Viscoplastic Couette Flow in the Presence of Wall Slip with Non-Zero Slip Yield Stress

Abstract

:1. Introduction

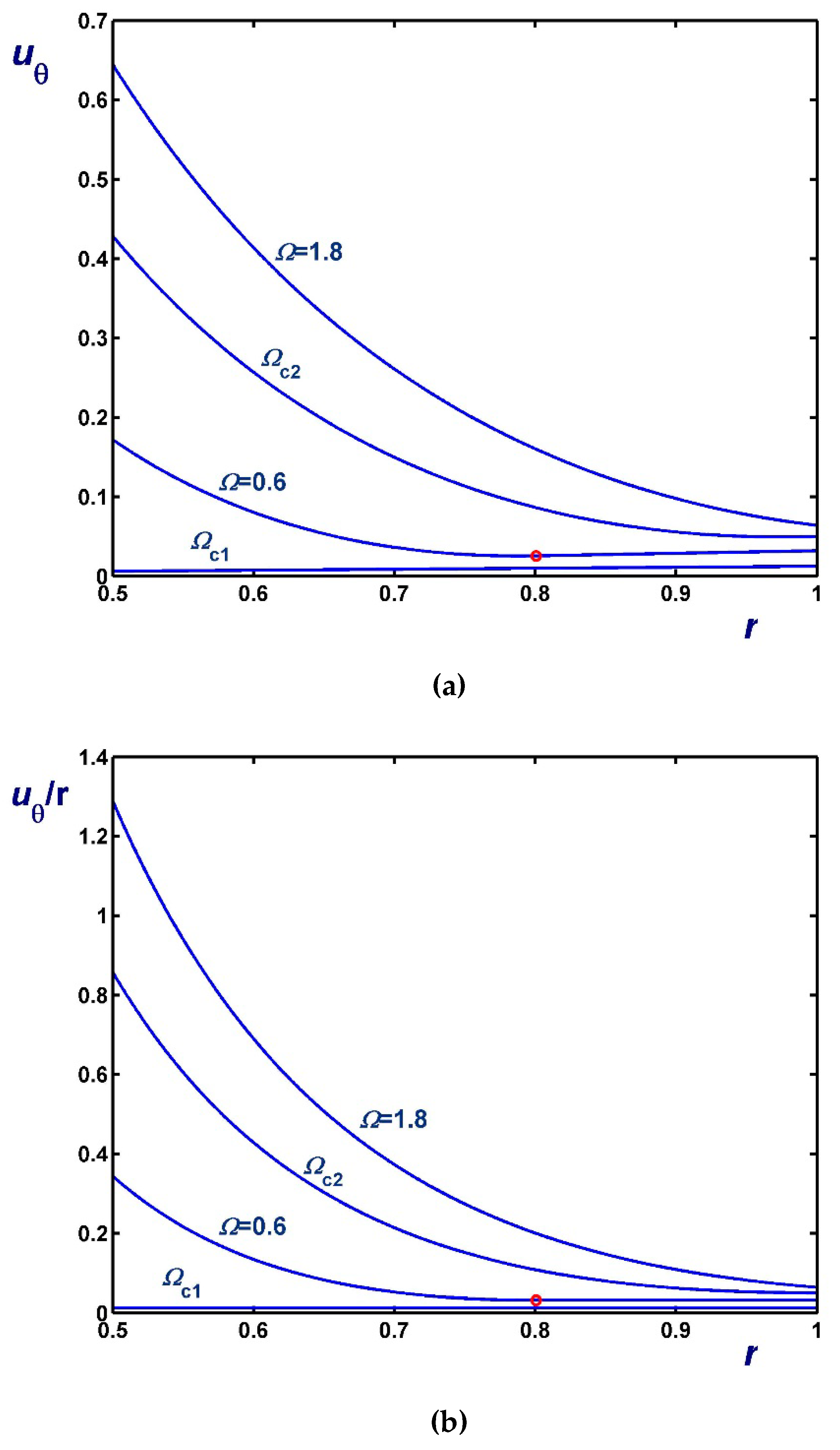

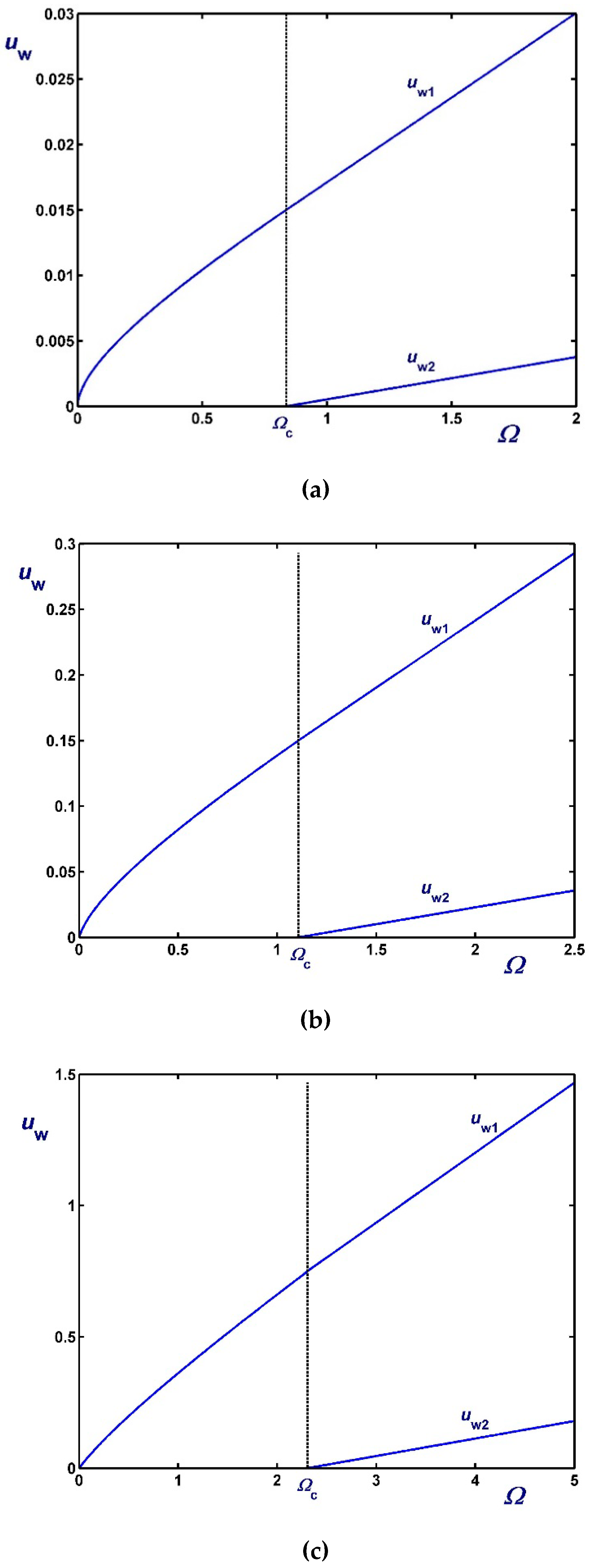

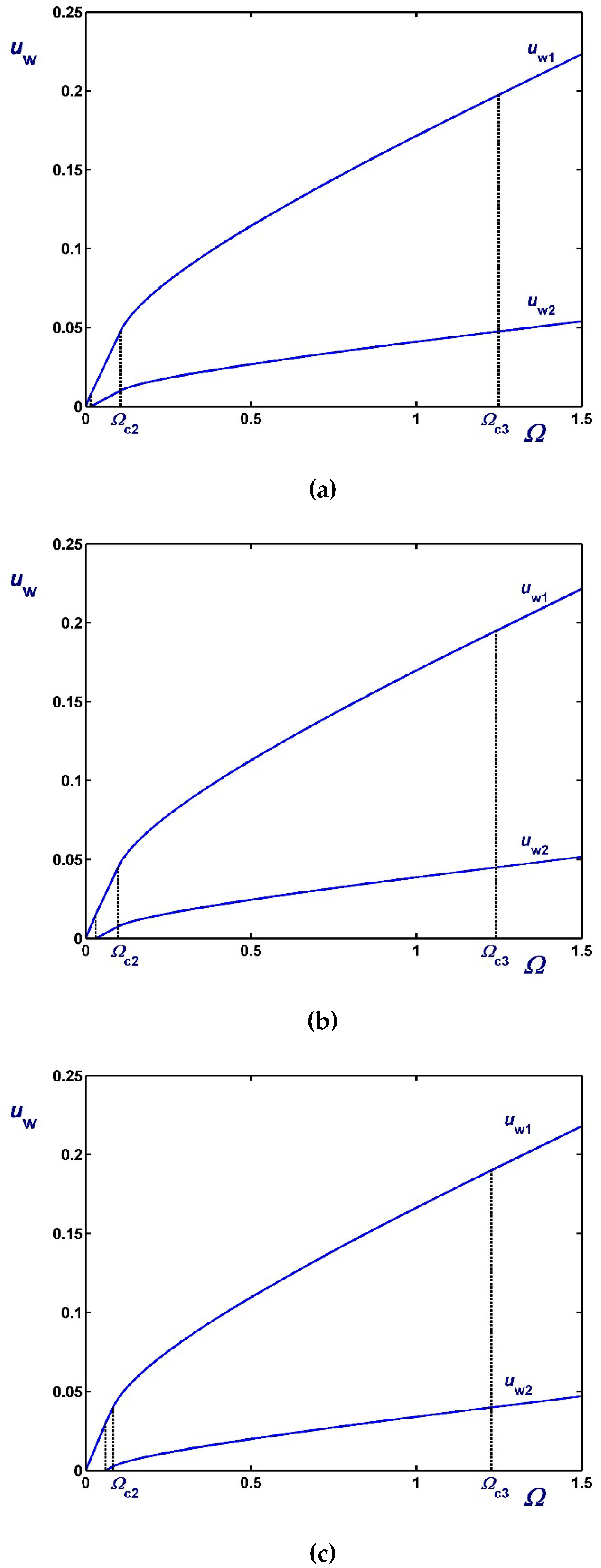

2. Navier Slip

- (a)

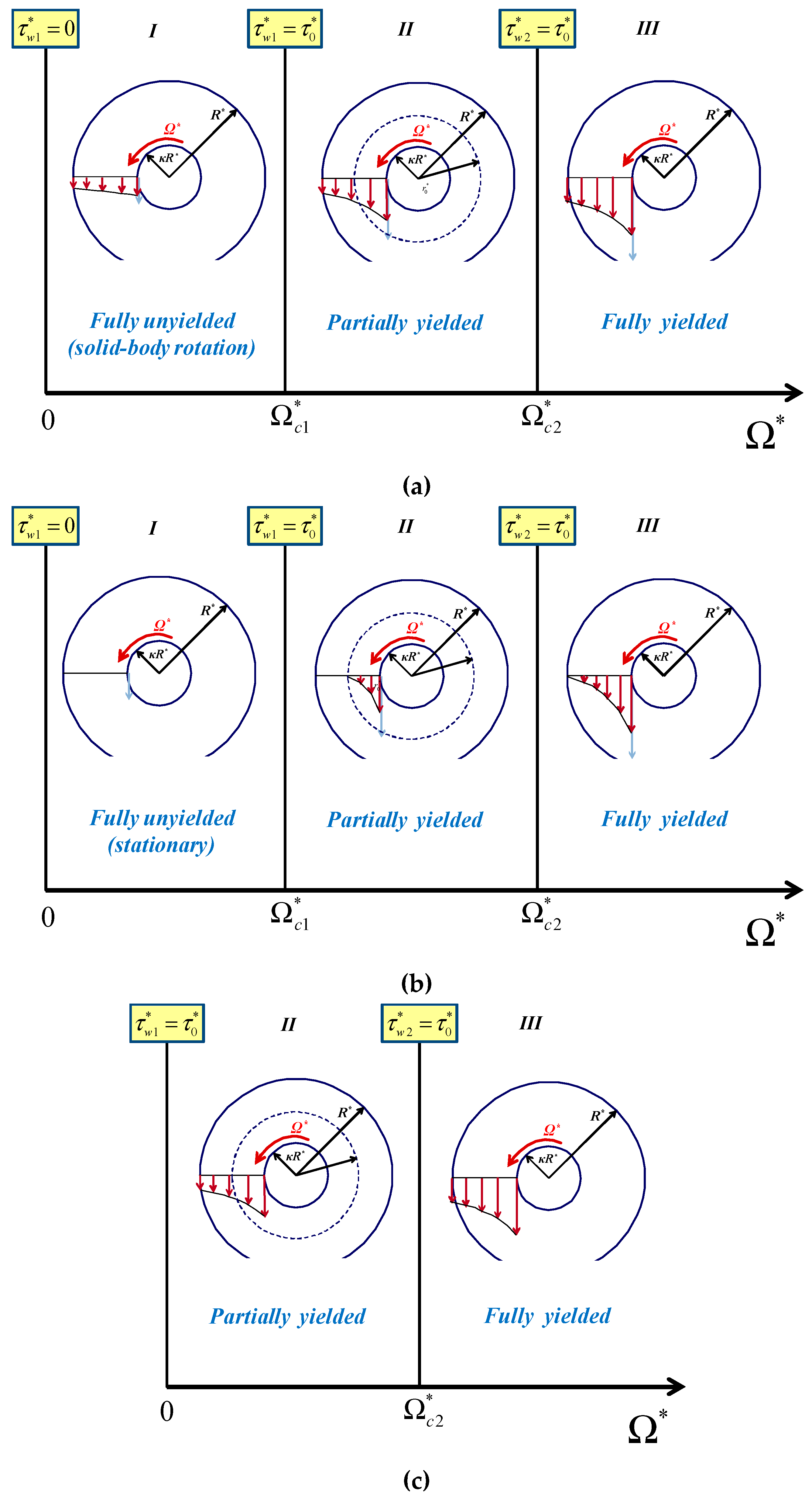

- Regime I. When all the material is unyielded rotating as a solid body with an angular velocity , which is smaller than the angular velocity of the inner cylinder (). In the case of no-slip along the outer cylinder, the material is stationary (Figure 2b), while in the case of no slip along both walls this regime is not observed (Figure 2c). It should be noted that the velocities sketched in Figure 2 are indicative sketches (i.e., not accurate); for example, in the regions of solid-body rotation the velocity is actually increasing with r.

- (b)

- Regime II. When and the material in the gap is partially yielded, i.e., it yields only for , where is the outer radius of the yielded core, i.e., the radius at which . The material in the unyielded annulus rotates as a solid body when slip is imposed on the outer cylinder. Otherwise, the unyielded material is stationary (Figure 2b). As the inner wall shear stress is increased in this regime the radius increases from to .

- (c)

- Regime III. When the material in the gap is fully yielded.

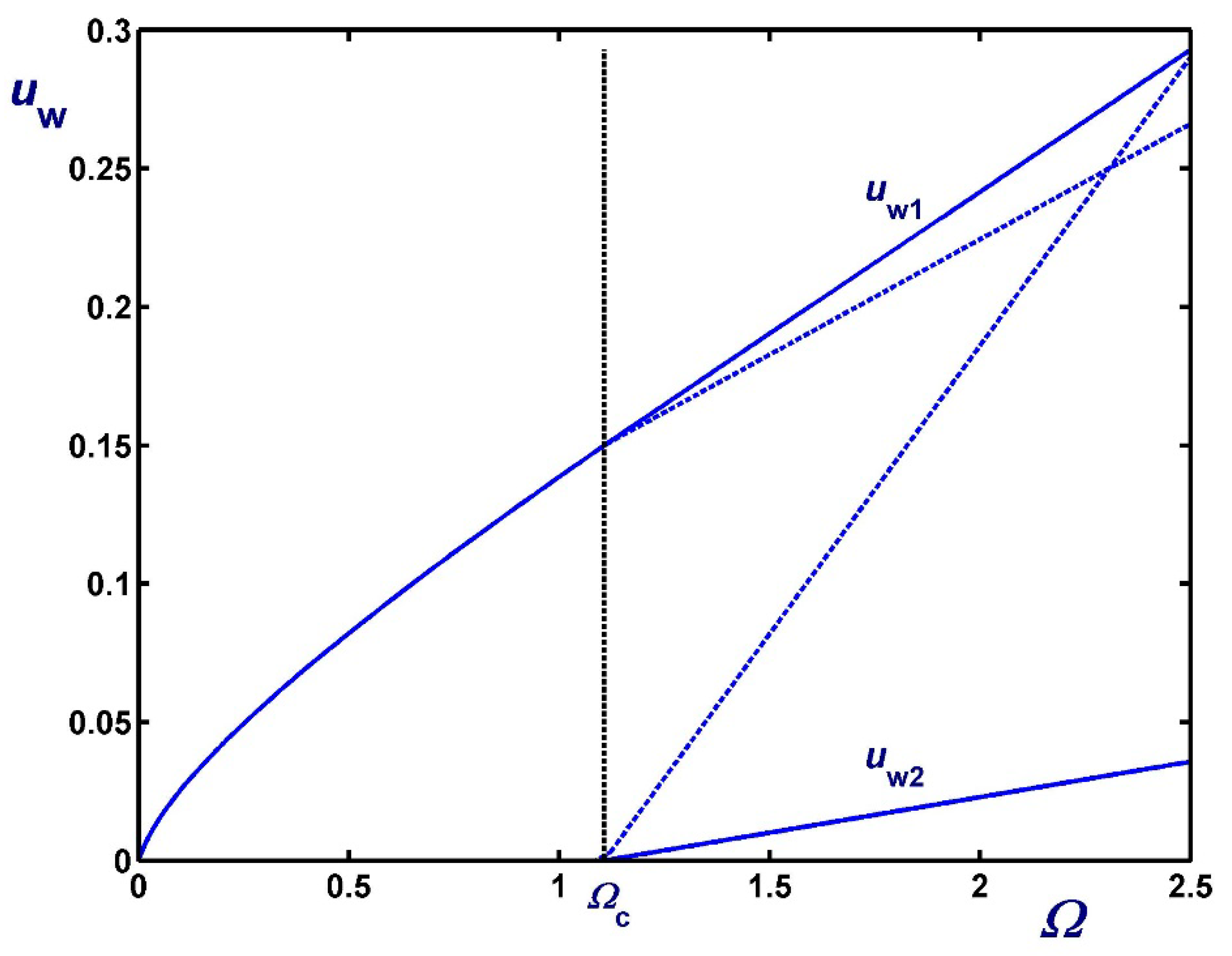

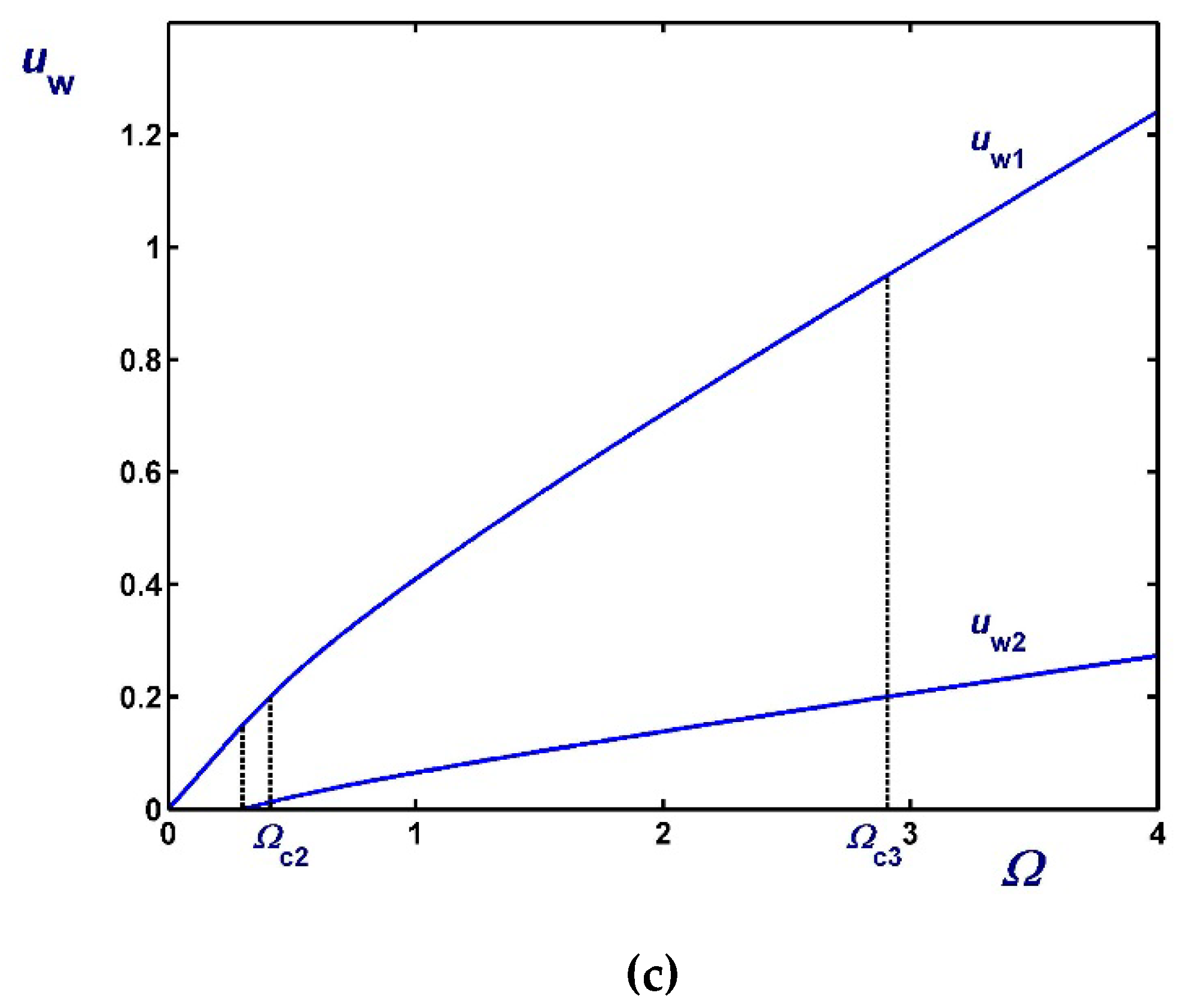

3. Solution with Non-Zero Slip Yield Stress

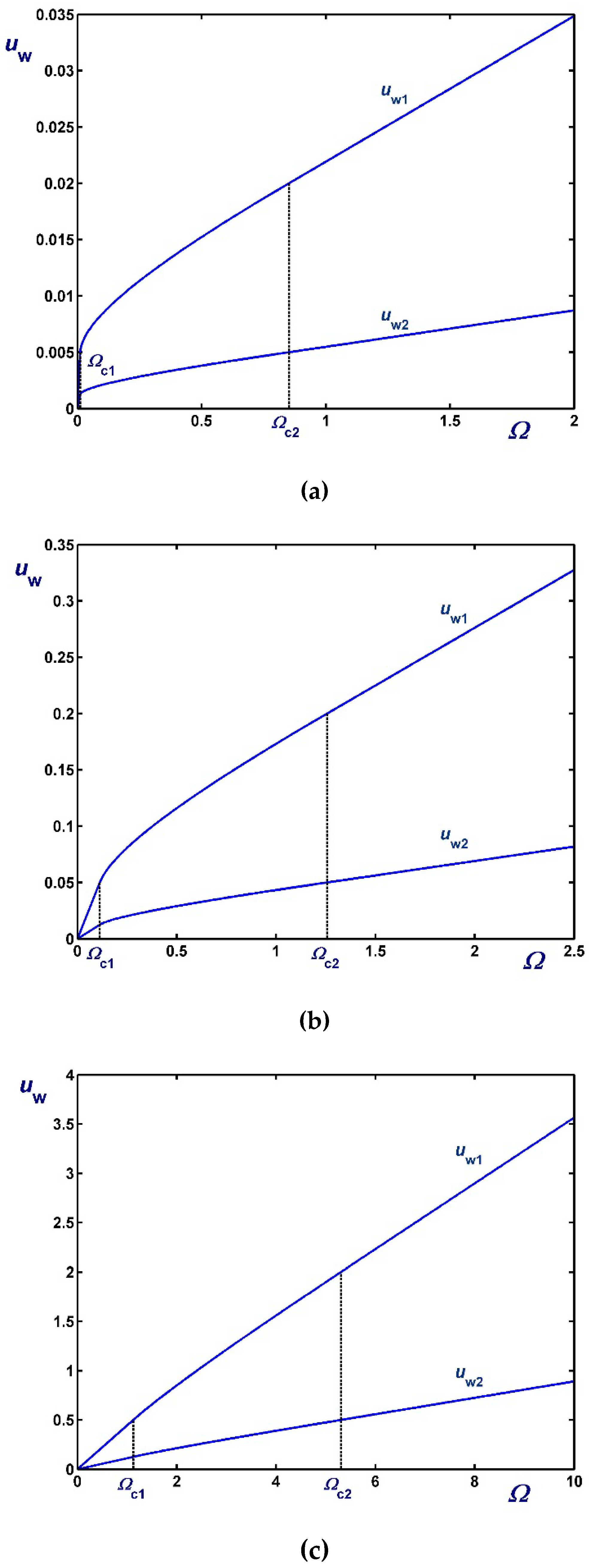

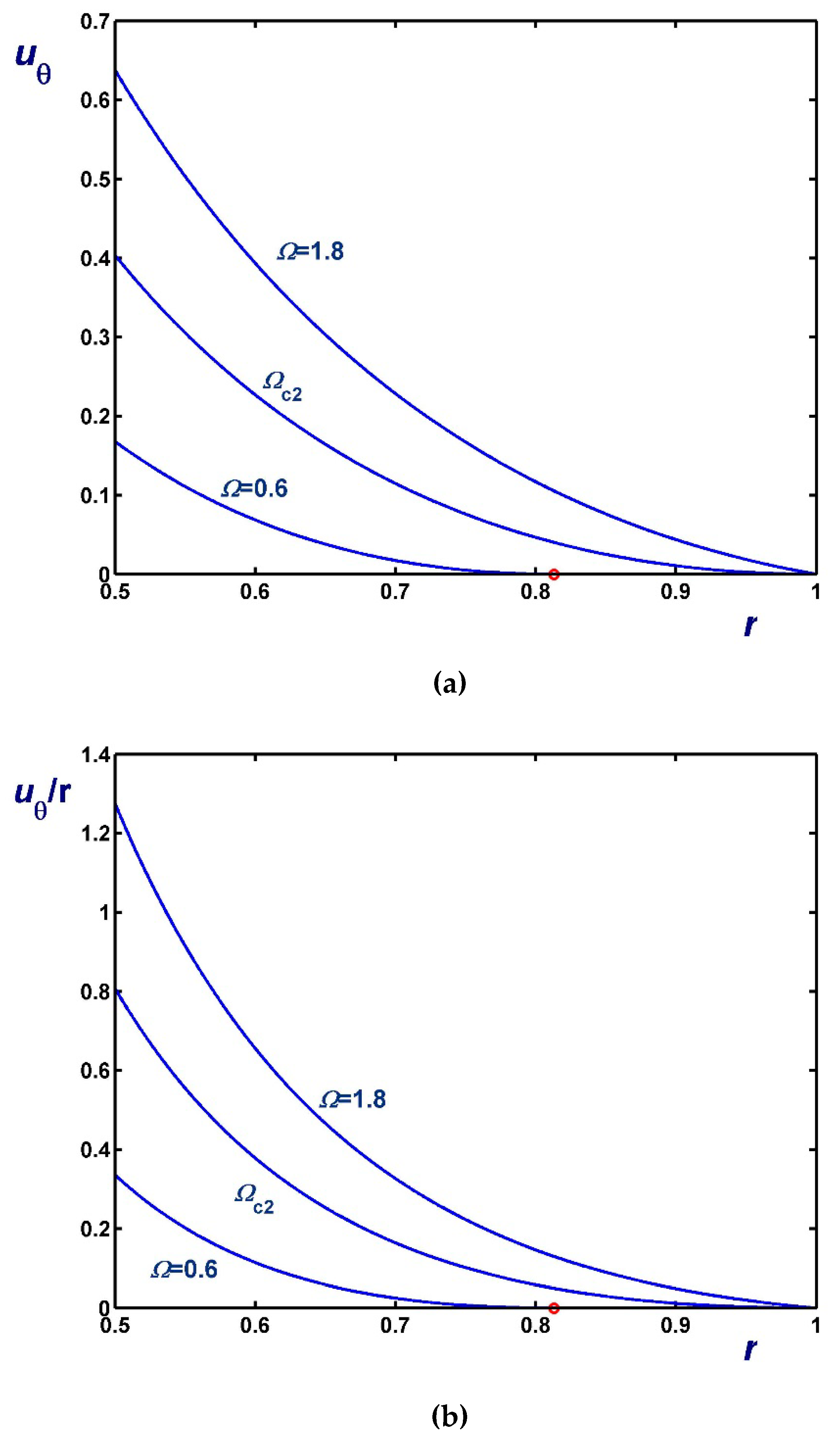

3.1. The Case

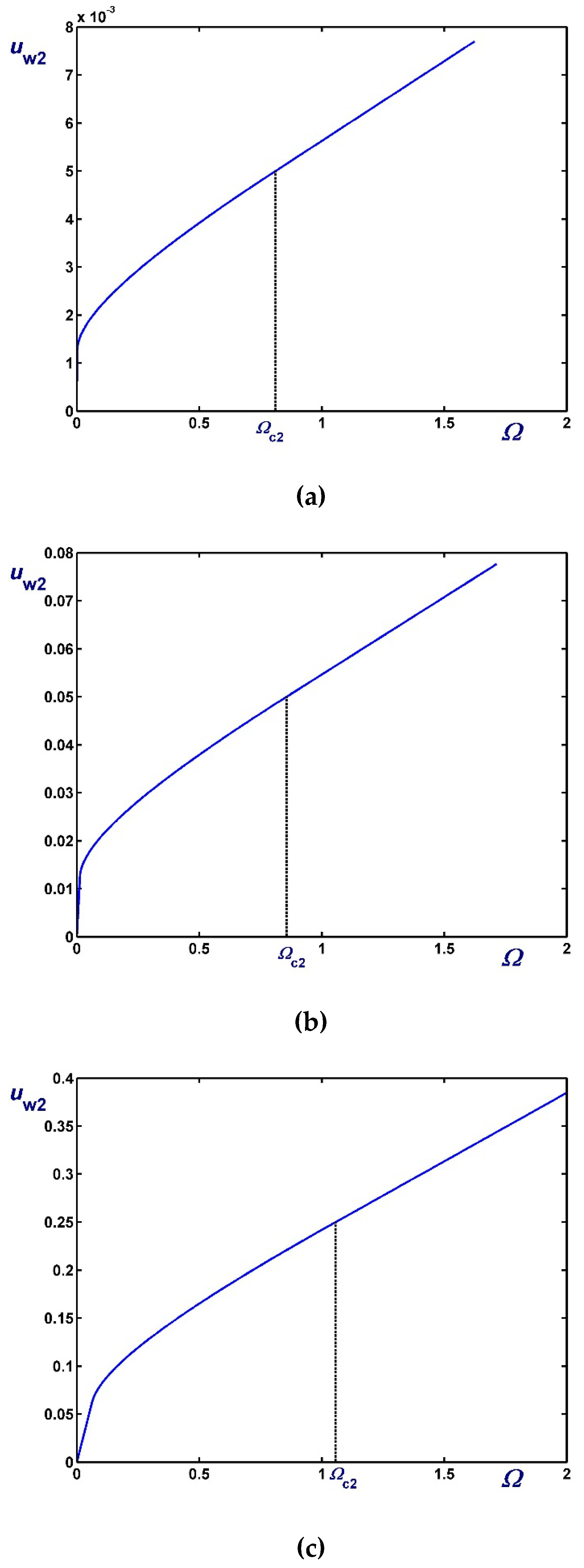

3.2. The Case

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Coussot, P. Yield stress fluid flows: A review of experimental data. J. Non-Newton. Fluid Mech. 2014, 211, 31–49. [Google Scholar] [CrossRef]

- Balmforth, N.J.; Frigaard, I.A.; Ovarlez, G. Yielding to stress: Recent developments in viscoplastic fluid mechanics. Annu. Rev. Fluid Mech. 2014, 46, 121–146. [Google Scholar] [CrossRef]

- Mitsoulis, E.; Tsamopoulos, J. Numerical simulations of complex yield-stress fluid flows. Rheol. Acta 2017, 56, 231–258. [Google Scholar] [CrossRef]

- Dimakopoulos, Y.; Makrigiorgos, G.; Georgiou, G.C.; Tsamopoulos, J. The PAL (Penalized Augmented Lagrangian) method for computing viscoplastic flows: A new fast converging scheme. J. Non-Newton. Fluid Mech. 2018, 236, 23–51. [Google Scholar] [CrossRef]

- Kalyon, D.M.; Malik, M. Axial laminar flow of viscoplastic fluids in a concentric annulus subject to wall slip. Rheol. Acta 2012, 51, 805–820. [Google Scholar] [CrossRef]

- Cloitre, M.; Bonnecaze, R.T. A review on wall slip in high solid dispersions. Rheol. Acta 2017, 56, 283–305. [Google Scholar] [CrossRef]

- Hatzikiriakos, S.G. Slip mechanisms in complex fluid flows. Soft Matter 2015, 11, 7851–7856. [Google Scholar] [CrossRef]

- Barnes, H.A. A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: Its cause, character, and cure. J. Non-Newton. Fluid Mech. 1995, 56, 221–251. [Google Scholar] [CrossRef]

- Denn, M.M. Extrusion instabilities and wall slip. Annu. Rev. Fluid Mech. 2001, 33, 265–287. [Google Scholar] [CrossRef]

- Hatzikiriakos, S.G. Wall slip of molten polymers. Progr. Polym. Sci. 2012, 37, 624–643. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Patlazhan, S.A. Wall slip for complex fluids–Phenomenon and its causes. Adv. Colloid Interface Sci. 2018, 257, 42–57. [Google Scholar] [CrossRef] [PubMed]

- Spikes, H.; Granick, S. Equation for slip of simple liquids at smooth solid surfaces. Langmuir 2003, 19, 5065–5071. [Google Scholar] [CrossRef]

- Kalyon, D.M. Apparent slip and viscoplasticity of concentrated suspensions. J. Rheol. 2005, 49, 621–640. [Google Scholar] [CrossRef]

- Sochi, T. Slip at fluid-solid interface. Polym. Rev. 2011, 51, 309–340. [Google Scholar] [CrossRef]

- Damianou, Y.; Georgiou, G.C.; Moulitsas, I. Combined effects of compressibility and slip in flows of a Herchel-Bulkley fluid. J. Non-Newton. Fluid Mech. 2013, 193, 89–102. [Google Scholar] [CrossRef]

- Damianou, Y.; Philippou, M.; Kaoullas, G.; Georgiou, G.C. Cessation of viscoplastic Poiseuille flow with wall slip. J. Non-Newton. Fluid Mech. 2014, 203, 24–37. [Google Scholar] [CrossRef]

- Yilmazer, U.; Kalyon, D.M. Slip effects in capillary and parallel disk torsional flows of highly filled suspensions. J. Rheol. 1989, 33, 1197–1212. [Google Scholar] [CrossRef]

- Meeker, S.P.; Bonnecaze, R.T.; Cloitre, M. Slip and flow in soft particle pastes. Phys. Rev. Lett. 2004, 92, 198302. [Google Scholar] [CrossRef]

- Ballesta, P.; Besseling, R.; Isa, L.; Petekidis, G.; Poon, W.C.K. Slip and flow of hard-sphere colloidal glasses. Phys. Rev. Lett. 2008, 101, 258301. [Google Scholar] [CrossRef]

- Ballesta, P.; Petekidis, G.; Isa, L.; Poon, W.C.K.; Besseling, R. Wall slip and flow of concentrated hard-sphere colloidal suspensions. J. Rheol. 2012, 56, 1005–1037. [Google Scholar] [CrossRef]

- Piau, J.M. Carbopol gels: Elastoviscoplastic and slippery glasses made of individual swollen sponges: Meso- and macroscopic properties, constitutive equations and scaling laws. J. Non-Newton. Fluid Mech. 2007, 144, 1–29. [Google Scholar] [CrossRef]

- Daneshi, N.; Pourzahedi, A.; Martinez, D.M.; Grecov, D. Characterising wall-slip behaviour of Carbopol gels in a fully-developed Poiseuille flow. J. Non-Newton. Fluid Mech. 2019, 269, 65–72. [Google Scholar] [CrossRef]

- Navier, C.L.M.H. Mémoire sur les lois du mouvement des fluids. Mem. Acad. R. Sci. Inst. Fr. 1827, 6, 389–440. [Google Scholar]

- Kaoullas, G.; Georgiou, G.C. Newtonian Poiseuille flows with wall slip and non-zero slip yield stress. J. Non-Newton. Fluid Mech. 2013, 197, 24–30. [Google Scholar] [CrossRef]

- Georgiou, G.C.; Kaoullas, G. Newtonian flow in a triangular duct with slip at the wall. Meccanica 2013, 48, 2577–2583. [Google Scholar] [CrossRef]

- Kaoullas, G.; Georgiou, G.C. Slip yield stress effects in start-up Newtonian Poiseuille flows. Rheol. Acta 2013, 52, 913–925. [Google Scholar] [CrossRef]

- Métivier, C.; Magnin, A. The effect of wall slip on the stability of the Rayleigh-Bénard Poiseuille flow of viscoplastic fluids. J. Non-Newton. Fluid Mech. 2011, 166, 839–846. [Google Scholar] [CrossRef]

- Seth, J.R.; Locatelli-Champagne, C.; Monti, F.; Bonnecaze, R.T.; Cloitre, M. How do soft particle glasses yield and flow near solid surfaces. Soft Matter 2012, 8, 140–148. [Google Scholar] [CrossRef]

- Seth, J.R.; Cloitre, M.; Bonnecaze, R.T. Influence of short-range forces on wall-slip in microgel pastes. J. Rheol. 2008, 52, 1241–1268. [Google Scholar] [CrossRef]

- Bertola, V.; Bertrand, F.; Tabuteau, H.; Bonn, D.; Coussot, P. Wall slip and yielding in pasty materials. J. Rheol. 2003, 47, 1211–1226. [Google Scholar] [CrossRef]

- Poumaere, A.; Moyers-Gonzalez, M.; Castelain, C.; Burghelea, T. Unsteady laminar flows of a Carbopol gel in the presence of wall slip. J. Non-Newton. Fluid Mech. 2014, 205, 28–40. [Google Scholar] [CrossRef]

- Ovarlez, G. Rheometry of visco-plastic fluids. In Lectures on Visco-Plastic Fluid Mechanics; Ovarlez, G., Hormozi, S., Eds.; CISM International Centre for Mechanical Sciences: Udine, Italy, 2019. [Google Scholar]

- Nguyen, Q.D.; Boger, D.V. Characterization of yield stress fluids using concentric cylinder viscometers. Rheol. Acta 1987, 26, 508–515. [Google Scholar] [CrossRef]

- Chatzimina, M.; Georgiou, G.; Alexandrou, A.N. Circular Couette flows of viscoplastic fluids. Appl. Rheol. 2009, 19, 34288. [Google Scholar]

- Alexandrou, A.N.; Georgiou, G.C.; Economides, E.A.; Modigell, M.; Zang, C. Determining true material constants of viscoplastic materials from rotational rheometer data. J. Non-Newton. Fluid Mech. 2018, 260, 101–108. [Google Scholar] [CrossRef]

- Feys, D.; Wallevik, J.E.; Yahia, A.; Khayat, K.H.; Wallevik, O.H. Extension of the Reiner–Riwlin equation to determine modified Bingham parameters measured in coaxial cylinders rheometers. Mater. Struct. 2013, 46, 289–311. [Google Scholar] [CrossRef]

- Yoshimura, A.; Prud’homme, R.K. Wall slip corrections for Couette and parallel disc viscometers. J. Rheol. 1988, 32, 53–67. [Google Scholar] [CrossRef]

- Yeow, Y.L.; Choon, B.; Karniawan, L.; Santoso, L. Obtaining the shear rate function and the slip velocity function from Couette viscometric data. J. Non-Newton. Fluid Mech. 2004, 124, 43–49. [Google Scholar] [CrossRef]

- Hron, J.; Le Roux, C.; Málek, J.; Rajagopal, K.R. Simple flows of incompressible fluids subject to Navier’s slip on the boundary. Comput. Math. Appl. 2008, 56, 2128–2143. [Google Scholar] [CrossRef]

- Ren, L.; Zhu, K.Q. Couette flow of electrorheological fluids between two concentric cylinders with wall slip. Smart Mater. Struct. 2006, 15, 1794. [Google Scholar] [CrossRef]

- Philippou, M.; Damianou, Y.; Miscouridou, X.; Georgiou, G.C. Cessation of Newtonian circular and plane Couette flows with wall slip and non-zero slip yield stress. Meccanica 2017, 52, 2081–2099. [Google Scholar] [CrossRef]

- Whittle, M.; Atkin, R.J.; Bullough, W.A. Fluid dynamic limitation on the performance of an electrorheological clutch. J. Non-Newton. Fluid Mech. 1995, 57, 61–81. [Google Scholar] [CrossRef]

- Ashrafi, N.; Karimi-Haghighi, H. Improved nonlinear fluid model in rotating flow. Appl. Math. Mech.–Engl. Ed. 2012, 33, 1419–1430. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damianou, Y.; Panaseti, P.; Georgiou, G.C. Viscoplastic Couette Flow in the Presence of Wall Slip with Non-Zero Slip Yield Stress. Materials 2019, 12, 3574. https://doi.org/10.3390/ma12213574

Damianou Y, Panaseti P, Georgiou GC. Viscoplastic Couette Flow in the Presence of Wall Slip with Non-Zero Slip Yield Stress. Materials. 2019; 12(21):3574. https://doi.org/10.3390/ma12213574

Chicago/Turabian StyleDamianou, Yiolanda, Pandelitsa Panaseti, and Georgios C. Georgiou. 2019. "Viscoplastic Couette Flow in the Presence of Wall Slip with Non-Zero Slip Yield Stress" Materials 12, no. 21: 3574. https://doi.org/10.3390/ma12213574

APA StyleDamianou, Y., Panaseti, P., & Georgiou, G. C. (2019). Viscoplastic Couette Flow in the Presence of Wall Slip with Non-Zero Slip Yield Stress. Materials, 12(21), 3574. https://doi.org/10.3390/ma12213574