Using Carbonated BOF Slag Aggregates in Alkali-Activated Concretes

Abstract

1. Introduction

2. Experimental Plan

2.1. Materials and Mix Design

2.2. Casting and Curing

2.3. Characterisation of Specimens

2.3.1. Ultrasonic Pulse Velocity (UPV)

2.3.2. Flexural Strength

2.3.3. Compressive Strength

2.3.4. Carbonation Test

2.3.5. High-Temperature Resistance

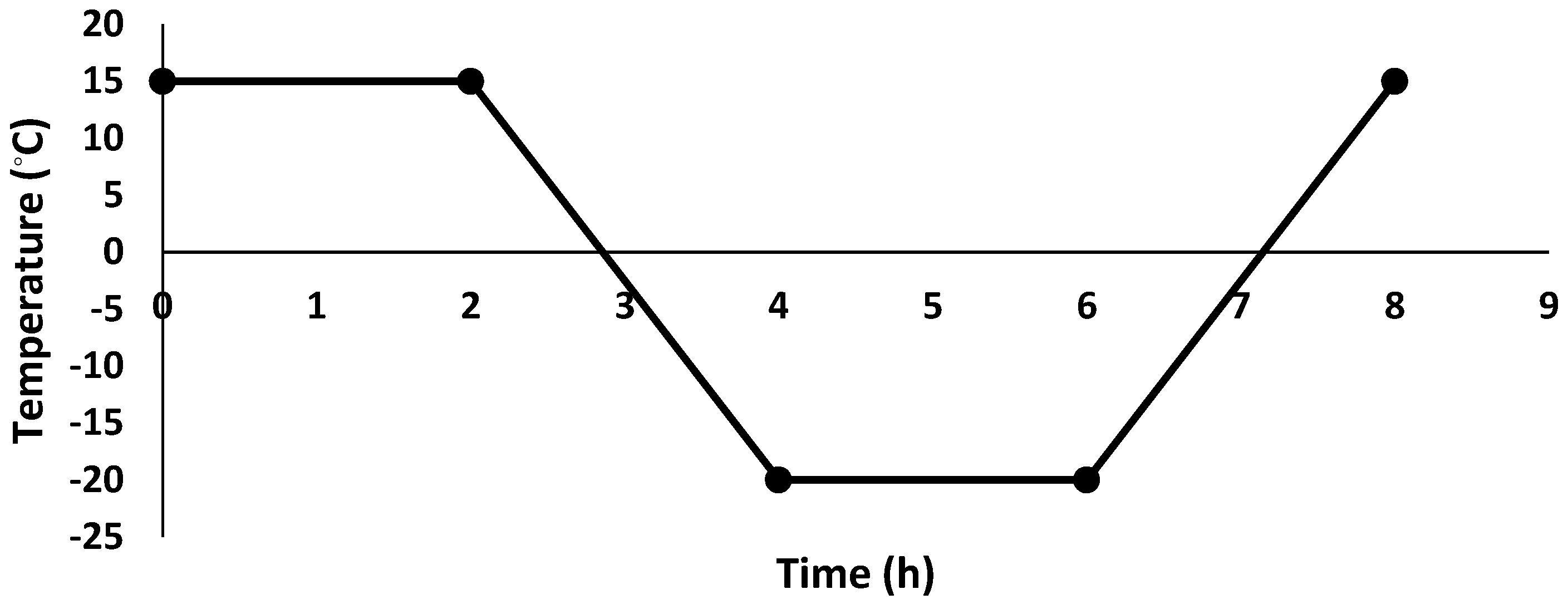

2.3.6. Freeze/Thaw Resistance

2.3.7. Drying Shrinkage

2.3.8. Efflorescence Rates

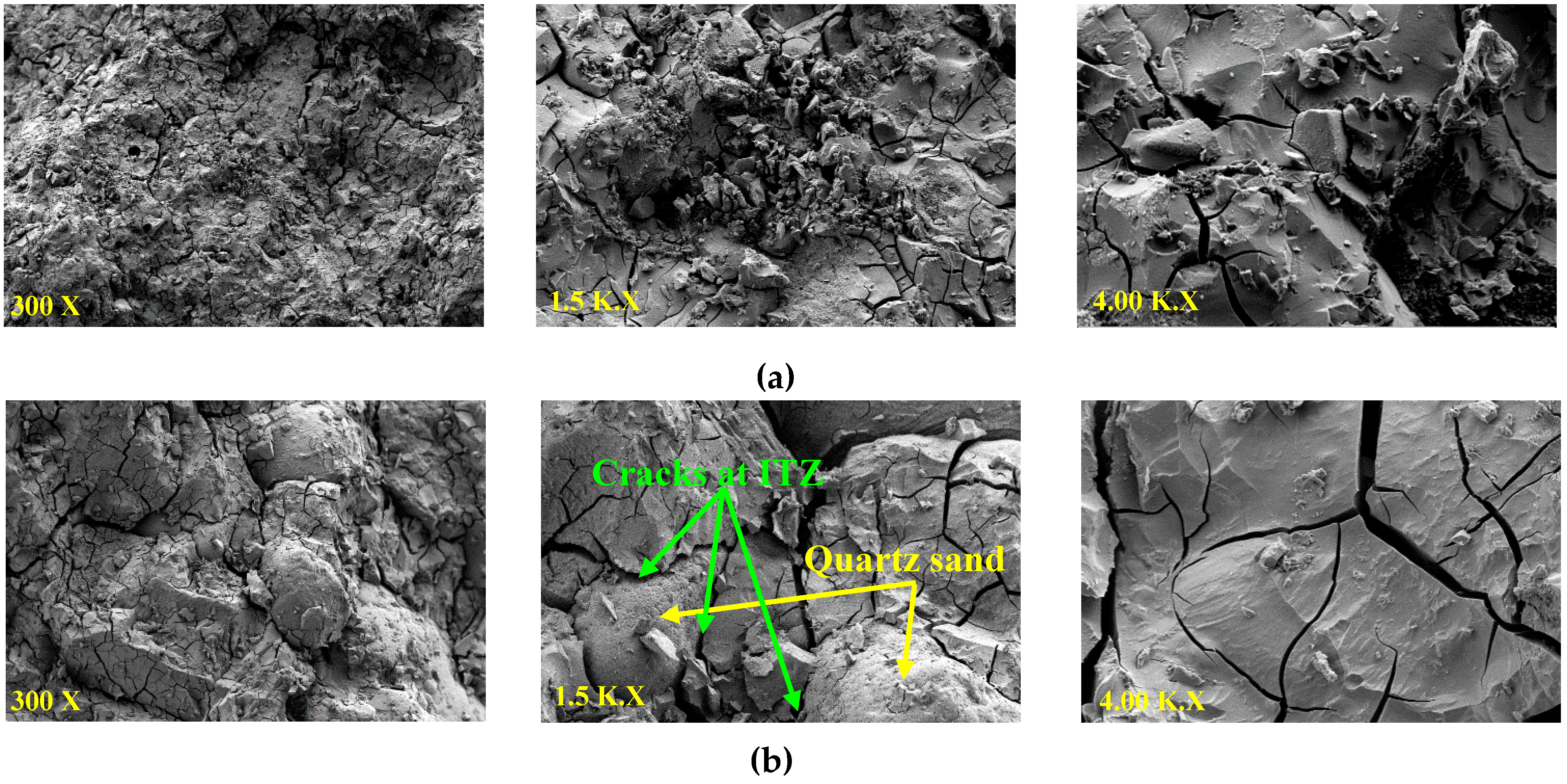

2.3.9. SEM Analysis

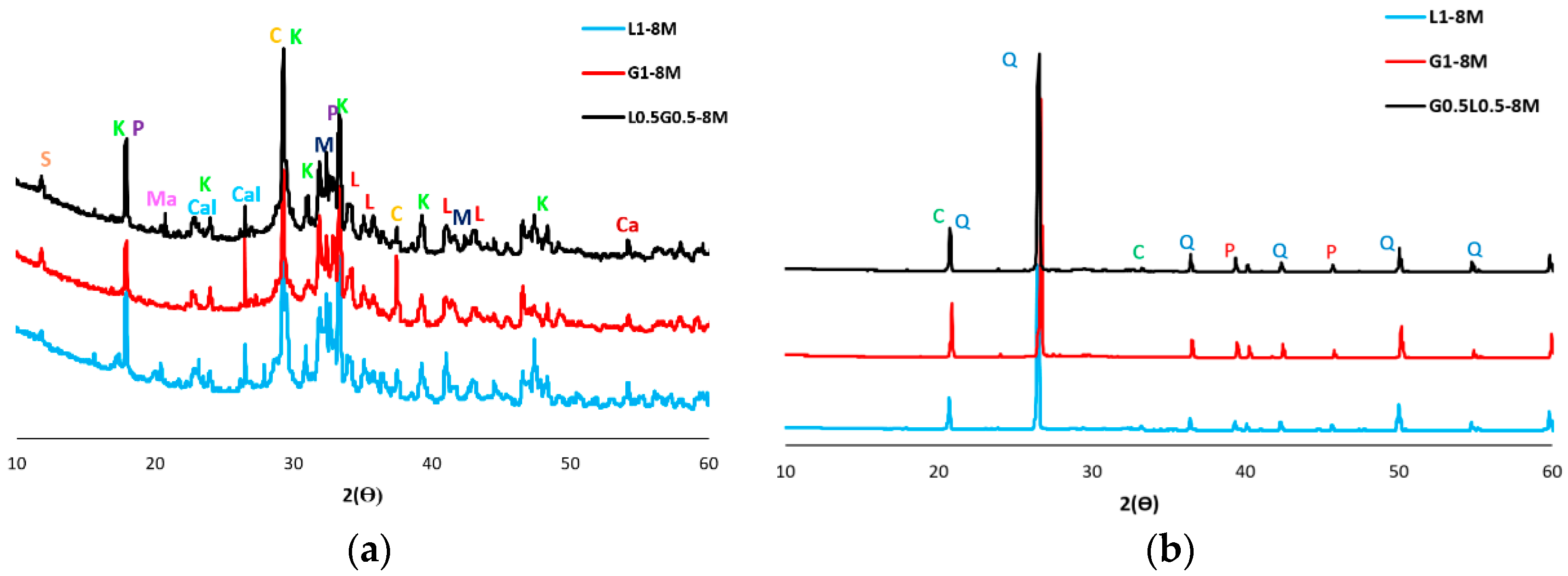

2.3.10. X-ray Diffraction (XRD) Analysis

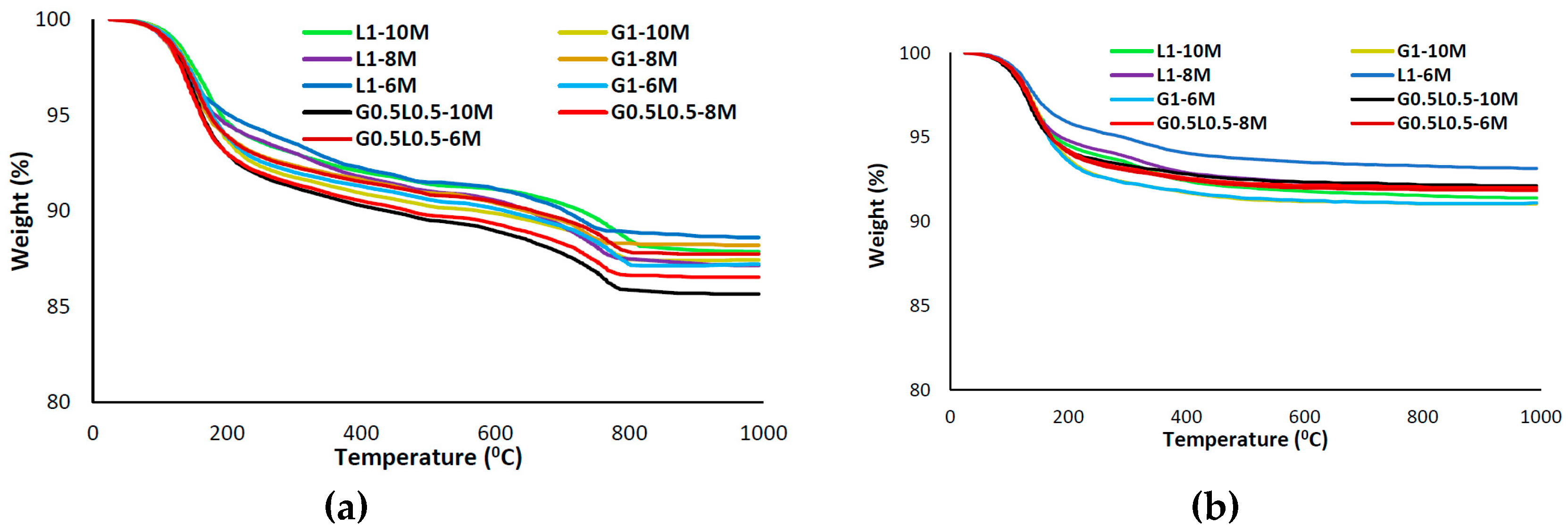

2.3.11. Thermogravimetric Analysis (TGA) and Differential Thermogravimetry (DTG) Analysis

3. Results and Discussion

3.1. Development of Alkali-Activated Slag-Based Concretes with Carbonated BOF Aggregates

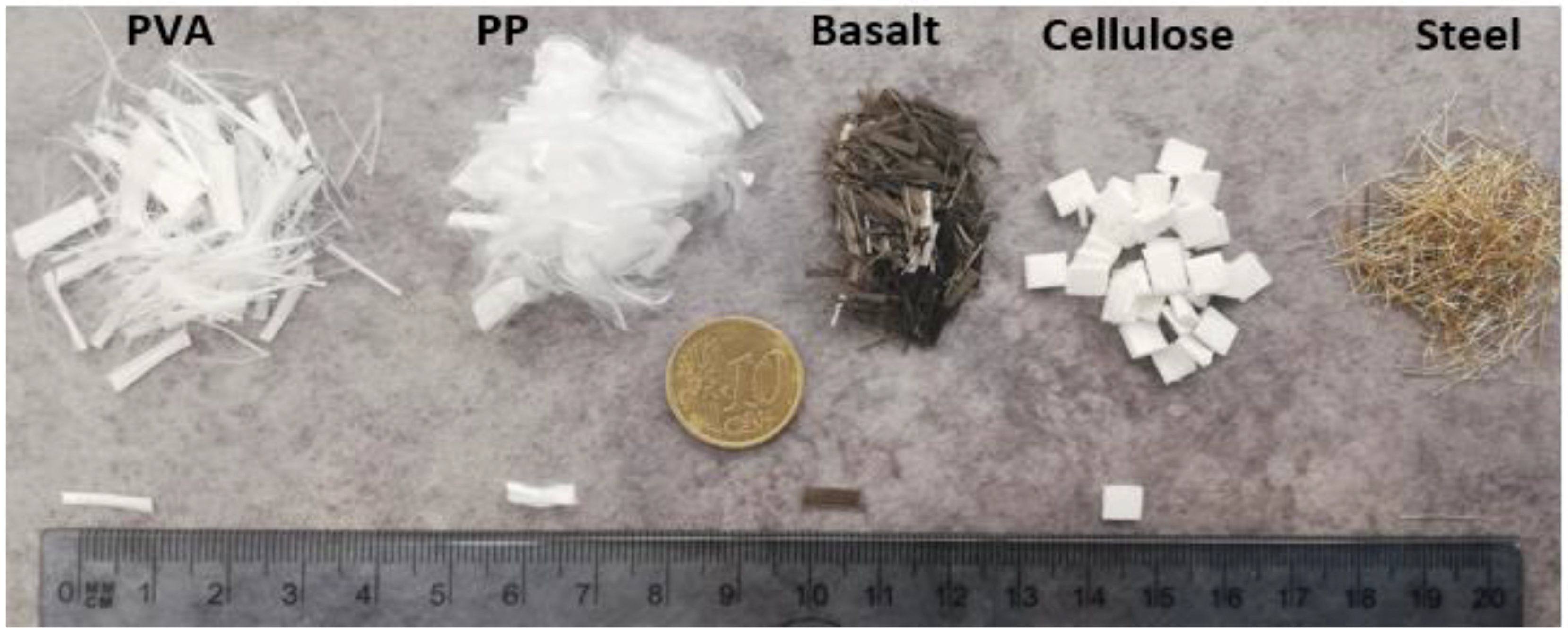

3.2. Comparative Effects of Different Fibres on the Hardened State Properties

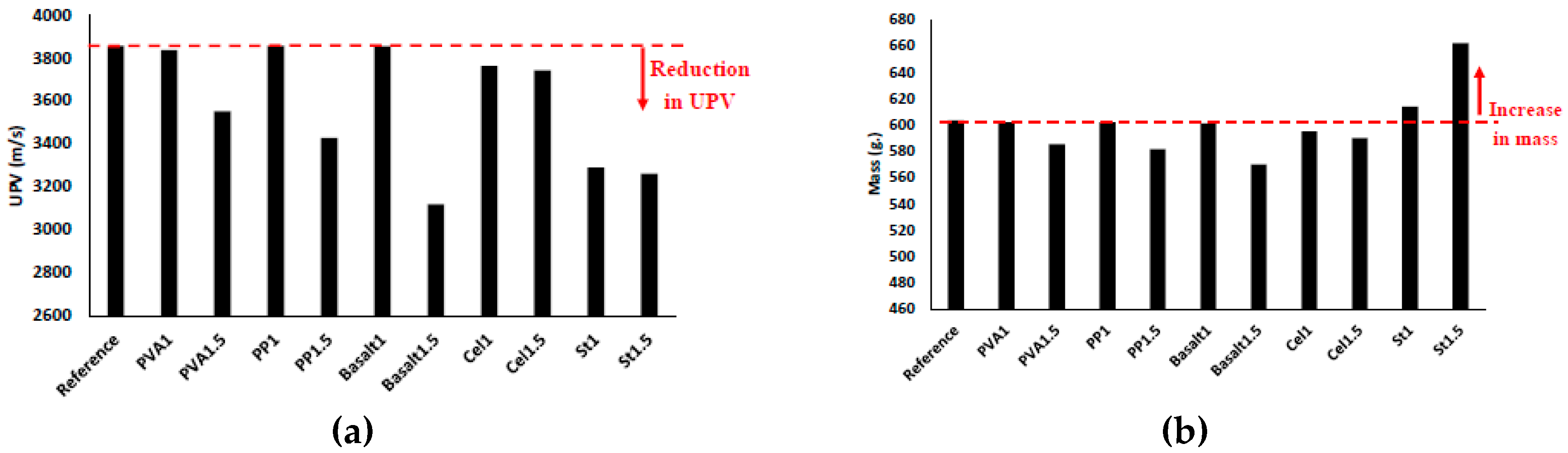

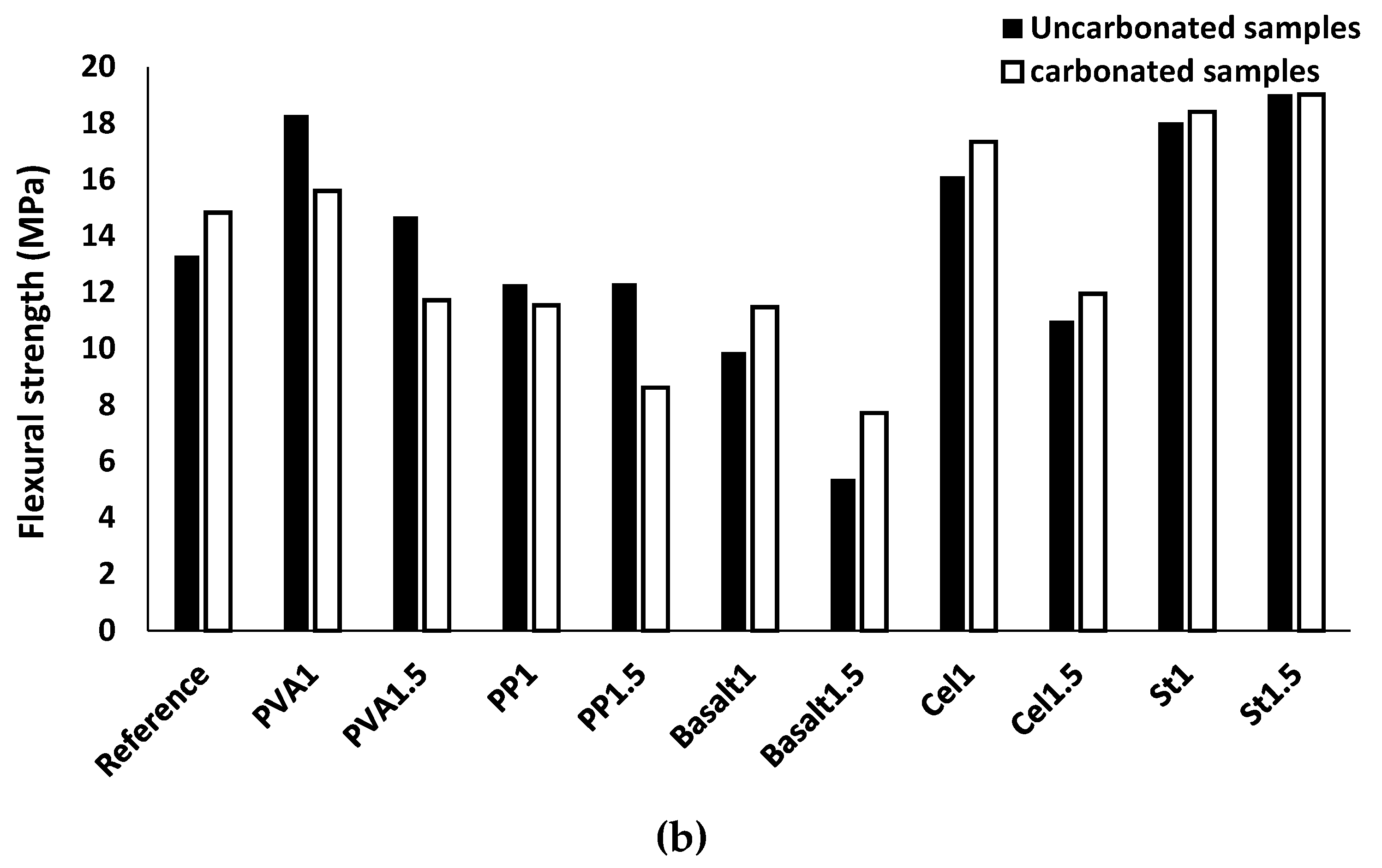

3.2.1. Ultrasonic Pulse Velocity (UPV)

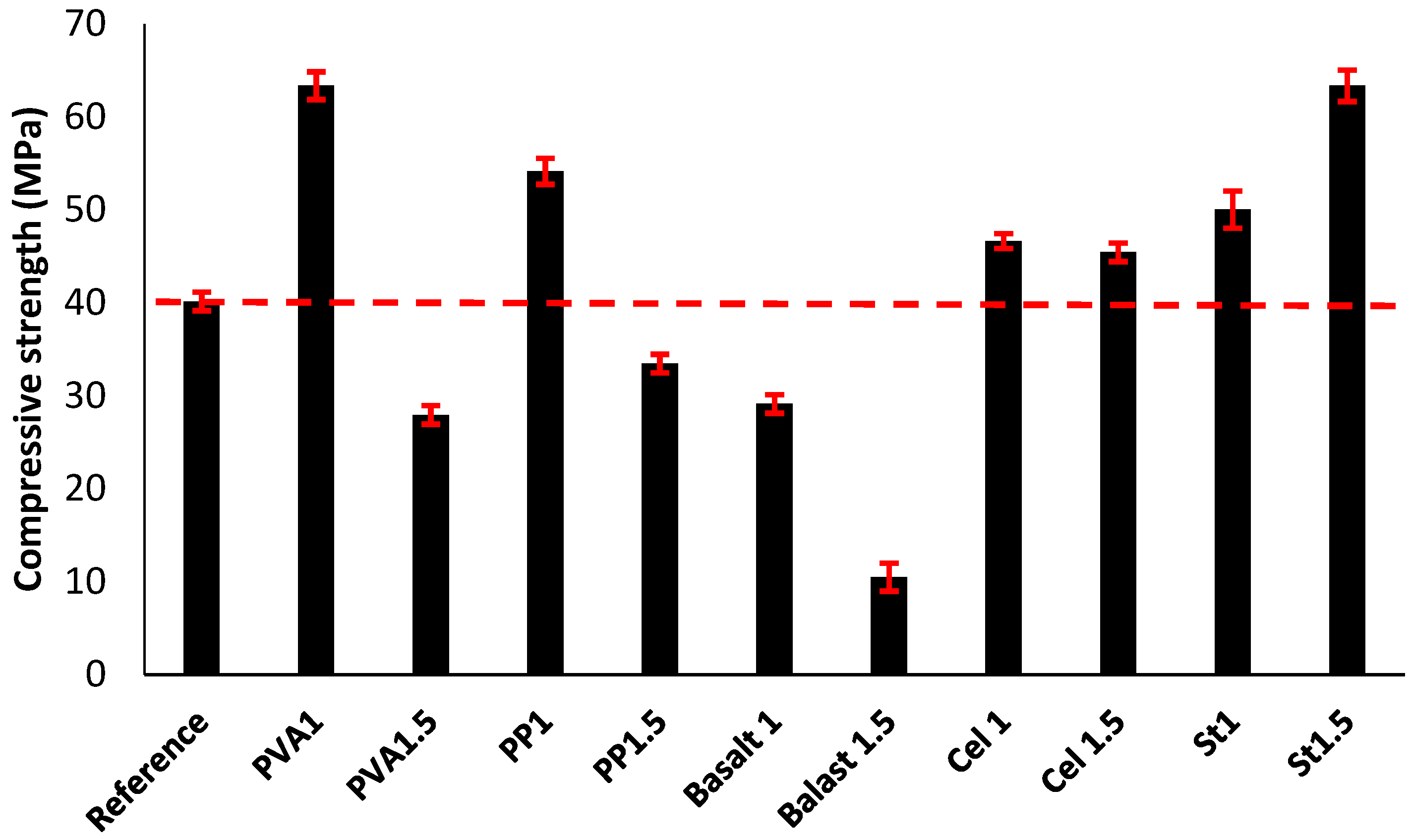

3.2.2. Compressive Strength

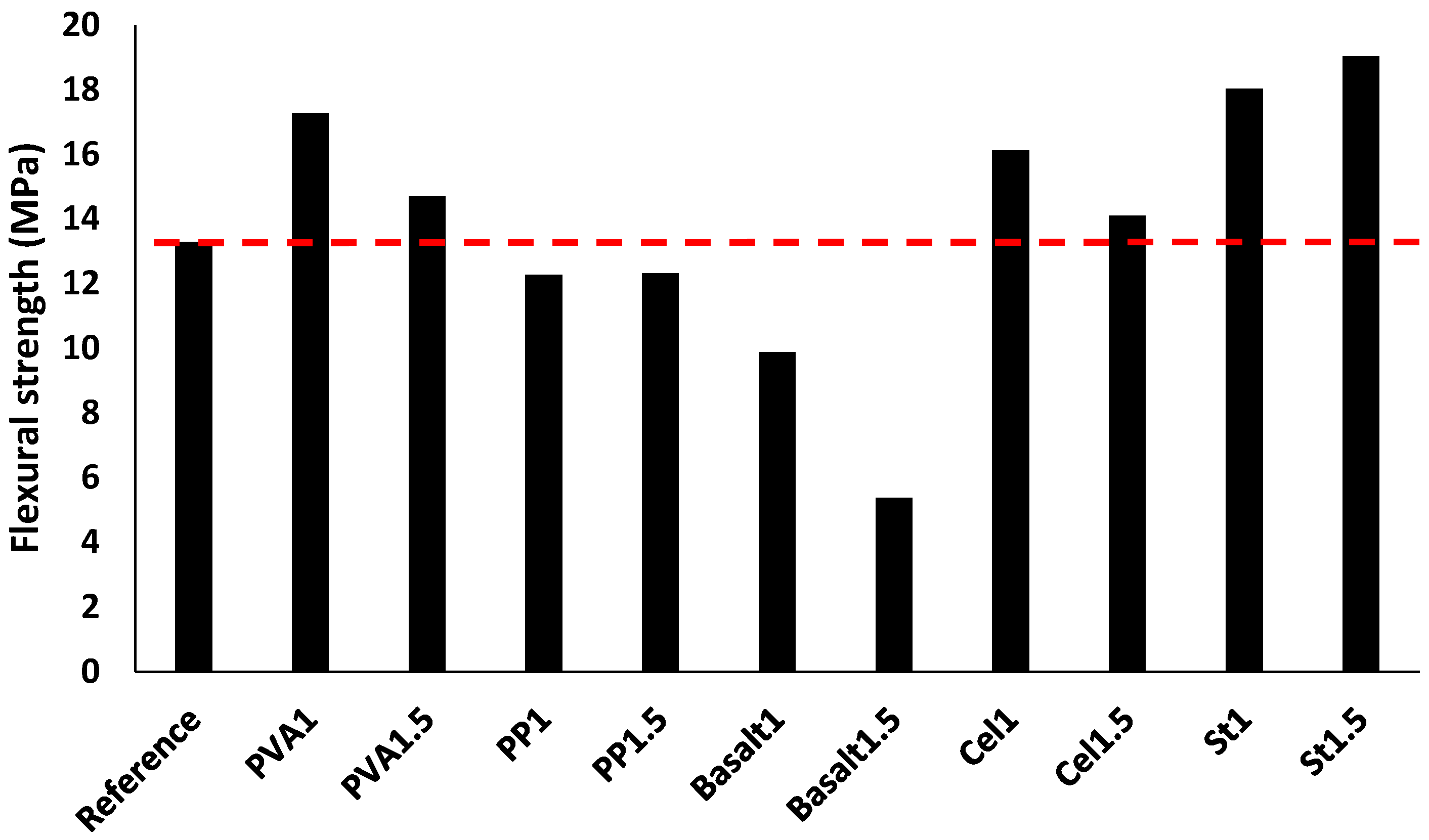

3.2.3. Flexural Strength

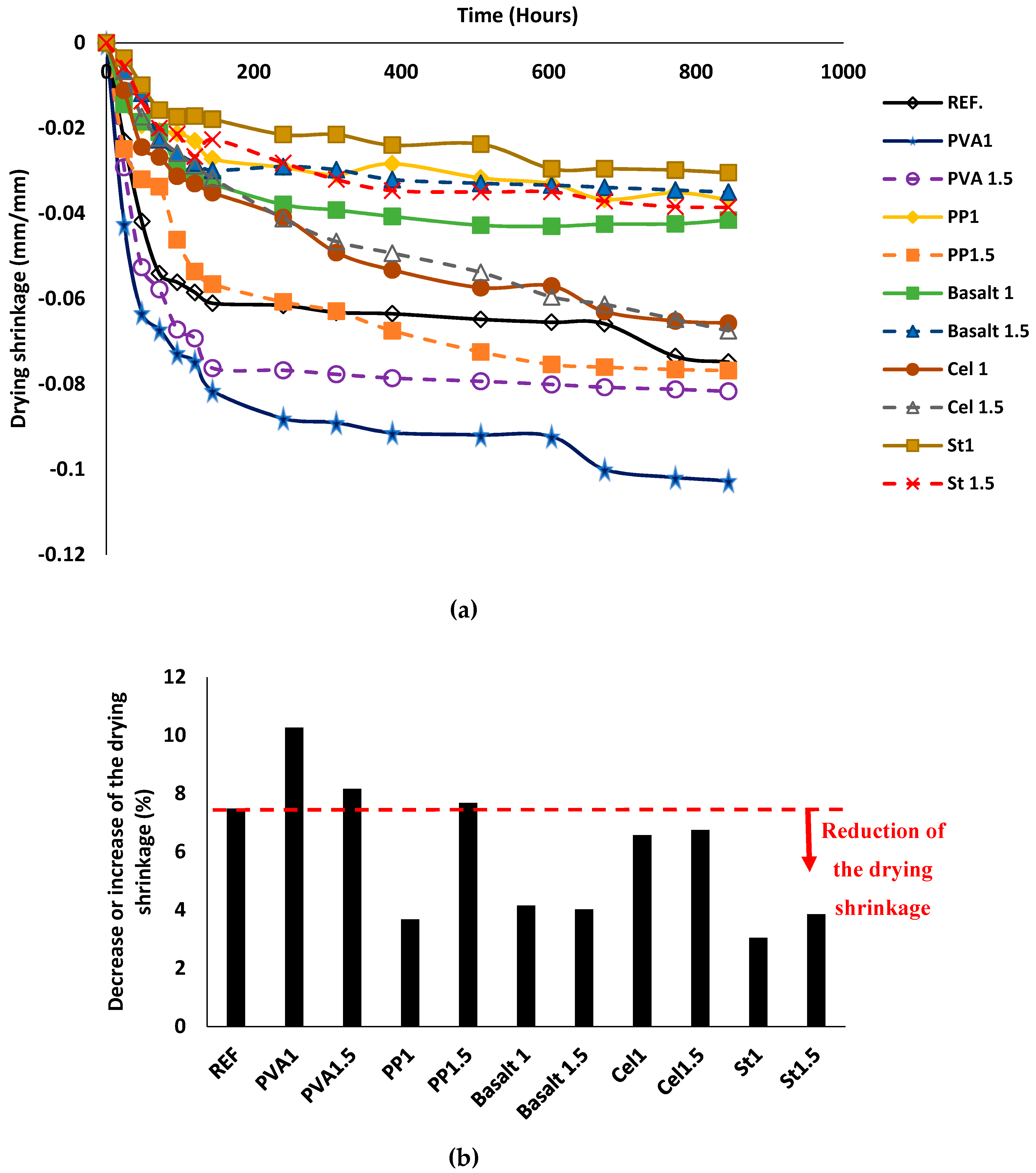

3.2.4. Drying Shrinkage

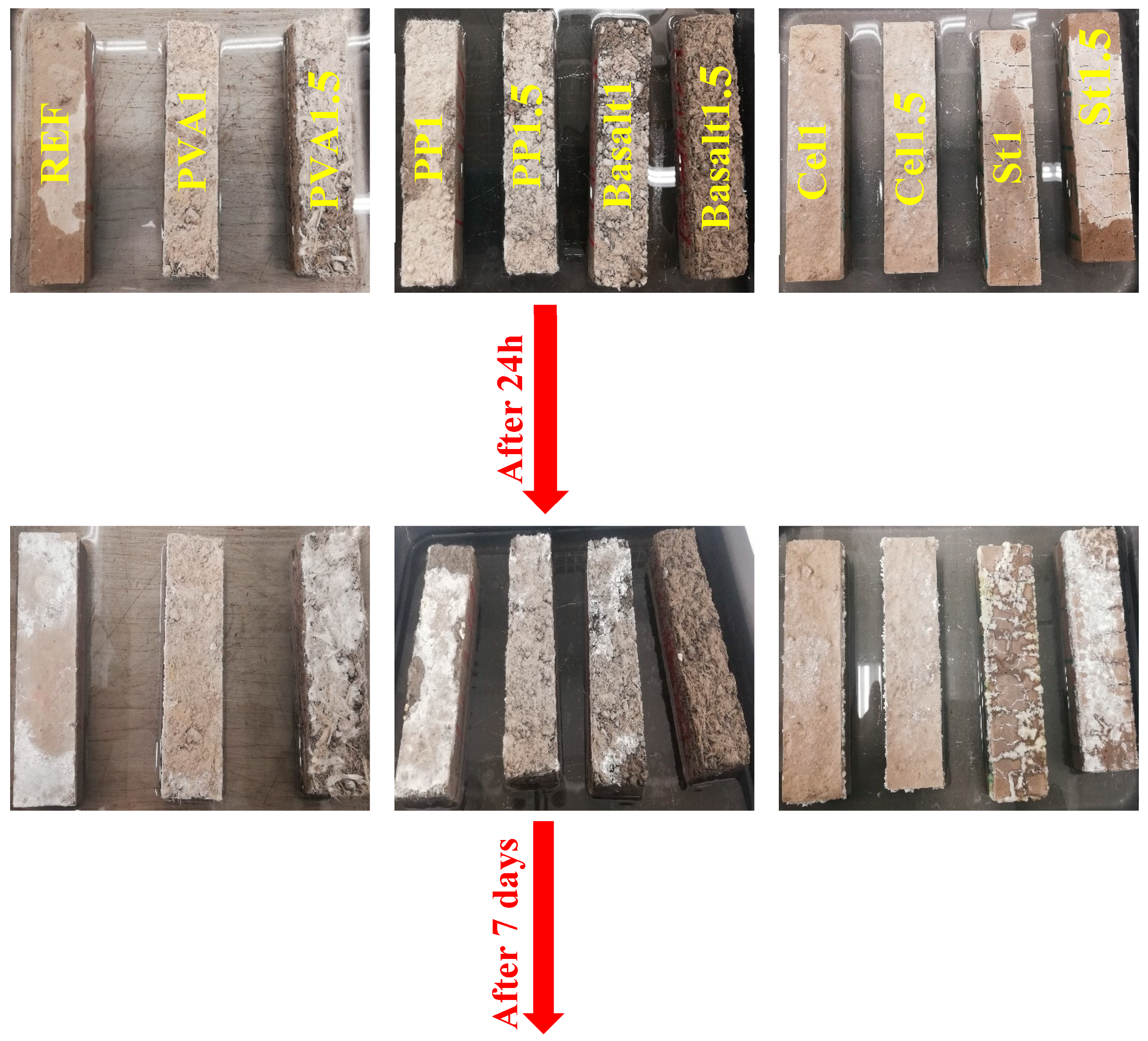

3.2.5. The Efflorescence Rates

3.3. Effects of Aggressive Conditions on Hardened State Properties

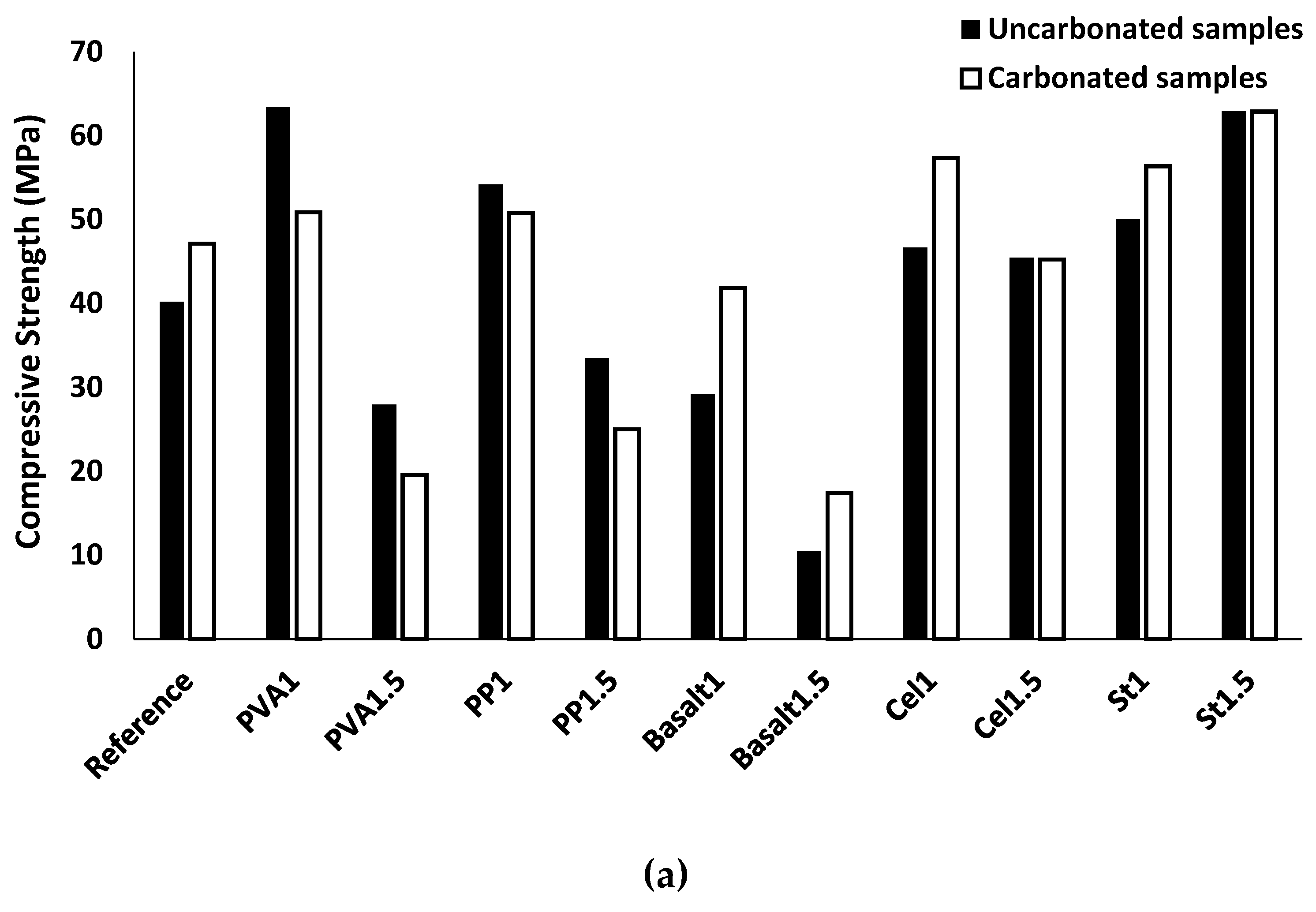

3.3.1. Carbonation Test

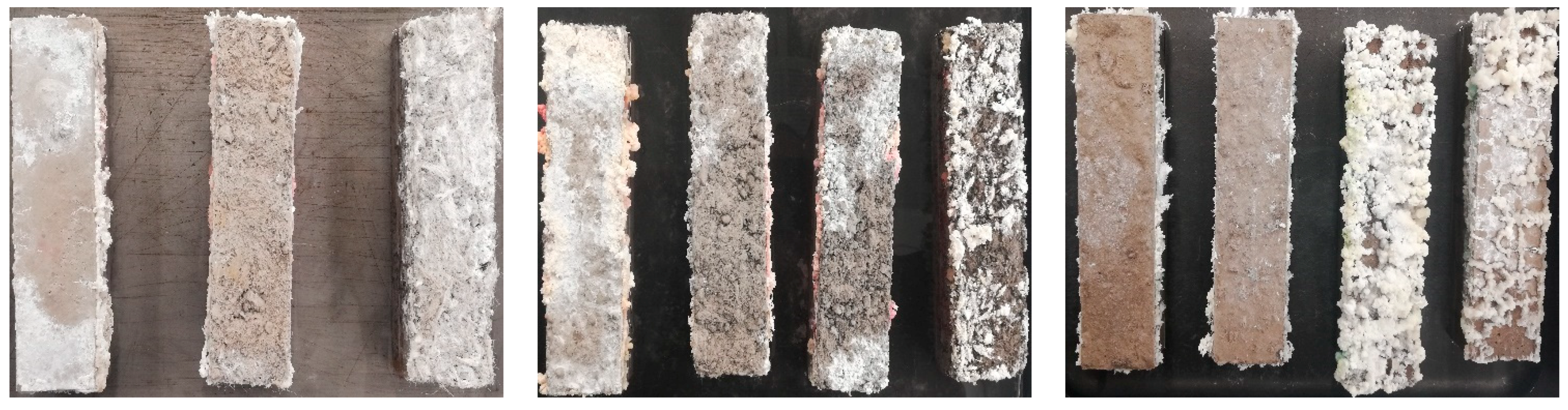

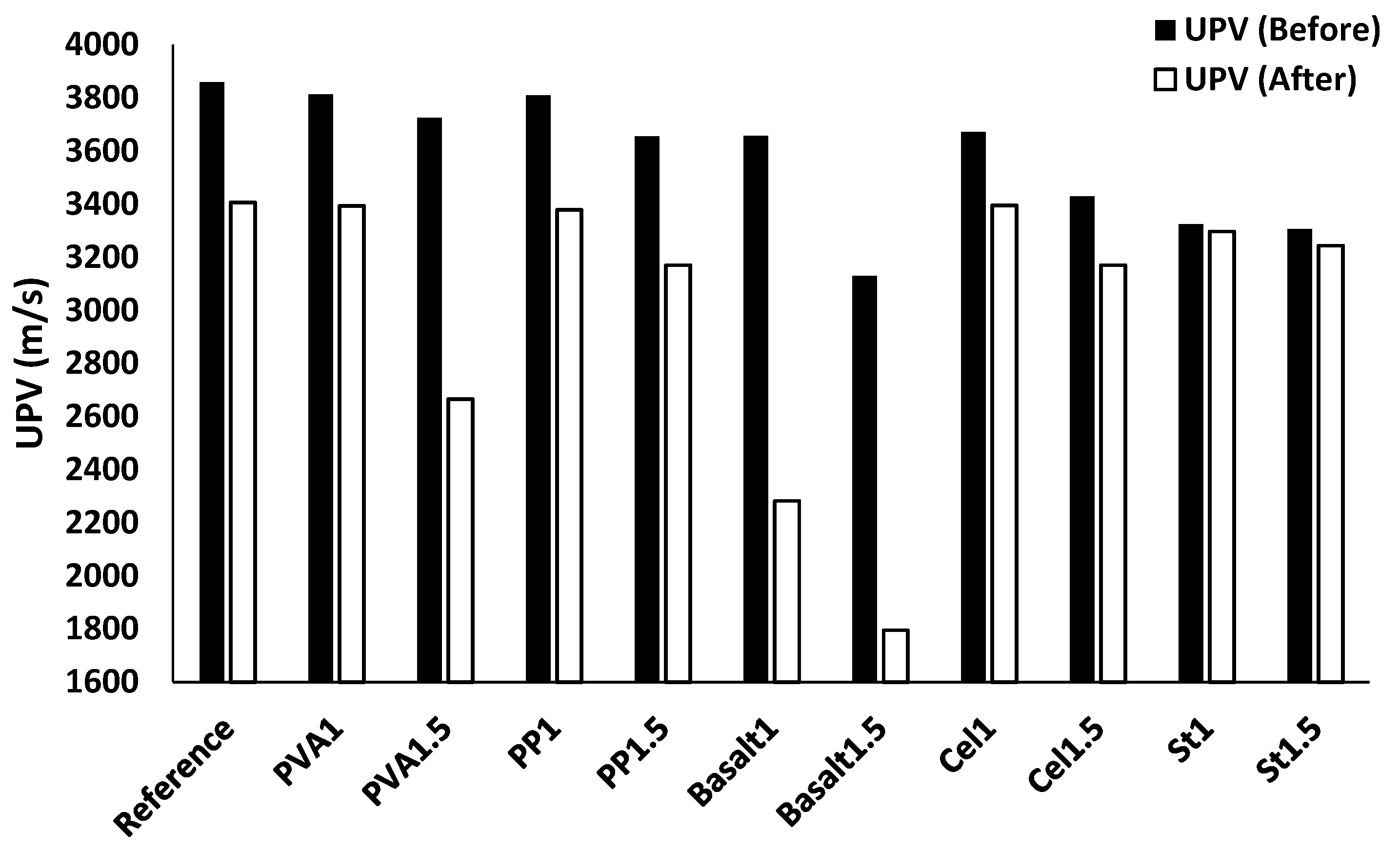

3.3.2. Freeze/Thaw Resistance

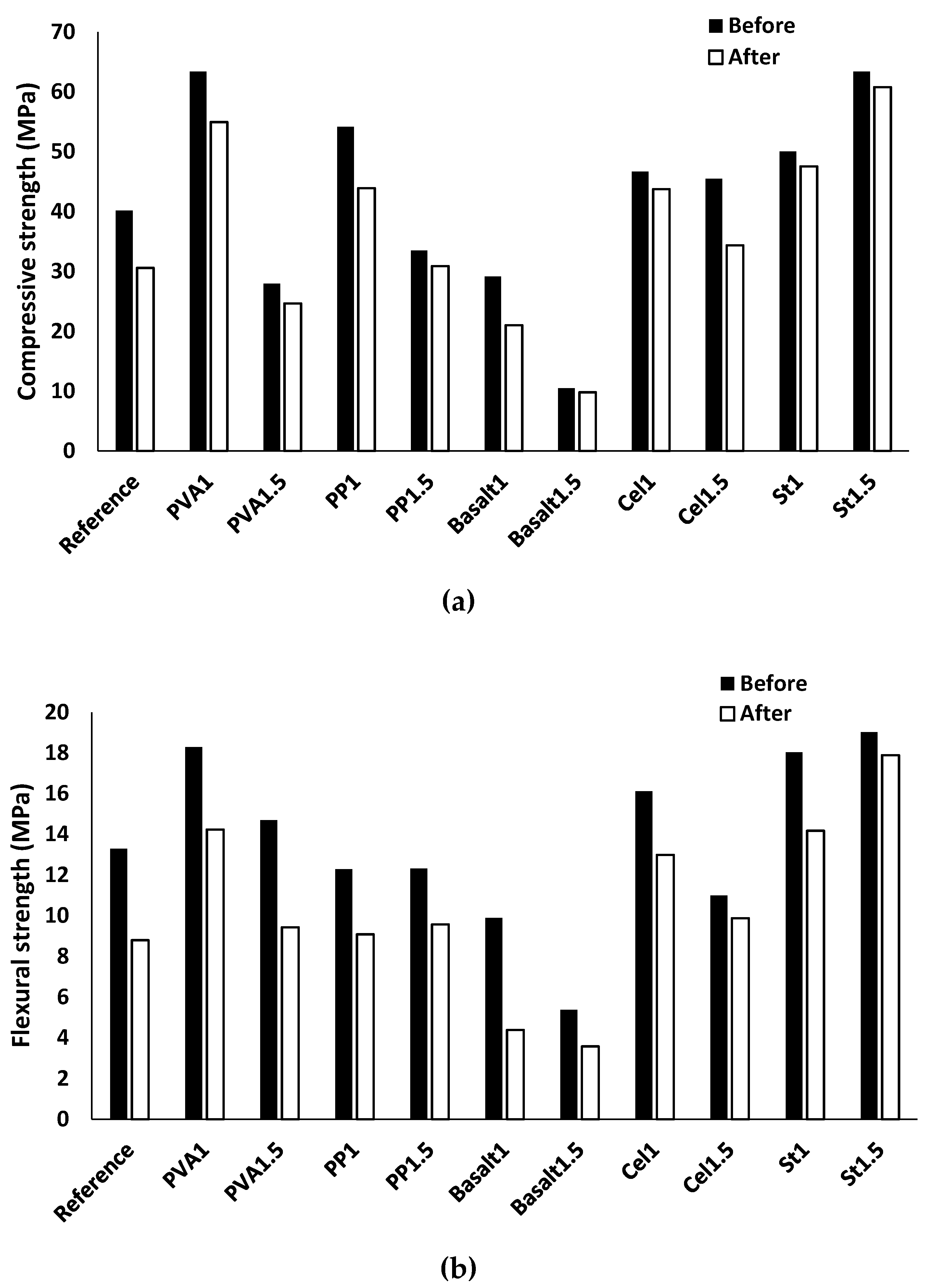

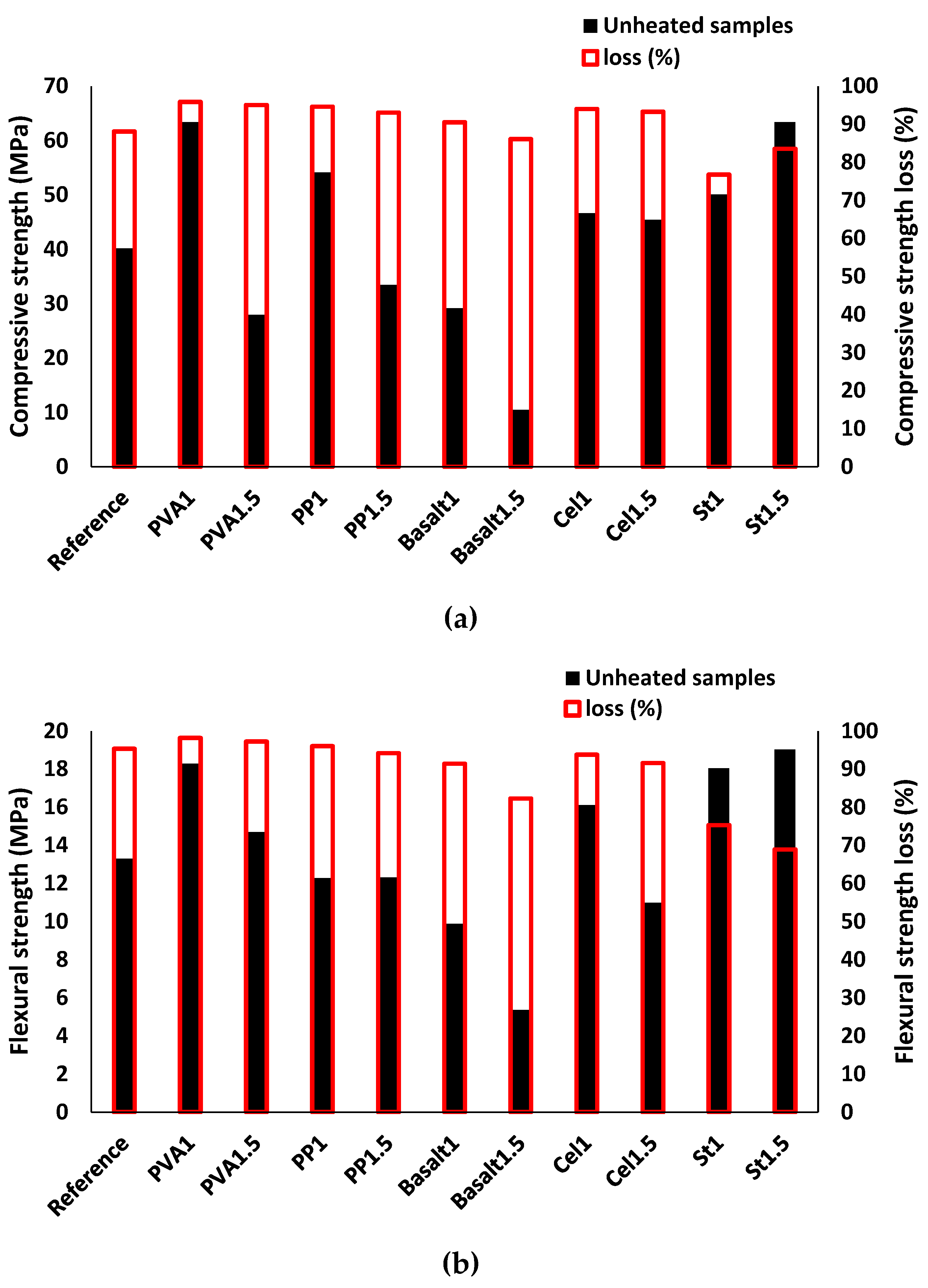

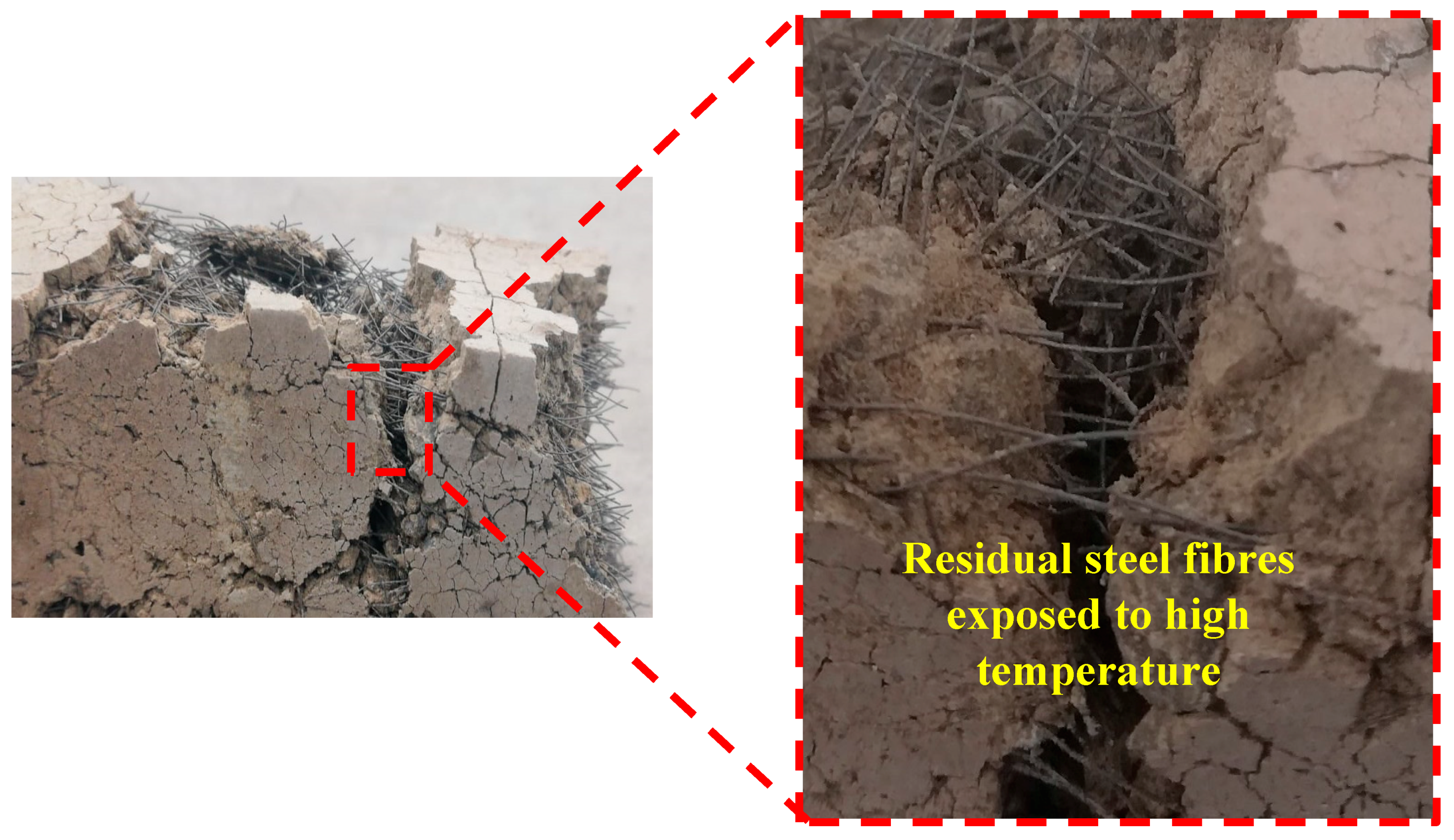

3.3.3. High Temperature Resistance

4. Conclusions

- Using carbonated BOF slag aggregates improved both compressive and flexural strengths up to three times. The maximum strength in alkali-activated concretes with carbonated BOF slag aggregates was obtained when a combination of ladle slag (50% of binder mass) and GGBFS (50% of binder mass) was used. Using carbonated BOF slag aggregates provided a denser matrix than normal aggregates.

- The highest enhancements in the mechanical properties were gained in the reinforced mixtures with 1.5% steel fibre (increase of 60% both compressive and flexural strengths).

- The formation of crystals due to exposure to CO2 gas reduced the porosity and improved the mechanical strengths of the plain mixture.

- The addition of fibre enhanced the freeze/thaw resistance. The reinforced mixtures with steel fibre, regardless of fibre content, showed the lowest strength reduction (5%), while the reinforced mixtures with basalt fibres (1%) showed the maximum strength reductions.

- Under aggressive conditions (high temperature, carbonation, and freeze/thaw tests), the minimum strength reduction was recorded in the reinforced mixtures with steel fibre.

- Drying shrinkage was governed by fibre type and content. The St1 mixture demonstrated the minimum drying shrinkage and showed a reduction of 60% compared to the plain mixture.

- The visual observations revealed that cellulose fibre had the highest efficiency in limiting efflorescence after seven days.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Acronyms

| BOF | Basic oxygen furnace |

| CO2 | Carbon dioxide |

| OPC | Ordinary Portland cement |

| SS | Sodium silicate |

| SH | Sodium hydroxide |

| B | Binder |

| A | Alkali activator |

| PVA | Polyvinyl alcohol |

| PP | Polypropylene |

| LS | Ladle slag |

| GGBFS | Granulated blast furnace slag |

| TPB | Three point bending |

| XRF | X-ray fluorescence |

| XRD | X-ray diffraction |

| UPV | Ultrasonic pulse velocity |

| SEM | Scanning electron microscope |

| TGA | Thermogravimetric analyses |

| DTG | Differential thermogravimetry |

References

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2017, 103, 21–34. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2017, 114, 40–48. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Provis, J.L.; Van Deventer, J.S. The effect of silica availability on the mechanism of geopolymerisation. Cem. Concr. Res. 2011, 41, 210–216. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Shi, C.; Pan, S.-Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Sharif, A.M.; Shameem, M.; Ibrahim, M.; Barry, M. Comparison of properties of steel slag and crushed limestone aggregate concretes. Constr. Mater. 2003, 17, 105–112. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Feng, J. A discussion on improving hydration activity of steel slag by altering its mineral compositions. J. Hazard. Mater. 2011, 186, 1070–1075. [Google Scholar] [CrossRef] [PubMed]

- Palankar, N.; Shankar, A.R.; Mithun, B. Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. J. Clean. Prod. 2016, 129, 437–448. [Google Scholar] [CrossRef]

- Palankar, N.; Shankar, A.R.; Mithun, B.M. Air-cured alkali activated binders for concrete pavements. Int. J. Pavement Res. Technol. 2015, 8, 289–294. [Google Scholar]

- Mithun, B.; Narasimhan, M. Performance of alkali activated slag concrete mixes incorporating copper slag as fine aggregate. J. Clean. Prod. 2016, 112, 837–844. [Google Scholar] [CrossRef]

- Yang, K.-H.; Lee, K.-H.; Song, J.-K.; Gong, M.-H. Properties and sustainability of alkali-activated slag foamed concrete. J. Clean. Prod. 2014, 68, 226–233. [Google Scholar] [CrossRef]

- Mithun, B.; Narasimhan, M.; Nitendra, P.; Ravishankar, A. Flexural Fatigue performance of Alkali Activated Slag Concrete mixes incorporating Copper Slag as Fine Aggregate. Sel. Sci. Pap. J. Civ. Eng. 2015, 10, 7–18. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Ameri, M.; Shahabishahmiri, H.; Kazemzadehazad, S. Evaluation of the use of steel slag in concrete. In Proceedings of the 25th sARRB Conference, Perth, WA, Australia, 23–26 September 2012. [Google Scholar]

- Palankar, N.; Ravi Shankar, A.U.; Mithun, B.M. Investigations on Alkali-Activated Slag/Fly Ash Concrete with steel slag coarse aggregate for pavement structures. Int. J. Pavement Eng. 2017, 18, 500–512. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Isomoisio, H.; Karhu, M.; Illikainen, M. Mechanical and acoustic properties of fiber-reinforced alkali-activated slag foam concretes containing lightweight structural aggregates. Constr. Mater. 2018, 187, 371–381. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. The effect of fiber properties on high performance alkali-activated slag/silica fume mortars. Compos. Part B: Eng. 2013, 45, 63–69. [Google Scholar] [CrossRef]

- Wallah, S.; Hardjito, D. Assessing the shrinkage and creep of alkali-activated concrete binders. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Elsevier: Amsterdam, The Netherlands, 2015; pp. 265–290. [Google Scholar]

- Pratt, P.L.; Wang, S.-D.; Pu, X.-C.; Scrivener, K.L. Alkali-activated slag cement and concrete: A review of properties and problems. Adv. Cem. Res. 1995, 7, 93–102. [Google Scholar]

- Ding, Y.-C.; Cheng, T.-W.; Liu, P.-C.; Lee, W.-H. Study on the treatment of BOF slag to replace fine aggregate in concrete. Constr. Mater. 2017, 146, 644–651. [Google Scholar] [CrossRef]

- Mahieux, P.-Y.; Aubert, J.-E.; Escadeillas, G. Utilization of weathered basic oxygen furnace slag in the production of hydraulic road binders. Constr. Mater. 2009, 23, 742–747. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.; Xu, H. Utilization of carbonated and granulated steel slag aggregate in concrete. Constr. Mater. 2015, 84, 454–467. [Google Scholar] [CrossRef]

- Bodor, M.; Santos, R.M.; Cristea, G.; Salman, M.; Cizer, Ö.; Iacobescu, R.I.; Chiang, Y.W.; Van Balen, K.; Vlad, M.; Van Gerven, T. Laboratory investigation of carbonated BOF slag used as partial replacement of natural aggregate in cement mortars. Cem. Concr. Compos. 2016, 65, 55–66. [Google Scholar] [CrossRef]

- Adegoloye, G.; Beaucour, A.-L.; Ortola, S.; Noumowe, A. Mineralogical composition of EAF slag and stabilised AOD slag aggregates and dimensional stability of slag aggregate concretes. Constr. Mater. 2016, 115, 171–178. [Google Scholar] [CrossRef]

- Reddy, A.S.; Pradhan, R.; Chandra, S. Utilization of Basic Oxygen Furnace (BOF) slag in the production of a hydraulic cement binder. Int. J. Process. 2006, 79, 98–105. [Google Scholar] [CrossRef]

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Performance of waste based alkaline mortars submitted to accelerated carbon dioxide curing. Resour. Conserv. Recycl. 2018, 129, 12–19. [Google Scholar] [CrossRef]

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Carbon dioxide sequestration of fly ash alkaline-based mortars containing recycled aggregates and reinforced by hemp fibres. Constr. Mater. 2018, 160, 48–56. [Google Scholar] [CrossRef]

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Carbon dioxide sequestration of fly ash/waste glass alkaline-based mortars with recycled aggregates: Compressive strength, hydration products, carbon footprint and cost analysis. In Carbon Dioxide Sequestration Based Cementitious Construction Materials; Woodhead Publishing: Cambridge, UK, 2018; Volume 1, pp. 299–348. [Google Scholar]

- Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Carbon dioxide sequestration of fly ash alkaline-based mortars containing recycled aggregates and reinforced by hemp fibers: Properties, freeze-thaw resistance, and carbon footprint. In Carbon Dioxide Sequestration Based Cementitious Construction Materials; Woodhead Publishing: Cambridge, UK, 2018; Volume 1, pp. 393–409. [Google Scholar]

- Mastali, M.; Dalvand, A.; Sattarifard, A.; Abdollahnejad, Z.; Illikainen, M. Characterization and optimization of hardened properties of self-consolidating concrete incorporating recycled steel, industrial steel, polypropylene and hybrid fibers. Compos. Part B: Eng. 2018, 151, 186–200. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. Fiber-reinforced one-part alkali-activated slag/ceramic binders. Ceram. Int. 2018, 44, 8963–8976. [Google Scholar] [CrossRef]

- ASTM C597. Standard Test Method for Pulse Velocity through Concrete; ASTM International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 18 April 2019).

- ASTM C78. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2010; Available online: www.astm.org (accessed on 18 April 2019).

- ASTM C349. Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure); ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 18 April 2019).

- Adesanya, E.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Properties and durability of alkali-activated ladle slag. Mater. Struct. 2017, 50, 255. [Google Scholar] [CrossRef]

- ASTM C157/C157M-17. Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 18 April 2019).

- Ma, X.; Zhang, Z.; Wang, A. The transition of fly ash-based geopolymer gels into ordered structures and the effect on the compressive strength. Constr. Mater. 2016, 104, 25–33. [Google Scholar] [CrossRef]

- Heikal, M.; El-Didamony, H.; Sokkary, T.; Ahmed, I. Behavior of composite cement pastes containing microsilica and fly ash at elevated temperature. Constr. Mater. 2013, 38, 1180–1190. [Google Scholar] [CrossRef]

- Szeląg, M. Development of Cracking Patterns in Modified Cement Matrix with Microsilica. Materials 2018, 11, 1928. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Wang, Q.; Zhang, Z.; Ou, Z. Composition design and performance of alkali-activated cements. Mater. Struct. 2017, 50, 997. [Google Scholar] [CrossRef]

- Nath, S.; Maitra, S.; Mukherjee, S.; Kumar, S. Microstructural and morphological evolution of fly ash based geopolymers. Constr. Mater. 2016, 111, 758–765. [Google Scholar] [CrossRef]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Shaikh, F.U.; Supit, S.W. Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr. Mater. 2014, 70, 309–321. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Fly ash-based geopolymers: The relationship between composition, pore structure and efflorescence. Cem. Concr. Res. 2014, 64, 30–41. [Google Scholar] [CrossRef]

- Šelih, J. Performance of concrete exposed to freezing and thawing in different saline environments. J. Civ. Eng. Manag. 2010, 16, 306–311. [Google Scholar] [CrossRef]

- Sun, P.; Wu, H.C. Chemical and freeze–thaw resistance of fly ash-based inorganic mortars. Fuel 2013, 111, 740–745. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Lourenço, L.; Barros, J.; Alves, J.A. Fiber reinforced concrete of enhanced fire resistance for tunnel segments. ACI 2011, 276, 1–34. [Google Scholar]

- Yermak, N.; Pliya, P.; Beaucour, A.-L.; Simon, A.; Noumowé, A. Influence of steel and/or polypropylene fibres on the behaviour of concrete at high temperature: Spalling, transfer and mechanical properties. Constr. Mater. 2017, 132, 240–250. [Google Scholar] [CrossRef]

| Material | Element/Oxides (%, w/w) | |||||

|---|---|---|---|---|---|---|

| CaO | MgO | Al2O3 | SiO2 | SO3 | Fe2O3 | |

| LS | 50.96 | 6.31 | 27.87 | 8.27 | 0.8 | 1.13 |

| GGBFS | 38.51 | 10.24 | 9.58 | 32.33 | 4.00 | 1.23 |

| Carbonated BOF | 54.59 | 1.86 | 1.15 | 12.99 | 0.18 | 21.35 |

| Specimen Designation | LD | GGBFS | Aggregates/B | A/B | SS/SH | SH (M) |

|---|---|---|---|---|---|---|

| G1-6M | 0 | 1 | 3 or 5 (carbonated BOF slag or quartz sand) | 1 | 2.5 | 6 |

| G1-8M | 0 | 1 | 8 | |||

| G1-10M | 0 | 1 | 10 | |||

| L1-6M | 1 | 0 | 6 | |||

| L1-8M | 1 | 0 | 8 | |||

| L1-10M | 1 | 0 | 10 | |||

| G0.5L0.5-6M | 0.5 | 0.5 | 6 | |||

| G0.5L0.5-8M | 0.5 | 0.5 | 8 | |||

| G0.5L0.5-10M | 0.5 | 0.5 | 10 |

| Fibre Type | Length/Diameter (mm/mm) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|---|

| PVA | 200 | 41.0 | 1600 | 6 | 1.30 |

| PP | 833 | 9.6 | 910 | <12 | 0.91 |

| Basalt | 333 | 100.0 | 4500 | 3.1 | 2.63 |

| Cellulose | 117 | 8.5 | 750 | - | 1.10 |

| Indented steel | 47 | 200.0 | 1300 | - | 7.80 |

| Mixtures | Fibre Type | Fibre Content (%, in Vol.) | |||||

|---|---|---|---|---|---|---|---|

| Reference | 0.5 | 0.5 | 0.96 | 2.5 | 3 | --- | 0 |

| PVA1 | PVA | 1 | |||||

| PVA1.5 | 1.5 | ||||||

| PP1 | PP | 1 | |||||

| PP1.5 | 1.5 | ||||||

| Basalt1 | Basalt | 1 | |||||

| Basalt1.5 | 1.5 | ||||||

| Cel.1 | Cellulose | 1 | |||||

| Cel.1.5 | 1.5 | ||||||

| St.1 | Indented steel | 1 | |||||

| St.1.5 | 1.5 |

| ID | Reference | PVA1 | PVA1.5 | PP1 | PP1.5 | Basalt 1 | Basalt 1.5 | Cel1 | Cel1.5 | St1 | St1.5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass change (%) | −1.02 | −1.02 | −1.75 | −1.12 | −1.33 | −1.71 | −2.63 | −0.93 | −1.16 | −1.52 | −1.53 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mastali, M.; Alzaza, A.; Mohammad Shaad, K.; Kinnunen, P.; Abdollahnejad, Z.; Woof, B.; Illikainen, M. Using Carbonated BOF Slag Aggregates in Alkali-Activated Concretes. Materials 2019, 12, 1288. https://doi.org/10.3390/ma12081288

Mastali M, Alzaza A, Mohammad Shaad K, Kinnunen P, Abdollahnejad Z, Woof B, Illikainen M. Using Carbonated BOF Slag Aggregates in Alkali-Activated Concretes. Materials. 2019; 12(8):1288. https://doi.org/10.3390/ma12081288

Chicago/Turabian StyleMastali, Mohammad, Ahmad Alzaza, Khaled Mohammad Shaad, Paivo Kinnunen, Zahra Abdollahnejad, Bethany Woof, and Mirja Illikainen. 2019. "Using Carbonated BOF Slag Aggregates in Alkali-Activated Concretes" Materials 12, no. 8: 1288. https://doi.org/10.3390/ma12081288

APA StyleMastali, M., Alzaza, A., Mohammad Shaad, K., Kinnunen, P., Abdollahnejad, Z., Woof, B., & Illikainen, M. (2019). Using Carbonated BOF Slag Aggregates in Alkali-Activated Concretes. Materials, 12(8), 1288. https://doi.org/10.3390/ma12081288