3.1. Development of Alkali-Activated Slag-Based Concretes with Carbonated BOF Aggregates

The effects of using different contents of carbonated BOF and normal aggregates on the compressive and flexural strengths are shown in

Figure 5. Generally, it was observed that using carbonated BOF as an aggregate significantly increased the strength compared to normal aggregate.

The results indicated that impacts of carbonated BOF aggregates depend on the precursor type. Maximum strength was measured in the mixtures incorporating both ladle slag and GGBFS, in which the maximum compressive strength was approximately 55 MPa in the mixture of G0.5L0.5-8M with a carbonated BOF-to-binder ratio of 3 (see

Figure 5a). Additionally, it was revealed that increasing the ratio of carbonated BOF aggregates from 3 to 5 achieved a lower compressive strength. As shown in

Figure 5a,b, the maximum influence of replacing normal aggregates with carbonated BOF aggregates on increasing the strength was detected in L1-6M with an aggregate-to-binder ratio of 5 (more than three times). The influences of different contents of carbonated BOF and normal aggregates on the flexural strength are illustrated in

Figure 5c,d. Similar to the compressive strength, replacing normal aggregates with carbonated BOF aggregates increased the flexural strength, and the maximum flexural strength was recorded in the mixture of G0.5L0.5-8M (around 15 MPa).

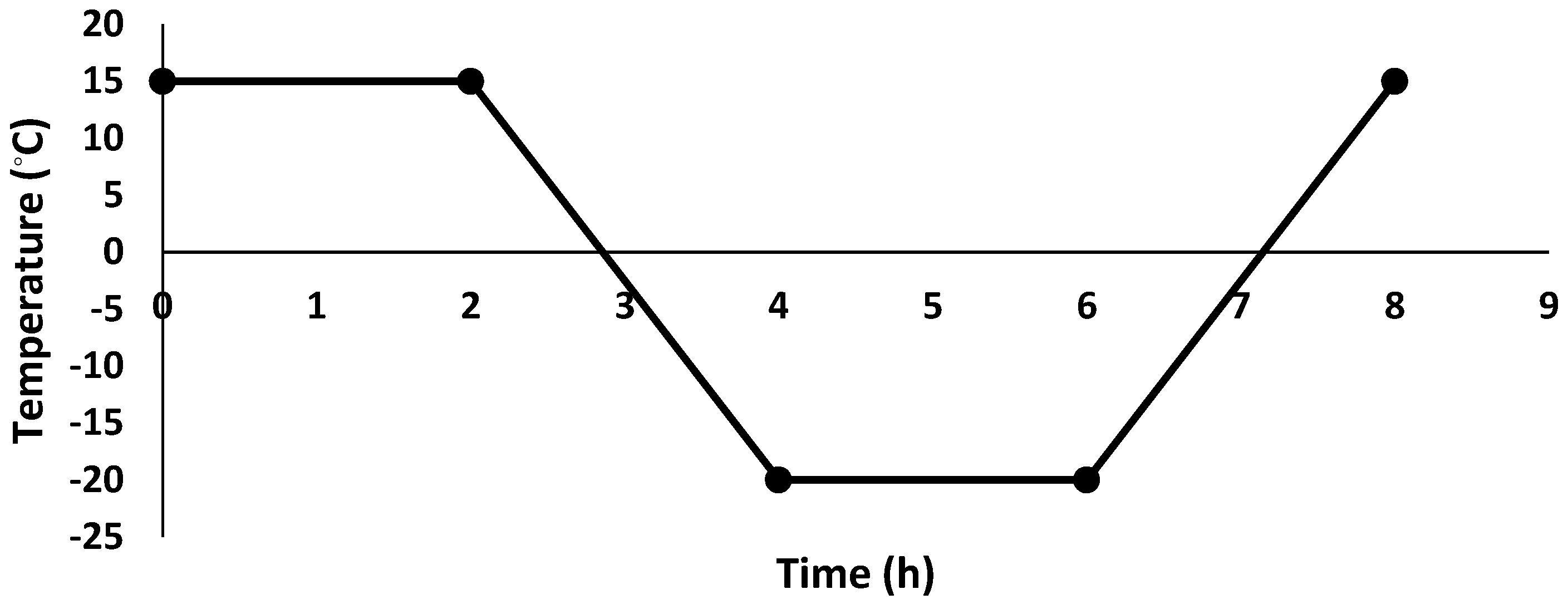

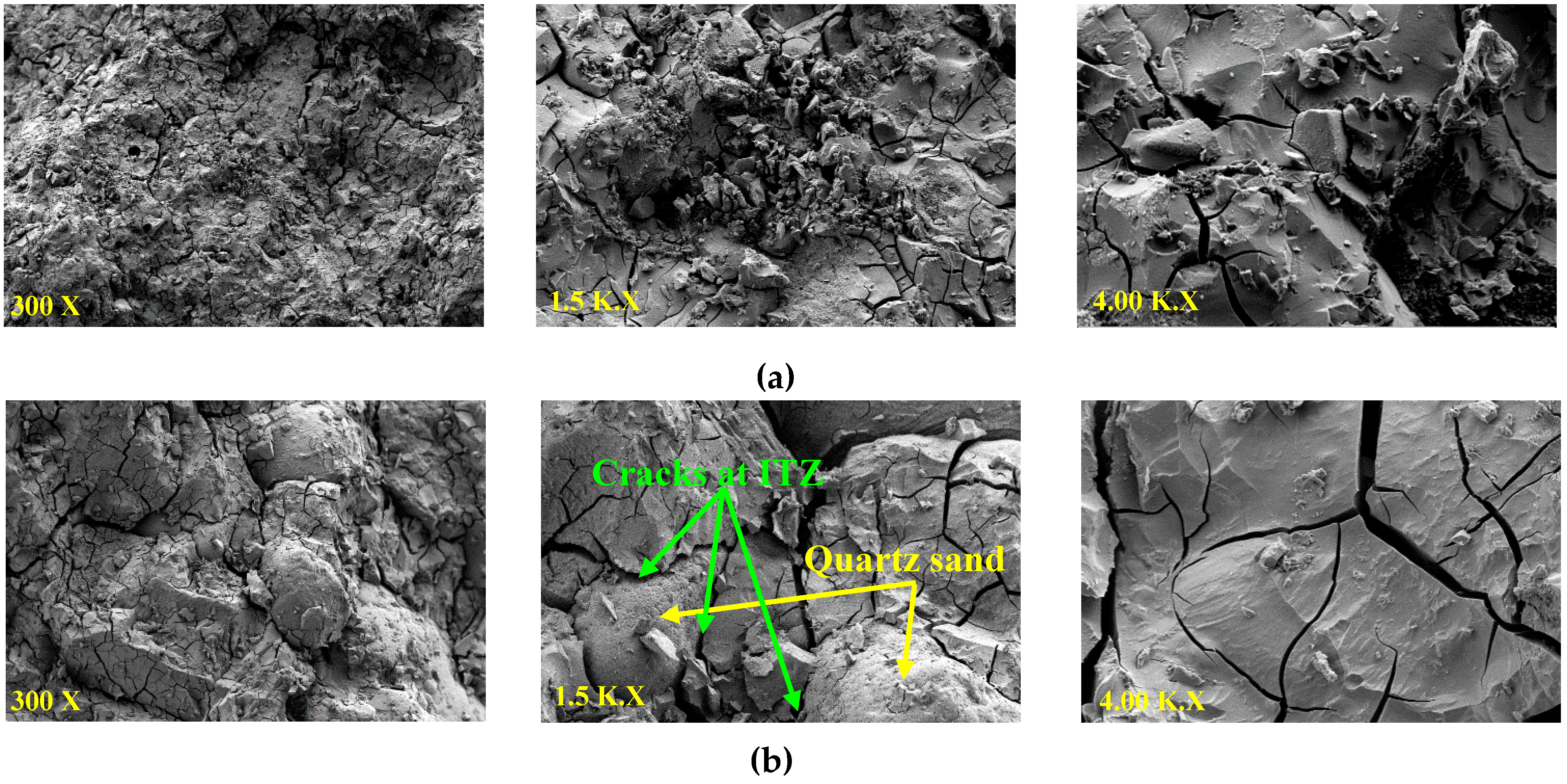

The morphologies of the G0.5L0.5-8M mixture containing carbonated BOF and normal aggregates are shown in

Figure 6a,b, respectively. Using carbonated BOF aggregates increased the calcium oxide content and provided a denser matrix than the mixture with normal aggregates. A higher CaO/SiO

2 ratio justifies higher strength in the mixtures containing carbonated BOF aggregates than normal aggregates (quartz-based sand). Additionally, some cracks formed at the interfacial transition zone (ITZ) between normal aggregates and the matrix, which could degrade mechanical strength.

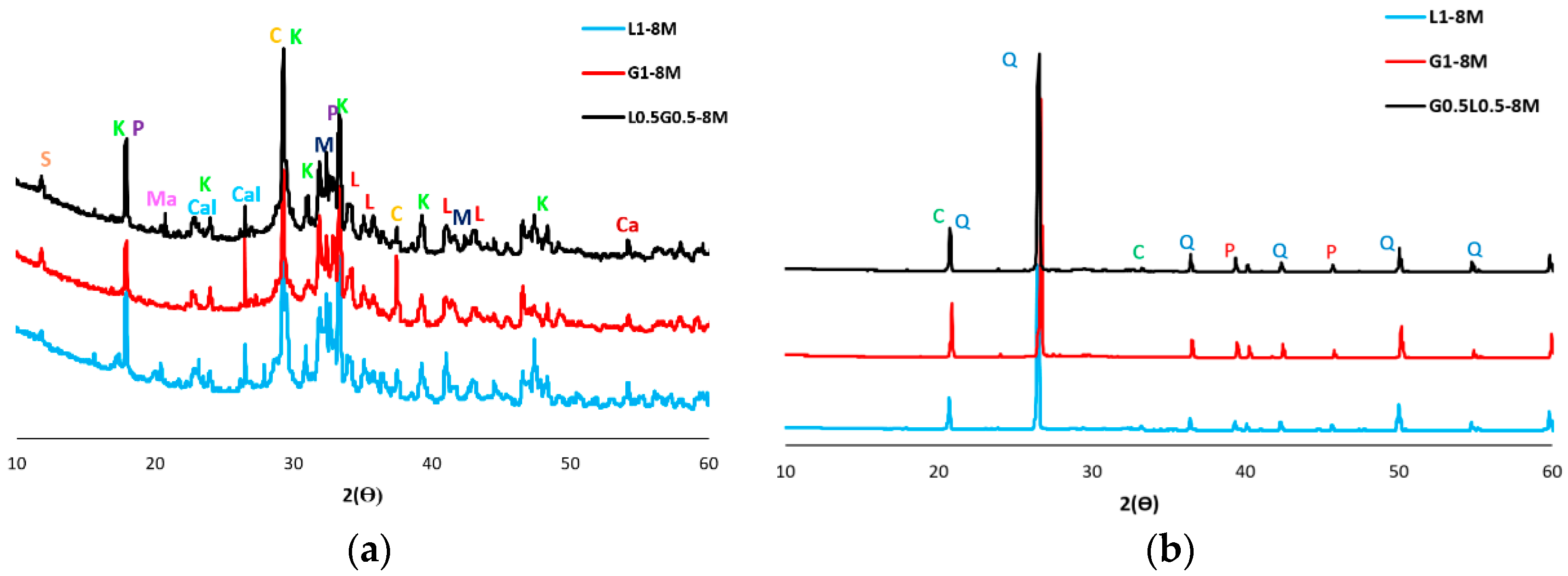

As discussed earlier, regardless of the sodium hydroxide molarity, it was found that a precursor consisting of a combination of ladle slag and GGBFS results in maximum strength. Therefore, a comparative XRD analysis was conducted in this phase to determine the impacts of forming different crystals in alkali-activated ladle slag-based binders, alkali-activated GGBFS-based binders, and alkali-activated ladle/GGBFS slag-based binders.

The mineral patterns of the mixtures containing carbonated BOF and normal aggregates and activated with sodium hydroxide of 8M are shown in

Figure 7. The result indicates that similar XRD patterns are formed in the mixtures, regardless of differences in precursor type. However, the precursor type (ladle slag, GGBFS and ladle slag/GGBFS) affected the intensity characteristics of the diffraction peaks, and higher diffraction peaks formed in G0.5L0.5-8M. Comparing the mixtures with carbonated BOF and normal aggregates shows that carbonated BOF significantly increased crystallisation and changed the formed chemical products. These impacts could affect the morphologies of the mixtures, which this finding was in line with the SEM analysis.

The increased crystallinity could either enhance or degrade mechanical properties, depending on whether enough space exists in the mixture to be filled by the formed crystalline phases. The transition of amorphous gels to more ordered structures causes the local microstructure to change, introducing internal stresses [

36]. The matrix would be denser if enough space is available for the formed crystalline, otherwise crystallisations form micro-cracks (as observed in

Figure 6b). The differences in strength development may be justified by differences in the microscopic analysis. Furthermore, similar micro-cracks could be observed in the microstructure of the cement pastes with the addition of micro silica; these micro-cracks mainly come from increasing the crystallisation pressure of hydrated calcium silicates gel [

37,

38].

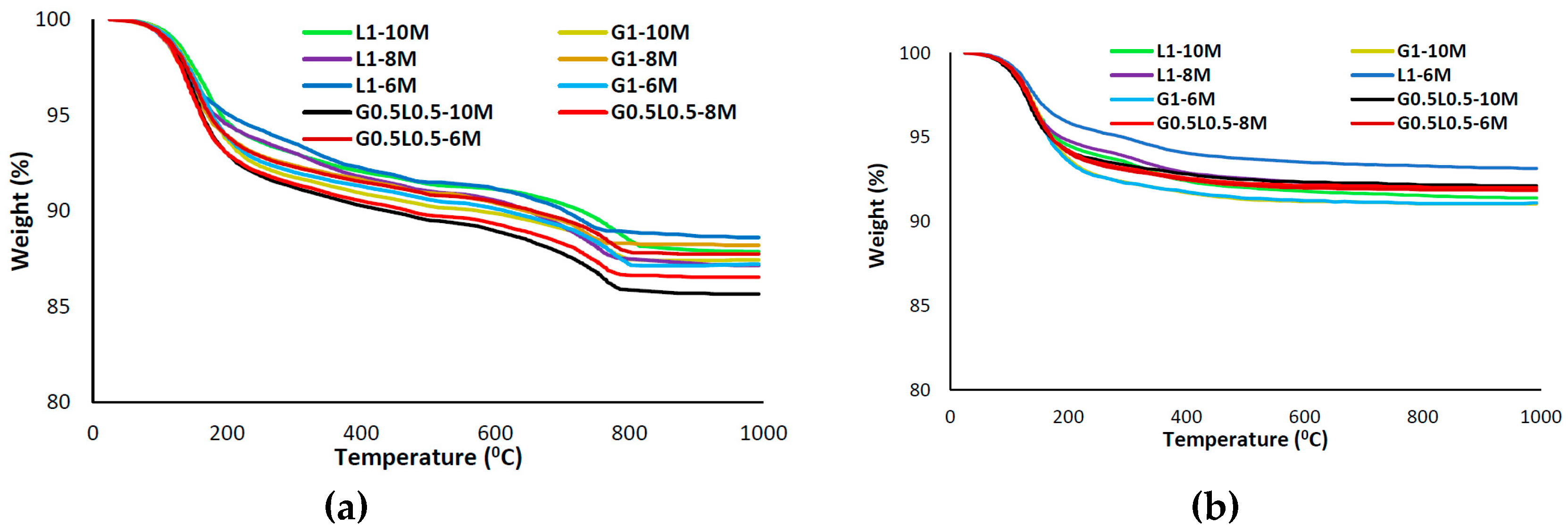

Figure 8 depicts the weight loss (due to increase of temperature up to 1000 °C) and derivative weight of the mixtures. Similar to other microscopic analyses, using carbonated BOF aggregates greatly affected the TGA and DTG curves. Weight losses in TGA could be considered in temperatures between 100 °C to 800 °C [

39]. Both free water and structurally bonded water are available in the first stage. The free water could be evaporated up to 100 °C, and the weight loss from 100 °C to 800 °C is attributed to the structural water [

39]. The mass loss rate slowed after 250 °C owing to the chemically bonded water and OH groups [

40].

According to the TGA results in

Figure 8a,b, higher mass loss was recorded in alkali-activated concretes containing carbonated BOF aggregates compared to normal aggregates. It shows that the mixture with carbonated BOF aggregates possesses more chemical products than the mixtures incorporating normal aggregates.

Regarding the DTA curves in

Figure 8c,d, three major endothermic peaks at approximately 180 °C, 500 °C and 780 °C were observed in the mixtures with carbonated BOF aggregates; the large shoulder below 200 °C is contributed to the dehydration of the calcium-rich silicate (C-S-H) gel [

41]. The second major endothermic peak could be assigned to Portlandite (Ca(OH)

2) [

42]. The third destruction phase (at 780 °C) could be attributed to the decomposition of calcite (CaCO

3) [

42]. The differences in the major endothermic peaks of the DTA curves indicate that additional gel formation may have occurred owing to carbonated BOF aggregates, since only one major endothermic peak at approximately 170 °C was observed in the mixtures with normal aggregates.

In the first phase of this paper, it was generally observed that using carbonated BOF aggregates had greater impact on increasing mechanical strengths of alkali-activated concretes than using normal aggregates. The G0.5L0.5-8M mixture with an aggregate-to-binder ratio of 3 demonstrated the maximum strength. Therefore, this mix composition was chosen to be reinforced for the next phase of this paper.

3.2. Comparative Effects of Different Fibres on the Hardened State Properties

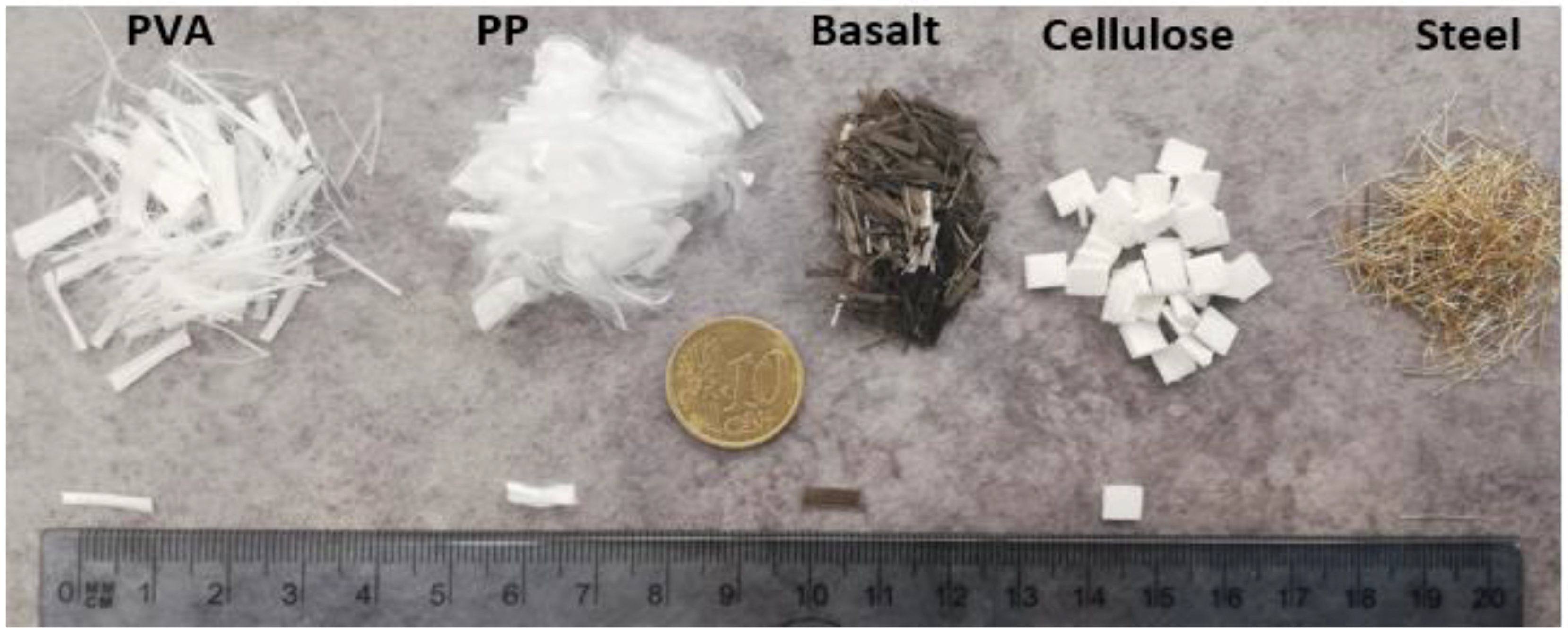

After developing the plain alkali-activated slag-based binders containing carbonated BOF aggregates in the first phase of this work, this mix composition was reinforced by using different fibre types and dosages. In this section, the effects of the reinforcement of mix compositions on hardened state properties were investigated and the results were interpreted.

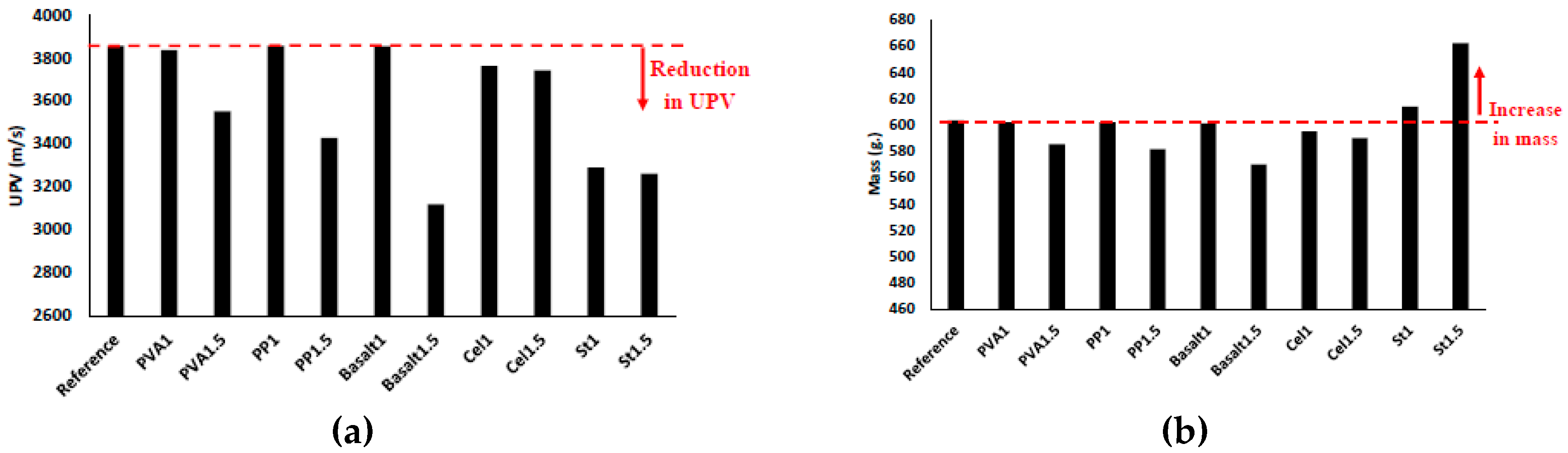

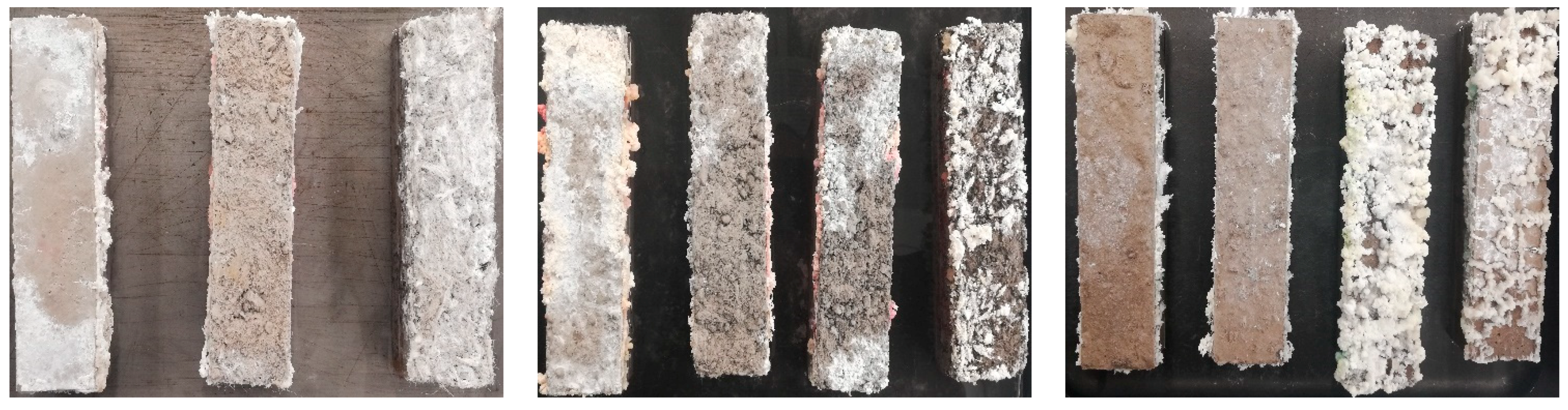

3.2.1. Ultrasonic Pulse Velocity (UPV)

Figure 9a,b show the effects of adding different fibres on the UPV and mass of the different mix compositions, respectively. Since UPV can assess the quality and compactness of the concrete, it can also evaluate the efficiency of the fibres on increasing the porosity of the concrete. According to the results, the fibre types and contents affect the UPV and mass. The addition of the fibres reduced the UPV and mass of all mix compositions significantly, except mixtures of PVA1, PP1, and basalt1. For instance, the maximum reductions of UPV and mass were approximately 20% and 5%, respectively, which were observed in the mixtures reinforced with 1.5% basalt fibre. The reduction in the UPV and mass can be attributed to the increased number of air voids because of the addition of fibres, and the same observation was noticed in [

29].

According to the results, UPV reduction is directly proportional to mass reduction and the increase of fibre volume fraction for all fibres except steel fibre. In the reinforced mixtures with PVA fibre, increasing the fibre content from 1% to 1.5% decreased the UPV and mass by about 5% and 3%, respectively. In the PP1.5 mixture, reductions of approximately 10% and 3% were observed in UPV and mass, respectively. The UPV and mass of the basalt fibre mixtures decreased by approximately 15% and 5%, respectively, with increasing the fibre content. Moreover, limited changes were noticed in the reinforced mixtures with cellulose fibre due to the increase in fibre content (from 1% to 1.5%), whereas a 3% and 2% reduction of UPV and mass were detected, respectively. The UPV loss of the mixtures reinforced with steel fibre was unaffected by increasing the fibre content from 1% to 1.5%, while both St1 and St1.5 mixtures showed approximately 15% UPV reductions. However, increasing the steel fibre content resulted in a 10% mass gain.

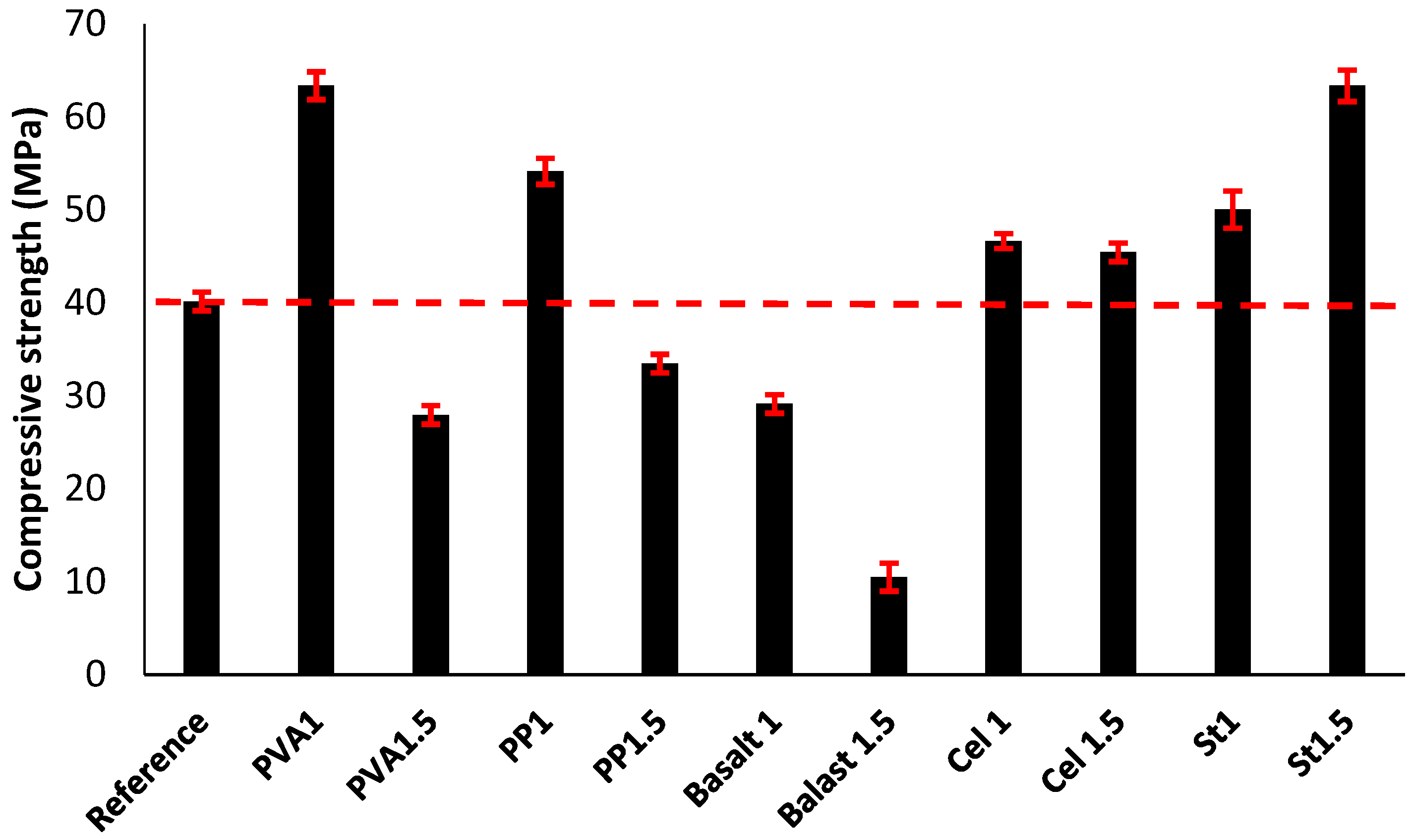

3.2.2. Compressive Strength

The impacts of fibre inclusion on the compressive strength of the mixtures are shown in

Figure 10. The addition of fibres to the mixtures did not specifically increase or decrease the compressive strength. Fibres influence the compressive strength negatively by increasing the air voids in the mixtures or positively by limiting the crack propagations [

30]. According to

Figure 10, the fluctuation in the effects of fibres is highly dependent on the fibre type and content in each mixture. Using different fibres with different physical and mechanical properties affected the bond properties at the fibre/matrix interface as well as the mechanical anchorage. According to the results, the maximum increase of the compressive strength was measured at around 60% (65 MPa) in both the PVA1 and St1.5 mixtures. These enhancements come from the strong bond at the fibre/matrix interface, which limits the crack propagation under the compression load. Mastali et al. [

29] investigated the effect of reinforcing self-consolidating concrete with recycled steel, industrial steel, PP and their combination on the physical and hardened state properties. Their findings also demonstrated that the mixtures reinforced with 1.5% industrial steel fibre have the highest compressive strength.

The maximum reduction in compressive strength of about 70% (10 MPa) was obtained in the basalt1.5 mixture. This reduction, which was the maximum strength loss, was mainly due to the provided high porosity in the basalt1.5 mixture (proven by the highest UPV reduction [20%]).

In the reinforced mixtures with PVA fibre, increasing the fibre content from 1% to 1.5% reduced the compressive strength by 30%. Similarly, reductions in compressive strength due to the increased fibre volume fraction were measured approximately 15% and 70% in the reinforced mixtures with PP and basalt fibres, respectively. The PP1 mixture indicated an approximate 35% increase in the compressive strength. A limited reduction (2 MPa) was measured due to an increased cellulose fibre volume fraction from 1% to 1.5%. However, both mixtures (Cel1 and Cel1.5) showed approximately 20% improvement in the compressive strength compared with the plain mixture. The reduction in the compressive strength, caused to the increase of fibre content, was mainly because of the higher porosity of the reinforced mixtures with 1.5% fibre content (which was proven by the corresponding lower UPV). On the contrary, increasing the fibre content of the steel fibre increased the compressive strength. Aydin et al. [

16] studied the effects of using steel fibre on the compressive strength of alkali-activated slag/silica fume mortar. Their results revealed that increasing steel fibre content in the mixtures increased the compressive strength.

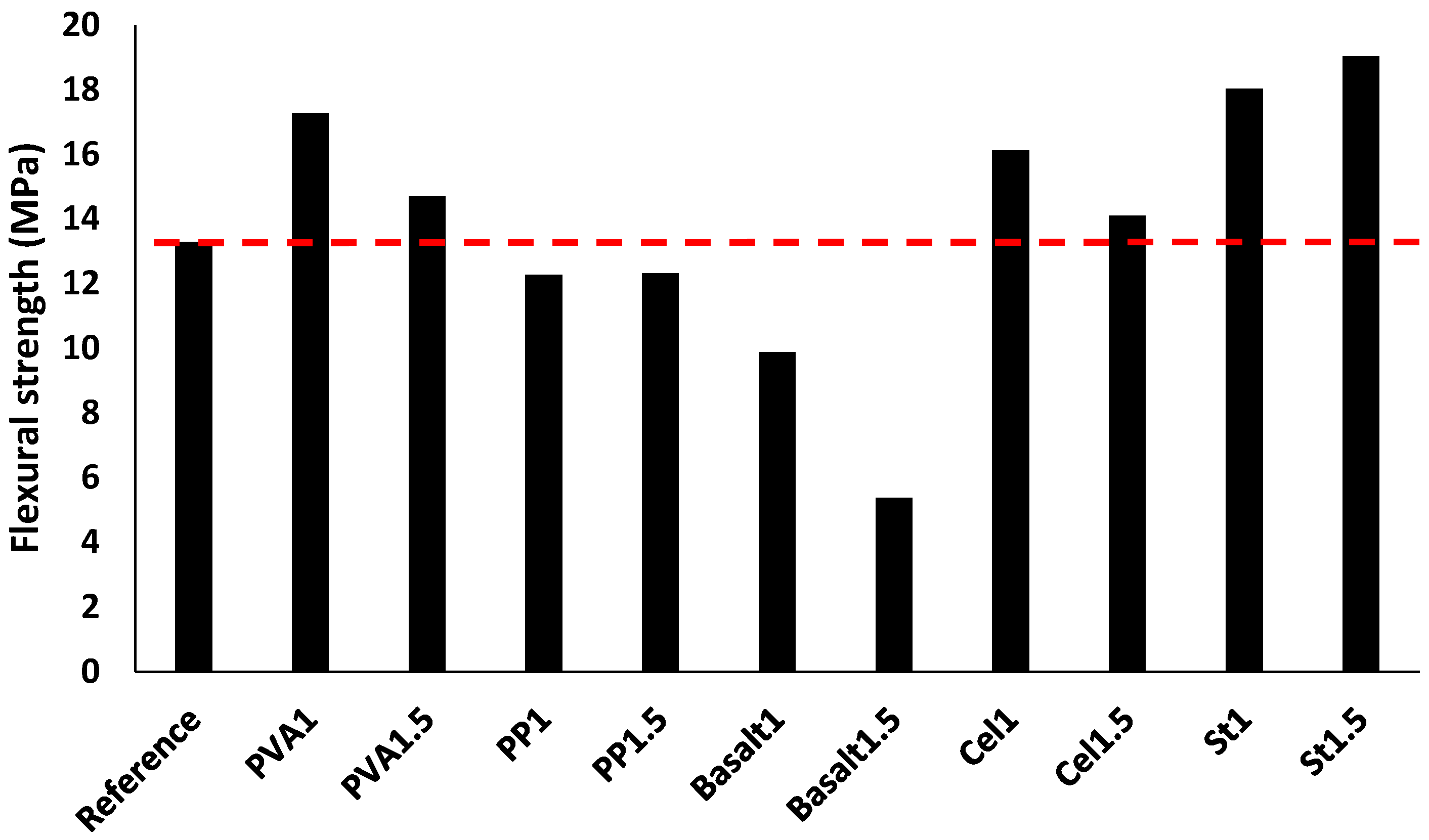

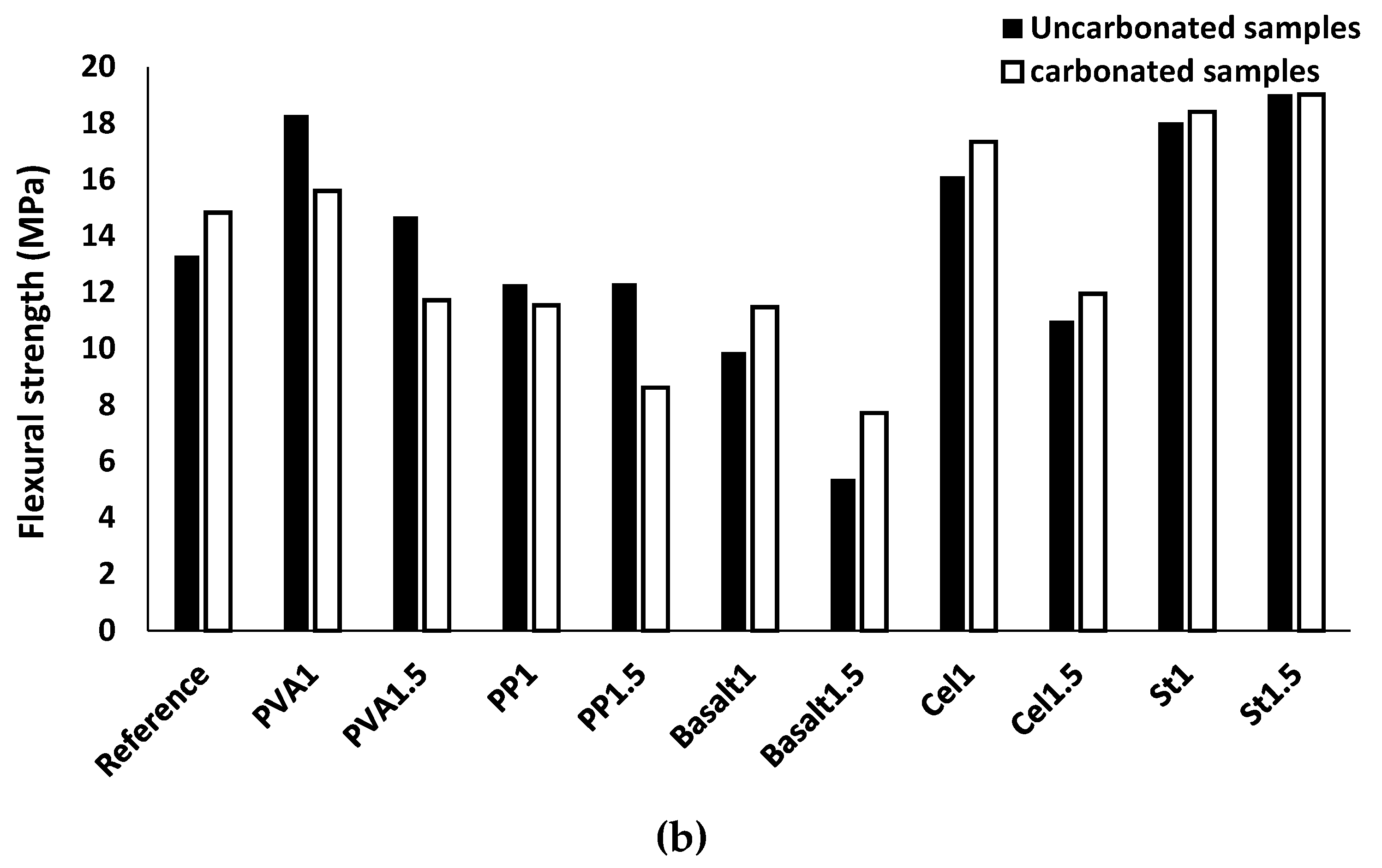

3.2.3. Flexural Strength

Figure 11 presents the impacts of reinforcing the prismatic beams on the flexural strengths. According to the results, the flexural strength of the mixtures was governed by the fibre type and content. Similar to compressive strength, the maximum increase of the flexural strength was measured approximately 60% (20 MPa) in the reinforced mixture with 1.5% steel fibre, compared to the reference mixture (13 MPa). The flexural strength superiority of the 1.5% steel fibre-reinforced mixture was also proven in [

29]. The enhancement of the flexural strength was attributed to the mechanical anchorage of the fibres. The maximum flexural strength reduction of approximately 60% (6 MPa) was achieved in the basalt1.5 mixture, which can be explained by the highest UPV reduction with respect to the plain mixture. Moreover, unfavourable impacts of fibre balling in mixtures, which affects the fibre bridging action, explains the reduction in flexural strength of the basalt1.5 mixture. The flexural strength of the reinforced mixtures with PVA, cellulose and steel fibres increased, regardless of fibre content. An increase of approximately 10–40% was achieved in the reinforced mixture with PVA. Additionally, the reinforced mixtures with cellulose and steel fibres indicated 6–25% and 35–55% improvements in the flexural strength, respectively. The strong chemical bond at the fibre/matrix interface explains the flexural strength enhancement in the reinforced mixtures with PVA, cellulose and steel fibres. Moreover, the increase in flexural strength of the reinforced mixtures with steel fibre is mainly due to the mechanical bond between the fibre and matrix and higher mechanical anchorage provided by the geometry of the indented short-length steel fibre. Mastali et al. [

29] showed a higher flexural strength for the reinforced mix compositions using hooked-end industrial steel fibre.

On the contrary, the flexural strength decreased by 5% and 25–60% with the addition of PP and basalt fibres in the mixtures, respectively. The reduction of the flexural strength in the reinforced mixtures with PP fibres was mainly due to the smooth surface of the PP fibre, which led to a weak bond at the fibre/matrix interfacial zone during debonding [

29].

Interestingly, a reduction was monitored in the reinforced mixtures with PVA and cellulose fibres when the fibre content increased from 1% to 1.5%, while the mixtures reinforced by PP fibre were unaffected by increased fibre content. Moreover, in line with the findings in [

16], the flexural strength of the steel reinforced mixtures increased (5%) with increased fibre content.

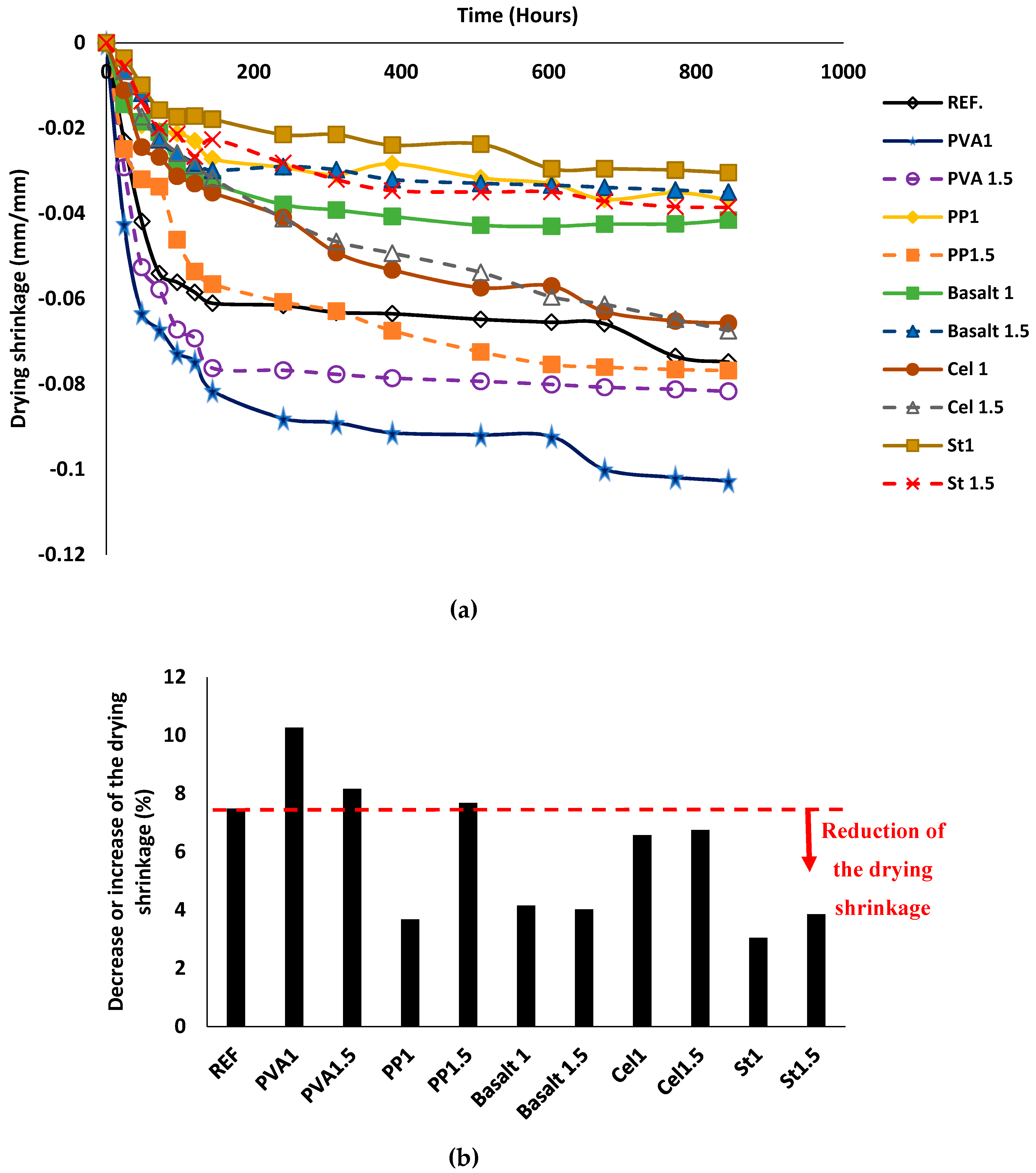

3.2.4. Drying Shrinkage

Figure 12 depicts the drying shrinkage of mix compositions. According to the results, the length stabilisation was measured for all mixtures after ≈ 850 h. In general, all mixtures reached 90% of their ultimate drying shrinkage after 250 h (almost 10 days) (see

Figure 12a). The length changes varied from 3–10%, regardless of fibre type and content (see

Figure 12b). The reference mixture showed a drying shrinkage approximately 7% compared to the initial length. The minimum rate of the drying shrinkage was obtained in the St1 mixture (≈ 3%), while the maximum drying shrinking was measured in the PVA1 mixture (≈ 10%), in respect to their initial lengths. Generally, introducing different fibres had no specific trend of decreasing or increasing the drying shrinkage in alkali-activated slag-based concretes. For instance, addition of PVA fibre increased the drying shrinkage by 9–37% compared to the reference mixture. Since a 10–60% reduction in the drying shrinkage was recorded compared to the reference mixture when PP, basalt, cellulose and steel fibres were used.

In addition, no consistent trend was found between the drying shrinkage and fibre dosage. For instance, using 1% PP fibre reduced the drying shrinkage about 50%, whereas 1.5% PP fibre increased the drying shrinkage ≈ 3%. However, an increase of 35% in the drying shrinkage was reported in the PVA1 mixture, while the PVA1.5 mixture increased the drying shrinkage by approximately 10%. On the other hand, the drying shrinkages for basalt and cellulose-reinforced mixtures were unaffected by increasing the fibre content.

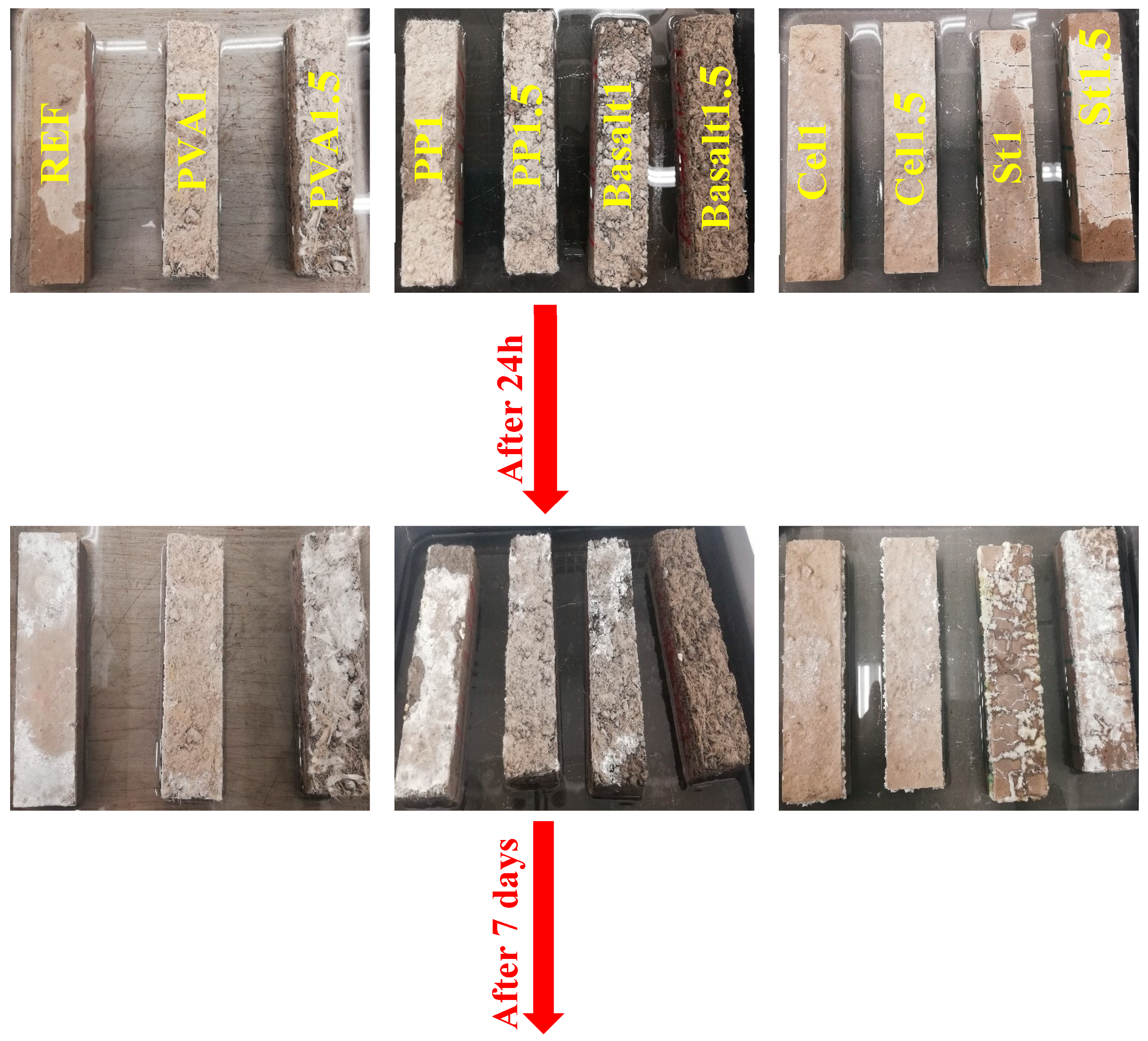

3.2.5. The Efflorescence Rates

Figure 13 illustrates the visual observations of the efflorescence rates of each mixture up to seven days. As the fibre type and content are the only differences between the mixtures, it was assumed that the variations of efflorescence rates could be attributed to the fibre type and content. According to the observations in

Figure 13, fibres could have different impacts on the efflorescence rates, depending on the fibre type, length and shape. Fibres could physically provide a confinement around the specimens and affect the efflorescence intensity. The efficiency of this confinement could be governed by the fibre orientations and dispersions in the mix compositions. Therefore, different influences were observed on the efflorescence rates due to use of different fibres.

Regarding the efflorescence rates, all mixtures showed similar rates compared to the reference mixture with the insignificant impact of fibre on the rate of efflorescence during the first day (24 h), except for the steel fibre-reinforced mixtures. After seven days observation, cellulose fibre had the highest efficiency in limiting efflorescence, regardless of fibre content. PVA1 and PP1.5 fibres showed a high efficiency in reducing the efflorescence. In addition, no consistent trend was noticed between efflorescence rate and fibre dosage. As shown in

Figure 9, increasing fibre dosage increased the porosity of the mixture (lower UPV), and it was claimed in [

43] that lower porosity was accompanied by the lower efflorescence, and the opposite observation was noticed in this study, as PP1 had lower porosity and higher efflorescence than PP1.5. On the other hand, PVA1.5 displayed higher porosity and efflorescence than PVA1. The mixture reinforced with 1% basalt fibre indicated similar efflorescence rate compared to the reference mixture after seven days, whereas basalt1.5 had higher efflorescence rate.

3.3. Effects of Aggressive Conditions on Hardened State Properties

3.3.1. Carbonation Test

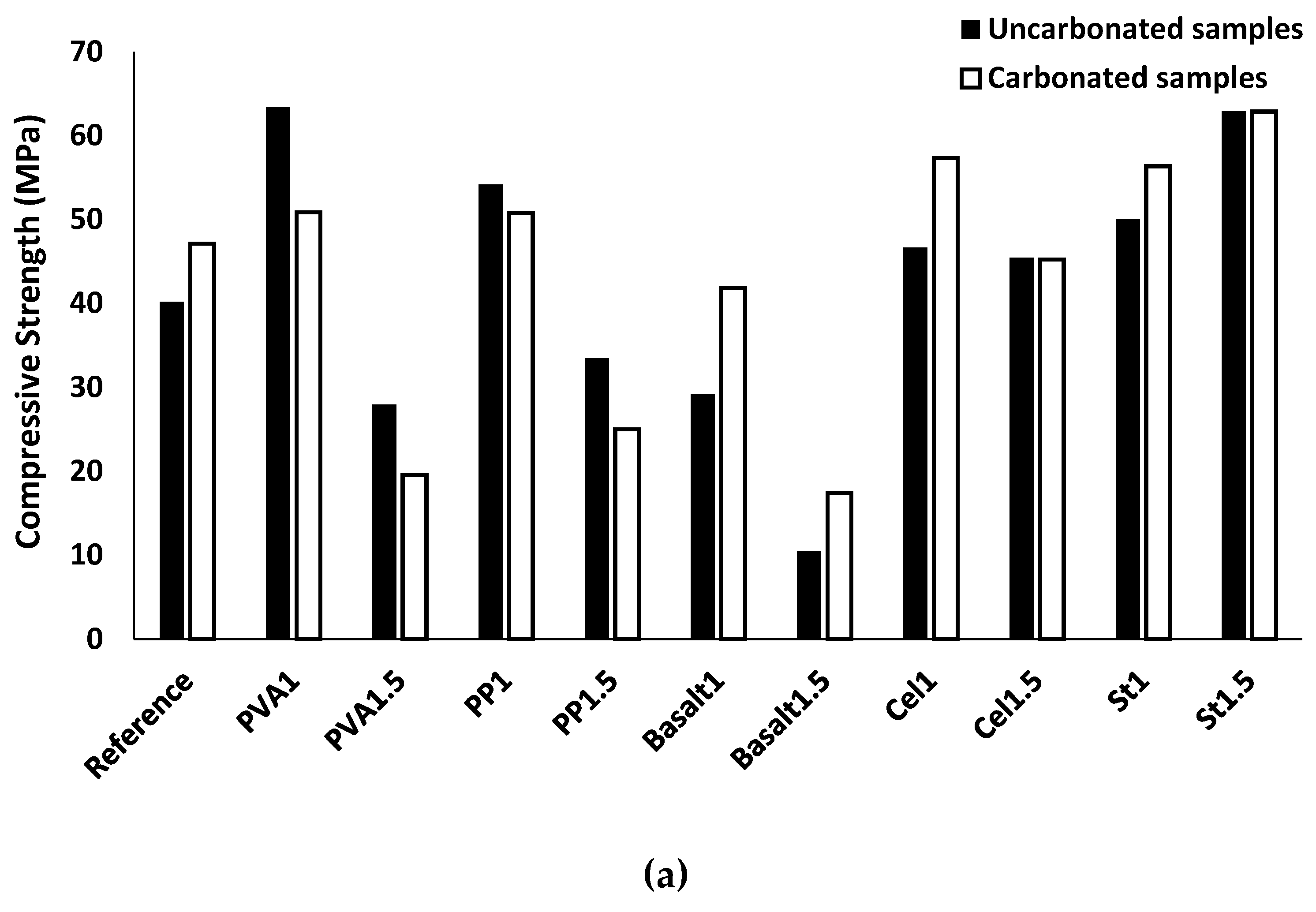

The effects of carbonation on the UPV and mass of the plain and reinforced alkali-activated concretes are shown in

Figure 14a,b, respectively. Penetration of carbon dioxide gas into the mixture led to the consumption of the calcium source and formation of calcite crystals. This resulted in lower porosity for all mixtures; hence, slight increases in UPV and mass could be observed.

For all carbonated mixtures, the effect of carbonation on the mass gain was limited (≈ 1%). The carbonated plain mixture showed an increase of 0.2% in the UPV compared to the uncarbonated plain mixture. The reinforced mixtures with PVA fibres indicated an increase of approximately 5% for the UPV, regardless of the fibre volume fraction, when compared with their uncarbonated conditions. However, a combination of both carbonation impacts and increasing PP and basalt fibre contents in the reinforced mixtures increased the UPV from ≈ 0.1% for 1% fibre content to around 3% for reinforced mixtures with 1.5%. A slight increase (≈ 0.1%) in the UPV of the reinforced mixtures with cellulose and steel fibres was also observed when exposed to CO2 gas, regardless of fibre content. The increase of the UPV and mass gains in all mixtures were mainly due to the formation of CaCO3, which resulted in filling the gaps and reducing the porosity.

The produced calcium carbonate crystals in the mixtures due to the CO2 reaction with CaO and Ca(OH)2 in alkali-activated concrete positively affected the compressive strength by filling the gaps and reducing the porosity of the mixtures. Therefore, denser reinforced mixtures provided a stronger bond with fibres at the fibre/matrix interface, resulting in flexural strength enhancement. However, the formation of CaCO3 generates internal stresses in the reinforced mixtures, resulting in internal micro-cracks. Because of the internal micro-cracks in the reinforced mixture, a degradation in compressive strength can be observed, as flexural strength deterioration is affected by the effects of carbonation on the chemical bond between the fibre and its surrounding matrix.

In the carbonated plain mixture, the compressive and flexural strengths increased by approximately 20% compared to the uncarbonated condition (see

Figure 15). Maximum increases in the compressive and flexural strengths reached 65% and 45%, respectively, were measured in the basalt1.5 mixture. The maximum reduction for both compressive and flexural strengths was registered around 30% due to carbonation in the PVA1.5 and PP1.5 mixtures.

The compressive and flexural strengths of the reinforced mixtures with basalt, cellulose and steel fibres increased, regardless of fibre content. The reinforced mixture with basalt fibre increased up to 45–65% and 15–45% for the compressive and flexural strengths, respectively. An approximate 25% increase was found in the compressive strength of the carbonated Cel1 mixture, while the compressive strength of the carbonated Cel1.5 mixture was unaffected. Moreover, the flexural strength of carbonated Cel1 and Cel1.5 mixtures increased by 10%. The carbonated St1 mixture showed 15% and 5% improvements for the compressive and flexural strengths, respectively. However, the mechanical strengths of the St1.5 mixture were unaffected by carbonation.

As indicated in

Figure 15a, the increases in the compressive strength of the plain mixture and reinforced mixtures with basalt, cellulose, and steel fibres are mainly due to the lower porosity of their carbonated mixtures. According the results presented in

Figure 15b, enhancement of the flexural strength in the reinforced mixtures with basalt, cellulose and steel fibres indicated positive influences of carbonation on their chemical bond with the matrix, which increases the load carrying capacity of specimens during debonding. Moreover, the flexural strength gain in the reinforced mixture with the indented steel fibre was due to the higher mechanical bond and interconnectivity between the fibre and surrounding matrix, resulting from the increased compactness of matric due to the formation of CaCO

3 crystals.

However, the reinforced mixture with PVA fibre revealed an approximate 20% reduction for the compressive strength after exposing the carbonation conditions. Moreover, the PVA1 and PVA1.5 mixtures showed 15% and 20% reduction for the flexural strength, respectively. Similarly, the carbonated reinforced mixtures with PP fibre underwent a 5–10% reduction in compressive and flexural strengths. The compressive strength reduction in mixtures reinforced with PVA and PP was mainly due to the internal micro-cracks generated by internal stresses caused by the formed CaCO3 because of the limited efficiency of the used fibres in introducing enough air voids. A reduction in the flexural strength was recorded in reinforced mixtures with PVA and PP fibres, indicating negative effects of carbonation on the chemical bond properties at ITZ of the fibre/matrix.

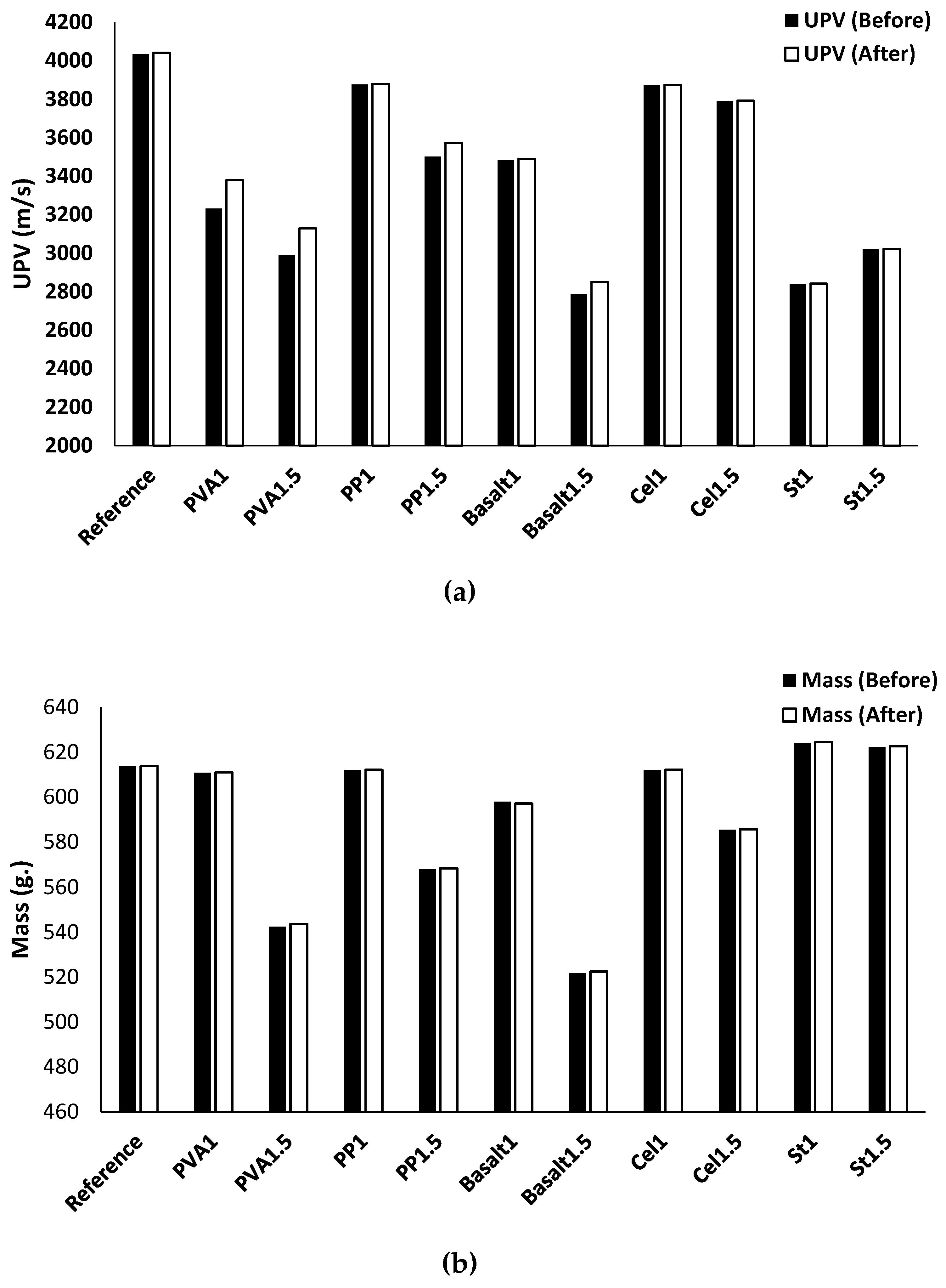

3.3.2. Freeze/Thaw Resistance

Table 5 presents the mass change of each mix composition. The mass loss resulted from freeze/thaw is notable and well-known in OPC concrete [

44,

45]; therefore, it is worthwhile to monitor changes in the mass of alkali-activated concrete. According to the results shown in

Table 5, all mixtures underwent a mass loss. The mass loss was governed by the fibre types and contents. The plain mixture resulted in a ≈ 1% mass loss in the freeze/thaw test. The Cel1 mixture had the minimum mass loss of ≈ 0.9%, and the basalt1.5 mixture returned with the maximum mass loss of ≈ 2.6%. Increasing the fibre content increased the mass loss for all fibre types, where steel fibres showed the lowest mass change (≈ 0.01%) due to the increase in fibre content from 1% to 1.5%. For instance, the mass loss of the PVA1 mixture was ≈ 1%, while a mass loss of ≈ 1.75% was observed in the PVA1.5 mixture. Similarly, the PP1 mixture lost 1.1% of its mass in 60 freeze/thaw cycles, while PP1.5 lost 1.3%.

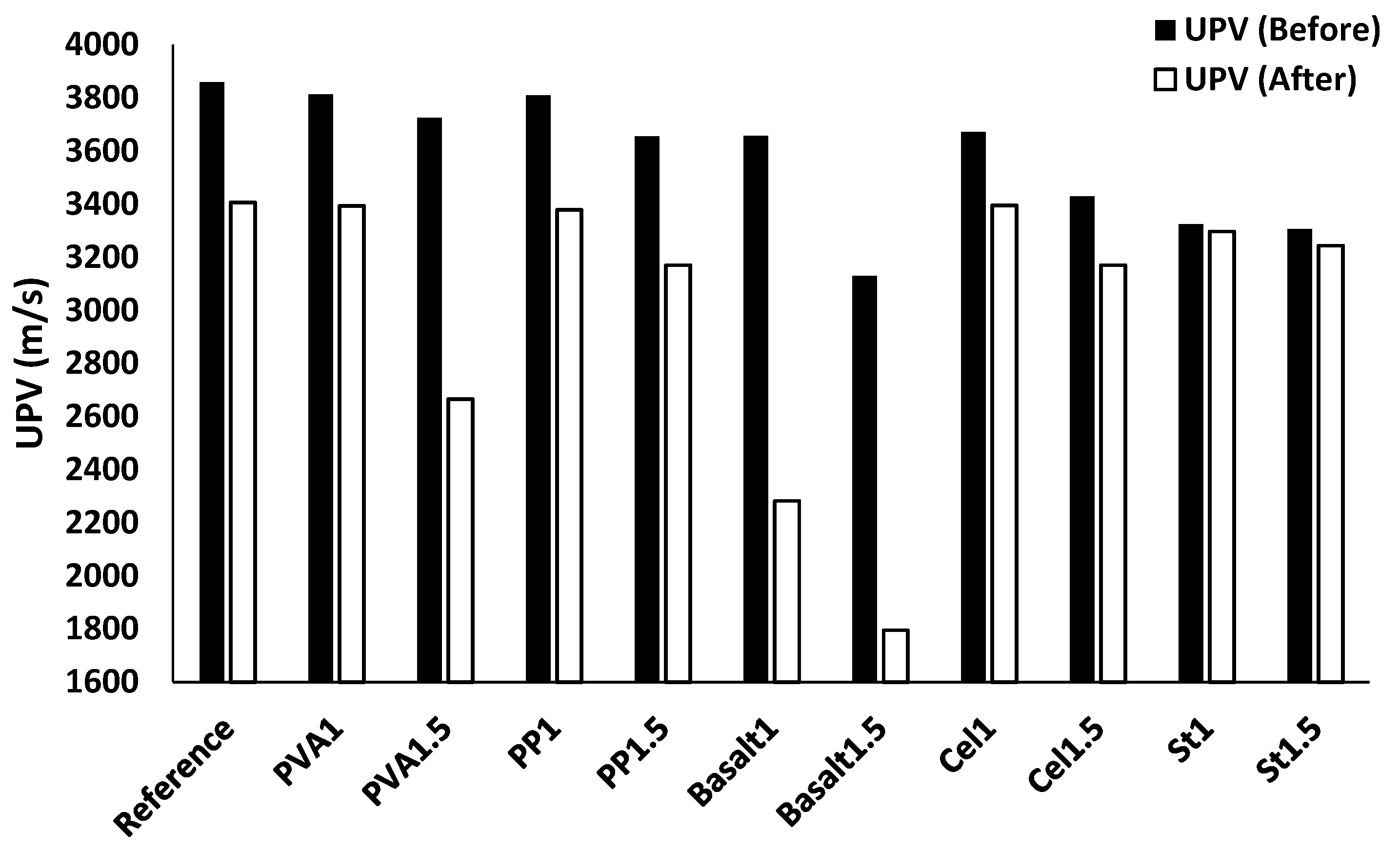

In line with mass loss,

Figure 16 illustrates the UPV before and after experiencing 60 freeze/thaw cycles. All mixtures showed a reduction in the UPV after 60 freeze/thaw cycles.

Regarding the fibre-reinforced mixtures, the highest UPV reduction (≈ 40%) was measured in the basalt1.5 mixture, as well as the maximum mass loss (see

Table 5). Reinforced mixtures with steel fibre showed the densest structure against freeze/thaw cycles and led to the lowest UPV reduction of ≈ 1% compared to their UPV before the test. St1 mixture (3297 m/s) showed lower UPV reduction than the St1.5 mixture (3244 m/s). Increasing the fibre content resulted in increasing the UPV reduction under different freeze/thaw cycles for all fibre types except PP and cellulose fibres, which can be explained by the higher porosity resulting from the high fibre content. For instance, a UPV reduction of ≈ 10% was measured in the mixture of PVA1, while a reduction of ≈ 25% was observed in the mixture of PVA1.5. On the contrary, 10% and 5% UPV reductions were achieved by fibre-reinforced mixtures with PP and cellulose fibres, respectively, regardless of fibre content.

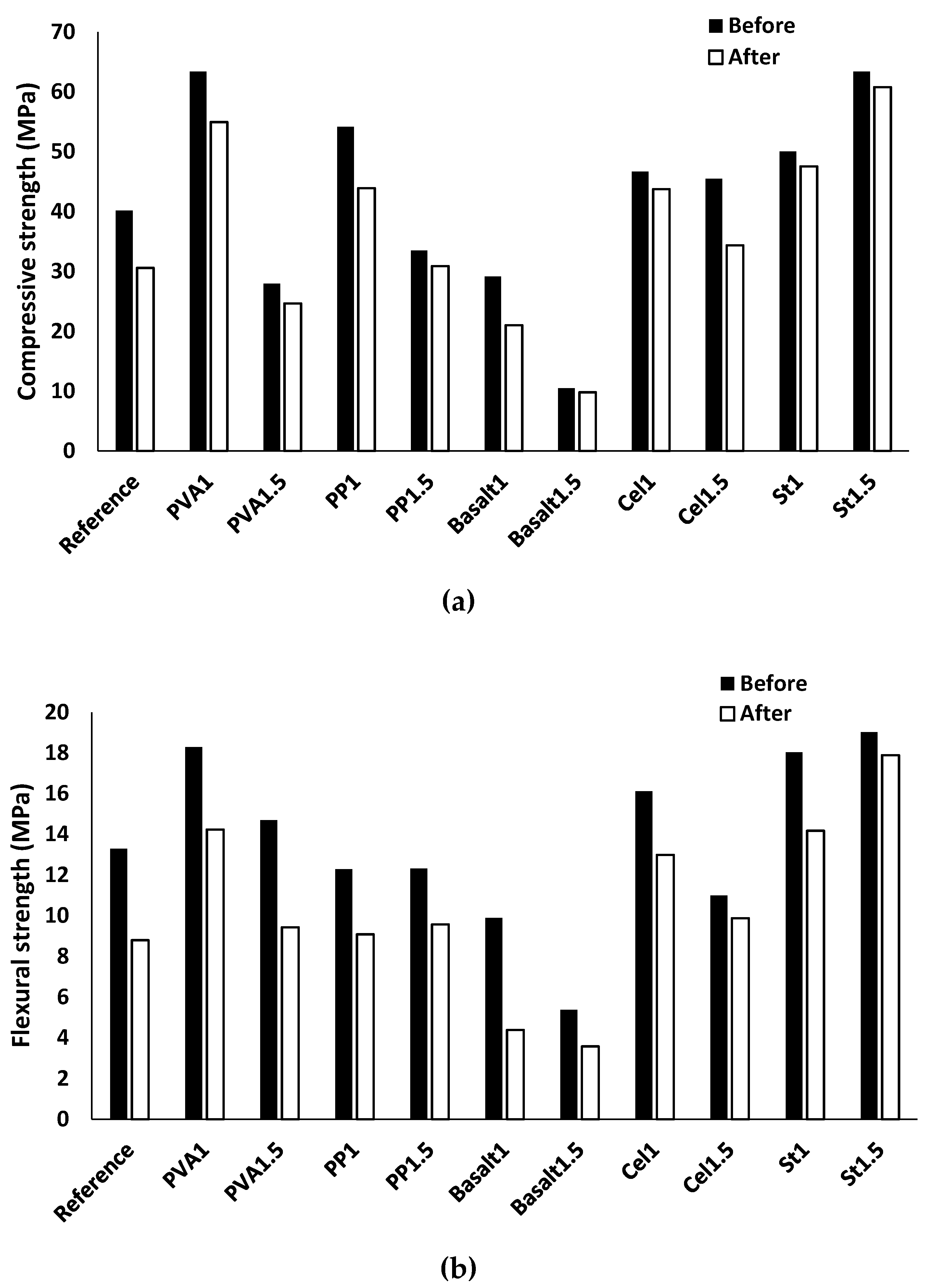

Figure 17a,b depict the compressive and flexural strengths of the mix compositions before and after experiencing 60 freeze/thaw cycles, respectively. A reduction was noticed in the compressive and flexural strengths for all mixtures. The results showed that the compressive and flexural strengths of the plain mixture were reduced by 20% (30 MPa) and 30% (8MPa), respectively. The maximum reductions of the compressive strength (≈ 25%) and flexural strength (55%) were obtained for the mixture of basalt1. The highest resistance and the lowest strength reduction were obtained for St1.5, where an approximate 5% reduction was measured for both compressive and flexural strengths. The reductions in compressive strength can be explained by the internal micro-cracks resulting from the increase in volume of frozen water; similar observations were found in [

46]. Yawei et al. [

46] investigated the freeze/thaw resistance of alkali-activated blast furnace slag concrete (ASC) and reported that the internal structural damage and induced micro-cracks were caused mainly by the higher volume of frozen water.

According to the results indicated in

Figure 17, increasing the fibre content enhanced the freeze-thaw resistance, except for cellulose fibre where the Cel1.5 mixture showed a higher compressive strength reduction (≈ 20%) than the Cel1 mixture (≈ 5%). Moreover, increasing the fibre content in the mixture PVA1.5 resulted in a higher flexural strength reduction (≈ 35%) than in PVA1 (≈ 20%). Furthermore, the compressive and flexural strengths decreased approximately 15% and 25% for the mixture of PP1, respectively, while PP1.5 underwent 5% and 20% reductions.

With respect to the visual observations of the mixtures after contacting with water and experiencing 60 freeze/thaw cycles, no swelling was observed. This demonstrates the efficiency of the accelerated CO2 treatment for minimising this problem in the BOF slag.

To date, no experimental data are available indicating the efficiency of using accelerated CO

2 treatment for minimising the swelling of BOF aggregates in alkali-activated concretes. Bodor et al. [

22] investigated the swelling of carbonated and uncarbonated BOF aggregates in cementitious-based mortars. They used carbonated BOF under pressure and elevated temperature in a stirred batch autoclave reactor (90 °C, 20 bar CO

2 pressure, for 2 h). Their findings showed that all mixtures prepared with uncarbonated BOF aggregates displayed swelling in the range of 11.4–91.7 mm after immersing the mixtures in water at 20 °C for 24 h and boiling water for 3 h. They also recorded approximately 16 mm of swelling in mixtures containing carbonated BOF aggregates (0.5–1.6 mm). The swelling in mixtures incorporating carbonated BOF aggregates was mainly due to insufficient carbonation of the slag [

22].

3.3.3. High Temperature Resistance

The impacts of high temperature on the UPV and mass losses are presented in

Figure 18a,b, respectively. Similar to other reported results, the UPV and mass losses due to high temperature were governed by fibre type and content. Exposure to high temperatures led to a mass loss of ≈ 10% and UPV loss of ≈ 80% in the reference mixture. Minimum UPV reductions of 55% and 70% were assigned for the specimens of St1.5 and St1, respectively (see

Figure 18a). Moreover, as indicated in

Figure 18b, these mixtures showed the minimum mass loss (≈ 10%) when compared to the unheated condition. The PVA1.5 mixture exhibited the maximum UPV reduction (≈ 90%) and the maximum mass loss of ≈ 20% compared to its unheated state.

Based on the results obtained, increasing the fibre content from 1% to 1.5% had a minor effect on the UPV and mass loss, except for steel fibre. The PP, basalt, and cellulose-reinforced mixtures had similar mass loss (≈ 15%), but their UPV reduced by 85%, 75%, and 80%, respectively, regardless of fibre content. Higher UPV losses were observed in the reinforced mixtures with nonmetallic fibres (e.g., PVA, PP, cellulose), which could be justified by the formed micro-channels and air voids when the nonmetallic fibres melted in high temperatures [

47].

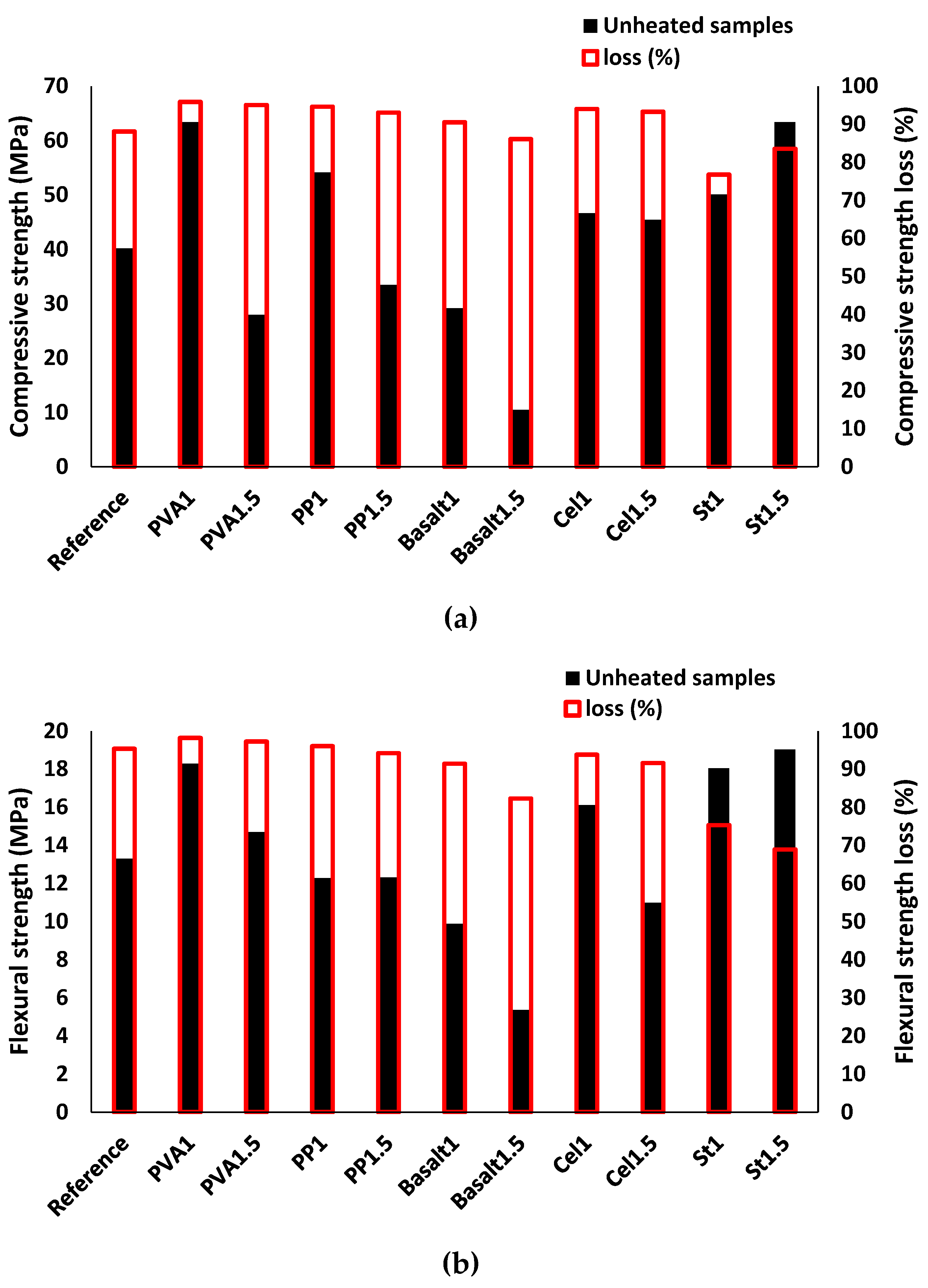

Losses in the compressive and flexural strengths are indicated in

Figure 19a,b, respectively. Reduction in strength was observed for all mixtures. Like the UPV and mass reductions, the losses in the compressive and flexural strengths were functioned by the fibre type and content. The compressive and flexural strengths were reduced by 85% and 95% in the plain mixture, respectively. In line with UPV and mass losses, the maximum reductions of 85–95% were measured for both compressive and flexural strengths in the mixtures reinforced with PVA, PP, cellulose, and basalt fibres, regardless of the fibre volume fraction. The minimum compressive and flexural strength reduction of ≈ 75% was registered for steel-fibre reinforced mixtures with 1% and 1.5% fibre dosage.

The primary reason for the high losses may be attributed to the thermal mismatch between shrink paste and expanded aggregates, which caused volume changes resulting in debonding the fibres from the matrix (depending on the temperature and fibre type), increasing the porosity and propagation of the cracks [

48]. Higher reductions in the compressive and flexural strengths of the mixtures reinforced with PVA, PP and cellulose fibres are mainly because of their low resistance to high temperatures, as reported in [

48]. Yermak et al. [

48] indicated that PP fibres melted at 170 °C, and the same behavior was expected in PVA and cellulose fibres, resulting in losing the fibre action in resisting the crack propagations and transferring the tensile stress over the fracture surfaces. Moreover, melting the fibres increased the mixture porosity, which diversely affected the strength.

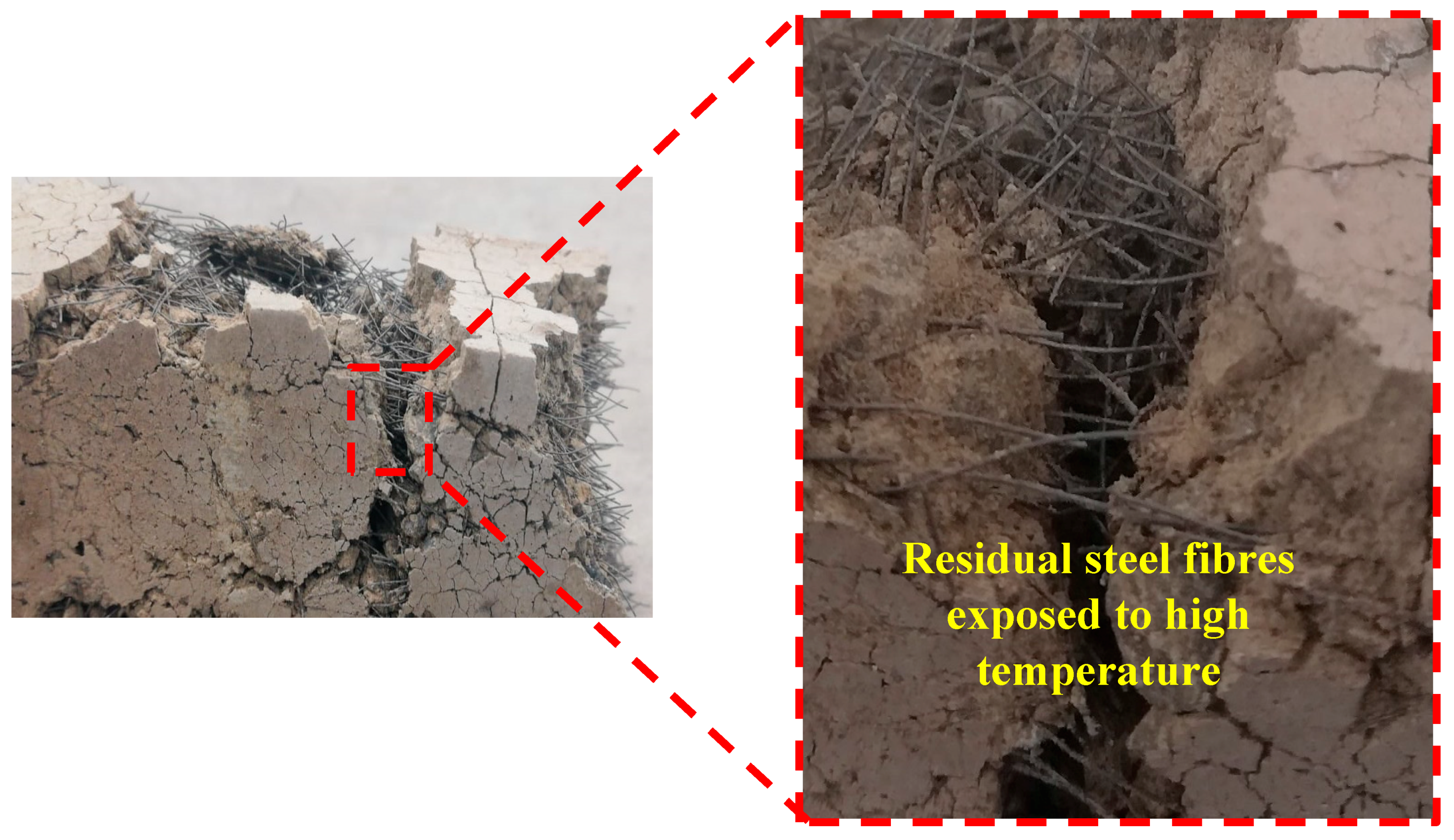

As shown in

Figure 20, the steel fibres did not melt, and steel fibres could transfer the tensile stress across the fracture surfaces. Lourenço et al. [

47] proved the efficiency of steel fibre in increasing the post-cracking resistance of concrete in high temperatures.

In addition, the visual observations indicated that in fibre-reinforced specimens with basalt fibre, no signs of burned fibre were detected, demonstrating a better performance of these fibres compared to the other nonmetallic fibres when exposed to high temperatures.