

- Wei, J.; Huang, G.; Yin, D.; Li, K.; Wang, Q.; Zhou, H. Effects of ECAP and Annealing Treatment on the Microstructure and Mechanical Properties of Mg-1Y (wt. %) Binary Alloy. Metals 2017, 7, 119. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Parizi, M.T. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Erman, A.; Groza, J.; Li, X.; Choi, H.; Cao, G. Nanoparticle effects in cast Mg-1 wt% SiC nano-composites. Mater. Sci. Eng. A 2012, 558, 39–43. [Google Scholar] [CrossRef]

- Yuan, Q.; Zeng, X.; Liu, Y.; Luo, L.; Wu, J.; Wang, Y.; Zhou, G. Microstructure and mechanical properties of AZ91 alloy reinforced by carbon nanotubes coated with MgO. Carbon N. Y. 2016, 96, 843–855. [Google Scholar] [CrossRef]

- Arsenault, R.J.; Shi, N. Dislocation generation due to differences between the coefficients of thermal expansion. Mater. Sci. Eng. 1986, 81, 175–187. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Effect of Sample Preparation on the Microstructural Evaluation of Al--GNPs Nanocomposites. Met. Microstruct. Anal. 2017, 6, 619–622. [Google Scholar] [CrossRef]

- Khorshid, M.T.; Jahromi, S.A.J.; Moshksar, M.M. Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron-sized Al2O3 particulates developed by wet attrition milling and hot extrusion. Mater. Des. 2010, 31, 3880–3884. [Google Scholar] [CrossRef]

- Yao, B.; Hofmeister, C.; Patterson, T.; Sohn, Y.; van den Bergh, M.; Delahanty, T.; Cho, K. Microstructural features influencing the strength of Trimodal Aluminum Metal-Matrix-Composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 933–941. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Morsi, K.; Sayed, A.; Taher, M.; Lanka, S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminum composites. Compos. Sci. Technol. 2010, 70, 2237–2241. [Google Scholar] [CrossRef]

- Kondoh, K.; Umeda, J.; Watanabe, R. Cavitation resistance of powder metallurgy aluminum matrix composite with AlN dispersoids. Mater. Sci. Eng. A 2009, 499, 440–444. [Google Scholar] [CrossRef]

- Ünlü, B.S. Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater. Des. 2008, 29, 2002–2008. [Google Scholar] [CrossRef]

- Garbiec, D.; Jurczyk, M.; Levintant-Zayonts, N.; Mościcki, T. Properties of Al–Al2O3 composites synthesized by spark plasma sintering method. Arch. Civ. Mech. Eng. 2015, 15, 933–939. [Google Scholar] [CrossRef]

- Arslan, G.; Kara, F.; Turan, S. Quantitative X-ray diffraction analysis of reactive infiltrated boron carbide–aluminum composites. J. Eur. Ceram. Soc. 2003, 23, 1243–1255. [Google Scholar] [CrossRef]

- Ghasali, E.; Alizadeh, M.; Ebadzadeh, T. Mechanical and microstructure comparison between microwave and spark plasma sintering of Al-B4C composite. J. Alloys Compd. 2016, 655, 93–98. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ebrahimifard, R.; Baghchesara, M.A. Composites: Part B Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: A comparative study. Compos. Part B 2014, 56, 217–221. [Google Scholar] [CrossRef]

- Chawla, N.; Deng, X.; Schnell, D.R.M. Thermal expansion anisotropy in extruded SiC particle reinforced 2080 aluminum alloy matrix composites. Mater. Sci. Eng. A 2006, 426, 314–322. [Google Scholar] [CrossRef]

- Boostani, A.F.; Tahamtan, S.; Jiang, Z.Y.; Wei, D.; Yazdani, S.; Khosroshahi, R.A.; Mousavian, R.T.; Xu, J.; Zhang, X.; Gong, D. Enhanced tensile properties of aluminum matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos. Part A 2015, 68, 155–163. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, X.; Wu, G. Interfacial microstructure of SiCp/Al composite produced by the pressureless infiltration technique. Ceram. Int. 2013, 39, 4893–4897. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Park, J.H.; Ahn, Z.S. Study of the oxidation and sintering behaviours of Al-Al2O3 powder mixture by using a home-style microwave oven. JOM 1995, 30, 3339–3345. [Google Scholar] [CrossRef]

- Saboori, A.; Novara, C.; Pavese, M.; Badini, C.; Giorgis, F.; Fino, P. An Investigation on the Sinterability and the Compaction Behavior of Aluminum/Graphene Nanoplatelets (GNPs) Prepared by Powder Metallurgy. J. Mater. Eng. Perform. 2017, 26, 993–999. [Google Scholar] [CrossRef]

- Saboori, A.; Pietroluongo, M.; Pavese, M.; Badini, C.; Fino, P. Fino Influence of Graphene nanoplatelets (GNPs) on compressibility and sinterability of Al matrix nanocomposites prepared by powder metallurgy. In World PM2016; EPMA: Hamburg, Germany, 2016; p. 8. [Google Scholar]

- Shao, P.; Yang, W.; Zhang, Q.; Meng, Q.; Tan, X.; Xiu, Z.; Qiao, J.; Yu, Z.; Wu, G. Microstructure and tensile properties of 5083 Al matrix composites reinforced with graphene oxide and graphene nanoplates prepared by pressure infiltration method. Compos. Part A Appl. Sci. Manuf. 2018, 109, 151–162. [Google Scholar] [CrossRef]

- Ghazaly, A.; Seif, B.; Salem, H.G. Mechanical and Tribological Properties of AA2124-Graphene Self Lubricating Nanocomposite. In Light Metals 2013; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2013; pp. 411–415. ISBN 9781118663189. [Google Scholar]

- Latief, F.H.; Sherif, E.-S.M. Effects of sintering temperature and graphite addition on the mechanical properties of aluminum. J. Ind. Eng. Chem. 2012, 18, 2129–2134. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Microstructure and Thermal Conductivity of Al--Graphene Composites Fabricated by Powder Metallurgy and Hot Rolling Techniques. Acta Metall. Sin. 2017, 30, 675–687. [Google Scholar] [CrossRef]

- Saboori, A.; Casati, R.; Zanatta, A.; Pavese, M.; Badini, C.; Vedani, M. Effect of graphene nanoplatelets on microstructure and mechanical properties of alsi10mg nanocomposites produced by hot extrusion. Powder Metall. Met. Ceram. 2018, 56, 647–655. [Google Scholar] [CrossRef]

- Renguo, G.; Chao, L.; Zhanyong, Z.; Runze, C.; Chunming, L. Study on preparation of graphene and Al-graphene Composite. Rare Met. Mater Eng. 2012, 41 (Suppl. 2), 607–611. [Google Scholar]

- Wejrzanowski, T.; Grybczuk, M.; Chmielewski, M.; Pietrzak, K.; Kurzydlowski, K.J.; Strojny-nedza, A. Thermal conductivity of metal-graphene composites. Mater. Des. 2016, 99, 163–173. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Lu, Y.; Asif, M.; Hussain, S.; She, J.; Gou, J.; Mao, J. Effect of graphene nanoplatelets (GNPs) addition on strength and ductility of magnesium-titanium alloys. J. Magnes. Alloy. 2013, 1, 242–248. [Google Scholar] [CrossRef] [Green Version]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M.; She, J.; Gou, J.; Mao, J.; Hu, H. Development of magnesium-graphene nanoplatelets composite. Compos. Mater 2014, 27, 806–815. [Google Scholar] [CrossRef]

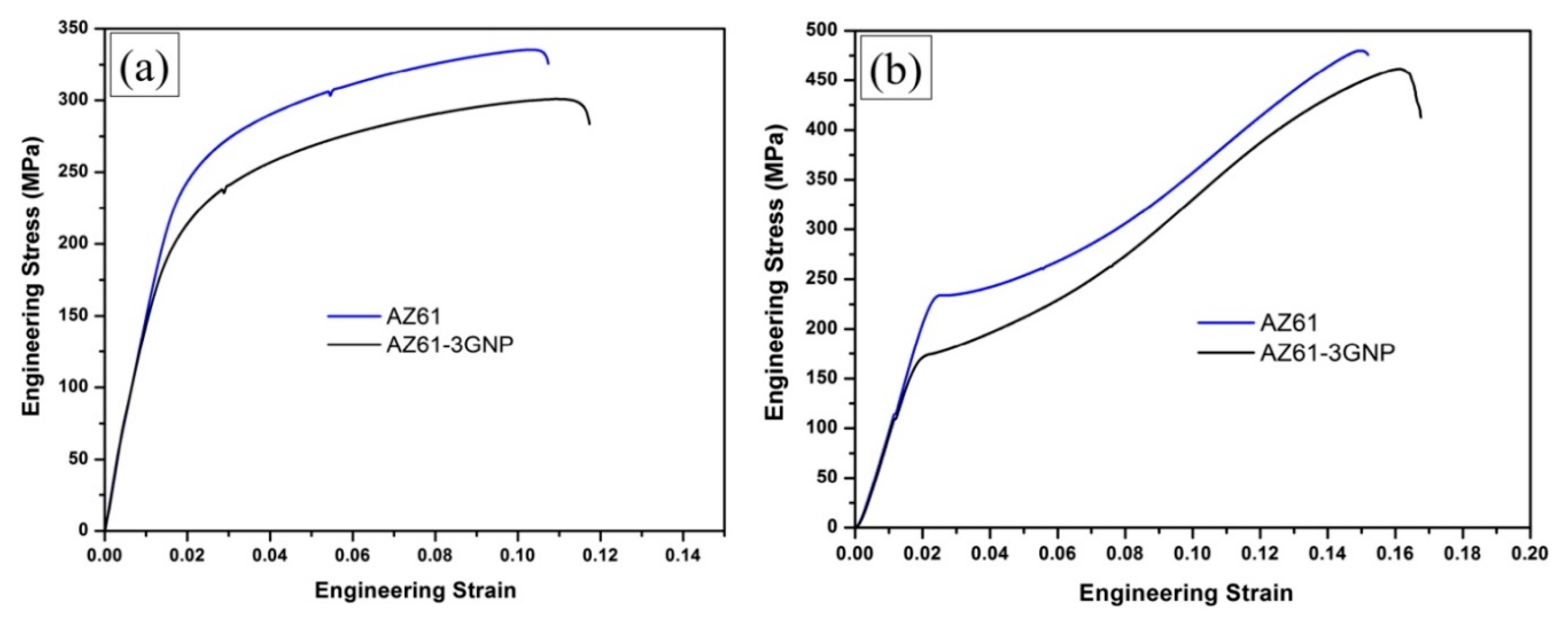

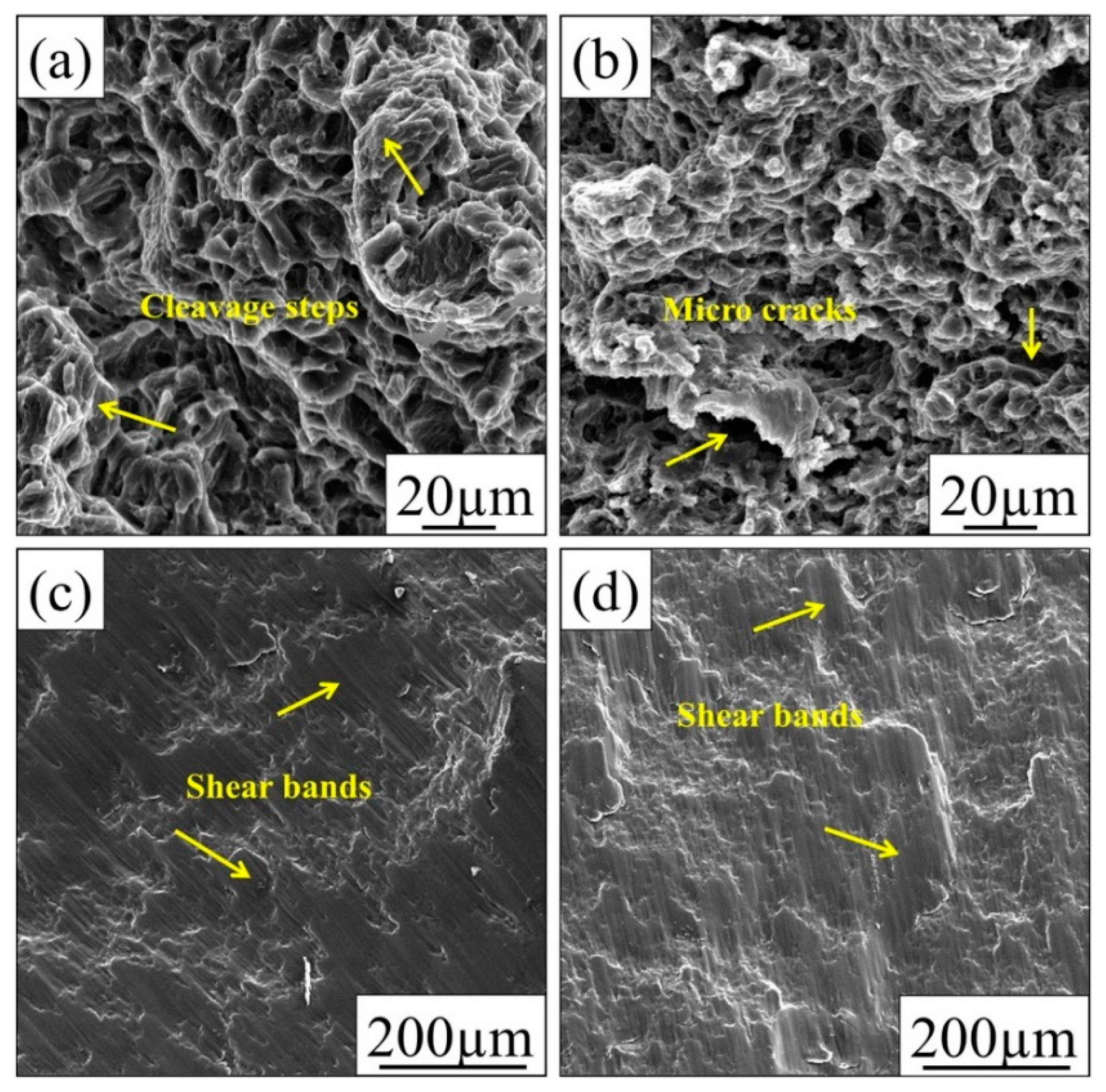

- Rashad, M.; Pan, F.; Lin, D.; Asif, M. High temperature mechanical behavior of AZ61 magnesium alloy reinforced with graphene nanoplatelets. Mater. Des. 2016, 89, 1242–1250. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Shi, D.L.; Feng, X.Q.; Huang, Y.Y.; Hwang, K.C. Critical Evaluation of the Stiffening Effect of Carbon Nanotubes in Composites. In Advances in Fracture and Failure Prevention; Key Engineering Materials; Trans Tech Publications: Warwick, NY, USA, 2004; Volume 261, pp. 1487–1492. [Google Scholar]

- Chen, L.; Zhao, Y.; Hou, H.; Zhang, T.; Liang, J.; Li, M.; Li, J. Development of AZ91D magnesium alloy-graphene nanoplatelets composites using thixomolding process. J. Alloys Compd. 2019, 778, 359–374. [Google Scholar] [CrossRef]

- Li, M.; Che, H.; Liu, X.; Liang, S.; Xie, H. Highly enhanced mechanical properties in Cu matrix composites reinforced with graphene decorated metallic nanoparticles. J. Mater. Sci. 2014, 49, 3725–3731. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A. Microstructure, Electrical Conductivity and Hardness of Multilayer Graphene/Copper Nanocomposites Synthesized by Flake Powder Metallurgy. Met. Mater. Int. 2015, 21, 704–712. [Google Scholar] [CrossRef]

- Li, J.F.; Zhang, L.; Xiao, J.K.; Zhou, K.C. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite. Trans. Nonferrous Met. Soc. China 2015, 25, 3354–3362. [Google Scholar] [CrossRef]

- Zhang, D.; Zhan, Z. Strengthening effect of graphene derivatives in copper matrix composites. J. Alloys Compd. 2016, 654, 226–233. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Liu, M.; Crimp, M.A.; Wang, Y.; Qu, Z. Anisotropic thermal expansion coefficient of multilayer graphene reinforced copper matrix composites. J. Alloys Compd. 2018, 755, 114–122. [Google Scholar] [CrossRef]

- Salvo, C.; Mangalaraja, R.V.; Udayabashkar, R.; Lopez, M.; Aguilar, C. Enhanced mechanical and electrical properties of novel graphene reinforced copper matrix composites. J. Alloys Compd. 2019, 777, 309–316. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Approach to Enhance the Mechanical Strength and Electrical and Thermal Conductivity of Cu-GNP Nanocomposites. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49. [Google Scholar] [CrossRef]

- Hao, X.; Wang, X.; Zhou, S.; Zhang, H.; Liu, M. Microstructure and properties of silver matrix composites reinforced with Ag-doped graphene. Mater. Chem. Phys. 2018, 215, 327–331. [Google Scholar] [CrossRef]

- Fu, K.; Zhang, X.; Shi, C.; Liu, E.; He, F.; Li, J.; Zhao, N.; He, C. An approach for fabricating Ni@graphene reinforced nickel matrix composites with enhanced mechanical properties. Mater. Sci. Eng. A 2018, 715, 108–116. [Google Scholar] [CrossRef]

- Mu, X.N.; Cai, H.N.; Zhang, H.M.; Fan, Q.B.; Zhang, Z.H.; Wu, Y.; Ge, Y.X.; Wang, D.D. Interface evolution and superior tensile properties of multi-layer graphene reinforced pure Ti matrix composite. Mater. Des. 2018, 140, 431–441. [Google Scholar] [CrossRef]

- Xiao, W.; Lu, S.; Wang, Y.; Shi, J. Mechanical and tribological behaviors of graphene/Inconel 718 composites. Trans. Nonferrous Met. Soc. China 2018, 28, 1958–1969. [Google Scholar] [CrossRef]

- Zhai, W.; Shi, X.; Yao, J.; Ibrahim, A.M.M.; Xu, Z.; Zhu, Q.; Xiao, Y.; Chen, L.; Zhang, Q. Investigation of mechanical and tribological behaviors of multilayer graphene reinforced Ni3Al matrix composites. Compos. Part B Eng. 2015, 70, 149–155. [Google Scholar] [CrossRef]

- Zhang, L.X.; Zhang, B.; Sun, Z.; Tian, X.Y.; Lei, M.; Feng, J.C. Preparation of the graphene nanosheets reinforced AgCuTi based composite for brazing graphite and Cu. J. Alloys Compd. 2019, 782, 981–985. [Google Scholar] [CrossRef]

- Kuang, D.; Xu, L.; Liu, L.; Hu, W.; Wu, Y. Graphene–nickel composites. Appl. Surf. Sci. 2013, 273, 484–490. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A. V Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Mu, X.N.; Cai, H.N.; Zhang, H.M.; Fan, Q.B.; Wang, F.C.; Zhang, Z.H.; Ge, Y.X.; Shi, R.; Wu, Y.; Wang, Z.; et al. Uniform dispersion and interface analysis of nickel coated graphene nanoflakes/ pure titanium matrix composites. Carbon N. Y. 2018, 137, 146–155. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, K.; Zhang, M. Fabrication and properties of Ni-modified graphene nanosheets reinforced Sn-Ag-Cu composite solder. J. Alloys Compd. 2019, 781, 761–772. [Google Scholar] [CrossRef]

- Manige, S.T.; Gowd, D.G.H.; Reddy, D.B.C.M. Processing of Magnesium Metal Matrix Composite Reinforced with Graphene Nano Platelets through Vacuum Stir Casting and Investigating its Mechanical Behaviour. J. Thin Film. Coat. Sci. Technol. Appl. 2018, 5. [Google Scholar]

- Pavithra, C.L.P.; Sarada, B.V.; Rajulapati, K.V.; Rao, T.N.; Sundararajan, G. A New Electrochemical Approach for the Synthesis of Copper-Graphene Nanocomposite Foils with High Hardness. Sci. Rep. 2014, 4, 4049. [Google Scholar] [CrossRef] [PubMed]

- Du, X.M.; Zhen, K.F.; Liu, F.G. Graphene reinforced magnesium matrix composites by hot pressed sintering. Dig. J. Nanomater. Bios. 2018, 13, 827–833. [Google Scholar]

- Zhou, K.; Zhu, Y.; Yang, X.; Luo, J.; Li, C.; Luan, S. A novel hydrogen peroxide biosensor based on Au–graphene–HRP–chitosan biocomposites. Electrochim. Acta 2010, 55, 3055–3060. [Google Scholar] [CrossRef]

- Chou, S.-L.; Wang, J.-Z.; Choucair, M.; Liu, H.-K.; Stride, J.A.; Dou, S.-X. Enhanced reversible lithium storage in a nanosize silicon/graphene composite. Electrochem. Commun. 2010, 12, 303–306. [Google Scholar] [CrossRef]

- Li, Y.; Tang, L.; Li, J. Preparation and electrochemical performance for methanol oxidation of pt/graphene nanocomposites. Electrochem. Commun. 2009, 11, 846–849. [Google Scholar] [CrossRef]

| Matrix | Reinforcement Content | Production Method | Features | Ref. |

|---|---|---|---|---|

| Al | 0.3 wt.% graphene | BM and CPM |

| [37] |

| 0.1 wt.% graphene | Blending, BM, HIP and extruding |

| [38] | |

| 0.3 wt.% GNSs | CPM and EX |

| [39] | |

| 0.3 wt.% RGO | Compacting and HP |

| [40] | |

| 2 wt.% GNSs | Liquid state |

| [41] | |

| 8–10 vol.% FLG | Electrochemical co-deposition |

| [42] | |

| 0.7 vol.% FLG | BM and HR |

| [43] | |

| 1 wt.% FLG | BM, pre-compaction and hot compaction |

| [44] | |

| 0.5–1.0 wt.% GNFs | Cryomilling and HEX |

| [45] | |

| 0.25–1.0 wt.% GNPs | BM and CPM |

| [46] | |

| 0.1–0.5 wt.% graphene | HP |

| [47] | |

| 0.5, 1, 1.5, 2 wt.% graphene | Blending, cryo-milling, degassing and EX |

| [48] | |

| Al 2009 | 1 wt.% GNPs | CPM and multi-pass friction stir |

| [49] |

| Al7055 | 1.0–5.0 wt.% graphene | SPS |

| [50] |

| Cu | 0.5, 1 vol.% graphene | BM and (HRDSR) |

| [51] |

| 3, 5, 8, 12 vol.% graphene | Compacting and sintering |

| [52] | |

| 0–4 vol.% GNPs | Molecular-level mixing process, SPS |

| [53] | |

| 1.3 wt.% GNPs | Electroless plating, SPS tensile |

| [54] | |

| GNPs | Electrochemical deposition |

| [55] | |

| 0.5 wt.% GNPs | In-situ CVD |

| [56] | |

| 0.3 wt.% RGO | GO fill in ‘brick-and-mortar’ Hot pressing |

| [57] | |

| Mg | 0.3 wt.% graphene | Semi-powder metallurgy |

| [58] |

| Mg–1 wt.% Al | 0.3 wt.% GNPs | Powder metallurgy |

| [59] |

| 0.18 wt.% GNPs |

| |||

| 0.09 wt.% GNPs |

| |||

| Mg | 1.0 vol.% GNPs | BM, SPS |

| [60] |

| 2 vol.% GNPs |

| |||

| 5 vol.% GNPs |

| |||

| 1.2 vol.% GNPs | Liquid state ultrasonic and solid state friction stirring |

| [61] | |

| 0.25, 0.75vol% GNPs | HP, HR |

| [62] | |

| Mg–1 wt.% Al | 0.60 wt.% GNPs | Compaction, sintering and EX |

| [63] |

| Mg–1 wt.% Al 1 wt.% Sn | 0.18 wt.% GNPs | Semi-CPM and HEX |

| [58] |

| Mg–0.5 wt.% Al | 0.18 wt.% GNPs | Semi powder metallurgy, HEX |

| [64] |

| Mg—1.0 wt.% Al |

| |||

| Mg—1.5 wt.% Al |

| |||

| Mg alloy (ZK60) | 0.05 wt.% GNPs | Facile melt stirring and HEX |

| [65] |

| Mg—6Zn | 0.5 wt.% GNPs | Disintegrated melt deposition |

| [66] |

| 1.5 wt.% GNPs |

|

| Property | Graphene | Ref. |

|---|---|---|

| Resistivity | 10−6 Ω·cm | [84] |

| Thermal conductivity | 5.3 × 103 W·m−1·K−1 | |

| Transmittance | >95% for 2 nm thick film >70% for 10 nm thick film | [85] |

| Young’s modulus | 0.5–1 TPa | |

| Thermal Expansion Coefficient | −6 × 10−4/K | |

| Young’s modulus | 0.5–1 TPa | |

| Specific Surface area | 2630 m2·g−1 | |

| Ultimate tensile strength | 130 GPa | |

| Thermal conductivity | 5.3 × 103 W·m−1·K−1 |

| Material | Thermal Conductivity (W·m−1·K−1) | Thermal Expansion Coefficient (106 k−1) | Density (g·cm−3) | Melting Point (°C) | Vickers Hardness (HV) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|---|

| Graphite | 25–470 | 0.6–4.3 | 1.3–1.95 | - | - | 8–15 |

| Diamond | 2400 | - | 3.52 | 3550 | 8000 | 930 |

| Graphene | 5300 | −0.8–0.7 | 1.8–2.2 | - | - | 1020 |

| SWCNTs | Up to 2900 | Negligible | 1.8 | - | - | 1000 |

| Materials | Elastic Modulus, TPa | Tensile Strength, GPa | Experimental Methods | Ref. |

|---|---|---|---|---|

| Graphene | 1.02 | 130 | Nanoindentation in AFM | [102] |

| GNP | ~1 | ~10–20 | - | [104] |

| Arc-grown MWNT | 1.8 | - | Amplitudes of thermal vibrations of MWNTs placed inside TEM | [105] |

| SWNT | 1.25 | - | Amplitudes of thermal vibrations of SWNTs placed inside TEM | [106] |

| Arc-grown MWNT | 1.28 | - | Bending of pinned MWNT inside AFM | [107] |

| Arc-grown MWNT | 0.81 | - | Bending of pinned MWNT inside AFM | [108] |

| CVD-grown MWNT | 0.027 | - | Bending of pinned MWNT inside AFM | |

| Arc-grown MWNT | 0.27–0.95 | 11–63 | Tensile test of MWNT in SEM | [109] |

| SWNT rope | 0.32–1.47 | 13–52 | Tensile test of nanotube rope in SEM | [110] |

| Arc-grown MWNT | 0.9 | 150 | Tensile test of MWNT in TEM | [111] |

| Pyrolytic stripped CNF | 0.18 | 2.90 | Micro electromechanical device | [112] |

| Graphitized CNF | 0.245 | 2.35 | Micro electromechanical device |

| Materials | Tensile Strength, GPa | Tensile Modulus, GPa | Thermal Conductivity, W·m−1·K−1 |

|---|---|---|---|

| CF (T300; Cytec Thornel | 3.65 | 231 | 8.5 |

| SWNT | - | 1000 | 3500 |

| MWNT | 150 | 270–950 | 500–2069 |

| CNF (Graphitized) | 2.35 | 245 | 1950 |

| Graphene | 130 | 1002 | 4840–5300 |

| Composites | Reinforcement (vol.%) | Microhardness (HV) | Bending Strength (MPa) | Relative Density (%) |

|---|---|---|---|---|

| Cu–GNPs | 2.5 | 66.5 | 362.03 | 98.9 |

| 5 | 69.2 | 294.39 | 98.5 | |

| 7.5 | 74.2 | 185.68 | 98.4 | |

| 10 | 68.9 | 149.01 | 98.2 | |

| Cu–GNSs | 2.5 | 67.8 | 441.27 | 99.1 |

| 5 | 71.7 | 301.16 | 98.9 | |

| 7.5 | 97.4 | 284.01 | 98.7 | |

| 10 | 56.8 | 211.85 | 97.5 |

| Mechanical Features | Pure Cu | Cu-0.1 wt.% GNPs | Cu-0.2 wt.% GNPs | Cu-0.3 wt.% GNPs |

|---|---|---|---|---|

| Yield strength (MPa) | 126 | 159 | 171 | 117 |

| Tensile strength (MPa) | 183 | 214 | 233 | 172 |

| Elongation (%) | 29 | 26 | 23 | 18 |

| Vickers hardness (HV) | 90 | 105 | 108.6 | 88 |

| Content of Reinforcement | Electrical Conductivity (%IACS) | Production Technique | Ref. |

|---|---|---|---|

| 1–5 wt.% MLG | 78.5–61.5 | Flake PM | [188] |

| 0–4 vol.% GNPs | 80–92 | SPS | [53] |

| 1 wt.% FLG | 94 (at 600 °C) 81 (at 700 °C) | Mechanical milling and HP | [192] |

| 2 vol.% GNPs | 77 | Sintering and HIPing | [193] |

| 4 vol.% GNPs | 72.5 | ||

| 8 vol.% GNPs | 67.5 |

| Composite | Content of Reinforcement | Production Method | Properties | Ref. |

|---|---|---|---|---|

| Ni | 0.5 wt.% 3D-GNs | In-situ high-temperature CVD, impregnation-reduction process and SPS |

| [195] |

| 1.0 wt.% 3D-GNs |

| |||

| Ti | 0.1 wt.% MLG | SPS and HR |

| [196] |

| 0.2 wt.% MLG |

| |||

| Inconel 718 | 0.25 wt.% GNPs | Selective laser melting |

| [197] |

| 1.0 wt.% GNPs |

| |||

| Ni3Al alloy | 1.0 wt.% MLG | BM, CPM and SPS process |

| [198] |

| Ni | 0.12 wt.% GO (1.2 nm) | Electro deposition |

| [200] |

| Fe | 2 wt.% GO single layer | Laser sintering |

| [184] |

| ZK60 | 0.05wt.% GNPs | Melt stirring HEX |

| [65] |

| Ag–Cu–Ti alloy | GNSs | Melting |

| [199] |

| Steel | 10 g/L GO | - |

| [201] |

| Ti | Ni–0.05 wt.% GNFs | BM, SPS, HR |

| [202] |

| 0.05 wt.% GNFs |

| |||

| Ag | 0.5 wt.% Ag-doped GNSs | Chemical reduction and CPM |

| [194] |

| Ag-doped GNSs (1.5 wt.%) |

| |||

| Ag-doped GNSs (3 wt.%) |

| |||

| Sn–2.5Ag–0.7Cu | Ni–0.03–0.05wt.% GNSs | MA |

| [203] |

| MMNCs | Properties and Applications | Ref. |

|---|---|---|

| Cu/Graphene | High thermal and electrical conductive foil for electronic packaging | [205] |

| Mg/graphene | Ultra-high performance parts for automotive industries | [206] |

| Au/Graphene | H2O2 biosensor | [207] |

| Si/Graphene | Anode materials for Li-ion battery | [208] |

| Pt/Graphene | Super capacitor-fuel cell | [209] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dadkhah, M.; Saboori, A.; Fino, P. An Overview of the Recent Developments in Metal Matrix Nanocomposites Reinforced by Graphene. Materials 2019, 12, 2823. https://doi.org/10.3390/ma12172823

Dadkhah M, Saboori A, Fino P. An Overview of the Recent Developments in Metal Matrix Nanocomposites Reinforced by Graphene. Materials. 2019; 12(17):2823. https://doi.org/10.3390/ma12172823

Chicago/Turabian StyleDadkhah, Mehran, Abdollah Saboori, and Paolo Fino. 2019. "An Overview of the Recent Developments in Metal Matrix Nanocomposites Reinforced by Graphene" Materials 12, no. 17: 2823. https://doi.org/10.3390/ma12172823

APA StyleDadkhah, M., Saboori, A., & Fino, P. (2019). An Overview of the Recent Developments in Metal Matrix Nanocomposites Reinforced by Graphene. Materials, 12(17), 2823. https://doi.org/10.3390/ma12172823