Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

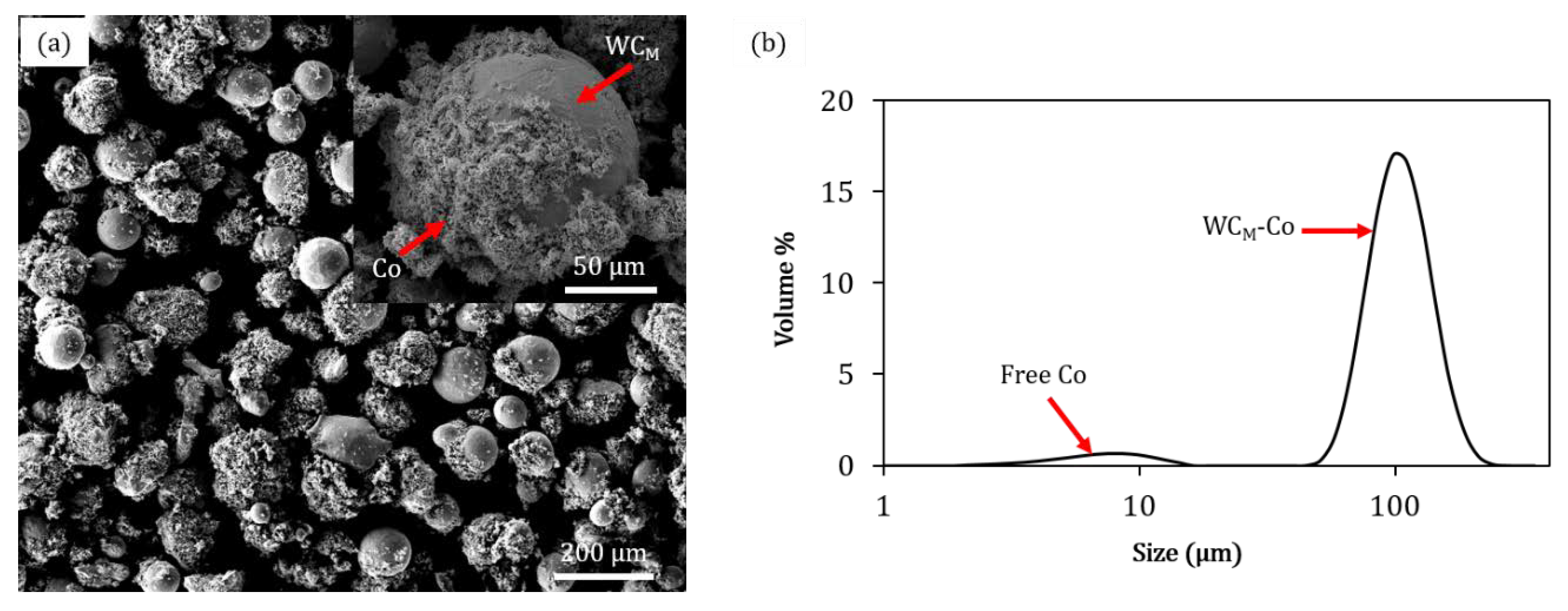

2.1. Characterization of the Powder Feedstock Used in the Present Research

2.2. Single-Track Formation during Laser Powder-Bed Fusion

2.3. Characterization of the Single Tracks

3. Results

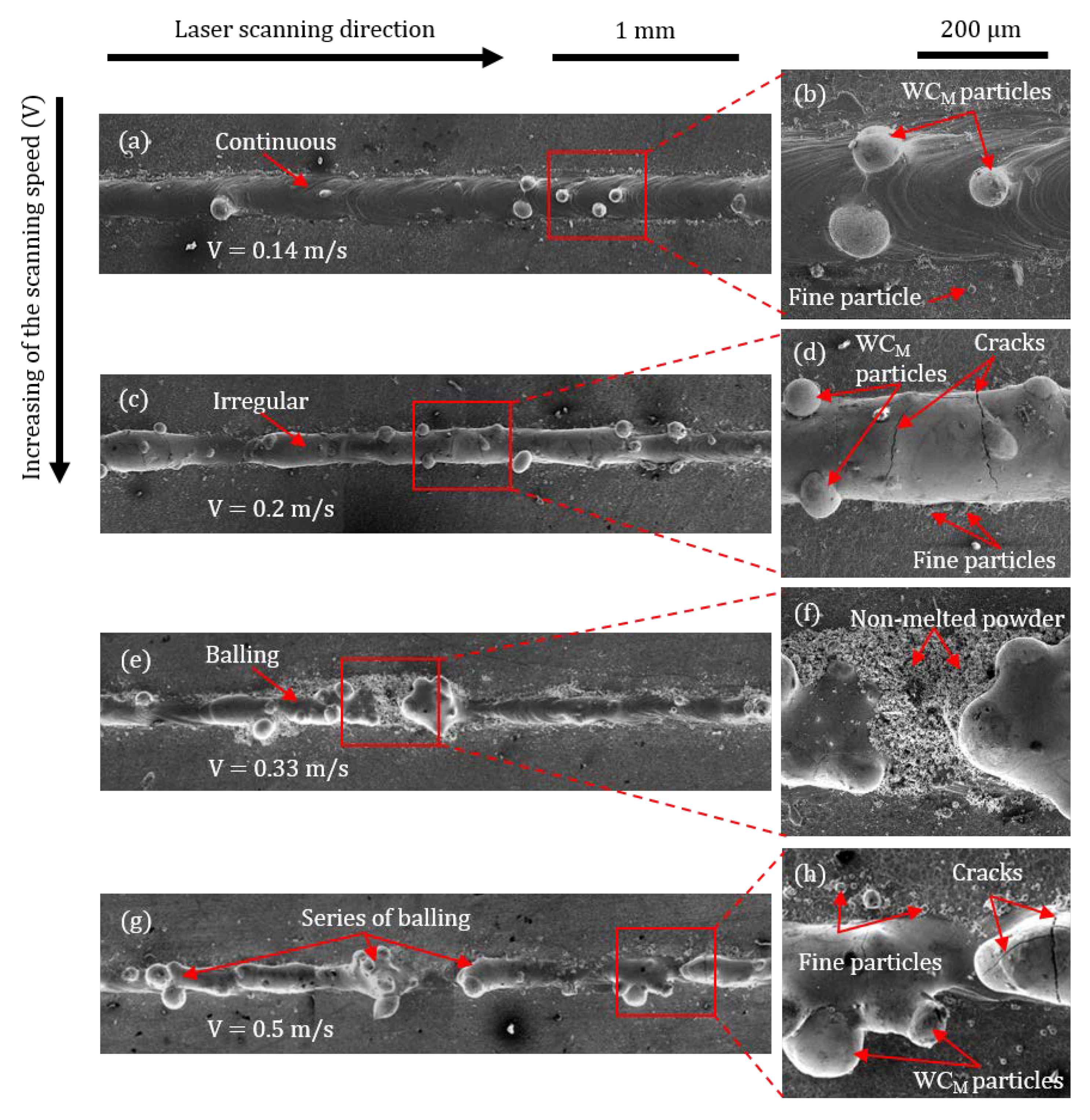

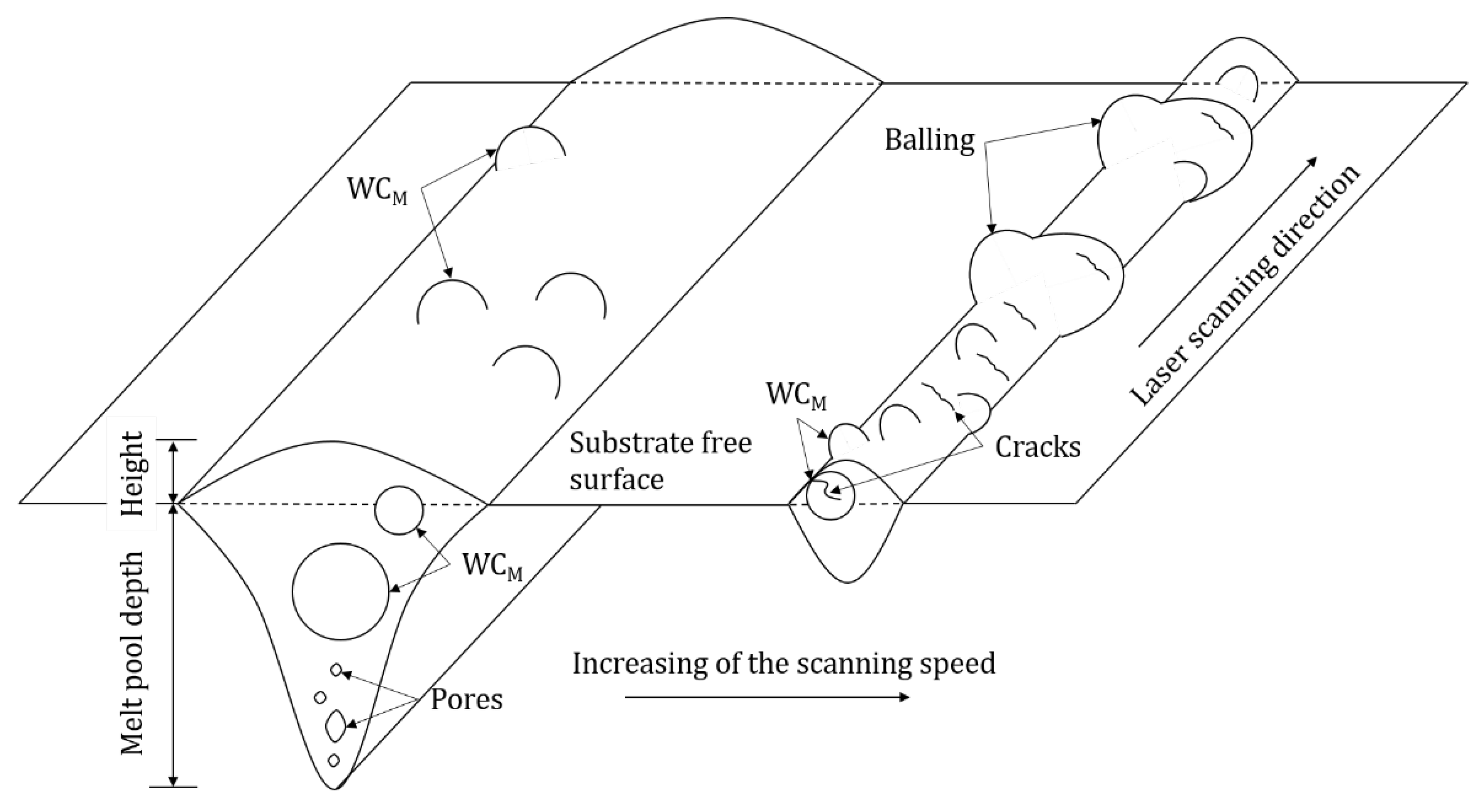

3.1. Evolution of the Track Morphology as a Function of Laser-Scanning Speed

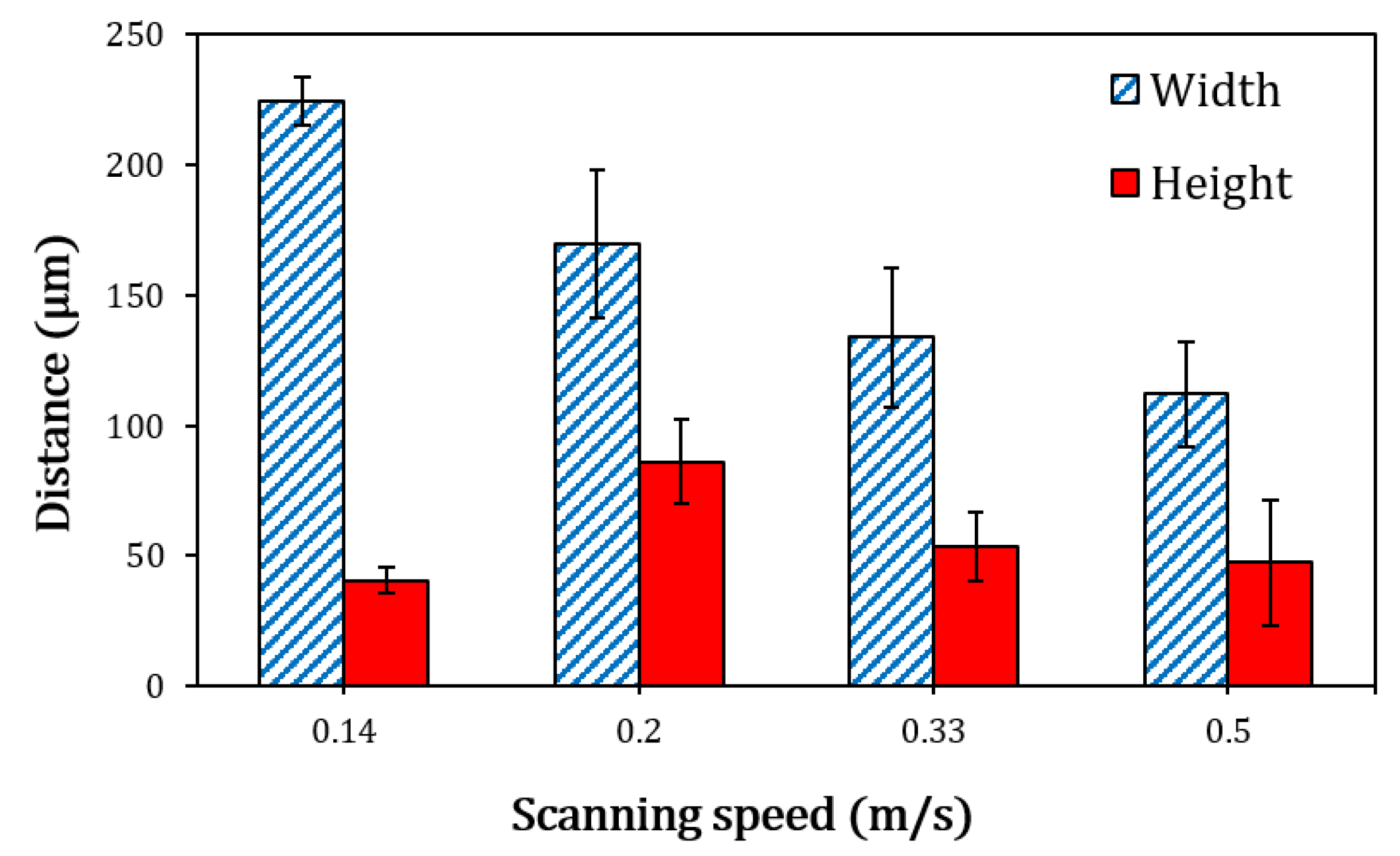

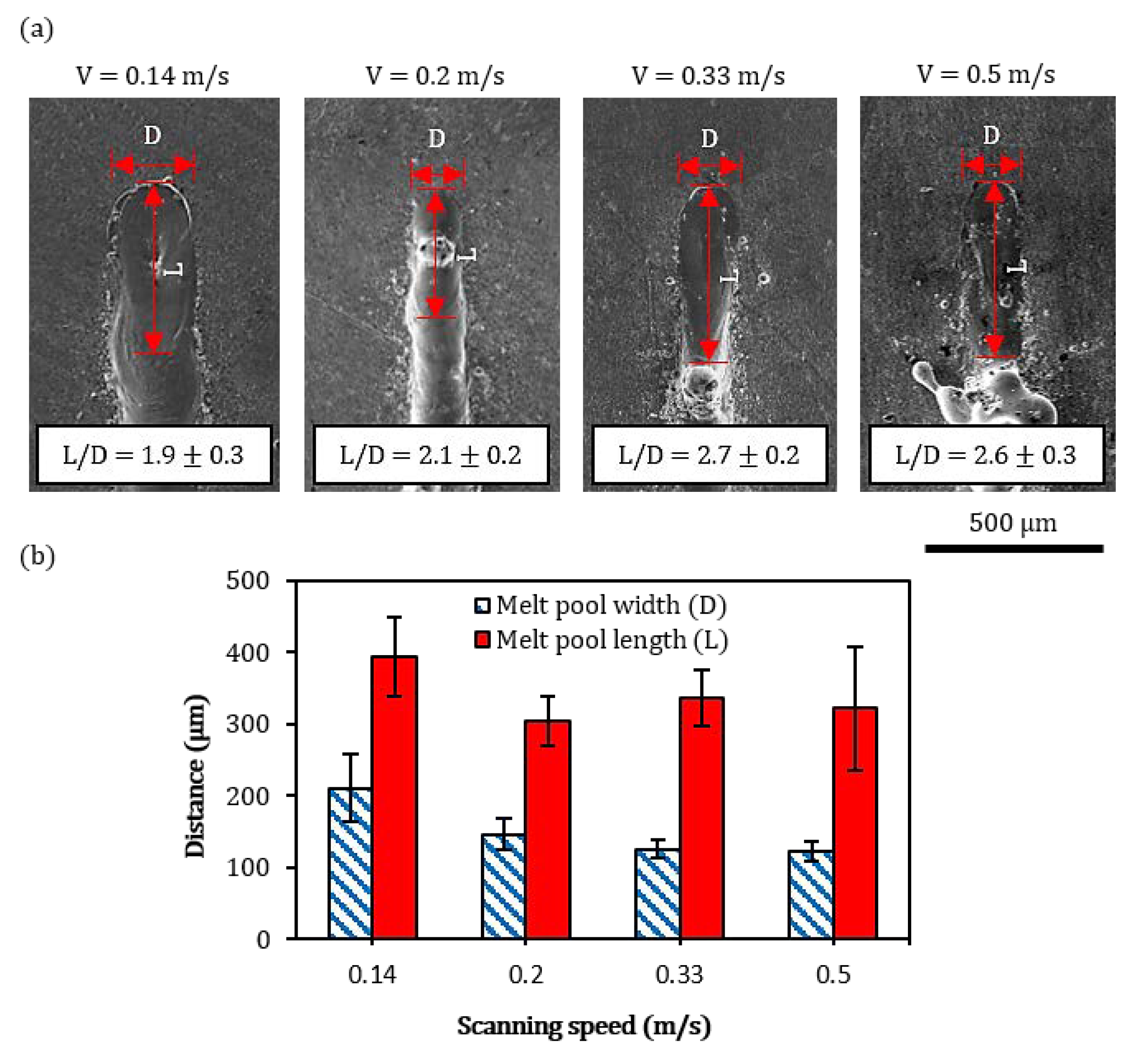

3.2. Track Width, Height, and Melt-Pool Length Measurements

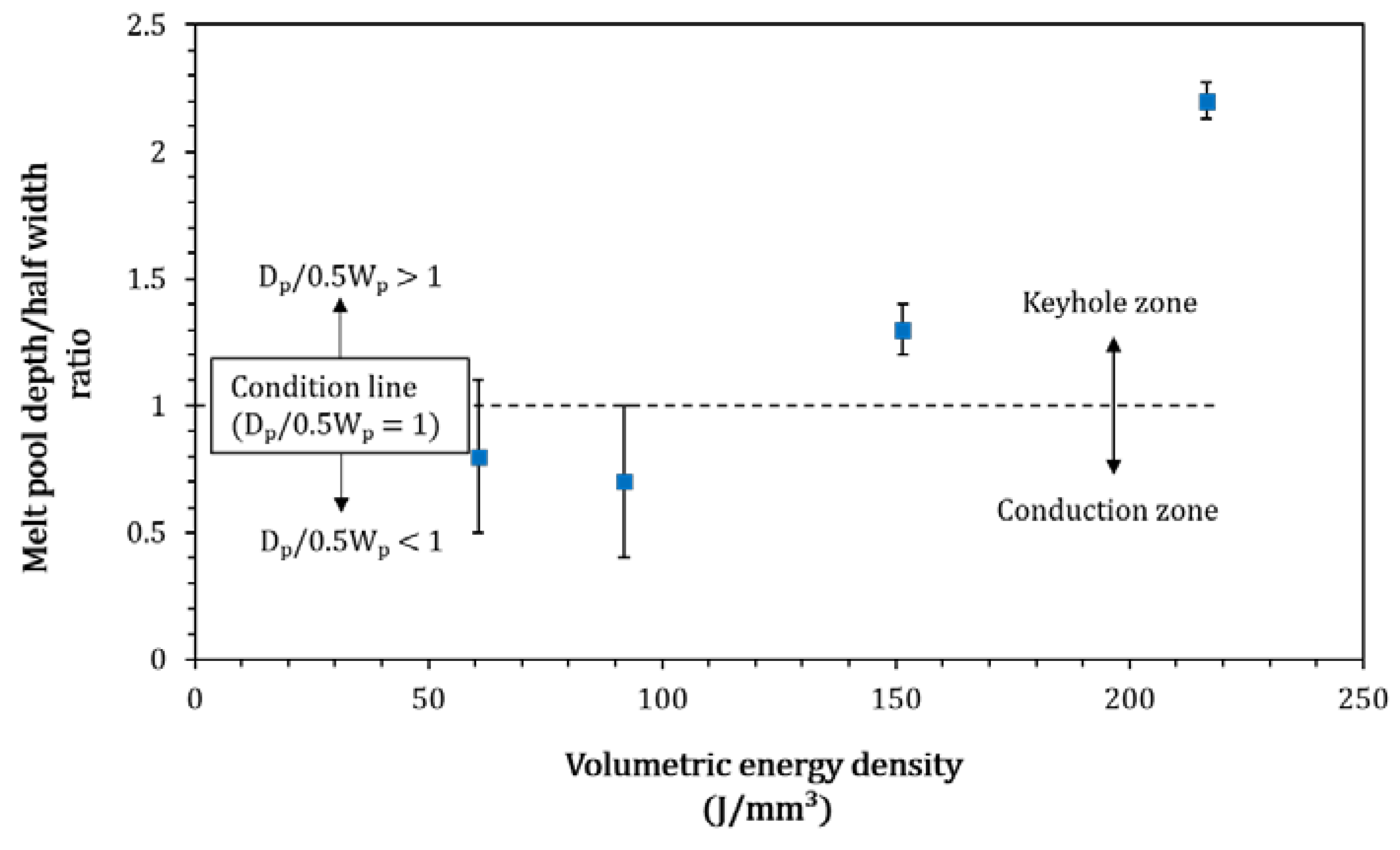

3.3. Cross-Sections and Melted-Depth Characteristics

4. Discussion

4.1. The Evolution of the Track Morphologies as a Function of Laser-Scanning Speed

4.2. Melting Regimes as a Function of Laser-Scanning Speed

5. Conclusions

- For VED > 200 J/mm3, continuous tracks of WCM-12 wt.% Co can be formed; the tracks present minimal cracking and porosity but large WCM particles are found to be sintered to sides of the tracks.

- For VED < 200 J/mm3, as the energy is decreased, tracks become discontinuous with evidence of balling and powder bed denudation.

- A clear transition between conduction to keyhole-mode melting with respect to the values of volumetric energy density was observed and correlated to the melt-pool characteristics.

- The low packing density of the feedstock produced significant shrinkage during melting; this should be taken into account when a multi-layered component is to be fabricated.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schwanekamp, T.; Bräuer, M.; Reuber, M. Geometrical and topological potentialities and restrictions in selective laser sintering of customized carbide precision tools. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 26–29 June 2017. [Google Scholar]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Ajdelsztajn, L.; Schoenung, J.M. Fabrication of WC–Co cermets by laser engineered net shaping. Mater. Sci. Eng. A 2008, 493, 261–266. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Amato, K.; Gaytan, S.; Murr, L.; Martinez, E.; Shindo, P.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon steel parts produced using Selective Laser Melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Attar, H.; Prashanth, K.G.; Zhang, L.-C.; Calin, M.; Okulov, I.V.; Scudino, S.; Yang, C.; Eckert, J. Effect of powder particle shape on the properties of in situ Ti–TiB composite materials produced by selective laser melting. J. Mater. Sci. Technol. 2015, 31, 1001–1005. [Google Scholar] [CrossRef]

- Simonelli, M.; Aboulkhair, N.T.; Cohen, P.; Murray, J.W.; Clare, A.T.; Tuck, C.; Hague, R.J. A comparison of Ti-6Al-4V in-situ alloying in Selective Laser Melting using simply-mixed and satellited powder blend feedstocks. Mater. Charact. 2018, 143, 118–126. [Google Scholar] [CrossRef]

- Uhlmann, E.; Bergmann, A.; Gridin, W. Investigation on additive manufacturing of tungsten carbide-cobalt by selective laser melting. Proced. CIRP 2015, 35, 8–15. [Google Scholar] [CrossRef]

- Schwanekamp, T.; Reuber, M. Additive Manufacturing of application optimized tungsten carbide precision tools. In Proceedings of the 6th International Conference on Additive Technologies, Nürenberg, Germany, 29–30 November 2016. [Google Scholar]

- Fortunato, A.; Valli, G.; Liverani, E.; Ascari, A. Additive Manufacturing of WC-Co Cutting Tools for Gear Production. Lasers Manuf. Mater. Process. 2019, 6, 247–262. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Safronov, V.A.; Gusarov, A.V. Synthesis of nanostructured WC-Co hardmetal by selective laser melting. Proced. IUTAM 2017, 23, 114–119. [Google Scholar] [CrossRef]

- Domashenkov, A.; Borbély, A.; Smurov, I. Structural modifications of WC/Co nanophased and conventional powders processed by selective laser melting. Mater. Manuf. Process. 2017, 32, 93–100. [Google Scholar] [CrossRef] [Green Version]

- Khmyrov, R.S.; Shevchukov, A.P.; Gusarov, A.V.; Tarasova, T.V. Phase composition and microstructure of WC–Co alloys obtained by selective laser melting. Mech. Ind. 2017, 18, 714. [Google Scholar] [CrossRef] [Green Version]

- Khmyrov, R.; Safronov, V.; Gusarov, A. Obtaining crack-free WC-Co alloys by selective laser melting. Phys. Proced. 2016, 83, 874–881. [Google Scholar] [CrossRef] [Green Version]

- Davydova, A.; Domashenkov, A.; Sova, A.; Movtchan, I.; Bertrand, P.; Desplanques, B.; Peillon, N.; Saunier, S.; Desrayaud, C.; Bucher, S. Selective laser melting of boron carbide particles coated by a cobalt-based metal layer. J. Mater. Process. Technol. 2016, 229, 361–366. [Google Scholar] [CrossRef]

- Clare, A.; Kennedy, A. Additive Manufacturing. Google Patent WO 2015/036802 A3, 19 March 2015. [Google Scholar]

- Zhang, F.; Mei, M.; Al-Hamdani, K.; Tan, H.; Clare, A.T. Novel nucleation mechanisms through satelliting in direct metal deposition of Ti-15Mo. Mater. Lett. 2018, 213, 197–200. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W. Microstructure characteristics and formation mechanisms of in situ WC cemented carbide based hardmetals prepared by Selective Laser Melting. Mater. Sci. Eng. A 2010, 527, 7585–7592. [Google Scholar] [CrossRef]

- Paul, C.; Alemohammad, H.; Toyserkani, E.; Khajepour, A.; Corbin, S. Cladding of WC–12 Co on low carbon steel using a pulsed Nd: YAG laser. Mater. Sci. Eng. A 2007, 464, 170–176. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef] [Green Version]

- Maamoun, A.; Elbestawi, M.; Veldhuis, S. Influence of shot peening on AlSi10Mg parts fabricated by additive manufacturing. J. Manuf. Mater. Process. 2018, 2, 40. [Google Scholar] [CrossRef] [Green Version]

- Gao, P.; Wang, Z.; Zeng, X. Effect of process parameters on morphology, sectional characteristics and crack sensitivity of Ti-40Al-9V-0.5 Y alloy single tracks produced by selective laser melting. Int. J. Lightweight Mater. Manuf. 2019, 2, 355–361. [Google Scholar]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

| Process Parameters | Values (units)/Direction | |||

|---|---|---|---|---|

| Measured powder layer thickness | 150 (µm) | |||

| Oxygen level | <0.5% | |||

| Substrate pre-heating temperature | 200 (°C) | |||

| Scanning strategy | Uni-directional | |||

| Measured laser power | 100 (W) | |||

| Exposure time | 70 (µs) | 50 (µs) | 30 (µs) | 20 (µs) |

| Nominal laser scanning speed | 0.14 (m/s) | 0.2 (m/s) | 0.33 (m/s) | 0.5 (m/s) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Thamir, M.; McCartney, D.G.; Simonelli, M.; Hague, R.; Clare, A. Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion. Materials 2020, 13, 50. https://doi.org/10.3390/ma13010050

Al-Thamir M, McCartney DG, Simonelli M, Hague R, Clare A. Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion. Materials. 2020; 13(1):50. https://doi.org/10.3390/ma13010050

Chicago/Turabian StyleAl-Thamir, Mohaimen, D. Graham McCartney, Marco Simonelli, Richard Hague, and Adam Clare. 2020. "Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion" Materials 13, no. 1: 50. https://doi.org/10.3390/ma13010050

APA StyleAl-Thamir, M., McCartney, D. G., Simonelli, M., Hague, R., & Clare, A. (2020). Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion. Materials, 13(1), 50. https://doi.org/10.3390/ma13010050