Influence of Selected Warm Mix Asphalt Additives on Cracking Susceptibility of Asphalt Mixtures

Abstract

:1. Introduction

1.1. Background

1.2. Objectives

2. Materials and Methods

2.1. Materials

2.1.1. Bitumen

2.1.2. Warm Mix Asphalt Additives

2.1.3. Asphalt Mixture

2.1.4. Samples Preparation

2.2. Tests Methods

2.2.1. Uniaxial Tension Tests

2.2.2. Semi-Circular Bending Test (SCB)

3. Results and Discussion

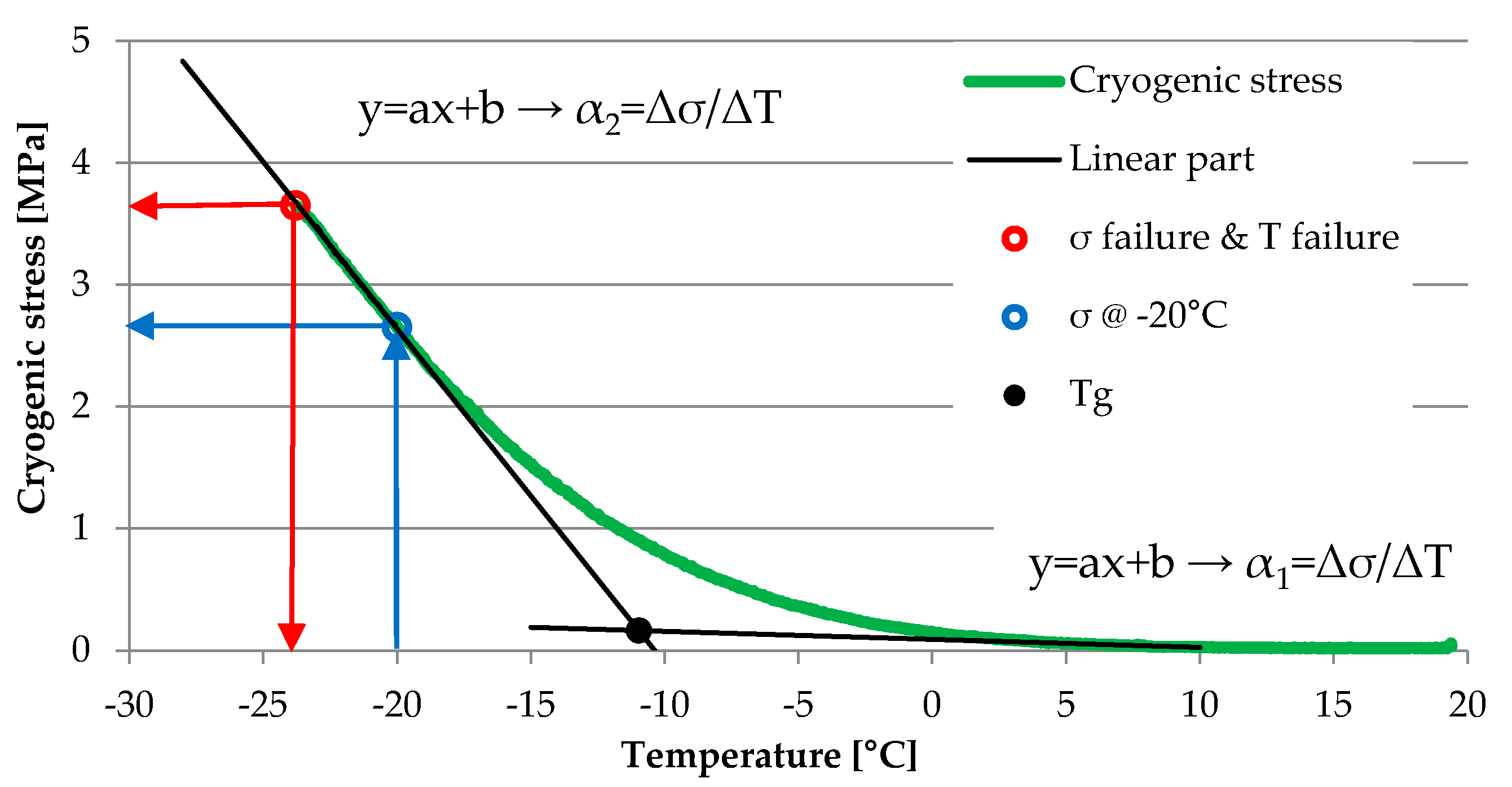

3.1. Results Form the Thermal Stress Restrained Specimen Test (TSRST) and their Analysis

3.2. Results of Fracture Toughness from the Semi-Circular Bending Test (SCB) and their Analysis

4. Conclusions

- Certain WMA additives, especially those belonging to the group of wax-based additives, can affect bitumen properties.

- Additive that are based on surfactant-based molecules and incorporates a different type of temperature reduction mechanism based on adhesion promotion and reduced surface tension do not affect bitumen properties to such an extent.

- Incorporation of wax-based WMA additives into bitumen can shift the PG grade to the next level. The initial PG grade of neat 50/70 bitumen was changed from 64-22 to 70-16 after adding two wax-based WMA additives. Thus, when using such additives, great care must be taken during the binder selection. In some cases, it would be likely advisable to initially select a binder with a lower PG grade, so as to obtain the desired PG level in terms of traffic requirements and climatic conditions after a WMA additive is incorporated. This issue requires further research.

- Recorded changes of bitumen properties, which shifted the binder with some WMA additives to the next level of the PG grade did not reproduce in asphalt mixtures to the same extent. Values obtained through the TSRT test were mostly within a range of standard deviation. It should be remembered that the standard rate of cooling of 10 °C/h that was used in this study does not represent real cooling rates that may occur in real field conditions (which, in fact, are much lower) and this may attribute to the fact that, in this test, asphalt mixtures with wax-based additives showed similar performance to mixtures with other additives.

- Results of the SCB test at the temperature of −20 °C were inconclusive and cannot be used for evaluating WMA additives. Results obtained for the temperature of 10° C were in accordance with the results of the BBR test and TSRST test.

- This may be attributed to the fact that, at the temperature of −20 °C, during the SCB test with a constant rate of deformation, there is almost no post peak phase of loading. Destruction of the sample occurs almost immediately after the crack appears.

- The conducted research and analysis of the test results do not disqualify any of the evaluated WMA additives in certain cases of pavement construction, traffic, and climatic conditions. They only show which asphalt mixture would be more prone to cracking when used in the field.

- The correlation between cracking properties of WMA asphalt mixtures produced in laboratory conditions with samples extracted from the real pavements will be the subject of future studies. This is especially important since some of the additives that have shown a negative impact on the binder properties are continuously being used and pavements with such additives perform fairly well.

Author Contributions

Funding

Conflicts of Interest

References

- Kheradmand, B.; Muniandy, R.; Hua, L.T.; Yunus, R.B.; Solouki, A. An overview of the emerging warm mix asphalt technology. Int. J. Pavement Eng. 2014, 15, 79–94. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Vorobjovas, V.; Perveneckas, Z. Influence of warm mix asphalt technology on asphalt physical and mechanical properties. Constr. Build. Mater. 2016, 112, 800–806. [Google Scholar] [CrossRef]

- West, R.C.; Rodezno, C.; Grant, J.; Prowell, B.D.; Frank, B.; Osborn, L.V.; Kriech, T. NCHRP Report 779-Field Performance of Warm Mix Asphalt Technologies; Transportation Research Board: Washington, DC, USA, 2014; ISBN 9780309308038. [Google Scholar]

- D’Angelo, J.; Harm, E.; Bartoszek, J.; Baumgardner, G.; Corrigan, M.; Cowsert, J.; Harman, T.; Jamshidi, M.; Jones, W.; Newcomb, D.E.; et al. Warm-Mix Asphalt: European Practice; U.S. Department of Transportation: Washington, DC, USA, 2008.

- Iwański, M.; Chomicz-Kowalska, A.; Maciejewski, K. Application of synthetic wax for improvement of foamed bitumen parameters. Constr. Build. Mater. 2015, 83, 62–69. [Google Scholar] [CrossRef] [Green Version]

- Iwański, M.M.; Chomicz-Kowalska, A.; Maciejewski, K. Effect of Surface Active Agent (SAA) on 50/70 Bitumen Foaming Characteristics. Materials 2019, 12, 3514. [Google Scholar] [CrossRef] [Green Version]

- Williams, B.A.; Willis, J.R.; Ross, T.C. Annual Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2018, 9th Annual Survey (IS 138); National Asphalt Pavement Association: Greenbelt, MD, USA, 2019. [Google Scholar]

- Woszuk, A.; Panek, R.; Madej, J.; Zofka, A.; Franus, W. Mesoporous silica material MCM-41: Novel additive for warm mix asphalts. Constr. Build. Mater. 2018, 183, 270–274. [Google Scholar] [CrossRef]

- Gao, J.; Yan, K.; He, W.; Yang, S.; You, L. High temperature performance of asphalt modified with Sasobit and Deurex. Constr. Build. Mater. 2018, 164, 783–791. [Google Scholar] [CrossRef]

- Luo, H.; Leng, H.; Ding, H.; Xu, J.; Lin, H.; Ai, C.; Qiu, Y. Low-temperature cracking resistance, fatigue performance and emission reduction of a novel silica gel warm mix asphalt binder. Constr. Build. Mater. 2020, 231, 117118. [Google Scholar] [CrossRef]

- Woszuk, A. Application of fly ash derived zeolites in warm-mix asphalt technology. Materials 2018, 11, 1542. [Google Scholar] [CrossRef] [Green Version]

- Ji, J.; Suo, Z.; Xu, Y. Laboratory Evaluation on the Long-term Aging Characterization of Warm Modified Binders. Procedia-Soc. Behav. Sci. 2013, 96, 1640–1647. [Google Scholar] [CrossRef] [Green Version]

- Almeida, A.; Sergio, M. Evaluation of the potential of sasobit REDUX additive to lowerwarm-mix asphalt production temperature. Materials 2019, 12, 1285. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Zhu, J.; Zhang, K.; Wu, J.; Yin, J.; Shi, X. Effects of mixing sequence on mechanical properties of graphene oxide and warm mix additive composite modified asphalt binder. Constr. Build. Mater. 2019, 217, 301–309. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Performance of hot and warm mix asphalt mixtures enhanced by nano-sized graphene oxide. Constr. Build. Mater. 2019, 217, 273–282. [Google Scholar] [CrossRef]

- Khani Sanij, H.; Afkhamy Meybodi, P.; Amiri Hormozaky, M.; Hosseini, S.H.; Olazar, M. Evaluation of performance and moisture sensitivity of glass-containing warm mix asphalt modified with zycotherm TM as an anti-stripping additive. Constr. Build. Mater. 2019, 197, 185–194. [Google Scholar] [CrossRef]

- Xiao, F.; Zhao, W.; Gandhi, T.; Amirkhanian, S.N. Influence of Antistripping Additives on Moisture Susceptibility of Warm Mix Asphalt Mixtures. J. Mater. Civ. Eng. 2010, 22, 1047–1055. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Austerman, A.J.; Kassem, E.; Masad, E. Moisture Damage Characteristics of Warm Mix Asphalt Mixtures. AAPT J. 2011, 80, 491–526. [Google Scholar]

- Mogawer, W.S.; Austerman, A.J.; Bahia, H.U. Evaluating the Effect of Warm-Mix Asphalt Technologies on Moisture Characteristics of Asphalt Binders and Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2011, 2209, 52–60. [Google Scholar] [CrossRef]

- Ghabchi, R.; Singh, D.; Zaman, M.M. Laboratory evaluation of stiffness, low-temperature cracking, rutting, moisture damage, and fatigue performance of WMA mixes. Road Mater. Pavement Des. 2015, 16, 334–357. [Google Scholar] [CrossRef]

- Xu, S.; Xiao, F.; Amirkhanian, S.; Singh, D. Moisture characteristics of mixtures with warm mix asphalt technologies—A review. Constr. Build. Mater. 2017, 142, 148–161. [Google Scholar] [CrossRef]

- Bairgi, B.K.; Tarefder, R.A.; Ahmed, M.U. Long-term rutting and stripping characteristics of foamed warm-mix asphalt (WMA) through laboratory and field investigation. Constr. Build. Mater. 2018, 170, 790–800. [Google Scholar] [CrossRef]

- Yoo, M.-Y.; Jeong, S.-H.; Park, J.-Y.; Kim, N.-H.; Kim, K.-W. Low-Temperature Fracture Characteristics of Selected Warm-Mix Asphalt Concretes. Transp. Res. Rec. J. Transp. Res. Board 2011, 2208, 40–47. [Google Scholar] [CrossRef]

- Bernier, A.; Zofka, A.; Josen, R.; Mahoney, J. Warm-Mix Asphalt Pilot Project in Connecticut. Transp. Res. Rec. J. Transp. Res. Board 2012, 2294, 106–116. [Google Scholar] [CrossRef]

- Das, P.K.; Tasdemir, Y.; Birgisson, B. Low temperature cracking performance of WMA with the use of the Superpave indirect tensile test. Constr. Build. Mater. 2012, 30, 643–649. [Google Scholar] [CrossRef]

- Das, P.K.; Tasdemir, Y.; Birgisson, B. Evaluation of fracture and moisture damage performance of wax modified asphalt mixtures. Road Mater. Pavement Des. 2012, 13, 142–155. [Google Scholar] [CrossRef]

- Hill, B.; Behnia, B.; Hakimzadeh, S.; Buttlar, W.G.; Reis, H. Evaluation of the Low Temperature Cracking Performance of WMA Mixtures. J. Transp. Res. Board 2012, 2294, 81–88. [Google Scholar] [CrossRef]

- Medeiros, M.S.; Daniel, J.S.; Bolton, H.L.; Meagher, W.C. Evaluation of moisture and low-temperature cracking susceptibility of warm-mixture asphalt. Int. J. Pavement Eng. 2012, 13, 395–400. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Alavi, M.Z.; Morian, N.E.; Sebaaly, P.E. Effect of select warm-mix additives on thermo-viscoelastic properties of asphalt mixtures. Road Mater. Pavement Des. 2013, 14, 175–186. [Google Scholar] [CrossRef]

- Hasan, Z.; Hamid, B.; Amir, I.; Danial, N. Long term performance of warm mix asphalt versus hot mix asphalt. J. Cent. South. Univ. 2013, 20, 256–266. [Google Scholar] [CrossRef]

- Akisetty, C.K.; Xiao, F.; Gandhi, T.; Amirkhanian, S.N. Estimating correlations between rheological and engineering properties of rubberized asphalt concrete mixtures containing warm mix asphalt additive. Constr. Build. Mater. 2011, 25, 950–956. [Google Scholar] [CrossRef]

- Singh, D.; Ashish, P.K.; Chitragar, S.F. Laboratory performance of Recycled Asphalt Mixes containing wax and chemical based Warm Mix Additives using Semi Circular Bending and Tensile Strength Ratio tests. Constr. Build. Mater. 2018, 158, 1003–1014. [Google Scholar] [CrossRef]

- Razmi, A.; Mirsayar, M.M. Fracture resistance of asphalt concrete modified with crumb rubber at low temperatures. Int. J. Pavement Res. Technol. 2018, 11, 265–273. [Google Scholar] [CrossRef]

- Cao, W.; Barghabany, P.; Mohammad, L.; Cooper, S.B.; Balamurugan, S. Chemical and rheological evaluation of asphalts incorporating RAP/RAS binders and warm-mix technologies in relation to crack resistance. Constr. Build. Mater. 2019, 198, 256–268. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Hajj, E.Y.; Piratheepan, M. Evaluation of selected warm mix asphalt technologies. Road Mater. Pavement Des. 2015, 16, 475–486. [Google Scholar] [CrossRef]

- Buss, A.; Williams, R.C.; Schram, S. The influence of warm mix asphalt on binders in mixes that contain recycled asphalt materials. Constr. Build. Mater. 2015, 77, 50–58. [Google Scholar] [CrossRef]

- Standard EN 13108-1:2016-07-Bituminous mixtures-Material specifications-Part 1: Asphalt Concrete; European Committee for Standardization CEN: Paris, France, 2016.

- Asphalt Pavements for National Roads-WT-2 2014-Part I-Asphalt mixtures-Technical Guidelines; General Director for National Roads and Highways: Warsaw, Poland, 2014.

- Standard EN 12697-35 Bituminous mixtures-Test methods for hot mix asphalt-Part 35: Laboratory mixing; European Committee for Standardization CEN: Paris, France, 2016.

- Standard EN 12697-33 Bituminous mixtures-Test methods for hot mix asphal-Part 33: Specimen prepared by roller compactor; European Committee for Standardization CEN: Paris, France, 2019.

- Standard EN 12697-46 Bituminous mixtures-Test methods for hot mix asphalt-Part 46: Low temperature cracking and properties by uniaxial tension tests; European Committee for Standardization CEN: Paris, France, 2012.

- Standard EN 12697-44 Bituminous mixtures-Test methods for hot mix asphalt-Part 44: Crack propagation by semi-circular bending tes; European Committee for Standardization CEN: Paris, France, 2019.

- Pszczola, M.; Szydlowski, C. Influence of bitumen type and asphalt mixture composition on low-temperature strength properties according to various test methods. Materials 2018, 11, 2118. [Google Scholar] [CrossRef] [Green Version]

| Additive Designation | Chemical Composition | Type of Additive | Form |

|---|---|---|---|

| Sasobit | Aliphatic synthetic wax produced with the use of the Fisher–Tropsch method | Viscosity modifier | Granules |

| Licomont BS 100 | Mixture of fatty acid derivatives | Viscosity modifier | Fine powder |

| Rediset WMX | Organic combined with adhesion promoter | Viscosity modifier and adhesion promoter of surface tension between the asphalt binder and aggregate | Pellets |

| Ceca Base Bio | Formulation of biodegradable and mostly bio-sourced surfactant-based molecules (ionic and non-ionic) | Adhesion promoter and reducer of the surface tension | Liquid |

| Ceca Base LQ | Formulation of surfactant-based molecules (ionic and non-ionic) | Adhesion promoter and reducer of the surface tension | Liquid |

| Property | Designation of Bitumen or Additive | |||||

|---|---|---|---|---|---|---|

| Neat Bitumen 50/70 | Sasobit | Licomont BS100 | Rediset WMX | Ceca Base BIO | Ceca Base LQ | |

| Dosage rate of additive, % by wt. of asphalt binder | - | 3% | 3% | 2% | 0.35% | 0.35% |

| Penetration at 25 °C, 0.1 mm, acc. to EN 1426 | 48.2 | 30.0 | 34.6 | 45.6 | 55.0 | 49.4 |

| Softening point, °C, acc. to EN 1427 | 49.9 | 78.9 | 76.6 | 55.2 | 48.5 | 48.9 |

| PG grade, acc. to AASHTO M 320 | 64−2 | 70−16 | 70−16 | 64−22 | 64−22 | 64−22 |

| BBR S-critical temperature, °C | −12 | −12 | −12 | −12 | −12 | −12 |

| BBR m-critical temperature, °C | −12 | −6 | −6 | −12 | −12 | −12 |

| Properties | Value |

|---|---|

| Maximum size of aggregate, mm | 11 |

| Binder content, wt.% | 5.6 |

| Air voids in Marshall samples (2 × 75 blows) [%] | 3.1 |

| Voids filled with bitumen VFB [%] | 81.5 |

| Voids in the mineral aggregate VMA [%] | 16.7 |

| Bitumen Type | σcry, failure, [MPa] | Tfailure, [°C] | σcry, @-20°C, [MPa] | α2, [N/mm2/°C] | α1, [N/mm2/°C] | Tg, [°C] | |

|---|---|---|---|---|---|---|---|

| 50/70 | mean value | 3.926 | −24.6 | 2.679 | −0.286 | −0.006 | −11.2 |

| st. deviation | 0.313 | 1.1 | 0.024 | 0.012 | 0.001 | 0.2 | |

| CV, [%] | 8.0 | 4.3 | 0.9 | 4.2 | 9.1 | 1.9 | |

| Sasobit | mean value | 4.243 | −23.3 | 3.382 | −0.273 | −0.014 | −8.8 |

| st. deviation | 0.224 | 0.1 | 0.151 | 0.007 | 0.003 | 0.2 | |

| CV, [%] | 5.3 | 0.4 | 4.5 | 2.4 | 17.6 | 2.0 | |

| Licomont BS 100 | mean value | 4.100 | −25.3 | 2.736 | −0.262 | −0.009 | −10.0 |

| st. deviation | 0.273 | 1.4 | 0.072 | 0.006 | 0.000 | 0.6 | |

| CV, [%] | 6.7 | 5.4 | 2.6 | 2.3 | 0.0 | 5.7 | |

| Rediset WMX | mean value | 3.872 | −25.5 | 2.513 | −0.267 | −0.006 | −11.2 |

| st. deviation | 0.113 | 1.2 | 0.275 | 0.014 | 0.001 | 0.8 | |

| CV, [%] | 2.9 | 4.5 | 10.9 | 5.1 | 18.2 | 6.7 | |

| Ceca Base RT BIO | mean value | 3.775 | −25.7 | 2.409 | −0.259 | −0.007 | −11.0 |

| st. deviation | 0.242 | 0.5 | 0.053 | 0.002 | 0.001 | 0.2 | |

| CV [%] | 6.4 | 1.9 | 2.2 | 0.6 | 14.3 | 1.9 | |

| Ceca Base RT | mean value | 4.073 | −26.0 | 2.509 | −0.262 | −0.006 | −10.9 |

| st. deviation | 0.072 | 1.2 | 0.199 | 0.012 | 0.001 | 0.2 | |

| CV [%] | 1.8 | 4.5 | 7.9 | 4.5 | 18.2 | 2.1 |

| Bitumen Type | Notch Depth [mm] | Fmax [N] | dFmax [mm] | KIC [N×mm−3/2] | UPRE-PEAK [N×mm] | UTOTAL [N×mm] | S1 [N/mm] | S2 [N/mm] | JC [kJ/m2] |

|---|---|---|---|---|---|---|---|---|---|

| 50/70 | 10 | 5837 | 0.88 | 19.8 | 2985 | 6188 | 9287 | −12,572 | 1.98 |

| 20 | 4272 | 0.71 | 21.3 | 1746 | 4170 | 7876 | −6131 | ||

| 30 | 3052 | 0.6 | 19.9 | 1082 | 3092 | 6940 | −4531 | ||

| Sasobit | 10 | 5740 | 0.70 | 19.4 | 2360 | 4872 | 10,635 | −15,564 | 1.53 |

| 20 | 4302 | 0.53 | 21.1 | 1320 | 2966 | 10,149 | −11,508 | ||

| 30 | 3398 | 0.50 | 22.1 | 890 | 2355 | 9077 | −7575 | ||

| Licomont BS 100 | 10 | 5200 | 0.73 | 17.3 | 2265 | 4687 | 9495 | −10,900 | 1.41 |

| 20 | 3939 | 0.63 | 19.3 | 1422 | 3236 | 8834 | −8098 | ||

| 30 | 3049 | 0.56 | 19.7 | 886 | 2436 | 7163 | −4380 | ||

| Rediset WMX | 10 | 5033 | 0.79 | 16.9 | 2476 | 4936 | 8256 | −9422 | 1.59 |

| 20 | 3546 | 0.61 | 17.1 | 1285 | 3310 | 7828 | −6200 | ||

| 30 | 2835 | 0.54 | 18.5 | 915 | 2690 | 6611 | −3527 | ||

| Ceca Base RT BIO | 10 | 4828 | 0.94 | 16.3 | 2902 | 6473 | 6943 | −5537 | 1.65 |

| 20 | 4052 | 0.79 | 19.9 | 2023 | 4914 | 7126 | −4908 | ||

| 30 | 3123 | 0.70 | 20.3 | 1308 | 3465 | 5838 | −4560 | ||

| Ceca Base RT | 10 | 5091 | 0.96 | 16.7 | 2892 | 6023 | 8184 | −7514 | 1.77 |

| 20 | 3711 | 0.83 | 17.9 | 1891 | 4338 | 6013 | −4327 | ||

| 30 | 2850 | 0.63 | 18.5 | 1132 | 3288 | 6723 | −3927 |

| Bitumen Type | Notch Depth [mm] | Fmax [N] | dFmax [mm] | KIC [N×mm−3/2] | UPRE-PEAK [N×mm] | S1 [N/mm] | JC [kJ/m2] |

|---|---|---|---|---|---|---|---|

| 50/70 | 10 | 9988 | 0.47 | 33.7 | 1945 | 28,197 | 1.10 |

| 20 | 7469 | 0.51 | 36.6 | 1419 | 24,895 | ||

| 30 | 5230 | 0.4 | 34.3 | 872 | 18,478 | ||

| Sasobit | 10 | 10,187 | 0.59 | 34.4 | 2173 | 26,089 | 1.45 |

| 20 | 7242 | 0.37 | 36.2 | 1108 | 26,243 | ||

| 30 | 5256 | 0.35 | 34.3 | 783 | 20,200 | ||

| Licomont BS 100 | 10 | 10,126 | 0.47 | 33.8 | 1952 | 28,310 | 1.22 |

| 20 | 6992 | 0.38 | 34.1 | 1110 | 24,132 | ||

| 30 | 5234 | 0.39 | 33.7 | 786 | 20,310 | ||

| Rediset WMX | 10 | 10,070 | 0.48 | 34 | 1928 | 28,859 | 1.31 |

| 20 | 7159 | 0.38 | 34 | 1198 | 23,607 | ||

| 30 | 4707 | 0.33 | 30.5 | 667 | 18,305 | ||

| Ceca Base RT BIO | 10 | 9438 | 0.42 | 31.5 | 1721 | 28,460 | 1.17 |

| 20 | 6868 | 0.4 | 33.6 | 1146 | 22,738 | ||

| 30 | 4656 | 0.33 | 30.2 | 591 | 21,434 | ||

| Ceca Base RT | 10 | 9488 | 0.51 | 31.8 | 1841 | 26,611 | 1.08 |

| 20 | 7640 | 0.44 | 35.8 | 1378 | 22,666 | ||

| 30 | 5377 | 0.33 | 35 | 798 | 20,390 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stienss, M.; Szydlowski, C. Influence of Selected Warm Mix Asphalt Additives on Cracking Susceptibility of Asphalt Mixtures. Materials 2020, 13, 202. https://doi.org/10.3390/ma13010202

Stienss M, Szydlowski C. Influence of Selected Warm Mix Asphalt Additives on Cracking Susceptibility of Asphalt Mixtures. Materials. 2020; 13(1):202. https://doi.org/10.3390/ma13010202

Chicago/Turabian StyleStienss, Marcin, and Cezary Szydlowski. 2020. "Influence of Selected Warm Mix Asphalt Additives on Cracking Susceptibility of Asphalt Mixtures" Materials 13, no. 1: 202. https://doi.org/10.3390/ma13010202