Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning

Abstract

:1. Introduction

2. Experimental Program

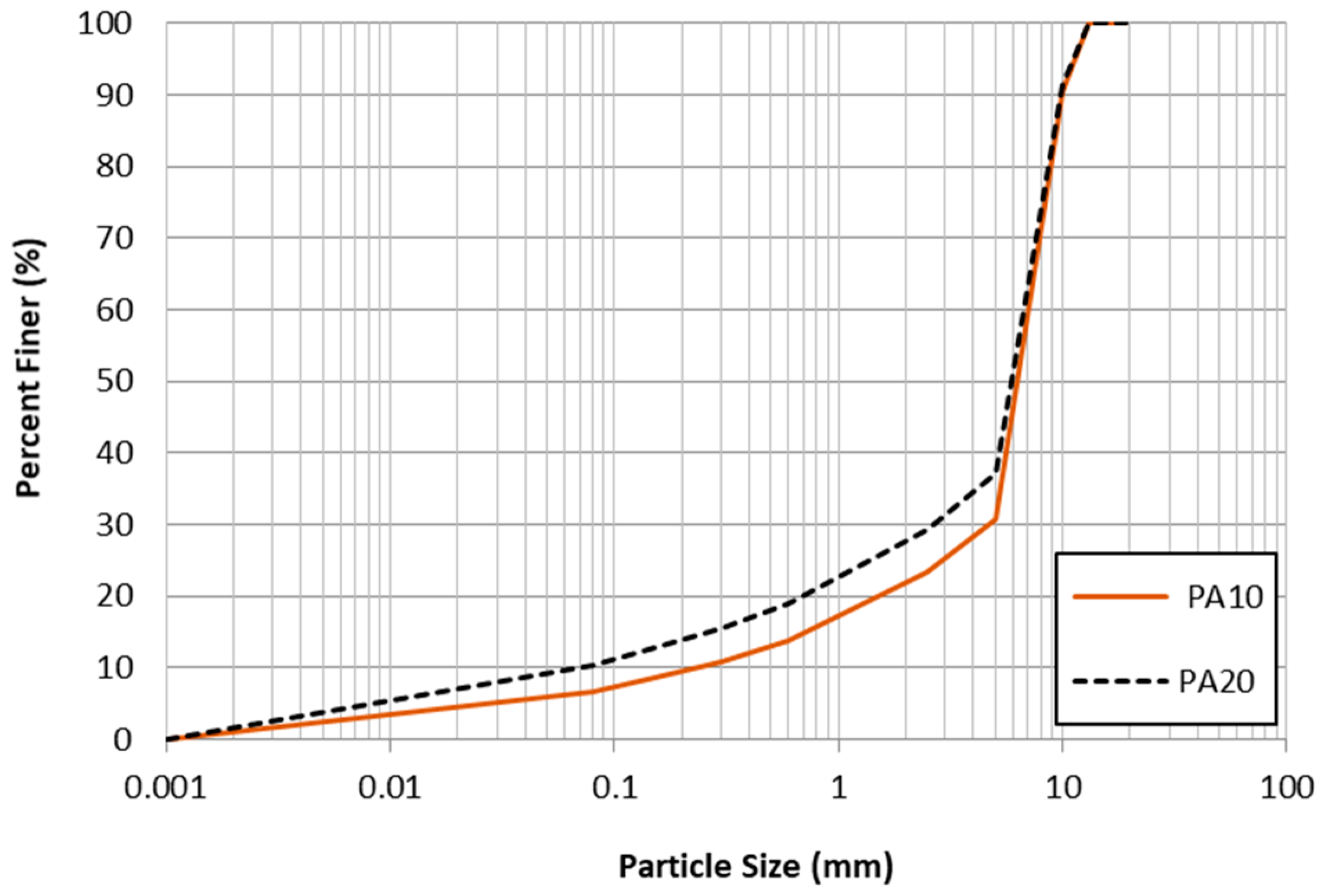

2.1. PA Specimens

2.2. Equipment

2.3. Test Setup

3. Dynamic Modulus and the Effect of Moisture Conditioning

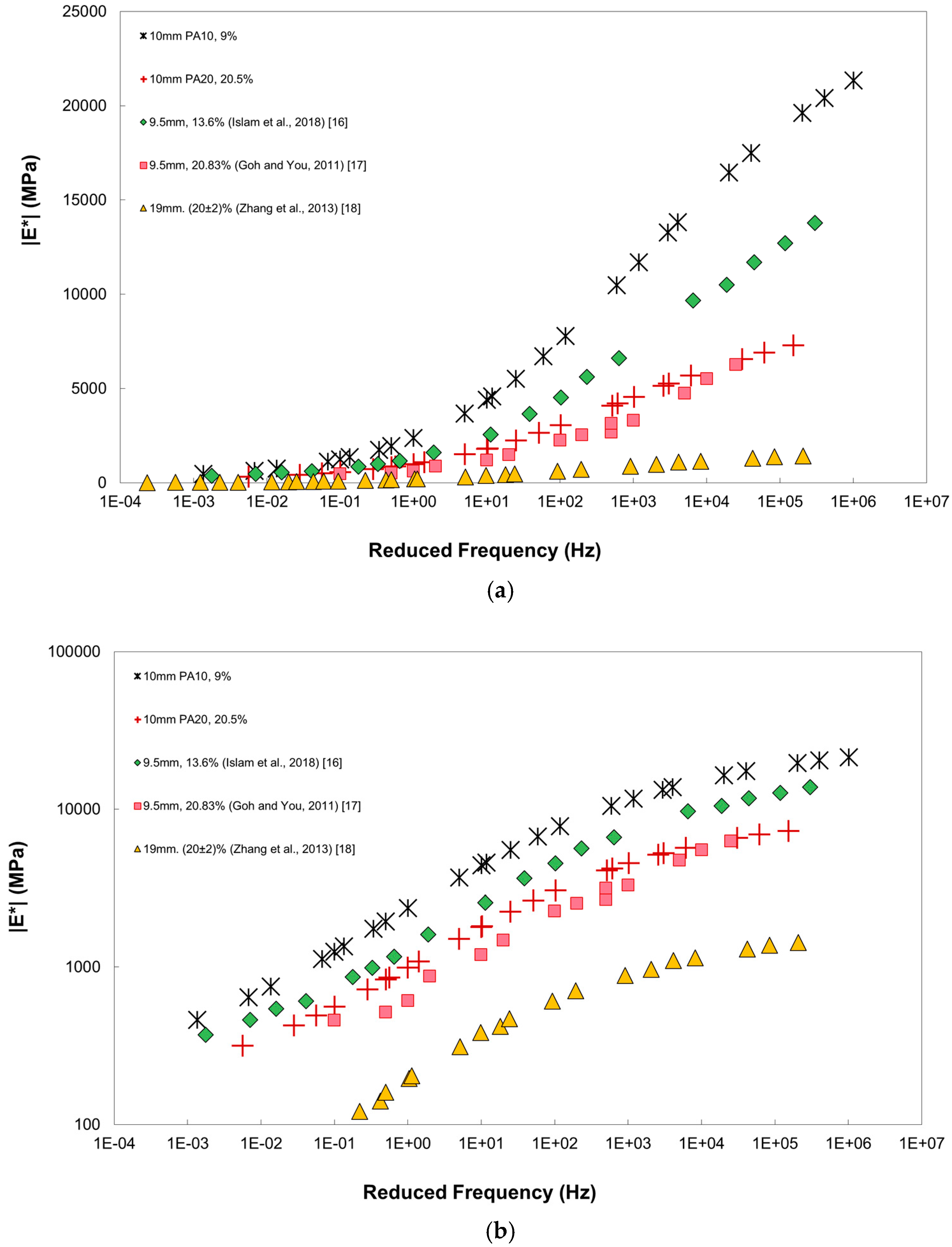

3.1. Dynamic Modulus

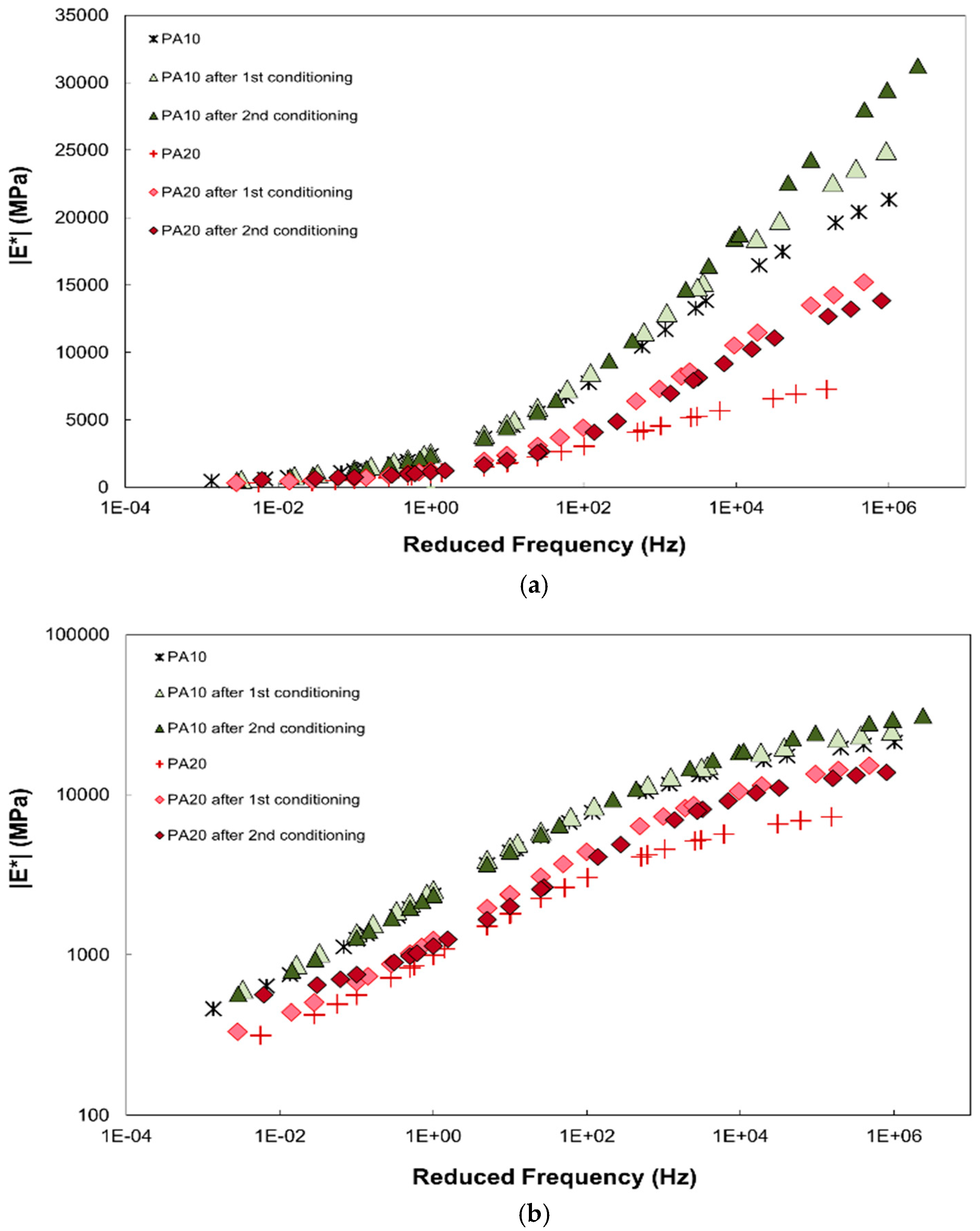

3.2. Effect of Moisture Conditioning

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- NCHRP Report 589, Improved Conditioning and Testing Procedures for HMA Moisture Susceptibility; Transportation Research Board: Washington, DC, USA, 2007; Volume 589.

- Nadkarni, A.; Kaloush, K.; Zeiada, W.; Biligiri, K. Using dynamic modulus test to evaluate moisture susceptibility of asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 2009, 29–35. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Diefenderfer, B.K. Evaluation of Moisture Susceptibility of High-Porosity ATPB Drainage Layer Materials Using Modified Dynamic Modulus Test. J. Mater. Civ. Eng. 2016, 28, 04016091. [Google Scholar] [CrossRef]

- El-Hakim, M.; Tighe, S. Impact of freeze-thaw cycles on mechanical properties of asphalt mixes. Transp. Res. Rec. J. Transp. Res. Board 2014, 20–27. [Google Scholar] [CrossRef]

- Lee, J.; Moon, S.-J.; Im, J.; Yang, S. Evaluation of Moisture Susceptibility of Asphalt Mixtures Using Dynamic Modulus. J. Test. Eval. 2016, 45, 1280–1288. [Google Scholar] [CrossRef]

- Badeli, S.; Carter, A.; Doré, G. Effect of laboratory compaction on the viscoelastic characteristics of an asphalt mix before and after rapid freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 146, 98–109. [Google Scholar] [CrossRef]

- Korean Standards Association. KS F 2349. In Hot Mix Asphalt Mixtures; Korean Standards Association: Seoul, Korea, 2010. [Google Scholar]

- SK Asphalt. Available online: http://www.skasphalt.com/ap_data/ap_data_view.asp?idx=169&code=2 (accessed on 20 February 2019).

- Korean Standards Association. KS F 2489. In Standard Test Method for Determination of Draindown in Uncompacted Asphalt Mixtures; Korean Standards Association: Seoul, Korea, 2015. [Google Scholar]

- Korean Standards Association. KS F 2492. In Standard Test Method for Cantabro Test for Porous Asphalt Mixtures; Korean Standards Association: Seoul, Korea, 2017. [Google Scholar]

- MTS Landmark® Testing Solutions. Available online: https://www.mts.com/cs/groups/public/documents/library/dev_004324.pdf (accessed on 20 February 2019).

- Cooper Technology Company. Available online: https://www.cooper.co.uk/shop/asphalt-testing/dynamic-modulus-test-system/ (accessed on 20 February 2019).

- AASHTO. 342-11. In Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA); American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2011; p. 19. [Google Scholar]

- AASHTO. 283-08. In Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2008. [Google Scholar]

- Olidis, C.; Hein, D. Guide for Mechanistic–Empirical Design of New and Rehabilitated Pavement Structures. In Proceedings of the 2004 Annual Conference of the Transportation Association of Canada, Québec City, QC, Canada; 19–22 September 2004. [Google Scholar]

- Islam, M.R.; Rahman, A.A.; Tarefder, R.A. Open Graded Friction Course in Resisting Low-Temperature Transverse Cracking in Asphalt Pavement. J. Cold Reg. Eng. 2018, 32, 04018006. [Google Scholar] [CrossRef]

- Goh, S.W.; You, Z. Mechanical properties of porous asphalt pavement materials with warm mix asphalt and RAP. J. Transp. Eng. 2011, 138, 90–97. [Google Scholar] [CrossRef]

- Zhang, J.; Alvarez, A.E.; Lee, S.I.; Torres, A.; Walubita, L.F. Comparison of flow number, dynamic modulus, and repeated load tests for evaluation of HMA permanent deformation. Constr. Build. Mater. 2013, 44, 391–398. [Google Scholar] [CrossRef]

- Arshad, A.K.; Masri, K.; Ahmad, J.; Samsudin, M. Dynamic modulus of nanosilica modified porous asphalt. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2017; Volume 271, p. 012008. [Google Scholar]

- Coplantz, J.S.; Newcomb, D.E. Water sensitivity test methods for asphalt concrete mixtures: A laboratory comparison. Transp. Res. Rec. 1988, 1171, 44–50. [Google Scholar]

- Lottman, R.P. Predicting Moisture-Induced Damage to Asphaltic Concrete Field Evaluation. NCHRP Rep. 1982. Available online: https://trid.trb.org/view/180935 (accessed on 20 February 2019).

- Bausano, J.; Williams, R.C. Transitioning from AASHTO T283 to the simple performance test using moisture conditioning. J. Mater. Civ. Eng. 2009, 21, 73–82. [Google Scholar] [CrossRef]

| Test | Value | Unit |

|---|---|---|

| Viscosity (135 °C) | 3.4 | Pa·s |

| G*/sinδ (Original) (82 °C) | 1.27 | kPa |

| G*/sinδ (After RTFO) (82 °C) | 2.49 | kPa |

| G*·sinδ (After PAV) (28 °C) | 564 | kPa |

| Flash Point | 342 | °C |

| Stiffness (−24 °C) | 194 | MPa |

| m-value (−24 °C) | 0.32 | °C |

| Mixture | PA10 | PA20 | |

|---|---|---|---|

| Asphalt content (%) | 6.1 | 5.9 | |

| Air void content (%) | 9.0 | 20.5 | |

| Draindown (%) | 0.15 | 0.19 | |

| Cantabro Loss (%) | −20 °C | 12.29 | 43.9 |

| 20 °C | 0.64 | 10.91 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.H.; Ahn, J.; Lee, J.; Kim, J.-H. Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning. Materials 2019, 12, 1230. https://doi.org/10.3390/ma12081230

Nguyen TH, Ahn J, Lee J, Kim J-H. Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning. Materials. 2019; 12(8):1230. https://doi.org/10.3390/ma12081230

Chicago/Turabian StyleNguyen, Tan Hung, Jaehun Ahn, Jaejun Lee, and Jin-Hwan Kim. 2019. "Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning" Materials 12, no. 8: 1230. https://doi.org/10.3390/ma12081230