Abstract

The feasibility and effectivity of recycling waste rubber and waste plastic (WRP) into asphalt binder as a waste treatment approach has been documented. However, directly blending WRP with asphalt binder brings secondary environmental pollution. Recent research has shown that the addition of WRP into asphalt binder may potentially improve the workability of asphalt binder without significantly compromising its mechanical properties. This study evaluates the feasibility of using the additives derived from WRP as a multifunctional additive which improves both the workability and mechanical properties of asphalt binder. For this purpose, WRP-derived additives were prepared in laboratory. Then, three empirical characteristics—viscosity, rutting factor, fatigue life were analyzed. Fourier transform infrared spectroscopy (FTIR) and differential scanning calorimetry (DSC) were employed to evaluate the effect of WRP-derived additive on the workability and chemical and mechanical properties of base binder. The dispersity of WRP-derived additive inside asphalt binder was also characterized using fluorescence microscope (FM). Results from this study showed that adding WRP-derived additive increases the workability of base binder. The WRP-derived additive appears positive on the high- and low- temperature performance as well as the fatigue life of base binder. The distribution of the WRP-derived additive inside base binder was uniform. In addition, the modification mechanism of WRP-derived additive was also proposed in this paper.

1. Introduction

The extensive use of rubber and plastic creates more convenient lives for citizens. However, the waste treatment department is under high pressure due to the rapid increase of waste rubber and waste plastic (WRP) [1]. Conventionally, the WRP are treated through landfilling or burning, although these methods result in new environmental concerns, e.g., air pollution, dioxin emissions, land pollution, and even ocean pollution [1,2,3,4,5,6,7]. Asphalt binder is commonly used in pavement industry around the world as a paving material because of its merits such as easy construction and driving comfort [8,9,10,11,12,13,14,15]. By means of incorporating wastes into asphalt binder, a large amount of domestic garbage or industrial refuse can be consumed with environmental benefits [1,16,17,18,19]. Thus, attention has been focused on the possibility of using asphalt binder as an innovative waste treatment method [20,21,22]. Specifically, previous studies have demonstrated the feasibility of recycling various types of waste materials into asphalt materials, for instance, end-of-life vehicle tires [23], waste plastic [2,24], electronic waste powders [17], marble waste [25], waste bleaching clays [26], waste glass powder [27], waste wood resources [28], etc.

During the late 1980s and early 1990s, highway industry was encouraged by the US Department of Transportation (USDOT) and Federal Highway Administration (FHWA) to utilize recycled crumb rubber (CR) in highway construction [29,30]. Numerous studies focusing on CR modified asphalt binder were then carried out. Previous studies reported that CR significantly increase the mechanical properties of asphalt binder [31,32,33]. By applying CR powders, both the high and low temperature performance of asphalt binder can be significantly enhanced [22,33,34]. Specifically, CR increases the viscosity and rutting resistance of base binder at high temperatures as well as the creep compliance at low temperatures [35]. The fracture resistance property of CR modified asphalt binder (CRMA) was also proved to be much better than that of base binder [36,37]. Numerous efforts were also spent to dig into the modification mechanism. It is believed that the swelling and dissolution occurring between rubber particle and asphalt binder play a fundamental role in increasing binder’s viscosity [31,38,39,40,41].

Inspired by the success of the value-added application of waste rubber, asphalt engineers and researchers put their eyes on waste plastic which is another source of pollution that is difficult to manage [42]. Like waste rubber, the feasibility of applying waste plastic into asphalt pavement as a modifier was also demonstrated [2,24,43]. Previous studies revealed that waste plastic can be an alternative for the current binder modifiers. It was reported that waste plastic can improve the rutting resistance, fracture resistance, thermal stability, degradation, and low temperature cracking properties of base binder [44,45]. Waste plastic was demonstrated to have the potential to perform as an anti-aging and anti-striping agent in base binder [46,47].

However, recycling WRP into asphalt raises the environmental concerns about emissions generated during mixing and paving processes of asphalt mixture. This is because WRP improves the viscosity of base binder which in turn results in higher manufacturing and paving temperatures of the asphalt mixture [48]. Furthermore, poor workability caused by binder’s high viscosity becomes another hurdle to promote the application of WRP modified asphalt binder [23]. One feasible approach to handle the abovementioned issue is integrating the WPR additive with warm mix technologies [49,50]. Previous studies documented that by combining warm mix technology, WRP can be effectively consumed in asphalt binder with enhanced mechanical properties as well as environmental benefits. By incorporating warm mix technologies, the manufacturing and paving temperature of WRP modified asphalt mixture can be reduced by around 20 °C [51,52]. Based on the mechanism, the warm mix technologies can be grouped into three categories: foaming technologies, addition of chemical additives, and addition of organic additives [53]. Aspha-min, Evotherm, and Sasobit are the corresponding represent commercial products, respectively. The organic additives added into base binder are waxes. When the binder’s temperature increases above the melting point of wax, the viscosity of the binder decreases. Nevertheless, it should be considered that the use of warm mix technologies creates extra cost for pavement construction. Therefore, producing a modifier derived from WRP with the capacity for increasing service property and workability of asphalt binder would be a win-win solution for the abovementioned issues.

Chemically, rubber and plastic are both high-molecular polymers which can be thermally cracked into small-molecules. Rubber can be thermally cracked into pyrolysis gas, pyrolysis oil, and heavy lysate [54,55]. Plastic can be thermally cracked into wax [56]. And the components of these pyrolysis depend on the thermal cracking condition. Thus, by choosing suitable thermal cracking conditions, it is possible to produce an asphalt binder modifier derived from WRP for the purpose of increasing both workability and mechanical properties of asphalt binder.

The objective of this study is to evaluate the effect of a binder additive, which is produced by thermal cracking WRP in laboratory, on mechanical and chemical properties of base binder. To this end, three empirical characteristics—namely, penetration, softening point, and ductility—were measured. Rheological properties including viscosity, rutting factor, fatigue life, and bending stiffness were characterized. The effect of thermally cracked WRP (CWRP) on chemical properties of asphalt binder was also investigated with Fourier transform infrared spectroscopy (FTIR) and differential scanning calorimetry (DSC). The dispersity of CWRP inside asphalt binder was evaluated using fluorescence microscope (FM).

2. Materials and Experimental Program

2.1. Materials

In this study, asphalt binder with a penetration grade of 70 (Pen 70) was used as the base binder. The asphalt binder used in this study is supplied by Shell Co., Ltd. (Foshan, China). Its properties are presented in Table 1.

Table 1.

Properties of Pen 70 asphalt binder.

WRP particles used in this study were provided by two plants in Chongqing, China. The waste plastic particles utilized in this study are mainly composed of polypropylene (PP) and various dyeing agents, as shown in Figure 1.

Figure 1.

Waste plastic particles with different colors: (a) black and (b) red.

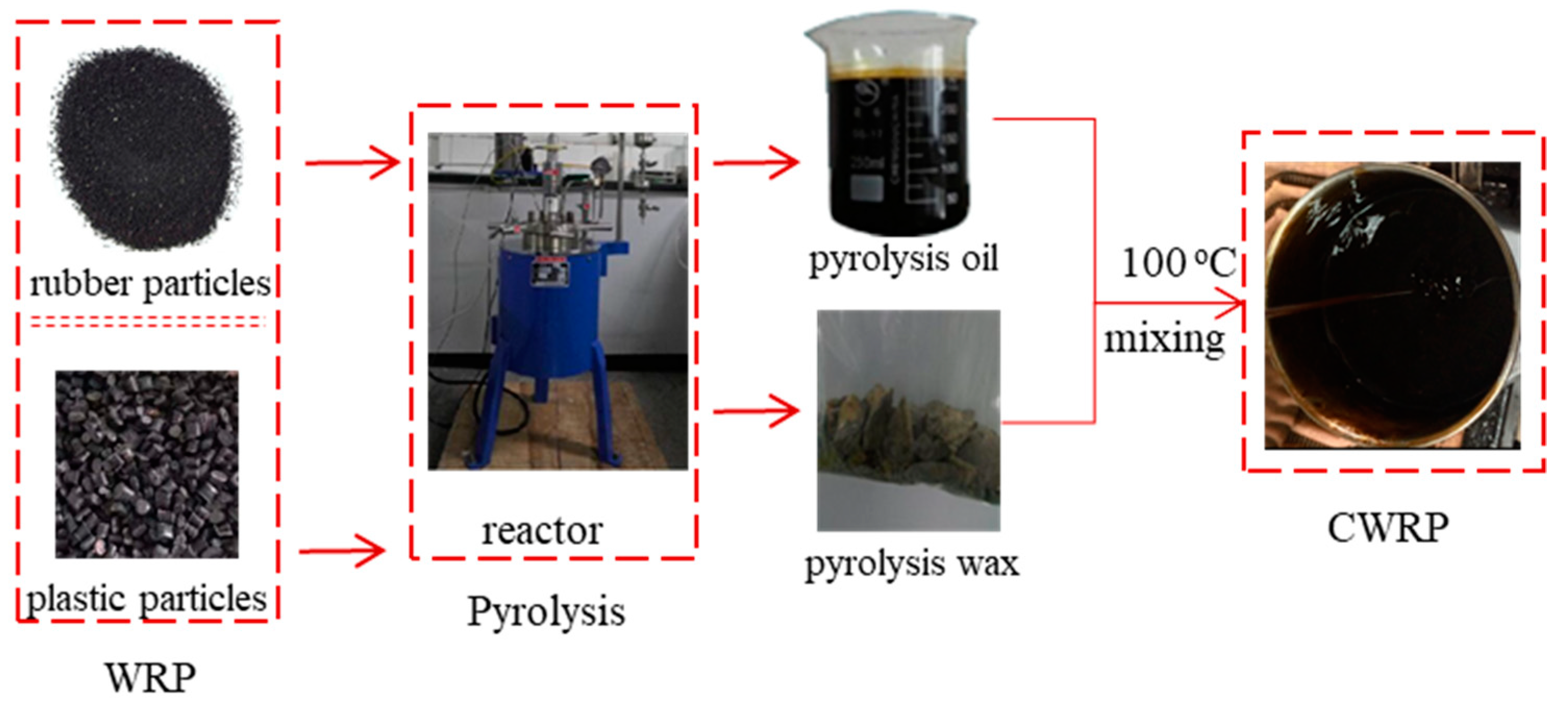

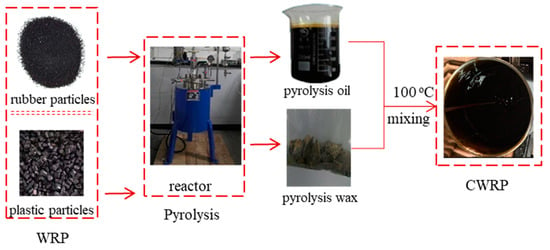

Figure 2 illustrates the production program of CWRP. As can be seen, pyrolysis oil (PO) and pyrolysis wax (PW) were prepared by pyrolyzing waste rubber and waste plastic, respectively. The PO and PW were then mixed with a weight ratio of 6:1 at 100 °C. 100 °C was set as the mixing temperature of PW and PO as the melting point of PW is around 90 °C.

Figure 2.

Production program of CWRP.

The CWRP modified asphalt binders (CMA) were prepared by blending CWRP and base binder using a high-speed shear mixer at 115 °C with a rotation speed of 800 rpm for 10 min. The dosage of WRP additive is 5% by weight of base binder. By each blending, around 500 g CMA can be prepared. The mixing temperature of the CMA was determined based on its viscosity–temperature curve.

2.2. Experimental Program

The three empirical characteristics—namely, penetration, softening point, and ductility—were employed to evaluate the conventional physical properties of CWRP modified and neat binders. Penetration test were performed at three temperatures (5 °C, 15 °C, and 25 °C) for calculating the penetration index (PI) of binder. The calculated PI was used to characterize the temperature sensitivity of asphalt binders. A Brookfield viscometer was employed to characterize the workability of all types of asphalt binders. The viscosity tests were carried out from 80 °C to 120 °C, with an interval of 10 °C. For each specimen, three replicate tests were conducted.

A DHR-2 dynamic shear rheometer (DSR, TA Instruments, Inc., New Castle, DE, USA) was utilized to evaluate the rheological performance of asphalt binder. The high temperature performance of asphalt binder was assessed based on the measured rutting factors [66]. Two 20-mm plates with a plate gap of 1 mm were used in the rutting factor test in accordance with ASTM D6373-16 [66]. The rutting factor test was performed on asphalt binders before and after rolling thin film oven (RTFO) aging. Rutting factor was measured under the oscillate load with strain of 12% and 10% for unaged and RTFO aged asphalt binder, respectively. The load frequency was set at 10 rad/s. Testing temperature increases from 52 °C at 6 °C interval until the value of rutting factor equal to or less than 1.0 kPa for unaged binders and 2.2 kPa for RTFO aged binders.

The fatigue property of asphalt binder was characterized using time sweep test [67]. Time sweep tests were carried out at 20 °C under a control–displacement model. The oscillation displacement was set as 6 rad. Repeated sinusoidal load with a constant loading frequency of 10 rad/s was applied on all types of specimens. During the test, complex modulus and phase angles were monitored as a function of loading cycles. For each specimen, three replicate tests were performed.

The low temperature performance was evaluated by Bending Beam Rheometer (BBR) test. This test was performed at a beginning temperature of −12 °C in accordance with ASTM D6648-08 [68]. The test temperature was increased or decreased at 6 °C interval until the conditions (creep stiffness, S ≤ 300 MPa and m-value ≥ 0.300) were reached. Three replicates were prepared and tested.

To evaluate the dispersity of CWRP additive inside neat binder, an XSZ-H FM (Chongqing Optical Instrument Co., Ltd, Chongqing, China) was utilized in this study. FM morphology observation was conducted on the CMA at 100 times magnification. The obtained FM images were further analyzed using MATLAB R2018a software.

To investigate the modification mechanism of CWRP additive, FTIR and DSC were performed on base binder, CWRP and CMA. A Nicolet IS50 FTIR (Nicolet Instrument Technologies, Inc., Madison, WI, USA) with attenuated total reflection (ATR) reflection mode was used to obtain the infrared spectrum. The sample preparation methods of test specimens, as well as the technical parameters of FTIR, were documented in previous studies [9]. DSC Q20 (TA Instruments, Inc., New Castle, DE, USA) was performed under nitrogen atmosphere. Testing temperature increases from −80 °C at a rate of 10 °C per minute until the ended temperature (200 °C) was reached.

3. Findings and Discussion

3.1. Viscosity

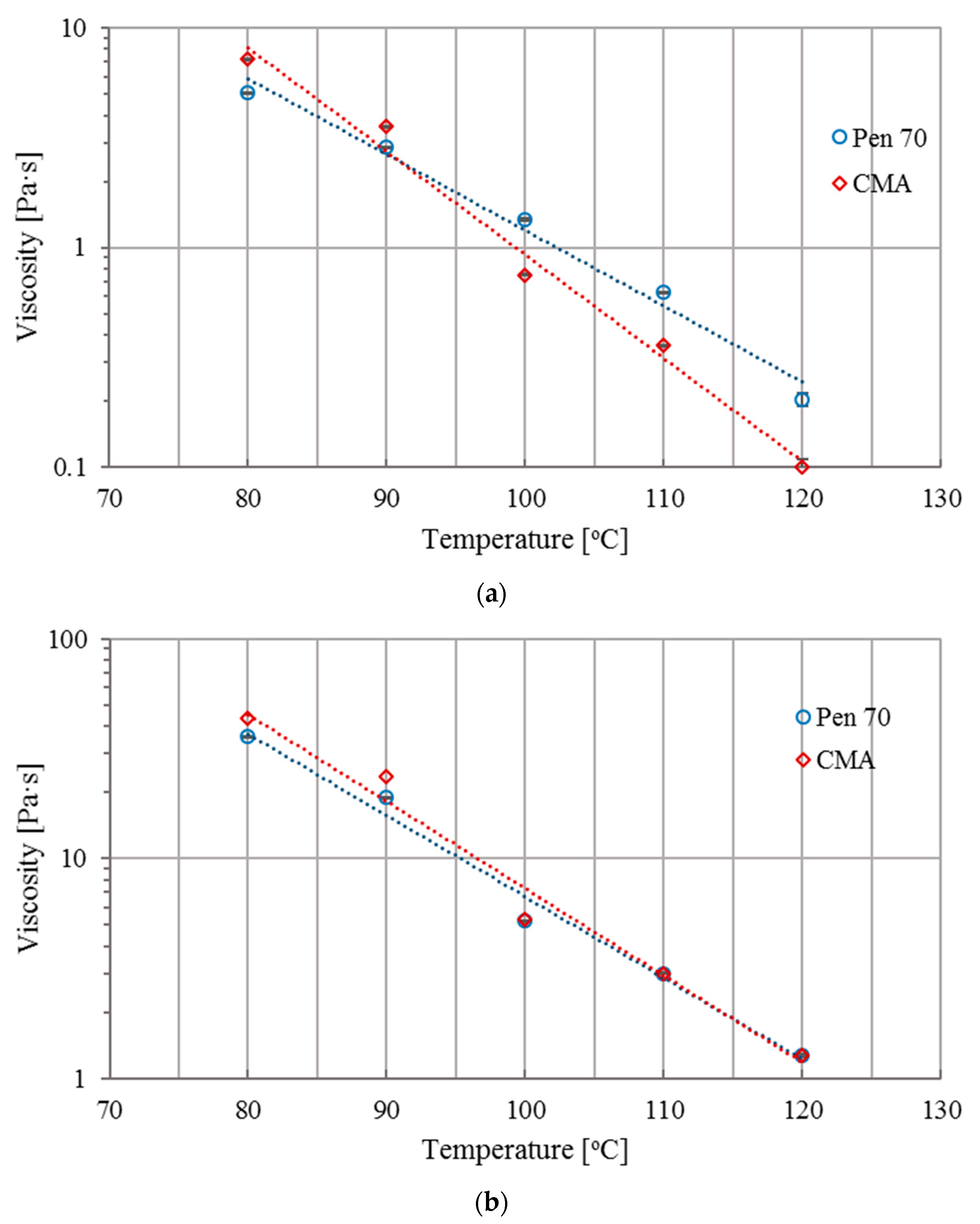

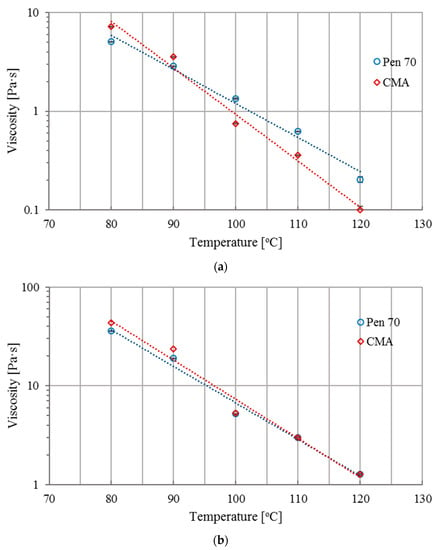

Viscosity of all asphalt binders from 80 °C to 120 °C were investigated for evaluating the workability of asphalt binders. The viscosity of asphalt binders before and after short-term aging is presented in Figure 3a,b, respectively. It can be seen in Figure 3a that the viscosity of CMA at 115 °C is around 0.17 Pa·s. According to the Superpave mix design manual [69], 115 °C can be set as CMA’s mixing temperature which is 50 °C lower than that of Pen 70. Consequently, CMA was RTFO aged at 120 °C for 85 min for better simulating the short-term aging process [65,70]. In this study, the error bars were drawn based on the standard deviation of the test results.

Figure 3.

Viscosity of asphalt binders: (a) before and (b) after RTFO aging.

As shown in Figure 3a, for both base and CWRP modified binder, viscosity declines as the temperature increases, although the decrease rate of CWRP modified binder is higher than that of Pen 70. The decrease rate of CMA sharply increased when temperature was higher than 90 °C, while the decrease rate of Pen 70 remains almost constant. In addition, it is interesting to know that the viscosity of CMA is higher compared to that of Pen 70 if the test temperature is lower than 90 °C. When temperature increases above 90 °C, the viscosity of CMA is much lower than that of Pen 70. This phenomenon is caused by the melting of added PW. When temperature increases above the melting point of PW, PW melts which declines the viscosity of asphalt binder. It indicates that adding CWRP increases the workability of neat binder.

Similarly, the turning point of CMA’s viscosity curve can be observed in the RTFO aged specimens. In addition, data presented in Figure 3b illustrates that within the whole temperature range, the viscosity of short-term aged CMA is higher than that of short-term aged Pen 70 which indicates a better bonding performance of CMA.

3.2. Three Empirical Characteristics

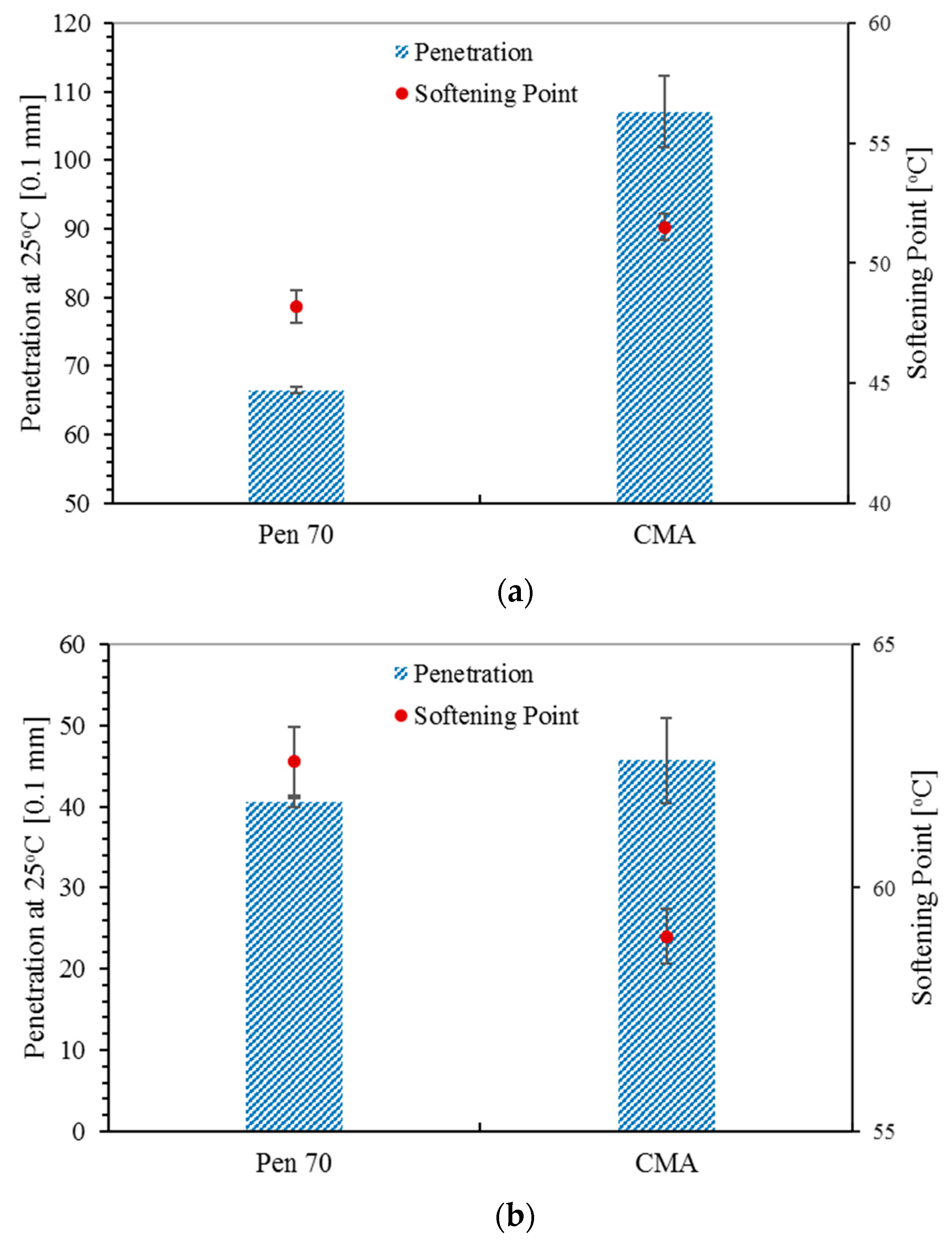

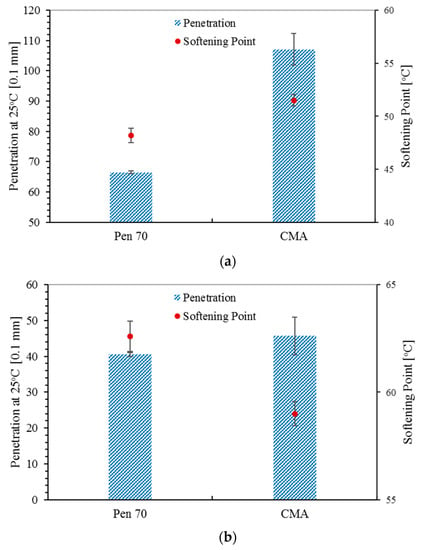

The results of the penetration (25 °C) and softening point tests are presented in Figure 4.

Figure 4.

Penetration and softening point of asphalt binders: (a) before and (b) after RTFO aging.

According to the softening points presented in Figure 4a, it was found that the CWRP modifier increases the softening point of asphalt binder. Like rubber asphalt and other polymer modified asphalt binders, the increasing of softening point could be explained by the swelling and dissolution of the polymers in CWRP. In addition, the wax inside the CWRP also plays a role in increasing the softening point of CMA. After RTFO aging, although the softening point of CMA and Pen 70 are both increased, the softening point of CMA is lower than that of Pen 70. This might be because lighter components in asphalt binder have a strong affinity for CWRP, which is less likely to be volatilized. Consequently, the volatilization of lighter components in asphalt binder during RTFO aging process is weakened. Considering the changes on the properties of asphalt binder resulting from RTFO aging are mainly because of the volatilization of lighter components in asphalt binder, lower volatility leads to a smaller change on penetration value and softening point. Due to the same reason, in comparison with Pen 70, the penetration value of CMA presents a lower sensitivity to RTFO aging.

Based on the penetration values, PI, which is defined by Equations (1) and (2), was calculated for evaluating the temperature sensitivity of asphalt binder. The calculated PIs are listed in Table 2.

where,

Table 2.

PI of asphalt binder.

- T is the temperature at which the penetration test is performed

- P is the penetration value at the corresponding test temperature

- A and K are determined by the lg (penetration value) vs. temperature curve

PI reveals that the temperature sensitivity of CMA is comparable to that of Pen 70, which means adding CWRP does not negatively affect the temperature sensitivity of binder.

The ductility of CMA at 15 °C is larger than 150 cm while that of Pen 70 is 105.8 cm. This indicates that, in comparison with Pen 70, CMA may have a better low-temperature performance.

3.3. High-Temperature Performance

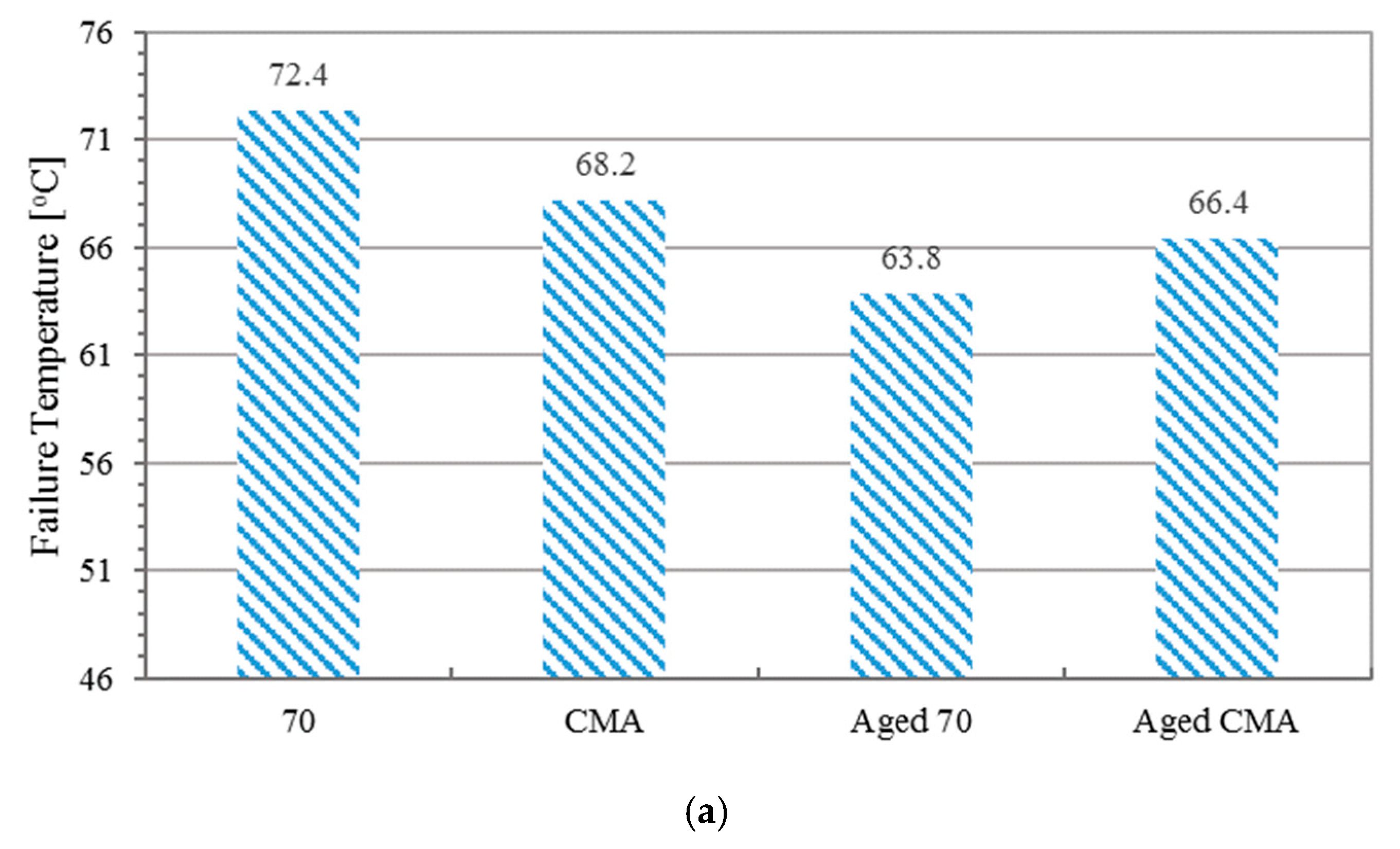

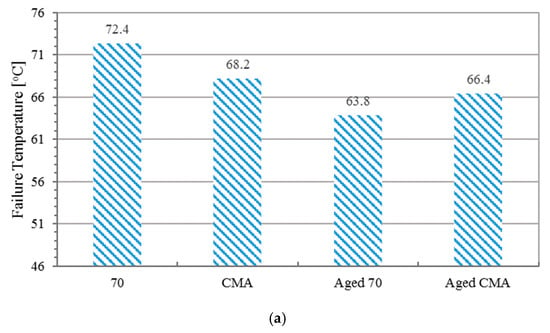

The high-temperature performance was evaluated by the temperature sweep test. Rutting factors, as well as the failure temperatures, are presented in Figure 5.

Figure 5.

Results of temperature sweep test: (a) failure temperature, rutting factor for unaged samples (b), and aged samples (c).

As shown in Figure 5a, the failure temperature values of unaged binders are higher than those of aged binders. Before RTFO aging, failure temperature value of neat binder is higher than that of CMA binder. Conversely, after RTFO aging, the failure temperature value of CMA is higher than that of based binder. Consistent with the failure temperature, base binder and CMA show higher rutting factors before and after aging, respectively. Since rutting happened on short-term aged asphalt mixture, CMA shows a better rutting resistance performance.

3.4. Low-Temperature Performance

Low temperature performance of both base binder and modified binder were evaluated using both stiffness value and m-value obtained from Bending Beam Rheology (BBR) tests. The test results are listed in Table 3.

Table 3.

Results of BBR test.

According to Table 3, it can be found that the stiffnesses of CMA are much lower than that of Pen 70. While the m-values of CMA are bigger than that of Pen 70. According to the ASTM standard [68], stiffness value should be less than 300 MPa, while the m-value should be larger than 0.3 for a specific temperature grade. Low-temperature cracking is more likely to occur on asphalt binder with higher stiffness. The BBR test results reveals that CWRP significantly increases the low-temperature performance of base binder.

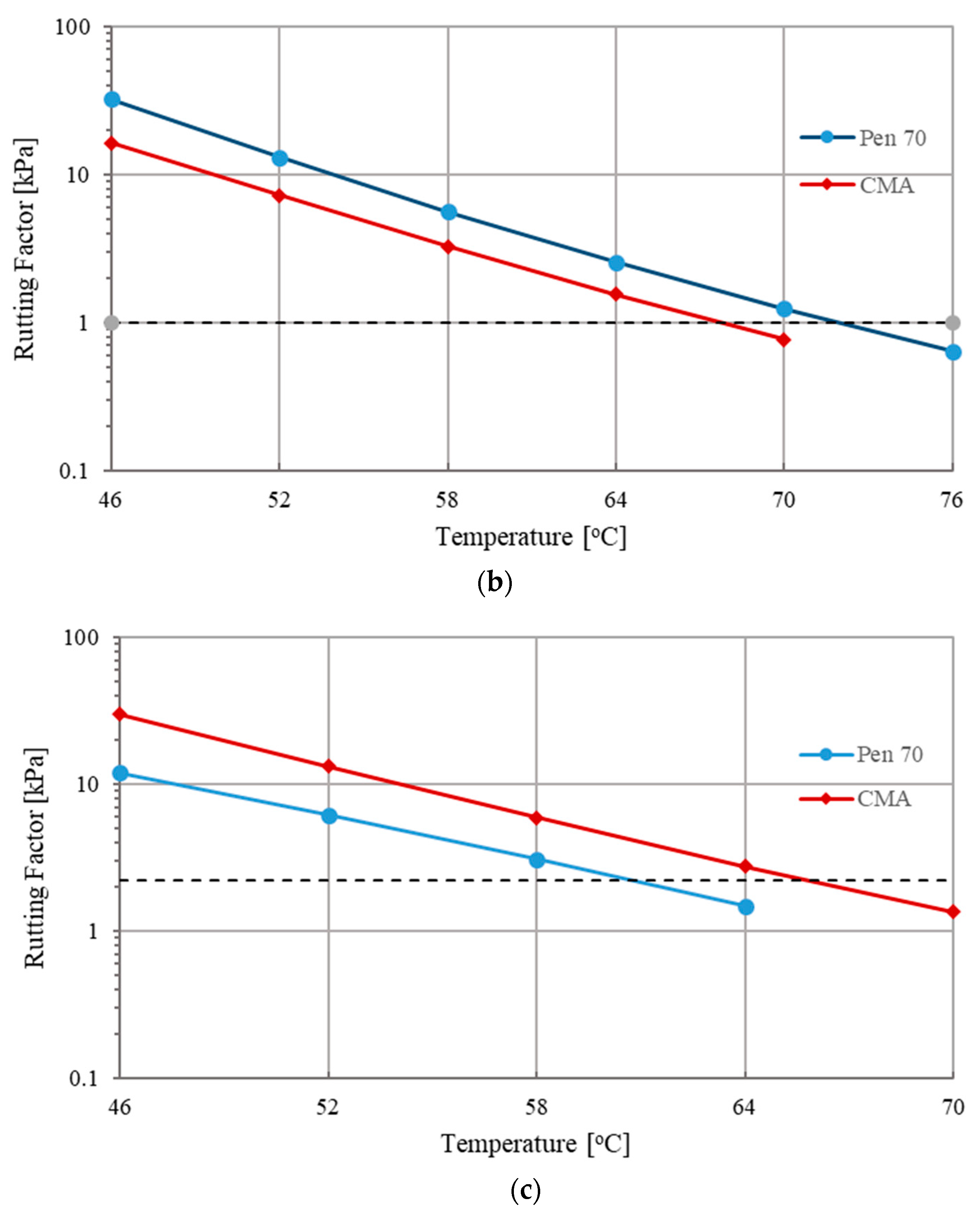

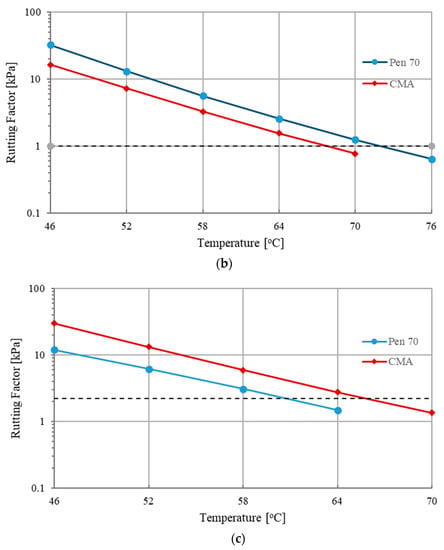

3.5. Fatigue Performance

Fatigue performance is evaluated by time sweep test at 25 °C. The results of time sweep test is shown in Figure 6. 50% reduction of initial complex modulus method was utilized to define the fatigue failure point of asphalt binder. The number of failure values (Nf) is presented in Table 4. Higher Nf indicates superior fatigue resistance at the tested strain level.

Figure 6.

Results of time sweep test: (a) Pen 70, (b) CMA, (c) Aged Pen 70, and (d) Aged CMA.

Table 4.

Number of failure values.

As can be seen, regardless of the aging state, Nf of CMA is higher than that of Pen 70. It indicates that CMA shows longer fatigue life, which means that CWRP can increase the fatigue life of binder at the selected strain level.

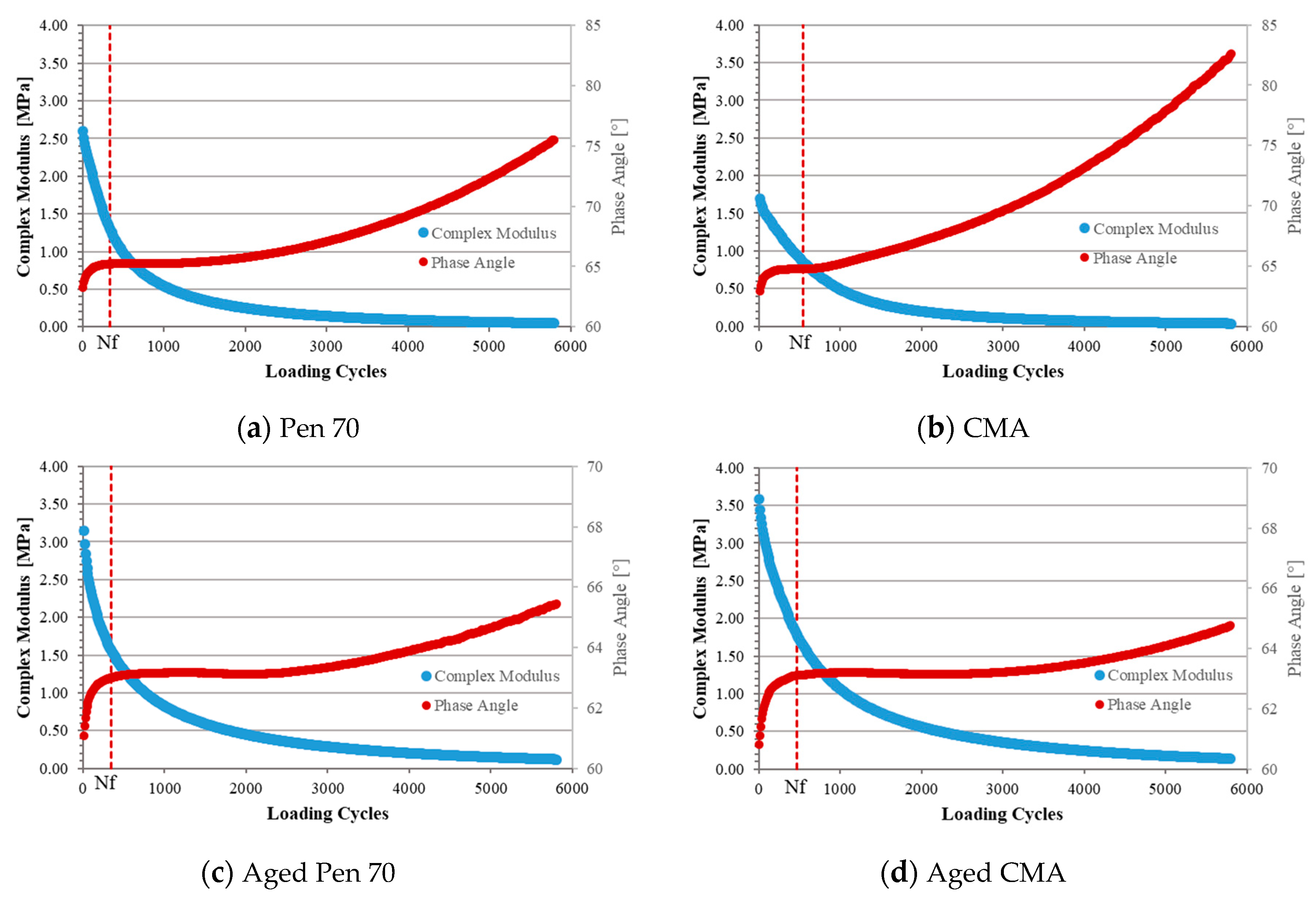

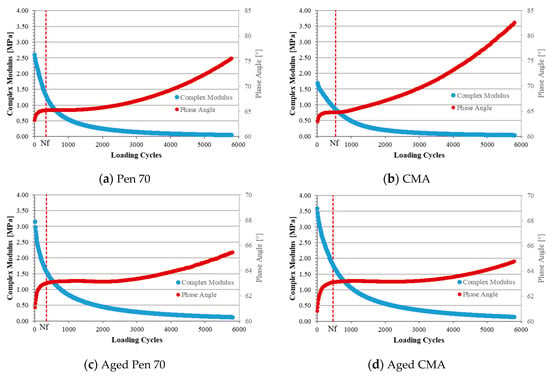

3.6. Dispersity

The dispersity is characterized by FM observation providing information on the polymer and insoluble component in the modified binder. Dispersity refers to the degree of fragmentation of the dispersed phase. Dispersity can be characterized by evaluating the average diameter of dispersed phase. FM observed information was analyzed using MATLAB to calculate the number of particles and the corresponding diameters. Figure 7 shows the FM image of CWRP modified asphalt binder.

Figure 7.

FM image of CWRP modified asphalt binder: (a) FM image and (b) gridded FM image.

As shown, the FM image was gridded into 16 sections. In each section, particle numbers and particle diameters were collected from the FM image. The average diameters were then calculated based on the collected particle number and particle diameter. Particle numbers in each section and the corresponding average diameters were listed in Table 5.

Table 5.

Particle number and average diameter in each section.

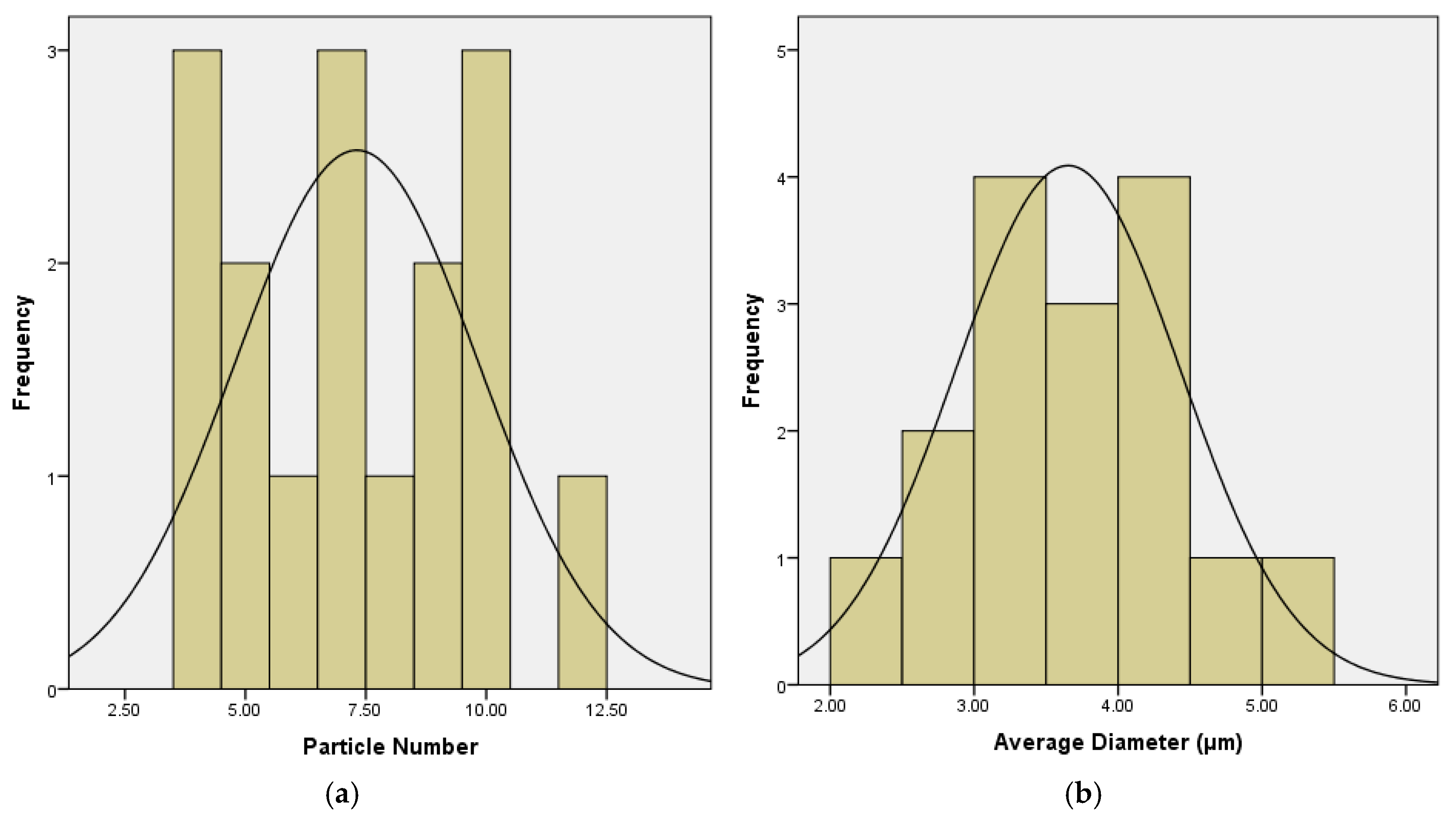

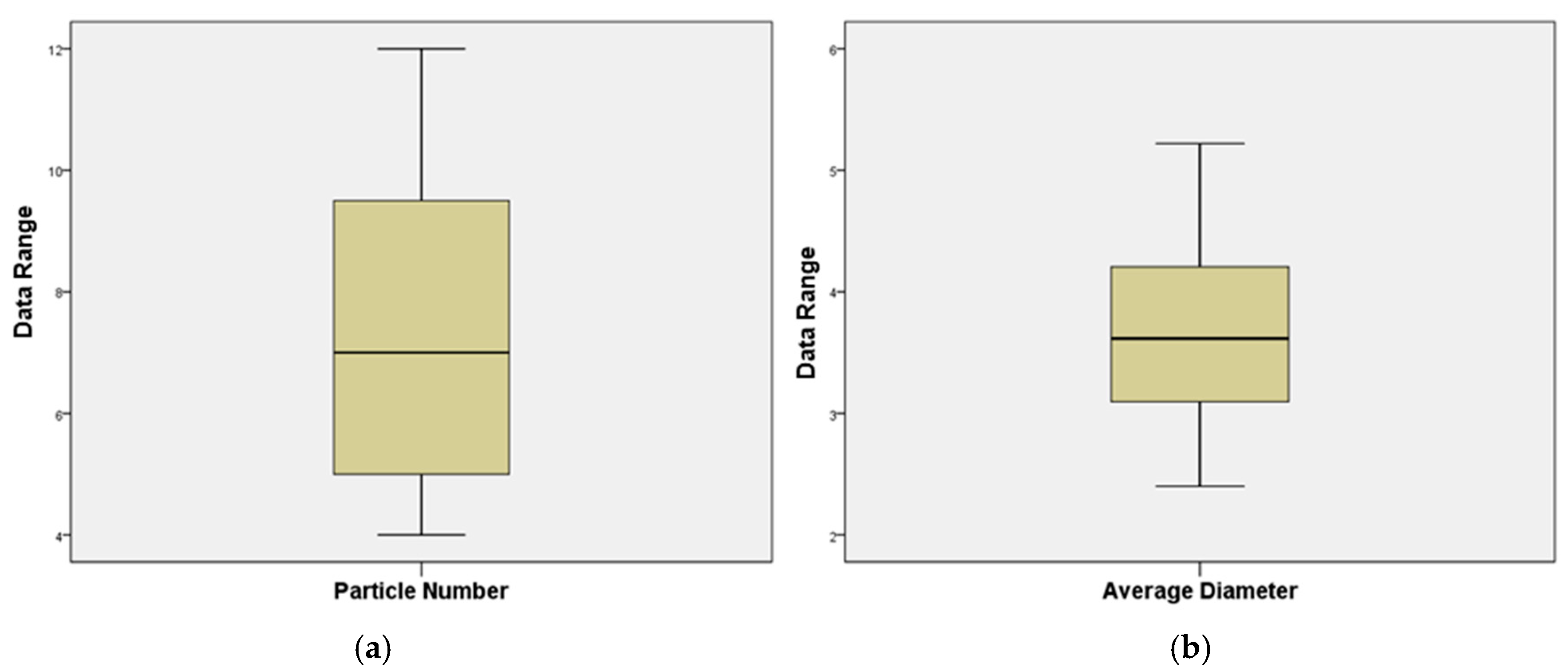

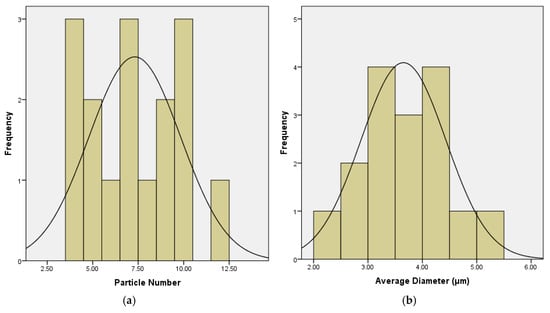

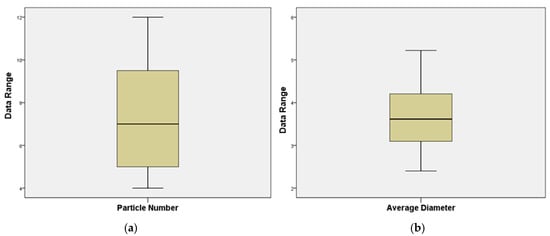

To evaluate the differences among particle numbers and average diameter, normality tests and outlier test were performed in advance. Kolmogorov-Smirnov (K-S) testing was performed on both the particular number and average diameter. The K-S test results are shown in Table 6.

Table 6.

Results of Kolmogorov–Smirnov test.

As can be seen, for both particular number and average diameter, the Asymptotic Significance (Asymp. Sig.) is larger than 0.05 which indicates that the distribution of the particular number and average diameter is normal.

The results of normality testing and outlier testing are presented in Figure 8 and Figure 9, respectively. As expected, both particle number and average diameter follow the normal distribution with the mean value of 7.31 and 3.65, respectively.

Figure 8.

Results of normality test: (a) particle number and (b) average diameter.

Figure 9.

Results of outlier test: (a) particle number and (b) average diameter.

Box plot was employed to detect the outliers of the data set. The upper and lower limit of the non-outlier were determined based on the quantile and an empirical constant K (K = 1.5). Specifically, if Q1 and Q3 are the lower and upper quartiles, respectively, then the non-outlier range is defined as [Q1 − k(Q3 − Q1), Q3 + k(Q3 − Q1)]. Data out of the range is defined as outliers. As shown in Figure 9, since all the data were observed within the non-outlier range, it can be concluded that no outliers were detected in these two data sets.

To further analyze the difference among the particle number and average diameter in each section, the sections were divided into eight groups. Section 1 and 2 are group 1, section 3 and 4 are group 2, and so on. ANOVA testing was then performed at a 95% confidence interval for determining the relationship between group and particle number and average diameter. The ANOVA test results are shown in Table 7. This table illustrates that for both particle number and average diameter, no significant difference between groups can be detected, which means the dispersity of CWRP inside base binder is statistically uniform.

Table 7.

Results of ANOVA test.

3.7. Fourier Transform Infrared Spectroscopy

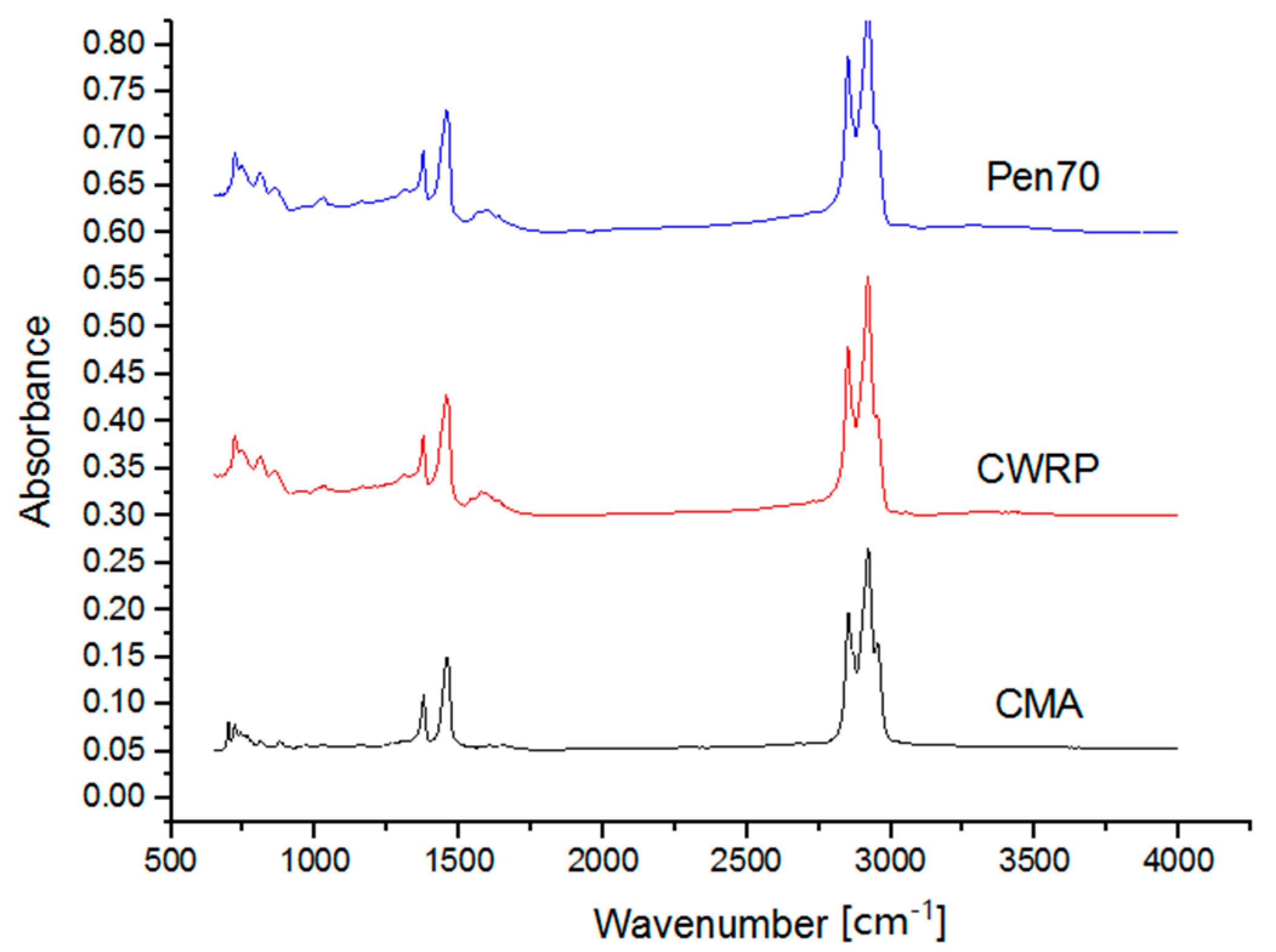

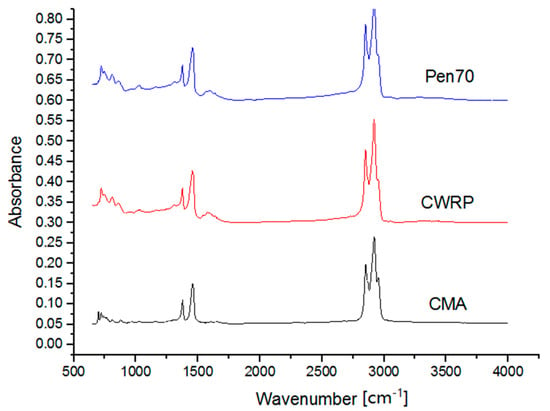

FTIR tests were performed on both asphalt binders and the additive for determining the effects of CWRP additive on the chemical composition of base binder. Figure 10 illustrates the FTIR spectrum of Pen 70 base binder, CWRP modifier, and CWRP modified asphalt binder.

Figure 10.

FTIR test results.

In these spectrums, the major bands around 2920 cm−1 and 2852 cm−1 resulted from the vibration of stretching vibrations of Alkyl C–H and Aliphatic C–H, respectively. The absorption at around 1456.50 cm−1 and 1376.47 cm−1 are caused by the blending vibration of methylene and methyl, respectively, while those at 720.78 cm−1 and 698.12 cm−1 are due to the plane swing vibration of the methylene in alkyl group.

As can be seen, both the binders and modifier have the absorption peaks at same wavenumbers, so no major chemical reactions were detected due to the addition of CWRP modifier.

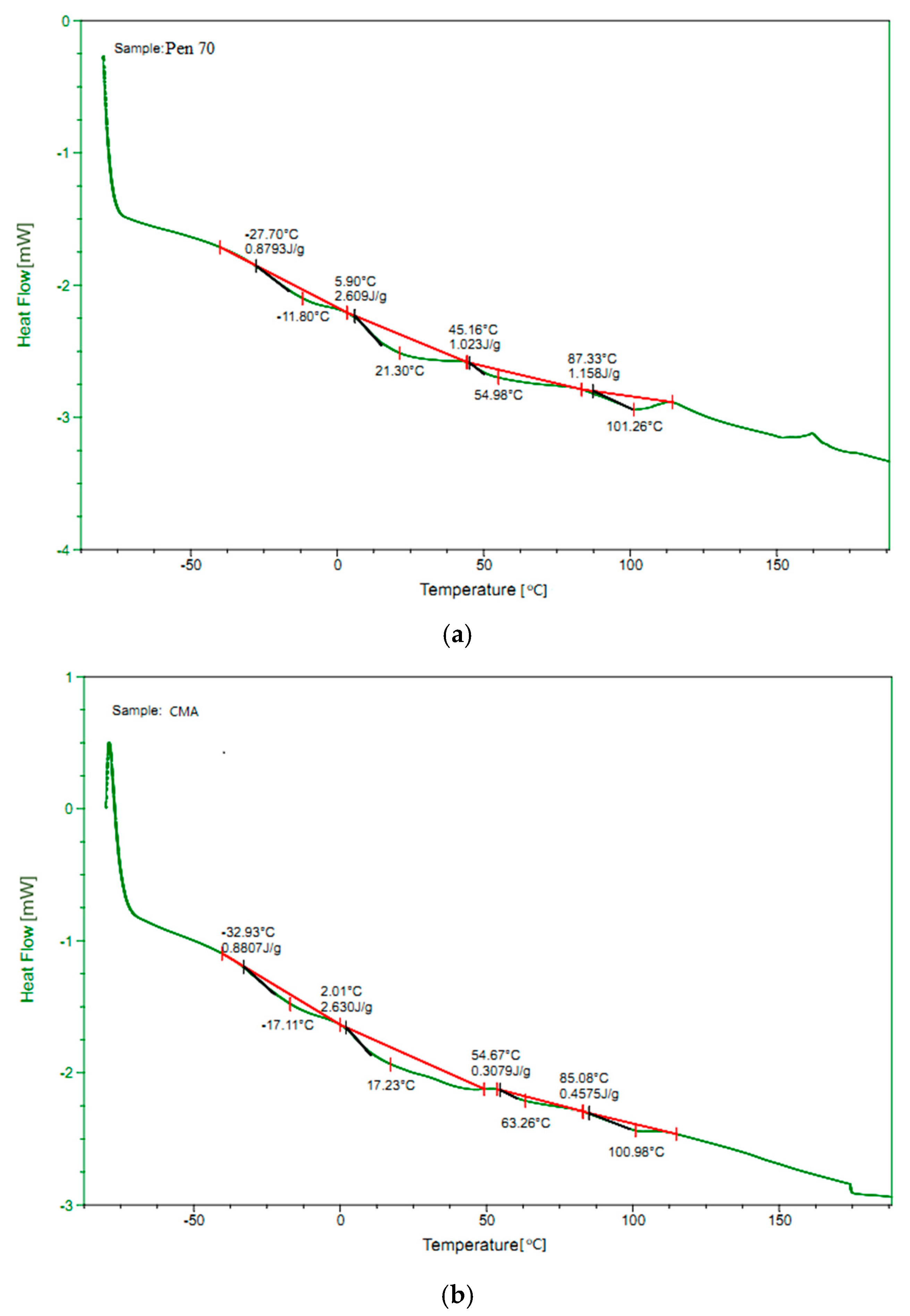

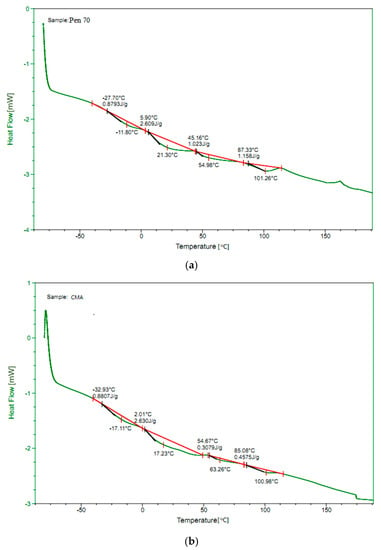

3.8. Differential Scanning Calorimetry

Differential scanning calorimetry (DSC) is a thermos-analytical method that allows the determination of physical changes in a material associated with a heat exchange. The properties that are especially relevant for bitumen are physical changes such as glass transition temperature (Tg) and phase transition such as melting and crystallization. The DSC tests were carried out to characterize the thermal property of all the asphalt binders. Figure 11 shows the DSC results.

Figure 11.

Result of DSC tests: (a) Pen 70 and (b) CMA.

Previous studies demonstrated that lower Tg indicates better low-temperature performance, and vice versa [71,72]. Thus, Tg were utilized to evaluate the low temperature of asphalt binder. As can be seen, the Tg of CMA is around 5.3 °C lower than that of Pen 70. Again, it indicates that CWRP have positive influence on the low-temperature performance of asphalt binder. In addition, around the softening point of asphalt binder, the exothermic peak of CMA occurred few degrees later than that of Pen 70 which reveals the adding CWRP also increases the high-temperature performance of asphalt binder. In addition, no significant differences can be found between the DSC curve of CMA and Pen 70. By combining with the results of FTIR, it can be proposed that the modification mechanism of CWRP is mainly because of the physical change instead of chemical reaction.

4. Findings and Recommendations

This paper presents a laboratory study to characterize and compare the rheological properties of Pen 70 modified with CWRP. According to the test results on viscosity, rutting factors, time sweep, BBR test, FM test, FTIR, and DSC, the following major findings have been obtained:

- The incorporation of CWRP additives enhances the rutting resistance, low-temperature, and fatigue life of virgin asphalt binder. The enhancement comes from the modification effect by the polymers in CWRP.

- Adding CWRP increases the workability because of the lighter compositions and wax in CWRP.

- CWRP is found to be uniformly distributed inside asphalt binder.

- Chemical reaction between CWRP and based binder cannot be detected. The modification of CWRP is more likely due to physical change.

Based on the limited findings of this study, recycling WRP into asphalt binder towards enhanced mechanical properties and environmental benefits appears promising. CWRP has been found to be able to increase the workability and service performance of asphalt binder. Further research on the performance of asphalt mixture is required. In addition, adjusting the thermal cracking process for producing asphalt binder modifier with better performance is also recommended.

Author Contributions

Conceptualization, C.L. and Y.L.; Methodology, T.L. and Y.L.; Formal analysis, Y.L. and Z.Z.; Investigation, Y.L.; Resources, Y.L.; Data curation, Y.L.; Writing—original draft preparation, Z.Z.; Writing—review and editing, Y.L., T.L., C.L., and Z.Z.; Visualization, Z.Z.; Supervision, T.L. and M.O.; Project administration, C.L. and Z.Z.; Funding acquisition, C.L., T.L., and M.O.

Funding

This research was funded by Science and Technology Planning Project of Department of Transportation of Henan Province, no. 2014-2-5; German Research Foundation, no. OE 514/10-1; Basic Science and Frontier Technology Research Program of Chongqing, no. cstc2017jcyjAX0310; Science and Technology Research Program of Chongqing Municipal Education Commission, no. KJ1705124 and Chongqing Social Undertakings and People’s Livelihood Guarantee Science and Technology Innovation Special Project, no. cstc2017shmsA1224.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Hu, C.C.; Lin, W.J.; Partl, M.; Wang, D.Y.; Yu, H.Y.; Zhang, Z. Waste packaging tape as a novel bitumen modifier for hot-mix asphalt. Constr. Build. Mater. 2018, 193, 23–31. [Google Scholar] [CrossRef]

- Tsai, C.J.; Chen, M.L.; Chang, K.F.; Chang, F.K.; Mao, I.F. The pollution characteristics of odor, volatile organochlorinated compounds and polycyclic aromatic hydrocarbons emitted from plastic waste recycling plants. Chemosphere 2009, 74, 1104–1110. [Google Scholar] [CrossRef]

- Verma, R.; Vinoda, K.; Papireddy, M.; Gowda, A. Toxic pollutants from plastic waste—A review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Lehmann, C.M.B.; Rostam-Abadi, M.; Rood, M.J.; Sun, J. Reprocessing and reuse of waste tire rubber to solve air-quality related problems. Energy Fuels 1998, 12, 1095–1099. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Leng, Z.; Zhang, Z.Y.; Zhang, Y.; Wang, Y.Y.; Yu, H.Y.; Ling, T.Q. Laboratory evaluation of electromagnetic density gauges for hot-mix asphalt mixture density measurement. Constr. Build. Mater. 2018, 158, 1055–1064. [Google Scholar] [CrossRef]

- Zhang, Y.; Leng, Z. Quantification of bituminous mortar ageing and its application in ravelling evaluation of porous asphalt wearing courses. Mater. Des. 2017, 119, 1–11. [Google Scholar] [CrossRef]

- Lv, S.T.; Liu, C.C.; Chen, D.; Zheng, J.L.; You, Z.P.; You, L.Y. Normalization of fatigue characteristics for asphalt mixtures under different stress states. Constr. Build. Mater. 2018, 177, 33–42. [Google Scholar] [CrossRef]

- Zhang, Y.; van de Ven, M.; Molenaar, A.; Wu, S. Preventive maintenance of porous asphalt concrete using surface treatment technology. Mater. Des. 2016, 99, 262–272. [Google Scholar] [CrossRef]

- Lv, S.T.; Liu, C.C.; Lan, J.T.; Zhang, H.W.; Zheng, J.L.; You, Z.P. Fatigue Equation of Cement-Treated Aggregate Base Materials under a True Stress Ratio. Appl. Sci. 2018, 8, 691. [Google Scholar] [CrossRef]

- Lv, S.T.; Liu, C.C.; Yao, H.; Zheng, J.L. Comparisons of synchronous measurement methods on various moduli of asphalt mixtures. Constr. Build. Mater. 2018, 158, 1035–1045. [Google Scholar] [CrossRef]

- Xu, H.; Xing, C.; Zhang, H.; Li, H.; Tan, Y. Moisture seepage in asphalt mixture using X-ray imaging technology. Int. J. Heat Mass Transf. 2019, 131, 375–384. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Fang, K.; Pei, J.; Xu, L. Development and validation of nonlinear viscoelastic damage (NLVED) model for three-stage permanent deformation of asphalt concrete. Constr. Build. Mater. 2016, 102, 384–392. [Google Scholar] [CrossRef]

- Sun, D.Q.; Lu, T.; Xiao, F.P.; Zhu, X.Y.; Sun, G.Q. Formulation and aging resistance of modified bio-asphalt containing high percentage of waste cooking oil residues. J. Clean. Prod. 2017, 161, 1203–1214. [Google Scholar] [CrossRef]

- Colbert, B.W.; You, Z.P. Properties of Modified Asphalt Binders Blended with Electronic Waste Powders. J. Mater. Civ. Eng. 2012, 24, 1261–1267. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Non-Newtonian behaviors of crumb rubber-modified bituminous binders. Appl. Sci. 2018, 8, 1760. [Google Scholar] [CrossRef]

- Yu, H.Y.; Leng, Z.; Zhou, Z.Y.; Shih, K.M.; Xiao, F.P.; Gao, Z.M. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- Tang, N.P.; Huang, W.D.; Xiao, F.P. Chemical and rheological investigation of high-cured crumb rubber-modified asphalt. Constr. Build. Mater. 2016, 123, 847–854. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Rheological behavior and its chemical interpretation of crumb rubber modified asphalt containing warm-mix additives. Transp. Res. Rec. 2018, 2672, 337–348. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.S. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Akbulut, H.; Gurer, C. Use of aggregates produced from marble quarry waste in asphalt pavements. Build. Environ. 2007, 42, 1921–1930. [Google Scholar] [CrossRef]

- Mazzotta, F.; Sangiorgi, C.; Vignali, V.; Lantieri, C.; Dondi, G. Rheological characterization of bituminous mastics containing waste bleaching clays. In 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar]

- Simone, A.; Mazzotta, F.; Eskandarsefat, S.; Sangiorgi, C.; Vignali, V.; Lantieri, C.; Dondi, G. Experimental application of waste glass powder filler in recycled dense-graded asphalt mixtures. Road Mater. Pavement Des. 2019, 20, 592–607. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q.; Mills-Beale, J. Mechanical performance of asphalt mixtures modified by bio-oils derived from waste wood resources. Constr. Build. Mater. 2014, 51, 424–431. [Google Scholar] [CrossRef]

- Heitzman, M.A. State of the Practice-Design and Construction of Asphalt Paving Materials with Crumb Rubber Modifier; Federal Highway Administration: Washington, DC, USA, 1992.

- Epps, J.A.; Mason, L. Uses of Recycled Rubber Tires in Highways: A Synthesis of Highway Practice. Final Report; National Cooperative Highway Research Program: Washington, DC, USA, 1994. [Google Scholar]

- Zanzotto, L.; Kennepohl, G. Development of rubber and asphalt binders by depolymerization and devulcanization of scrap tires in asphalt. Transp. Res. Rec. 1996, 1530, 51–58. [Google Scholar] [CrossRef]

- Bahia, H.U.; Davies, R. Effect of crumb rubber modifiers (CRM) on performance related properties of asphalt binders. Asph. Paving Technol. 1994, 63, 414. [Google Scholar]

- Wang, H.; You, Z.; Mills-Beale, J.; Hao, P. Laboratory evaluation on high temperature viscosity and low temperature stiffness of asphalt binder with high percent scrap tire rubber. Constr. Build. Mater. 2012, 26, 583–590. [Google Scholar] [CrossRef]

- Shen, J.; Serji, A.; Xiao, F.P.; Tang, B.M. Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber modified binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Lee, S.J.; Akisetty, C.K.; Amirkhanian, S.N. The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements. Constr. Build. Mater. 2008, 22, 1368–1376. [Google Scholar] [CrossRef]

- Mull, M.A.; Stuart, K.; Yehia, A. Fracture resistance characterization of chemically modified crumb rubber asphalt pavement. J. Mater. Sci. 2002, 37, 557–566. [Google Scholar] [CrossRef]

- Yu, J.; Yu, X.; Gao, Z.; Guo, F.; Wang, D.; Yu, H. Fatigue resistance characterization of warm asphalt rubber by multiple approaches. Appl. Sci. 2018, 8, 1495. [Google Scholar] [CrossRef]

- Heitzman, M. Design and Construction of Asphalt Paving Materials with Crumb Rubber Modifier; No. 1339; Transportation Research Board: Washington, DC, USA, 1992. [Google Scholar]

- Dong, D.W.; Huang, X.X.; Li, X.L.; Zhang, L.Q. Swelling process of rubber in asphalt and its effect on the structure and properties of rubber and asphalt. Constr. Build. Mater. 2012, 29, 316–322. [Google Scholar] [CrossRef]

- Airey, G.D.; Singleton, T.M.; Collop, A.C. Properties of polymer modified bitumen after rubber-bitumen interaction. J. Mater. Civ. Eng. 2002, 14, 344–354. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Zhang, H.; Apostolidis, P.; Scarpas, T.; Erkens, S. Asphalt-rubber interaction and performance evaluation of rubberised asphalt binders containing non-foaming warm-mix additives. Road Mater. Pavement Des. 2018. [Google Scholar] [CrossRef]

- Garcia-Morales, M.; Partal, P.; Navarro, F.; Gallegos, C. Effect of waste polymer addition on the rheology of modified bitumen. Fuel 2006, 85, 936–943. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z.F. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Yu, R.; Fang, C.; Liu, P.; Liu, X.; Li, Y. Storage stability and rheological properties of asphalt modified with waste packaging polyethylene and organic montmorillonite. Appl. Clay Sci. 2015, 104, 1–7. [Google Scholar] [CrossRef]

- Naskar, M.; Chaki, T.K.; Reddy, K.S. Effect of waste plastic as modifier on thermal stability and degradation kinetics of bitumen/waste plastics blend. Thermochim. Acta 2010, 509, 128–134. [Google Scholar] [CrossRef]

- Troy, K.; Sebaaly, P.; Epps, J. Evaluation systems for crumb rubber modified binders and mixtures. Transp. Res. Rec. 1996, 1530, 3–10. [Google Scholar] [CrossRef]

- Gürü, M.; Çubuk, M.K.; Arslan, D.; Farzanian, S.A.; Bilici, I. An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material. J. Hazard. Mater. 2014, 279, 302–310. [Google Scholar] [CrossRef] [PubMed]

- García-Morales, M.; Partal, P.; Navarro, F.; Martínez-Boza, F.; Gallegos, C.; González, N.; González, O.; Muñoz, M. Viscous properties and microstructure of recycled eva modified bitumen. Fuel 2004, 83, 31–38. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Yu, X.; Leng, Z.; Wei, T. Investigation of the rheological modification mechanism of warm-mix additives on crumb-rubber-modified asphalt. J. Mater. Civ. Eng. 2013, 26, 312–319. [Google Scholar] [CrossRef]

- Yu, H.Y.; Leng, Z.; Gao, Z.M. Thermal analysis on the component interaction of asphalt binders modified with crumb rubber and warm mix additives. Constr. Build. Mater. 2016, 125, 168–174. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Xiao, F.; Gao, Z. Rheological and chemical characteristics of rubberized binders with non-foaming warm mix additives. Constr. Build. Mater. 2016, 111, 671–678. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Huang, H.; Tang, L.; Wu, C. Characterization of gaseous and solid product from thermal plasma pyrolysis of waste rubber. Environ. Sci. Technol. 2003, 37, 4463–4467. [Google Scholar] [CrossRef]

- Fang, Y.; Zhan, M.; Wang, Y. The status of recycling of waste rubber. Mater. Des. 2001, 22, 123–128. [Google Scholar] [CrossRef]

- Williams, P.T.; Williams, E.A. Interaction of plastics in mixed-plastics pyrolysis. Energy Fuels 1999, 13, 188–196. [Google Scholar] [CrossRef]

- ASTM International. ASTM D5/D5M-13 Standard Test Method for Penetration of Bituminous Materials; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM International. ASTM D36/D36M-14e1 Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. ASTM D4402/D4402M-15 Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. ASTM D113-17 Standard Test Method for Ductility of Asphalt Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- German Insititue for Standardization. DIN EN 12606-1 Bitumen and Bituminous Binders—Determination of the Paraffin Wax Content—Part 1: Method by Distillation; Deutsches Institut fur Normung E.V. (DIN): Berlin, Germany, 2015. [Google Scholar]

- ASTM International. ASTM D92-18 Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. ASTM D70-03 Standard Test Method for Specific Gravity and Density of Semi-Solid Bituminous Materials (Pycnometer Method); ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM International. ASTM D2042-15 Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. ASTM D2872-12e1 Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test); ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. ASTM D6373-16 Standard Specification for Performance Graded Asphalt Binder; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Underwood, B.S. A continuum damage model for asphalt cement and asphalt mastic fatigue. Int. J. Fatigue 2016, 82, 387–401. [Google Scholar] [CrossRef]

- ASTM International. ASTM D6648-08 Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Asphalt Institute. Superpave Mix Design. Superpave Series No. 2 (SP-02); Asphalt Institute: Lexington, KY, USA, 2003. [Google Scholar]

- Lee, S.-J.; Amirkhanian, S.N.; Kim, K.W. Laboratory evaluation of the effects of short-term oven aging on asphalt binders in asphalt mixtures using HP-GPC. Constr. Build. Mater. 2009, 23, 3087–3093. [Google Scholar] [CrossRef]

- Zhang, L.; Tan, Y.Q.; Bahia, H.U. Relationship between glass transition temperature and low temperature properties of oil modified binders. Constr. Build. Mater. 2016, 104, 92–98. [Google Scholar]

- Tabatabaee, H.A.; Velasquez, R.; Bahia, H.U. Predicting low temperature physical hardening in asphalt binders. Constr. Build. Mater. 2012, 34, 162–169. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).