Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming

Abstract

1. Introduction

2. Materials and Methods

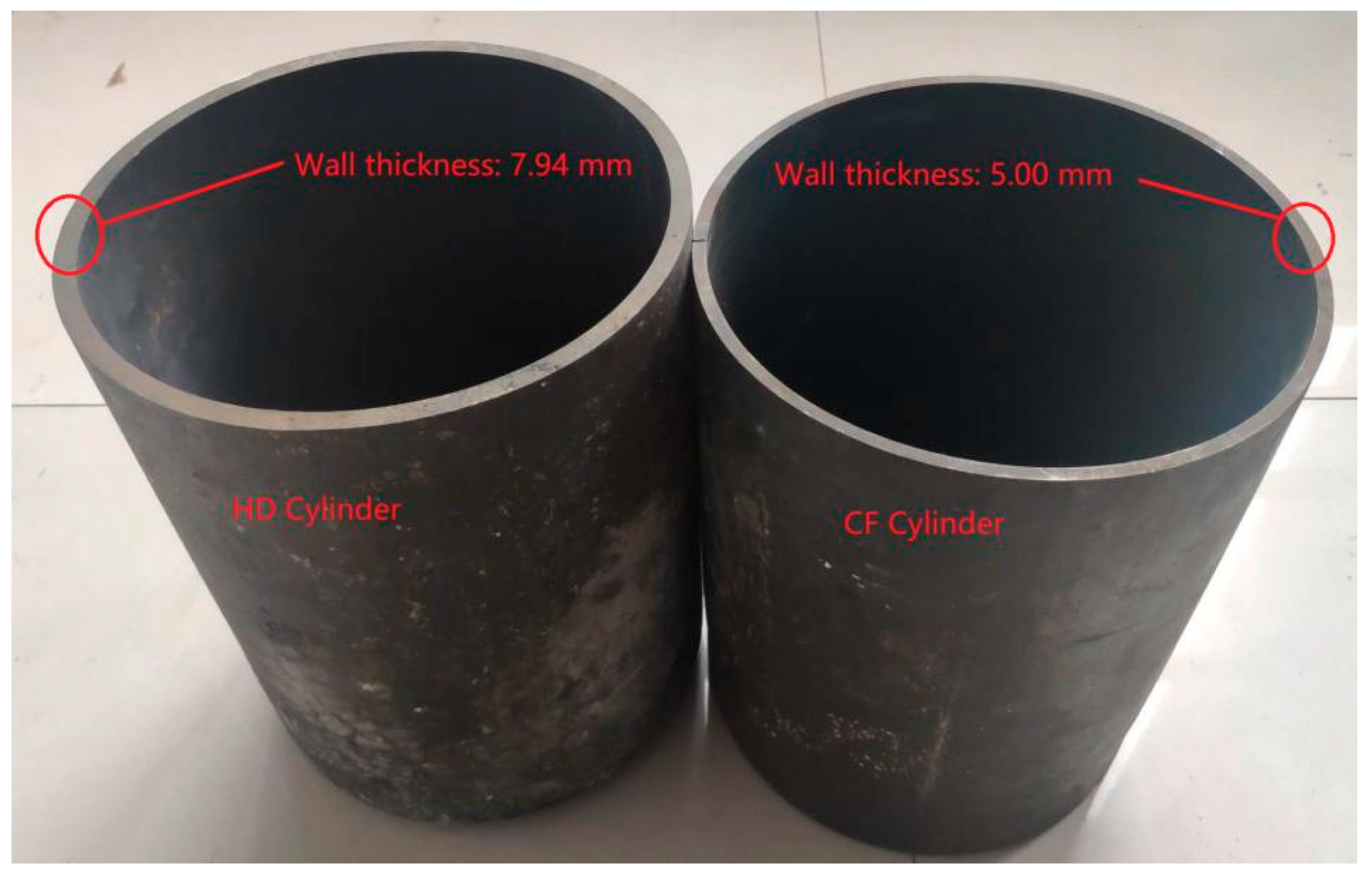

2.1. Materials and Cylinders

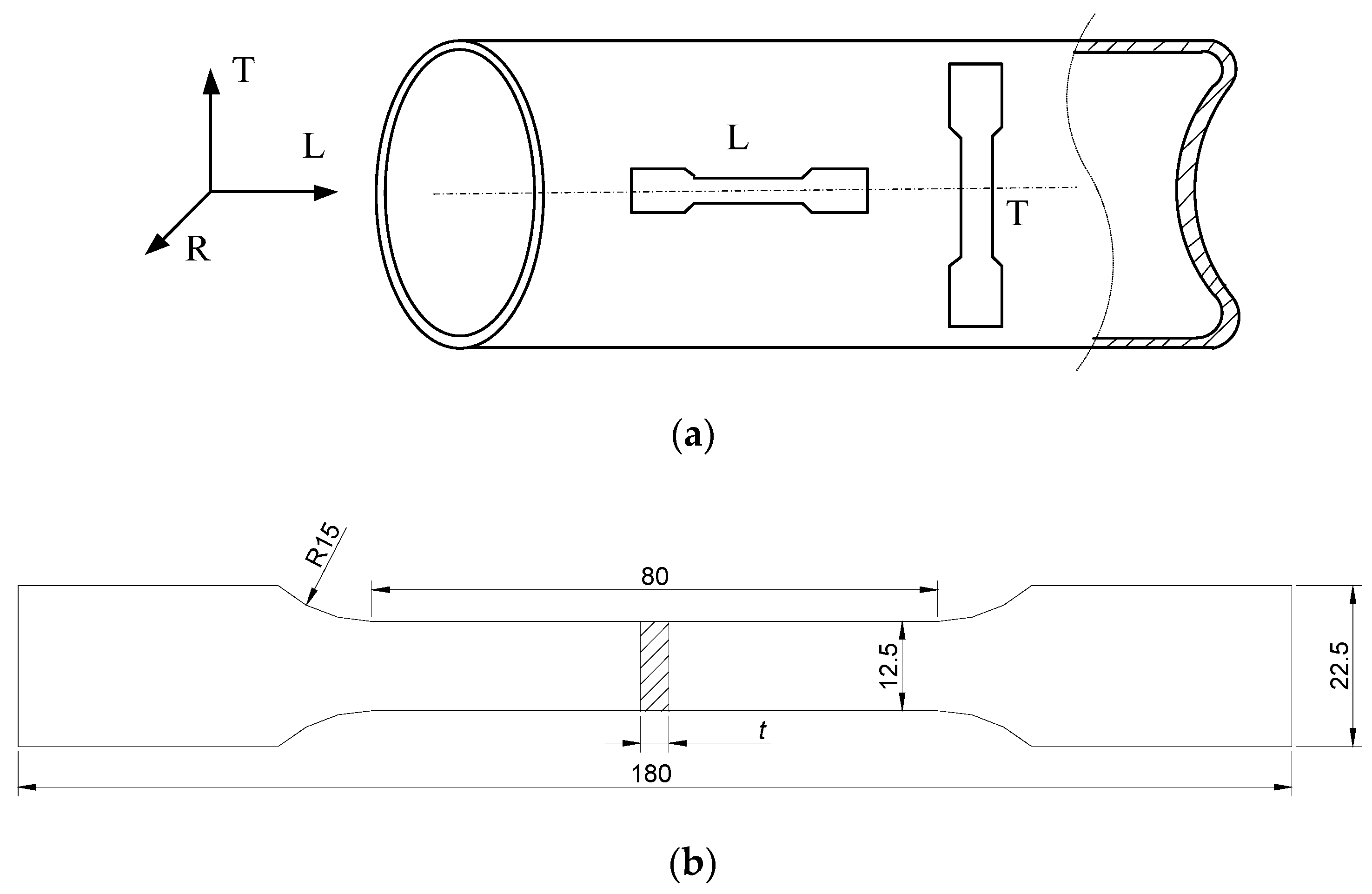

2.2. Tensile Tests

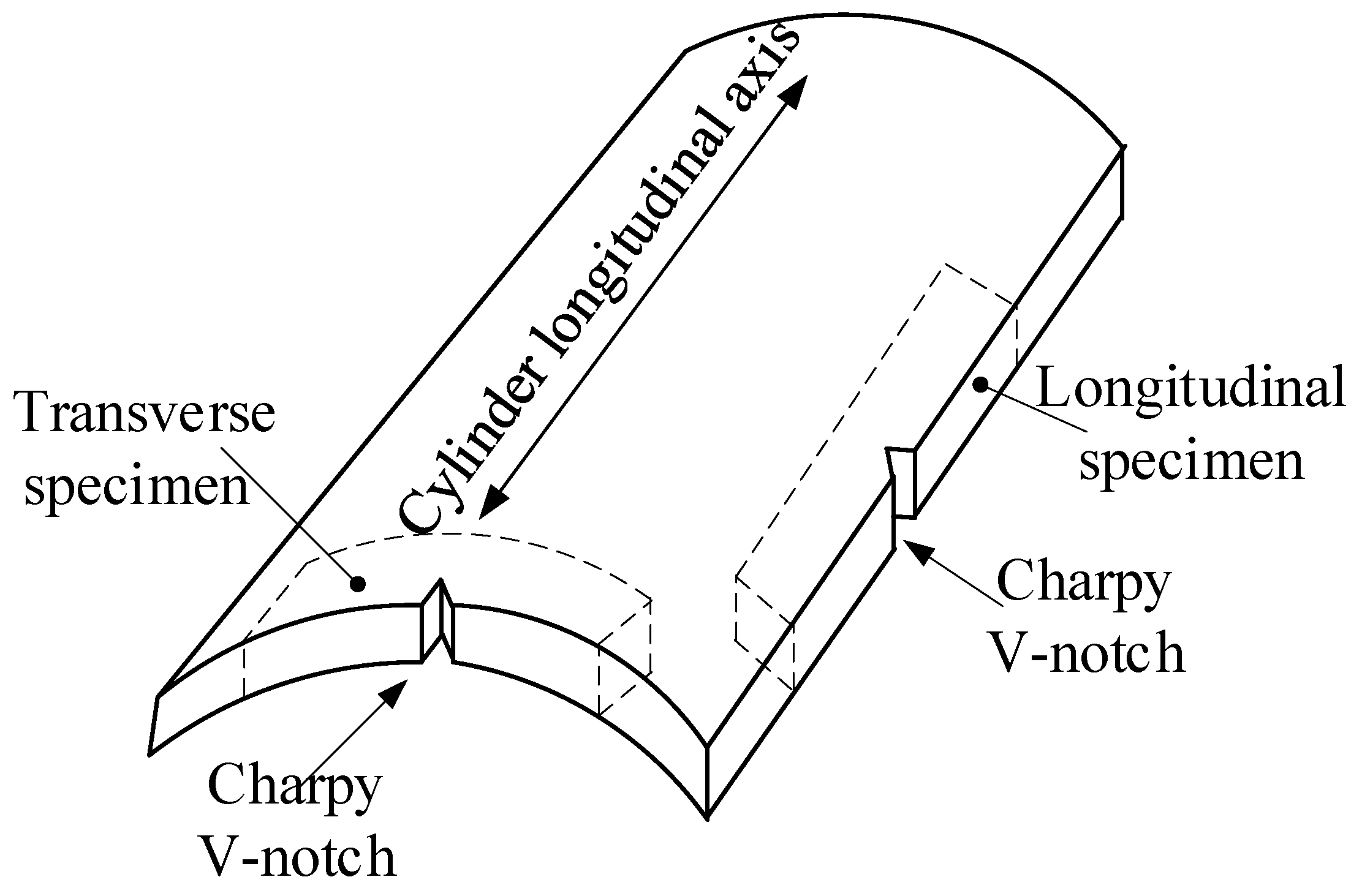

2.3. Charpy Impact Tests

2.4. Hardness Tests

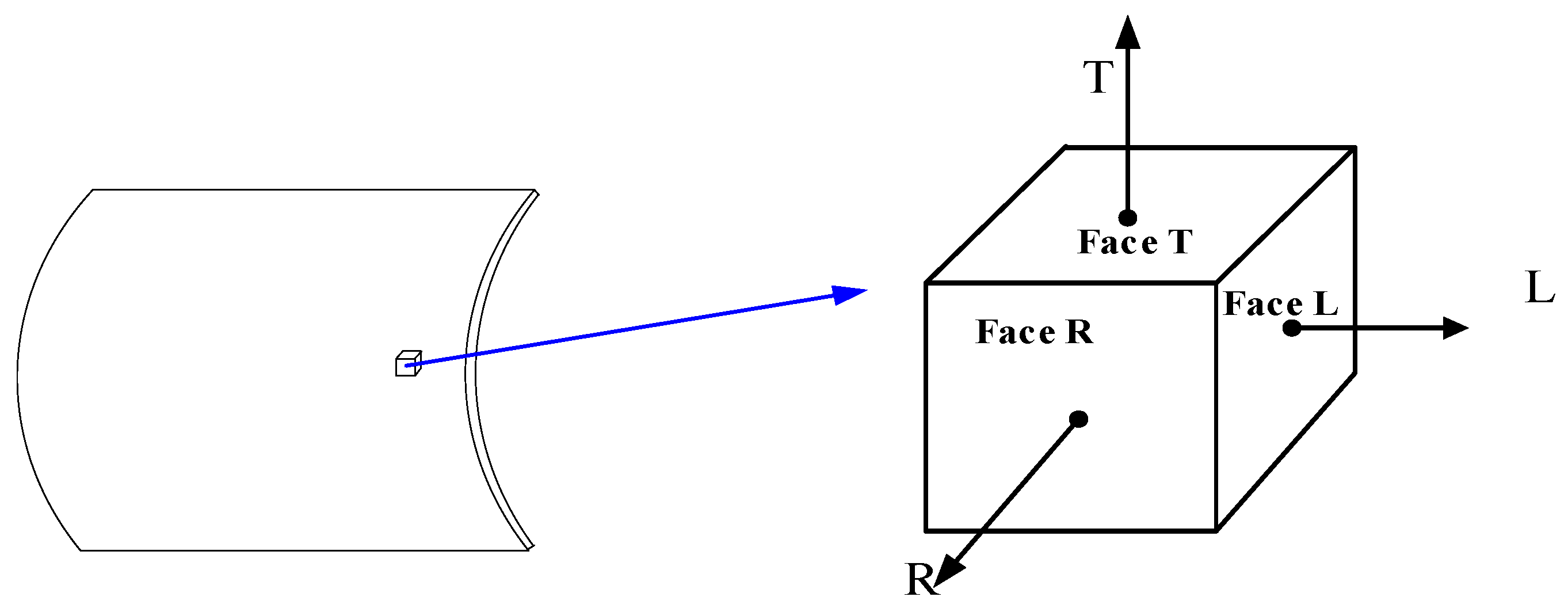

2.5. Microstructure Tests

3. Results

3.1. Mechanical Properties

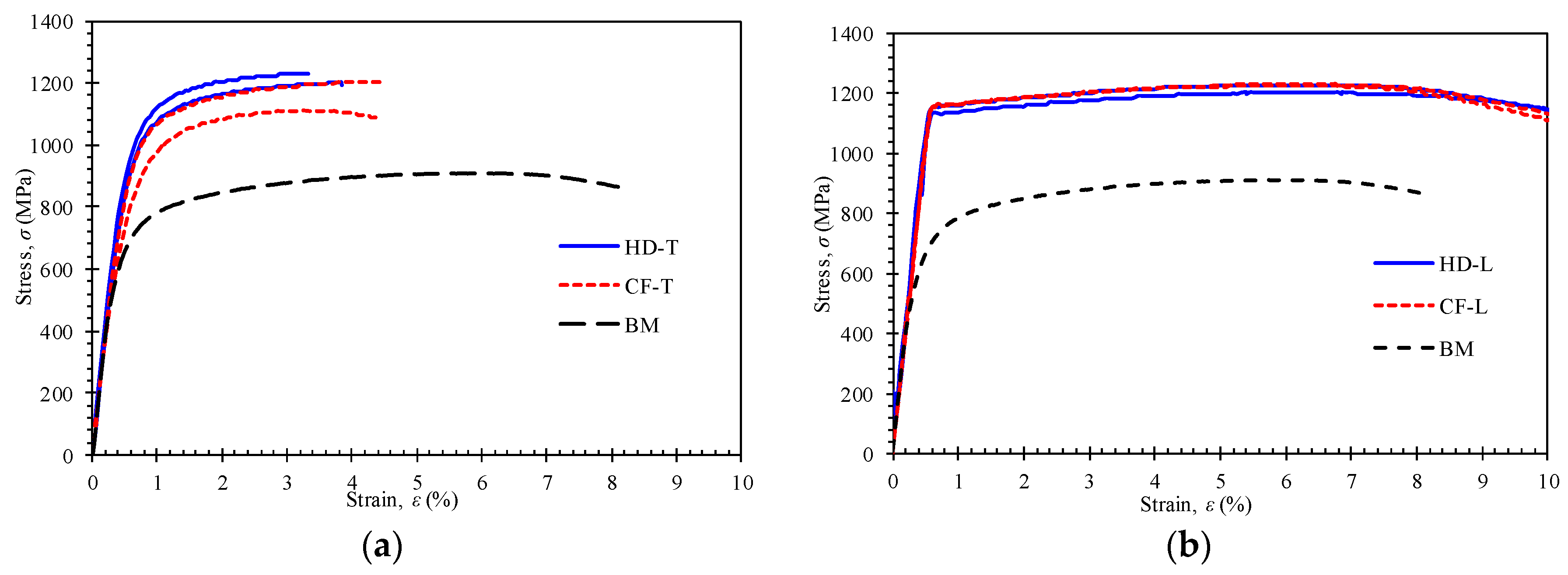

3.1.1. Tensile Properties

3.1.2. Impact Properties

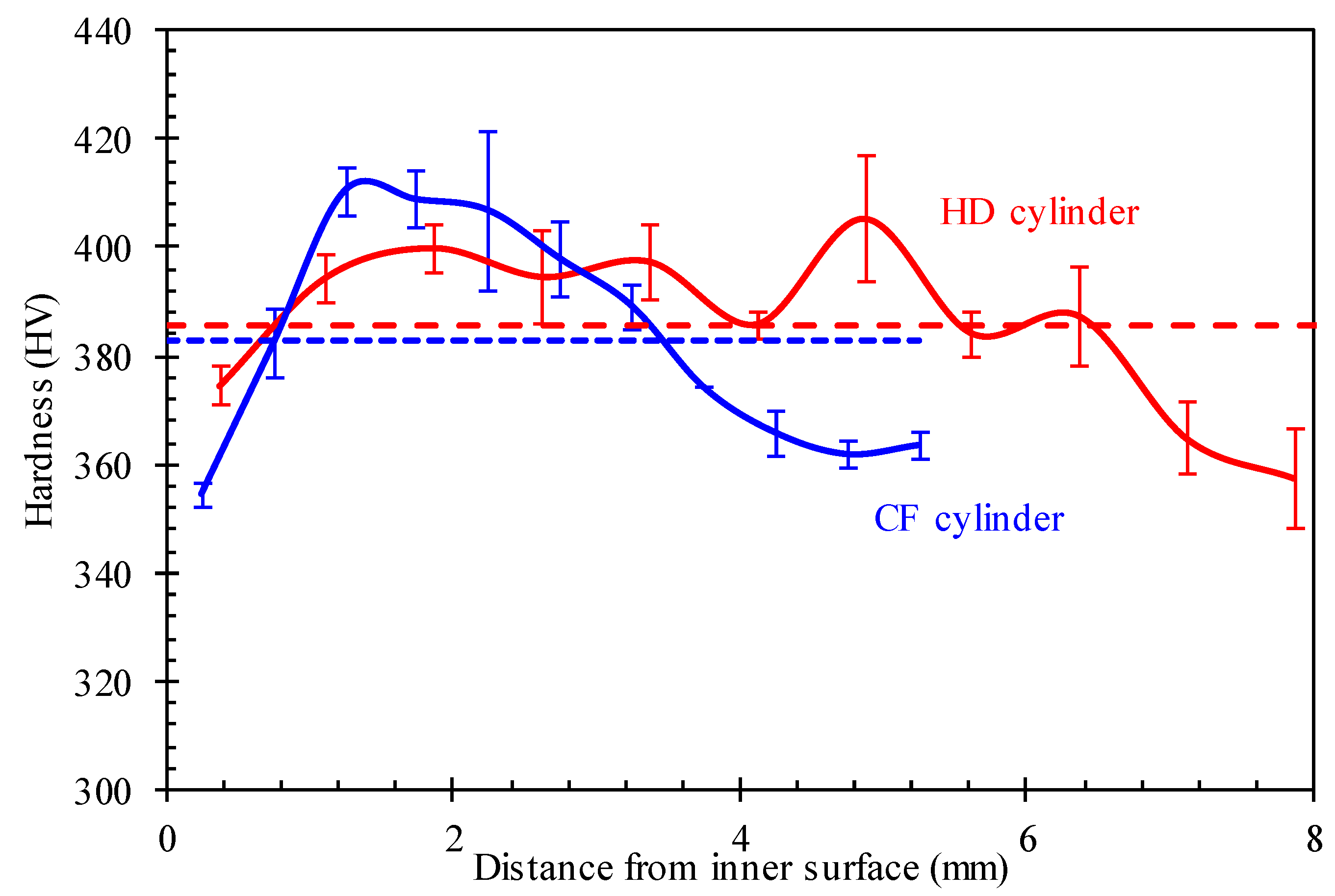

3.1.3. Hardness

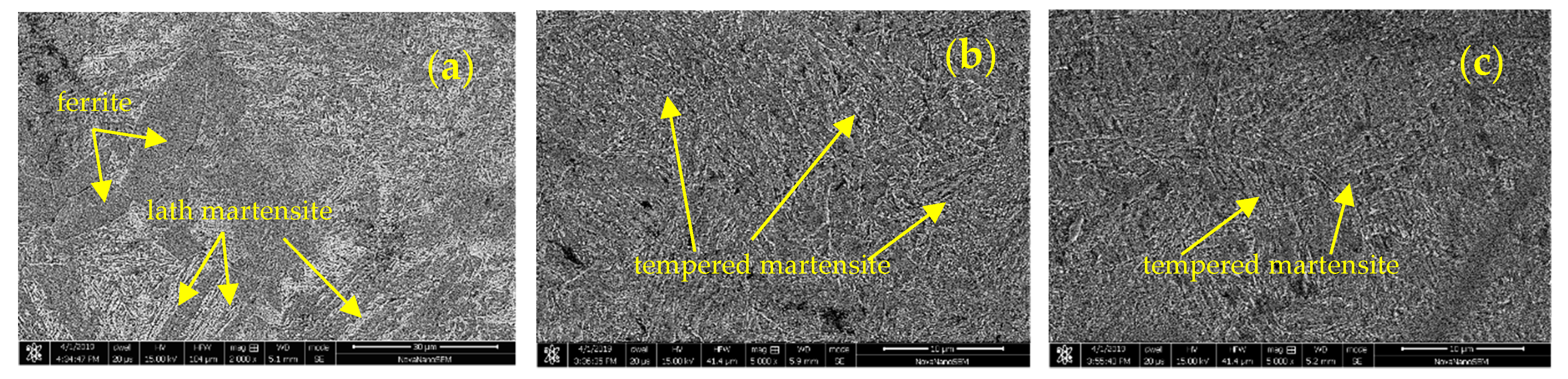

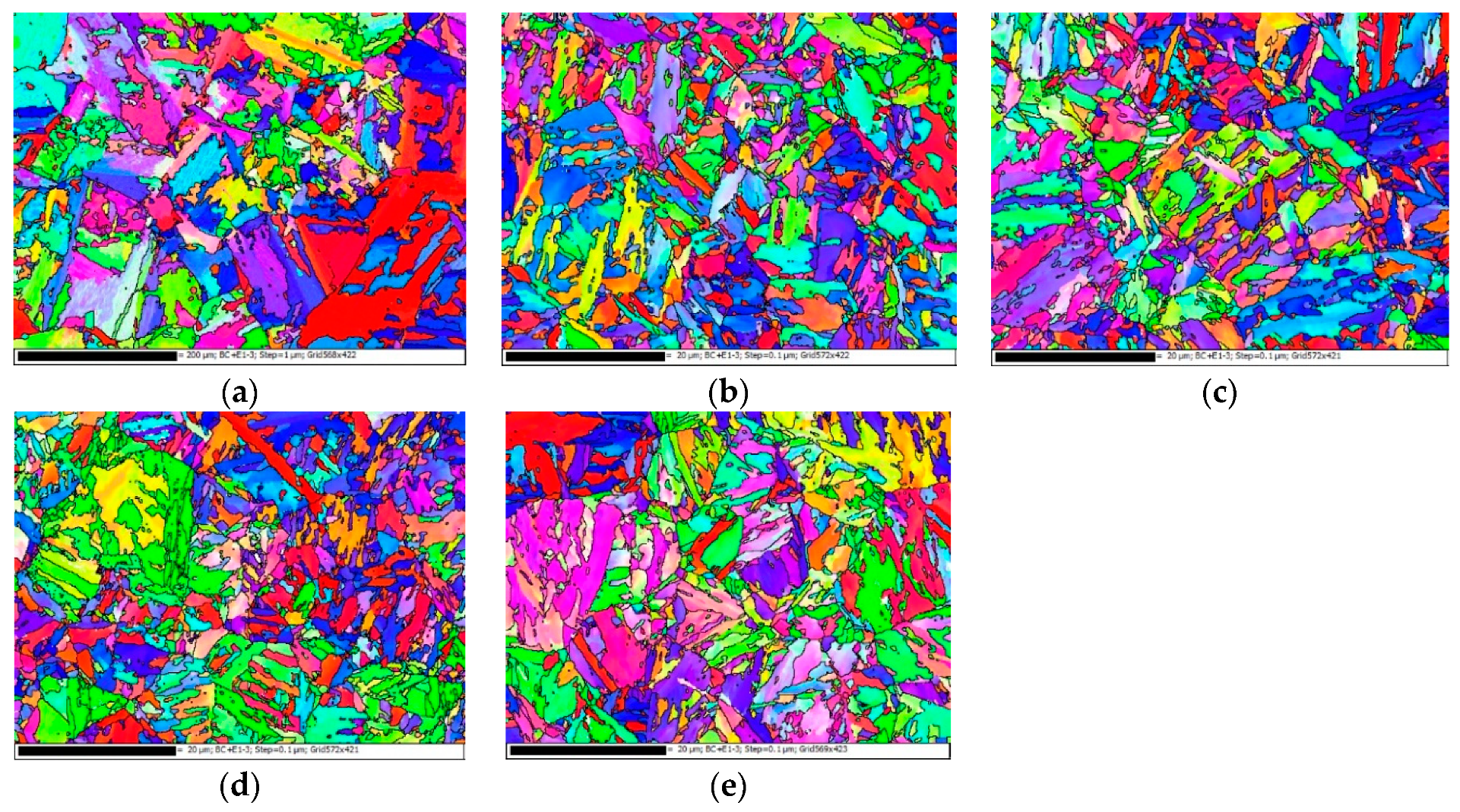

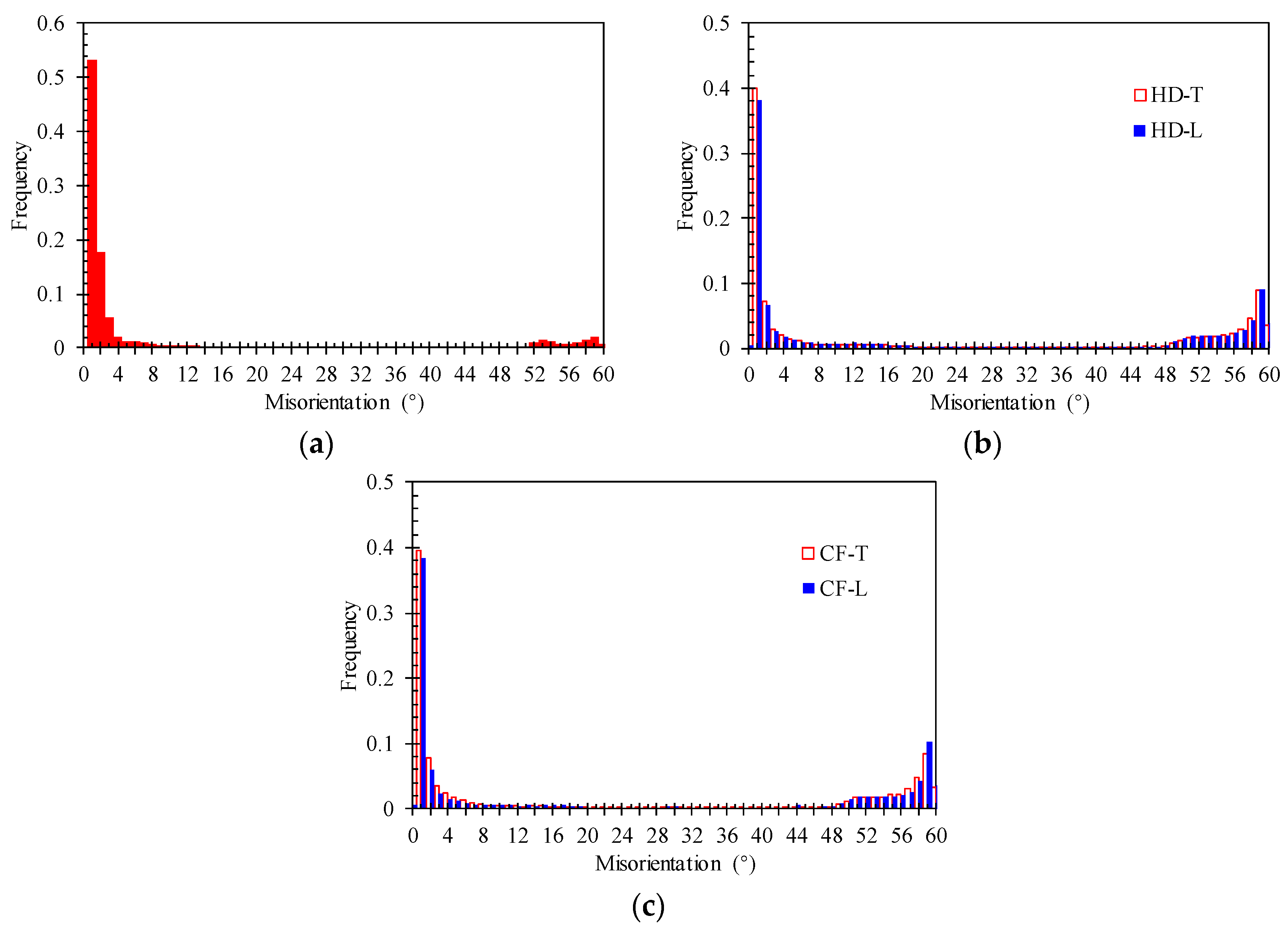

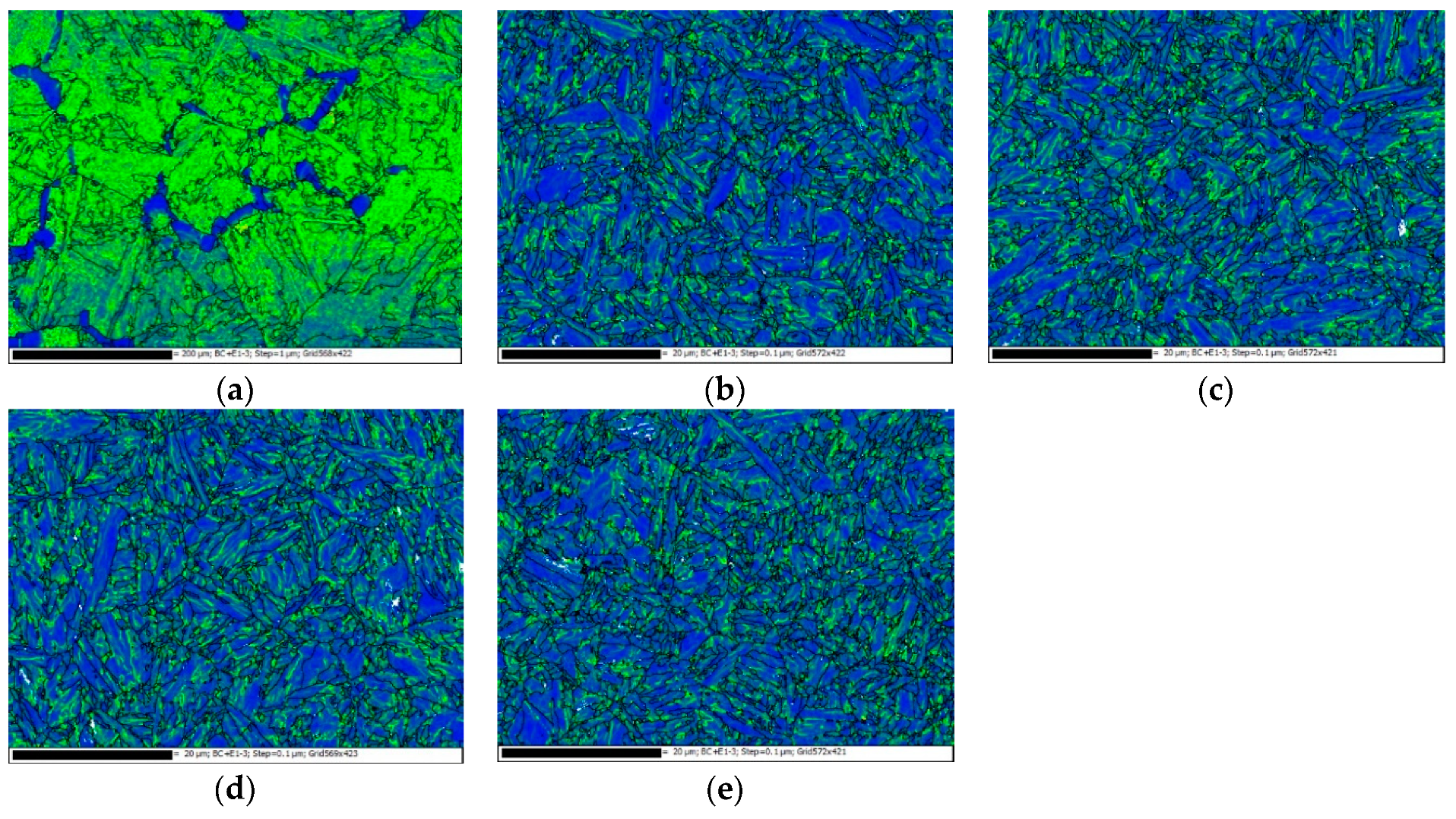

3.2. Microstructures

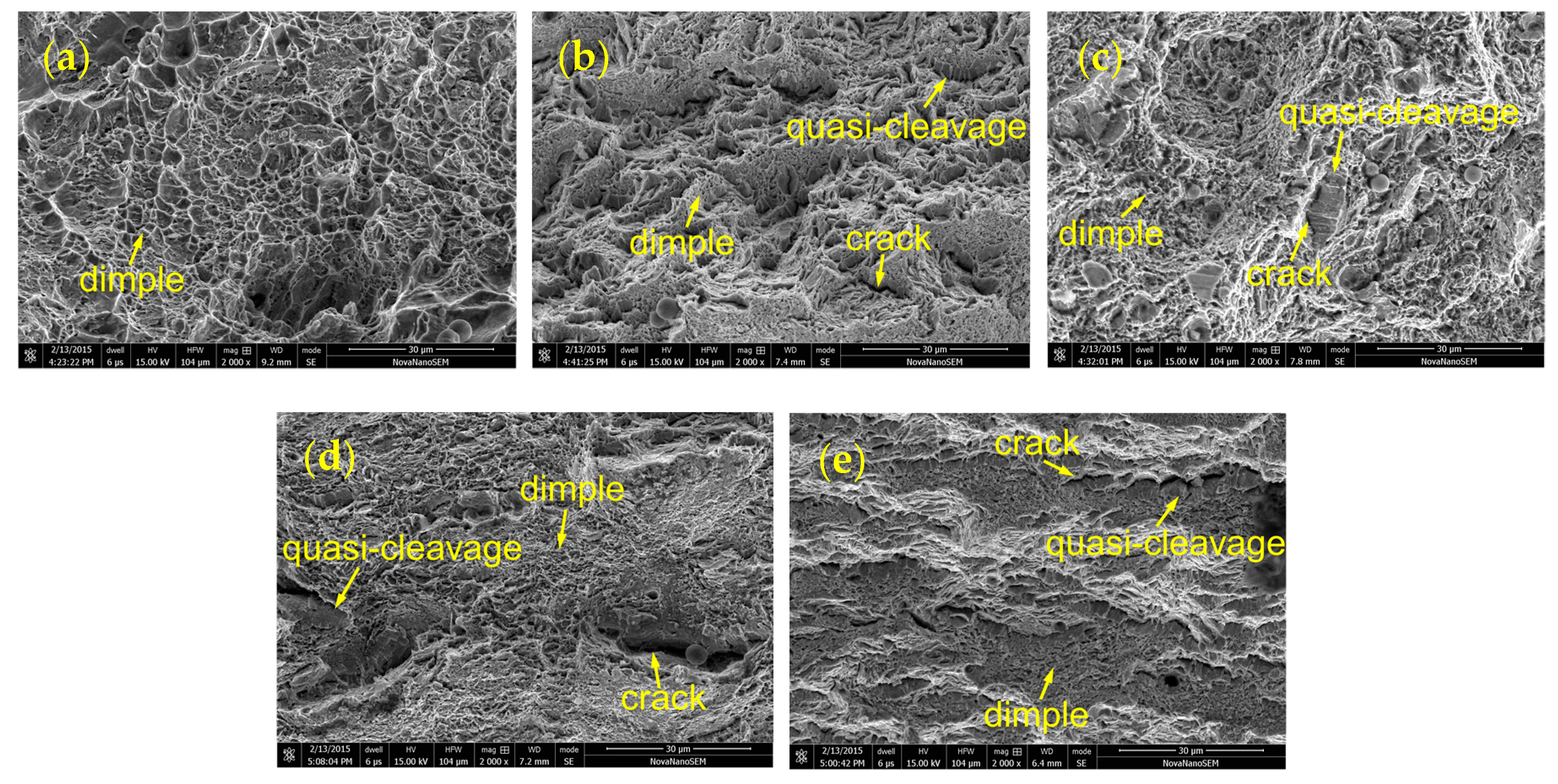

4. Discussion

5. Conclusions

- (1)

- The mechanical properties of the product cylinder materials all satisfy the requirements of the material standard. The tensile properties of the 34CrMo4 steel gas cylinders are obviously improved after the hot drawing and cold flow forming processes plus heat treatment compared with the base material. Therefore, the proposed manufacturing process and heat treatment used in the manufacture of the gas cylinders are acceptable.

- (2)

- The mechanical properties and the impact toughness of the cold flow-formed cylinder are very similar to those of the hot drawing cylinder after heat treatment. Therefore, the cold forming process would not cause a reduction of the material’s strength and the process parameters and heat treatment plan are acceptable.

- (3)

- The grain sizes of the HD and CF materials are significantly smaller than those of the BM, leading to the increase in the mechanical properties of the HD and CF materials. The microstructures of the HD and CF materials are very similar, including grain size, subgrain boundaries, and residual strain. This confirms the correctness of the processing parameters and the heat treatment plan used in the manufacture of the gas cylinders.

- (4)

- The primary sites for voids and cracks during the mechanical tests of the BM are the interfaces with large dispersion of dislocation density. Meanwhile, the voids and cracks should be preferentially initiated at and propagated along the serrated boundaries and triple joints of the grain boundaries in the HD and CF materials during the tensile and impact tests.

Author Contributions

Funding

Conflicts of Interest

References

- Demirbas, A. Fuel properties of hydrogen, liquefied petroleum gas (LPG), and compressed natural gas (CNG) for transportation. Energy Sources 2002, 24, 601–610. [Google Scholar] [CrossRef]

- Jin, W.; Li, Y.; Zhou, M.; Gao, Z. Reliability Study on a New Integrity Pressure Relief Device in Nonrefillable Steel Gas Cylinder. J. Press. Vessel Technol. Trans. ASME 2018, 140, 051602. [Google Scholar] [CrossRef]

- Nourani, M.; Sajadifar, V.; Ketabchi, M.; Milani, A.S.; Yannacopoulos, S. On the microstructural evolution of 4130 steel during hot compression. Recent Pat. Mater. Sci. 2012, 5, 74–83. [Google Scholar] [CrossRef]

- Chamberlain, S. Development of a Physics of Failure Model and Quatitative Assessment of the Fire Fatality Risks of Compressed Natural Gas Bus Cylinders. Ph.D. Thesis, University of Maryland, College Park, MD, USA, July 2004. [Google Scholar]

- Jin, W.; Li, Y.; Gao, Z.; Yin, X.; Ma, X. Reliability analysis of integral hot deep drawing and cold flow forming process for large-diameter seamless steel gas cylinders. Int. J. Adv. Manuf. Technol. 2018, 97, 1–9. [Google Scholar] [CrossRef]

- Rajan, K.; Deshpande, P.; Narasimhan, K. Effect of heat treatment of preform on the mechanical properties of flow formed AISI 4130 Steel Tubes—a theoretical and experimental assessment. J. Mater. Process. Technol. 2002, 125, 503–511. [Google Scholar] [CrossRef]

- FAR, S.V.; Ketabchi, M.; Nourani, M.R. Hot deformation characteristics of 34CrMo4 steel. Iron Steel Res. Int. 2010, 17, 65. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Ketabchi, M.; Nourani, M. Modeling of mechanical characteristics in hot deformation of 4130 steel. Steel Res. Int. 2011, 82, 934–939. [Google Scholar] [CrossRef]

- Wuertemberger, L.; Palazotto, A.N. Evaluation of Flow and Failure Properties of Treated 4130 Steel. J. Dyn. Behav. Mater. 2016, 2, 207–222. [Google Scholar] [CrossRef]

- Piao, M.; Huh, H.; Lee, I.; Park, L. Characterization of hardening behaviors of 4130 Steel, OFHC Copper, Ti6Al4V alloy considering ultra-high strain rates and high temperatures. Int. J. Mech. Sci. 2017, 131, 1117–1129. [Google Scholar] [CrossRef]

- Xu, W.; Zou, M.; Zhang, L. Constitutive analysis to predict the hot deformation behavior of 34CrMo4 steel with an optimum solution method for stress multiplier. Int. J. Pressure Vessels Pip. 2014, 123, 70–76. [Google Scholar] [CrossRef]

- Marini, D.; Cunningham, D.; Xirouchakis, P.; Corney, J.R. Flow forming: A review of research methodologies, prediction models and their applications. Int. J. Mech. Eng. Tech. 2016, 7, 285–315. [Google Scholar]

- Wang, C.C.; Danno, A.; Tong, K.K.; Yong, M.S. Cold rotary forming of thin-wall component from flat-disc blank. J. Mater. Process. Technol. 2008, 208, 53–62. [Google Scholar] [CrossRef]

- Wong, C.C.; Dean, T.A.; Lin, J. Incremental forming of solid cylindrical components using flow forming principles. J. Mater. Process. Technol. 2004, 153, 60–66. [Google Scholar] [CrossRef]

- Tsivoulas, D.; Da Fonseca, J.; Tuffs, M.; Preuss, M. Measurement and modelling of textures in flow formed Cr-Mo-V steel tubes. Mater. Sci. Eng. A 2017, 685, 7–18. [Google Scholar] [CrossRef]

- Wang, X.; Zhan, M.; Fu, M.; Gao, P.; Guo, J.; Ma, F. Microstructure evolution of Ti-6Al-2Zr-1Mo-1V alloy and its mechanism in multi-pass flow forming. J. Mater. Process. Technol. 2018, 261, 86–97. [Google Scholar] [CrossRef]

- Maj, P.; Błyskun, P.; Kut, S.; Romelczyk-Baishya, B.; Mrugała, T.; Adamczyk-Cieslak, B.; Mizera, J. Flow forming and heat-treatment of Inconel 718 cylinders. J. Mater. Process. Technol. 2018, 253, 64–71. [Google Scholar] [CrossRef]

- Rajan, K.M.; Narasimhan, K. An investigation of the development of defects during flow forming of high strength thin wall steel tubes. Practical Fail. Anal. 2001, 1, 69–76. [Google Scholar] [CrossRef]

- Podder, B.; Mondal, C.; Ramesh, K.K.; Yadav, D.R. Effect of preform heat treatment on the flow formability and mechanical properties of AISI4340 steel. Mater. Des. 2012, 37, 174–181. [Google Scholar] [CrossRef]

- BS EN 10083-3. Steels for Quenching and Tempering—Part 3: Technical Delivery Conditions for Alloy Steels; British Standards Institution: London, UK, 2006.

- Mandal, A.; Syed, B.; Bhandari, K.; Bhattacharya, B.; Deb, A.; Singh, S.B.; Chakrabarti, D. Cold-bending of linepipe steel plate to pipe, detrimental or beneficial? Mater. Sci. Eng. A 2019, 746, 58–72. [Google Scholar] [CrossRef]

- Sohn, S.S.; Han, S.Y.; Shin, S.Y.; Bae, J.; Lee, S. Effects of microstructure and pre-strain on Bauschinger effect in API X70 and X80 linepipe steels. Met. Mater. Int. 2013, 19, 423–431. [Google Scholar] [CrossRef]

- Sohn, S.S.; Han, S.Y.; Bae, J.; Kim, H.S.; Lee, S. Effects of microstructure and pipe forming strain on yield strength before and after spiral pipe forming of API X70 and X80 linepipe steel sheets. Mater. Sci. Eng. A 2013, 573, 18–26. [Google Scholar] [CrossRef]

- Lu, C.; He, Y.; Gao, Z.; Yang, J.; Jin, W.; Xie, Z. Microstructural evolution and mechanical characterization for the A508–3 steel before and after phase transition. J. Nucl. Mater. 2017, 495, 103–110. [Google Scholar] [CrossRef]

- Masoumi, M.; Barros, I.; Herculano, L.F.G.; Coelho, H.L.F.; Abreu, H.F.G. Effect of microstructure and crystallographic texture on the Charpy impact test for maraging 300 steel. Mater. Charact. 2016, 120, 203–209. [Google Scholar] [CrossRef]

- Lawrence, S.K.; Somerday, B.P.; Moody, N.R.; Bahr, D.F. Grain Boundary Contributions to Hydrogen-Affected Plasticity in Ni-201. JOM 2014, 66, 1383–1389. [Google Scholar] [CrossRef]

- Rasooli, M.; Moshref-javadi, M.; Taherizadeh, A. Investigation of ultrasonic vibration effects on the microstructure and hardness of aluminum alloy 2024 tube spinning parts. Int. J. Adv. Manuf. Technol. 2015, 77, 2117–2124. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, F.; Dong, J.; Jin, L.; Liu, C.; Ding, W. Grain refinement and orientation of AZ31B magnesium alloy in hot flow forming under different thickness reductions. J. Mater. Sci. Tech. 2018, 34, 1091–1102. [Google Scholar] [CrossRef]

- Kučera, P.; Mazancová, E. Relation between the grain size development and mechanical properties of 34CrMo4 steel after four types of treatment. In Proceedings of the Metal 2015, Brno, Czech Republic, 3–5 June 2015. [Google Scholar]

- Xiao, B.; Xu, L.; Tang, Z.; Zhao, L.; Jing, H.; Han, Y.; Li, H. A physical-based yield strength model for the microstructural degradation of G115 steel during long-term creep. Mater. Sci. Eng. A 2019, 747, 161–176. [Google Scholar] [CrossRef]

- Lu, C.; He, Y.; Yang, J.; Zheng, W.; Xie, Z.; Gao, Z. An investigation of phase transition on the microstructural characteristic and creep behavior for the SA508 Gr.3 steel used for nuclear reactor pressure vessels. Mater. Sci. Eng. A 2018, 711, 659–669. [Google Scholar] [CrossRef]

| Source | C | Si | Mn | S | P | Cr | Mo | Ni | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Measured | 0.36 | 0.23 | 0.71 | 0.003 | 0.012 | 1.06 | 0.23 | 0.044 | 0.022 | Balance |

| BS EN 10083-3 [20] | 0.30–0.37 | Max. 0.40 | 0.60–0.90 | Max. 0.035 | Max. 0.025 | 0.90–1.20 | 0.15–0.30 | - | - | - |

| Specimen Name | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| BM | 674 ± 4.5 | 913 ± 3.1 | 16.0 ± 0.4 |

| HD-L | 1142 ± 10.3 | 1214 ± 11.4 | 16.0 ± 0.5 |

| HD-T | 988 ± 25.4 | 1215 ± 17 | 13.0 ± 0.1 |

| CF-L | 1164 ± 3.3 | 1230 ± 0.4 | 15.5 ± 0.5 |

| CF-T | 975 ± 23.7 | 1207 ± 0.2 | 12.5 ± 0.2 |

| BS EN 10083-3 [20] | Min. 650 | 900–1100 | 12 |

| Specimen Name | Width (mm) | Depth (mm) | Cross-Section Area (cm2) | Impact Energy (J) | Impact Toughness (J/cm2) |

|---|---|---|---|---|---|

| HD-L | 25 | 8.05 | 2.01 | 85.3 ± 5.3 | 42.4 ± 2.6 |

| HD-T | 25 | 8.10 | 2.03 | 85.5 ± 5.5 | 42.2 ± 2.7 |

| CF-L | 25 | 4.95 | 1.24 | 69.6 ± 4.5 | 54.3 ± 1.8 |

| CF-T | 25 | 5.75 | 1.44 | 75.0 ± 4.8 | 50.4 ± 1.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Fang, W.; Lu, C.; Gao, Z.; Ma, X.; Jin, W.; Ye, Y.; Wang, F. Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming. Materials 2019, 12, 1351. https://doi.org/10.3390/ma12081351

Li Y, Fang W, Lu C, Gao Z, Ma X, Jin W, Ye Y, Wang F. Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming. Materials. 2019; 12(8):1351. https://doi.org/10.3390/ma12081351

Chicago/Turabian StyleLi, Yuebing, Wei Fang, Chuanyang Lu, Zengliang Gao, Xiakang Ma, Weiya Jin, Yufeng Ye, and Fenghuai Wang. 2019. "Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming" Materials 12, no. 8: 1351. https://doi.org/10.3390/ma12081351

APA StyleLi, Y., Fang, W., Lu, C., Gao, Z., Ma, X., Jin, W., Ye, Y., & Wang, F. (2019). Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming. Materials, 12(8), 1351. https://doi.org/10.3390/ma12081351