Assessment for Sustainable Use of Quarry Fines as Pavement Construction Materials: Part I—Description of Basic Quarry Fine Properties

Abstract

:1. Introduction

2. Literature Review

3. Material Sampling and Preparation

4. Description of Basic Quarry Fine Properties

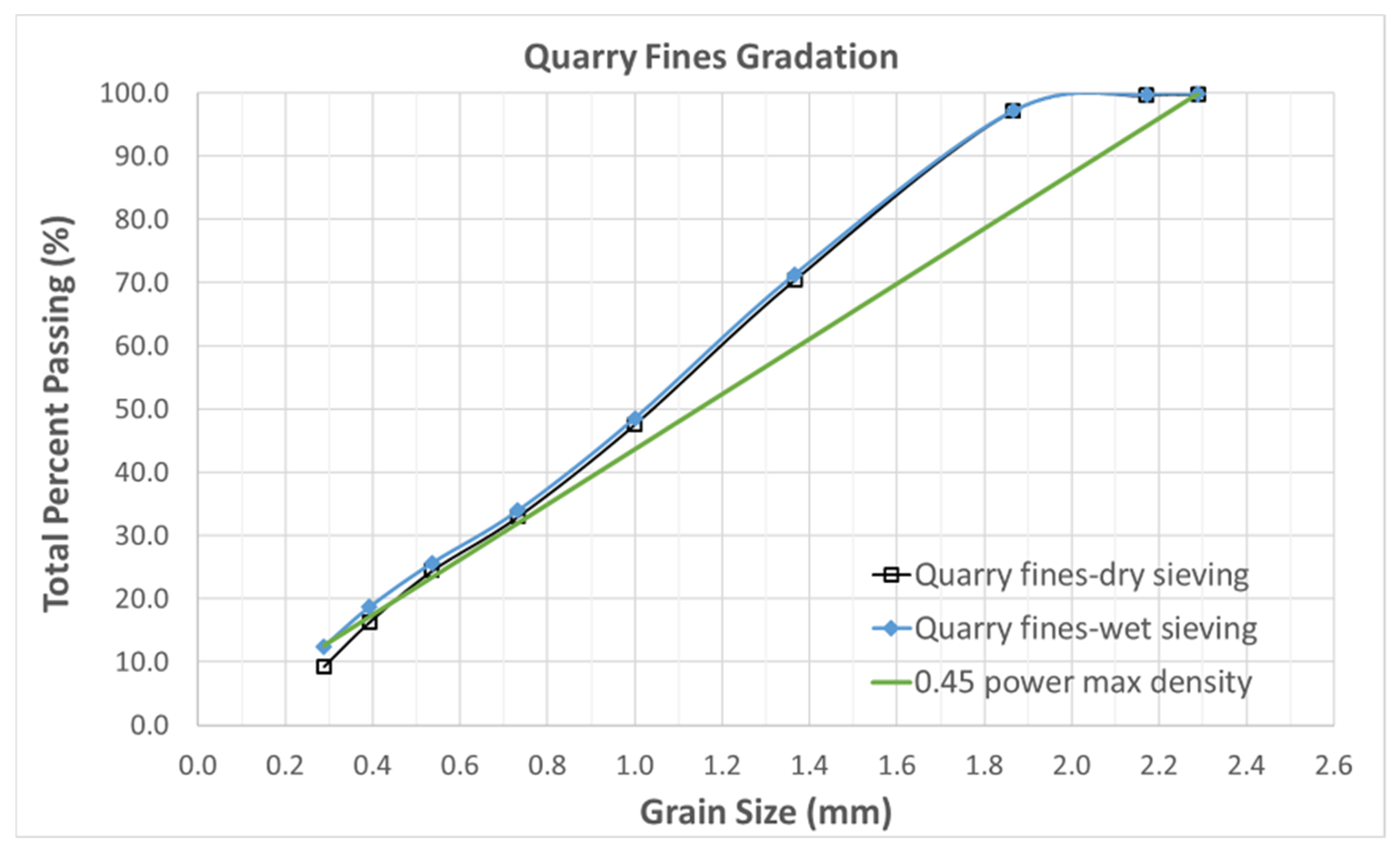

4.1. Gradation of the Quarry Fines

4.1.1. Wet Sieving Method

4.1.2. Hydrometer Method

4.2. Density and Water Content

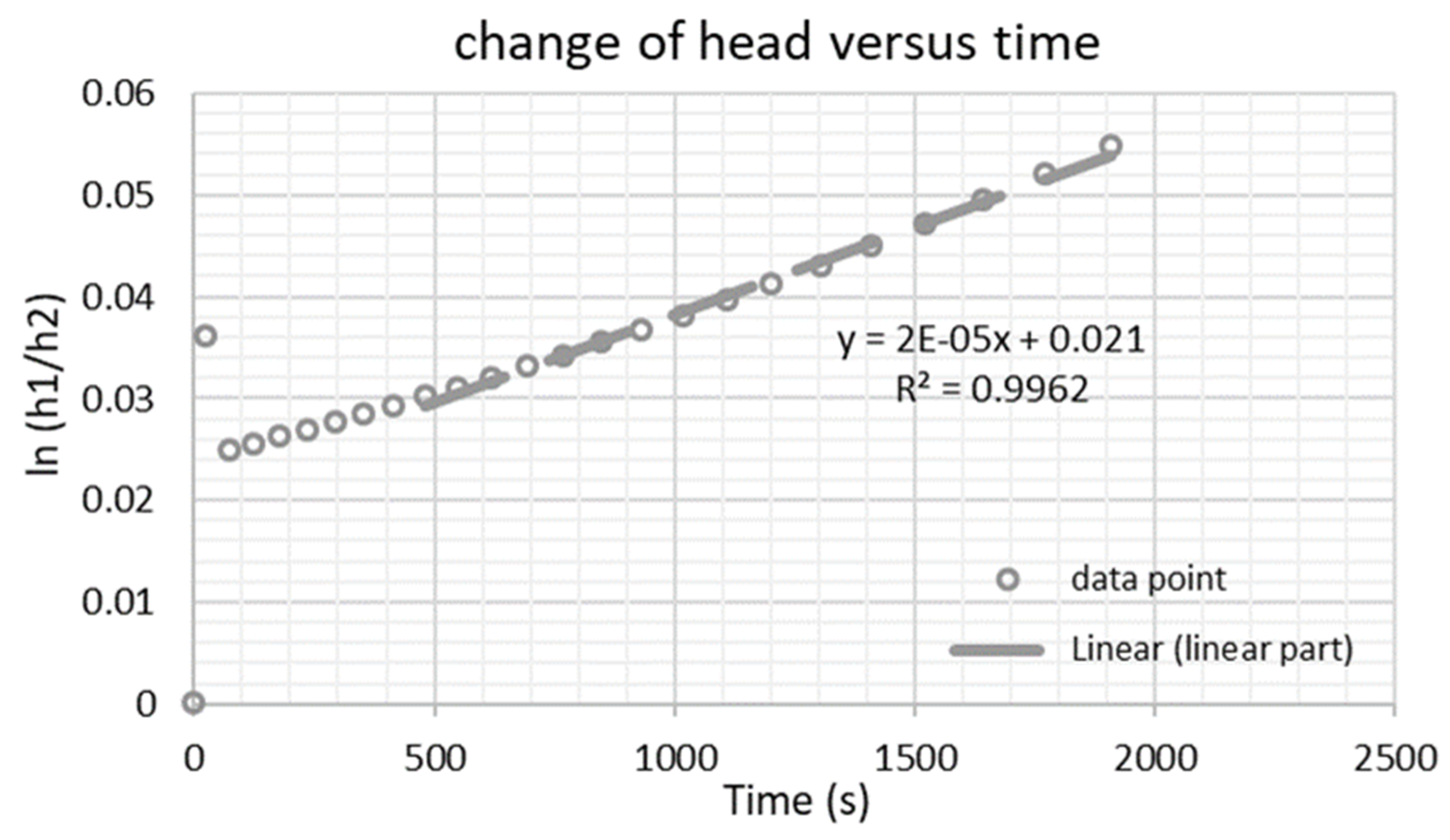

4.3. Permeability

4.4. Capillary Rise

4.5. Frost Heave

- h is the frost heave, or the change in height of the specimen during the test, in mm;

- z is the depth of frost penetration, which is the sum of the initial height and the frost heave minus the height of the unfrozen part of the specimen, in mm;

- h/z is the frost heave ratio, which is an indicator of the relative percentage of frost heaving from the depth of frost penetration, in %;

- SP is the segregation potential, or frost heave coefficient, which is the ratio between the frost heave rate and the actual temperature gradient over the frozen part of the specimen, in mm2/Kh.

5. Discussion and Conclusions

- The wet sieving method is more appropriate for determining the gradation curve of quarry fines with a 0–4 mm grain size. Based on gradation information obtained from laboratory sieving and hydrometer tests, the quarry fines used in this study can be classified as well-graded with the gradation characteristics of both fine- and dense-graded material. It also shows that virgin quarry fines can satisfy the requirements for a filter layer but not for a base or subbase, and indicates that quarry fines might be frost susceptible.

- The virgin quarry fines showed self-draining properties. Nevertheless, a maximum dry density exists at the optimal water content of 9.3%, even though only a very limited influence of water content can be observed on the dry density.

- The coefficient of permeability of unstabilized quarry fine specimen was around 5.75×10-5 m/s as determined by the falling head method. This value falls within the typical permeability ranges of commonly adopted conventional pavement base and subbase materials and can be validated for application in base, subbase, and other layers from the view of permeability. To be validated for filter layers, a higher degree of compaction is desirable to prevent fines immigration and frost actions in cold regions.

- According to the frost heave test results, it was found that the changing of total frost heave is closely related to the temperature and depth of frost penetration throughout the specimen.

- The quarry fine specimen in the unloaded frost heave test can be classified into the low frost-susceptibility class according to the segregation potential values. In addition, gradation information and capillary rise test results have all verified this finding. As a result, it is concluded that the unstabilized quarry fines should be classified as frost-susceptible to ensure sound and reliable design and good performance in the long-run. To improve the frost-susceptible properties of quarry fines, stabilization techniques are necessary to qualify their application as pavement construction materials. Further research is undergoing and will be presented in the future.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Finnish Road Administration. Tierakenteen Suunnittelu; Edita Prima Oy: Helsinki, Finland, 2004; p. 69. ISBN 951-803-403-6.

- Kolisoja, P. Resilient Deformation Characteristics of Granular Materials. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 1997. [Google Scholar]

- Betoni. Kiviaines. Available online: https://betoni.com/tietoa-betonista/perustietopaketti/betoni-rakennusmateriaalina/kiviaines/ (accessed on 7 December 2018).

- Hernesniemi, H.; Berg-Andersson, B.; Rantala, O. Kalliosta Kullaksi—Kummusta Klusteriksi; Elinkeinoelämän tutkimuslaitos. ETLA, Taloustieto: Helsinki, Finland, 2011; p. 241. ISBN 978-951-628-527-9. [Google Scholar]

- Korkiala-Tanttu, L.; Tenhunen, J.; Eskola, P.; Häkkinen, T.; Hiltunen, M.-R.; Tuominen, A. Environmental Values and Ecoindicators of the Infra Construction; Finnra Reports; Finnish Road Administration: Helsinki, Finland, 2006; p. 53. ISBN 951-803-713-2.

- Henrotay, C. Buildings as Materials Bank. In Proceedings of the Rakentamisen kiertotalouden ajankohtaispäivät, Helsinki, Finland, 7–8 November 2018. [Google Scholar]

- Ehrukainen, E. Kiviainesten kestävä kierrätys ja käyttö. Available online: http://www.uusiomaarakentaminen.fi/sites/default/files/Kiviainesten%20kest%C3%A4v%C3%A4%20kierr%C3%A4tys%20ja%20k%C3%A4ytt%C3%B6%20%E2%80%93%20Eija%20Ehrukainen_0.pdf (accessed on 7 December 2018).

- Levinen, R. Jätedirectiivin rakennusalaa koskevat muutokset, The changes for building industry caused by the waste directive. In Proceedings of the Rakentamisen kiertotalouden ajankohtaispäivät, Helsinki, Finland, 7–8 November 2018. [Google Scholar]

- European Commission. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA Relevance). 2018. Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj (accessed on 6 February 2019).

- United Nations. The Sustainable Development Agenda. 2018. Available online: https://www.un.org/sustainabledevelopment/development-agenda/ (accessed on 7 December 2018).

- Prime Minister’s Office. Government Report on the 2030 Agenda for Sustainable Development. Sustainable Development in Finland—Long-Term, Coherent and Inclusive Action; Prime Minister’s Office: Helsinki, Finland, 2017; p. 57. ISBN 978-952-287-392-7.

- Major of Helsinki. Hiilineutraali Helsinki 2035- Toimenpideohjelma. Available online: https://www.hel.fi/static/liitteet/kaupunkiymparisto/julkaisut/julkaisut/HNH-2035-toimenpideohjelma.pdf (accessed on 7 December 2018).

- EPA. Identification of Non-Hazardous Secondary Materials That Are Solid Waste. Available online: https://www.epa.gov/rcra/identification-non-hazardous-secondary-materials-are-solid-waste (accessed on 8 July 2018).

- European Commission. Raw Materials. Available online: http://ec.europa.eu/environment/green-growth/raw-materials/index_en.htm (accessed on 8 July 2018).

- Mitchell, C. Quarry Fines and Waste. Available online: https://www.bgs.ac.uk/downloads/start.cfm?id=1449 (accessed on 8 July 2018).

- Galetakis, M.; Soultana, A. A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- Pitkänen, I.-J. Selvitys Destia Oy:n kivituhkamääristä ja kivituhkan nykyisistä ja uusista käyttömahdollisuuksista. Bachelor’s Thesis, Savonia University of Applied Science, Kuopio, Finland, 2015. [Google Scholar]

- Melander, M. Kivituhkan soveltuminen sidotun kantavan kerroksen runkoaineeksi. Master’s Thesis, Aalto University, Espoo, Finland, 2018. [Google Scholar]

- Reid, J.M.; Evans, R.D.; Holnsteiner, R.; Wimmer, B.; Gaggl, W.; Berg, F.; Pihl, K.A.; Milvang-Jensen, O.; Hjelmar, O.; Rathmeyer, H.; et al. ALT-MAT: Alternative Materials in Road Construction. The European Commission under the Transport RTD Programme of the 4th Framework Programme. 2001, p. 190. Available online: https://trimis.ec.europa.eu/sites/default/files/project/documents/20040909_172706_52558_alt-mat.pdf. (accessed on 7 December 2018).

- Thomas, J.; Harilal, B. Mechanical properties of cold bonded quarry dust aggregate concrete subjected to elevated temperature. Constr. Build. Mater. 2016, 125, 724–730. [Google Scholar] [CrossRef]

- Dubois, V.; Wirquin, E.; Flament, C.; Sloma, P. Fresh and hardened state properties of hemp concrete made up of a large proportion of quarry fines for the production of blocks. Constr. Build. Mater. 2016, 102, 84–93. [Google Scholar] [CrossRef]

- Rai, B.; Kumar, S.; Satish, K. Effect of Fly Ash on Mortar Mixes with Quarry Dust as Fine Aggregate. Adv. Mater. Sci. Eng. 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Medina, G.; Sáez del Bosque, I.F.; Frías, M.; Sánchez de Rojas, M.I.; Medina, C. Durability of new recycled granite quarry dust-bearing cements. Constr. Build. Mater. 2018, 187, 414–425. [Google Scholar] [CrossRef]

- Amadi, A.A. Enhancing durability of quarry fines modified black cotton soil subgrade with cement kiln dust stabilization. Transp. Geotech. 2014, 1, 55–61. [Google Scholar] [CrossRef]

- Sivrikaya, O.; Kıyıldı, K.R.; Karaca, Z. Recycling waste from natural stone processing plants to stabilize clayey soil. Environ. Earth Sci. 2014, 71, 4397–4407. [Google Scholar] [CrossRef]

- Oncu, S.; Bilsel, H. Ageing effect on swell, shrinkage and flexural strength of sand and waste marble powder stabilized expansive soil. E3S Web Conf. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Gurbuz, A. Marble powder to stabilise clayey soils in subbases for road construction. Road Mater. Pavement Des. 2015, 16, 481–492. [Google Scholar] [CrossRef]

- Gautam, P.K.; Kalla, P.; Jethoo, A.S.; Agrawal, R.; Singh, H. Sustainable use of waste in flexible pavement: A review. Constr. Build. Mater. 2018, 180, 239–253. [Google Scholar] [CrossRef]

- Galetakis, M.; Piperidi, C.; Vasiliou, A.; Alevizos, G.; Steiakakis, E. Experimental investigation of the utilization of quarry dust for the production of microcement-based building elements by self-flowing molding casting. Constr. Build. Mater. 2016, 107, 247–254. [Google Scholar] [CrossRef]

- Vijayalakshmi, M.; Sekar, A.S.S.; Prabhu, G.G. Strength and durability properties of concrete made with granite industry waste. Constr. Build. Mater. 2013, 46, 1–7. [Google Scholar] [CrossRef]

- Galetakis, M.; Alevizos, G.; Leventakis, K. Evaluation of fine limestone quarry by-products, for the production of building elements—An experimental approach. Constr. Build. Mater. 2012, 26, 122–130. [Google Scholar] [CrossRef]

- Karasahin, M.; Terzi, S. Evaluation of marble waste dust in the mixture of asphaltic concrete. Constr. Build. Mater. 2007, 21, 616–620. [Google Scholar] [CrossRef]

- Karakus, A. Investigating on possible use of Diyarbakir basalt waste in Stone Mastic Asphalt. Constr. Build. Mater. 2011, 25, 3502–3507. [Google Scholar] [CrossRef]

- Akbulut, H.; Gurer, C. Use of aggregates produced from marble quarry waste in asphalt pavements. Build. Environ. 2007, 42, 1921–1930. [Google Scholar] [CrossRef]

- Finnish Standard Association. SFS-EN 932-1 Tests for General Properties of Aggregates. Part 1: Methods for Sampling; CENELEC Management Centre: Brussels, Belgium, 1997; p. 27. [Google Scholar]

- Finnish Standard Association. SFS-EN 1097-5 Tests for Mechanical and Physical Properties of Aggregates. Part 5: Determination of the Mater Content by Drying in a Ventilated Oven; CENELEC Management Centre: Brussels, Belgium, 2008; p. 11. [Google Scholar]

- Finnish Standard Association. SFS-EN 933-1 Tests for Geometrical Properties of Aggregates. Part 1: Determination of Particle Size Distribution. Sieving Method; CENELEC Management Centre: Brussels, Belgium, 2012; p. 18. [Google Scholar]

- Test Sieving: Principles and Procedures. A Discussion of the Uses, Capabilities, and Limitations of Testing Sieves as Analytical Tools. Available online: http://www.advantechmfg.com/pdf/Principles%20and%20Procedures%2002_21_2013.pdf (accessed on 8 July 2018).

- InfraRYL 2010 Code of Building Practice, Infrastructure, Part 1: Roads and Areas; 21300 Kantavat kerrokset; Rakennustieto Oy: Helsinki, Finland, 2010; pp. 318–320. ISBN 978-951-682-958-9.

- Finnish Standard Association. SFS-EN ISO 14688-2:2018 Geotechnical Investigation and Testing. Identification and Classification of Soil. Part 2: Principles for a Classification (ISO 14688-2:2017); CENELEC Management Centre: Brussels, Belgium, 2018; p. 18. [Google Scholar]

- Finnish Standard Association. SFS-EN ISO 17892-4:2016 Geotechnical Investigation and Testing. Laboratory Testing of Soil. Part 4: Determination of Particle Size Distribution; CENELEC Management Centre: Brussels, Belgium, 2016; p. 37. [Google Scholar]

- Slunga, E.; Saarelainen, S. Determination of frost-susceptibility of soils. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; Millpress: Rotterdam, The Netherlands, 2005; pp. 3577–3578. [Google Scholar]

- Finnish Standard Association. EN 13286-2: 2010 Unbound and Hydraulically Bound Mixtures- Part 2: Test Methods for Laboratory Reference Density and Water Content- Proctor Compaction; CENELEC Management Centre: Brussels, Belgium, 2010; p. 29. [Google Scholar]

- Road and Water Engineering Board. Construction Research and Design Part II Laboratory Tests; Government of Road and Water Construction: Helsinki, Finland, 1970. (In Finnish)

- Tangpithakkul, R. Study of Permeability of Pavement Base Materials. Master’s Thesis, Ohio University, Athens, OH, USA, 1997. [Google Scholar]

- Vermont Agency of Transportation. Permeability of Highway Base and Subbase Material. Available online: https://vtrans.vermont.gov/sites/aot/files/highway/documents/materialsandresearch/completedprojects/AOT_PermeabilityofHighwayBaseandSub-baseMaterial.pdf (accessed on 8 July 2018).

- Khoury, N.N.; Zaman, M.M.; Ghabchi, R.; Kazmee, H. Stability and Permeability of Proposed Aggregate Bases in Oklahoma. Report No.FHWA-OK-09-05; Oklahoma Department of Transportation Planning and Research Division: Oklahoma City, OK, USA, 2010; p. 243.

- Chamberlain, E.J. Frost Susceptibility of Soil Review of Index Tests. Report No. Monograph 81-2; Federal Aviation Administration (Systems Research and Development Service) and Federal Highway Administration (Office of Research): Washington, DC, USA, 1981; p. 121.

- Onninen, H. Method Description TPPT-R07 Frost Heave Test Thaw Compression Test; VTT Communities and Infrastructure: Espoo, Finland, 1999; p. 10. [Google Scholar]

- Slunga, E.; Saarelainen, S. Determination of Frost-Susceptibility of Soil. Available online: https://www.issmge.org/uploads/publications/1/33/1989_02_0171.pdf (accessed on 8 July 2018).

| Grain Size (mm) | 2016 (tons) | 2017 (tons) | Accumulation/Year (tons) | Accumulation since 2017 (%) |

|---|---|---|---|---|

| 0/3 | 824,300 | 875,800 | 51,500 | 5.9 |

| 0/6 | 118,000 | 127,300 | 9,300 | 7.3 |

| In total | 942,300 | 1,003,100 | 60,800 | 6.1 |

| Step | Loading Condition | Temperature | Time Period | Water Level of External Water Reservoir | |

|---|---|---|---|---|---|

| Top | Bottom | ||||

| Preliminary freezing | Unloaded * | −3 °C | +1 °C | 24 h | N/A |

| Thawing and preloading | 20 kPa | +3 °C | +3 °C | 24 h, or until constant height ** | Top level of specimen |

| Frost heave | unloaded | −3 °C | +1 °C | until zero net frost penetration *** (at least 24 h) | At the middle of specimen height |

| Intermediate thawing | 20 kPa | −0.5 °C | +15 °C | until constant height | At the middle of specimen height |

| 1st frost heave | 20 kPa | −3 °C | +1 °C | until zero net frost penetration (at least 24 h) | At the middle of specimen height |

| Intermediate thawing | 40 kPa | −0.5 °C | +15 °C | until constant height | At the middle of specimen height |

| 2nd frost heave | 40 kPa | −3 °C | +1 °C | until zero net frost penetration (at least 24 h) | At the middle of specimen height |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Korkiala-Tanttu, L.K.; Gustavsson, H.; Miksic, A. Assessment for Sustainable Use of Quarry Fines as Pavement Construction Materials: Part I—Description of Basic Quarry Fine Properties. Materials 2019, 12, 1209. https://doi.org/10.3390/ma12081209

Zhang Y, Korkiala-Tanttu LK, Gustavsson H, Miksic A. Assessment for Sustainable Use of Quarry Fines as Pavement Construction Materials: Part I—Description of Basic Quarry Fine Properties. Materials. 2019; 12(8):1209. https://doi.org/10.3390/ma12081209

Chicago/Turabian StyleZhang, Yinning, Leena Katariina Korkiala-Tanttu, Henry Gustavsson, and Amandine Miksic. 2019. "Assessment for Sustainable Use of Quarry Fines as Pavement Construction Materials: Part I—Description of Basic Quarry Fine Properties" Materials 12, no. 8: 1209. https://doi.org/10.3390/ma12081209

APA StyleZhang, Y., Korkiala-Tanttu, L. K., Gustavsson, H., & Miksic, A. (2019). Assessment for Sustainable Use of Quarry Fines as Pavement Construction Materials: Part I—Description of Basic Quarry Fine Properties. Materials, 12(8), 1209. https://doi.org/10.3390/ma12081209