The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Concrete Substrate Mix Design and Preparation

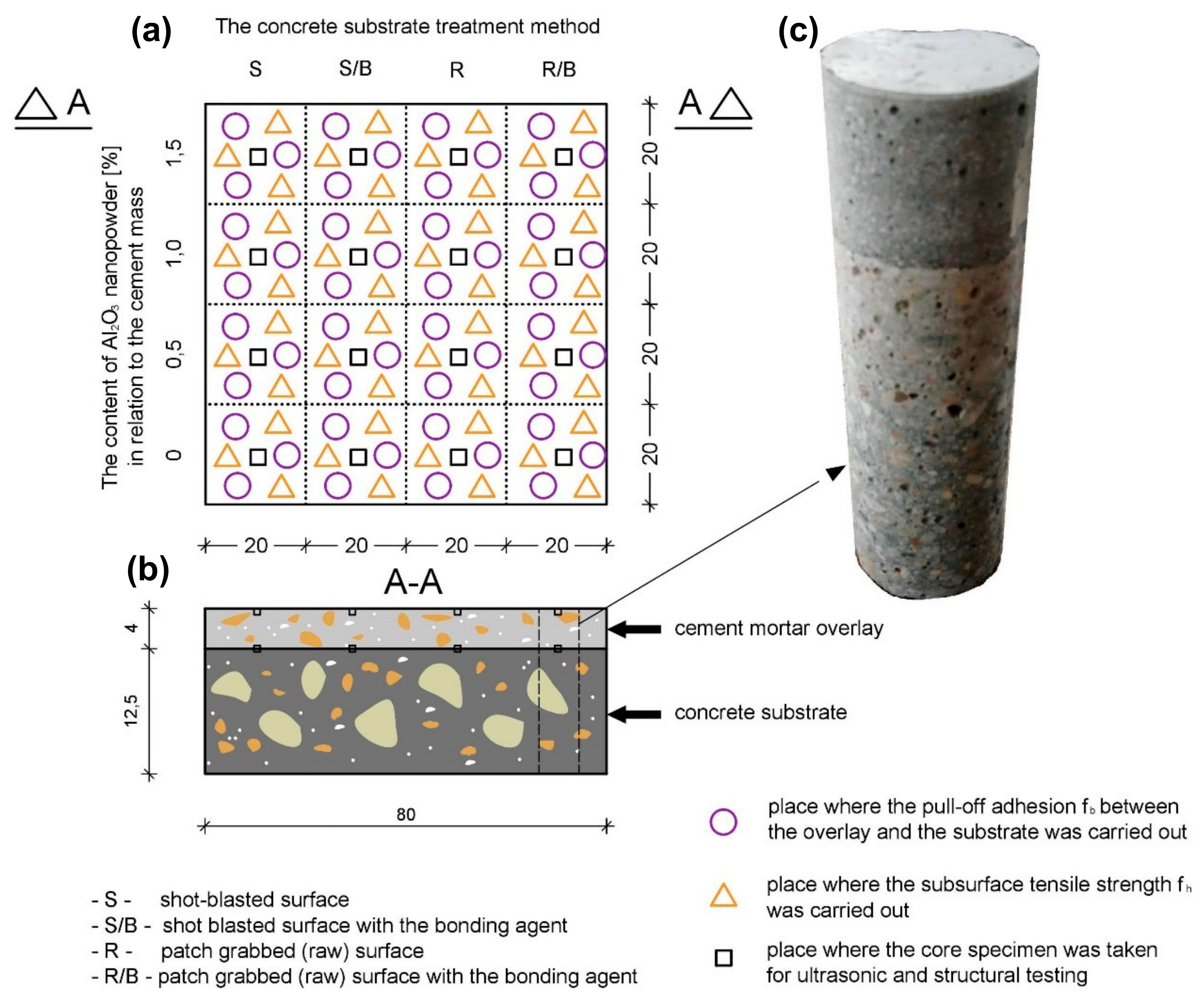

- S—shot-blasted surface obtained after shot-blasting with removal of dust;

- S/B—shot-blasted surface obtained after shot-blasting with removal of dust and the application of the bonding agent;

- R—patch grabbed (raw) surface obtained after casting;

- R/B—patch grabbed (raw) surface obtained after casting and the application of the bonding agent.

2.2. Mix Design of the Cement Mortar Used to Make the Overlay and Its Preparation

2.3. Determination of the Particle Size Distribution of Nanopowder Using Transmission Electron Microscopy (TEM)

2.4. Determination of the Consistency and Bulk Density of Fresh Mortars

2.5. Determination of the Mechanical Properties and Porosity of Hardened Cement Mortars

2.6. Determination of the Pull-Off Adhesion of the Cement Mortars Used to Make the Overlays to the Concrete Substrate

2.7. Determination of the Course of the Longitudinal Velocity of the Ultrasonic Wave along the Thickness of the Cement Mortar Used to Make the Overlay

2.8. Determination of the Abrasion Resistance of Cement Mortars

2.9. Determination of the Subsurface Tensile Strength and Subsurface Hardness of Cement Mortars

2.10. Determination of the Microstructure of the Samples Using a Scanning Electron Microscope (SEM)

3. Results and Analysis

3.1. The Particle Size Distribution of Nanopowder Using Transmission Electron Microscopy (TEM)

3.2. The Consistency and Bulk Density of Fresh Mortars

3.3. The Mechanical Properties and Porosity of Hardened Cement Mortars

3.4. The Pull-Off Adhesion of the Cement Mortar Used to Make the Overlay to the Concrete Substrate

3.5. The Course of the Longitudinal Velocity of the Ultrasonic Wave along the Thickness of the Cement Mortar Used to Make the Overlay

3.6. The Abrasion Resistance of Cement Mortars

3.7. The Subsurface Tensile Strength and Subsurface Hardness of Cement Mortars

3.8. The Microstructure of the Samples Using a Scanning Electron Microscope (SEM)

4. Conclusions

- The studies conducted of setting times, tests using the Novikow cone and tests of the bulk density of the fresh cement mortars showed that, with an increasing content of Al2O3 nanopowder in the cement mortar, the consistency of the mixture deteriorates. The exception is the addition of 0.5% of Al2O3 nanopowder, for which the consistency of the mix is at a lower level when compared to the mortar without nanopowder in its composition. In addition, the increase in content of Al2O3 nanopowder, compared to the reference mortar, causes the shortening of the initial setting time and extending of the final setting time. It was found that the bulk density of fresh mortar is higher, together with an increase of the content of Al2O3 nanopowder. However, this was not the case for the addition of 0.5%, for which the density is at the same level in relation to the reference mortar.

- It was found that the mechanical properties and porosity of the hardened mortar do not depend on the addition of Al2O3 nanopowder. Only the addition of 0.5% of Al2O3 nanopowder decreases the porosity in comparison to the reference mortar without nanopowder in its composition. In turn, the addition of 0.5%, 1.0% and 1.5% of Al2O3 nanopowder results in a lower compressive and flexural strengths than for the reference mortar.

- The results obtained using the pull-off method show that the addition of 0.5% of Al2O3 nanopowder has a positive effect on the pull-off adhesion fb of the cement mortar used to make the overlay to the concrete substrate. It was shown that the addition of Al2O3 nanopowder considerably reduces the coefficient of variation and standard deviation of the values obtained of the pull-off adhesion fb. This was confirmed by ultrasonic tests, which presented that the addition of Al2O3 nanopowder in cement mortar has a very positive effect on the longitudinal wave speed cL at a distance of about 15 mm from the interphase between the cement mortar used to make the overlay and the concrete substrate. This was also confirmed by the research carried out using a scanning electron microscope (SEM), which proved that the reason for improving the adhesion is the fact that the mortar with 0.5% of Al2O3 nanopowder is less porous compared to the reference mortar.

- The results of the abrasion resistance tests were that when using 1.0% and 1.5% of Al2O3 nanopowder, the abrasion resistance of the cement mortar used to make the overlay increased in comparison with the reference mortar. It was also found that the mortar made with 0.5%, 1.0% and 1.5% of Al2O3 nanopowder had a lower subsurface tensile strength in relation to the reference mortar. On the other hand, the subsurface hardness of the cement mortar used to make the overlay, detected using the sclerometric method, does not depend on the addition of Al2O3 nanopowder. The most favorable results, in terms of lower abrasion resistance and higher subsurface tensile strength, are mainly brought about by the use of 0.5% of Al2O3 nanopowder. The studies performed using SEM confirmed that the reason for the improvement in abrasion resistance and subsurface tensile strength is the fact that the mortar with the addition of 0.5% of Al2O3 nanopowder is less porous than the reference mortar.

Author Contributions

Funding

Conflicts of Interest

References

- Czarnecki, L.; Emmons, P.H. Repair and Protection of Concrete Structures; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Król, M. Naprawy i wzmocnienia konstrukcji budowlanych. Przegląd Bud. 2009, 80, 30–36. [Google Scholar]

- Ściślewski, Z. Ochrona konstrukcji żelbetowych; Arkady: Warszawa, Poland, 1999. [Google Scholar]

- Raupach, M.; Büttner, T. Concrete Repair to EN 1504: Diagnosis, Design, Principles and Practice; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Czarnecki, L.; Łukowski, P.; Garbacz, A. Naprawa i Ochrona Konstrukcji z Betonu–Komentarz do PN-EN 1504; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2017. [Google Scholar]

- Kosior-Kazberuk, M. Metody doboru materiałów do ochrony i napraw konstrukcji żelbetowych zgodnie z EN 1504. Zeszyty Naukowe Politechniki Białostockiej. Budownictwo 2007, 31, 151–161. [Google Scholar]

- Raupach, M. Concrete repair according to the new European standard EN 1504. In Concrete Repair, Rehabilitation and Retrofitting; Taylor & Francis: London, UK, 2006; pp. 6–8. [Google Scholar]

- Lukovic, M.; Ye, G.; Van Breugel, K. Reliable concrete repair: A critical review. In Proceedings of the 14th International Conference Structural Faults and Repair, Edinburgh, UK, 3–5 July 2012. [Google Scholar]

- Lukovic, M.; Ye, G. Effect of moisture exchange on interface formation in the repair system studied by X-ray absorption. Materials 2016, 91, 2. [Google Scholar] [CrossRef] [PubMed]

- Sadowski, Ł.; Mathia, T.G. Multi-scale metrology of concrete surface morphology: Fundamentals and specificity. Constr. Build. Mater. 2016, 113, 613–621. [Google Scholar] [CrossRef]

- Luković, M.; Ye, G.; Schlangen, E.; van Breugel, K. Moisture movement in cement-based repair systems monitored by X-ray absorption. Heron 2017, 621, 21. [Google Scholar]

- Luković, M.; Šavija, B.; Schlangen, E.; Ye, G.; van Breugel, K. A 3D lattice modelling study of drying shrinkage damage in concrete repair systems. Materials 2016, 97, 575. [Google Scholar] [CrossRef]

- Lukovic, M.; Schlangen, E.; Ye, G.; Savija, B. Impact of surface roughness on the debonding mechanism in concrete repairs. In Proceedings of the 8th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Toledo, Spain, 10–14 March 2013. [Google Scholar]

- Garbacz, A.; Górka, M.; Courard, L. Effect of concrete surface treatment on adhesion in repair systems. Mag. Concr. Res. 2005, 571, 49–60. [Google Scholar] [CrossRef]

- Van Der Putten, J.; De Schutter, G.; Van Tittelboom, K. Surface modification as a technique to improve inter-layer bonding strength in 3D printed cementitious materials. Rilem Tech. Lett. 2019, 4, 33–38. [Google Scholar] [CrossRef]

- Balakrishnan, V.S.; Obrosov, A.; Kuke, F.; Seidlitz, H.; Weiß, S. Influence of metal surface preparation on the flexural strength and impact damage behaviour of thermoplastic FRP reinforced metal laminate made by press forming. Compos. Part B Eng. 2019, 173, 106883. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Żak, A.; Hoła, J. Multi-sensor evaluation of the concrete within the interlayer bond with regard to pull-off adhesion. Arch. Civ. Mech. Eng. 2018, 18, 573–582. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Krzywiński, K.; Michoń, M. The influence of texturing of the surface of concrete substrate on its adhesion to cement mortar overlay. J. Adhes. Accept. 2019, 1–14. [Google Scholar] [CrossRef]

- Krzywiński, K.; Sadowski, Ł. The effect of texturing of the surface of concrete substrate on the pull-off strength of epoxy resin coating. Coatings 2019, 92, 143. [Google Scholar] [CrossRef]

- Santos, D.S.; Santos, P.M.D.; Dias-da-Costa, D. Effect of surface preparation and bonding agent on the concrete-to-concrete interface strength. Constr. Build. Mater. 2012, 37, 102–110. [Google Scholar] [CrossRef]

- Xiong, G.; Luo, B.; Wu, X.; Li, G.; Chen, L. Influence of silane coupling agent on quality of interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Compos. 2006, 28, 97–101. [Google Scholar] [CrossRef]

- Błaszczyński, T.; Jasiczak, J.; Ksit, B.; Siewczyńska, M. Aspects of bond layer role in concrete repairs. Arch. Civ. Mech. Eng. 2006, 6, 75–87. [Google Scholar] [CrossRef]

- Mohammadi, M.; Moghtadaei, R.M.; Ashraf Samani, N. Influence of silica fume and metakaolin with two different types of interfacial adhesives on the bond strength of repaired concrete. Constr. Build. Mater. 2014, 51, 141–150. [Google Scholar] [CrossRef]

- Kuo, W.T.; Liu, M.Y.; Juang, C.U. Bonding Behavior of Repair Material Using Fly-Ash/Ground Granulated Blast Furnace Slag-Based Geopolymer. Materials 2019, 1210, 1697. [Google Scholar] [CrossRef]

- Gomaa, E.; Gheni, A.A.; Kashosi, C.; ElGawady, M.A. Bond strength of eco-friendly class C fly ash based alkali-activated concrete to portland cement concrete. J. Clean. Prod. 2019, 235, 404–416. [Google Scholar] [CrossRef]

- Sabah, S.A.; Hassan, M.H.; Bunnori, N.M.; Johari, M.M. Bond strength of the interface between normal concrete substrate and GUSMRC repair material overlay. Constr. Build. Mater. 2019, 216, 261–271. [Google Scholar] [CrossRef]

- Zanotti, C.; Borges, P.H.; Bhutta, A.; Banthia, N. Bond strength between concrete substrate and metakaolin geopolymer repair mortar: Effect of curing regime and PVA fiber reinforcement. Cem. Concr. Compos. 2017, 80, 307–316. [Google Scholar] [CrossRef]

- Nunes, V.A.; Borges, P.H.; Zanotti, C. Mechanical compatibility and adhesion between alkali-activated repair mortars and Portland cement concrete substrate. Constr. Build. Mater. 2019, 215, 569–581. [Google Scholar] [CrossRef]

- El-Rakib, T.M.; Farahat, A.M.; El-Degwy, W.M.; Shaheen, H.H. Shear transfer parameters at the interface between old and new concrete. In Proceedings of the International Conference on Performance of Construction Materials in the New Millennium (ICPCM), Elmaarefa Printing House, Cairo, Egypt, 18–20 February 2003. [Google Scholar]

- Robayo-Salazar, R.; Jesús, C.; de Gutiérrez, R.M.; Pacheco-Torgal, F. Alkali-activated binary mortar based on natural volcanic pozzolan for repair applications. J. Build. Eng. 2019, 25, 100785. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; You, C.; Fan, Y.; Li, Z.; Wang, H. Bond behavior and interfacial micro-characteristics of magnesium phosphate cement onto old concrete substrate. Constr. Build. Mater. 2018, 167, 166–176. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Hoła, J. Wpływ wybranych kwarcowych dodatków mineralnych modyfikujących beton warstwy wierzchniej na jego zespolenie z podkładem betonowym. Bud. O Zoptymalizowanym Potencjale Energetycznym 2017, 119, 21–26. [Google Scholar] [CrossRef]

- Luković, M.; Šavija, B.; Dong, H.; Schlangen, E.; Ye, G. Micromechanical study of the interface properties in concrete repair systems. J. Adv. Concr. Technol. 2014, 129, 320–339. [Google Scholar] [CrossRef]

- Binici, H. Effect of crushed ceramic and basaltic pumice as fine aggregates on concrete mortars properties. Constr. Build. Mater. 2007, 216, 1191–1197. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Łagód, G.; Fic, S.; Jarosz-Hadam, M. Effect of Polysiloxanes on Roughness and Durability of Basalt Fibres–Reinforced Cement Mortar. Polymers 2018, 104, 420. [Google Scholar] [CrossRef]

- Halicka, A.; Ogrodnik, P.; Zegardlo, B. Using ceramic sanitary ware waste as concrete aggregate. Constr. Build. Mater. 2013, 48, 295–305. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Türkel, S.; Altuntaş, Y. Effects of steel fiber reinforcement on surface wear resistance of self-compacting repair mortars. Cem. Concr. Compos. 2007, 295, 391–396. [Google Scholar] [CrossRef]

- Giergiczny, Z. Dodatki mineralne–niezastąpione składniki współczesnego cementu i betonu. Mater. Bud. 2009, 3, 46–50. [Google Scholar]

- Golewski, G.L. A novel specific requirements for materials used in reinforced concrete composites subjected to dynamic loads. Compos. Struct. 2019, 223, 110939. [Google Scholar] [CrossRef]

- Golewski, G.L. An assessment of microcracks in the Interfacial Transition Zone of durable concrete composites with fly ash additives. Compos. Struct. 2018, 200, 515–520. [Google Scholar] [CrossRef]

- Kurdowski, W. Dodatki mineralne do cementu a trwałość betonu. Monografia 1991, 106, 109–120. [Google Scholar]

- Łukowski, P. Modyfikacja materiałowa betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2016. [Google Scholar]

- Karunarathne, V.K.; Paul, S.C.; Šavija, B. Development of Nano-SiO2 and Bentonite-Based Mortars for Corrosion Protection of Reinforcing Steel. Materials 2019, 1216, 2622. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Xuan, D.; Poon, C.S. Effects of nano-SiO2 and glass powder on mitigating alkali-silica reaction of cement glass mortars. Constr. Build. Mater. 2019, 201, 295–302. [Google Scholar] [CrossRef]

- Szymanowski, J. Evaluation of the adhesion between overlays and substrates in concrete floors: Literature survey, recent non-destructive and semi-destructive testing methods and research gaps. Buildings 2019, 9, 203. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Sikora, P.; Abd Elrahman, M.; Stephan, D. The Influence of nanomaterials on the thermal resistance of cement-based composites—A Review. Nanomaterials 2018, 87, 465. [Google Scholar] [CrossRef]

- Horszczaruk, E. Properties of cement-based composites modified with magnetite nanoparticles: A review. Materials 2019, 122, 326. [Google Scholar] [CrossRef]

- Czarnecki, L. Czy nanotechnologia to przyszłość betonu? Mater. Bud. 2007, 11, 4–5. [Google Scholar]

- Shah, S.P.; Hou, P.; Konsta-Gdoutos, M.S. Nano-modification of cementitious material: Toward a stronger and durable concrete. J. Sustain. Cem. Based Mater. 2016, 5, 1–22. [Google Scholar] [CrossRef]

- Yang, X.; Sun, L.; Huang, B.; Zhan, B.; Zhang, C.; Chu, Y.; An, D. Tuning the properties of functional adhesives with hybrid nanofillers for structural health monitoring. J. Adhes. 2019, 1–16. [Google Scholar] [CrossRef]

- Niewiadomski, P. Short overview of the effects of nanoparticles on mechanical properties of concrete. In Key Engineering Materials; Trans Tech Publications: Baech, Switzerland, 2015; Volume 662, pp. 257–260. [Google Scholar]

- Iskra-Kozak, W.; Konkol, J. Concrete nanomodification with selected nanoparticles. Czas. Inżynierii LądowejŚrodowiska I Archit. 2018, 65, 113–120. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, Ł. Functional and adhesive properties of cement-based overlays modifies with amorphous silica nanospheres. J. Adhes. 2019, 1–22. [Google Scholar] [CrossRef]

- Stefaniuk, D.; Niewiadomski, P.; Musiał, M.; Łydżba, D. Elastic properties of self-compacting concrete modified with nanoparticles: Multiscale approach. Arch. Civ. Mech. Eng. 2019, 194, 1150–1162. [Google Scholar] [CrossRef]

- Chen, J.; Liang, C.; Li, B.; Wang, E.; Li, G.; Hou, X. The effect of nano-γAl2O3 additive on early hydration of calcium aluminate cement. Constr. Build. Mater. 2018, 158, 755–760. [Google Scholar] [CrossRef]

- Zhai, L.L.; Ling, G.P.; Wang, Y.W. Effect of nano-Al2O3 on adhesion strength of epoxy adhesive and steel. Int. J. Adhes. Adhes. 2008, 28, 23–28. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Chindaprasirt, P.; Sata, V.; Hanjitsuwan, S.; Hatanaka, S. The effect of adding nano-SiO2 and nano-Al2O3 on properties of high calcium fly ash geopolymer cured at ambient temperature. Mater. Des. 2014, 55, 58–65. [Google Scholar] [CrossRef]

- Silva, J.V.; Ismael, R.; Carmo, R.N.F.; Lourenço, C.; Soldado, E.; Costa, H.; Júlio, E. Influence of nano-SiO2 and nano-Al2O3 additions on the shear strength and the bending moment capacity of RC beams. Constr. Build. Mater. 2016, 123, 35–46. [Google Scholar] [CrossRef]

- Gupta, S.K.; Shukla, D.K.; Kaustubh Ravindra, D. Effect of nanoalumina in epoxy adhesive on lap shear strength and fracture toughness of aluminium joints. J. Adhes. 2019, 1–23. [Google Scholar] [CrossRef]

- PN-B-04500:1985. Zaprawy budowlane—Badania cech fizycznych i wytrzymałościowych. Available online: http://sklep.pkn.pl/pn-b-04500-1985p.html (accessed on 16 March 2019).

- EN 1015-6:2000. Metody badań zapraw do murów—Określenie gęstości objętościowej świeżej zaprawy. Available online: http://sklep.pkn.pl/pn-en-1015-6-2000p.html (accessed on 16 March 2019).

- EN 196-1: 2016. Methods of testing cement—Part 1: Determination of compressive strength. Available online: http://sklep.pkn.pl/pn-en-196-1-2016-07p.html (accessed on 16 March 2019).

- EN 13892-2: 2004. Methods of test for screed materials—Part 2: Determination of flexural and compressive strength. Available online: http://sklep.pkn.pl/pn-en-13892-2-2004p.html (accessed on 16 March 2019).

- EN, B. 1542—Products and Systems for the Protection and Repair of Concrete Structures-Test Methods-Measurement of Bond Strength by Pull-Off; British Standard Institution: London, UK, 1999. [Google Scholar]

- Gudra, T.; Stawiski, B. Non-destructive strength characterization of concrete using surface waves. Ndt E Int. 2000, 33, 1–6. [Google Scholar] [CrossRef]

- Ongpeng, J.M.; Oreta, A.W.; Hirose, S. Characterization of Damage Using Ultrasonic Testing on Different Types of Concrete. Mater. Eval. 2018, 7611, 1532–1541. [Google Scholar]

- Czarnecki, S. Ultrasonic Evaluation of the pull-off adhesion between added repair layer and a concrete substrate. In IOP Conference Series: Materials Science and Engineering; IOP: London, UK, 2007; Volume 245, p. 032037. [Google Scholar]

- Szymanowski, J.; Sadowski, Ł. Ultrasonic Pulse Velocity Evaluation of the Pull-Off Adhesion between Epoxy Resin and Concrete Substrate. In Key Engineering Materials; Trans Tech Publications: Baech, Switzerland, 2017; Volume 728, pp. 390–395. [Google Scholar]

- Szymanowski, J.; Sadowski, Ł. Adhesion assessment between concrete layers using the ultrasonic pulse velocity method. In Applied Mechanics and Materials; Trans Tech Publications: Baech, Switzerland, 2015; Volume 797, pp. 145–150. [Google Scholar]

- Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S. Contact and Noncontact Ultrasonic Nondestructive Test in Reinforced Concrete Beam. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Michałek, J. Variation in Compressive Strength of Concrete across Thickness of Placed Layer. Materials 2019, 1213, 2162. [Google Scholar] [CrossRef] [PubMed]

- Skowroński, W.; Stawiski, B. Ultrasonic evaluation regarding the effects of biological corrosion of historical roof trusses. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 284, p. 07006. [Google Scholar]

- EN 13892-3:2005 Methods for Testing Materials for Undercoats—Part 3: Determination of Abrasion Resistance According to Bohme. Available online: http://sklep.pkn.pl/pn-en-13892-3-2015-02e.html (accessed on 16 March 2019).

- EN 12504-2:2013–Testing Concrete in Structures—Part 2: Nondestructive Testing—Determination of Rebound Number. Available online: http://sklep.pkn.pl/pn-en-12504-2-2013-03e.html (accessed on 16 March 2019).

- Wong, H.S.; Head, M.K.; Buenfeld, N.R. Pore segmentation of cement-based materials from backscattered electron images. Cem. Concr. Res. 2006, 366, 1083–1090. [Google Scholar] [CrossRef]

- Mohseni, E.; Miyandehi, B.M.; Yang, J.; Yazdi, M. A Single and combined effects of nano-SiO2, nano-Al2O3 and nano-TiO2 on the mechanical, rheological and durability properties of self-compacting mortar containing fly ash. Constr. Build. Mater. 2015, 84, 331–340. [Google Scholar] [CrossRef]

- Gowda, R.; Narendra, H.; Rangappa, D.; Prabhakar, R. Effect of nano-alumina on workability, compressive strength and residual strength at elevated temperature of Cement Mortar. Mater. Today Proc. 2017, 4, 12152–12156. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Improvement compressive strength of concrete in different curing media by Al2O3 nanoparticles. Mater. Sci. Eng. A 2011, 528, 1183–1191. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; He, S.; Lu, Y.; Wang, M. Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite. Mater. Lett. 2006, 603, 356–359. [Google Scholar] [CrossRef]

- Mohseni, E.; Tsavdaridis, K.D. Effect of nano-alumina on pore structure and durability of Class F Fly ash self-compacting mortar. Am. J. Eng. Appl. Sci. 2016, 9, 323–333. [Google Scholar] [CrossRef]

- Śliwiński, J. Wall effect—Essence of the phenomenon and the way of taking it into account in the concrete mix design. Cem. Lime Concr. 1998, 3, 151–154. [Google Scholar]

- Stawiski, B. The heterogeneity of mechanical properties of concrete in formed constructions horizontally. Arch. Civ. Met. Eng. 2012, 121, 90–94. [Google Scholar] [CrossRef]

- Stawiski, B. Ultradźwiękowe badania betonów i zapraw głowicami punktowymi. Prace Naukowe Instytutu Budownictwa Politechniki Wrocławskiej. Monografie 2009, 92, 154. [Google Scholar]

| Content of Al2O3 Nanopowder | Al2O3 Nanopowder | Cement type CEM I 42.5 R | Fine Aggregate (Sand) | Polycarboxylate-Based Superplasticizer | Water |

|---|---|---|---|---|---|

| (% of the mass of cement) | (g) | ||||

| 0 | 0 | 73.30 | 100.00 | 0.37 | 22.00 |

| 0.5 | 0.37 | 73.30 | 100.00 | 0.37 | 22.00 |

| 1.0 | 0.73 | 73.30 | 100.00 | 0.37 | 22.00 |

| 1.5 | 1.10 | 73.30 | 100.00 | 0.37 | 22.00 |

| Surface | Content of Al2O3 Nanopowder | Mean Values | Standard Deviation | Coefficients of Variation |

|---|---|---|---|---|

| (% of the Mass of Cement) | (MPa) | (-) | (%) | |

| R (Patch grabbed surface) | 0 | 1.05 | 0.07 | 6.67% |

| 0.5 | 1.22 | 0.04 | 3.07% | |

| 1.0 | 1.24 | 0.04 | 3.29% | |

| 1.5 | 1.36 | 0.03 | 2.42% | |

| R/B (patch grabbed with bonding agent) | 0 | 1.10 | 0.21 | 19.09% |

| 0.5 | 1.29 | 0.30 | 22.87% | |

| 1.0 | 1.77 | 0.42 | 23.54% | |

| 1.5 | 1.56 | 0.30 | 19.38% | |

| S (shot-blasted surface) | 0 | 1.75 | 0.05 | 2.65% |

| 0.5 | 2.08 | 0.08 | 4.08% | |

| 1.0 | 1.86 | 0.05 | 2.85% | |

| 1.5 | 1.63 | 0.06 | 3.68% | |

| S/B (shot-blasted surface with bonding agent) | 0 | 1.97 | 0.09 | 4.62% |

| 0.5 | 1.54 | 0.11 | 7.13% | |

| 1.0 | 1.91 | 0.11 | 5.65% | |

| 1.5 | 2.84 | 0.06 | 2.16% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szymanowski, J.; Sadowski, Ł. The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials 2019, 12, 3465. https://doi.org/10.3390/ma12213465

Szymanowski J, Sadowski Ł. The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials. 2019; 12(21):3465. https://doi.org/10.3390/ma12213465

Chicago/Turabian StyleSzymanowski, Jacek, and Łukasz Sadowski. 2019. "The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors" Materials 12, no. 21: 3465. https://doi.org/10.3390/ma12213465

APA StyleSzymanowski, J., & Sadowski, Ł. (2019). The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials, 12(21), 3465. https://doi.org/10.3390/ma12213465