Material Characterization of PMC/TBC Composite Under High Strain Rates and Elevated Temperatures

Abstract

:1. Introduction

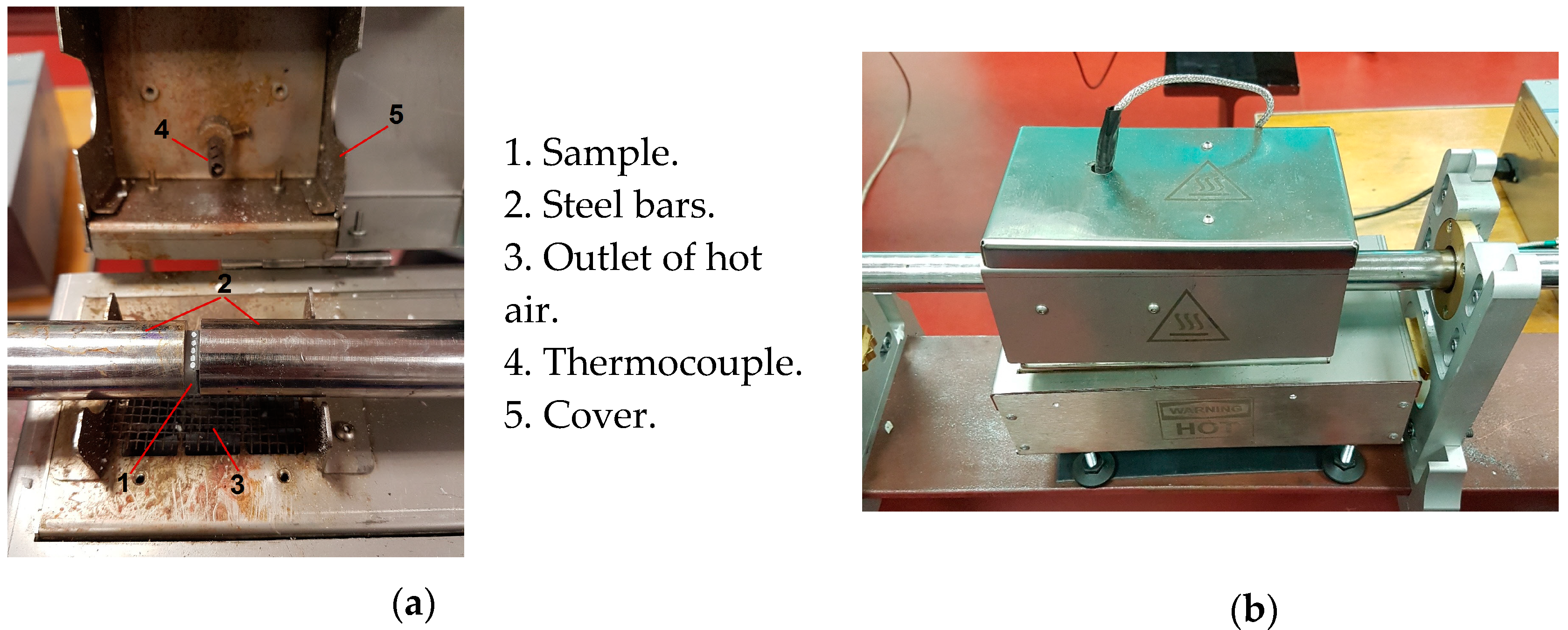

2. Research Using SHPB

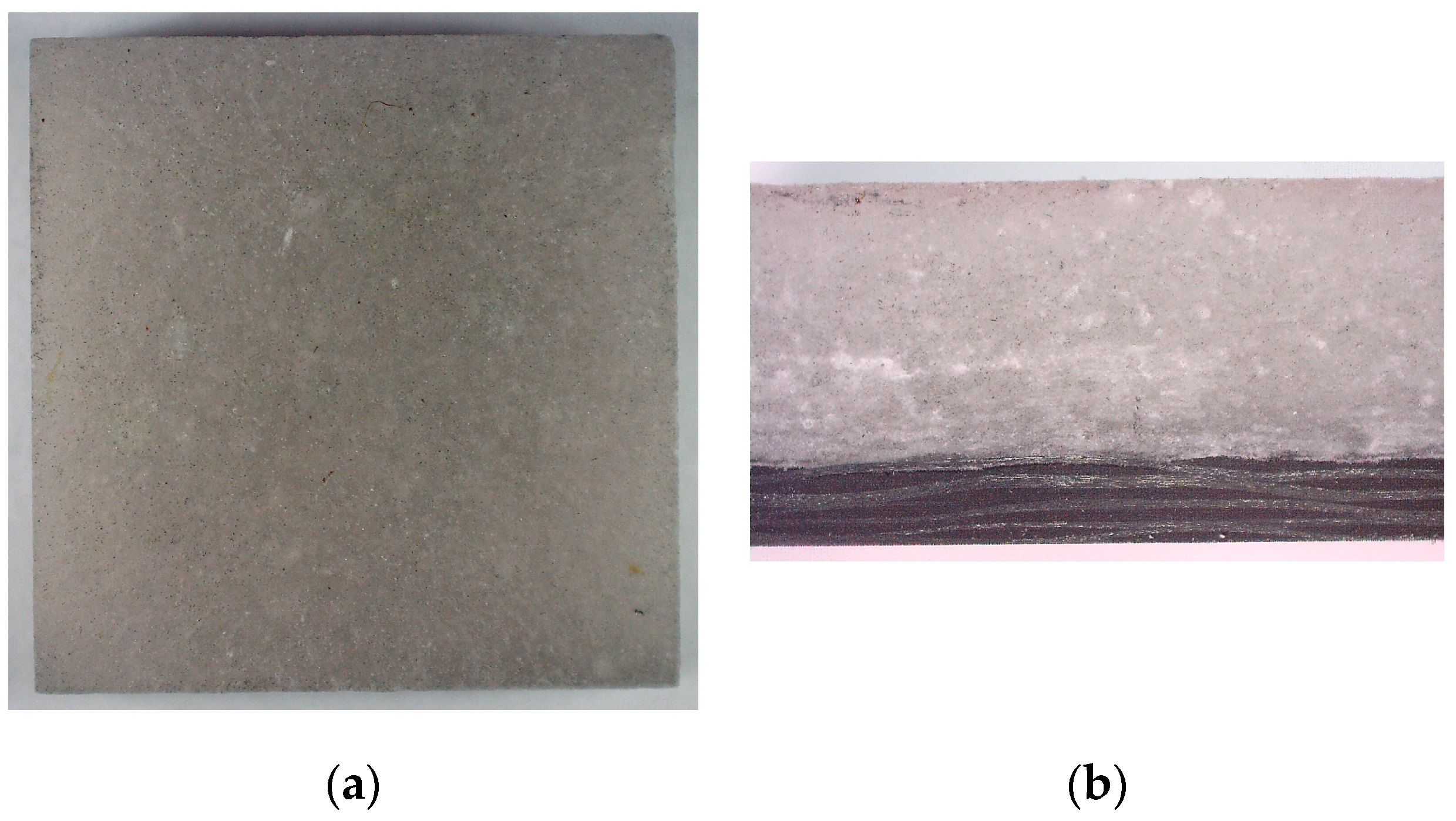

3. Materials and Methodology

4. Results and Discussion

4.1. Static Tests

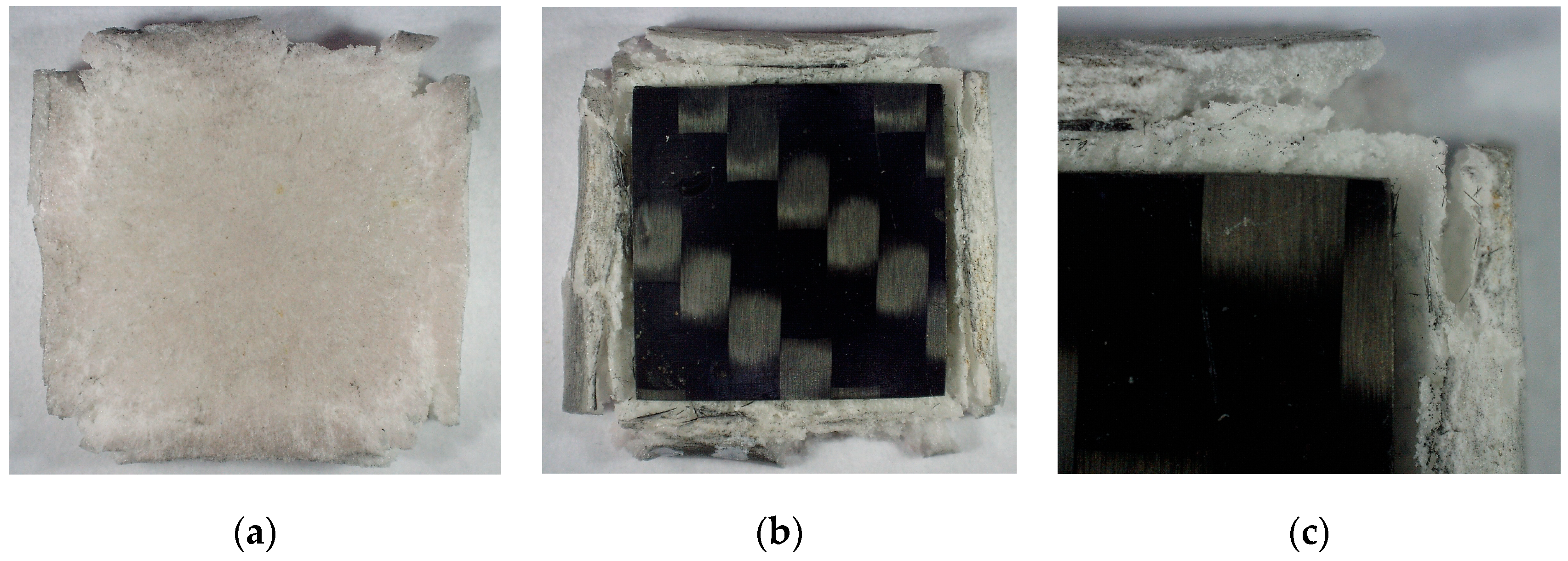

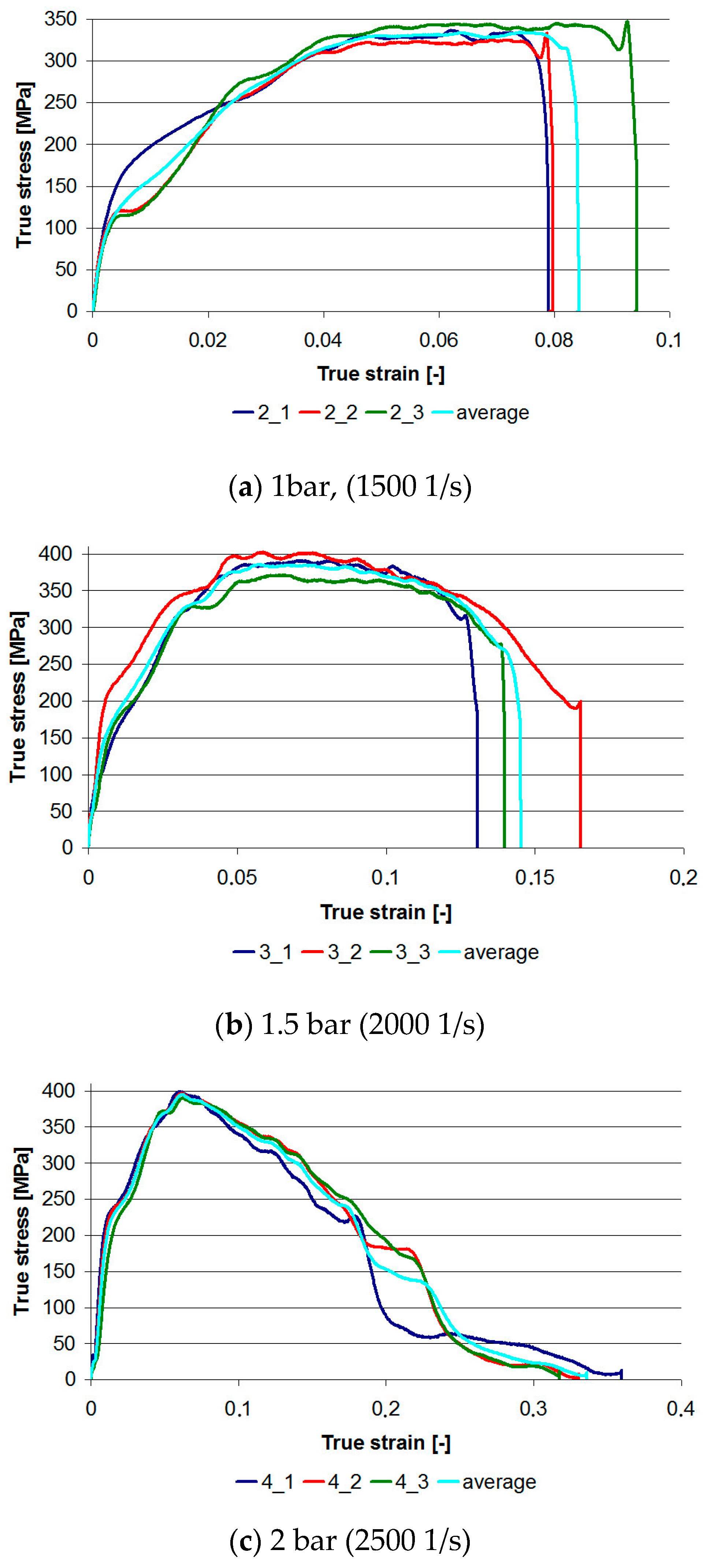

4.2. Dynamic Tests at Ambient Temperature

- With increasing impact velocity, repeatability of results is higher; however, to prove this thesis, it is necessary to perform tests on series with greater numbers of samples. Of course, there is no claim that the differences in the graphs are in the last stage when the sample is destroyed in an uncontrolled manner. However, for sample 1 and load 1 bar, and sample 2 and load 2 bar, there are differences in the first stage of loading.

- As the velocity of impact increases, the elastic limit increases: The elastic limit can be taken as the end of a straight section. It is especially noticeable for 1 bar and 2 bar loads. The elastic limits determined on the basis of the graphs are: 100 MPa, 160 MPa, and 220 MPa respectively, for 1, 1.5, and 2 bar loads or corresponding strain rates ≈1500, ≈2000, and ≈2500 1/s. The dynamic modulus, whose determination methods are presented in [30], was also increasing.

- There is a limit value for dynamic strength: As the load velocity increases, the maximum stress value increases from 350 MPa for a load of 1 bar to 400 MPa for a load of 1.5 bar. A similar value was also obtained for a 2 bar load.

- The nature of the damage can be determined from the shape of the graph.

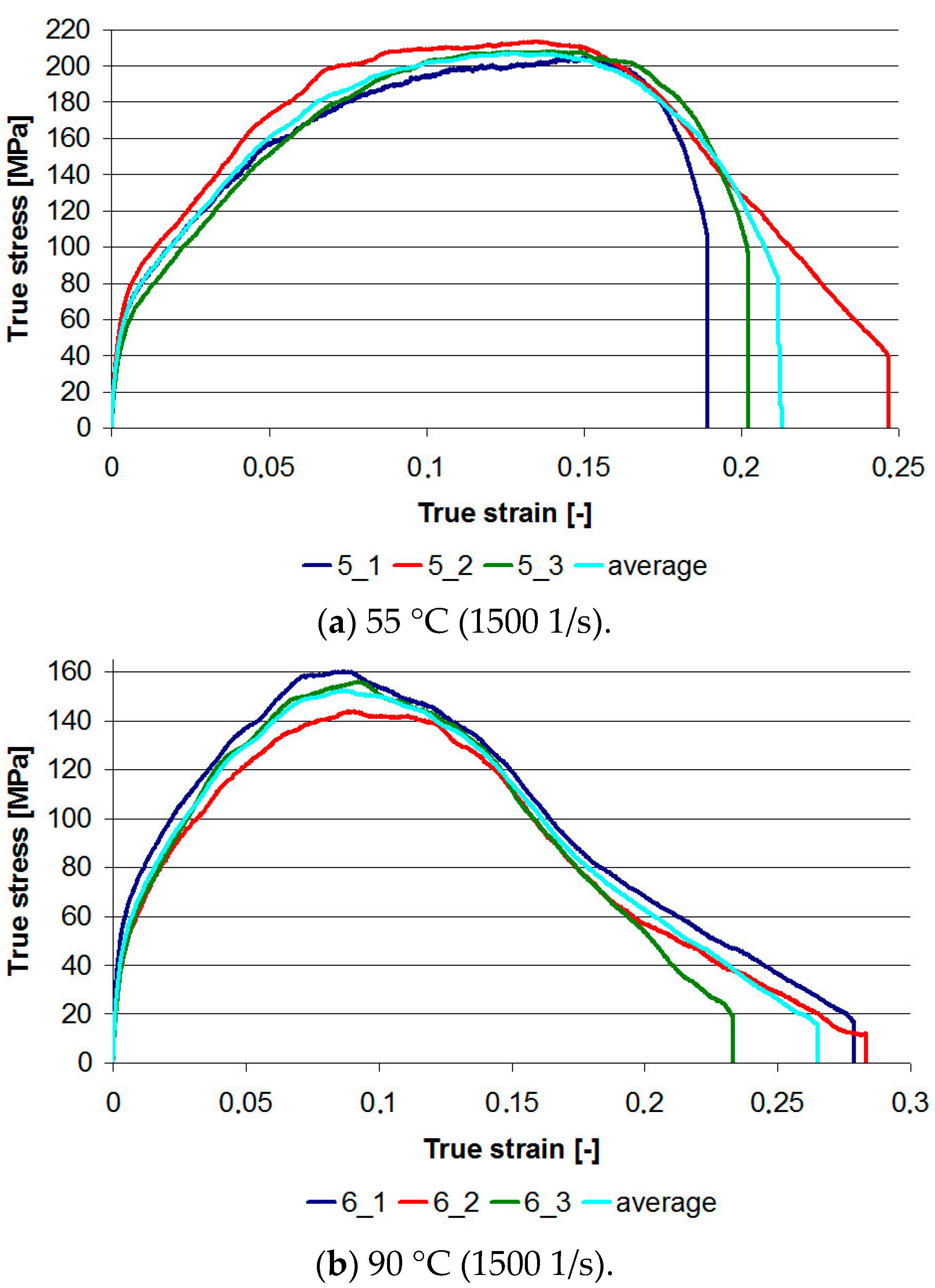

4.3. Dynamic Tests at Elevated Temperatures

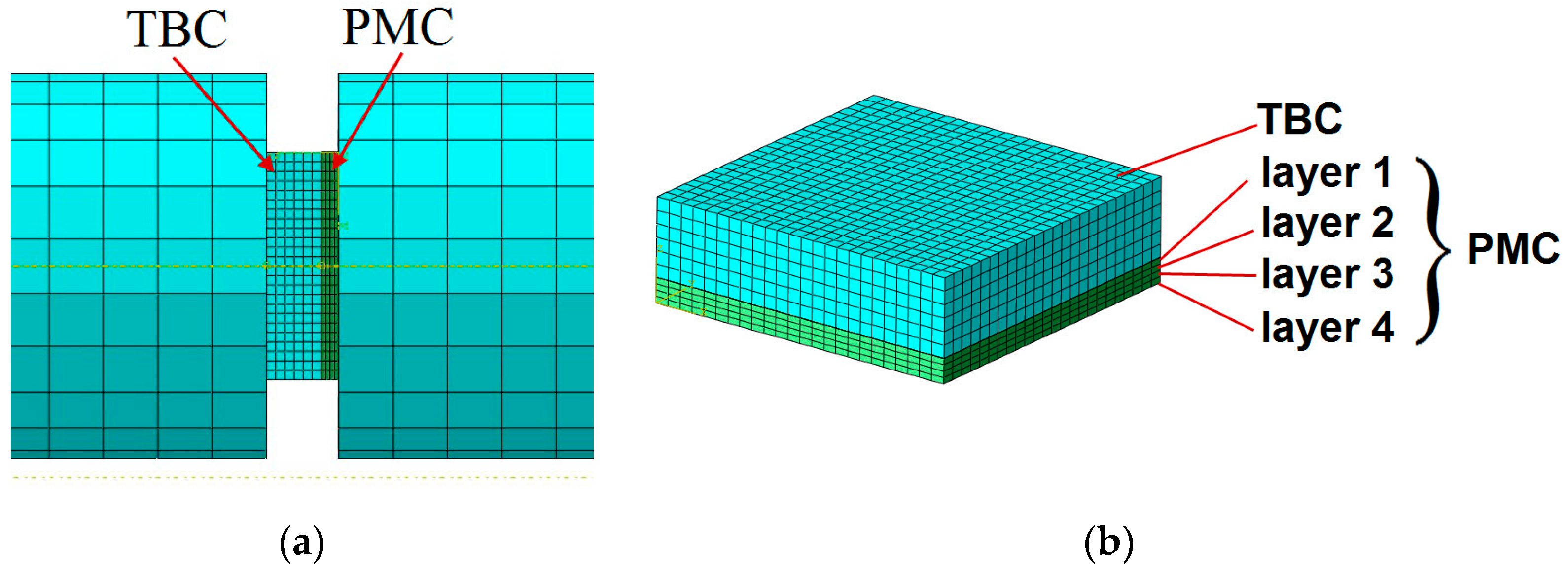

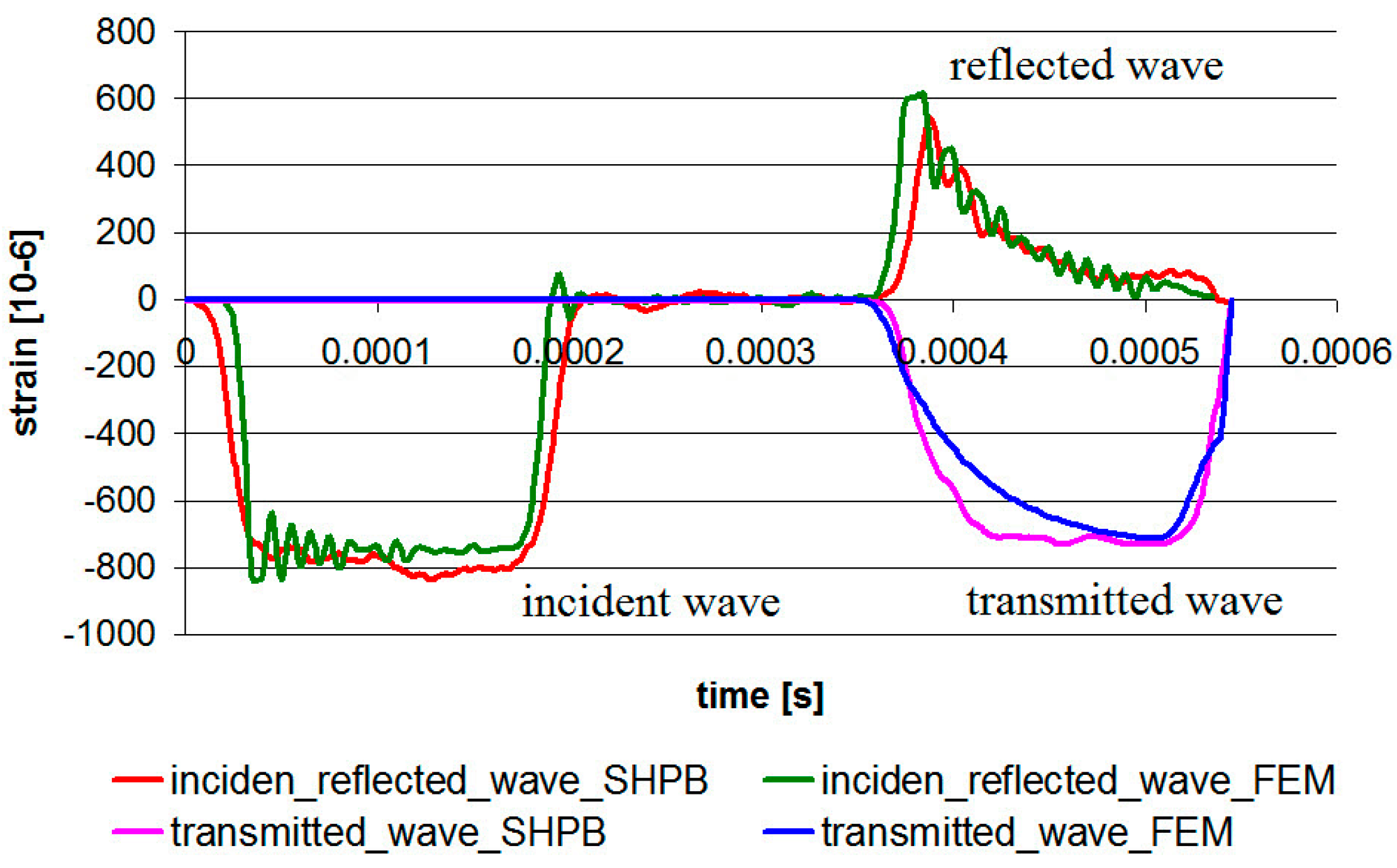

5. Numerical Studies

- σ11—the normal stresses in the first direction;

- σ22—the normal stresses in the second direction;

- τ12—the shear stresses;

- X1—the tensile strength in the first direction;

- X2—the tensile strength in the second direction;

- S—the shear strength.

6. Conclusions

- The technology presented in this work is not expensive and can be used to protect large composite objects.

- The dynamic load limit that the PMC/TBC structure may undergo has been determined. It corresponds to a pressure of 1 bar (strain rate ≈1500 1/s) and an impact speed V0 in the range of 7.73–8.26 m/s.

- Increasing the operating temperature of the PMC/TBC system to 90 °C results in a reduction of the dynamic strength of the protective coating by about 50%. Therefore, further research should be carried out for other materials stiffening the ceramic mat.

- The numerical model was made in the Abaqus program. Its version without damage description successfully predicted the elastic behavior of the PMC/TBC structure. The results obtained in the numerical simulation are consistent with the laboratory tests. The small difference in comparison to the experiments was due to imperfectly cubic samples’ geometry and lack of an ideal contact between bars and sample surfaces. A numerical model will be developed to include gradual degradation of the PMC/TBC structure under impact to the final failure.

- The FEM simulation allowed for a detailed determination of the effort of the substrate material and the protective layer. The stress in the protective layer was 300.2 MPa, while the effort in each layer of the composite was very low; i.e., did not exceed 53%.

- The reduced H–M–H stress distributions obtained in FEM simulation are consistent with images of damaged samples after laboratory tests. The middle part of the sample has the least effort, and the material begins to be damaged from the sample edges.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sadowski, T.; Golewski, P. The analysis of heat transfer and thermal stresses in thermal barrier coatings under exploitation. Defect Diffus. Forum 2012, 326, 530–535. [Google Scholar] [CrossRef]

- Tsai, J.; Sun, C.T. Dynamic compressive strengths of polymeric composites. Int. J. Solids Struct. 2004, 41, 3211–3224. [Google Scholar] [CrossRef]

- Luo, H.; Roy, S.; Lu, H. Dynamic compressive behavior of unidirectional IM7/5250-4 laminate after thermal oxidation. Compos. Sci. Technol. 2012, 72, 159–166. [Google Scholar] [CrossRef]

- Małachowska, A.; Winnicki, M.; Stachowicz, M.; Korzeniowski, M. Metallisation of polycarbonates using a low pressure cold spray method. Surf. Eng. 2018, 34, 251–258. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. A novel application of alumina fiber mats as TBC protection for CFRP/epoxy laminates—Laboratory tests and numerical modeling. J. Eur. Ceram. Soc. 2018, 38, 2920–2927. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. Description of thermal protection against heat transfer of carbon fiber reinforced plastics (CFRP) coated by stiffened ceramic mat (TBC). Compos. Struct. 2019, 229, 111489. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. The influence of TBC aging on crack propagation due to foreign object impact. Materials 2019, 12, 1488. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, T.; Golewski, P. Numerical and experimental analysis of foreign objects impact into the surface with TBC coating. Solid State Phenom. 2016, 254, 224–230. [Google Scholar] [CrossRef]

- Massaq, A.; Rusinek, A.; Klósak, M.; Boulouz, A.; Koutti, L. Analysis of the composite material behaviour subjected to dynamic bending using the Hopkinson Bar. Eng. Trans. 2016, 64, 115–131. [Google Scholar]

- Arbaoui, J.; Tarfaoui, M.; El Malki Alaoui, A. Mechanical behavior and damage kinetics of woven E-glass/vinylester laminate composites under high strain rate dynamic compressive loading: Experimental and numerical investigation. Int. J. Impact Eng. 2016, 87, 44–54. [Google Scholar] [CrossRef]

- Guedes, R.M.; De Moura, M.F.S.F.; Ferreira, F.J. Failure analysis of quasi-isotropic CFRP laminates under high strain rate compression loading. Compos. Struct. 2008, 84, 362–368. [Google Scholar] [CrossRef]

- Qian, X.; Wang, H.; Zhang, D.; Wen, G. High strain rate out-of-plane compression properties of aramid fabric reinforced polyamide composite. Polym. Test. 2016, 53, 314–322. [Google Scholar] [CrossRef]

- Reisa, V.L.; Opeltc, C.V.; Cândidoa, G.M.; Rezendec, M.C.; Donadona, M.V. Effect of fiber orientation on the compressive response of plain weave carbon fiber/epoxy composites submitted to high strain rates. Compos. Struct. 2018, 203, 952–959. [Google Scholar] [CrossRef]

- Ninan, L.; Tsai, J.; Sun, C.T. Use of split Hopkinson pressure bar for testing off-axis composites. Int. J. Impact Eng. 2001, 25, 291–313. [Google Scholar] [CrossRef]

- Hosur, M.V.; Alexander, J.; Vaidya, U.K.; Jeelani, S. High strain rate compression response of carbon/epoxy laminate composites. Compos. Struct. 2001, 52, 405–417. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Choukri, S.; Neme, A. Effect of fibre orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef] [Green Version]

- Sassi, S.; Tarfaoui, M.; Yahia, H.B. An investigation of in-plane dynamic behavior of adhesively-bonded composite joints under dynamic compression at high strain rate. Compos. Struct. 2018, 191, 168–179. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Lv, L.; Sun, B.; Qiu, Y.; Gu, B. Transverse impact behavior and energy absorption of three-dimensional orthogonal hybrid woven composites. Compos. Struct. 2007, 81, 202–209. [Google Scholar] [CrossRef]

- Pankow, M.; Waas, A.M.; Yen, C.F.; Ghiorse, S. Modeling the response. strength and degradation of 3D woven composites subjected to high rate loading. Compos. Struct. 2012, 94, 1590–1604. [Google Scholar] [CrossRef]

- Gillespie, J.W., Jr.; Gama, B.A.; Cichanowski, C.E.; Xiao, J.R. Interlaminar shear strength of plain weave S2-glass/SC79 composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2005, 65, 1891–1908. [Google Scholar] [CrossRef]

- Pankow, M.; Salvi, A.; Waas, A.M.; Yen, C.F.; Ghiorse, S. Split Hopkinson pressure bar testing of 3D woven composites. Compos. Sci. Technol. 2011, 71, 1196–1208. [Google Scholar] [CrossRef]

- Gu, B.; Chang, F.-K. Energy absorption features of 3-D braided rectangular composite under different strain rates compressive loading. Aerosp. Sci. Technol. 2007, 11, 535–545. [Google Scholar] [CrossRef]

- Gao, X.; Sun, B.; Gu, B. Damage mechanisms of 3-D rectangular braided composite under multiple impact compressions. Aerosp. Sci. Technol. 2018, 82, 46–60. [Google Scholar] [CrossRef]

- Li, D.-S.; Lu, Z.-X.; Jiang, N.; Fang, D.-N. High strain rate behavior and failure mechanism of three-dimensional five-directional carbon/phenolic braided composites under transverse compression. Compos. Part B 2011, 42, 309–317. [Google Scholar] [CrossRef]

- Song, Z.H.; Wang, Z.H.; Ma, H.W.; Xuan, H.J. Mechanical behavior and failure mode of woven carbon/epoxy laminate composites under dynamic compressive loading. Compos. Part B 2014, 60, 531–536. [Google Scholar] [CrossRef]

- Pan, Z.; Gu, B.; Sun, B. Experimental investigation of high-strain rate properties of 3-D braided composite material in cryogenic field. Compos. Part B 2015, 77, 379–390. [Google Scholar] [CrossRef]

- Li, D.-S.; Chen, H.-R.; Ge, D.-Y.; Jiang, N.; Jiang, L. Split Hopkinson pressure bar testing of 3D multi-axial warp knitted carbon/epoxy composites. Compos. Part B 2015, 79, 692–705. [Google Scholar] [CrossRef]

- Tarfaoui, M.; El Moumen, A.; Yahia, H.B. Damage detection versus heat dissipation in E-glass/Epoxy laminated composites under dynamic compression at high strain rate. Compos. Struct. 2018, 186, 50–61. [Google Scholar] [CrossRef] [Green Version]

- Sassia, S.; Tarfaouia, M.; Yahiaa, H.B. In-situ heat dissipation monitoring in adhesively bonded composite joints under dynamic compression loading using SHPB. Compos. Part B 2018, 154, 64–76. [Google Scholar] [CrossRef]

- Massaq, A.; Rusinek, A.; Klósak, M. Method for Determination of the Dynamic Elastic Modulus for Composite Materials. Eng. Trans. 2013, 61, 301–315. [Google Scholar]

- Singha, S.S.; Parameswaranb, V.; Kitey, R. Dynamic compression behavior of glass filled epoxy composites: Influence of filler shape and exposure to high temperature. Compos. Part B 2019, 164, 103–115. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, D.; Rodriguez-Millan, M.; Rusinek, A.; Arias, A. Investigation of mechanical impact behavior of short carbon-fiber-reinforced PEEK composites. Compos. Struct. 2015, 133, 1116–1126. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, T.; Golewski, P. Heat transfer and stress concentrations in a two-phase polycrystalline composite structure. Part I: Theoretical modelling of heat transfer. Mater. Werkst. 2013, 44, 497–505. [Google Scholar] [CrossRef]

- Massaq, A.; Rusinek, A.; Klosak, M.; Bahi, S.; Arias, A. Strain rate effect on the mechanical behavior of polyamide composites under compression loading. Compos. Struct. 2019, 214, 114–122. [Google Scholar] [CrossRef]

- Sadowski, T.; Kneć, M.; Golewski, P. Experimental investigation and numerical modelling of spot welding-adhesive joints response. Compos. Struct. 2014, 112, 66–77. [Google Scholar] [CrossRef]

- Birsan, M.; Sadowski, T.; Marsavina, L.; Linul, E.; Pietras, D. Mechanical behavior of sandwich composite beams made of foam and functionally graded materials. Int. J. Solids Struct. 2013, 50, 519–530. [Google Scholar] [CrossRef] [Green Version]

- Postek, E.; Sadowski, T. Distributed microcracking process of WC/Co cermet under dynamic impulse compressive loading. Compos. Struct. 2018, 194, 494–508. [Google Scholar] [CrossRef]

- Sadowski, T. Gradual degradation in two-phase ceramic composites under compression. Comput. Mater. Sci. 2012, 64, 209–211. [Google Scholar] [CrossRef]

- Burlayenko, V.; Altenbach, H.; Sadowski, T.; Dimitrova, S.D. Computational simulations of thermal shock cracking by the virtual crack closure technique in a functionally graded plate. Comput. Mater. Sci. 2016, 116, 11–21. [Google Scholar] [CrossRef]

- Sadowski, T.; Bęc, J. Effective properties for sandwich plates with aluminium foil honeycomb core and polymer foam filling—static and dynamic response. Comput. Mater. Sci. 2011, 50, 1269–1275. [Google Scholar] [CrossRef]

- Postek, E.; Sadowski, T. Dynamic pulse sensitivity of WC/Co composite. Compos. Struct. 2018, 203, 498–512. [Google Scholar] [CrossRef]

- Postek, E.; Sadowski, T. Impact model of WC/Co composite. Compos. Struct. 2019, 213, 231–242. [Google Scholar] [CrossRef]

- Burlayenko, V.; Altenbach, H.; Sadowski, T.; Dimitrova, S.D.; Bhaskar, A. Modelling functionally graded materials in heat transfer and thermal stress analysis by means of graded finite elements. Appl. Math. Model. 2017, 45, 422–438. [Google Scholar] [CrossRef]

| No. | Dimensions [mm] | Pressure [bar] | Initial Impact Velocity V0 [m/s] | Temperature T0 [°C] |

|---|---|---|---|---|

| 1_1 | 12.11 × 12.12 × 3.87 | Quasi-static test | 21 | |

| 1_2 | 12.18 × 12.22 × 3.96 | Quasi-static test | 21 | |

| 1_3 | 12.17 × 12.21 × 4.00 | Quasi-static test | 21 | |

| 2_1 | 12.12 × 12.13 × 3.84 | ≈1 | 7.730 | 21 |

| 2_2 | 12.14 × 12.28 × 3.91 | ≈1 | 7.717 | 21 |

| 2_3 | 12.12 × 12.12 × 3.86 | ≈1 | 8.266 | 21 |

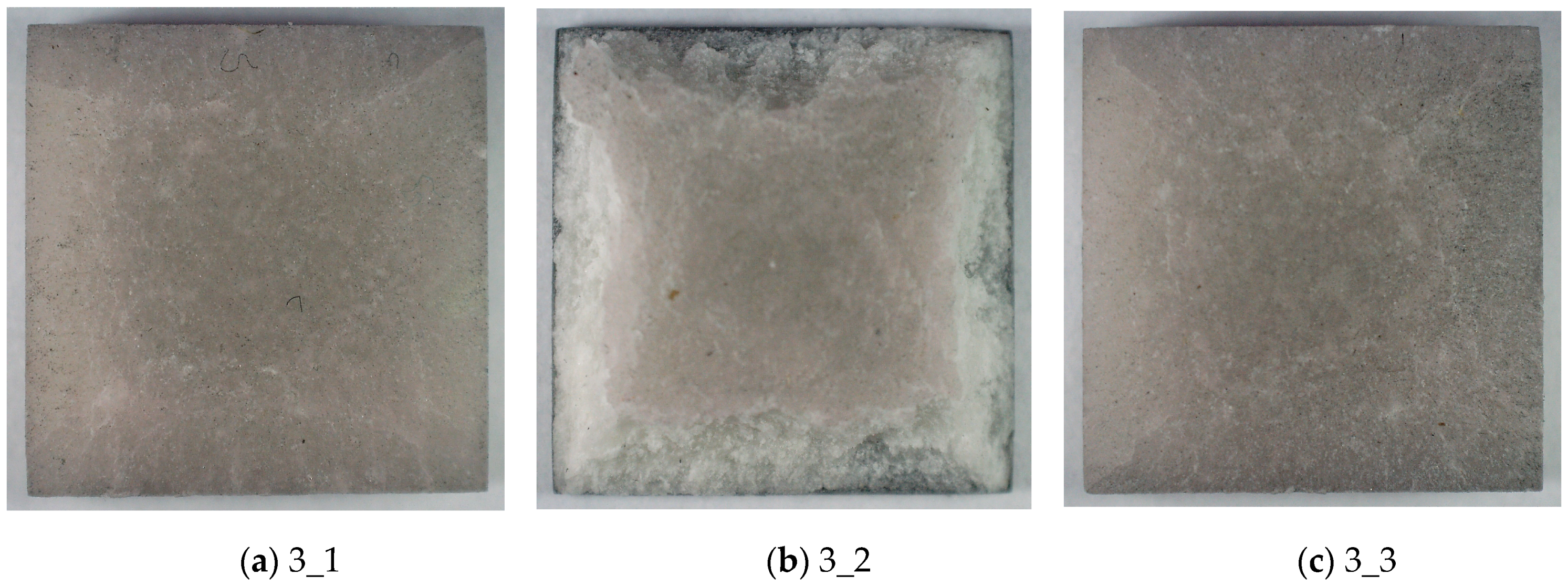

| 3_1 | 12.11 × 12.03 × 3.90 | ≈1.5 | 9.765 | 21 |

| 3_2 | 12.14 × 12.16 × 3.87 | ≈1.5 | 10.604 | 21 |

| 3_3 | 12.25 × 12.14 × 3.95 | ≈1.5 | 9.777 | 21 |

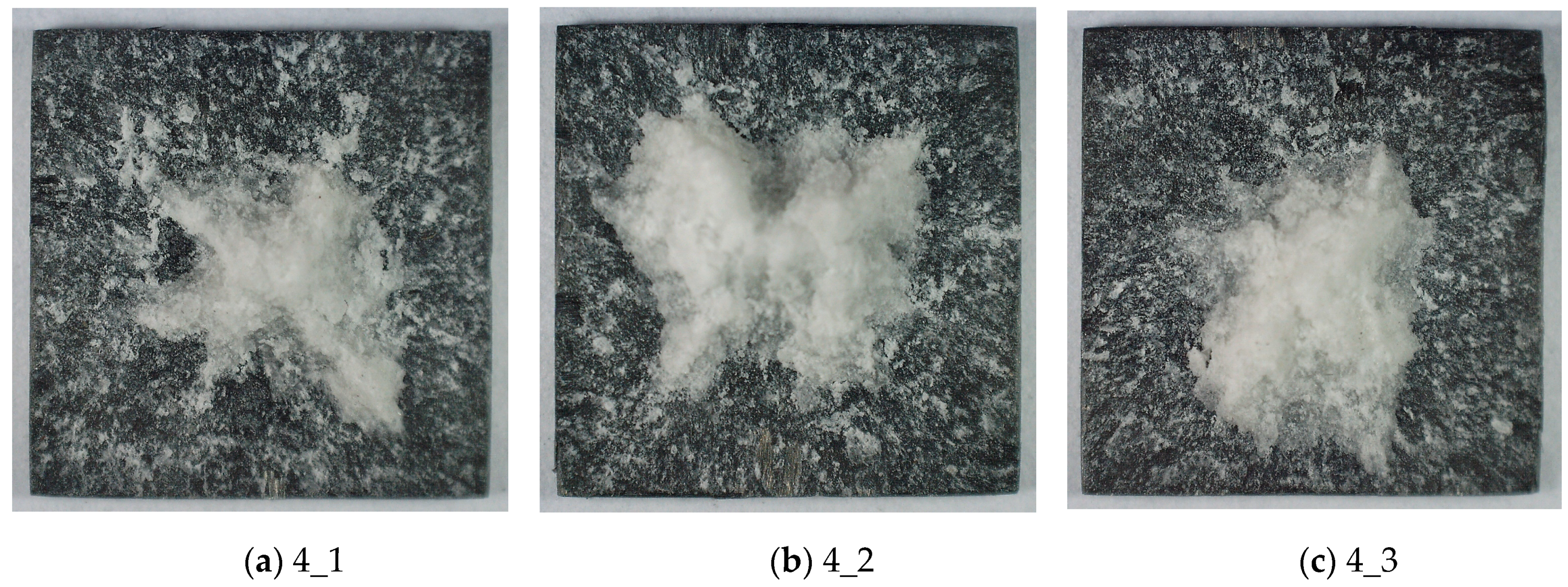

| 4_1 | 12.16 × 12.16 × 3.93 | ≈2 | 11.848 | 21 |

| 4_2 | 12.11 × 12.16 × 3.94 | ≈2 | 11.848 | 21 |

| 4_3 | 12.11 × 12.14 × 3.99 | ≈2 | 11.844 | 21 |

| 5_1 | 12.12 × 12.08 × 3.84 | ≈1 | 7.347 | 55 |

| 5_2 | 12.09 × 12.05 × 3.81 | ≈1 | 8.179 | 55 |

| 5_3 | 12.13 × 12.12 × 3.86 | ≈1 | 7.658 | 55 |

| 6_1 | 12.03 × 12.11 × 3.85 | ≈1 | 7.558 | 90 |

| 6_2 | 12.16 × 12.17 × 3.85 | ≈1 | 7.319 | 90 |

| 6_3 | 12.14 × 12.14 × 3.80 | ≈1 | 6.994 | 90 |

| E1 [GPa] | E1 [GPa] | ν12 [-] | G12 [GPa] | ||||

| 55.5 | 55.5 | 0.04 | 3.00 | ||||

| Xt [MPa] | Xc [MPa] | Yt [MPa] | Yc [MPa] | S [MPa] | |||

| 828 | 580 | 828 | 580 | 105 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golewski, P.; Rusinek, A.; Sadowski, T. Material Characterization of PMC/TBC Composite Under High Strain Rates and Elevated Temperatures. Materials 2020, 13, 167. https://doi.org/10.3390/ma13010167

Golewski P, Rusinek A, Sadowski T. Material Characterization of PMC/TBC Composite Under High Strain Rates and Elevated Temperatures. Materials. 2020; 13(1):167. https://doi.org/10.3390/ma13010167

Chicago/Turabian StyleGolewski, Przemysław, Alexis Rusinek, and Tomasz Sadowski. 2020. "Material Characterization of PMC/TBC Composite Under High Strain Rates and Elevated Temperatures" Materials 13, no. 1: 167. https://doi.org/10.3390/ma13010167

APA StyleGolewski, P., Rusinek, A., & Sadowski, T. (2020). Material Characterization of PMC/TBC Composite Under High Strain Rates and Elevated Temperatures. Materials, 13(1), 167. https://doi.org/10.3390/ma13010167